Study of Self-Locking Structure Based on Surface Microstructure of Dung Beetle Leg Joint

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimen Handling and Sample Preparation

2.2. Scanning Electron Microscopy

2.3. Micro-Computed Tomography

2.4. Preparation of Bionic Sample with Self-Locking Microstructure

2.5. Friction Testing

2.6. Material Preparation of Bionic Joint

2.7. Composition of Bionic Joint

2.8. Application of Bionic Joint

2.9. Statistical Analysis

3. Results and Discussion

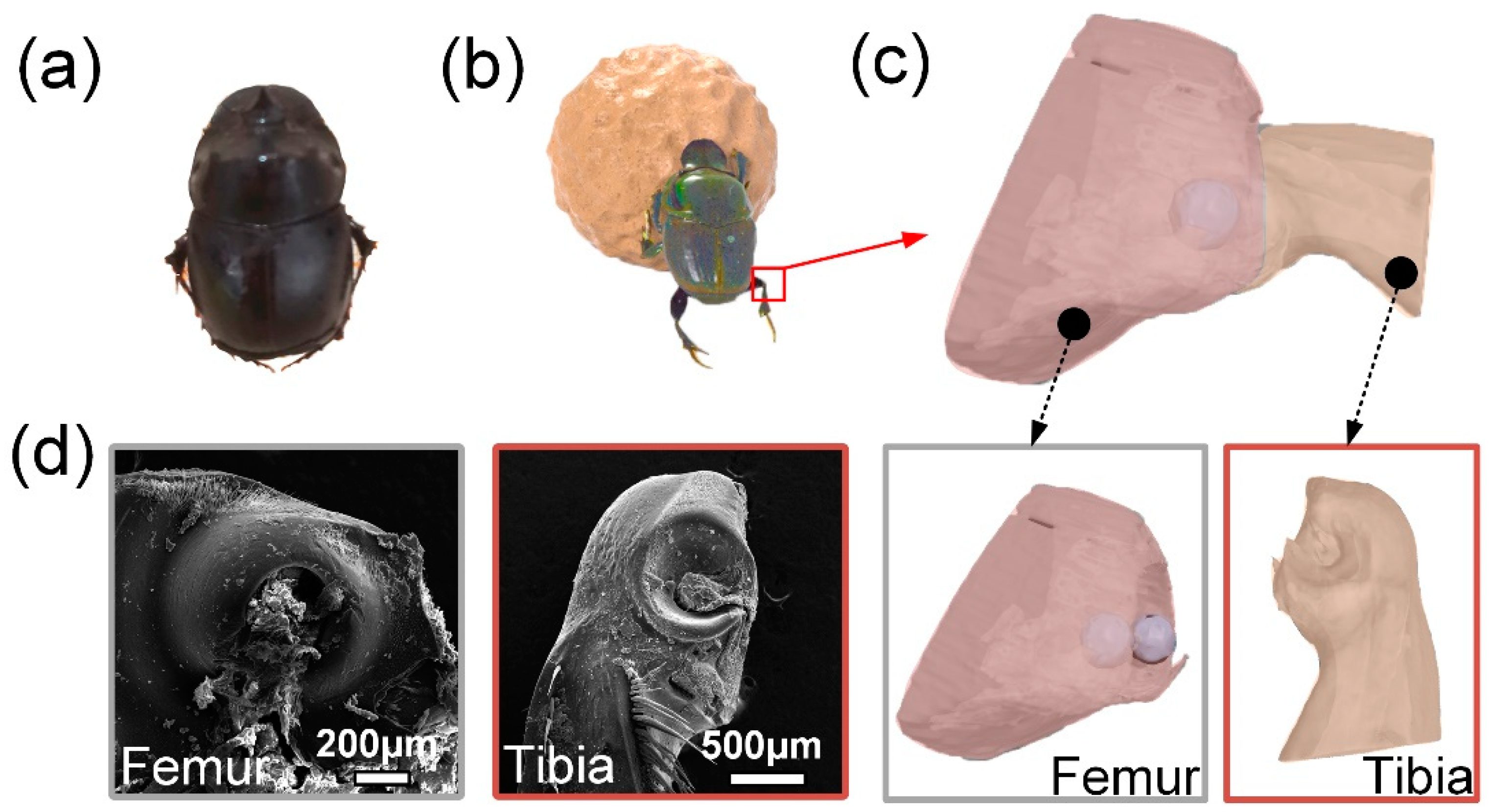

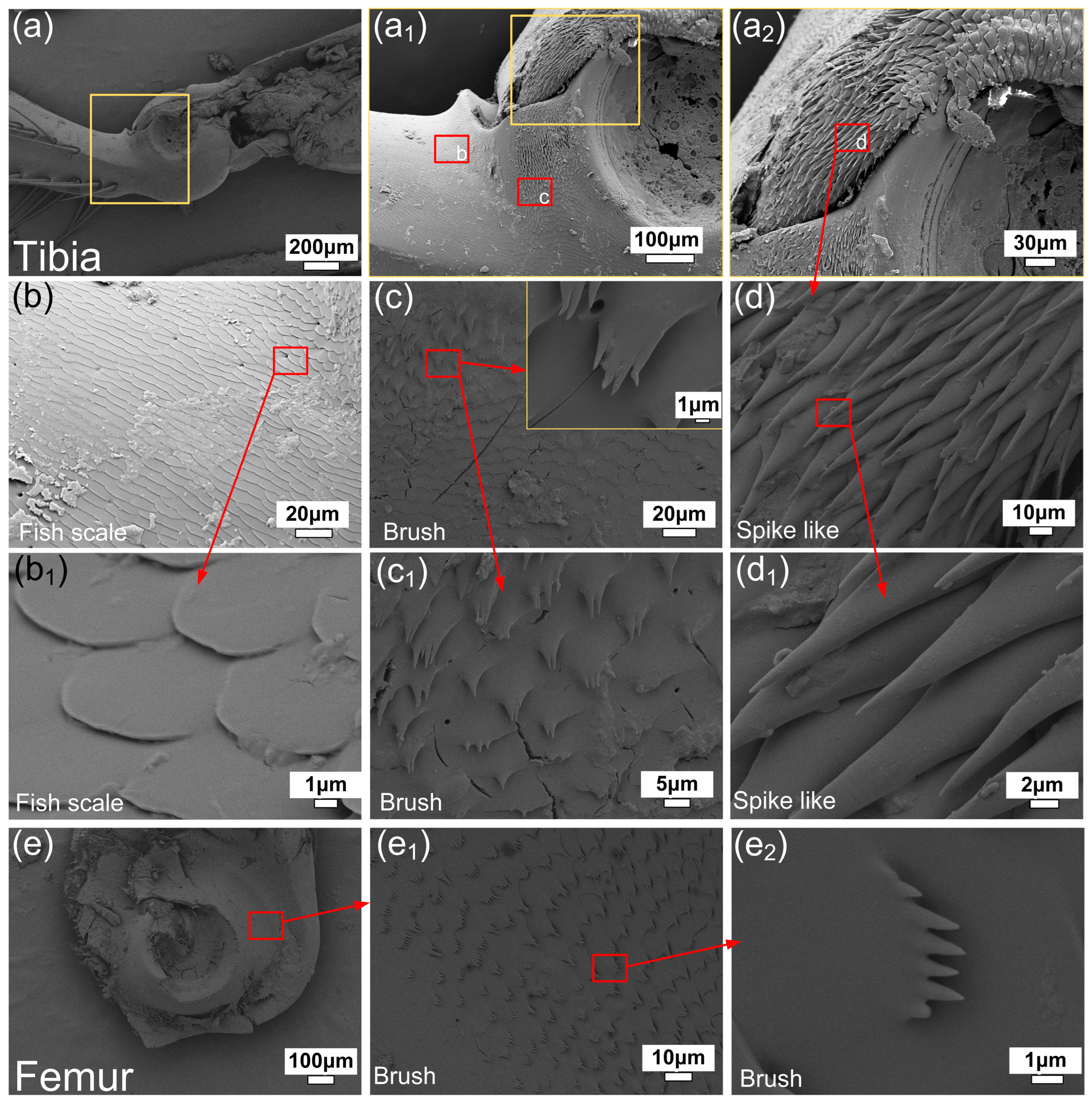

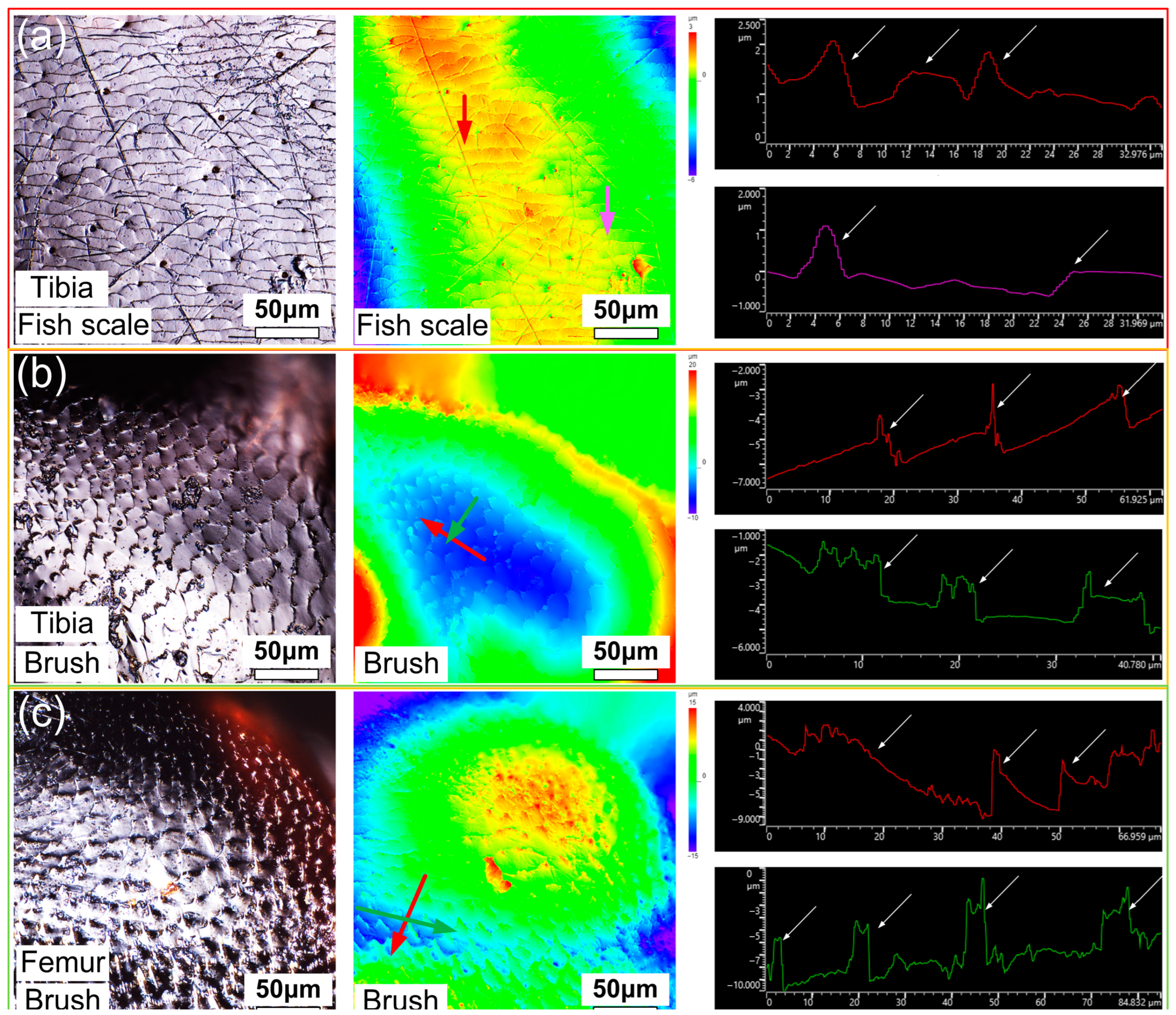

3.1. Microstructure and Morphology of the Leg Joint of Dung Beetle

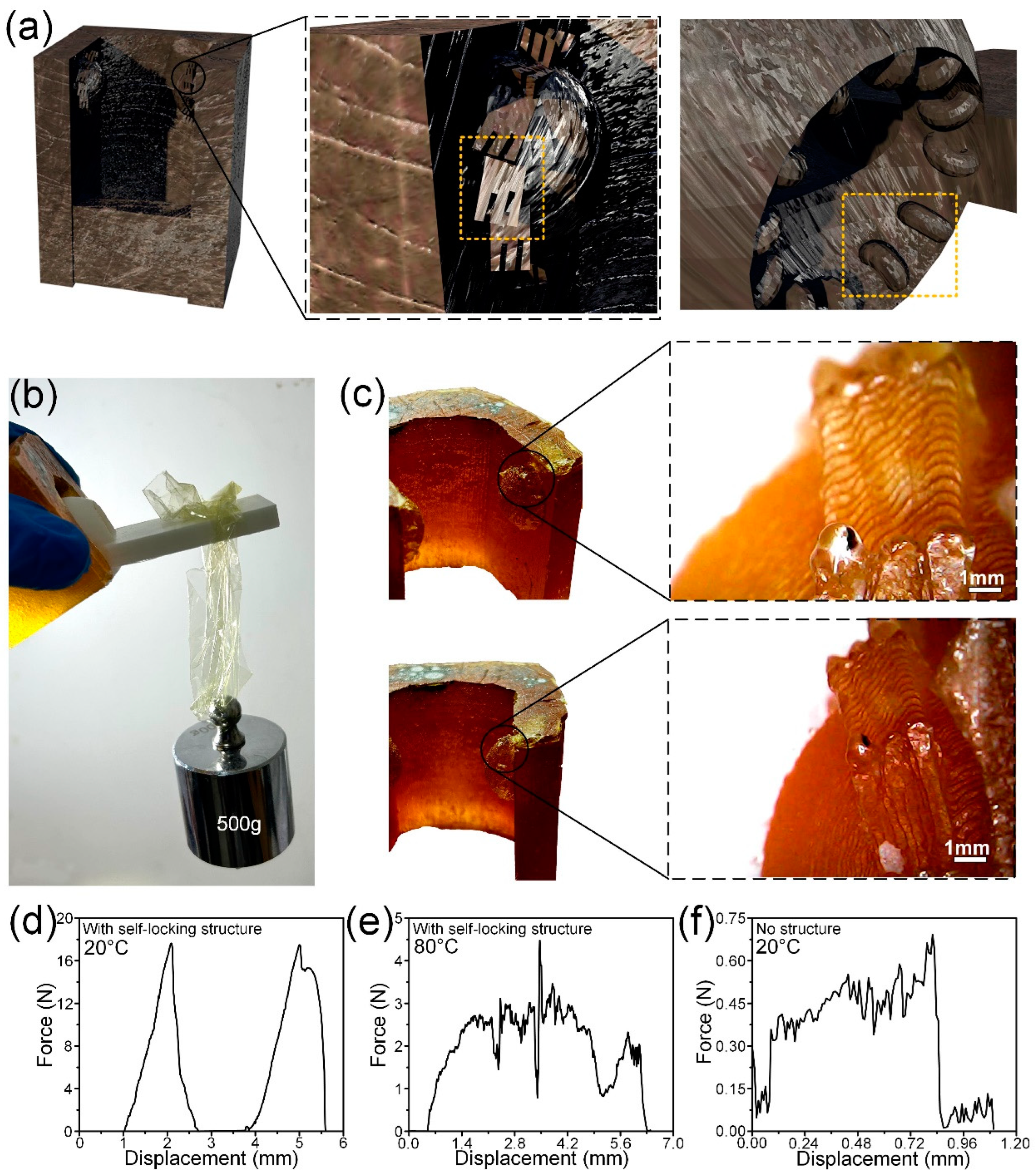

3.2. Bionic Self-Locking Structure Design and Performance Research

3.3. Application of Bionic Self-Locking Structure in Bionic Joint

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, R.; Zaheri, A.; Gao, W.; Hayashi, C.; Espinosa, H.D. AFM identification of beetle exocuticle: Bouligand structure and nanofiber anisotropic elastic properties. Adv. Funct. 2017, 27, 1603993. [Google Scholar] [CrossRef]

- Chen, Y.; Ma, Y.; Yin, Q.; Pan, F.; Cui, C.; Zhang, Z.; Liu, B. Advances in mechanics of hierarchical composite materials. Compos. Sci. Technol. 2021, 214, 108970. [Google Scholar] [CrossRef]

- Wegst, U.G.; Bai, H.; Saiz, E.; Tomsia, A.P.; Ritchie, R.O. Bioinspired structural materials. Nat. Mater. 2015, 14, 23–36. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Shishehbor, M.; Guarín-Zapata, N.; Kirchhofer, N.D.; Li, J.; Cruz, L.; Wang, T.; Bhowmick, S.; Stauffer, D.; Manimunda, P.; et al. A natural impact-resistant bicontinuous composite nanoparticle coating. Nat. Mater. 2020, 19, 1236–1243. [Google Scholar] [CrossRef]

- Grunenfelder, L.K.; Milliron, G.; Herrera, S.; Gallana, I.; Yaraghi, N.; Hughes, N.; Evans-Lutterodt, K.; Zavattieri, P.; Kisailus, D. Ecologically driven ultrastructural and hydrodynamic designs in stomatopod cuticles. Adv. Mater. 2018, 30, 1705295. [Google Scholar] [CrossRef]

- Tuo, Z.; Yang, K.; Ma, S.; Cui, J.; Shi, Y.; Zhao, H.; Liang, Y.; Liu, C.; Lin, Z.; Han, Z.; et al. Multi-Level Structural Enhancement Mechanism of the Excellent Mechanical Properties of Dung Beetle Leg Joint. Small 2024, 20, 2311588. [Google Scholar] [CrossRef]

- Rivera, J.; Murata, S.; Hosseini, M.S.; Trikanad, A.A.; James, R.; Pickle, A.; Yaraghi, N.; Matsumoto, N.; Yang, W.; Parkinson, D.Y.; et al. Structural design variations in beetle elytra. Adv. Funct. 2021, 31, 2106468. [Google Scholar] [CrossRef]

- Rivera, J.; Hosseini, M.S.; Restrepo, D.; Murata, S.; Vasile, D.; Parkinson, D.Y.; Barnard, H.S.; Arakaki, A.; Zavattieri, P.; Kisailus, D. Toughening mechanisms of the elytra of the diabolical ironclad beetle. Nature 2020, 586, 543–548. [Google Scholar] [CrossRef]

- Sun, J.; Bhushan, B. Structure and mechanical properties of beetle wings: A review. RSC Adv. 2012, 2, 12606–12623. [Google Scholar] [CrossRef]

- Scalet, J.M.; Sprouse, P.A.; Schroeder, J.D.; Dittmer, N.; Kramer, K.J.; Kanost, M.R.; Gehrke, S.H. Temporal changes in the physical and mechanical properties of beetle elytra during maturation. Acta Biomater. 2022, 151, 457–467. [Google Scholar] [CrossRef]

- Lomakin, J.; Huber, P.A.; Eichler, C.; Arakane, Y.; Kramer, K.J.; Beeman, R.W.; Kanost, M.R.; Gehrke, S.H. Mechanical properties of the beetle elytron, a biological composite material. Biomacromolecules 2011, 12, 321–335. [Google Scholar] [CrossRef] [PubMed]

- Dai, Z.; Yang, Z. Macro-/micro-structures of elytra, mechanical properties of the biomaterial and the coupling strength between elytra in beetles. J. Bionic Eng. 2010, 7, 6–12. [Google Scholar] [CrossRef]

- He, C.; Zu, Q.; Chen, J.; Noori, M.N. A review of the mechanical properties of beetle elytra and development of the biomimetic honeycomb plates. J. Sandw. Struct. Mater. 2015, 17, 399–416. [Google Scholar] [CrossRef]

- Kundanati, L.; Signetti, S.; Gupta, H.S.; Menegon, M.; Pugno, N.M. Multilayer stag beetle elytra perform better under external loading via non-symmetric bending properties. J. R. Soc. Interface 2018, 15, 20180427. [Google Scholar] [CrossRef] [PubMed]

- Goczał, J.; Beutel, R.G. Beetle elytra: Evolution, modifications and biological functions. Biol. Lett. 2023, 19, 20220559. [Google Scholar] [CrossRef]

- Nadein, K.; Kovalev, A.; Thøgersen, J.; Weidner, T.; Gorb, S. Insects use lubricants to minimize friction and wear in leg joints. Proc. R. Soc. B Biol. Sci. 2021, 288, 20211065. [Google Scholar] [CrossRef]

- Nadein, K.; Gorb, S. Smart joints: Auto-cleaning mechanism in the legs of beetles. Commun. Biol. 2022, 5, 1030. [Google Scholar] [CrossRef]

- Dai, Z.; Gorb, S.N. Micro-structure and frictional characteristics of beetle’s joint. Sci. China Phys. Mech. 2004, 47, 99–106. [Google Scholar] [CrossRef]

- Nadein, K.; Gorb, S. Lubrication in the joints of insects (Arthropoda: Insecta). J. Zool. 2022, 316, 24–39. [Google Scholar] [CrossRef]

- Vagts, S.; Schlattmann, J.; Kovalev, A.; Gorb, S.N. Structure and frictional properties of the leg joint of the beetle Pachnoda marginata (Scarabaeidae, Cetoniinae) as an inspiration for technical joints. Biomimetics 2020, 5, 14. [Google Scholar] [CrossRef]

- Vagts, S.; Schlattmann, J.; Kovalev, A.; Gorb, S.N. The topology of the leg joints of the beetle Pachnoda marginata (Scarabaeidae, Cetoniinae) and its implication for the tribological properties. Biomimetics 2018, 3, 12. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.Y.; Guo, Y.J.; Tong, J. Testing methods for nanoindentation property of the cuticle of bovine hoof wall and dung beetle’s foreleg femur. J. Terramechanics 2006, 43, 355–364. [Google Scholar] [CrossRef]

- Zhang, Z.; Jia, H.; Sun, J.; Tong, J. Nanoindentation investigation of the stress exponent for the creep of dung beetle (Copris ochus Motschulsky) cuticle. Bioengineered 2016, 7, 357–364. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Oh, J.K.; Behmer, S.T.; Marquess, R.; Yegin, C.; Scholar, E.A.; Akbulut, M. Structural, tribological, and mechanical properties of the hind leg joint of a jumping insect: Using katydids to inform bioinspired lubrication systems. Acta Biomater. 2017, 62, 284–292. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Jiang, X.; Li, X.; Ding, K.; Liu, X.; Huang, B.; Ding, J.; Qu, K.; Sun, W.; Xue, Z.; et al. Bionic ordered structured hydrogels: Structure types, design strategies, optimization mechanism of mechanical properties and applications. Mater. Horiz. 2023, 10, 4033–4058. [Google Scholar] [CrossRef]

- Li, J.; Chen, Q.; Zhang, Q.; Fan, T.; Gong, L.; Ye, W.; Fan, Z.; Cao, L. Improving mechanical properties and biocompatibilities by highly oriented long chain branching poly (lactic acid) with bionic surface structures. ACS Appl. Mater. Interfaces 2020, 12, 14365–14375. [Google Scholar] [CrossRef]

- Gu, Y.; Yu, L.; Mou, J.; Wu, D.; Zhou, P.; Xu, M. Mechanical properties and application analysis of spider silk bionic material. e-Polymers 2020, 20, 443–457. [Google Scholar] [CrossRef]

- Sun, Z.; Gong, Y.; Bian, Z.; Zhang, J.; Zhao, L.; Hu, N. Mechanical properties of bionic lattice and its hybrid structures based on the microstructural design of pomelo peel. Thin-Walled Struct. 2024, 198, 111715. [Google Scholar] [CrossRef]

- Wang, W.; Lu, L.; Lu, X.; Liang, Z.; Tang, B.; Xie, Y. Laser-induced jigsaw-like graphene structure inspired by Oxalis corniculata Linn. leaf. Bio-Des. Manuf. 2022, 5, 700–713. [Google Scholar] [CrossRef]

- Tuo, Z.; Chen, K.; Zhou, Q.; Wang, Y.; Wang, Q.; Zhang, Y.; Lin, Z.; Liang, Y. High-performance shape memory epoxy resin with high strength and toughness: Prepared by introducing hydrogen bonds through polycaprolactone and low melting point alloy. Compos. Sci. Technol. 2024, 250, 110510. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, D.; Lin, S.; Wang, Y.; Cui, J.; Tuo, Z.; Lin, Z.; Liang, Y.; Ren, L. Study of Self-Locking Structure Based on Surface Microstructure of Dung Beetle Leg Joint. Biomimetics 2024, 9, 622. https://doi.org/10.3390/biomimetics9100622

Sun D, Lin S, Wang Y, Cui J, Tuo Z, Lin Z, Liang Y, Ren L. Study of Self-Locking Structure Based on Surface Microstructure of Dung Beetle Leg Joint. Biomimetics. 2024; 9(10):622. https://doi.org/10.3390/biomimetics9100622

Chicago/Turabian StyleSun, Dexin, Sen Lin, Yubo Wang, Jiandong Cui, Zhiwei Tuo, Zhaohua Lin, Yunhong Liang, and Luquan Ren. 2024. "Study of Self-Locking Structure Based on Surface Microstructure of Dung Beetle Leg Joint" Biomimetics 9, no. 10: 622. https://doi.org/10.3390/biomimetics9100622

APA StyleSun, D., Lin, S., Wang, Y., Cui, J., Tuo, Z., Lin, Z., Liang, Y., & Ren, L. (2024). Study of Self-Locking Structure Based on Surface Microstructure of Dung Beetle Leg Joint. Biomimetics, 9(10), 622. https://doi.org/10.3390/biomimetics9100622