Design and Dynamic Control: A Free-Flying Space Robot Inspired by Water Striders

Abstract

:1. Introduction

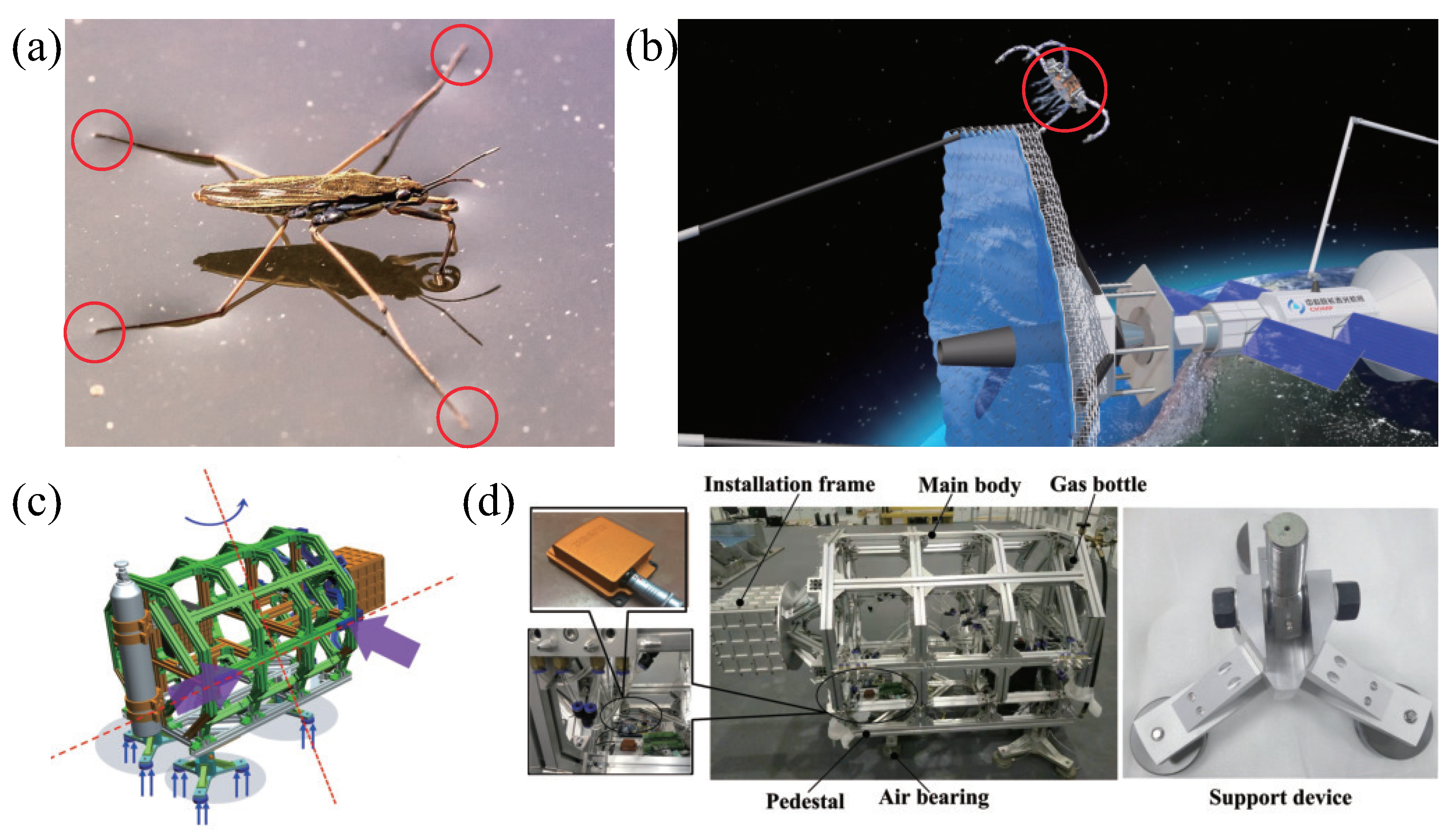

2. Design of the Free-Flying Space Robot

2.1. Mechanical Design of the FFSR

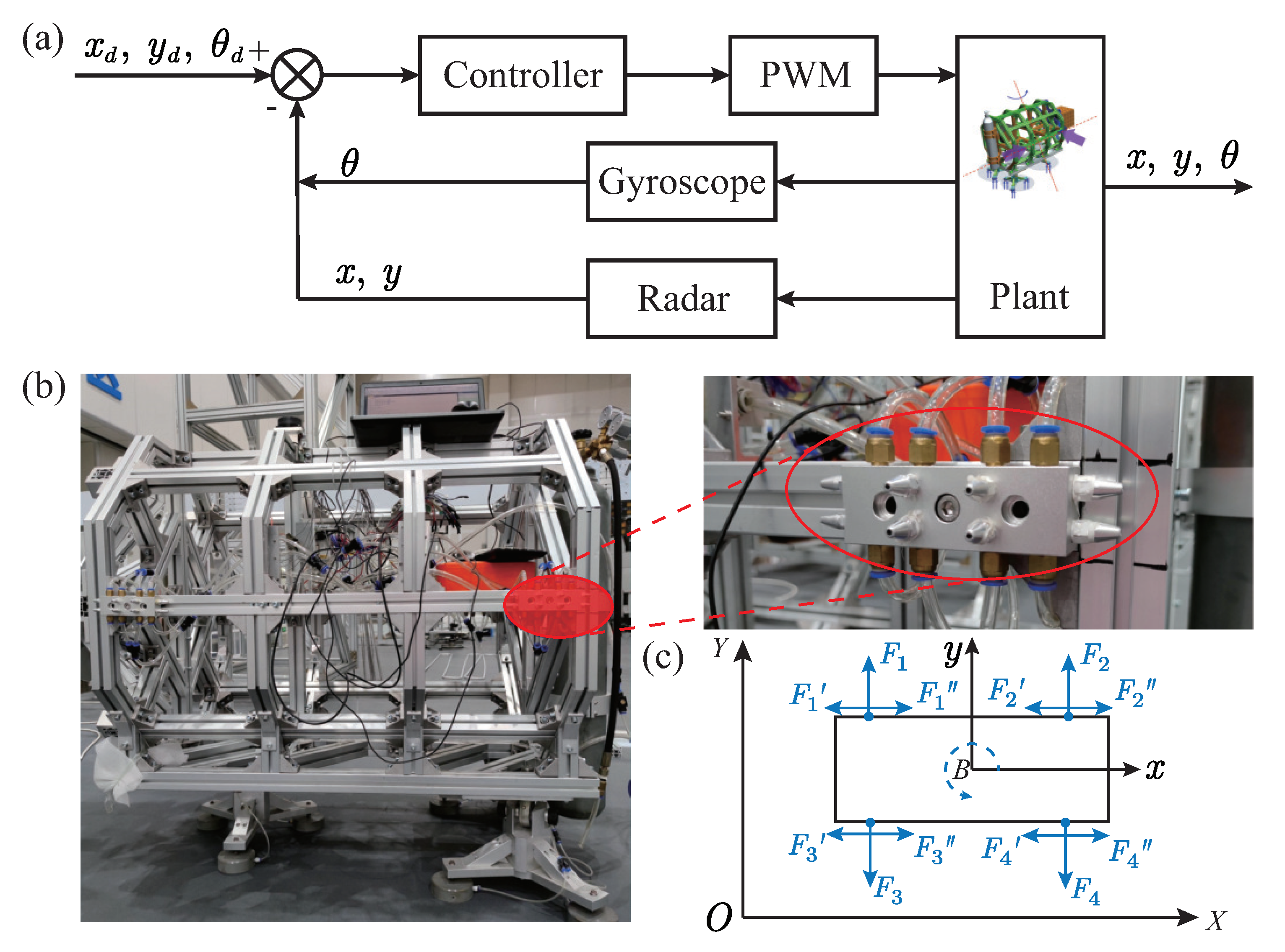

2.2. Drive System Design of FFSR

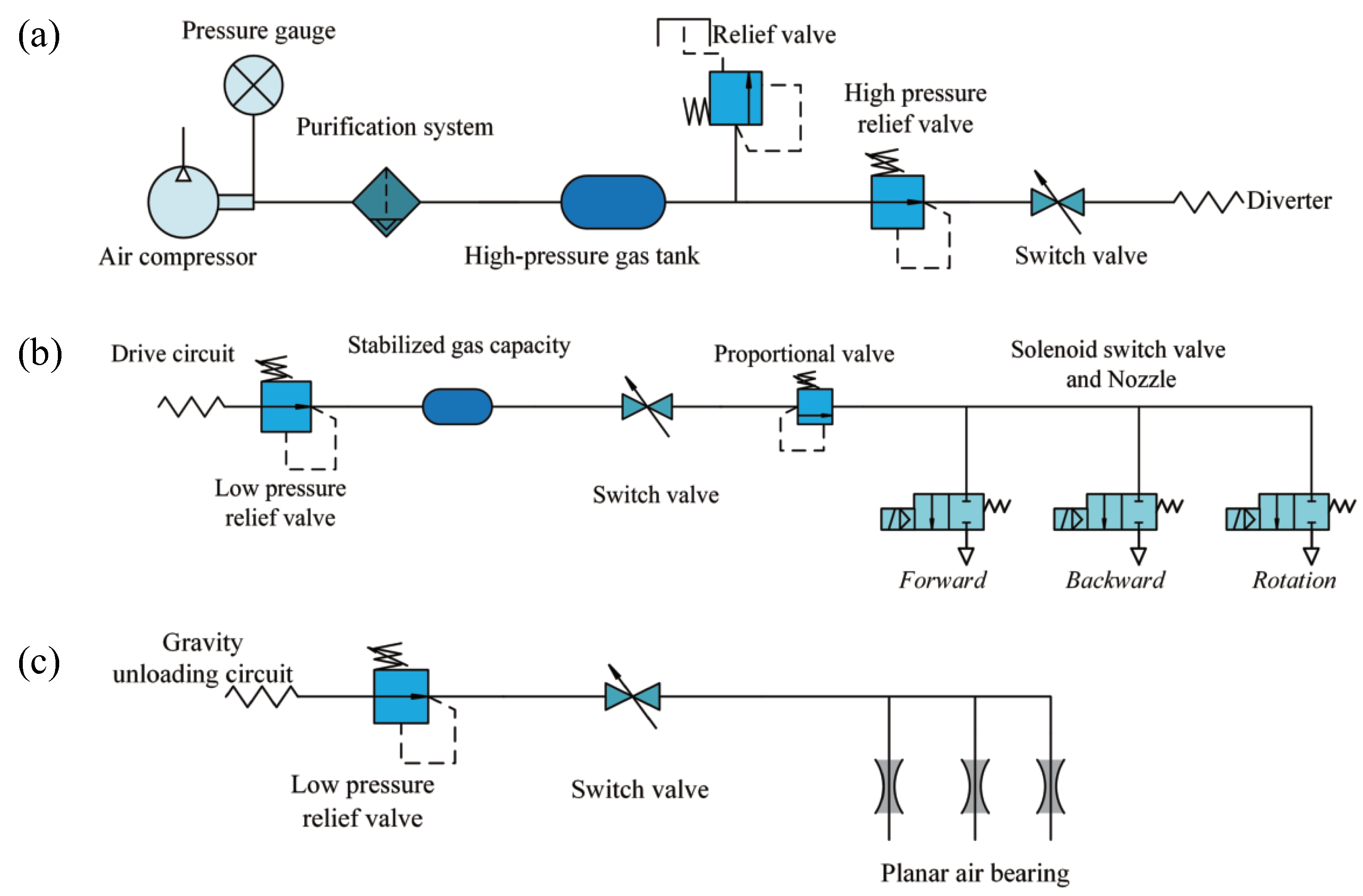

2.3. Gas Circuit Design of the FFSR

3. Kinematics and Dynamics Modeling of the Free-Flying Space Robot

3.1. Kinematic Modeling of the FFSR

3.2. Dynamic Modeling of the FFSR

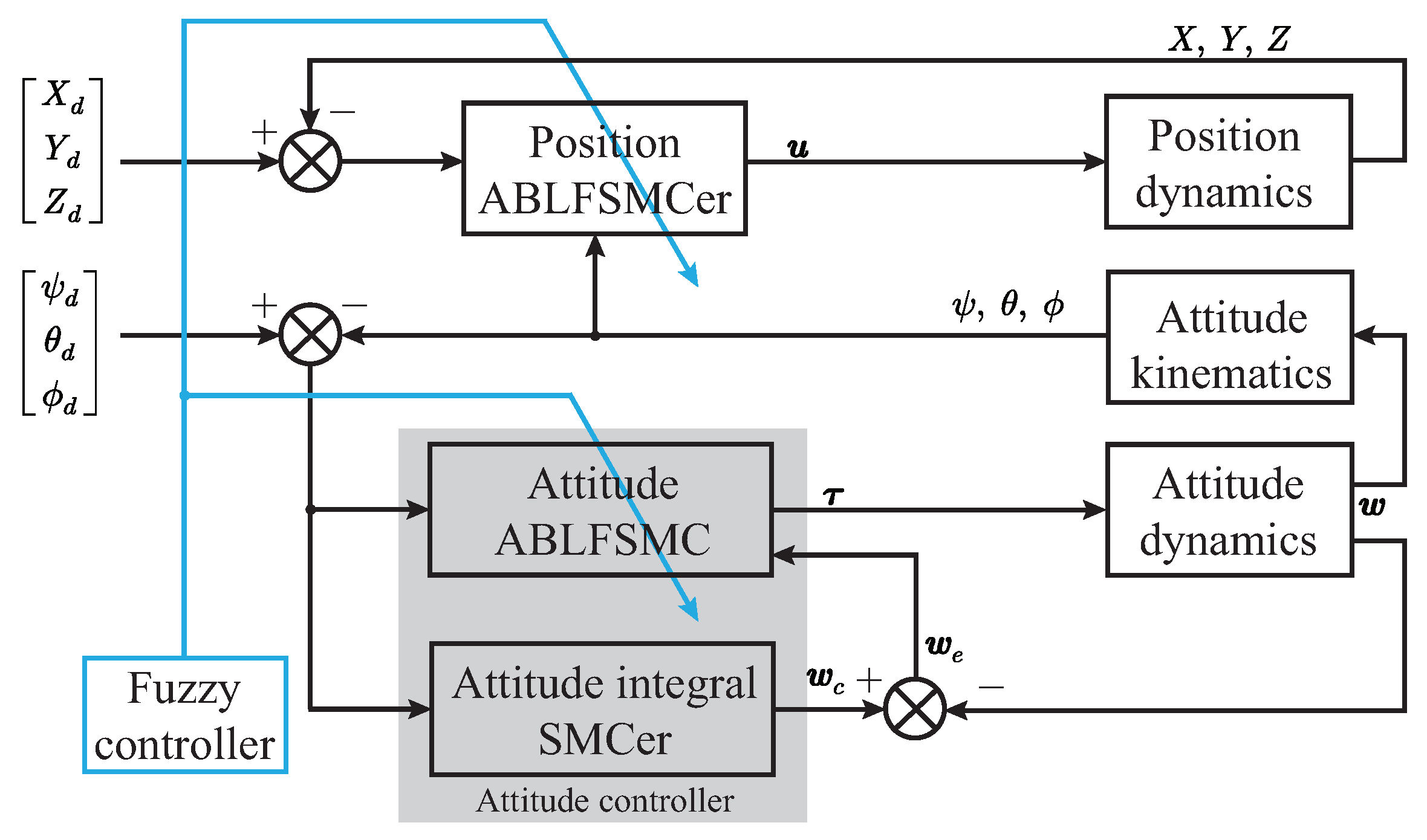

4. Design of Fuzzy Sliding Mode Controller

4.1. Design of the Sliding Mode Controller

4.2. Design of the Fuzzy Controller

4.3. Design of the Adaptive Boundary Layer Fuzzy Sliding Mode Control

5. Simulation and Experimental Results

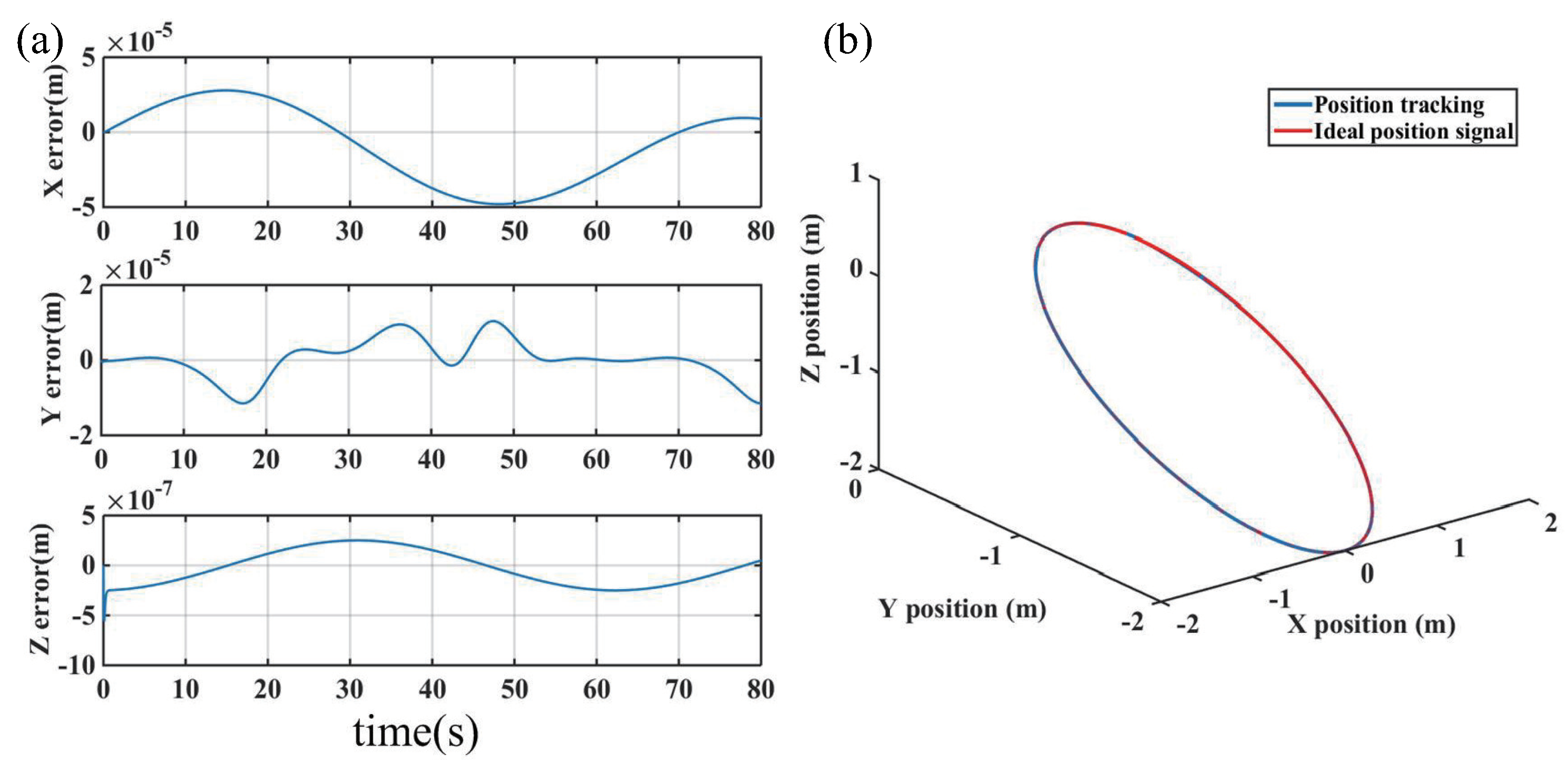

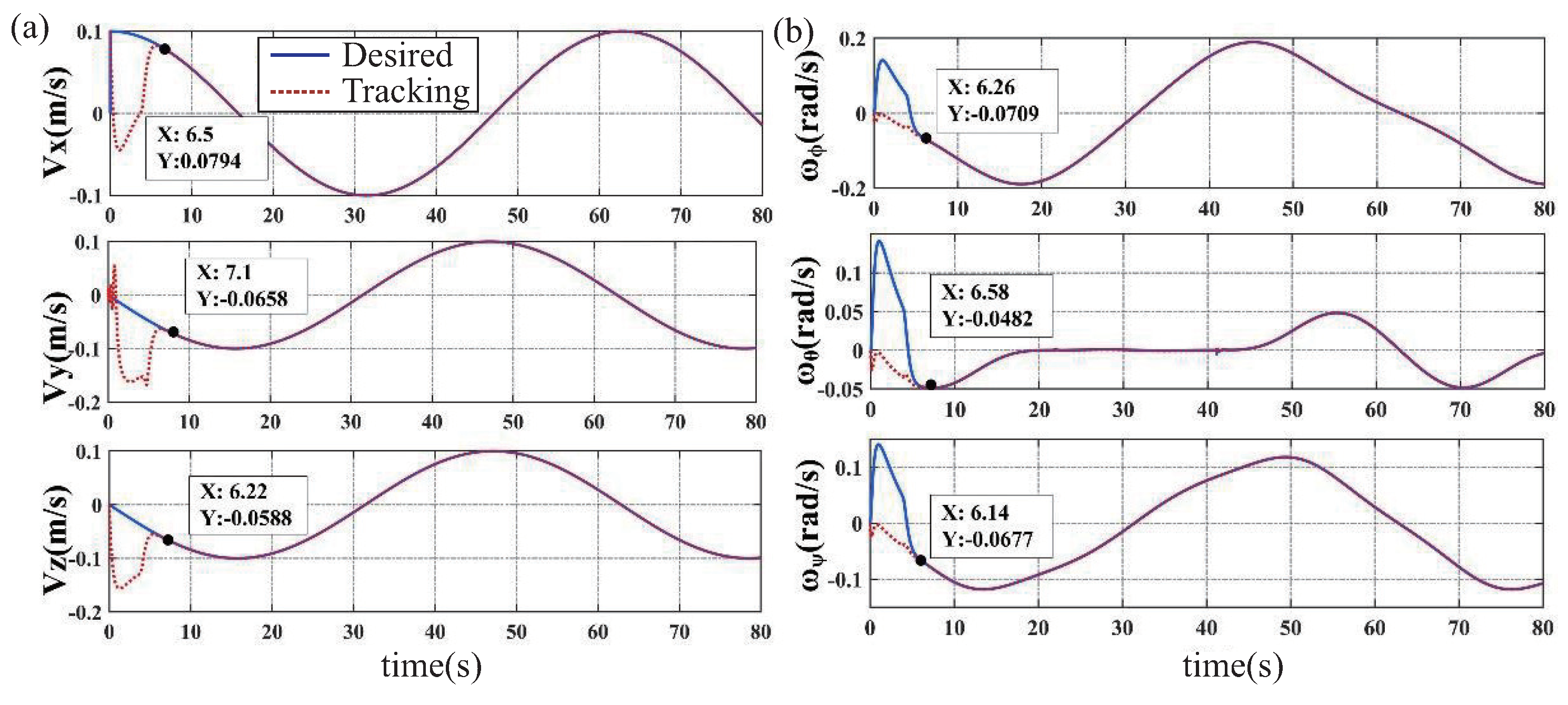

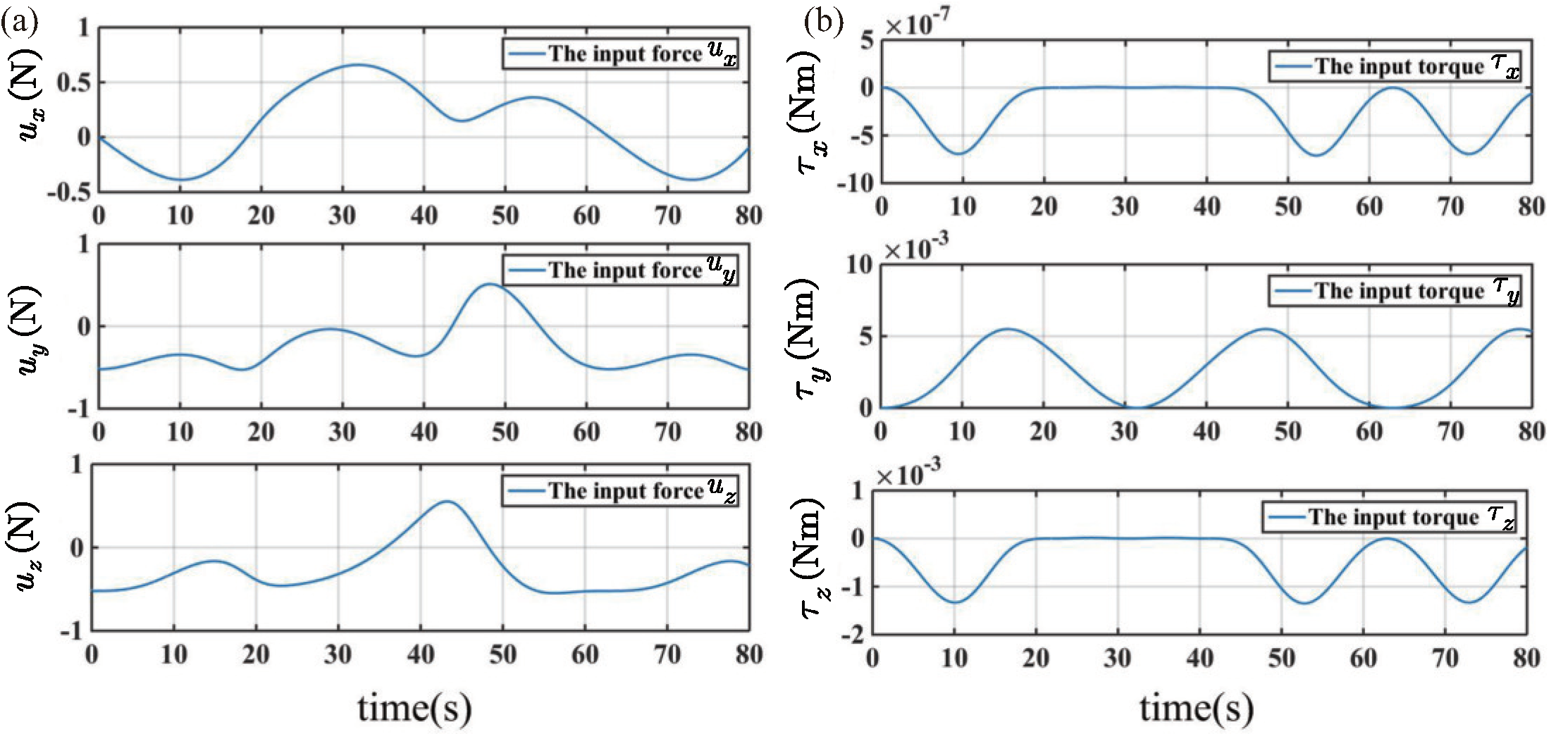

5.1. Simulation Results

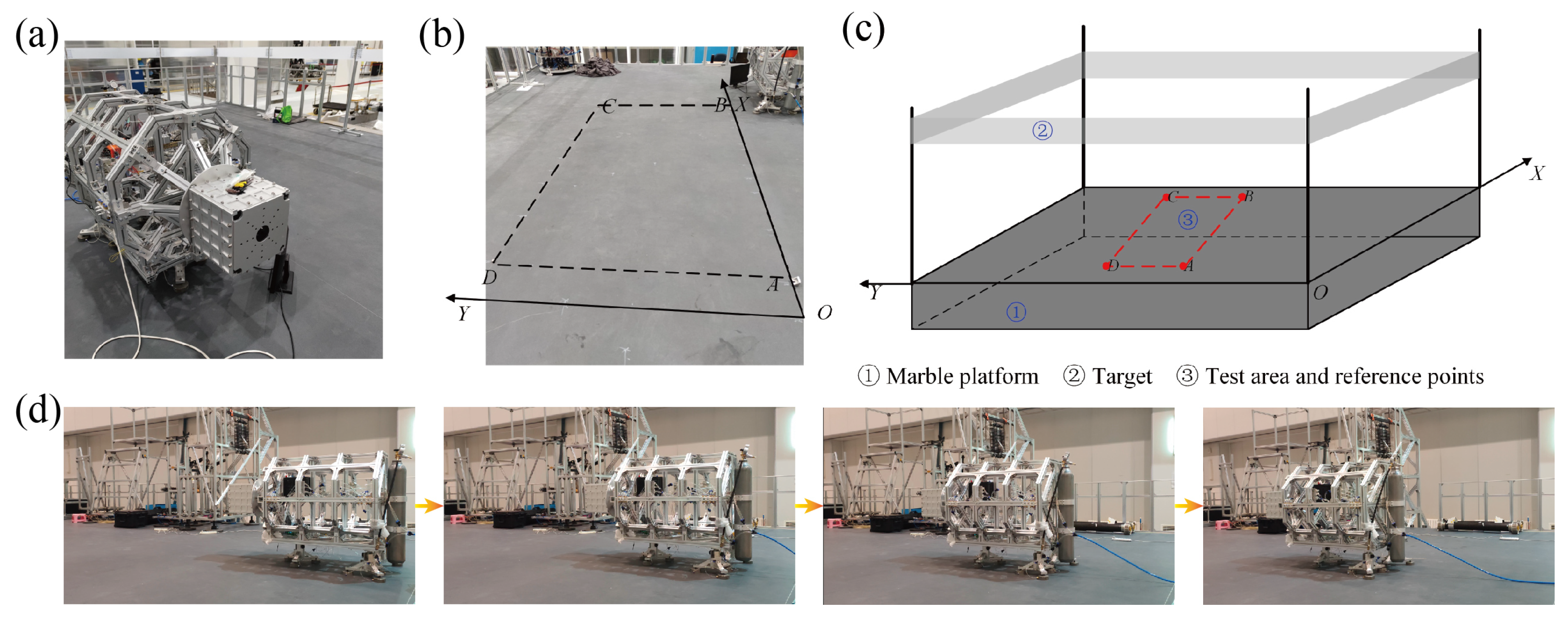

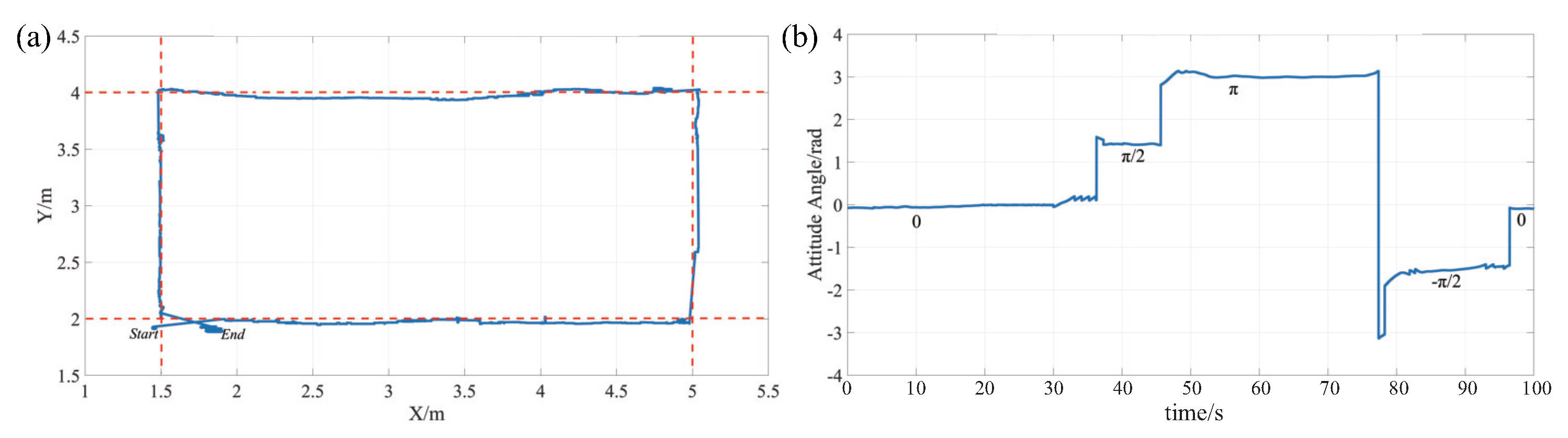

5.2. Experimental Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Lillie, C.F.; MacEwen, H.A.; Polidan, R.S.; Breckinridge, J.B. A 4-m evolvable space telescope configured for NASA’s HabEx Mission: The initial stage of LUVOIR. In Proceedings of the UV/Optical/IR Space Telescopes and Instruments: Innovative Technologies and Concepts VIII, San Diego, CA, USA, 25–26 August 2017; Volume 10398, pp. 266–282. [Google Scholar]

- Saunders, C.; Lobb, D.; Sweeting, M.; Gao, Y. Building large telescopes in orbit using small satellites. Acta Astronaut. 2017, 141, 183–195. [Google Scholar] [CrossRef]

- Miller, D.W.; Mohan, S.; Budinoff, J. Assembly of a large modular optical telescope (ALMOST). In Proceedings of the Space Telescopes and Instrumentation 2008: Optical, Infrared, and Millimeter, Marseille, France, 23–28 June 2008; Volume 7010, pp. 717–727. [Google Scholar]

- Song, Y.; Li, C.; Zhao, H.; Xia, S.; Li, X.; Fan, X. Review on on-orbit assembly of large space telescopes. In Proceedings of the AOPC 2019: Space Optics, Telescopes, and Instrumentation, Beijing, China, 7–9 July 2019; Volume 11341, pp. 11–22. [Google Scholar]

- Lillie, C.F.; MacEwen, H.A. In-space assembly and servicing infrastructures for the Evolvable Space Telescope (EST). In Proceedings of the Space Telescopes and Instrumentation 2016: Optical, Infrared, and Millimeter Wave, Edinburgh, UK, 24 June–1 July 2016; Volume 9904, pp. 574–585. [Google Scholar]

- She, Y.; Li, S.; Du, B.; Cao, K. On-orbit assembly mission planning considering topological constraint and attitude disturbance. Acta Astronaut. 2018, 152, 692–704. [Google Scholar] [CrossRef]

- Shi, Y.; Hou, X.; Gao, G.; Na, Z.; Liu, Y.; Deng, Z. Design and Simulation of On-Orbit Assembly System Based on Insect-Inspired Transportation. Biomimetics 2023, 8, 256. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Sharf, I.; Chen, L. Three-spacecraft autonomous orbit determination and observability analysis with inertial angles-only measurements. Acta Astronaut. 2020, 170, 106–121. [Google Scholar] [CrossRef]

- Belvin, W.K.; Doggett, W.R.; Watson, J.J.; Dorsey, J.T.; Warren, J.E.; Jones, T.C.; Komendera, E.E.; Mann, T.; Bowman, L.M. In-space structural assembly: Applications and technology. In Proceedings of the 3rd AIAA Spacecraft Structures Conference, San Diego, CA, USA, 4–8 January 2016; p. 2163. [Google Scholar]

- Dorsey, J.; Watson, J. Space assembly of large structural system architectures (SALSSA). In Proceedings of the AIAA SPACE 2016, Long Beach, CA, USA, 13–16 September 2016; p. 5481. [Google Scholar]

- Underwood, C.; Pellegrino, S.; Lappas, V.J.; Bridges, C.P.; Baker, J. Using CubeSat/micro-satellite technology to demonstrate the Autonomous Assembly of a Reconfigurable Space Telescope (AAReST). Acta Astronaut. 2015, 114, 112–122. [Google Scholar] [CrossRef]

- Uzo-Okoro, E.E. Robots Making Satellites: Advancing In-Space Manufacturing Through On-Orbit Robotic Assembly. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2022. [Google Scholar]

- Cheng, Z.; Hou, X.; Zhang, X.; Zhou, L.; Guo, J.; Song, C. In-orbit assembly mission for the space solar power station. Acta Astronaut. 2016, 129, 299–308. [Google Scholar] [CrossRef]

- Rybus, T.; Seweryn, K.; Oleś, J.; Basmadji, F.L.; Tarenko, K.; Moczydłowski, R.; Barciński, T.; Kindracki, J.; Mężyk, Ł.; Paszkiewicz, P.; et al. Application of a planar air-bearing microgravity simulator for demonstration of operations required for an orbital capture with a manipulator. Acta Astronaut. 2019, 155, 211–229. [Google Scholar] [CrossRef]

- Gao, Q.; Liu, J.; Tian, T.; Li, Y. Free-flying dynamics and control of an astronaut assistant robot based on fuzzy sliding mode algorithm. Acta Astronaut. 2017, 138, 462–474. [Google Scholar] [CrossRef]

- Fernandez, B.R.; Herrera, L.; Hudson, J.; Romano, M. Development of a tip-tilt air-bearing testbed for physically emulating proximity-flight orbital mechanics. Adv. Space Res. 2023, 71, 4332–4339. [Google Scholar] [CrossRef]

- Zhang, W.; Wen, H. Motion planning of a free-flying space robot system under end effector task constraints. Acta Astronaut. 2022, 199, 195–205. [Google Scholar] [CrossRef]

- Liu, L.; Yao, W.; Guo, Y. Prescribed performance tracking control of a free-flying flexible-joint space robot with disturbances under input saturation. J. Frankl. Inst. 2021, 358, 4571–4601. [Google Scholar] [CrossRef]

- Seddaoui, A.; Saaj, C.M. Combined nonlinear H∞ controller for a controlled-floating space robot. J. Guid. Control Dyn. 2019, 42, 1878–1885. [Google Scholar] [CrossRef]

- Kim, J.J.; Agrawal, B. System identification and automatic mass balancing of ground-based three-axis spacecraft simulator. In Proceedings of the AIAA Guidance, Navigation, and Control Conference and Exhibit, Keystone, Colorado, 21–24 August 2006; p. 6595. [Google Scholar]

- Romano, M.; Agrawal, B. Tracking and pointing of target by a bifocal relay mirror spacecraft using attitude control and fast steering mirrors tilting. In Proceedings of the AIAA Guidance, Navigation, and Control Conference and Exhibit, Monterey, CA, USA, 5–8 August 2002; p. 5030. [Google Scholar]

- Kim, B.; Velenis, E.; Kriengsiri, P.; Tsiotras, P. Designing a low-cost spacecraft simulator. IEEE Control Syst. Mag. 2003, 23, 26–37. [Google Scholar]

- Zappulla, R.; Virgili Llop, J.; Park, H.; Zagaris, C.; Romano, M. Floating spacecraft simulator test bed for the experimental testing of autonomous guidance, navigation, & control of spacecraft proximity maneuvers and operations. In Proceedings of the AIAA/AAS Astrodynamics Specialist Conference, Long Beach, CA, USA, 13–16 September 2016; p. 5268. [Google Scholar]

- Thomas, D.; Wolosik, A.T.; Black, J. CubeSat attitude control simulator design. In Proceedings of the 2018 AIAA Modeling and Simulation Technologies Conference, Atlanta, GA, USA, 25–29 June 2018; p. 1391. [Google Scholar]

- Deng, S.; Zhi, J.; Cai, H.; Chen, Z.; Wang, Y. The Design and Analysis of Light Passive Air-Bearing Simulator. In Proceedings of the 2022 6th International Conference on Robotics and Automation Sciences (ICRAS), Wuhan, China, 16–18 June 2022; pp. 152–156. [Google Scholar]

- Rekleitis, I.; Martin, E.; Rouleau, G.; L’Archevêque, R.; Parsa, K.; Dupuis, E. Autonomous capture of a tumbling satellite. J. Field Robot. 2007, 24, 275–296. [Google Scholar] [CrossRef]

- Ibrahimbegovic, A.; Knopf-Lenoir, C.; Kučerová, A.; Villon, P. Optimal design and optimal control of structures undergoing finite rotations and elastic deformations. Int. J. Numer. Methods Eng. 2004, 61, 2428–2460. [Google Scholar] [CrossRef]

- Meduri, A.; Shah, P.; Viereck, J.; Khadiv, M.; Havoutis, I.; Righetti, L. Biconmp: A nonlinear model predictive control framework for whole body motion planning. IEEE Trans. Robot. 2023, 39, 905–922. [Google Scholar] [CrossRef]

- Sai, H.; Xu, Z.; He, S.; Zhang, E.; Zhu, L. Adaptive nonsingular fixed-time sliding mode control for uncertain robotic manipulators under actuator saturation. Isa Trans. 2022, 123, 46–60. [Google Scholar] [CrossRef]

- Sai, H.; Xu, Z.; Xia, C.; Sun, X. Approximate continuous fixed-time terminal sliding mode control with prescribed performance for uncertain robotic manipulators. Nonlinear Dyn. 2022, 110, 431–448. [Google Scholar] [CrossRef]

- Sai, H.; Xu, Z.; Cui, J. Nonconservative adaptive practical predefined-time sliding mode tracking of uncertain robotic manipulators. Int. J. Robust Nonlinear Control 2023. [Google Scholar] [CrossRef]

- Sai, H.; Xia, C.; Li, H.; Xu, Z. Predefined-time Sliding Mode Control for Attitude Tracking Control of Space Free-flying Robots. In Proceedings of the 2022 IEEE International Conference on Mechatronics and Automation (ICMA), Guilin, China, 7–9 August 2022; pp. 292–297. [Google Scholar]

- Cao, L.; Qiao, D.; Xu, J. Suboptimal artificial potential function sliding mode control for spacecraft rendezvous with obstacle avoidance. Acta Astronaut. 2018, 143, 133–146. [Google Scholar] [CrossRef]

- Lian, C.; Xiao, F.; Gao, S.; Liu, J. Load torque and moment of inertia identification for permanent magnet synchronous motor drives based on sliding mode observer. IEEE Trans. Power Electron. 2018, 34, 5675–5683. [Google Scholar] [CrossRef]

- Wang, L.; Tang, Z.; Zhang, P.; Liu, X.; Wang, D.; Li, X. Double Extended Sliding Mode Observer-Based Synchronous Estimation of Total Inertia and Load Torque for PMSM-Driven Spindle-Tool Systems. IEEE Trans. Ind. Inform. 2022, 19, 8496–8507. [Google Scholar] [CrossRef]

- Bai, Y.; Biggs, J.D.; Wang, X.; Cui, N. Attitude tracking with an adaptive sliding mode response to reaction wheel failure. Eur. J. Control 2018, 42, 67–76. [Google Scholar] [CrossRef]

- Qureshi, M.S.; Swarnkar, P.; Gupta, S. A supervisory on-line tuned fuzzy logic based sliding mode control for robotics: An application to surgical robots. Robot. Auton. Syst. 2018, 109, 68–85. [Google Scholar] [CrossRef]

- Yang, Y.; Yan, Y. Attitude regulation for unmanned quadrotors using adaptive fuzzy gain-scheduling sliding mode control. Aerosp. Sci. Technol. 2016, 54, 208–217. [Google Scholar] [CrossRef]

- Yin, S.; Shi, P.; Yang, H. Adaptive fuzzy control of strict-feedback nonlinear time-delay systems with unmodeled dynamics. IEEE Trans. Cybern. 2015, 46, 1926–1938. [Google Scholar] [CrossRef]

- Xu, C.; Li, D.W.; He, S.; Xia, M.Y.; Xu, Z.B.; Zhao, Z.Y. Design of air-bearing simulator for free-flying robot. Opt. Precis. Eng. 2019, 27, 352–362. [Google Scholar]

| Parameters | Values |

|---|---|

| Mass (kg) | 158.7 |

| Inertia matrix () | |

| Geometric dimensions (m) | 1.6 × 0.9 × 1 |

| Maximum load (kg) | 800 |

| Maximum kinematic thrust (N) | 8 |

| Maximum runtime (min) | 34.3 |

| NB | NM | NS | Z | PS | PM | PB | ||

|---|---|---|---|---|---|---|---|---|

| s | ||||||||

| NB | NB | NB | NM | NM | NS | NS | Z | |

| NM | NB | NM | NM | NS | NS | Z | PS | |

| NS | NM | NM | NS | NS | Z | PS | PS | |

| Z | NM | NS | NS | Z | PS | PS | PM | |

| PS | NS | NS | Z | PS | PS | PM | PM | |

| PM | NS | Z | PS | PS | PM | PM | PB | |

| PB | Z | PS | PS | PM | PM | PB | PB | |

| NB | NM | NS | Z | PS | PM | PB | ||

|---|---|---|---|---|---|---|---|---|

| s | ||||||||

| NB | Z | PS | PM | PB | PM | PS | Z | |

| NM | PS | PM | PB | PB | PB | PM | PS | |

| NS | PM | PB | PB | PB | PB | PB | PM | |

| Z | PB | PB | PB | PB | PB | PB | PB | |

| PS | PM | PB | PB | PB | PB | PB | PM | |

| PM | PZ | PM | PB | PB | PB | PM | PZ | |

| PB | Z | PS | PM | PB | PM | PS | Z | |

| Parameters | Values |

|---|---|

| Mass (kg) | 50 |

| Moment of inertia () | diag (8, 11, 11) |

| Maximum torque () (Nm) | (2, 2, 2.5) |

| Maximum thrust (N) | 4 |

| Disturbance of the position controller (N) | (0.01sin(0.1t), 0.02sin(0.1t), 0.03sin(0.1t)) |

| Disturbance of the attitude controller (N) | (0.1sin(0.1t) + 0.1, 0.2sin(0.1t) + 0.2, 0.3sin(0.1t) + 0.3) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sai, H.; Xia, C.; Xu, Z.; Li, H. Design and Dynamic Control: A Free-Flying Space Robot Inspired by Water Striders. Biomimetics 2023, 8, 437. https://doi.org/10.3390/biomimetics8050437

Sai H, Xia C, Xu Z, Li H. Design and Dynamic Control: A Free-Flying Space Robot Inspired by Water Striders. Biomimetics. 2023; 8(5):437. https://doi.org/10.3390/biomimetics8050437

Chicago/Turabian StyleSai, Huayang, Chengkai Xia, Zhenbang Xu, and Hang Li. 2023. "Design and Dynamic Control: A Free-Flying Space Robot Inspired by Water Striders" Biomimetics 8, no. 5: 437. https://doi.org/10.3390/biomimetics8050437

APA StyleSai, H., Xia, C., Xu, Z., & Li, H. (2023). Design and Dynamic Control: A Free-Flying Space Robot Inspired by Water Striders. Biomimetics, 8(5), 437. https://doi.org/10.3390/biomimetics8050437