1. Introduction

Vapor compression refrigeration systems are used in various fields, such as food preservation in domestic settings, large-scale industrial food storage applications, and air conditioning applications to provide thermal comfort in spaces. It is estimated that approximately 1.5 billion household refrigerators are in operation in the world today, and it is also estimated that 17% of the world’s electricity consumption is spent on the refrigeration sector, 45% of which is used in residential applications [

1]. This situation highlights the importance of making some improvements to reduce energy consumption in cooling systems.

Various approaches have been proposed to improve the energy efficiency of cooling systems, such as improvements in heat exchangers, the use of alternative refrigerants, the commissioning of high-efficiency compressors, the use of improvements in insulation processes, and the implementation of modified refrigeration cycles [

2].

Some studies have been conducted to determine performance parameters such as compressor power consumption and COP of the refrigeration system operating with new-generation hydrocarbon-type (HC) refrigerants. In these studies, new-generation HC refrigerants caused a reduction in compressor power consumption compared to old-generation refrigerants and provided higher COP value in the refrigeration system [

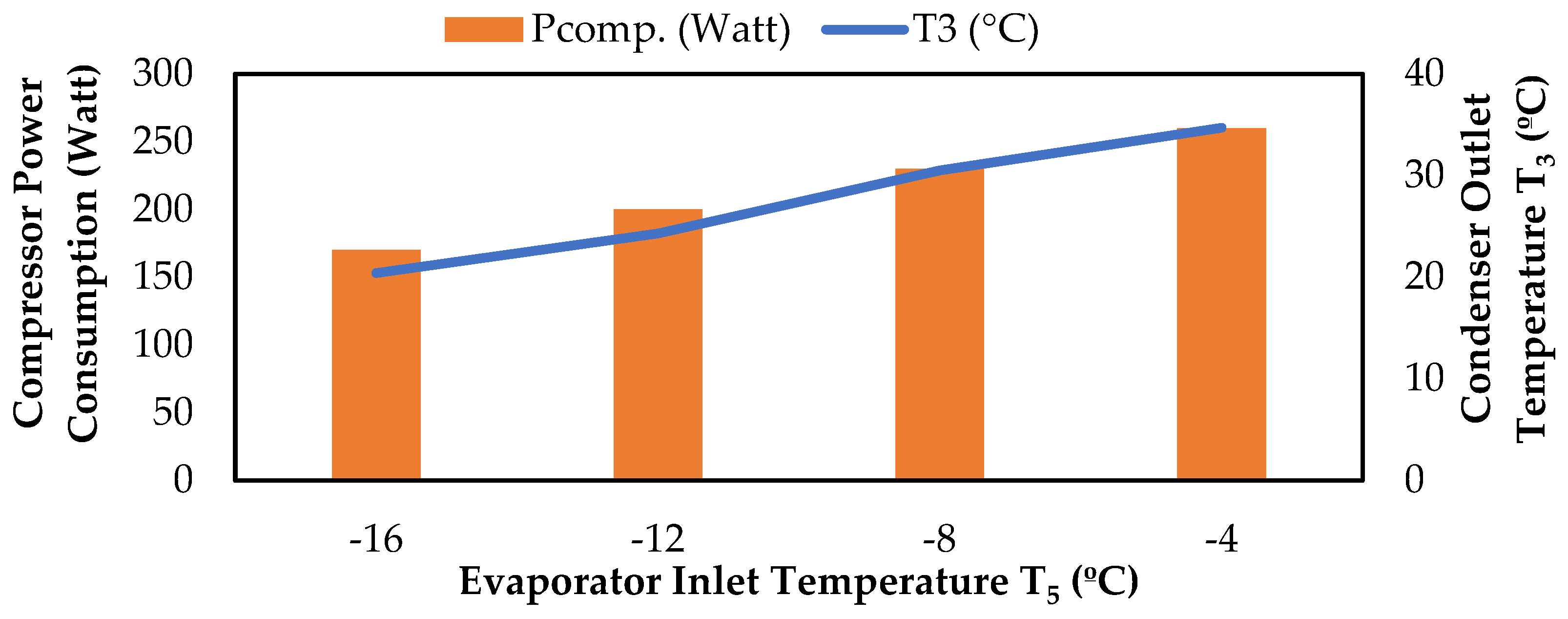

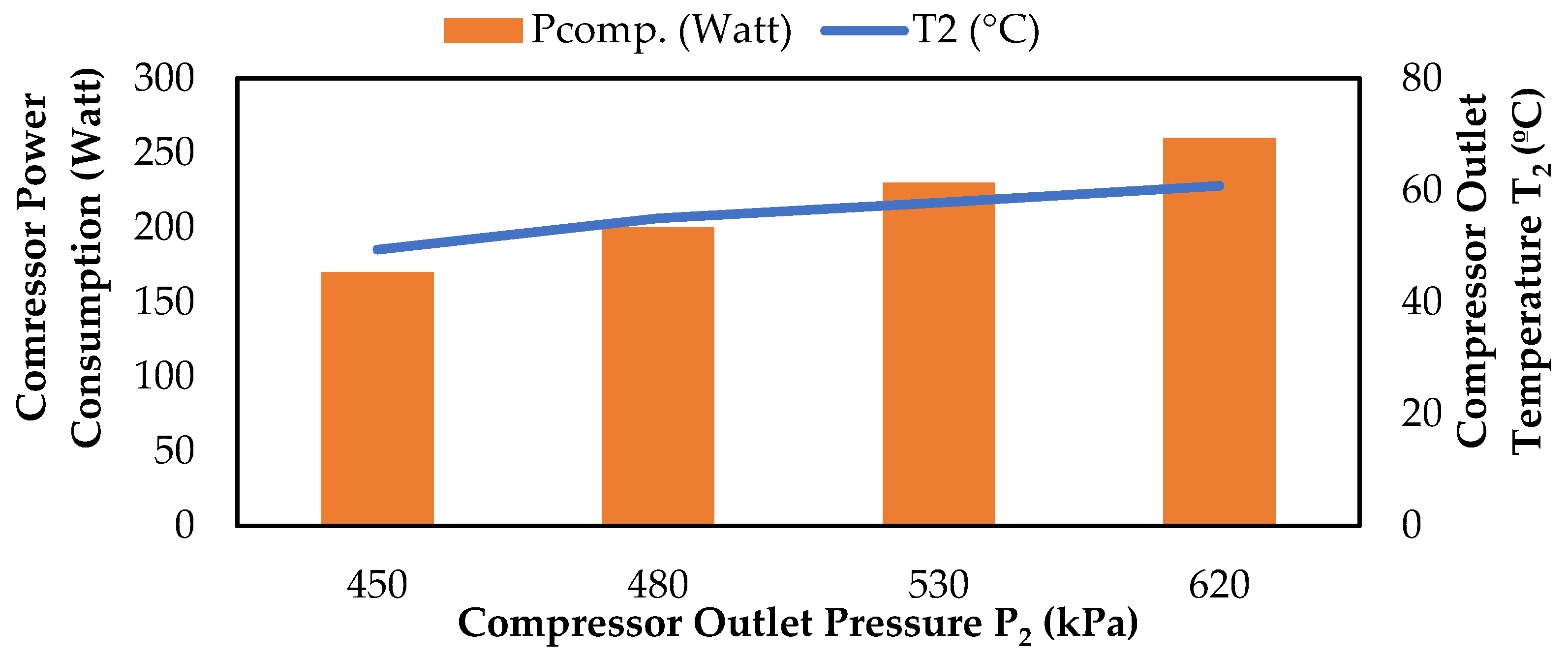

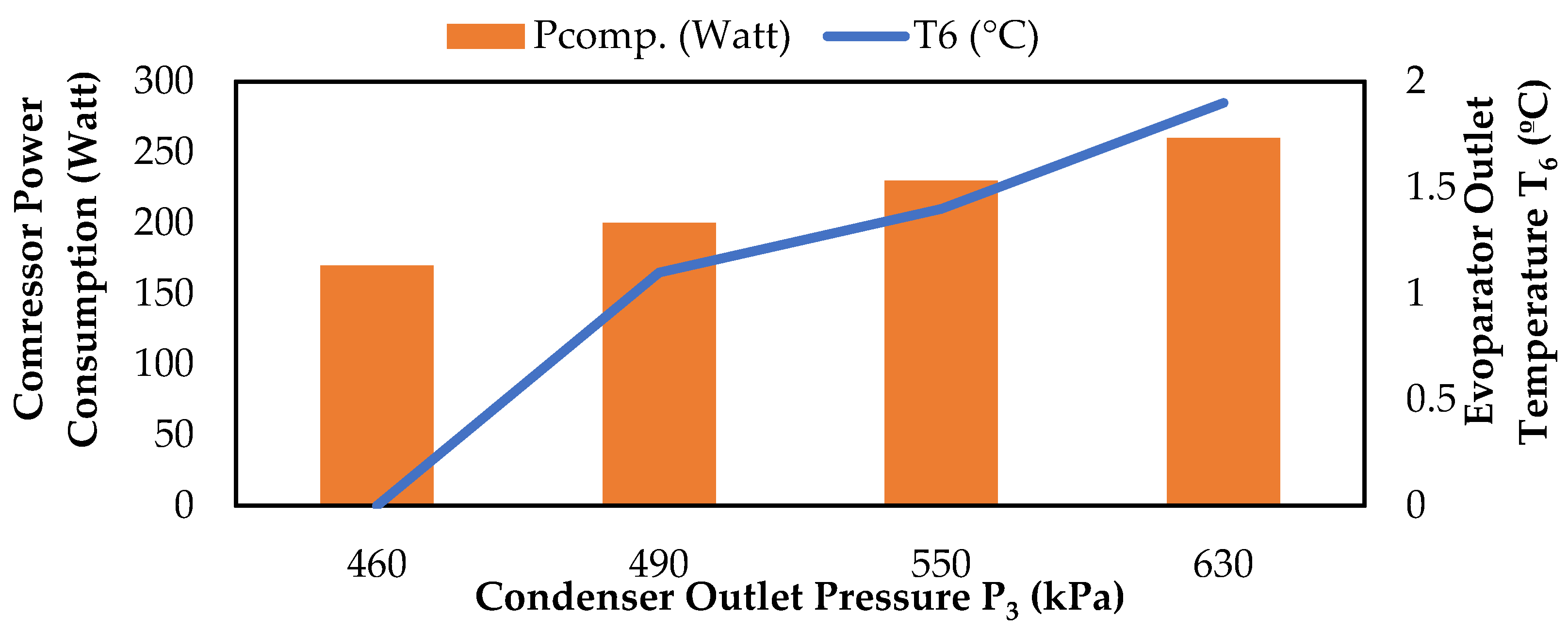

3]. Several studies have been conducted on different refrigerants in vapor compression refrigeration systems to examine compressor energy consumption. The parameters considered in these studies are condenser–evaporator operating temperatures and compressor inlet–outlet pressures.

In his study, Rashed examined the COP values of five different refrigerants to express energy consumption at different condenser operating temperatures (38 and 45 °C) in a vapor compression refrigeration system (VCRS). He stated that the least energy consumption was obtained for R600a gas [

4]. Madeira et al. examined the compressor power consumption of R134a and R600a gases at VCRS for the same condenser (32 °C) and evaporator (−9 °C) outlet temperatures. In all cases, R600a gas showed less power consumption characteristics [

5]. Soni et al. compared the compressor power consumption values of five refrigerants at different evaporator temperatures (−9, −8, −7, −6, and −5 °C) in a VCRS. They showed that the lowest consumption value belonged to R600a gas at all five different evaporator temperature values [

6]. Rasti et al. investigated the energy consumption of three different refrigerants at different condenser and evaporator operating temperatures in a domestic VCRS. They experimentally showed that the lowest energy consumption value was obtained for R600a gas [

7]. Sánchez et al. investigated the compressor power consumption values of six refrigerants at six different evaporator and condenser temperature operating conditions in a VCRS. From their experimental research, they explained that the gas with the lowest compressor power consumption value was R600a [

8]. Babarindea et al. examined the compressor energy consumption of R134a and R600a gases in VCRS. Different volume fractions of R600a gas and nanoparticulated R600a gas exhibited lower compressor power consumption [

9]. Elakhdar et al. investigated the effects on compressor power consumption by examining the saturation pressures of R134a, R290, and R600a refrigerants at different operating temperatures in a VCRS. R600a, with the lowest pressure, consumed less energy [

10]. In another study by Rasti et al. [

7], the refrigerator test bench with an HFC-type compressor consumed 7% less power using R600a instead of R134A, while it consumed 18.7% less power with an HC-type compressor.

When studies on R600a refrigerant in the literature were examined, it was seen that this gas provides low compressor consumption. Studies have shown that the parameters affecting compressor power consumption are condenser and evaporator operating temperatures. For this reason, compressor power consumption values of R600a gas were examined in experiments conducted at different evaporator–condenser temperatures, and different pressures and datasets were obtained during the experiments. Transparent models expressing the compressor power consumption values of R600a were produced using these datasets and explainable artificial intelligence methods.

In artificial intelligence studies related to refrigeration systems, different artificial intelligence methods, especially ANN (artificial neural network) and ANFIS (adaptive neuro-fuzzy inference system), have been applied to model compressor power consumption and energetic and exergetic performance parameters of different refrigerants. Recently, the modeling of various parameters (coefficient of performance, compressor power consumption, refrigerant gas temperature, etc.) in refrigeration systems with artificial intelligence methods has become very popular [

11]. Ghanbarpour et al. modeled the COP, cooling capacity, and carbon footprint of R449A and R404A refrigerants in a vapor compression refrigeration system with ANN. They stated that the error value between the model and experimental results did not exceed 10% [

12]. Maiorino et al. used ambient temperature and system set temperature as input data to model the energy consumption of a VCRS system with ANN. They calculated that the MAPE value between experimental and ANN values was 3.8 [

13]. Belman-Flores et al. estimated the energy consumption of a VCRS with the help of ANN using condenser and evaporator temperature values. They found the relative error between the predicted and experimental values to be 0.05 [

14]. Asensio-Delgado et al. used machine learning to predict the solubility of high GWP refrigerants in ionic liquids in refrigeration systems. The average RMSE value of the model they obtained was 0.04 [

15]. Yıldırım and Şahin estimated the energy and exergy performances of new-generation refrigerants (R515A, R516A, and R515B) in a VCRS with an adaptive-network-based fuzzy inference system. The average MAPE results of the predictive model for energy and exergy values of the three new-generation refrigerants were 5.7% and 5.5%, respectively [

16].

Artificial intelligence methods for the abovementioned cooling systems are black-box approaches that, while better in accuracy values, can be insufficient in terms of explainability of the model. In black-box approaches, it is unknown how components (inputs) affect the goal value (output). Extensive literature studies on artificial intelligence show that practically all of the studies are black-box systems. Despite their excellent accuracy, these systems’ models are woefully inadequate in terms of explainability, interpretability, and comprehensibility. As a result, intelligent classification models with high precision, accuracy, recall, and interpretability are required. The motivation for this study, which marks a difference from other studies in the literature, is to propose a new model based on automatic transparent rules based on explainable optimization that expresses the compressor energy consumption values of R600a gas in refrigeration systems. The model is obtained using experimental data. It is important to note that this dataset has different operating temperatures, pressure values, mass flow rates, and compressor power consumption values of R600a. Therefore, using a common dataset for this refrigerant and generating models with this dataset increases the applicability of the generated models to other refrigeration systems operating with different refrigerants and makes the current study different from others in the literature.

Many classification models and architectures employed for the problem in focus are commonly referred to as “black boxes” due to their complex internal structure and inability to provide precise information to arrive at a decision. In general, the best models may have the least explainability, and the worst models may have the most explainability. This study is the first attempt at developing an intelligible, comprehensible, and interpretable transparent artificial intelligence method for modeling the energy behavior of R600 gas in a VCRS by balancing and optimizing both explainability and accuracy.

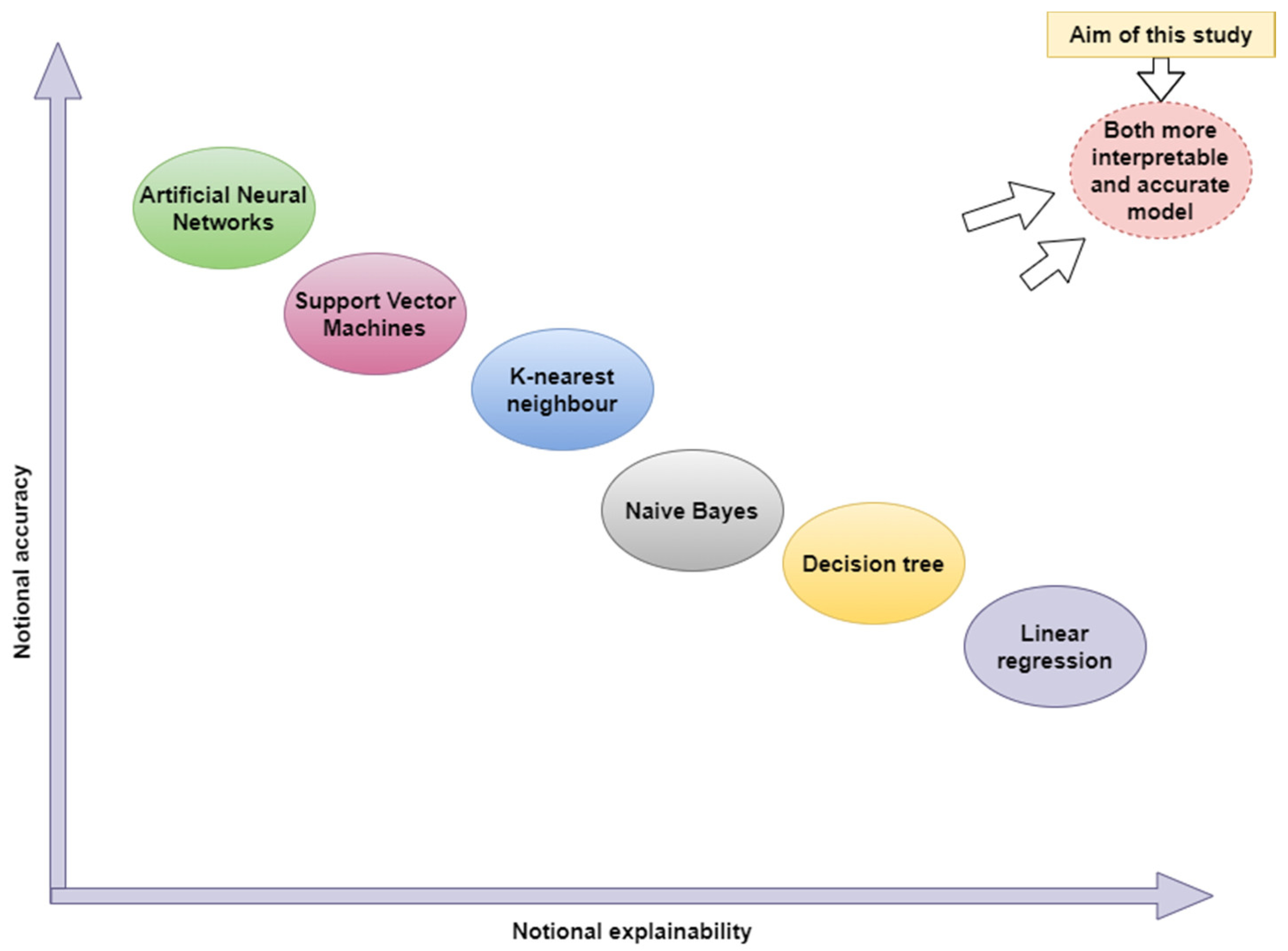

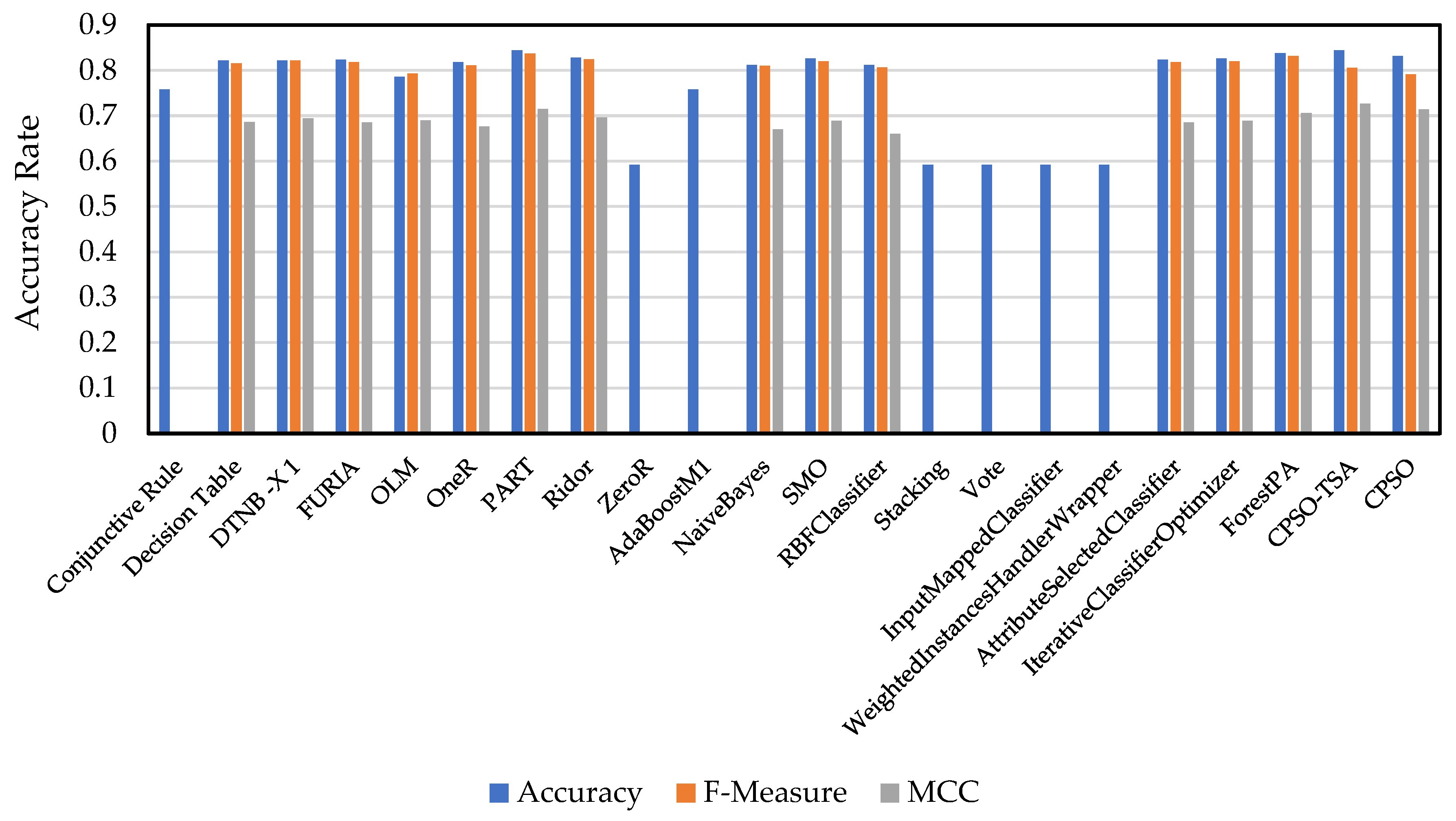

Figure 1 depicts accuracy vs. explainability of the main artificial intelligence classification algorithms [

17]. The models are ranked on the X-axis based on their interpretability, and the relative accuracy of these methods is mentioned on the Y-axis. Neural networks are at one end of the spectrum, achieving the highest accuracy but not being comprehensible and interpretable. The models where knowledge is most directly represented are located at the other side of the spectrum on the right. The current work aims to develop an optimization-based novel intelligent classification system with excellent explainability and accuracy capabilities.

The primary contributions of this work are listed as follows:

- -

The problem of obtaining models that determine the energy consumption values of R600a gas according to operating parameters is considered for the first time as an optimization problem with the goal of more successfully conducting classification in terms of various metrics.

- -

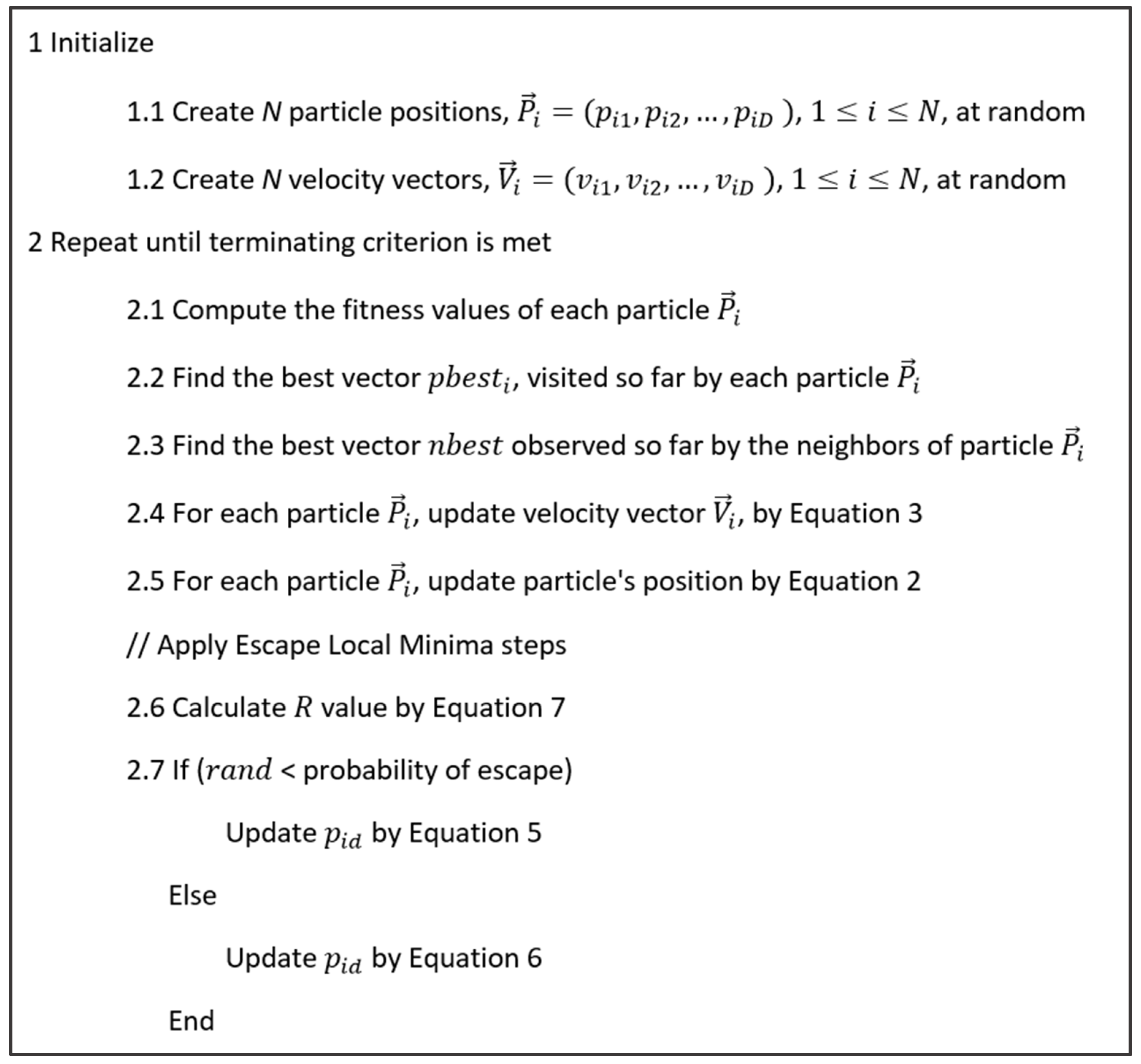

A hybrid intelligent optimization method that can be efficiently used for many search and optimization problems is proposed.

- -

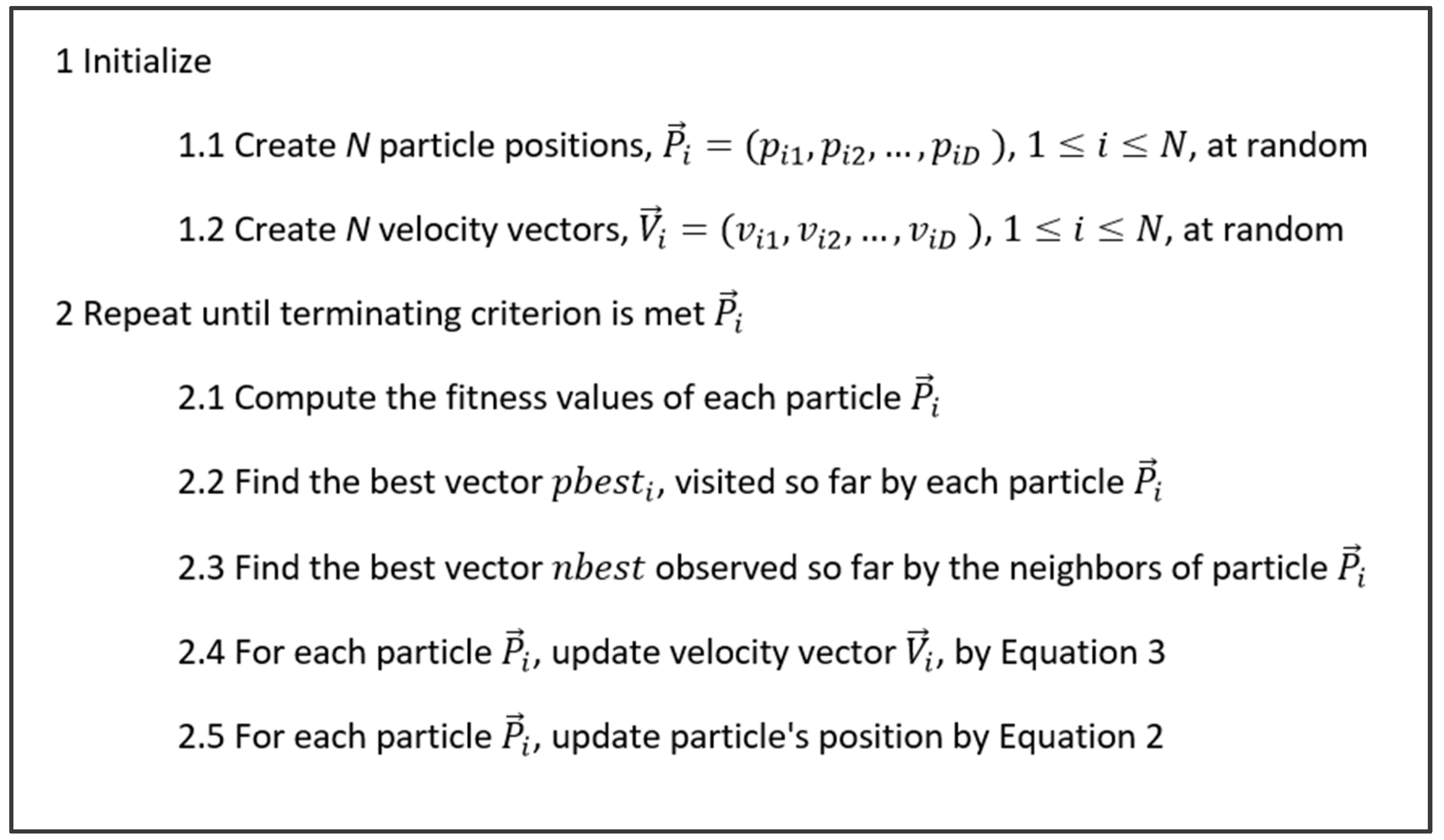

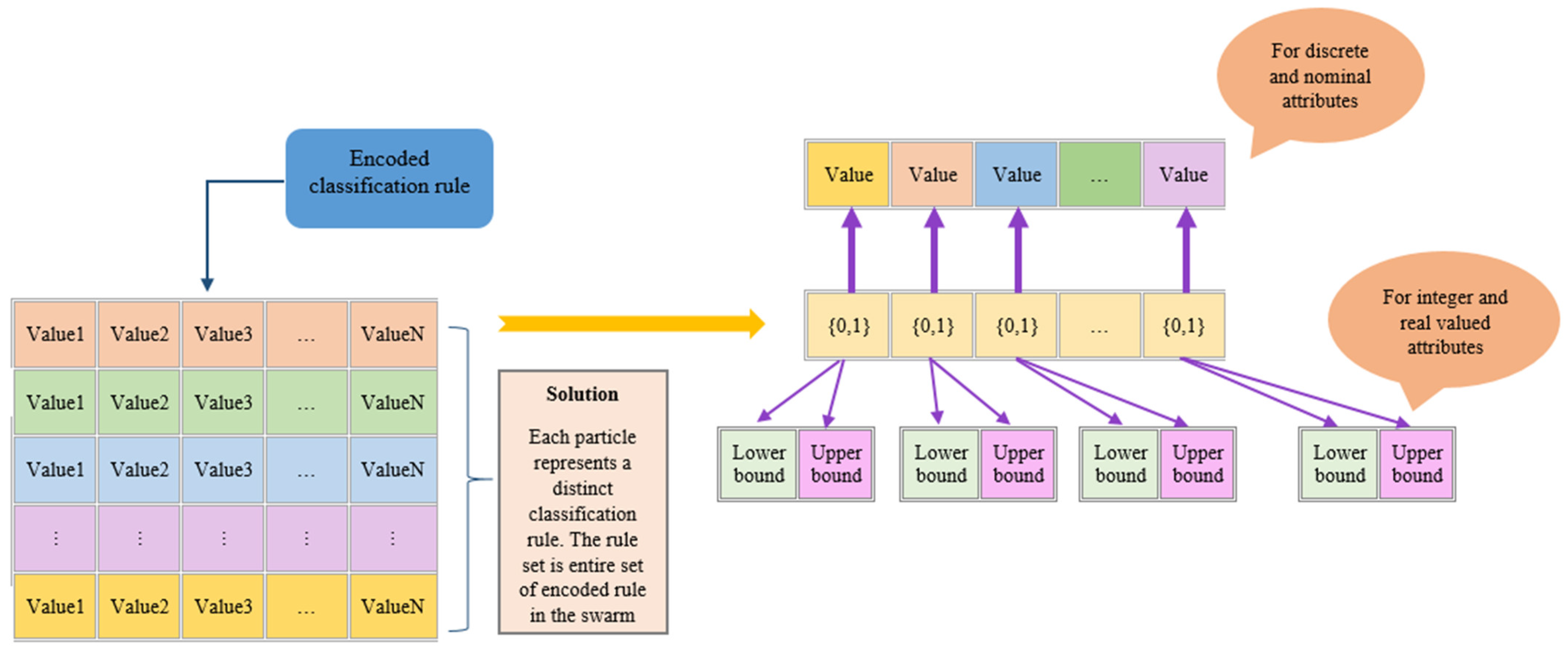

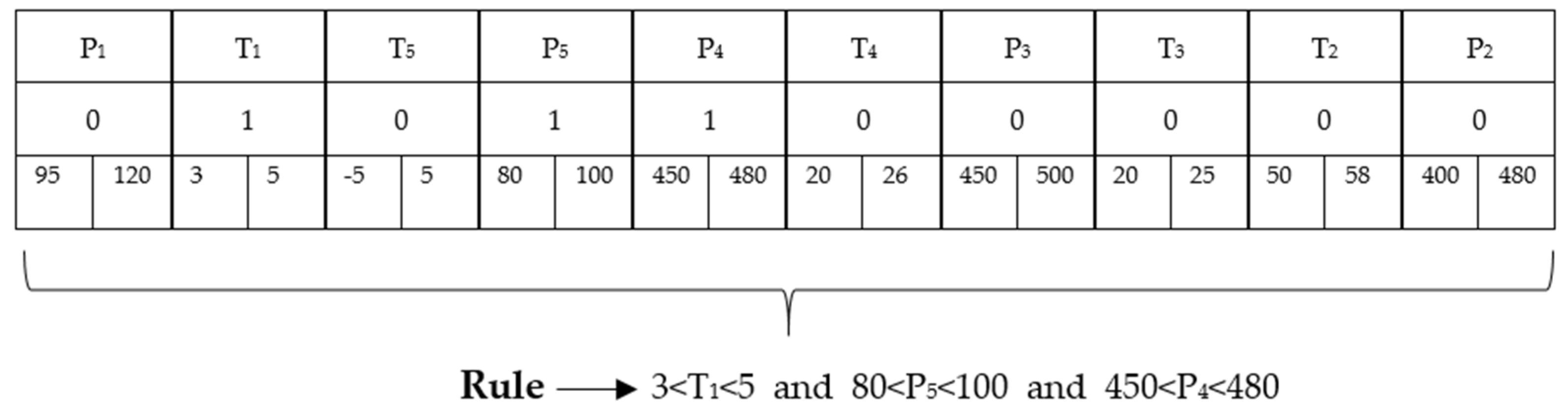

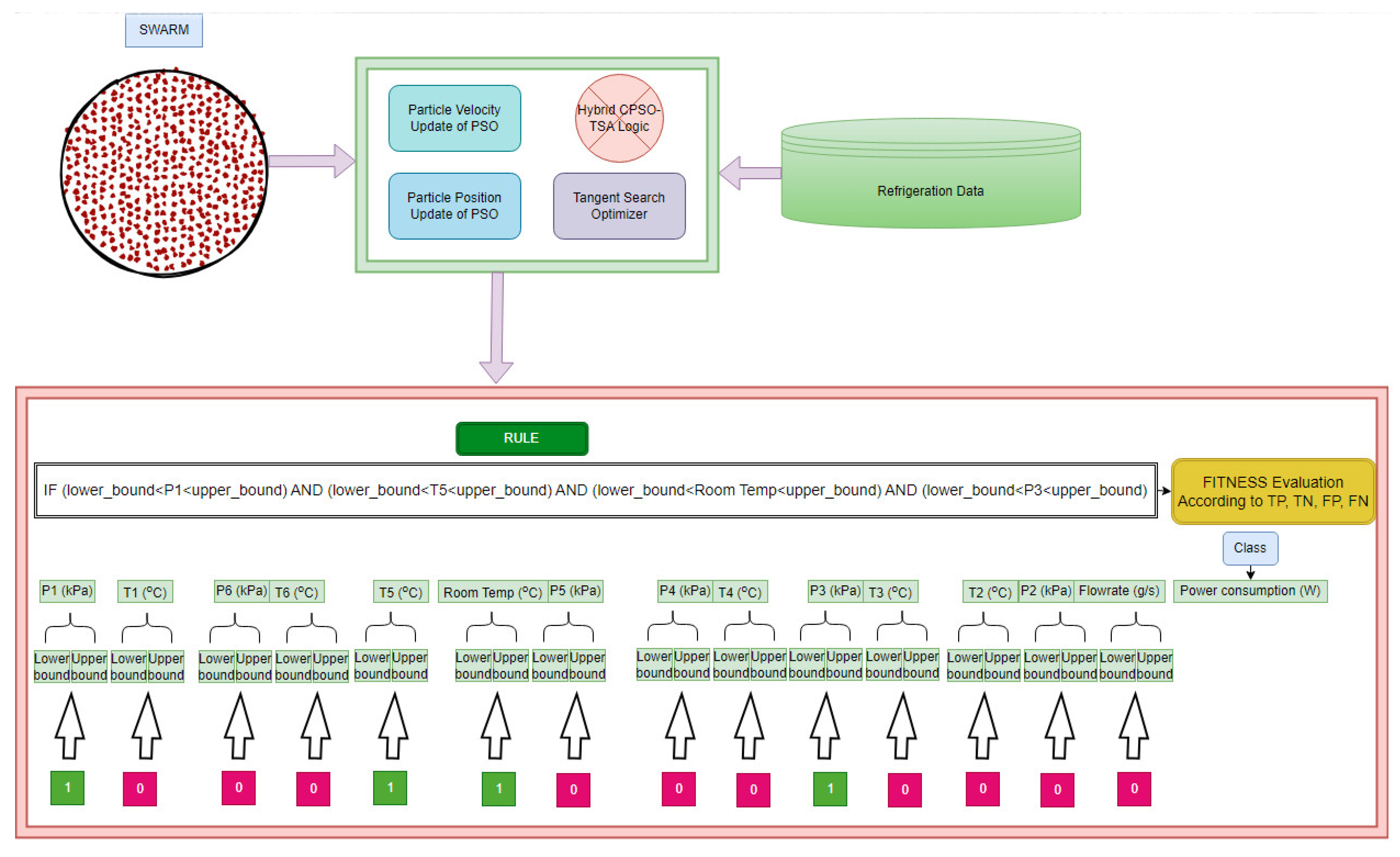

A common dataset for this refrigerant is considered as search spaces, and a hybrid intelligent optimization method that combines constricted particle swarm optimization and tangent search algorithm is proposed by modifying the search strategy of a successful classification model to determine the compressor energy consumption values of R600a gas in refrigeration systems.

- -

The proposed hybrid intelligent optimization algorithm is adapted to function as an explainable, interpretable, comprehensible, and understandable classification rule mining method for the first time. By overcoming the difficulty of constructing a comprehensive optimal model while maximizing the performance metrics, the proposed hybrid intelligent optimization algorithm is implemented as a direct interpretable classification methodology for the first time.

- -

The proposed methodology avoids data preprocessing, such as fuzzyfication, discretization, and so on, while still identifying suitable intervals for features without changing or manipulating the data during the development of the classification model.

- -

The proposed intelligent optimization-based classification model is compared with legacy and state-of-the-art supervised classification methods. Although the proposed interpretable algorithm is new, it can achieve better results in many metrics by surpassing other methods.

- -

The proposed approach provides an important innovation in determining the optimum operating conditions to obtain the minimum energy consumption conditions of different refrigerants.

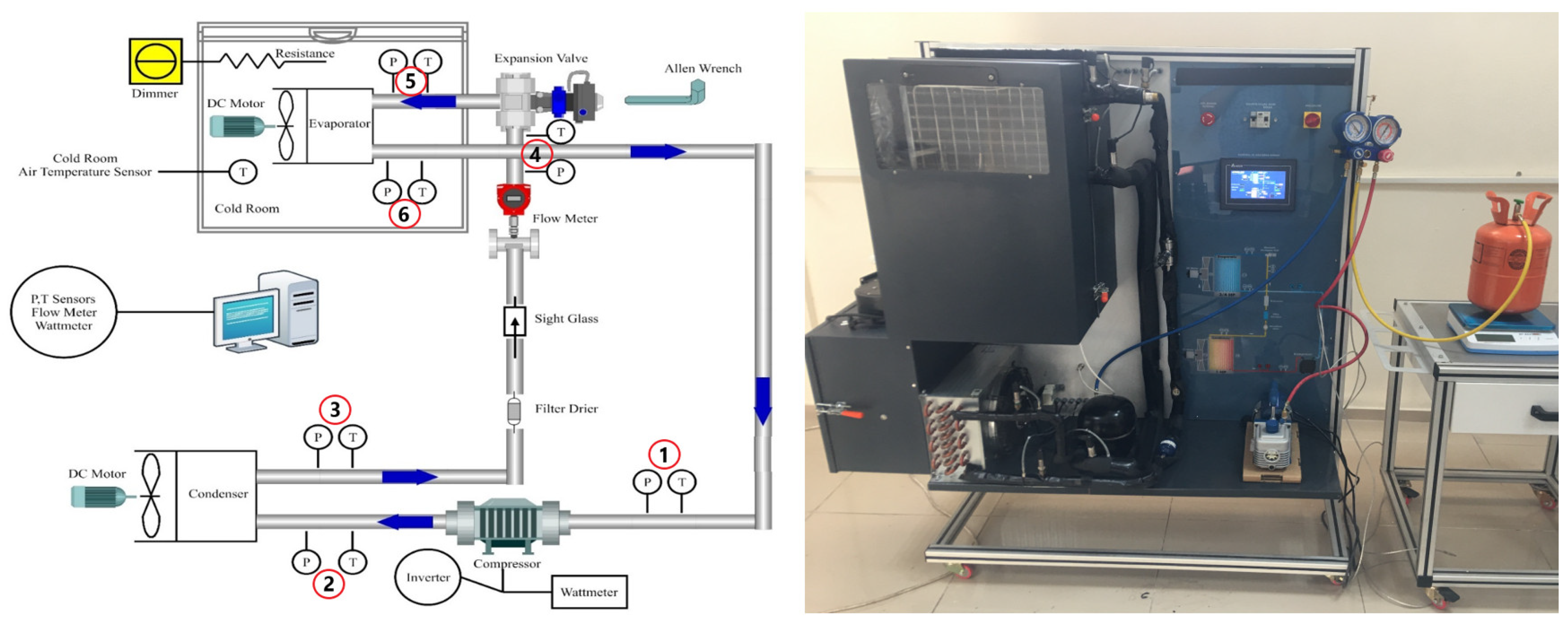

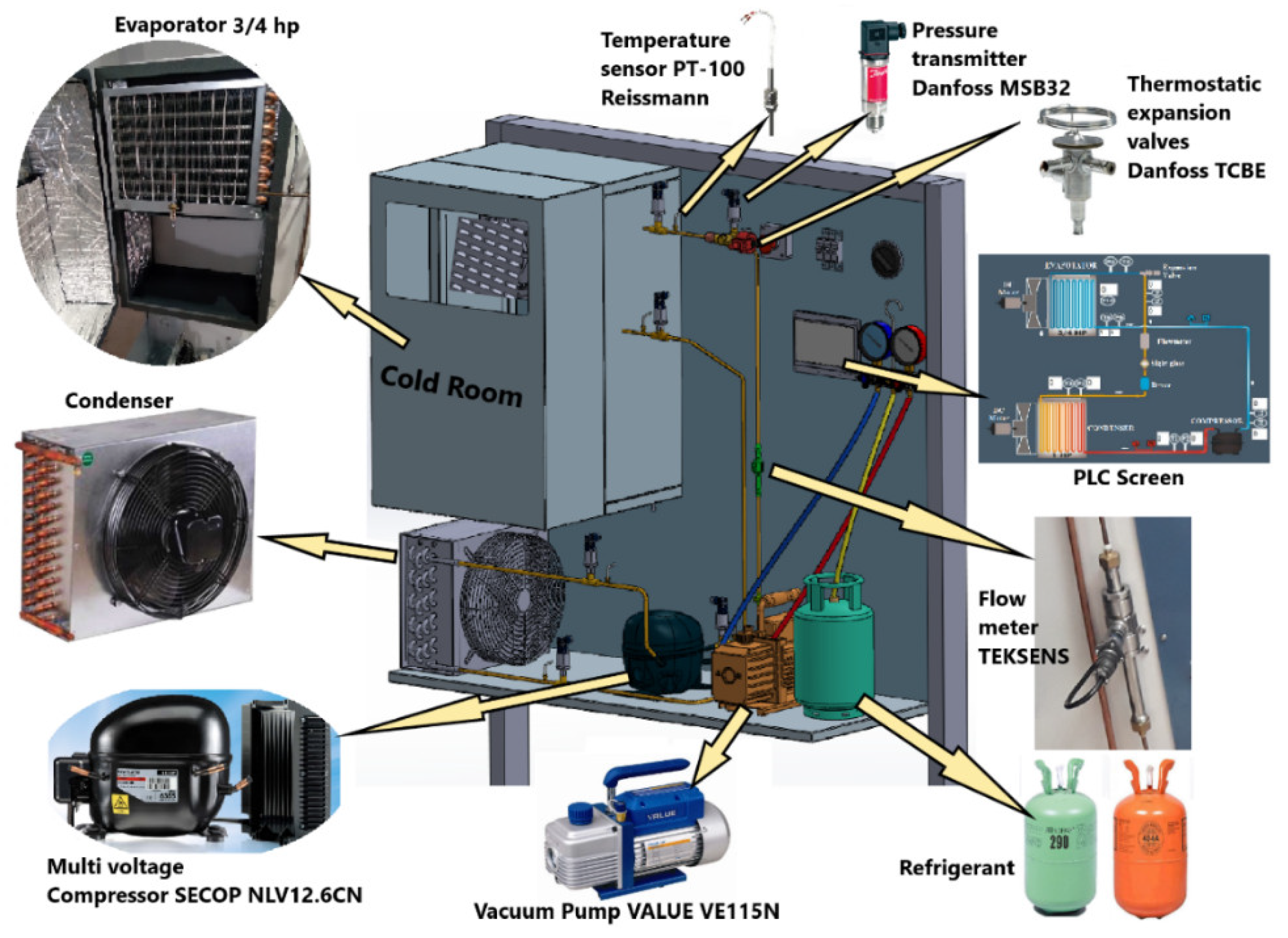

For R600a refrigerant gas, experiments were carried out at different condenser and evaporator operating temperatures in VCRS, and datasets consisting of measured parameters were obtained. Using this dataset, optimization-based, transparent, and explainable rules for the energy consumption of R600a gas in a refrigeration system under different operating conditions were obtained. The experimental setup, the measured parameters, and the artificial intelligence method are described in detail in the next sections.

4. Conclusions

Refrigerant gases, which are used in different processes according to their energy consumption values and are a basic cooling system component, are preferred primarily in terms of their energy consumption values and low global warming potential. For a sustainable environment and refrigeration technology, it is of critical importance to resize and examine the power consumption values of the components working with the increasingly popular R600a refrigerant gas. In this study, for the first time, the classification of energy consumption values of R600a gas according to operating parameters was considered as an optimization problem. In addition, in order to increase the performance of the CPSO algorithm, a new intelligent hybrid optimization method called CPSO-TSA, in which TSA’s escape local minima steps are applied, was proposed. Refrigerant dataset was considered as search spaces, and a hybrid intelligent optimization method was proposed by modifying the automatic direct search strategy of a successful classification model to determine the compressor energy consumption values of R600a gas in refrigeration systems. This study modeled determination of the optimum operating conditions to achieve minimum energy consumption conditions for different refrigerants as an automatic rule-based optimization problem, which is a novel concept, and interesting and promising results were obtained from this new methodology using the designed proper fitness function and suitable representation scheme. All performance criteria for the proposed optimization based direct classification model will be simultaneously improved in the future.

This paper presents explainable and interpretable rules for the energy consumption of R600 gas using system parameters measured in a VCRS. There are valuable studies in the literature that model system irreversibility using ANN [

33,

34,

35]. This study used direct compressor power consumption values as the basis for energy consumption values. In the future, performance parameters, including system irreversibility and power consumption, will be modeled with explainable artificial intelligence methods using different refrigerants. When the results were examined in general, the proposed hybrid CPSO-TSA model showed 84.4% success when used as training data, 80.6% when taken as

k = 3 fold, and 79.67% when taken as

k = 5. Compared to other algorithms, it gave very successful results. In addition, considering the error rates, it achieved good success by giving a very low value of 0.16 MAE. Similarly, it performed well, achieving 0.39 RMSE and 0.69 kappa statistics.

The proposed comprehensible, transparent, interpretable, and explainable artificial intelligence model provides an important innovation in determining the optimum operating conditions to obtain the minimum energy consumption conditions of different refrigerants. The proposed intelligent optimization-based interpretable methodology also seems to be successfully and easily adapted for numerous classification tasks. Different hybridization approaches, adaptive methods, and parallel versions of this method are other possible topics for further research.