Cushioning Performance of the Biomimetic Cobweb Cushioning Silicone Pad

Abstract

:1. Introduction

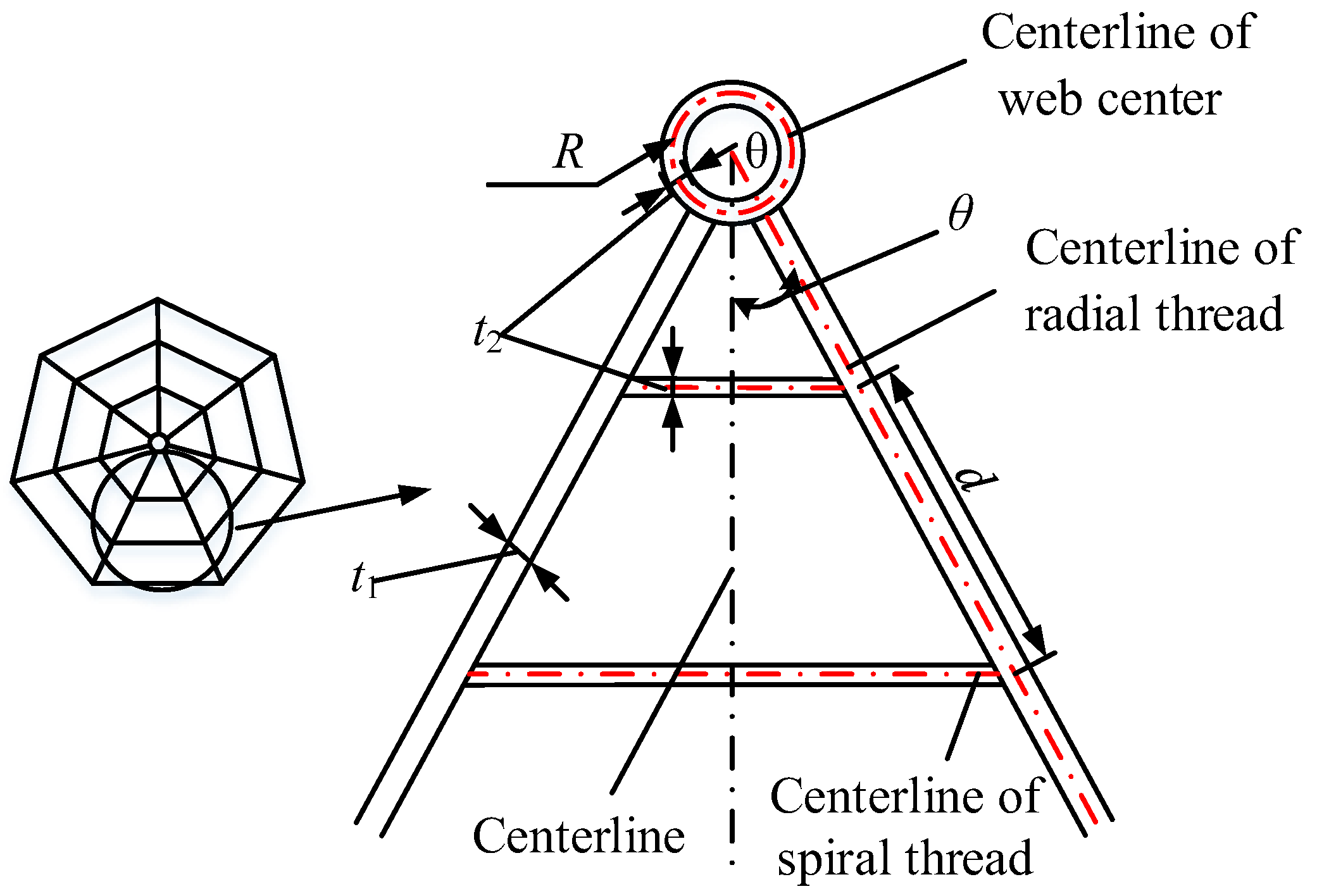

2. Biomimetic Research on Cobweb Configuration

2.1. Research on Cobweb Configuration

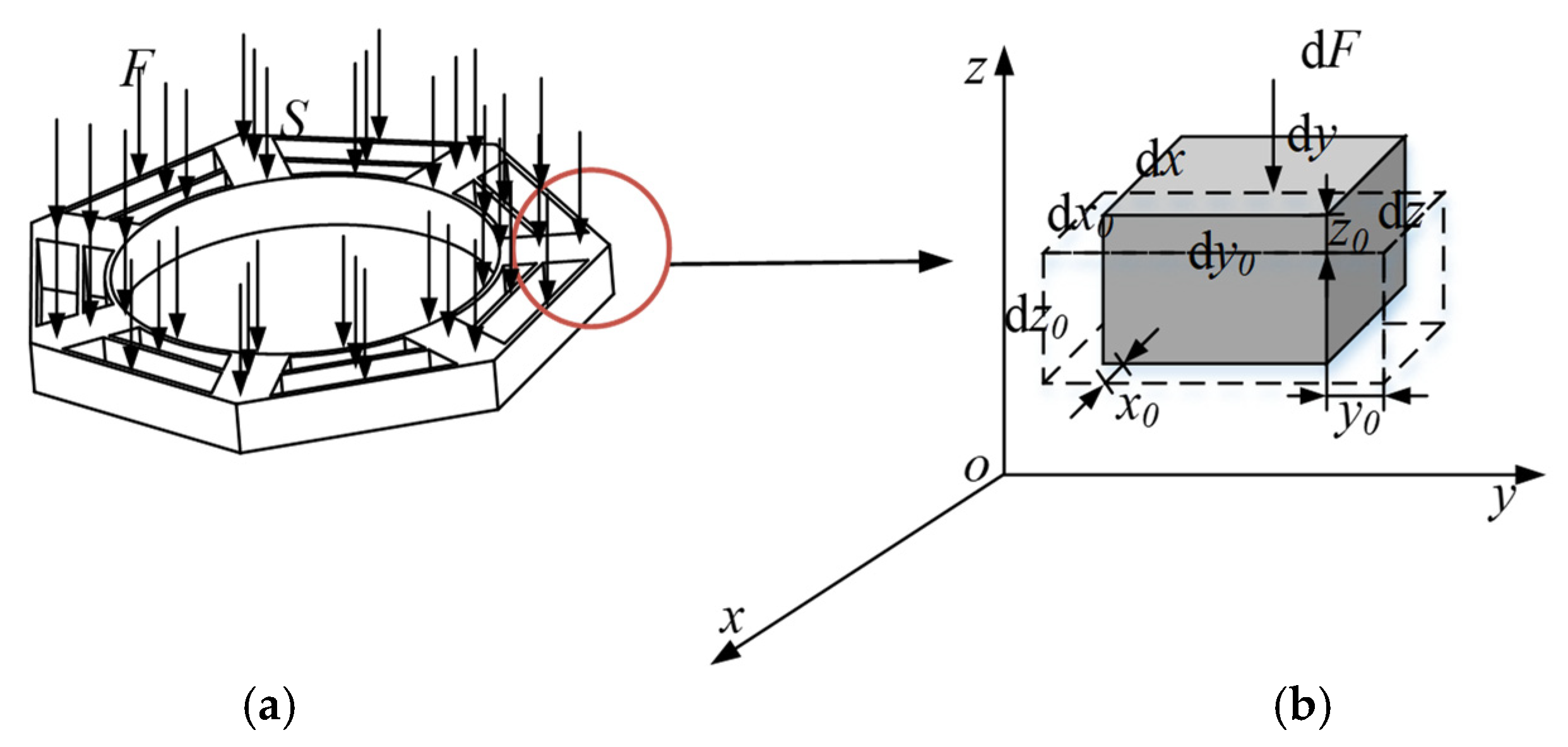

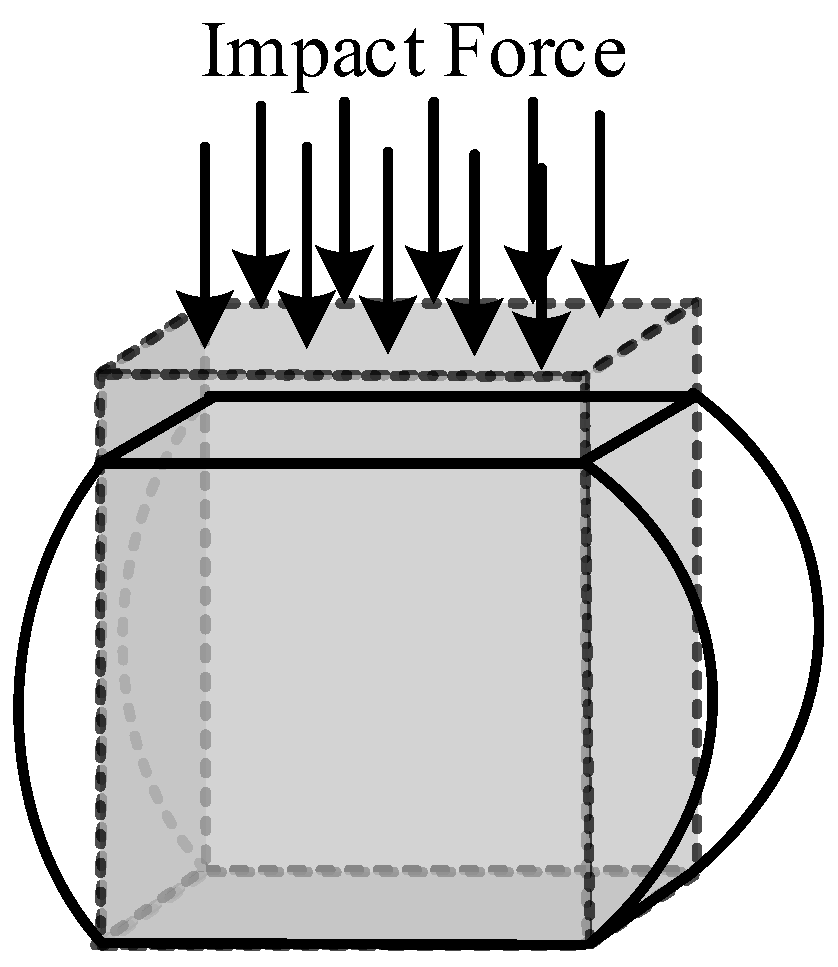

2.2. Mechanical Model of Cobweb Structure Cushion

2.3. Optimization of Structural Parameters of Cobweb Bionic Cushion

2.4. Calculation of Cushion Thickness of Cobweb Structure

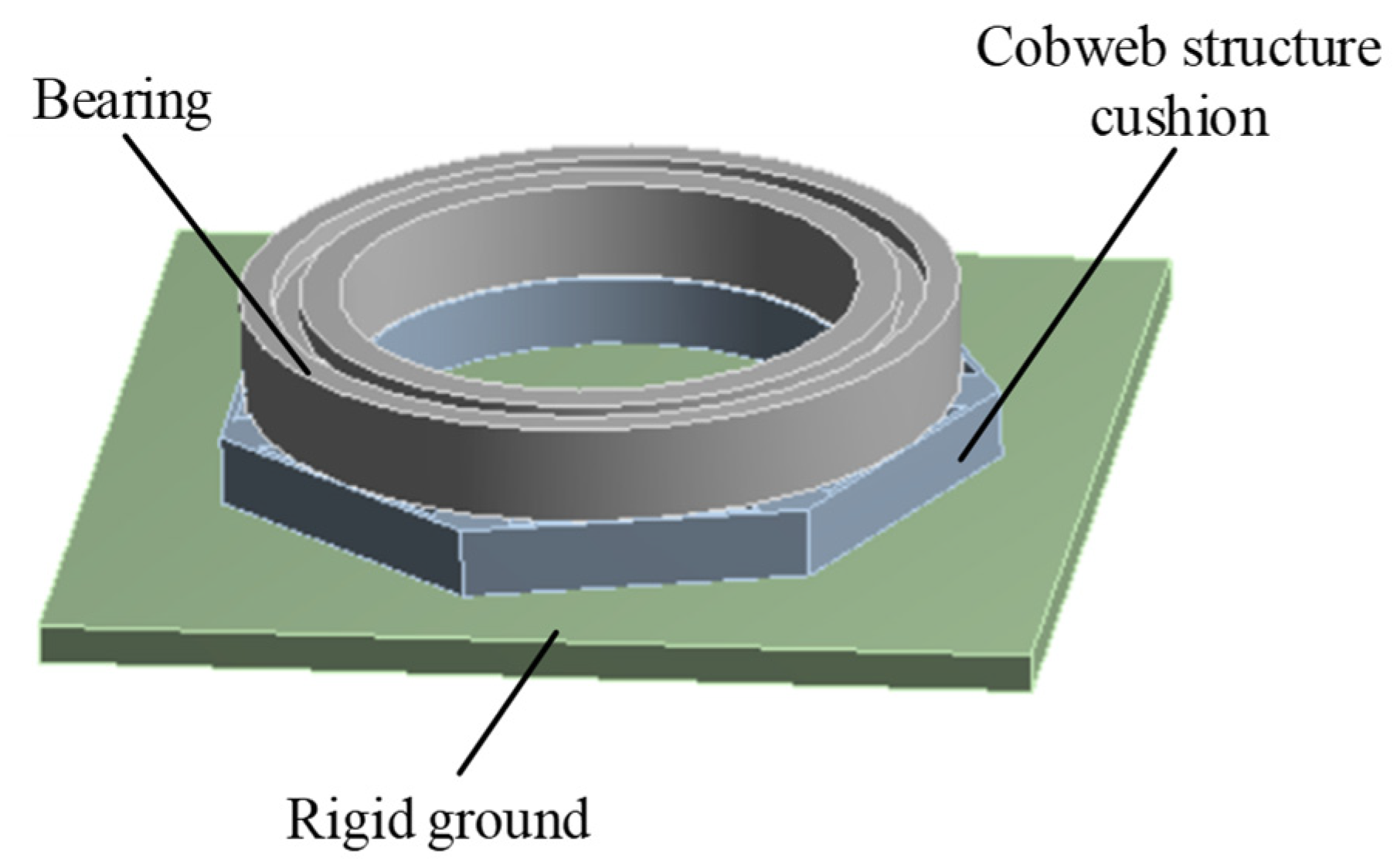

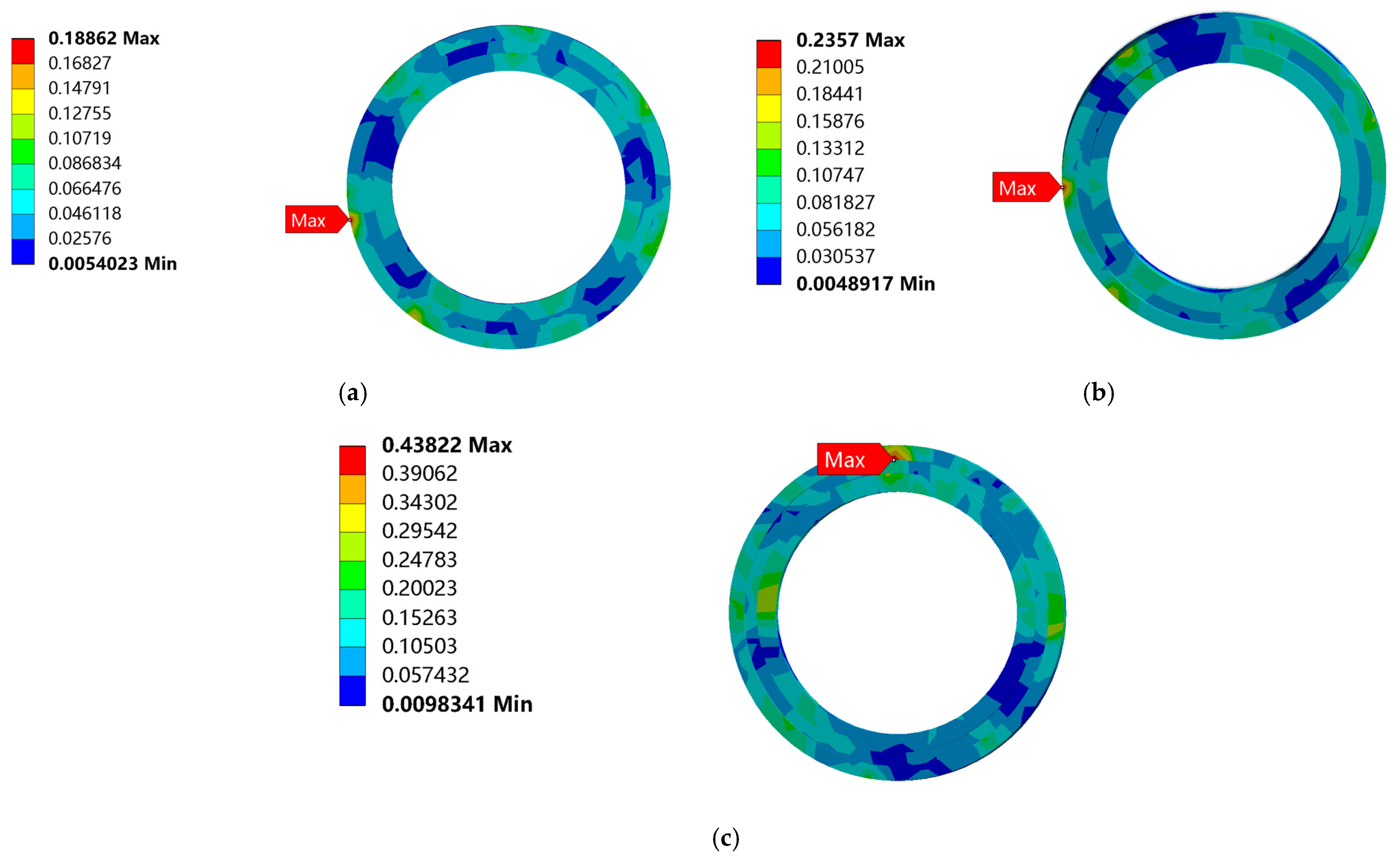

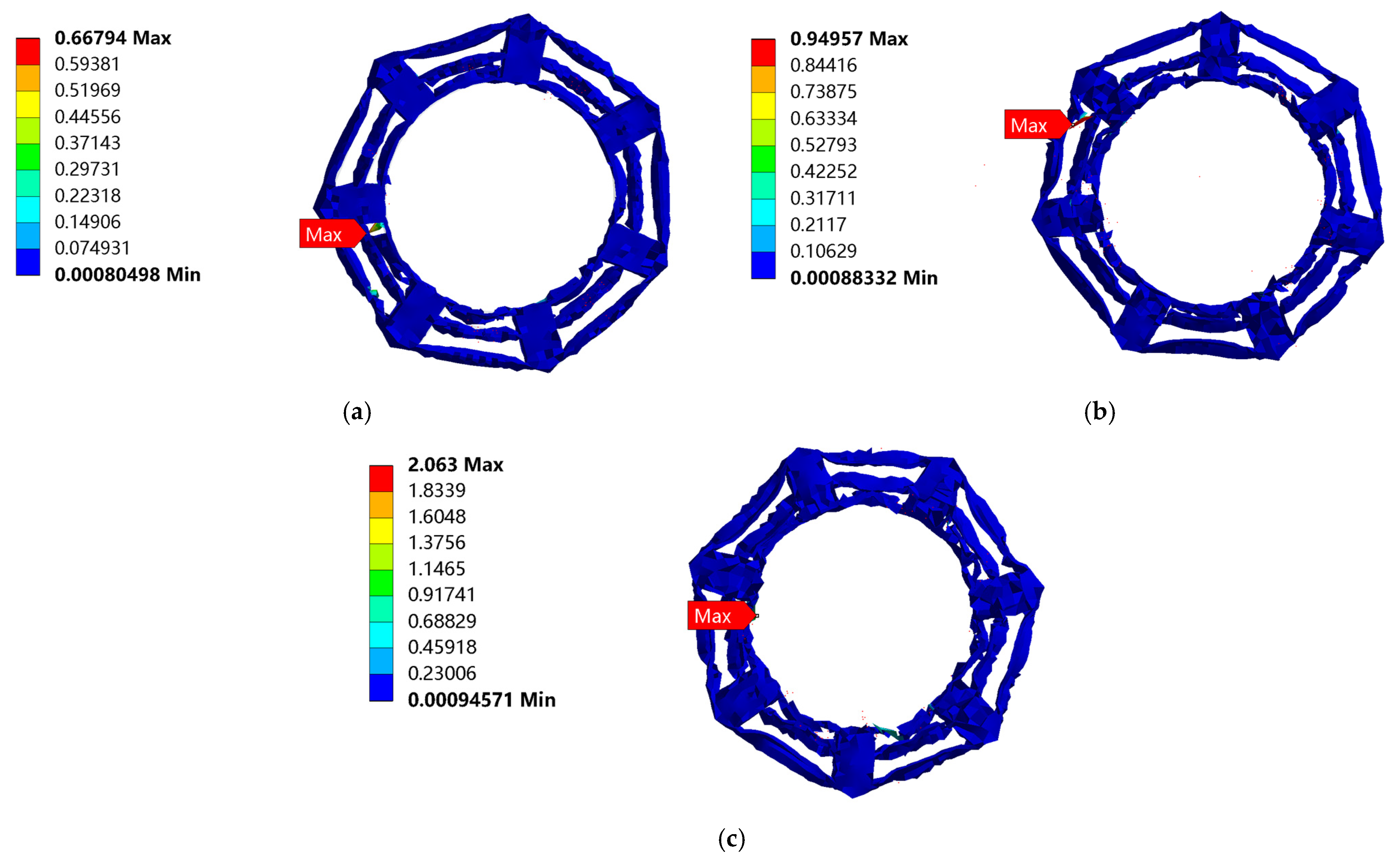

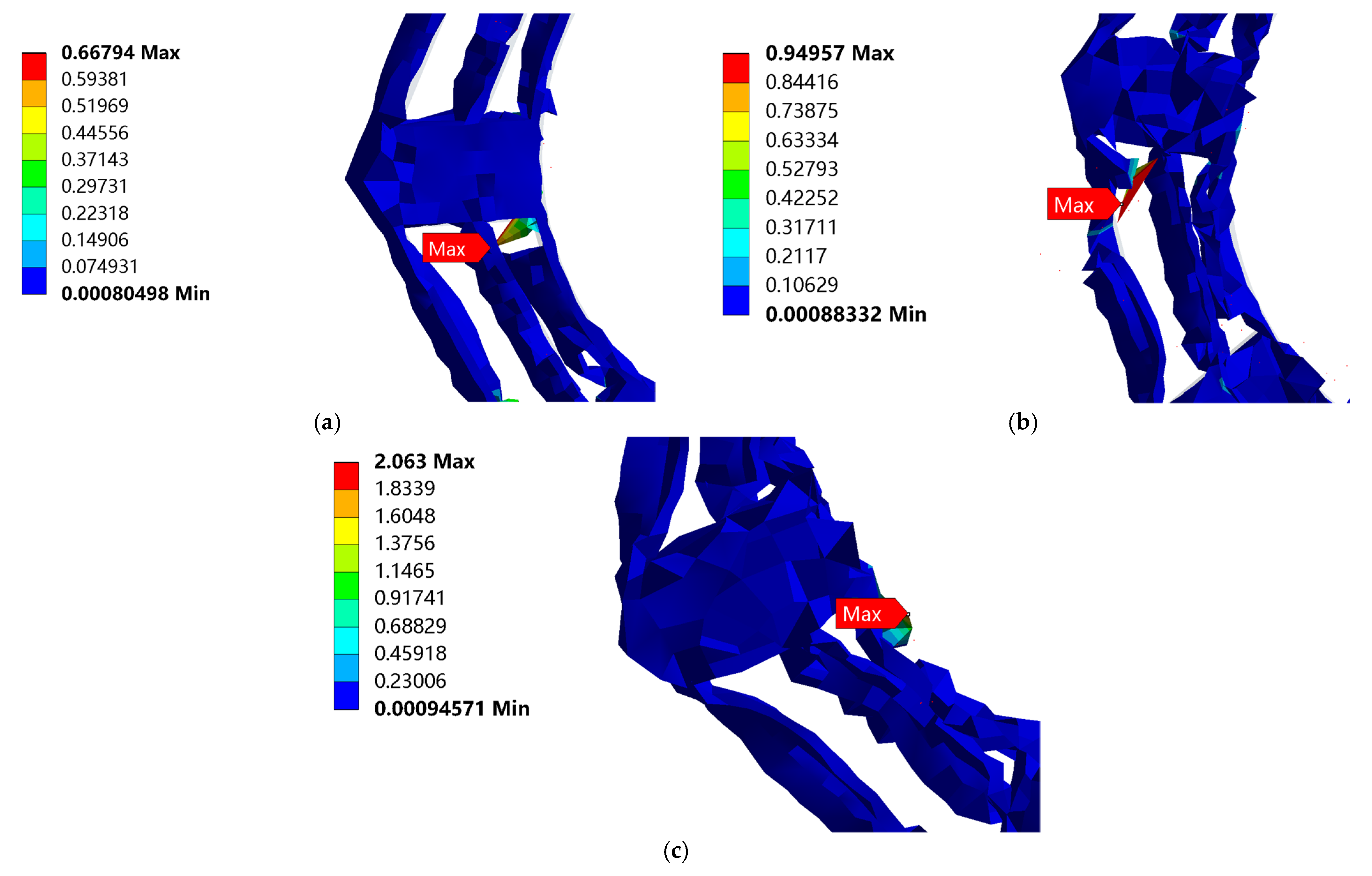

3. Simulation

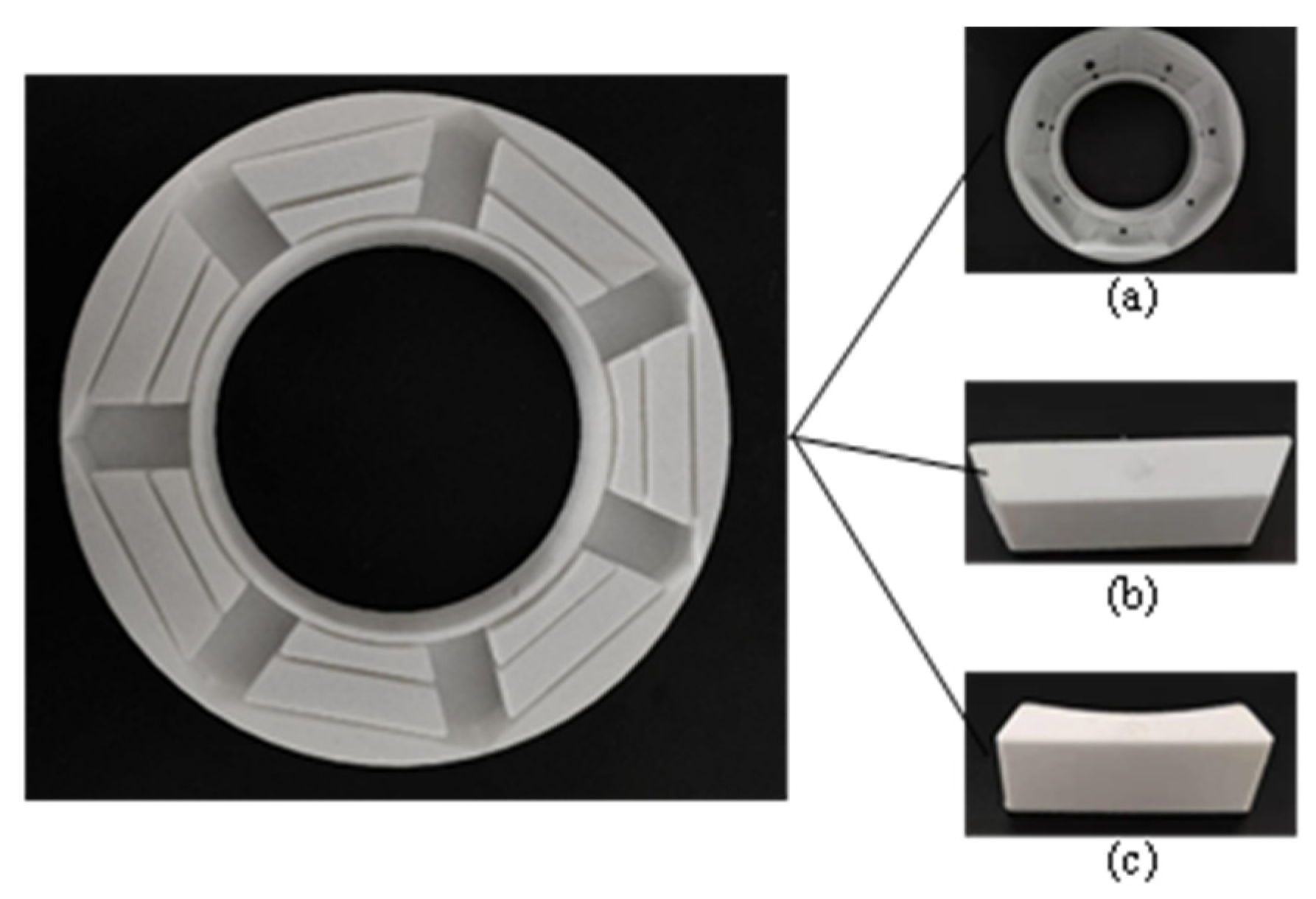

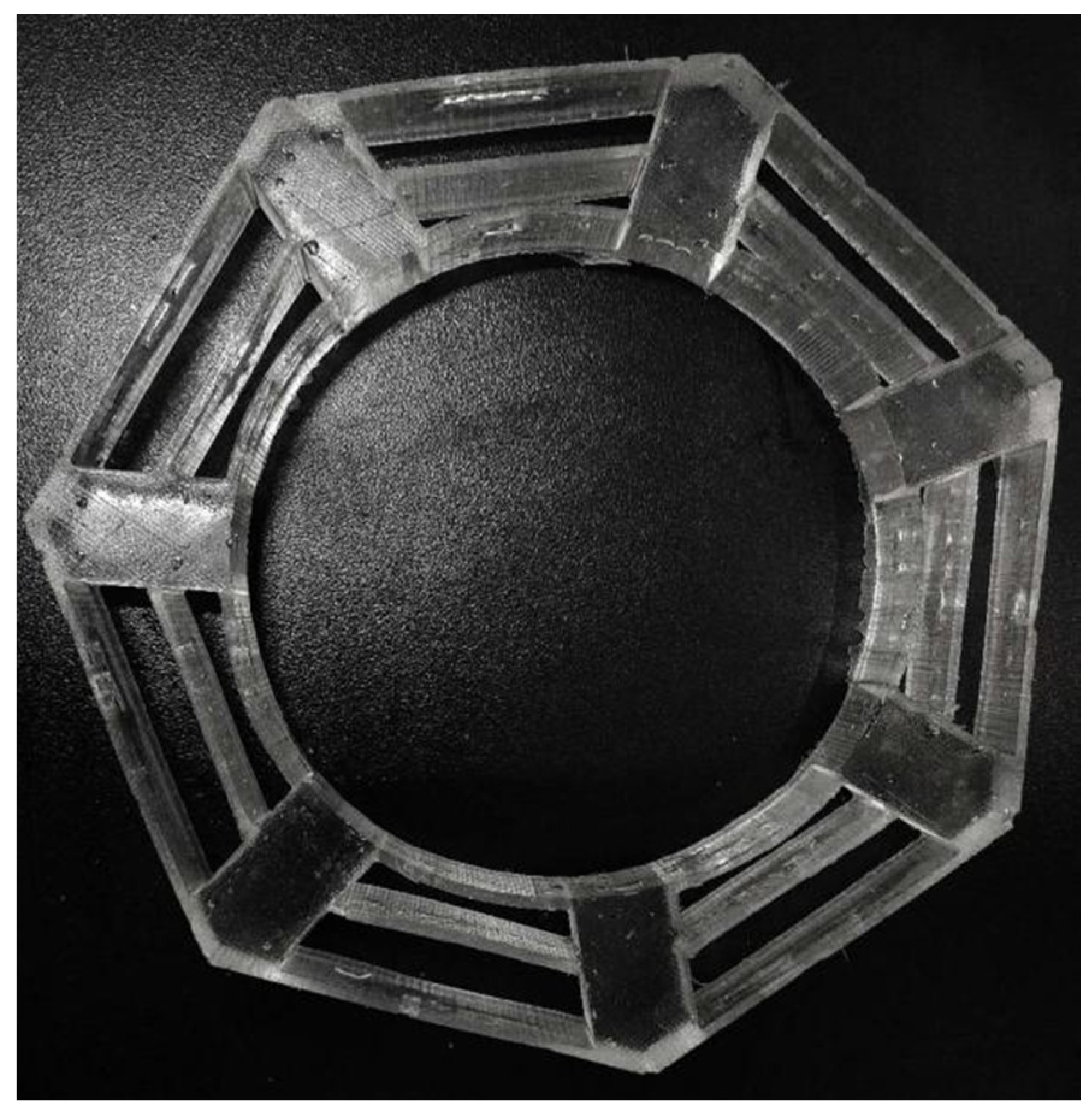

4. Preparation of the Cobweb Structure Cushion Material Cast

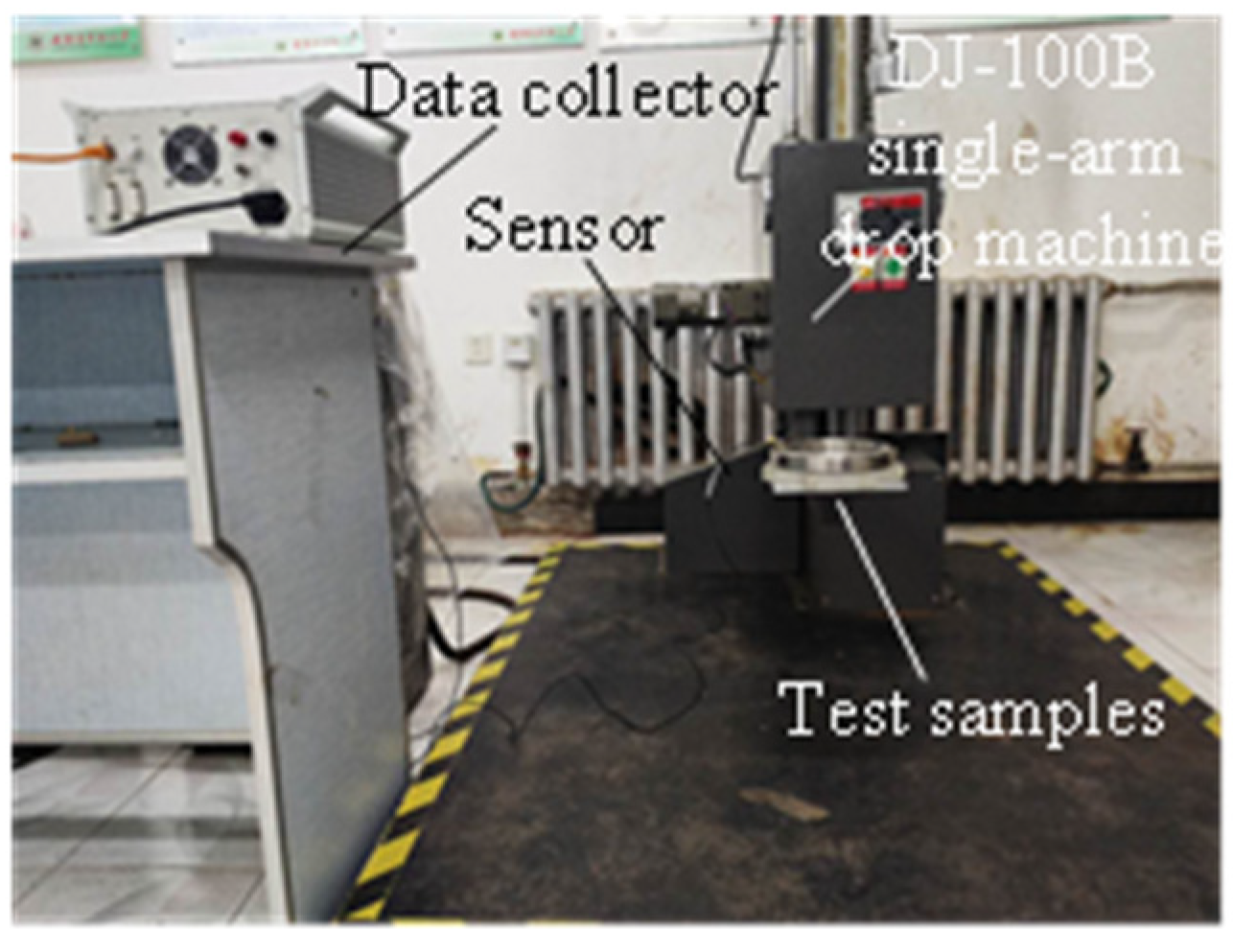

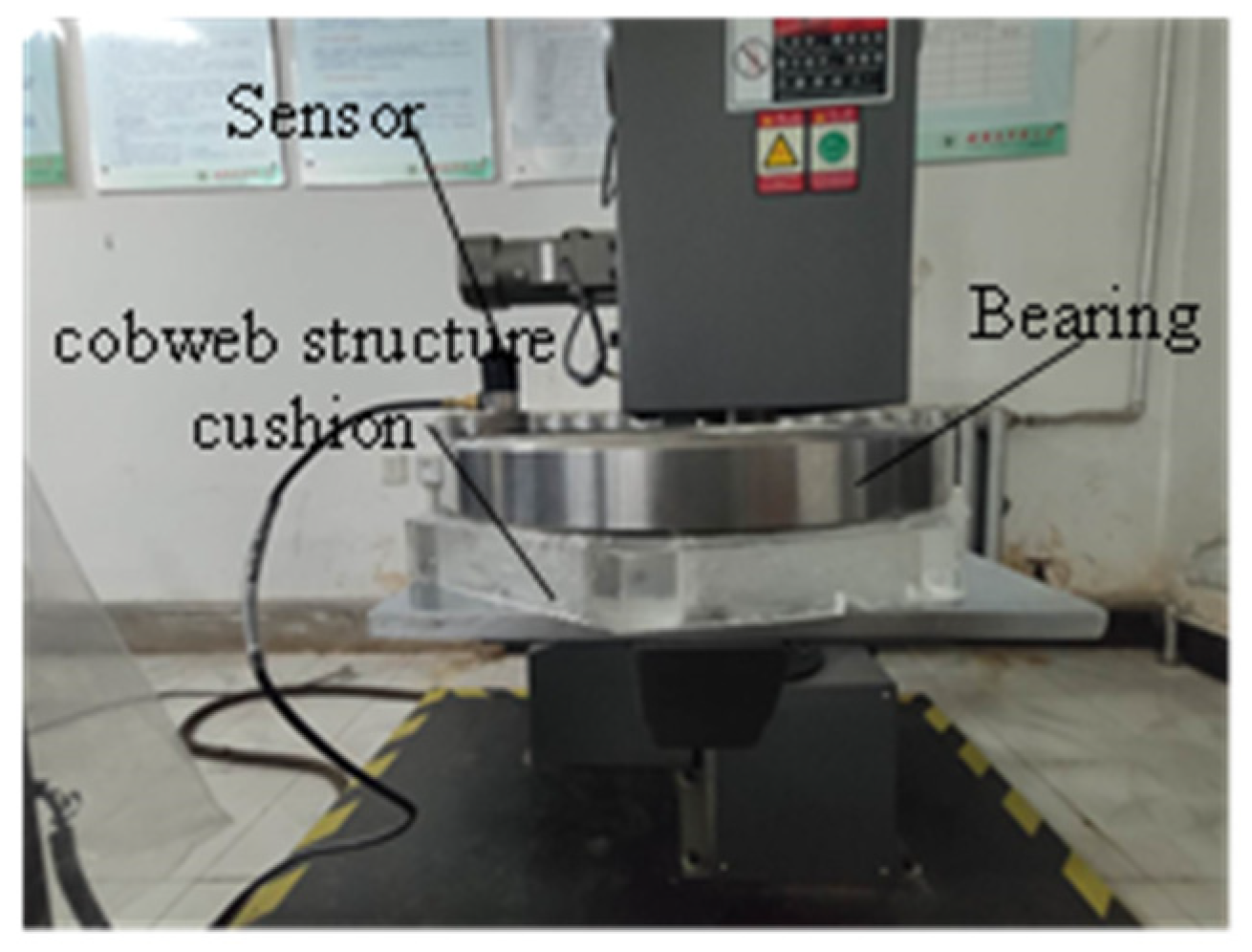

5. Drop Test

5.1. Test Methods and Equipment Required

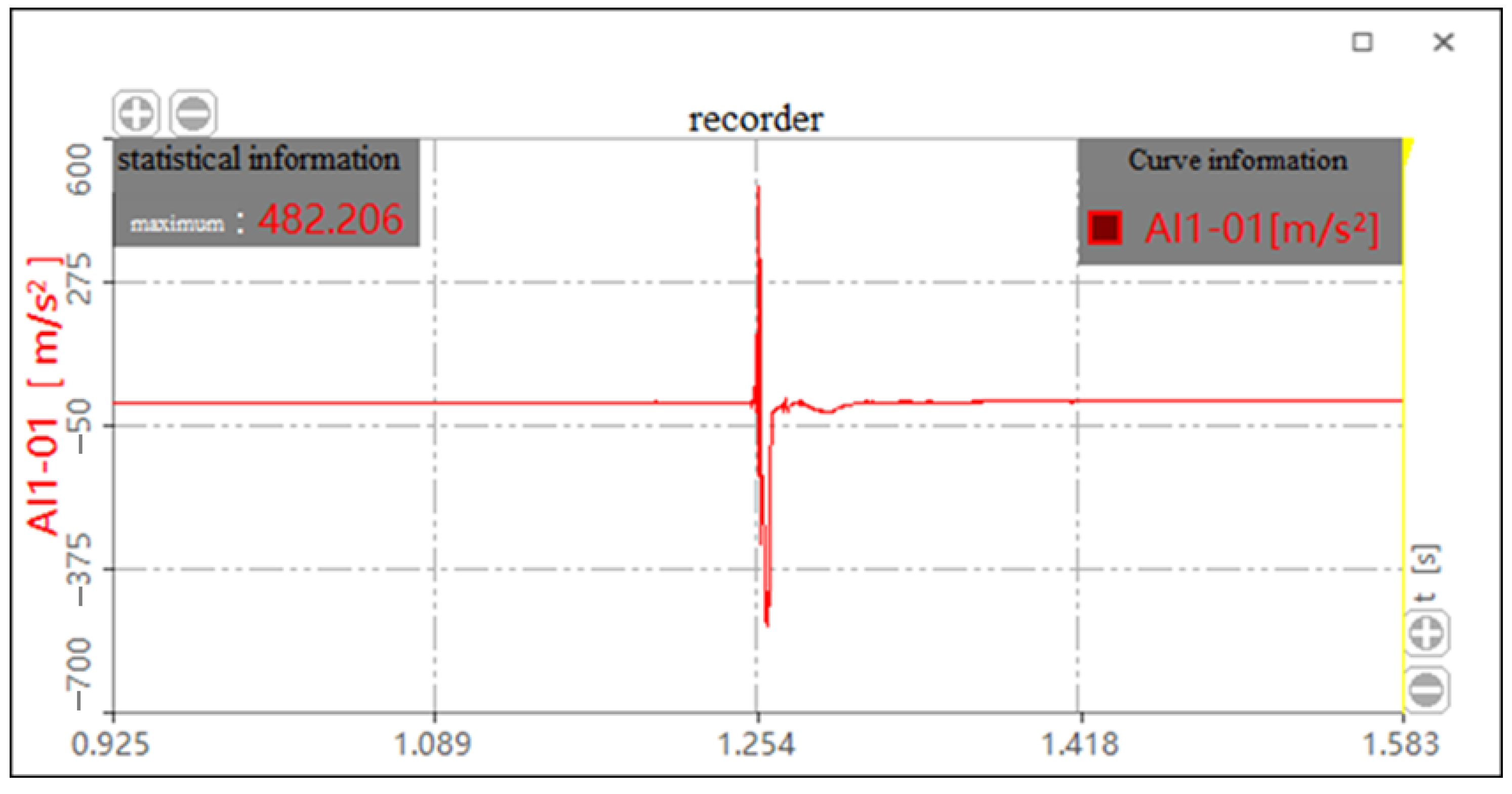

5.2. Analysis of the Test Results

6. Methods

- (1)

- A method of using organic silica gel as a cushion for aviation precision bearing packaging is proposed, and the structure of the cushion is designed based on a cobweb configuration.

- (2)

- By increasing the structural parameters of the radial thread as a bearing force carrier, the minimum cushion thickness was calculated and designed. The theoretical calculation accuracy was verified by conducting simulation analysis.

- (3)

- Using finite element software, drop simulations were carried out on a high-precision bearing packed with a biomimetic cobweb structure cushion, and stress cloud maps of the bearing and cushion were obtained.

- (4)

- The biomimetic cobweb structure cushion casting was carried out using a 3D printed cobweb cushion shell. The impact acceleration of the bearing was obtained using a drop test.

7. Conclusions

- (1)

- The structural parameters of the cobweb structure cushion were solved by the optimization equation, and then the thickness is 18 mm according to the actual situation.

- (2)

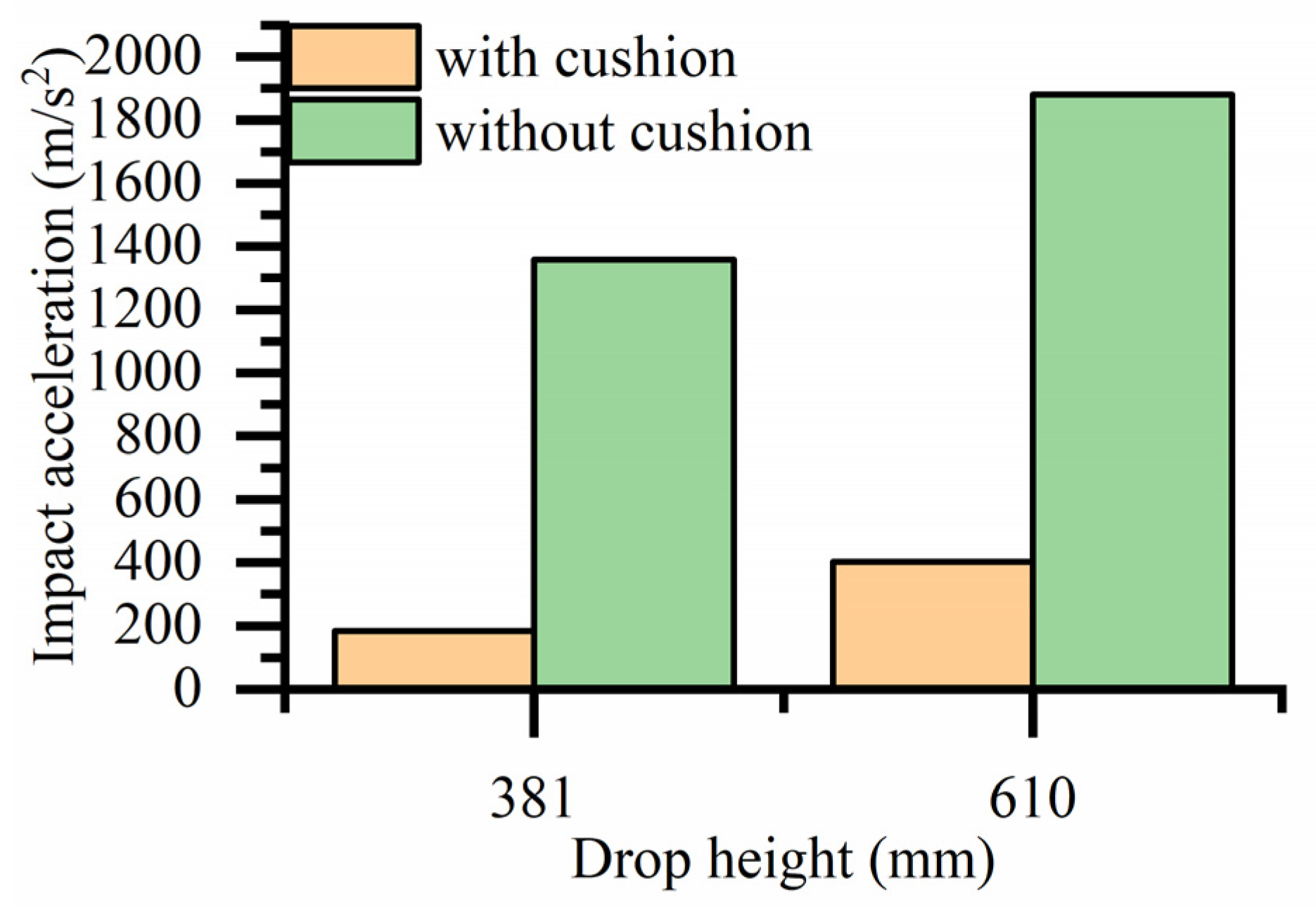

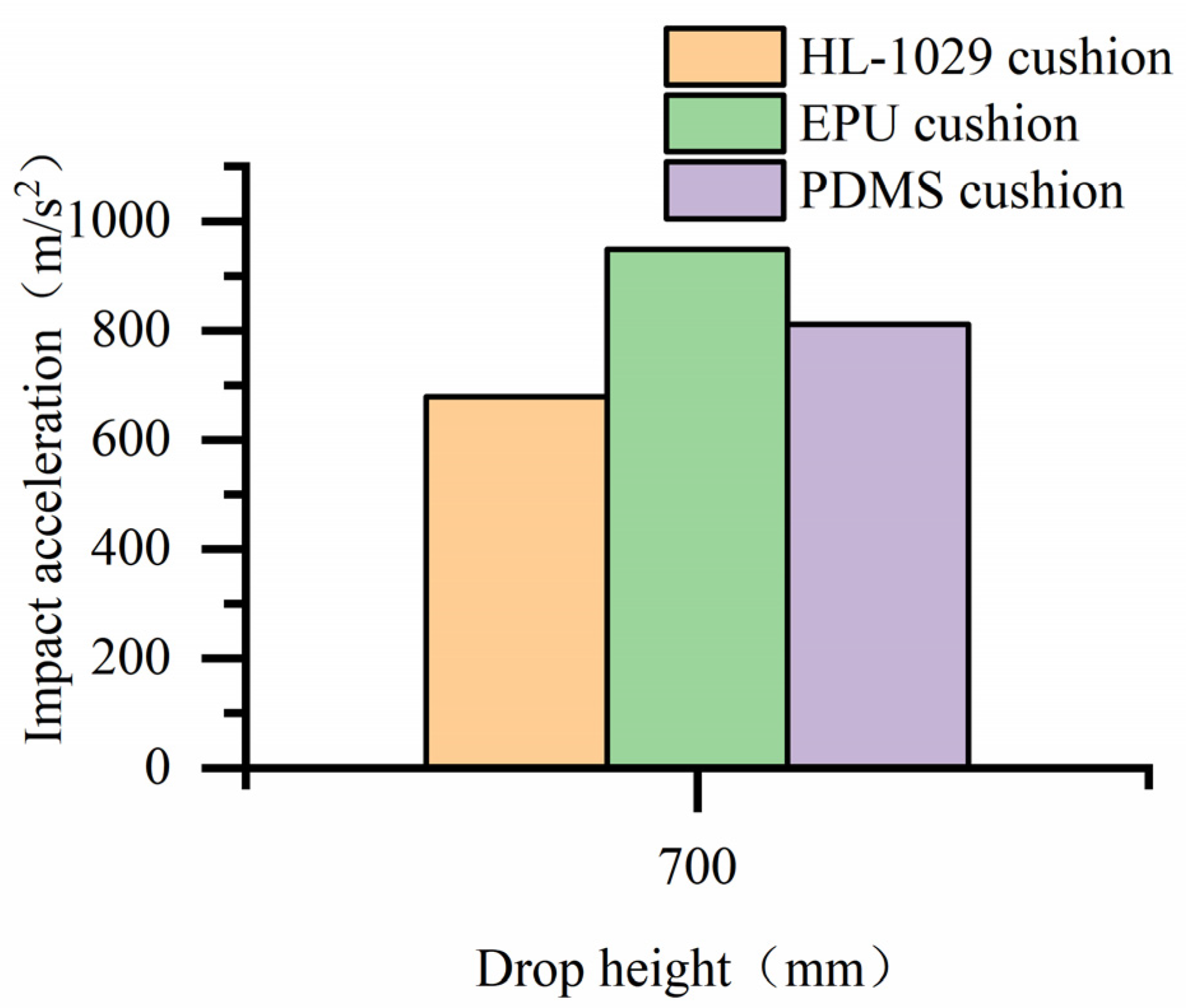

- Analysis and processing of the drop test results show that at a drop height of 381 mm and 610 mm, the impact acceleration of the bearing with a cobweb structure cushion is reduced by 86% and 78%, respectively, compared with the without cobweb structure cushion. At a drop height of 700 mm, the impact acceleration of the bearing with the HL-1029 cushion is reduced by 28% and 16% compared with the EPU cushion and PDMS cushion, respectively.

- (3)

- The test results showed that the biomimetic cobweb structure cushion could provide robust protection for high-precision bearings.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Tianyin, T.; Xiaofei, S. Calculation and analysis of bearing damage of electric drive system. Agric. Equip. Veh. Eng. 2023, 61, 167–170. [Google Scholar]

- Guihong, G.; Mingyue, Y. A Novel Method for Extracting Compound Faults Features ofRolling Bearing Based on ITD-Hjorth-TES. J. Fail. Anal. Prev. 2023, 23, 865–878. [Google Scholar]

- Quanwei, Q.; Bin, Y. Preparation and analysis of surface protective film of wind power insulated bearing. Bearing 2023, 4, 15–20. [Google Scholar]

- Zhenyu, B.; Xiaoqin, Z. Research status of protective measures and Al2O3 ceramic insulating coating for motor bearing. Surf. Technol. 2021, 50, 51–59. [Google Scholar]

- Matthis, G.; Florian, S. Validation of a finite-element model of a wind turbine blade bearing. Finite Elem. Anal. Amp. Des. 2023, 221, 103957. [Google Scholar]

- Cao, P.; Wang, H. Integration of Antifouling and Underwater Sound Absorption Properties into PDMS/MWCNT/SiO2 Coatings. Biomimetics 2022, 7, 248. [Google Scholar] [CrossRef]

- Li, J.; Li, Y. PDMS/PVDF Electrospinning Membranes for Water-in-Oil Emulsion Separation and UV Protection. Biomimetics 2022, 7, 217. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Fu, X. Preparation of a Novel Type of Zwitterionic Polymer and the Antifouling PDMS Coating. Biomimetics 2022, 7, 50. [Google Scholar] [CrossRef]

- Zhang, Z. Research on Packaging Design and Cushioning Performance of Engine Spindle Bearing; Harbin Institute of Technology: Harbin, China, 2020. [Google Scholar]

- Jianwei, C.; Dezhi, R. Resource utilisation of waste TPU: Reform and modification for improving a bentonite-based thermal insulation material’s performance. Inorg. Chem. Commun. 2023, 154, 110866. [Google Scholar]

- Yu, P.; Huang, S. Biomechanical properties of a customizable TPU/PCL blended esophageal stent fabricated by 3D printing. Mater. Today Commun. 2023, 34, 105196. [Google Scholar] [CrossRef]

- Yu, M.; Zhou, B. Study on Kelvin structural cushioning performance based on TPU material. Packag. Eng. 2022, 43, 82–92. [Google Scholar]

- Hu, Z.; Jiang, M. MoS2-decorated carbonized melamine foam/reduced graphene oxide network for constructing polyethylene-glycol-based multifunctional phase change materials toward multiple energy harvesting and microwave absorbing applications. Chem. Eng. J. 2023, 461, 141923. [Google Scholar] [CrossRef]

- Xia, X.; Gu, X.; Feng, L.; Wang, J.; Zhang, C. Research progress on toughening modification of melamine formaldehyde foam. Polym. Mater. Sci. Eng. 2019, 35, 182–190. [Google Scholar]

- Xu, T.; Liu, X. Study on compression and cushioning performance of melamine foam. Aerosp. Mater. Technol. 2023, 53, 90–95. [Google Scholar]

- Hiroyoshi, I.; Masuhiro, B. Effects of EPS density on blast mitigation performance in underground protective structures. Int. J. Impact Eng. 2022, 16, 104189. [Google Scholar]

- Meddage, D.P.P.; Chadee, A. Exploring the applicability of expanded polystyrene (EPS) based concrete panels as roof slab insulation in the tropics. Case Stud. Constr. Mater. 2022, 17, e01361. [Google Scholar] [CrossRef]

- Chong, H.; Xuesong, C. Performance analysis of EPP buffer material and its application in home appliance packaging. Home Appl. Sci. Technol. 2022, 0, 112–115. [Google Scholar]

- Zhao, P.; Xie, L. Large-scale rockfall impact experiments on a RC rock-shed with a newly proposed cushion layer composed of sand and EPE. Eng. Struct. 2018, 175, 386–398. [Google Scholar] [CrossRef]

- Yin, X.; Chen, Z. Dynamic cushioning performance of EPE/corrugated cardboard for express packaging. Packag. Eng. 2022, 43, 52–57. [Google Scholar]

- Bin, S.; Meng, Y. Improvement of finished product packaging of large tapered roller bearings. J. Anyang Inst. Technol. 2018, 17, 16–19. [Google Scholar]

- Yingnien, C.; Ihsun, Y. Biomimic Zwitterionic Polyamide/Polyurethane Elastic Blending Fabrics. Biomimetics 2023, 8, 198. [Google Scholar]

- Głowacz-Czerwonka, D.; Zakrzewska, P. The influence of biowaste-based fillers on the mechanical and fire properties of rigid polyurethane foams. Sustain. Mater. Technol. 2023, 36, e00610. [Google Scholar] [CrossRef]

- Hu, T.; Li, Q. Study on weather resistance of polyurethane cushioning materials in two typical environments. Equip. Environ. Eng. 2023, 20, 119–126. [Google Scholar]

- Wang, S.; Xia, H. Protective Behaviors of Bio-Inspired Honeycomb Column Thin-Walled Structure against RC Slab under Impact Loading. Biomimetics 2023, 8, 73. [Google Scholar] [CrossRef]

- Yu, Z.; Xin, R. Shock-Resistant and Energy-Absorbing Properties of Bionic NiTi Lattice Structure Manufactured by SLM. J. Bionic Eng. 2022, 19, 1684–1698. [Google Scholar] [CrossRef]

- Zhang, G.; Lu, M. Design of bearing packing carton. Harbin Bear. 2009, 30, 50–51. [Google Scholar]

- Zhigang, L. Analysis of damage causes and improvement measures of input shaft bearing of mine reducer. Mach. Manag. Dev. 2022, 37, 193–194+197. [Google Scholar]

- Wen, J.; Liu, W. Analysis of harmful elements in bearing inner packaging materials. Intern. Combust. Engine Accessories 2021, 4, 129–130. [Google Scholar]

- Yihao, H.; Yanping, Z. Quantitative analysis of spider web structure. J. Southwest Norm. Univ. 2013, 38, 44–48. [Google Scholar]

- Zheng, L.; Behrooz, M.; Rui, L. Performance of a Bio-Inspired Spider Web; Smart Structures: Encino, CA, USA, 2014; Volume 1, p. 4. [Google Scholar]

- Yuko, A.; Ko, O. Simple model for the mechanics of spider webs. Phys. Rev. Lett. 2010, 104, 038102. [Google Scholar]

- De, G.; Hongwei, B. Packaging Dynamics, 1st ed.; Light Industry Press: Beijing, China, 2010; pp. 56–89. [Google Scholar]

- ASTM D4169 01; Standard Practice for Performance Testing of Shipping Containers and Systems, American Society for Testing and Materials. ASTM: West Conshohocken, PA, USA, 2002.

- Rodi, A.; Satoshi, K. The Development of Biomimetic Aligned Skeletal Muscles in a Fully 3D Printed Microfluidic Device. Biomimetics 2022, 7, 2. [Google Scholar]

- Popkov, A.; Kononovich, N. Long Bone Defect Filling with Bioactive Degradable 3D-Implant: Experimental Study. Biomimetics 2023, 8, 138. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Value |

|---|---|

| Mixing ratio A:B | 1:1 |

| Gel time | 8–12 h (25 °C) |

| The available time of exposure to air | 1 h (25 °C, mixture 100 g) |

| Hardening time | 24 h (25 °C) |

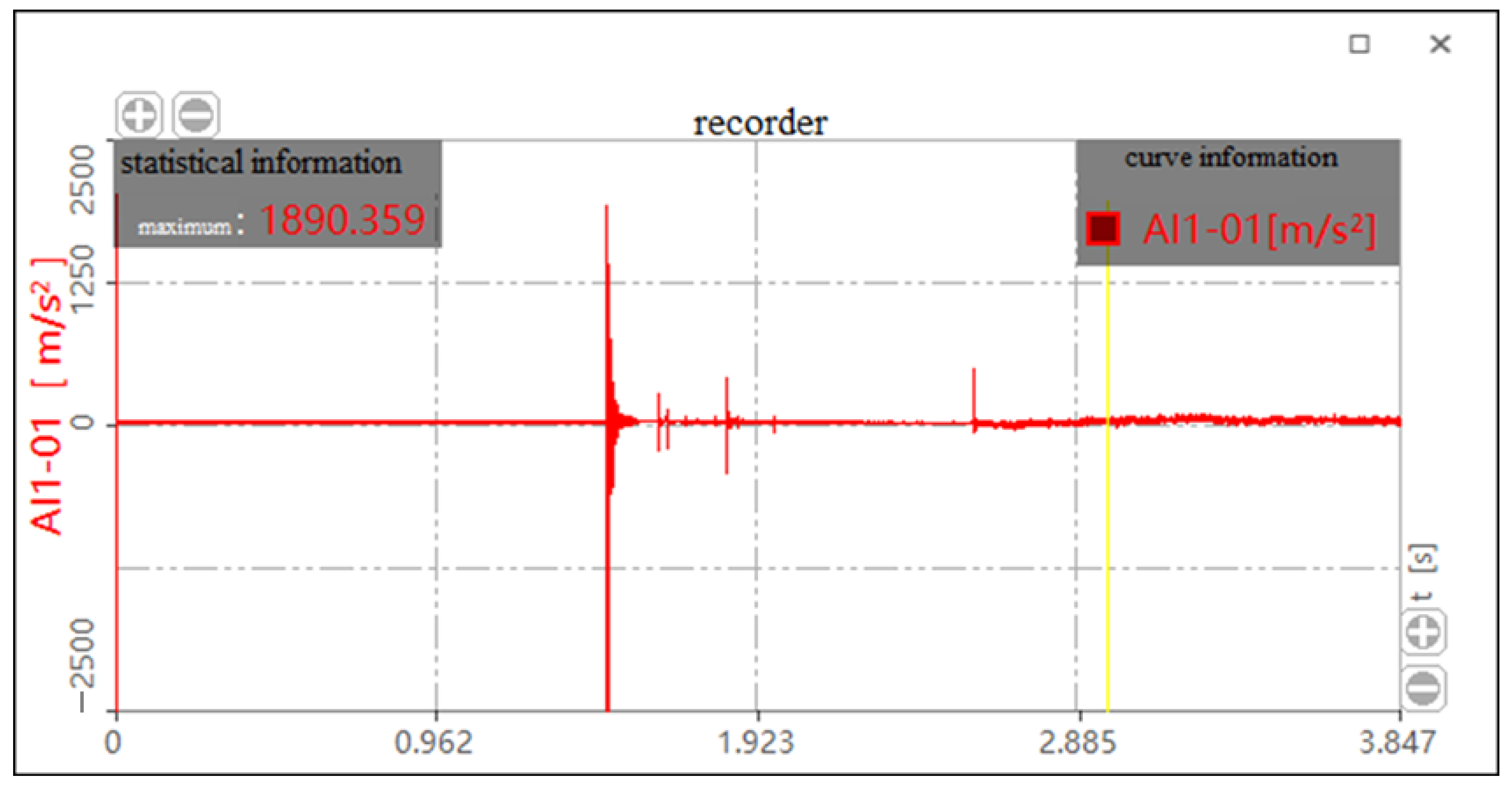

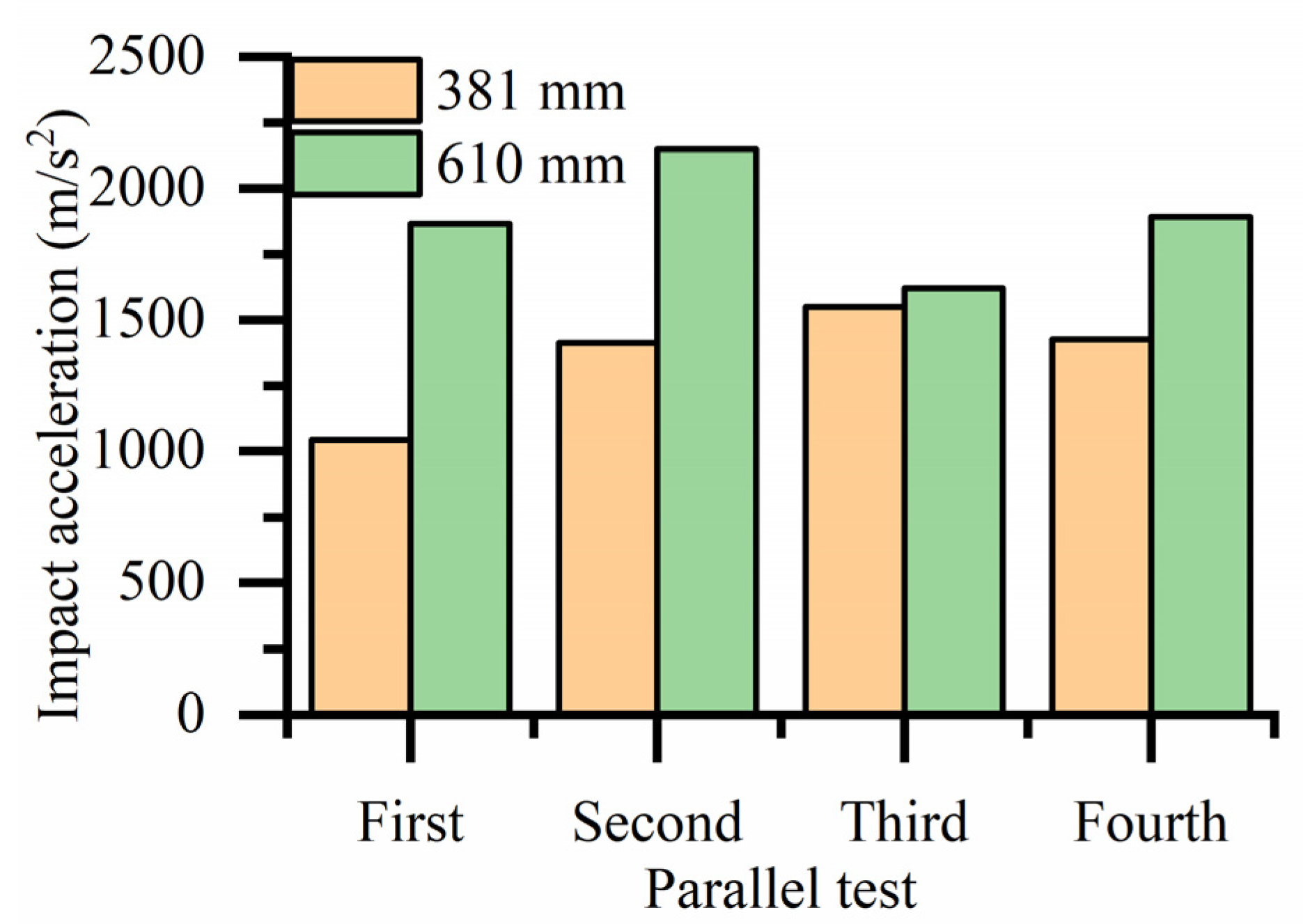

| Drop Height (mm) | a1 (m/s2) | a2 (m/s2) | a3 (m/s2) | a4 (m/s2) | Average Impact Acceleration (m/s2) |

|---|---|---|---|---|---|

| 381 | 1041.088 | 1412.530 | 1546.326 | 1426.754 | 1356.675 |

| 610 | 1864.119 | 2147.737 | 1619.964 | 1890.359 | 1880.545 |

| 700 | / | / | / | / | / |

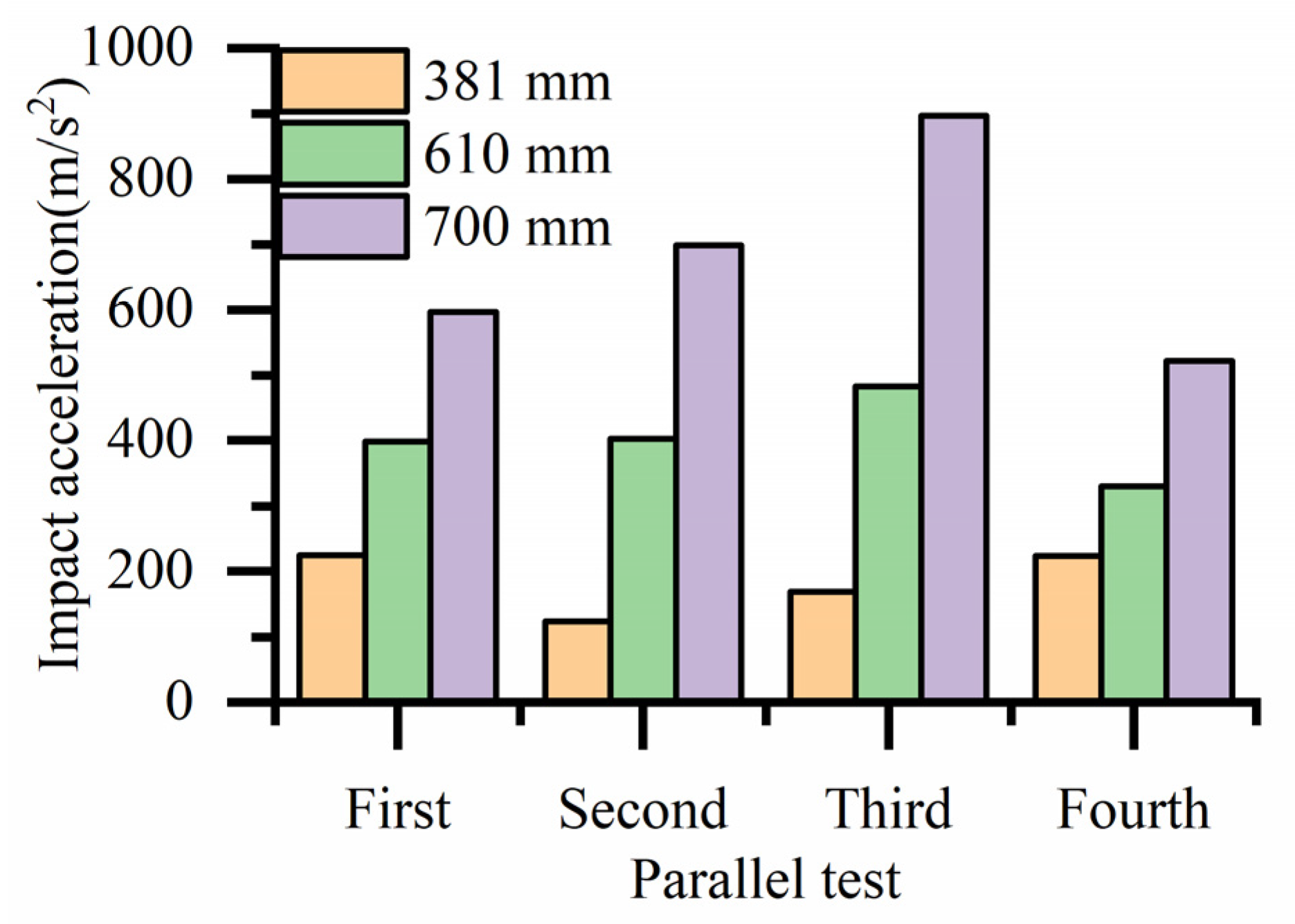

| Drop Height (mm) | a1 (m/s2) | a2 (m/s2) | a3 (m/s2) | a4 (m/s2) | Average Impact Acceleration (m/s2) |

|---|---|---|---|---|---|

| 381 | 224.055 | 122.693 | 168.220 | 223.283 | 184.563 |

| 610 | 398.359 | 401.640 | 482.206 | 329.835 | 403.009 |

| 700 | 596.466 | 698.199 | 896.778 | 522.056 | 678.375 |

| Different Materials Cushions | Impact Acceleration (m/s2) |

|---|---|

| HL-1029 | 678.375 |

| EPU | 948.555 |

| PDMS | 810.953 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, C.; Tian, Y.; Xu, W.; Zhang, J.; Sun, Z.; Liu, Z. Cushioning Performance of the Biomimetic Cobweb Cushioning Silicone Pad. Biomimetics 2023, 8, 276. https://doi.org/10.3390/biomimetics8030276

Liao C, Tian Y, Xu W, Zhang J, Sun Z, Liu Z. Cushioning Performance of the Biomimetic Cobweb Cushioning Silicone Pad. Biomimetics. 2023; 8(3):276. https://doi.org/10.3390/biomimetics8030276

Chicago/Turabian StyleLiao, Changyu, Ye Tian, Wei Xu, Jiahang Zhang, Zhihui Sun, and Zhuang Liu. 2023. "Cushioning Performance of the Biomimetic Cobweb Cushioning Silicone Pad" Biomimetics 8, no. 3: 276. https://doi.org/10.3390/biomimetics8030276

APA StyleLiao, C., Tian, Y., Xu, W., Zhang, J., Sun, Z., & Liu, Z. (2023). Cushioning Performance of the Biomimetic Cobweb Cushioning Silicone Pad. Biomimetics, 8(3), 276. https://doi.org/10.3390/biomimetics8030276