A TEC Cooling Soft Robot Driven by Twisted String Actuators

Abstract

1. Introduction

- In this study, a TEC and TPA were combined to develop a soft robot to improve the cooling effect of the TPA and the movement frequency of the robot. By testing different TPA cooling modes, we found that the TEC was easy to integrate and had a good cooling effect on the soft robot.

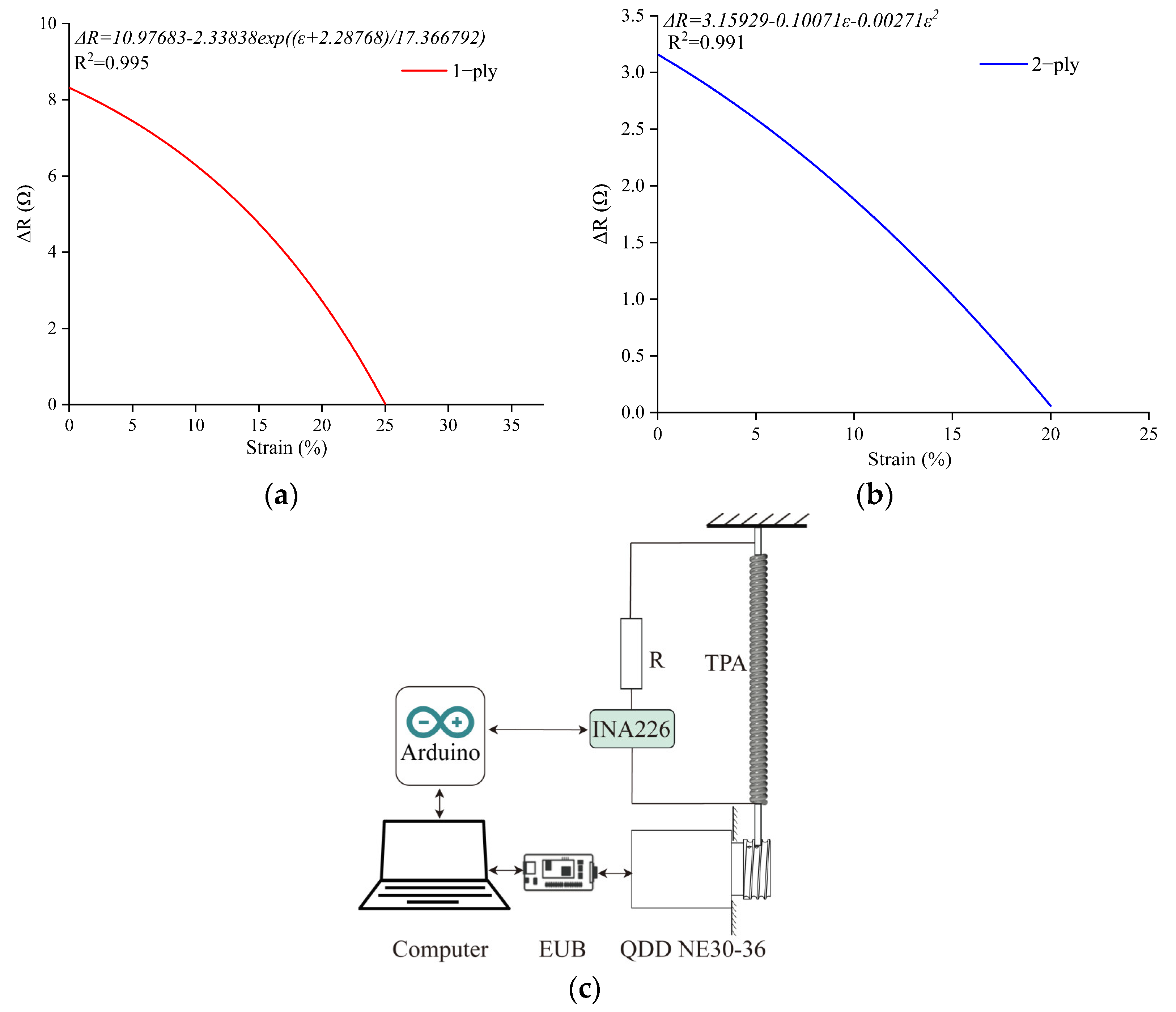

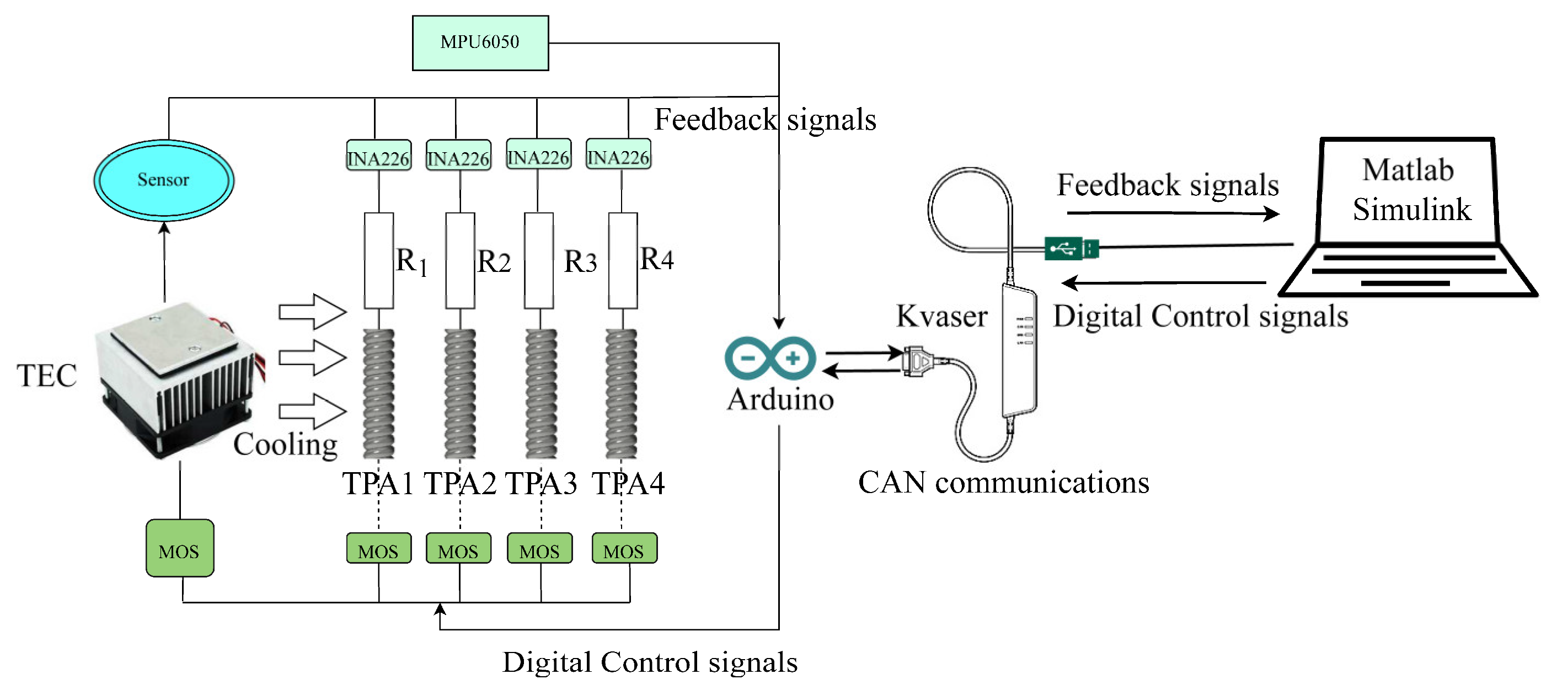

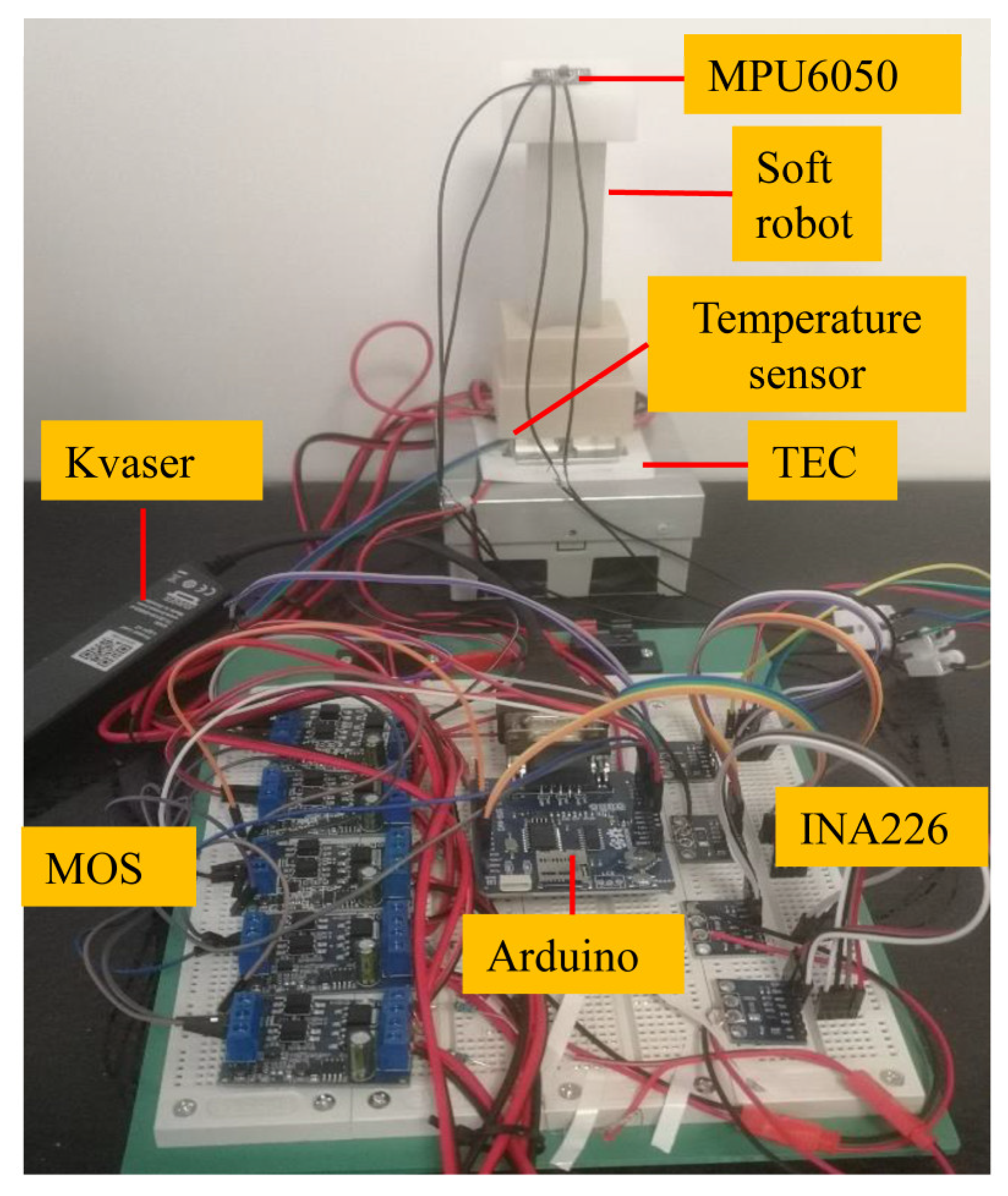

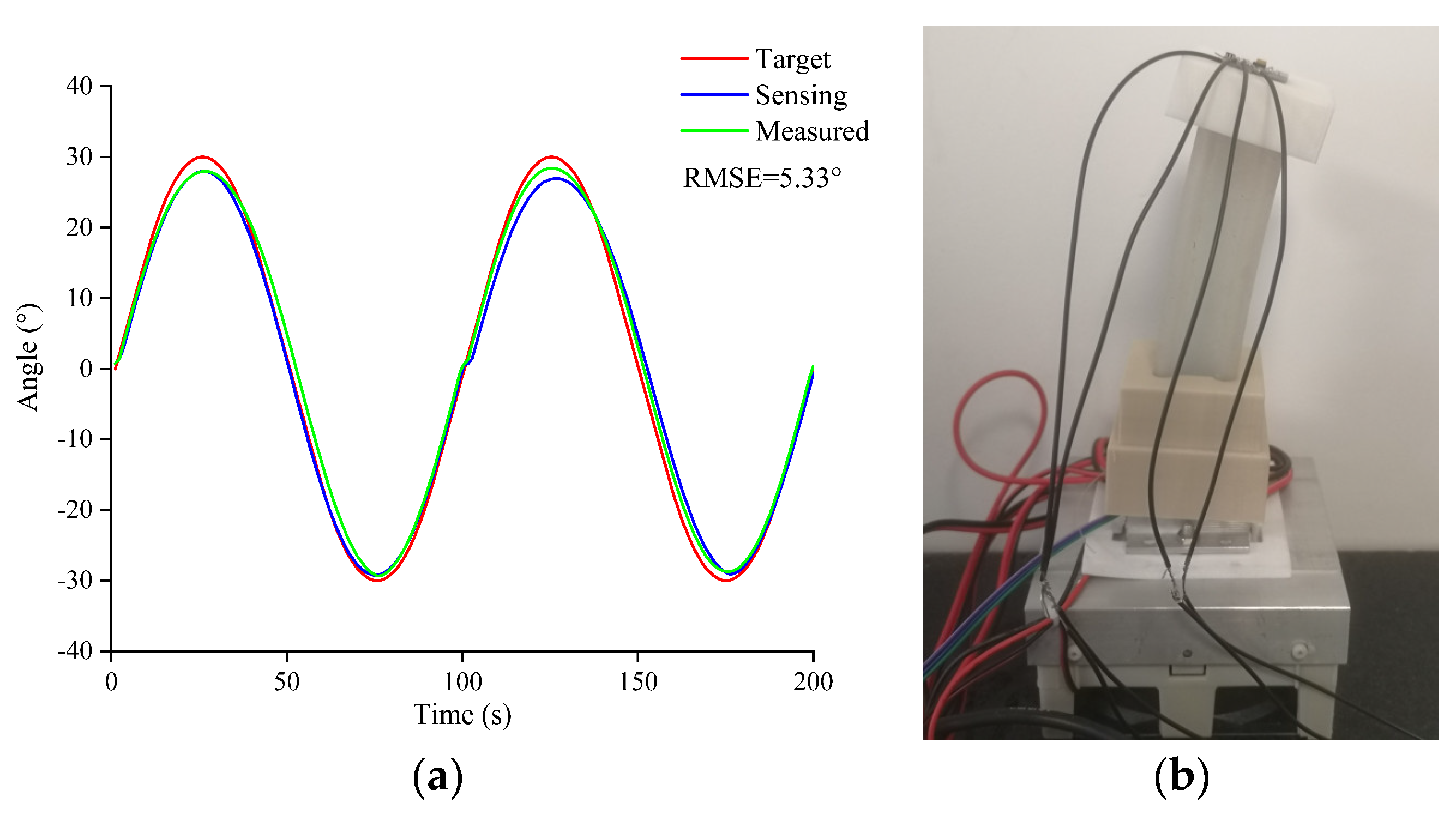

- This study proposed control of the TPA through Simulink for the first time, making it convenient for new researchers to learn the robot’s operation. The TPA data, namely, the resistance value of the sensor, was collected by Simulink through MATLAB, and the corresponding deformation was obtained through mathematical model calculations to realize self-sensing. Feedback signals from an MPU6050 were transmitted to the TPA through an Arduino to provide feedback.

2. Materials and Methods of the Soft Robot

2.1. Materials

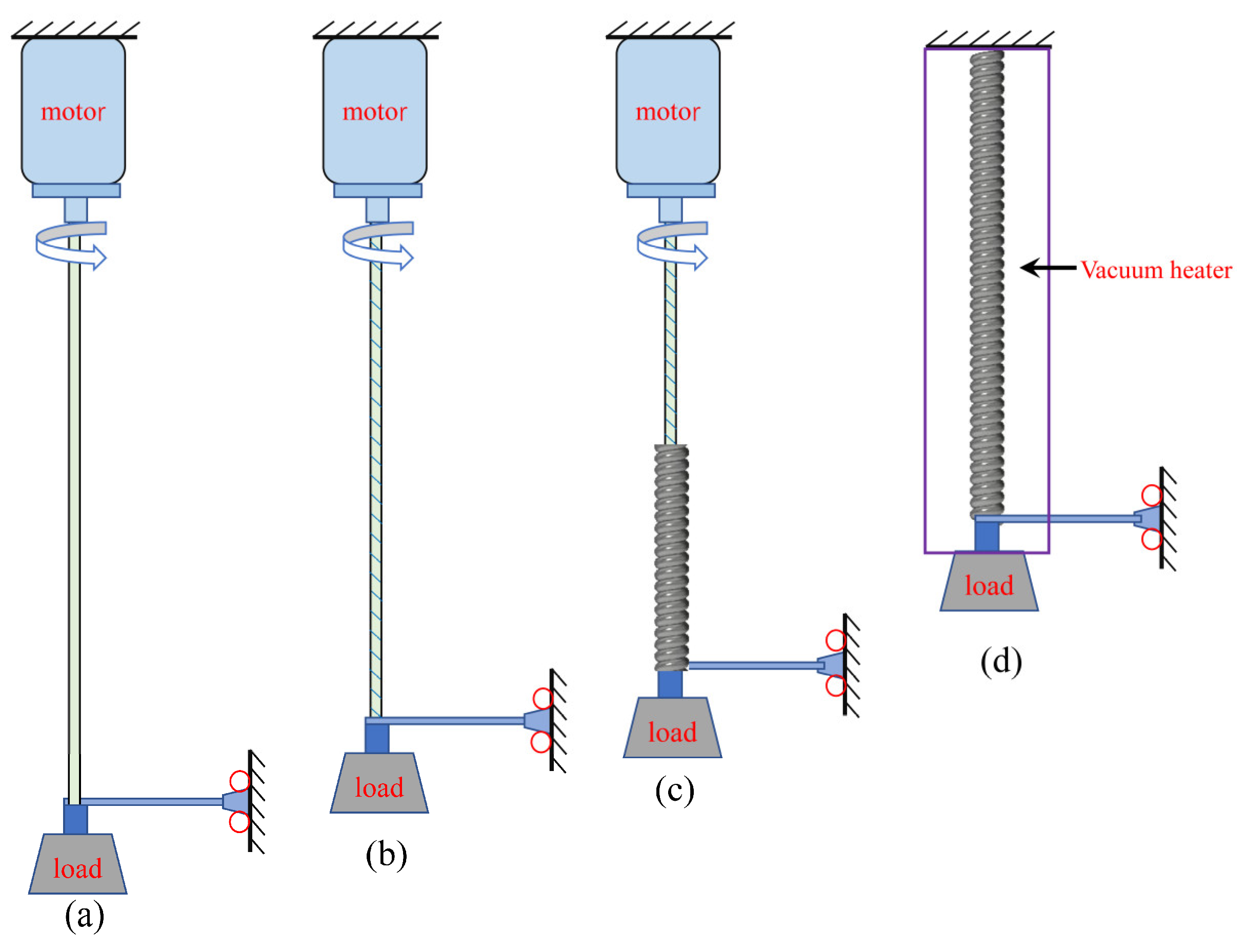

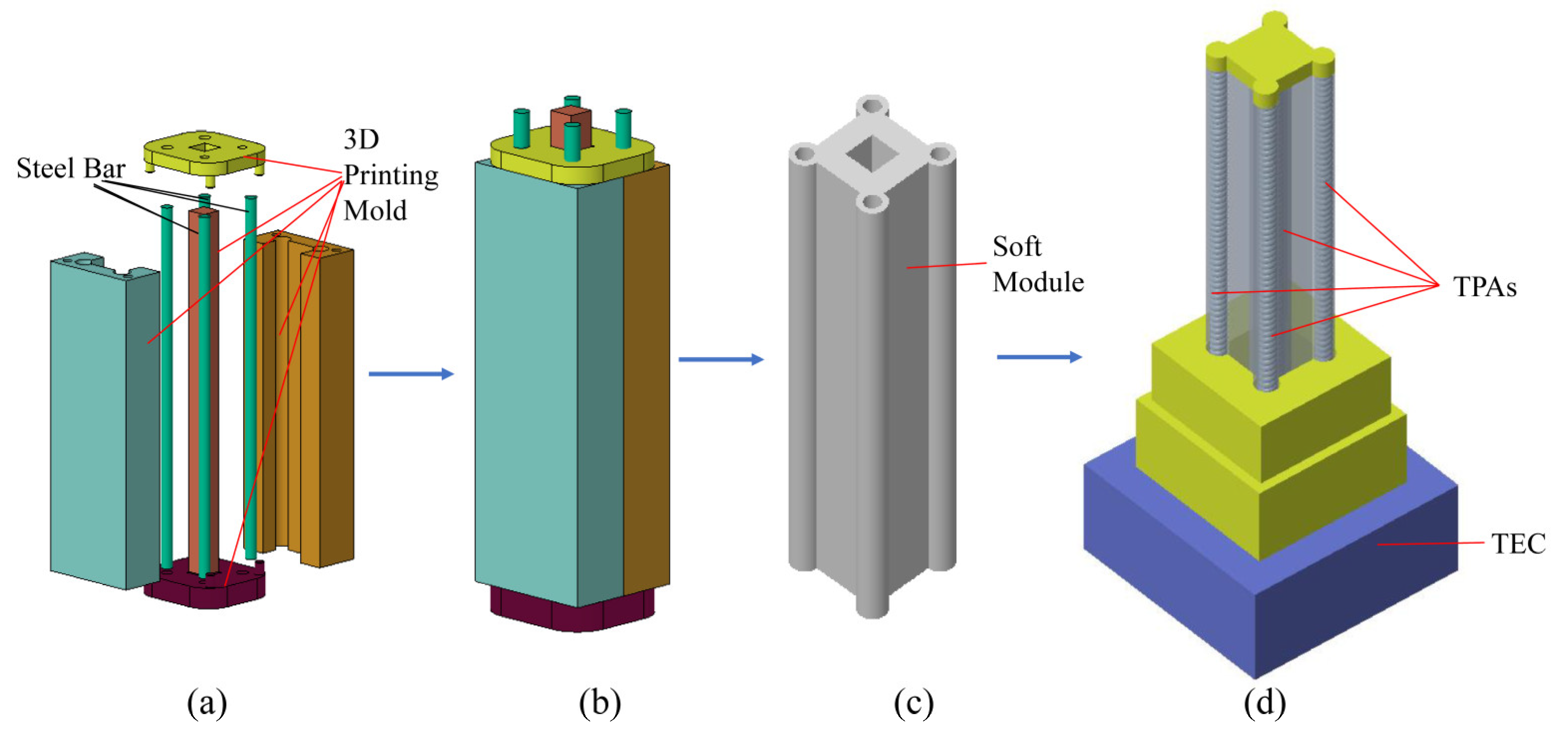

2.1.1. Manufacture

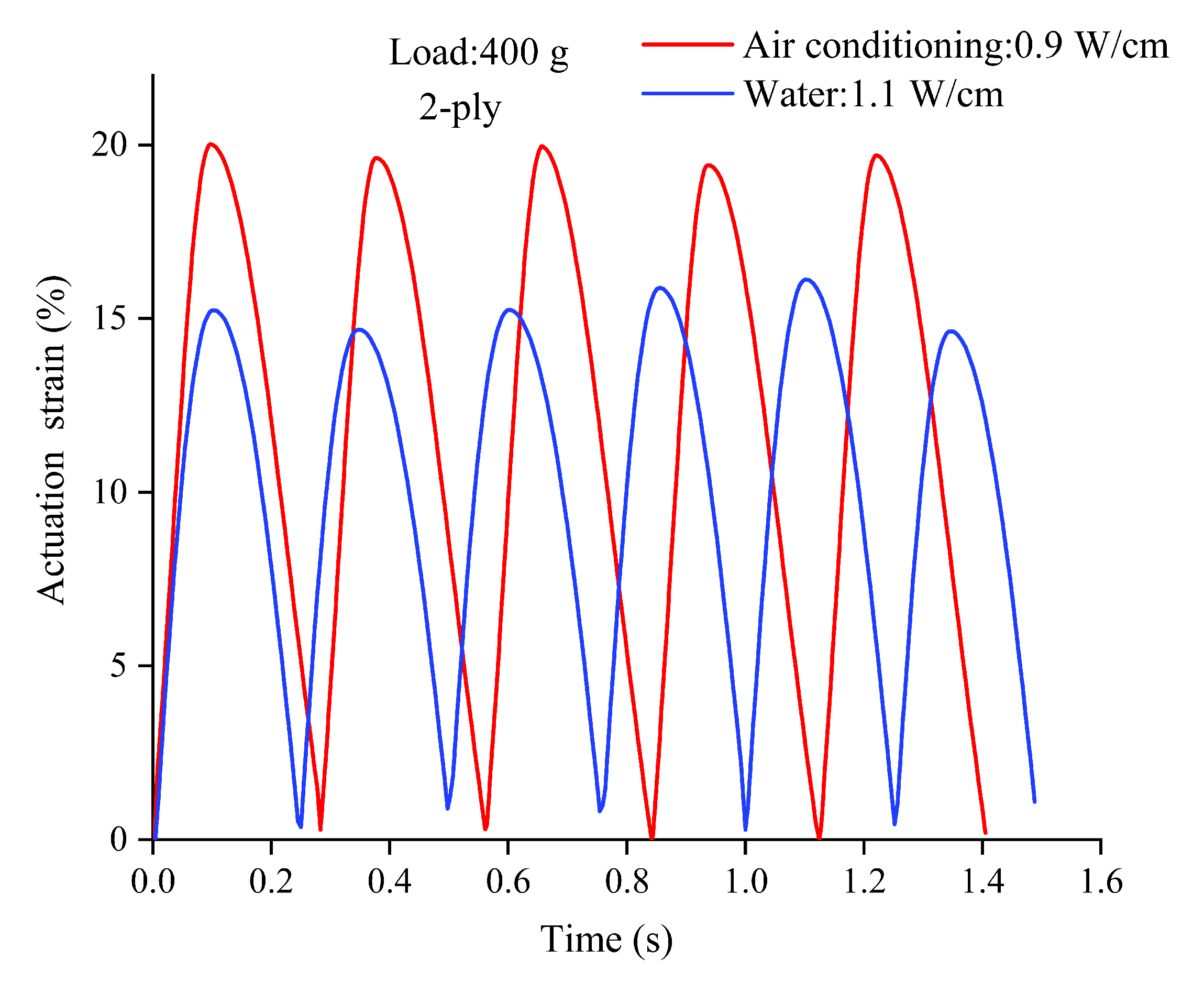

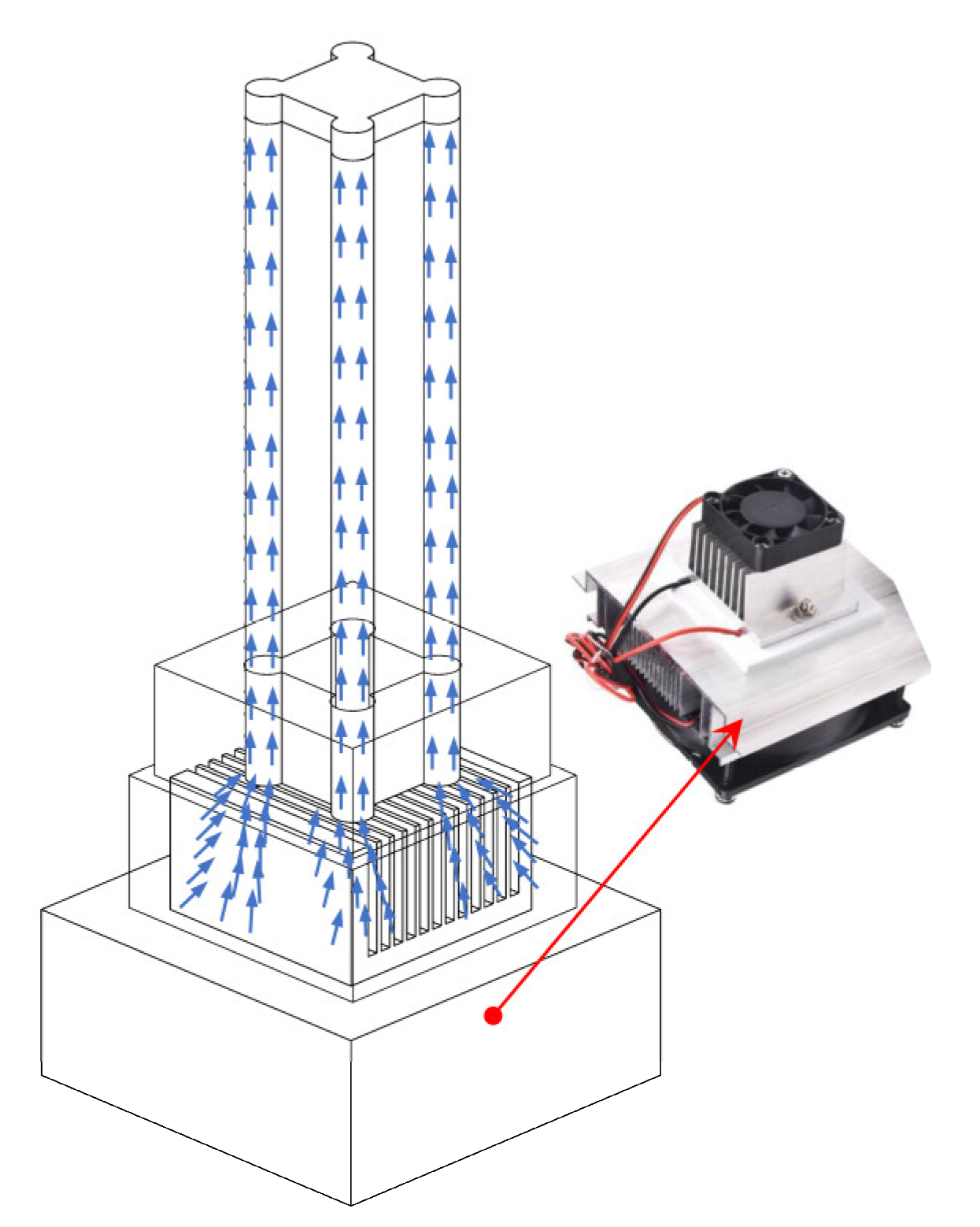

2.1.2. Cooling

2.1.3. Sensor Characterization

2.2. Design and Control of the Soft Robot

2.2.1. Manufacture

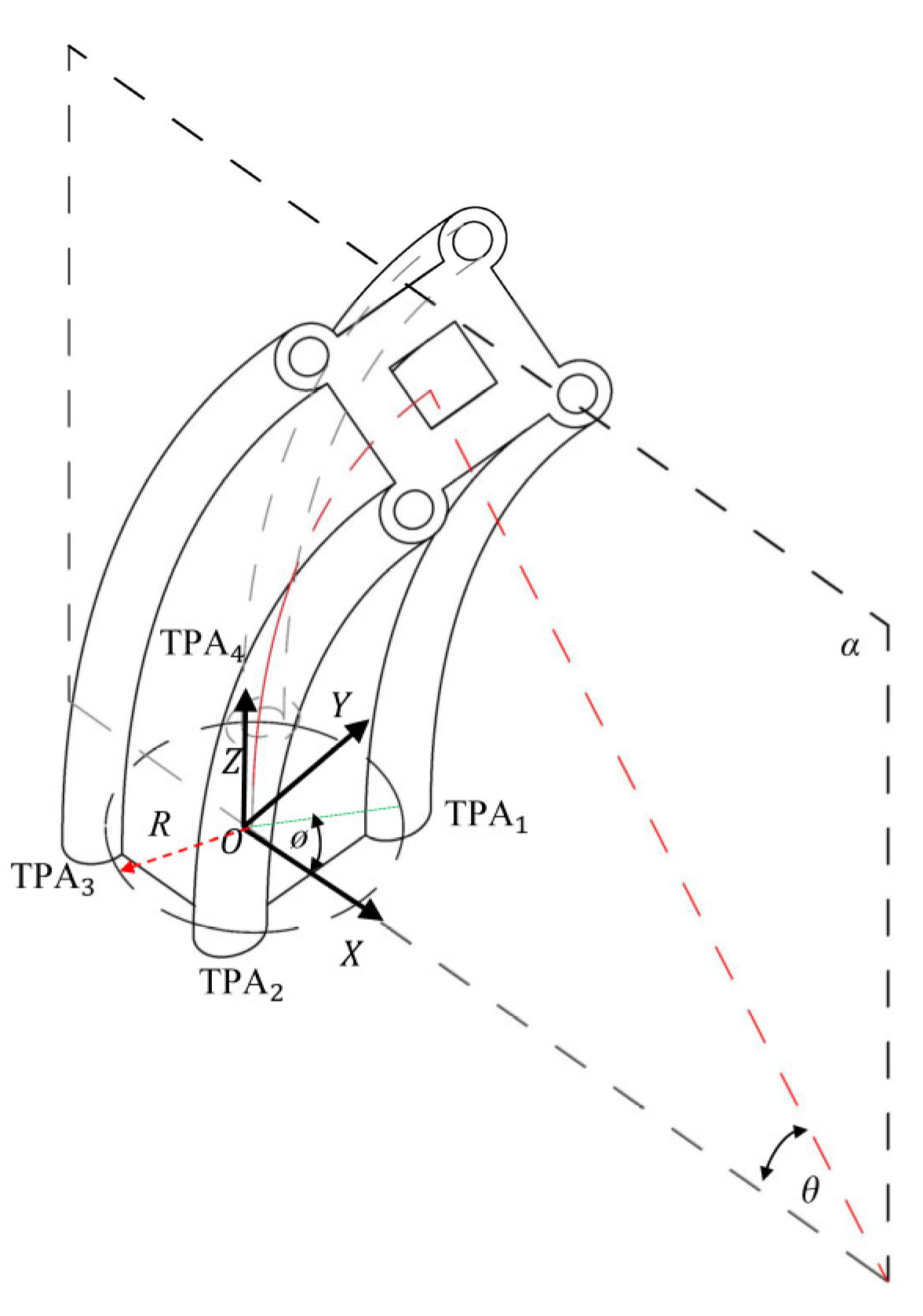

2.2.2. Bending Deformation Modelling

2.2.3. Control

- The temperature sensor detected the internal temperature of the soft robot. When the temperature was higher than 5 °C, the MOS tube connected to the Arduino controlled the TEC, which began cooling the system. When the temperature was lower than 5 °C, the input power to the MOS tube was stopped.

- Based on the theoretical model, the input power corresponding to the target bending angle was determined, which was used as the first bending motion of the soft robot. The actual angle collected by the MPU6050 was compared with the planned value, the results were transmitted to the angle PID controller, and the target angle was realized by continuously increasing the input power.

- When the actual angle was close to the target angle, the power transmitted to the contracted TPAs was gradually reduced. Then, the power to another pair of TPAs was increased to bend the robot in the opposite direction.

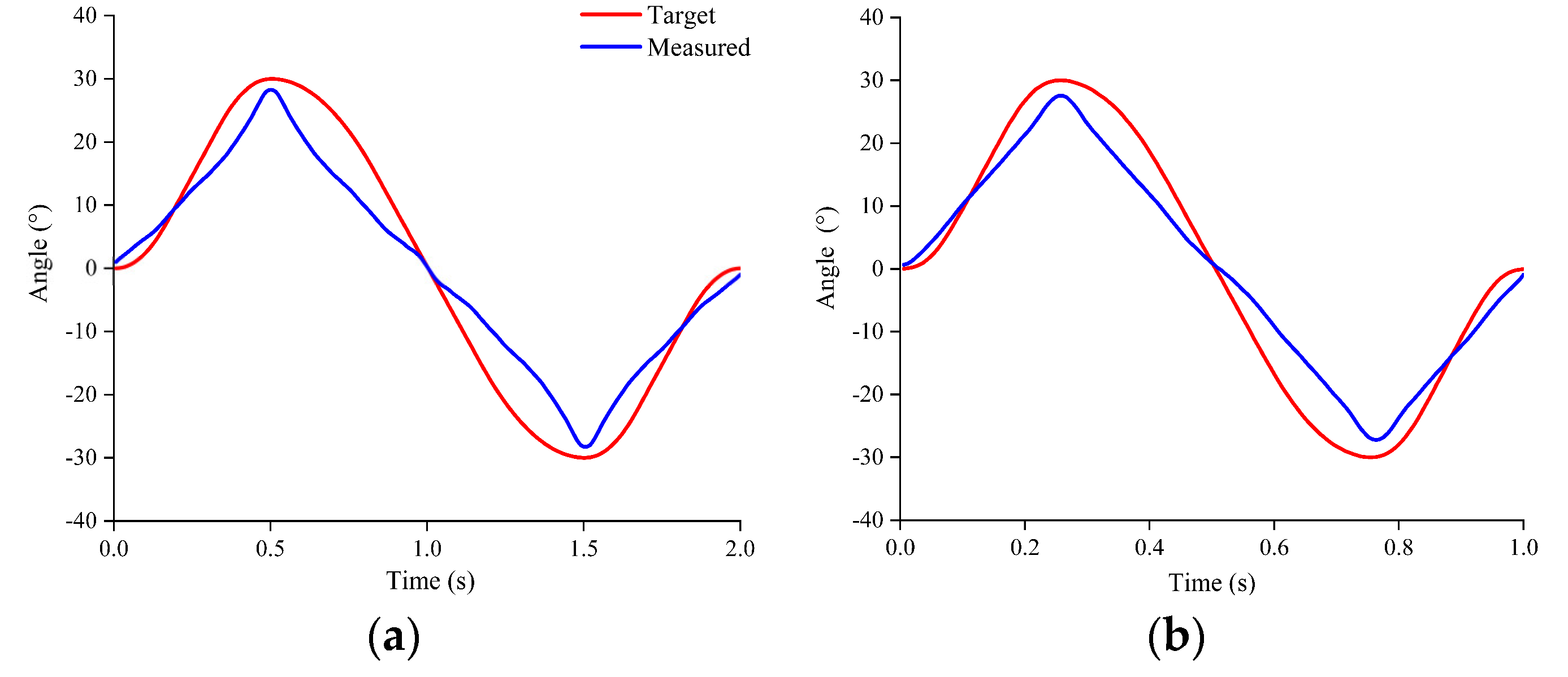

- The TPA length changed as the power changed. Therefore, the TPA could control the soft robot to produce bending motion. In the sensing stage, due to natural cooling, the input power needed to be kept within 3 W, as the TPA could burn if the temperature was too high. When the TEC cooled the system, the input power needed to be kept within 20 W because the TPA was less likely to burn during cooling, and the motion frequency was increased.

3. Results

3.1. Sensing

3.2. TEC Cooling

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef]

- Kim, S.; Laschi, C.; Trimmer, B. Soft robotics: A bioinspired evolution in robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef]

- Mirvakili, S.M.; Hunter, I.W. Artificial muscles: Mechanisms, applications, and challenges. Adv. Mater. 2018, 30, 1704407. [Google Scholar] [CrossRef]

- Spinks, G.M. Advanced actuator materials powered by biomimetic helical fiber topologies. Adv. Mater. 2020, 32, 1904093. [Google Scholar] [CrossRef] [PubMed]

- Anderson, I.A.; Gisby, T.A.; McKay, T.G.; O’Brien, B.M.; Calius, E.P. Multi-functional dielectric elastomer artificial muscles for soft and smart machines. J. Appl. Phys. 2012, 112, 041101. [Google Scholar] [CrossRef]

- Zou, M.; Li, S.; Hu, X.; Leng, X.; Wang, R.; Zhou, X.; Liu, Z. Progresses in tensile, torsional, and multifunctional soft actuators. Adv. Funct. Mater. 2021, 31, 2007437. [Google Scholar] [CrossRef]

- Huang, W. On the selection of shape memory alloys for actuators. Mater. Des. 2002, 23, 11–19. [Google Scholar] [CrossRef]

- Jayender, J.; Patel, R.V.; Nikumb, S.; Ostojic, M. Modeling and control of shape memory alloy actuators. IEEE Trans. Control Syst. Technol. 2008, 16, 279–287. [Google Scholar] [CrossRef]

- Lu, W.; Zu, M.; Byun, J.-H.; Kim, B.-S.; Chou, T.-W. State of the art of carbon nanotube fibers: Opportunities and challenges. Adv. Mater. 2012, 24, 1805–1833. [Google Scholar] [CrossRef]

- Lima, M.D.; Li, N.; De Andrade, M.J.; Fang, S.; Oh, J.; Spinks, G.M.; Kozlov, M.E.; Haines, C.S.; Suh, D.; Foroughi, J.; et al. Electrically, chemically, and photonically powered torsional and tensile actuation of hybrid carbon nanotube yarn muscles. Science 2012, 338, 928–932. [Google Scholar] [CrossRef]

- Gu, G.Y.; Zhu, J.; Zhu, L.M.; Zhu, X. A survey on dielectric elastomer actuators for soft robots. Bioinspir. Biomim. 2017, 12, 011003. [Google Scholar] [CrossRef] [PubMed]

- Plante, J.S.; Dubowsky, S. Large-scale failure modes of dielectric elastomer actuators. Int. J. Solids Struct. 2006, 43, 7727–7751. [Google Scholar] [CrossRef]

- Zhang, J.; Sheng, J.; O’Neill, C.T.; Walsh, C.J.; Wood, R.J.; Ryu, J.H.; Desai, J.P.; Yip, M.C. Robotic artificial muscles: Current progress and future perspectives. IEEE Trans. Robot. 2019, 35, 761–781. [Google Scholar] [CrossRef]

- Haines, C.S.; Lima, M.D.; Li, N.; Spinks, G.M.; Foroughi, J.; Madden, J.D.; Kim, S.H.; Fang, S.; De Andrade, M.J.; Göktepe, F.; et al. Artificial muscles from fishing line and sewing thread. Science 2014, 343, 868–872. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; De Andrade, M.J.; Rome, R.S.; Haines, C.; Lima, M.D.; Baughman, R.H.; Tadesse, Y. Nylon-Muscle-Actuated Robotic Finger. In Proceedings of the Active and Passive Smart Structures and Integrated Systems; SPIE: Bellingham, WA, USA, 2015; pp. 154–165. [Google Scholar]

- Yang, S.Y.; Cho, K.H.; Kim, Y.; Song, M.G.; Jung, H.S.; Yoo, J.W.; Moon, H.; Koo, J.C.; Nam, J.-D.; Choi, H.R. High performance twisted and coiled soft actuator with spandex fiber for artificial muscles. Smart Mater. Struct. 2017, 26, 105025. [Google Scholar] [CrossRef]

- Zhang, J.; Iyer, K.; Simeonov, A.; Yip, M.C. Modeling and inverse compensation of hysteresis in supercoiled polymer artificial muscles. IEEE Robot. Autom. Lett. 2017, 2, 773–780. [Google Scholar] [CrossRef]

- Yip, M.C.; Niemeyer, G. On the control and properties of supercoiled polymer artificial muscles. IEEE Trans. Robot. 2017, 33, 689–699. [Google Scholar] [CrossRef]

- Luong, T.; Kim, K.; Seo, S.; Jeon, J.; Park, C.; Doh, M.; Koo, J.C.; Choi, H.R.; Moon, H. Long short term memory model based position-stiffness control of antagonistically driven twisted-coiled polymer actuators using model predictive control. IEEE Robot. Autom. Lett. 2021, 6, 4141–4148. [Google Scholar] [CrossRef]

- Luong, T.; Kim, K.; Seo, S.; Jeon, J.; Koo, J.C.; Choi, H.R.; Moon, H. Simultaneous Position-Stiffness Control of Antagonistically Driven Twisted-Coiled Polymer Actuators Using Model Predictive Control. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 25–29 October 2020; Electronic Network: Montreal, QC, USA, 2020; pp. 8610–8616. [Google Scholar]

- Luong, T.; Kim, K.; Seo, S.; Park, J.H.; Kim, Y.; Yang, S.Y.; Cho, K.H.; Koo, J.C.; Choi, H.R.; Moon, H. Impedance Control of a High Performance Twisted-Coiled Polymer Actuator. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 8701–8706. [Google Scholar]

- Kianzad, S. A Treatise on Highly Twisted Artificial Muscle: Thermally Driven Shape Memory Alloy Yarn and Coiled Nylon Actuators; University of British Columbia: Vancouver, BC, Canada, 2015. [Google Scholar]

- Edmonds, B.P.R.; DeGroot, C.T.; Trejos, A.L. Thermal modeling and characterization of twisted coiled actuators for upper limb wearable devices. IEEE/ASME Trans. Mechatron. 2021, 26, 966–977. [Google Scholar] [CrossRef]

- Elgeneidy, K.; Lohse, N.; Jackson, M. Bending angle prediction and control of soft pneumatic actuators with embedded flex sensors—A data-driven approach. Mechatronics 2018, 50, 234–247. [Google Scholar] [CrossRef]

- Suzuki, M.; Kamamichi, N. Displacement control of an antagonistic-type twisted and coiled polymer actuator. Smart Mater. Struct. 2018, 27, 035003. [Google Scholar] [CrossRef]

- Abbas, A.; Zhao, J. Twisted and Coiled Sensor for Shape Estimation of Soft Robots. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 482–487. [Google Scholar]

- Tang, X.; Li, K.; Liu, Y.; Zhao, J. Coiled conductive polymer fiber used in soft manipulator as sensor. IEEE Sens. J. 2018, 18, 6123–6129. [Google Scholar] [CrossRef]

- Van Der Weijde, J.; Smit, B.; Fritschi, M.; Van De Kamp, C.; Vallery, H. Self-sensing of deflection, force, and temperature for joule-heated twisted and coiled polymer muscles via electrical impedance. IEEE/ASME Trans. Mechatron. 2017, 22, 1268–1275. [Google Scholar] [CrossRef]

- Zhou, D.; Liu, Y.; Tang, X.; Zhao, J. Differential sensing method for multidimensional soft angle measurement using coiled conductive polymer fiber. IEEE Trans. Ind. Electron. 2021, 68, 401–411. [Google Scholar] [CrossRef]

- Wu, L.; de Andrade, M.J.; Saharan, L.K.; Rome, R.S.; Baughman, R.H.; Tadesse, Y. Compact and low-cost humanoid hand powered by nylon artificial muscles. Bioinspir. Biomim. 2017, 12, 026004. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Huang, H.; Huang, H.; Li, B.; Huang, K. A lightweight soft gripper driven by self-sensing super-coiled polymer actuator. IEEE Robot. Autom. Lett. 2021, 6, 2775–2782. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, S.; Lu, X.; Wang, K.; Zhao, D.; Wang, X.; Ren, L.; Ren, L. A TEC Cooling Soft Robot Driven by Twisted String Actuators. Biomimetics 2023, 8, 221. https://doi.org/10.3390/biomimetics8020221

Zhao S, Lu X, Wang K, Zhao D, Wang X, Ren L, Ren L. A TEC Cooling Soft Robot Driven by Twisted String Actuators. Biomimetics. 2023; 8(2):221. https://doi.org/10.3390/biomimetics8020221

Chicago/Turabian StyleZhao, Shun, Xuewei Lu, Kunyang Wang, Di Zhao, Xu Wang, Lei Ren, and Luquan Ren. 2023. "A TEC Cooling Soft Robot Driven by Twisted String Actuators" Biomimetics 8, no. 2: 221. https://doi.org/10.3390/biomimetics8020221

APA StyleZhao, S., Lu, X., Wang, K., Zhao, D., Wang, X., Ren, L., & Ren, L. (2023). A TEC Cooling Soft Robot Driven by Twisted String Actuators. Biomimetics, 8(2), 221. https://doi.org/10.3390/biomimetics8020221