Mechanical and Biomimetic Characteristics of Bulk-Fill Resin Dental Composites Following Exposure in a Simulated Acidic Oral Environment

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimen Preparation for the Evaluation of the Three-Point Bending Test

2.2. Specimen Preparation for the Evaluation of Surface Hardness

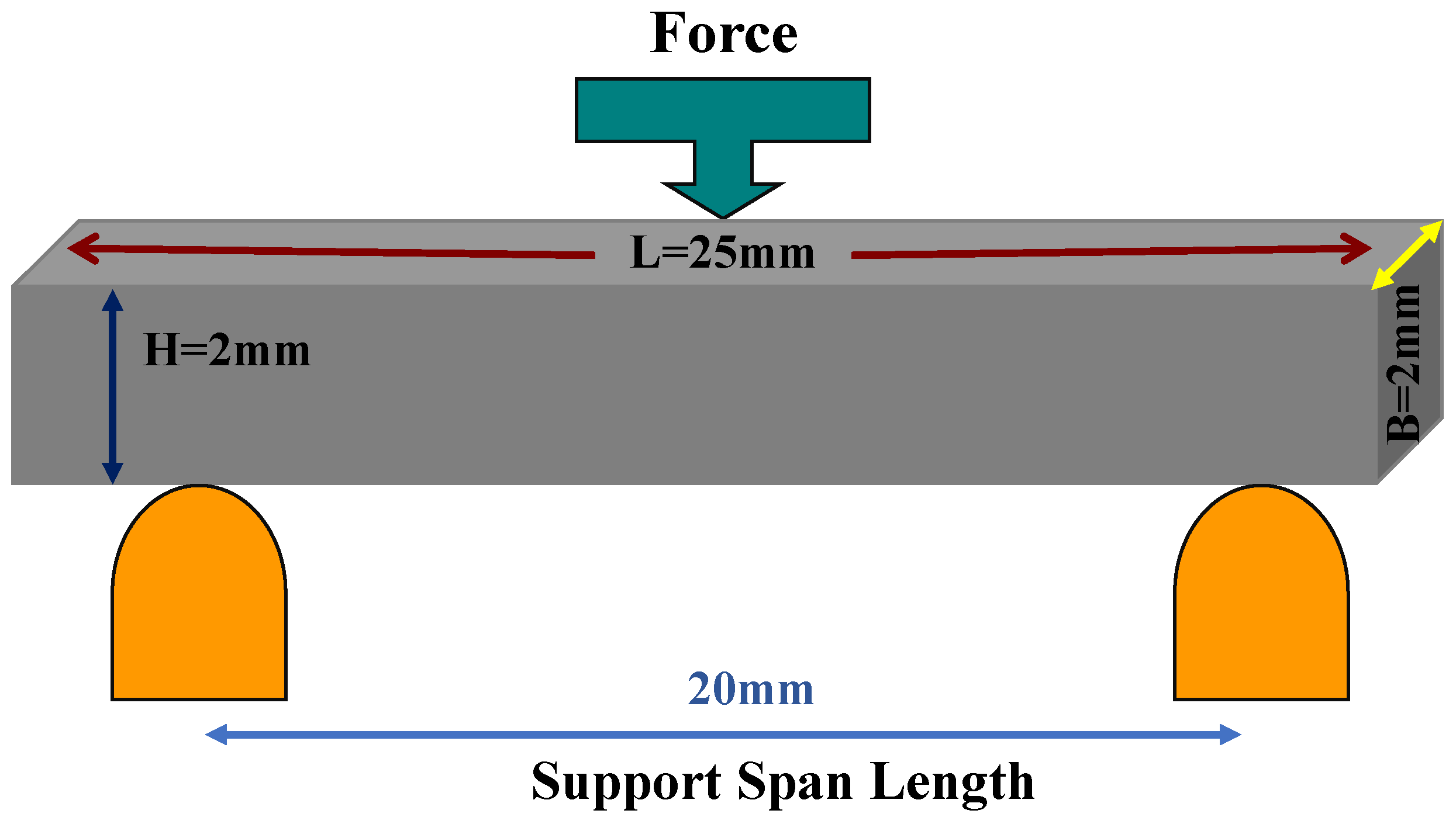

2.3. Determination of Flexural Strength and Modulus

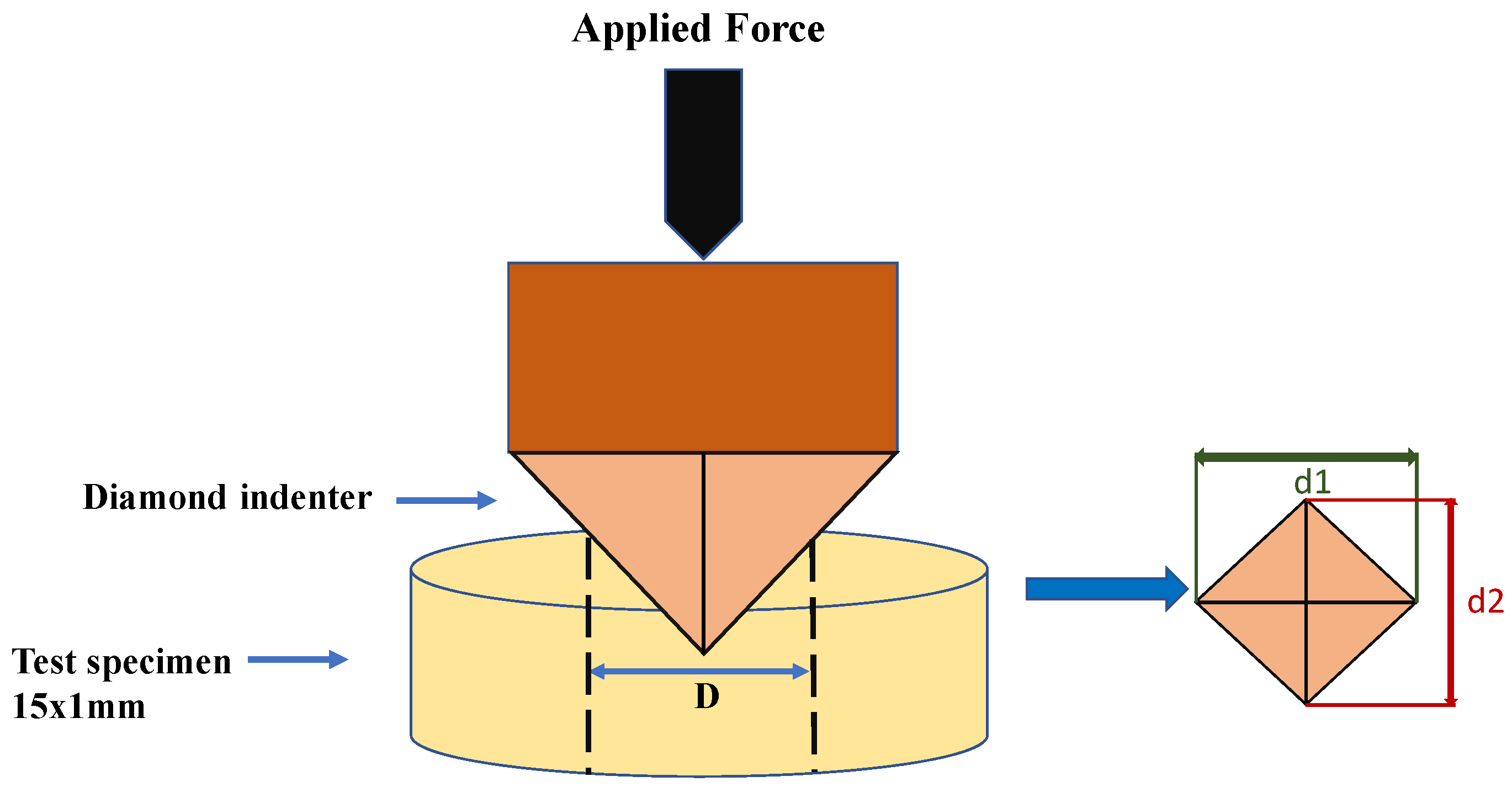

2.4. Evaluation of Surface Hardness (Vickers Microhardness)

2.5. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sabbagh, J.; Masri, L.E.; Fahd, J.; Nahas, P. A three-year randomized clinical trial evaluating direct posterior composite restorations placed with three self-etch adhesives. Biomater. Investig. Dent. 2021, 8, 92–103. [Google Scholar] [CrossRef]

- Badr, C.; Spagnuolo, G.; Amenta, F.; Khairallah, C.; Mahdi, S.S.; Daher, E.; Battineni, G.; Baba, N.Z.; Zogheib, T.; Qasim, S.S.B.; et al. A Two-Year Comparative Evaluation of Clinical Performance of a Nanohybrid Composite Resin to a Flowable Composite Resin. J. Funct. Biomater. 2021, 12, 51. [Google Scholar] [CrossRef] [PubMed]

- Arbildo-Vega, H.I.; Lapinska, B.; Panda, S.; Lamas-Lara, C.; Khan, A.S.; Lukomska-Szymanska, M. Clinical Effectiveness of Bulk-Fill and Conventional Resin Composite Restorations: Systematic Review and Meta-Analysis. Polymers 2020, 12, 1786. [Google Scholar] [CrossRef] [PubMed]

- Leprince, J.G.; Leveque, P.; Nysten, B.; Gallez, B.; Devaux, J.; Leloup, G. New insight into the ‘‘depth of cure’’ of dimethacrylate- based dental composites. Dent. Mater. 2012, 28, 512–520. [Google Scholar] [CrossRef] [PubMed]

- Lins, R.; Vinagre, A.; Alberto, N.; Domingues, M.F.; Messias, A.; Martins, L.R.; Nogueira, R.; Ramos, J.C. Polymerization Shrinkage Evaluation of Restorative Resin-Based Composites Using Fiber Bragg Grating Sensors. Polymers 2019, 11, 859. [Google Scholar] [CrossRef]

- Venus® Bulk Fill Technical Information. 2019. Available online: https://www.kulzer.com/EN/downloads/venus_7/venus_bulk_fill_2/Venus_Bulk_Fill_Product_Information_EN.pdf (accessed on 1 September 2022).

- Chen, H.Y.; Manhart, J.; Hickel, R.; Kunzelmann, K.H. Polymerization contraction stress in light-cured packable composite resins. Dent. Mater. 2001, 17, 253–259. [Google Scholar] [CrossRef]

- Askar, H.; Al-Abdi, A.; Blunck, U.; Göstemeyer, G.; Paris, S.; Schwendicke, F. Secondary Caries Adjacent to Bulk or Incrementally Filled Composites Placed after Selective Excavation In Vitro. Materials 2021, 14, 939. [Google Scholar] [CrossRef]

- Leinfelder, K.F. Posterior composite resins: The materials and their clinical performance. J. Am. Dent. Assoc. 1995, 126, 663–672. [Google Scholar] [CrossRef]

- Carvalho, R.M.; Pereira, J.C.; Yoshiyama, M.; Pashley, D.H. A review of polymerization contraction: The influence of stress development versus stress relief. Oper. Dent. 1996, 21, 17–24. [Google Scholar]

- Elsharkasi, M.M.; Platt, J.A.; Cook, N.B.; Yassen, G.H.; Matis, B.A. Cuspal Deflection in Premolar Teeth Restored with Bulk-Fill Resin-Based Composite Materials. Oper Dent. 2018, 43, E1–E9. [Google Scholar] [CrossRef]

- Santis, R.; Lodato, V.; Gallicchio, V.; Prisco, D.; Riccitiello, F.; Rengo, S.; Rengo, C. Cuspal Deflection and Temperature Rise of MOD Cavities Restored through the Bulk-Fill and Incremental Layering Techniques Using Flowable and Packable Bulk-Fill Composites. Materials 2020, 13, 5664. [Google Scholar] [CrossRef] [PubMed]

- Leprince, J.G.; Palin, W.M.; Vanacker, J.; Sabbagh, J.; Devaux, J.; Leloup, G. Physico-mechanical characteristics of commercially available bulk-fill composites. J. Dent. 2014, 42, 993–1000. [Google Scholar] [CrossRef]

- Ilie, N.; Bucuta, S.; Draenert, M. Bulk-fill resin-based composites: An in vitro assessment of their mechanical performance. Oper. Dent. 2013, 38, 618–625. [Google Scholar] [CrossRef] [PubMed]

- Bucuta, S.; Ilie, N. Light transmittance and micro-mechanical properties of bulk fill vs. conventional resin based composites. Clin. Oral Investig. 2014, 18, 1991–2000. [Google Scholar] [CrossRef] [PubMed]

- Moszner, N.; Fischer, U.K.; Ganster, B.; Liska, R.; Rheinberger, V. Benzoyl germanium derivatives as novel visible light photoinitiators for dental materials. Dent. Mater. 2008, 24, 901–907. [Google Scholar] [CrossRef] [PubMed]

- Surefil® SDR™ Flow Product Brochure. Dentsply International. 2017. Available online: https://assets.dentsplysirona.com/flagship/en/explore/restorative/sdr-flow_plus_us_version/dsp_911_SDRflow%2BBrochure_Final_082517.pdf (accessed on 1 September 2022).

- Burgess, J.; Cakir, D. Comparative properties of low shrinkage composite resins. Compend. Contin. Educ. Dent. 2010, 31, 10–15. [Google Scholar] [PubMed]

- Ilie, N.; Hickel, R. Investigations on a methacrylate- based flowable composite based on the SDR technology. Dent. Mater. 2011, 27, 348–355. [Google Scholar] [CrossRef]

- El-Safty, S.; Silikas, N.; Watts, D.C. Creep deformation of restorative resin-composites intended for bulk-fill placement. Dent. Mater. 2012, 28, 928–935. [Google Scholar] [CrossRef]

- Ellakwa, A.; Cho, N.; Lee, I.B. The effect of resin matrix composition on the polymerization shrinkage and rheological properties of experimental dental composites. Dent. Mater. 2007, 23, 1229–1235. [Google Scholar]

- Gopferich, A. Mechanisms of polymer degradation and erosion. Biomaterials 1996, 17, 103–114. [Google Scholar] [CrossRef]

- Lingstrom, P.; Imfeld, T.; Birkhed, D. Comparison of three different methods for measurement of Plaque-pH in humans after consumption of soft bread and potato chips. J. Dent. Res. 1993, 72, 865–870. [Google Scholar] [CrossRef] [PubMed]

- Zafar, M.S.; Amin, F.; Fareed, M.A.; Ghabbani, H.; Riaz, S.; Khurshid, Z.; Kumar, N. Biomimetic Aspects of Restorative Dentistry Biomaterials. Biomimetics 2020, 5, 34. [Google Scholar] [CrossRef]

- Khan, A.A.; Zafar, M.S.; Ali, A.; Ghubayri, A.; AlMufareh, N.A.; Binobaid, A.; Eskandrani, R.M.; Al-Kheraif, A.A. Polymerisation of restorative dental composites: Influence on physical, mechanical and chemical properties at various setting depths. Mater. Technol. 2022, 37, 2056–2062. [Google Scholar] [CrossRef]

- Khan, A.A.; AlKhureif, A.A.; Mohamed, B.A.; Bautista, L.S. Enhanced mechanical properties are possible with urethane dimethacrylate-based experimental restorative dental composite. Mater. Res. Express 2020, 7, 105307. [Google Scholar] [CrossRef]

- Borges, A.L.S.; Dal Piva, A.M.D.O.; Moecke, S.E.; de Morais, R.C.; Tribst, J.P.M. Polymerization Shrinkage, Hygroscopic Expansion, Elastic Modulus and Degree of Conversion of Different Composites for Dental Application. J. Compos. Sci. 2021, 5, 322. [Google Scholar] [CrossRef]

- Scribante, A.; Gallo, S.; Scarantino, S.; Dagna, A.; Poggio, C.; Colombo, M. Exposure of biomimetic composite materials to acidic challenges: Influence on flexural resistance and elastic modulus. Biomimetics 2020, 5, 56. [Google Scholar] [CrossRef]

- Alencar, M.F.; Pereira, M.T.; De-Moraes, M.D.R.; Santiago, S.L.; Passos, V.F. The effects of intrinsic and extrinsic acids on nanofilled and bulk fill resin composites: Roughness, surface hardness, and scanning electron microscopy analysis. Microsc. Res. Tech. 2020, 83, 202–207. [Google Scholar] [CrossRef]

- Henrique brugim, L.U.; Cenci, J.; Do Monte Ribeiro Busato, P.R.; Agner busato, M.C.; Camilotti, V.; Mendonça, J. Influence of Cola-Based Soft Drinks on the Microhardness of Nanohybrid and Bulk Fill Composites. J. Clin. Diagnostic Res. 2019, 1, 13. [Google Scholar]

- Colombo, M.; Gallo, S.; Poggio, C.; Ricaldone, V.; Arciola, C.R.; Scribante, A. New Resin-Based Bulk-Fill Composites: In vitro Evaluation of Micro-Hardness and Depth of Cure as Infection Risk Indexes. Materials 2020, 13, 1308. [Google Scholar] [CrossRef]

- Şişmanoğlu, S.; Sengez, G. Effects of Acidic Beverages on Color Stability of Bulk-Fill Composites with Different Viscosities. Odovtos-Int. J. Dent. Sc. 2022, 24, 338–347. [Google Scholar] [CrossRef]

- Borges, M.G.; Soares, C.J.; Maia, T.S.; Bicalho, A.A.; Barbosa, T.P.; Costa, H.L.; Menezes, M.S. Effect of acidic drinks on shade matching, surface topography, and mechanical properties of conventional and bulk-fill composite resins. J. Prosthet. Dent. 2019, 121, 868.e1–868.e8. [Google Scholar] [CrossRef]

- Kumar, N.; Amin, F.; Hashem, D.; Khan, S.; Zaidi, H.; Rahman, S.; Farhan, T.; Mahmood, S.J.; Asghar, M.A.; Zafar, M.S. Evaluating the pH of Various Commercially Available Beverages in Pakistan: Impact of Highly Acidic Beverages on the Surface Hardness and Weight Loss of Human Teeth. Biomimetics 2022, 7, 102. [Google Scholar] [CrossRef] [PubMed]

- Shawkat, E.S.; Shortall, A.C.; Addison, O.; Palin, W.M. Oxygen inhibition and incremental layer bond strengths of resin composites. Dent. Mater. 2009, 25, 1338–1346. [Google Scholar] [CrossRef]

- ISO 4049:2000; Dentistry—Polymer-Based Filling, Restorative and Luting Materials. International Organization for Standardization: Geneva, Switzerland, 2000.

- Palin, W.M.; Fleming, G.J.P.; Burke, F.J.T.; Marquis, P.M.; Randall, R.C. The influence of short and medium-term immersion on hydrolytic stability of novel low-shrink dental composites. Dent. Mater. 2005, 21, 852–863. [Google Scholar] [CrossRef] [PubMed]

- Ali, S.; Sangi, L.; Kumar, N.; Kumar, B.; Khurshid, Z.; Zafar, M.S. Evaluating antibacterial and surface mechanical properties of chitosan modified dental resin composites. Technol. Health Care 2020, 28, 165–173. [Google Scholar] [CrossRef] [PubMed]

- Junior, R.; Adalberto, S.; Zanchi, C.H.; Carvalho, R.V.D.; Demarco, F.F. Flexural strength and modulus of elasticity of different types of resin-based composites. Braz. Oral Res. 2007, 21, 16–21. [Google Scholar] [CrossRef] [PubMed]

- Ferracane, J.L.; Marker, V.A. Solvent degradation and reduced fracture toughness in aged composites. J. Dent. Res. 1992, 71, 13–19. [Google Scholar] [CrossRef]

- Turssi, C.P.; Hara, A.T.; Serra, M.C.; Rodrigues, A.L. Effect of storage media upon the surface micromorphology of resin-based restorative materials. J. Oral Rehabil. 2002, 29, 864–871. [Google Scholar] [CrossRef]

- Khan, A.A.; Siddiqui, A.Z.; Mohsin, S.F.; Al-Kheraif, A.A. Influence of mouth rinses on the surface hardness of dental resin nano-composite. Pak. J. Med. Sci. 2015, 31, 1485–1489. [Google Scholar] [CrossRef]

- Degirmenci, A.; Degirmenci, B.U.; Salameh, M. Long-Term Effect of Acidic Beverages on Dental Injectable Composite Resin: Microhardness, Surface Roughness, Elastic Modulus, and Flexural Strength Patterns. Strength Mater. 2022, 54, 331–343. [Google Scholar] [CrossRef]

- Widhawan, S.A.; Yap, A.U.; Ornaghi, B.P.; Banas, A.; Banas, K.; Neo, J.C.; Pfeifer, C.S.; Rosa, V. Fatigue stipulation of bulk-fill composites: An in vitro appraisal. Dent. Mater. 2015, 31, 1068–1074. [Google Scholar] [CrossRef]

- Leprince, J.; Palin, W.M.; Mullier, T.; Devaux, J.; Vreven, J.; Leloup, G. Investigating filler morphology and mechanical properties of new low-shrinkage resin composite types. J. Oral Rehabil. 2010, 37, 364–376. [Google Scholar] [CrossRef]

- Ilie, N.; Rencz, A.; Hickel, R. Investigations towards nano-hybrid resin-based composites. Clin. Oral Investig. 2013, 17, 185–193. [Google Scholar] [CrossRef] [PubMed]

- Sideridou, I.D.; Karabela, M.M.; Vouvoudi, E. Physical properties of current dental nanohybrid and nanofill light-cured resin composites. Dent. Mater. 2011, 27, 598–607. [Google Scholar] [CrossRef]

- Szalewski, L.; Wójcik, D.; Bogucki, M.; Szkutnik, J.; Różyło-Kalinowska, I. The Influence of Popular Beverages on Mechanical Properties of Composite Resins. Materials 2021, 14, 3097. [Google Scholar] [CrossRef]

- Szalewski, L.; Wójcik, D.; Sofińska-Chmiel, W.; Kuśmierz, M.; Różyło-Kalinowska, I. How the Duration and Mode of Photopolymerization Affect the Mechanical Properties of a Dental Composite Resin. Materials 2023, 16, 113. [Google Scholar] [CrossRef]

- Kumar, N.; Ghani, F.; Fareed, M.A.; Riaz, S.; Khurshid, Z.; Zafar, M.S. Bi-axial flexural strength of resin based dental composites—Influence and reliability of the testing method configuration. Mater. Technol. 2022, 37, 2166–2172. [Google Scholar] [CrossRef]

| Resin-Based Composite | Type | Manufacturer | Filler | Filler Weight%; Volume% | Resin Matrix |

|---|---|---|---|---|---|

| Filtek Bulk-fill (FBF) | Flowable | 3M ESPE, St Paul, MN, USA | Zirconia/silica and ytterbium Trifluoride | 64.5; 42.5 | Bis-GMA, UDMA, Bis-EMA, and Procrylat resins |

| Tetric Evoceram Bulk-fill (TBF) | Paste | Vivadent, Schaan, Liechtenstein | Ba-Al-Si-glass, prepolymer filler (monomer, glass filler, and ytterbium fluoride) Spherical mixed oxide | 79–81; (including 17% prepolymers); 60–61 | Bis-GMA and UDMA |

| X-tra fil (XBF) | Paste | VOCO (Cuxhaven, Germany) | N/P | 86; 70.1 | Bis-GMA, UDMA, and TEGDMA |

| QuiXfil (QBF) | Paste | Dentsply Caulk, Germany | Silinated strontium, aluminum sodium, fluoride phosphate, and silicate glass | 86; 66 | UDMA, TEGDMA, di- and trimethacrylate resins, and carboxylic acid-modified dimethacrylate resin |

| Grandio (GR) | Nanohybrid | VOCO (Cuxhaven, Germany) | Al-Si Glass and SiO2 | 87; 71 | Bis-GMA, UDMA, and TEGDMA |

| Materials | Storage Condition | Flexural Strength (MPa) Mean (SD) | Flexural Modulus (GPa) Mean (SD) | Surface Hardness (VHN) Mean (SD) |

|---|---|---|---|---|

| Filtek Bulk-Fill (FBF) | Dry Control | 132.72 (9.28) A | 6.20 (0.88) A | 50.00 (3.67) B |

| Distilled Water Control | 126.11 (8.91) A | 5.73 (0.38) A | 62.00 (6.16) A | |

| Orange Juice | 103.40 (8.36) B | 3.54 (0.47) B | 47.60 (2.07) B | |

| Coca-Cola | 94.32 (8.25) B | 2.68 (0.45) B | 47.20 (3.70) B | |

| Tetric EvoCeram Bulk-Fill (TBF) | Dry Control | 118.63 (7.76) A | 5.44 (0.95) A | 43.80 (2.77) B |

| Distilled Water Control | 109.99 (8.80) A | 4.96 (0.53) AB | 48.40 (2.88) AB | |

| Orange Juice | 89.14 (7.92) B | 3.97 (0.41) B | 52.60 (4.16) AB | |

| Coca-Cola | 89.19 (8.93) B | 3.95 (0.42) B | 49.40 (2.41) A | |

| X-tra fil (XBF) | Dry Control | 136.10 (12.46) A | 6.86 (0.36) A | 77.40 (4.72) A |

| Distilled Water Control | 128.77 (6.86) A | 6.32 (0.76) A | 75.80 (4.49) A | |

| Orange Juice | 108.67 (8.42) B | 5.01 (0.52) B | 75.20 (3.49) A | |

| Coca-Cola | 95.20 (6.67) B | 4.64 (0.53) B | 73.00 (2.00) A | |

| Quix Fill (QBF) | Dry Control | 115.44 (9.58) A | 5.48 (0.59) A | 69.60 (2.88) A |

| Distilled Water Control | 109.00 (11.81) A | 5.27 (0.70) A | 68.20 (2.59) A | |

| Orange Juice | 61.22 (8.93) B | 3.16 (0.58) B | 65.60 (1.14) A | |

| Coca-Cola | 50.73 (4.94) B | 2.33(0.34) B | 56.20 (3.03) B | |

| Grandio (GR) (Control) | Dry Control | 215.13 (8.13) A | 8.50 (0.44) A | 90.80 (2.16) A |

| Distilled Water Control | 205.83 (10.05) A | 8.33 (0.58) A | 85.00 (4.42) B | |

| Orange Juice | 212.42 (7.67) A | 7.82 (0.59) A | 79.80 (1.64) C | |

| Coca-Cola | 132.50 (7.37) B | 4.53 (0.48) B | 72.80 (1.92) D |

| Storage Condition | Materials | Flexural Strength (MPa) Mean (SD) | Flexural Modulus (GPa) Mean (SD) | Surface Hardness (VHN) Mean (SD) |

|---|---|---|---|---|

| Dry Control | Filtek Bulk-Fill (FBF) | 132.72 (9.28) BC | 6.20 (0.88) BC | 50.00 (3.67) D |

| Tetric EvoCeram Bulk-Fill (TBF) | 118.63 (7.76) BC | 5.44 (0.95) C | 43.80 (2.77) D | |

| X-tra fil (XBF) | 136.10 (12.46) B | 6.86 (0.36) B | 77.40 (4.72) B | |

| Quix Fill (QBF) | 115.44 (9.58) C | 5.48 (0.59) C | 69.60 (2.88) C | |

| Grandio (GR) | 215.13 (8.13) A | 8.50 (0.44) A | 90.80 (2.16) A | |

| Distilled Water Control | Filtek Bulk-Fill (FBF) | 126.11 (8.91) BC | 5.73 (0.38) BC | 62.00 (6.16) C |

| Tetric EvoCeram Bulk-Fill (TBF) | 109.99 (8.80) C | 4.96 (0.53) C | 48.40 (2.88) D | |

| X-tra fil (XBF) | 128.77 (6.86) B | 6.32 (0.76) B | 75.80 (4.49) B | |

| Quix Fill (QBF) | 109.00 (11.81) C | 5.27 (0.70) BC | 68.20 (2.59) BC | |

| Grandio (GR) | 205.83 (10.05) A | 8.33 (0.58) A | 85.00 (4.42) A | |

| Orange Juice | Filtek Bulk-Fill (FBF) | 103.40 (8.36) BC | 3.54 (0.47) C | 47.60 (2.07) C |

| Tetric EvoCeram Bulk-Fill (TBF) | 89.14 (7.92) C | 3.97 (0.41) C | 52.60 (4.16) C | |

| X-tra fil (XBF) | 108.67 (8.42) B | 5.01 (0.52) B | 75.20 (3.49) A | |

| Quix Fill (QBF) | 61.22 (8.93) D | 3.16 (0.58) C | 65.60 (1.14) B | |

| Grandio (GR) | 212.42 (7.67) A | 7.82 (0.59) A | 79.80 (1.64) A | |

| Coca-Cola | Filtek Bulk-Fill (FBF) | 94.32 (8.25) B | 2.68 (0.45) B | 47.20 (3.70) C |

| Tetric EvoCeram Bulk-Fill (TBF) | 89.19 (8.93) B | 3.95 (0.42) A | 49.40 (2.41) C | |

| X-tra fil (XBF) | 95.20 (6.67) B | 4.64 (0.53) A | 73.00 (2.00) A | |

| Quix Fill (QBF) | 50.73 (4.94) C | 2.33 (0.34) B | 56.20 (3.03) B | |

| Grandio (GR) | 132.50 (7.37) A | 4.53 (0.48) A | 72.80 (1.92) A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dahri, W.M.; Kumar, N.; Altaf, N.; Mughal, W.; Zafar, M.S. Mechanical and Biomimetic Characteristics of Bulk-Fill Resin Dental Composites Following Exposure in a Simulated Acidic Oral Environment. Biomimetics 2023, 8, 19. https://doi.org/10.3390/biomimetics8010019

Dahri WM, Kumar N, Altaf N, Mughal W, Zafar MS. Mechanical and Biomimetic Characteristics of Bulk-Fill Resin Dental Composites Following Exposure in a Simulated Acidic Oral Environment. Biomimetics. 2023; 8(1):19. https://doi.org/10.3390/biomimetics8010019

Chicago/Turabian StyleDahri, Waheed Murad, Naresh Kumar, Noorulain Altaf, Waqas Mughal, and Muhammad Sohail Zafar. 2023. "Mechanical and Biomimetic Characteristics of Bulk-Fill Resin Dental Composites Following Exposure in a Simulated Acidic Oral Environment" Biomimetics 8, no. 1: 19. https://doi.org/10.3390/biomimetics8010019

APA StyleDahri, W. M., Kumar, N., Altaf, N., Mughal, W., & Zafar, M. S. (2023). Mechanical and Biomimetic Characteristics of Bulk-Fill Resin Dental Composites Following Exposure in a Simulated Acidic Oral Environment. Biomimetics, 8(1), 19. https://doi.org/10.3390/biomimetics8010019