The New Standard Is Biodigital: Durable and Elastic 3D-Printed Biodigital Clay Bricks

Abstract

1. Introduction

2. Materials and Methods

2.1. 3D Printed Biodigital Clay Brick Production

2.2. Elasticity Test

2.3. Compression Test

3. Results and Discussion

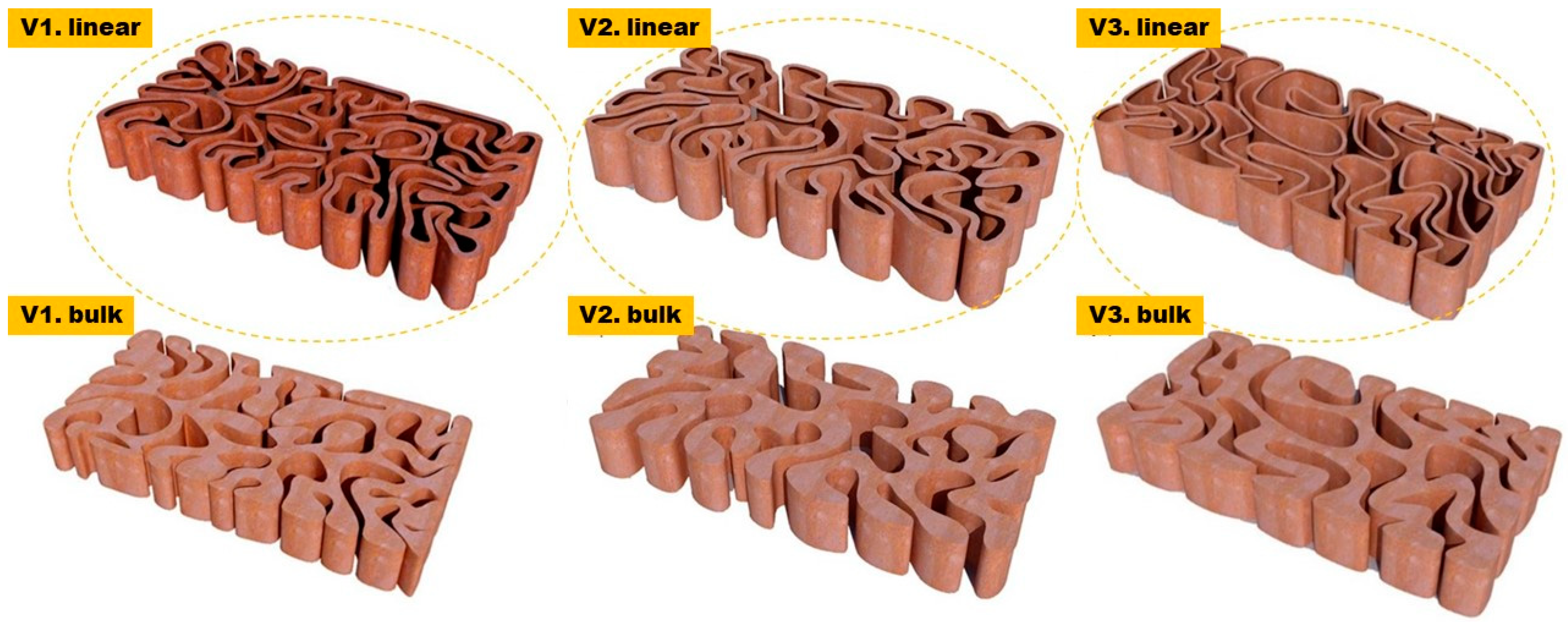

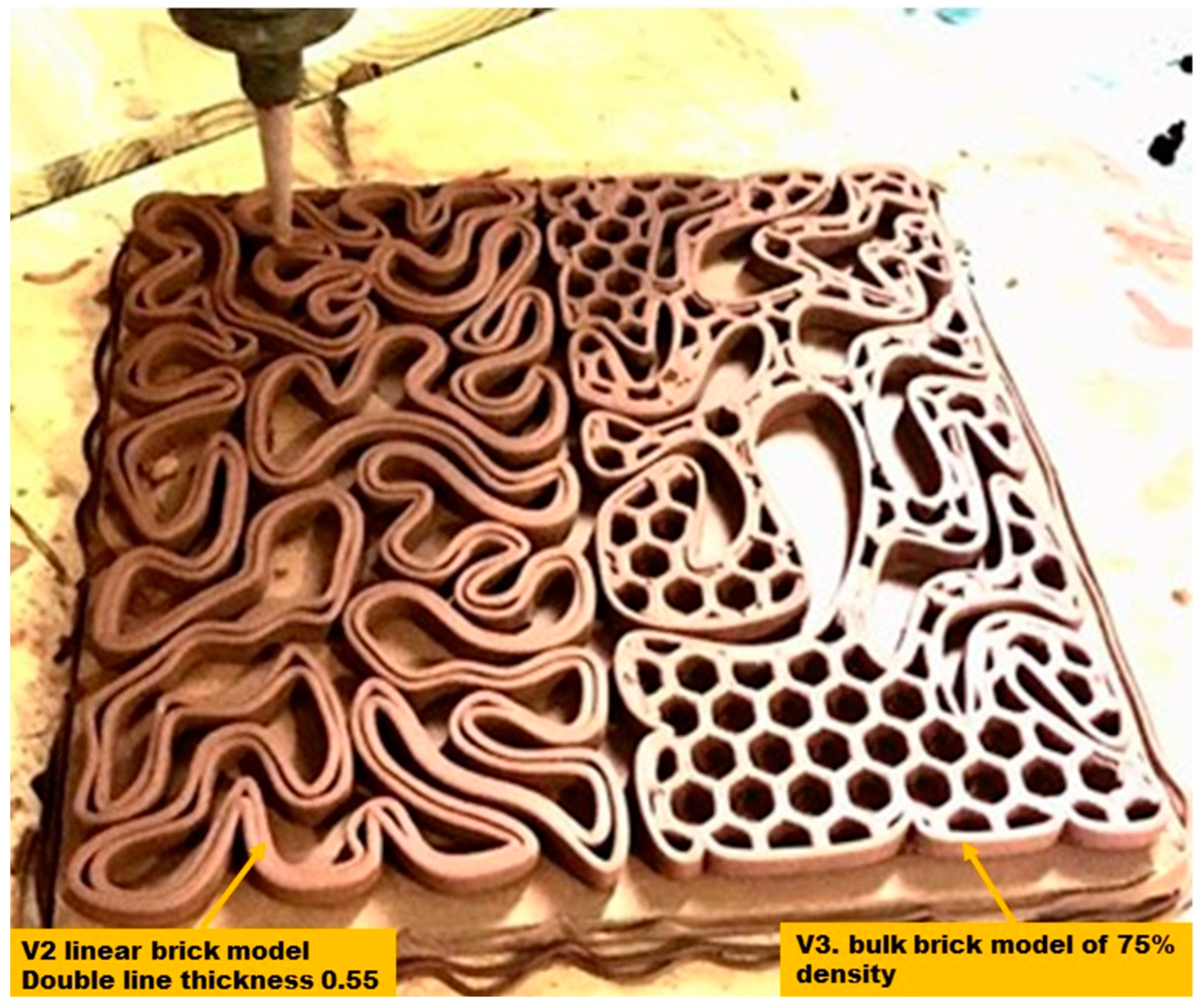

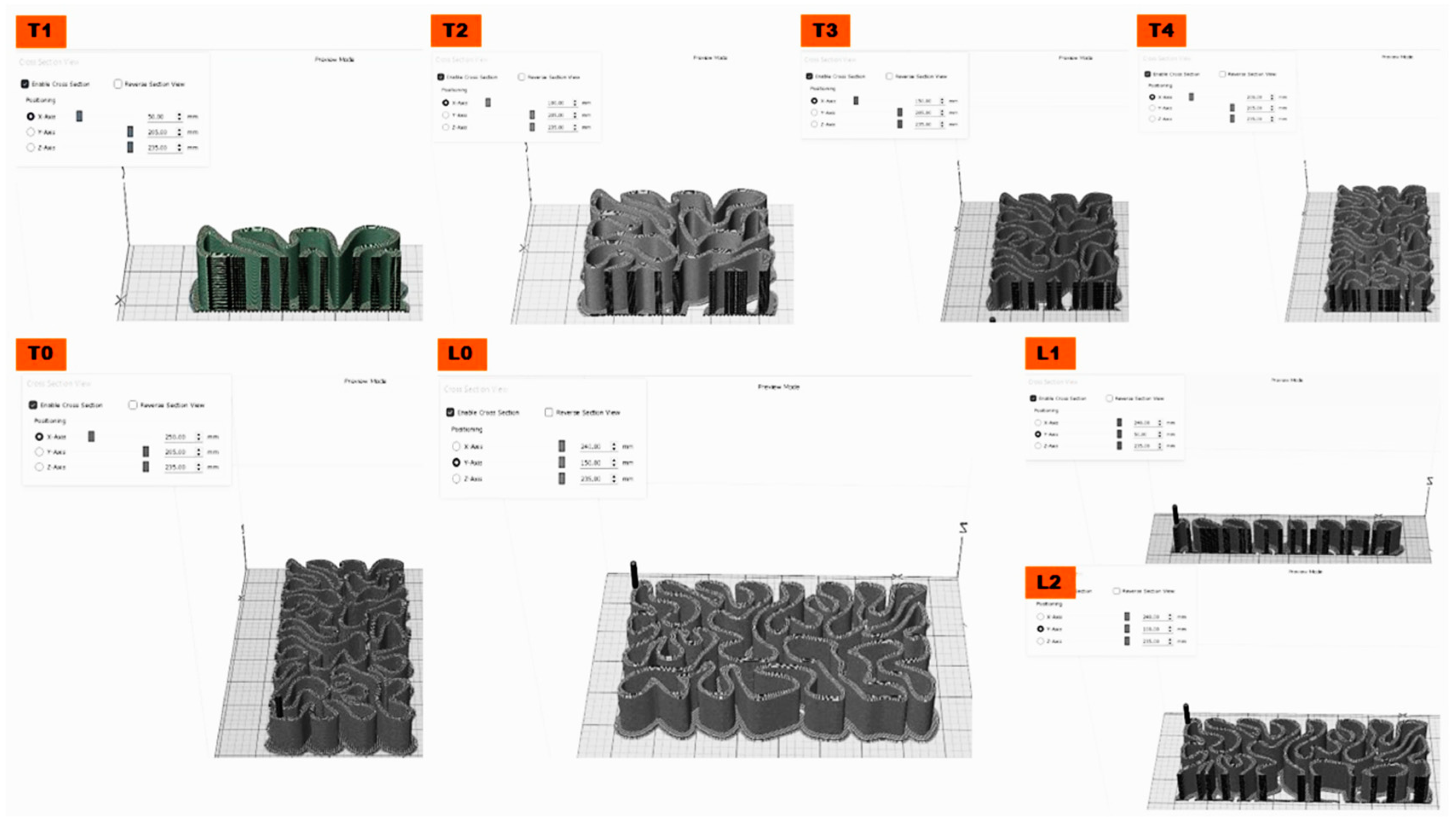

3.1. Material/Fabrication Conditions Standardisation

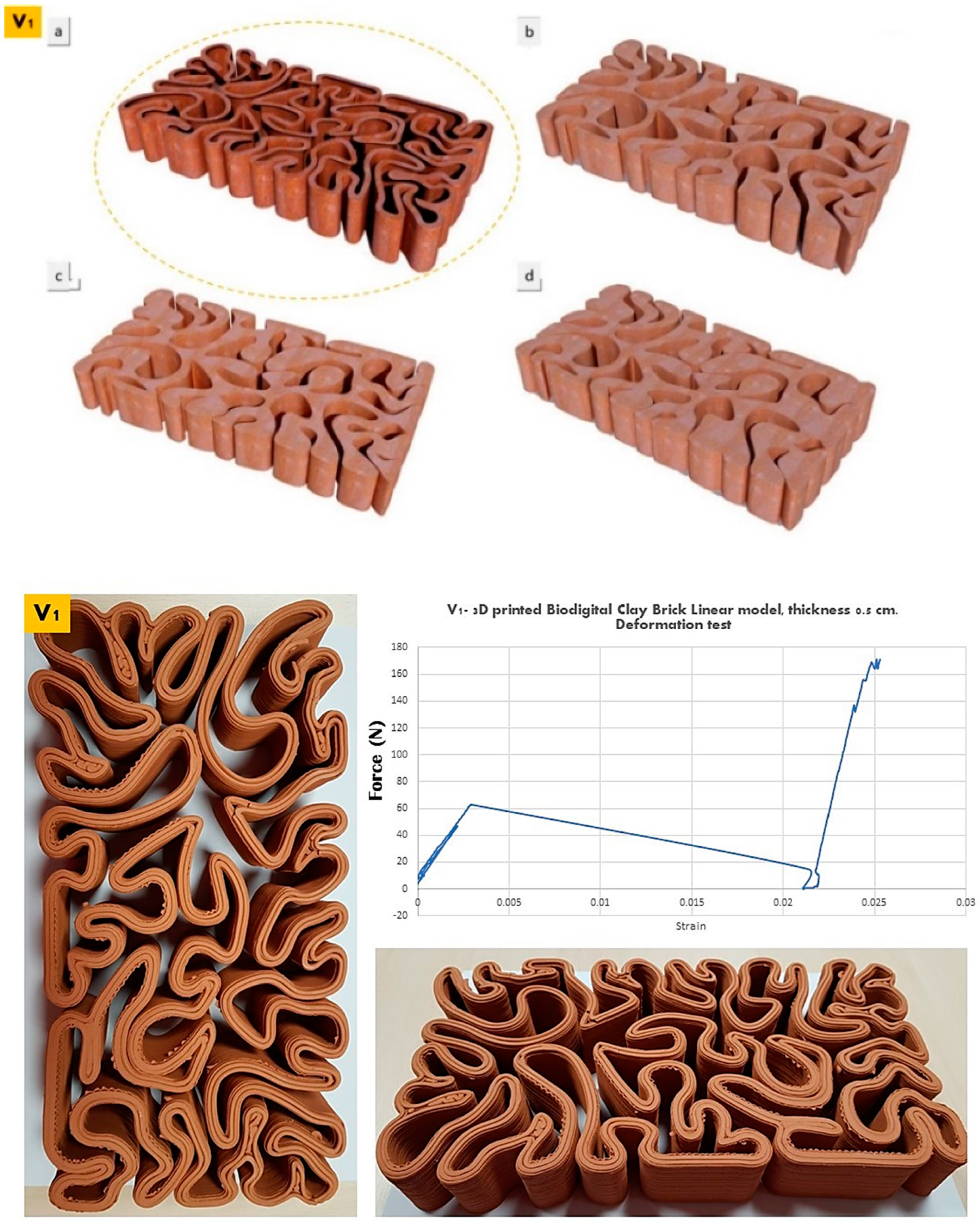

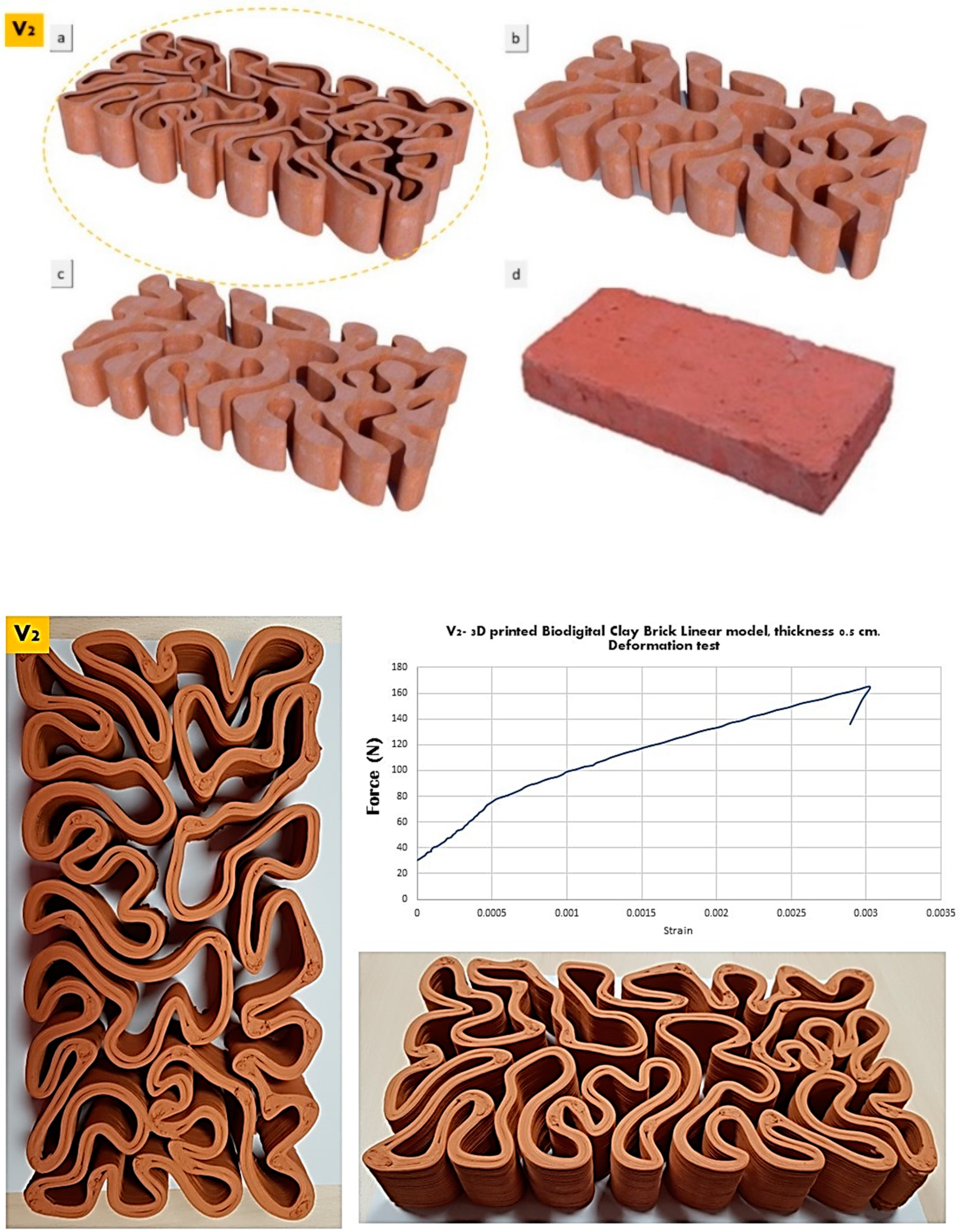

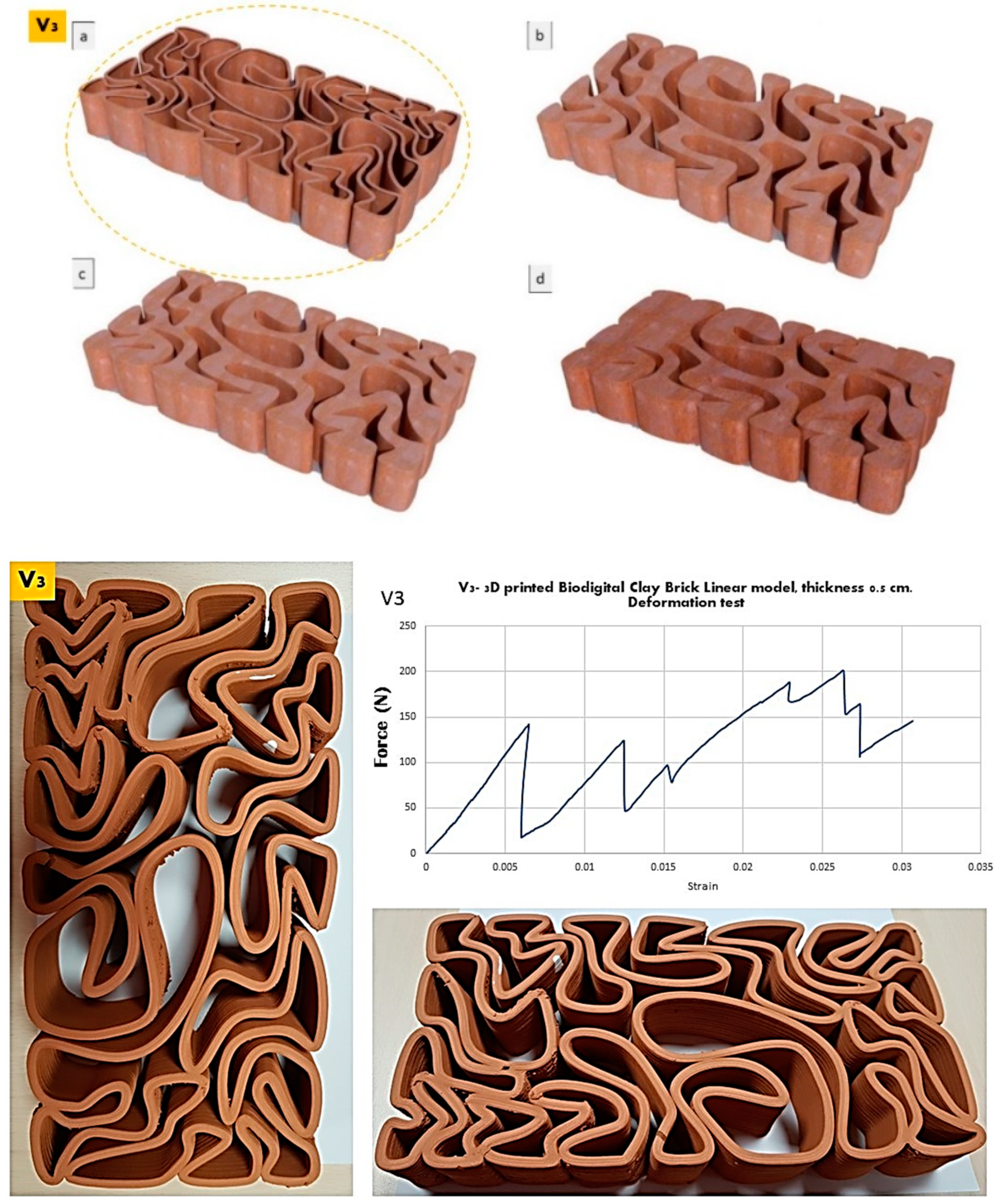

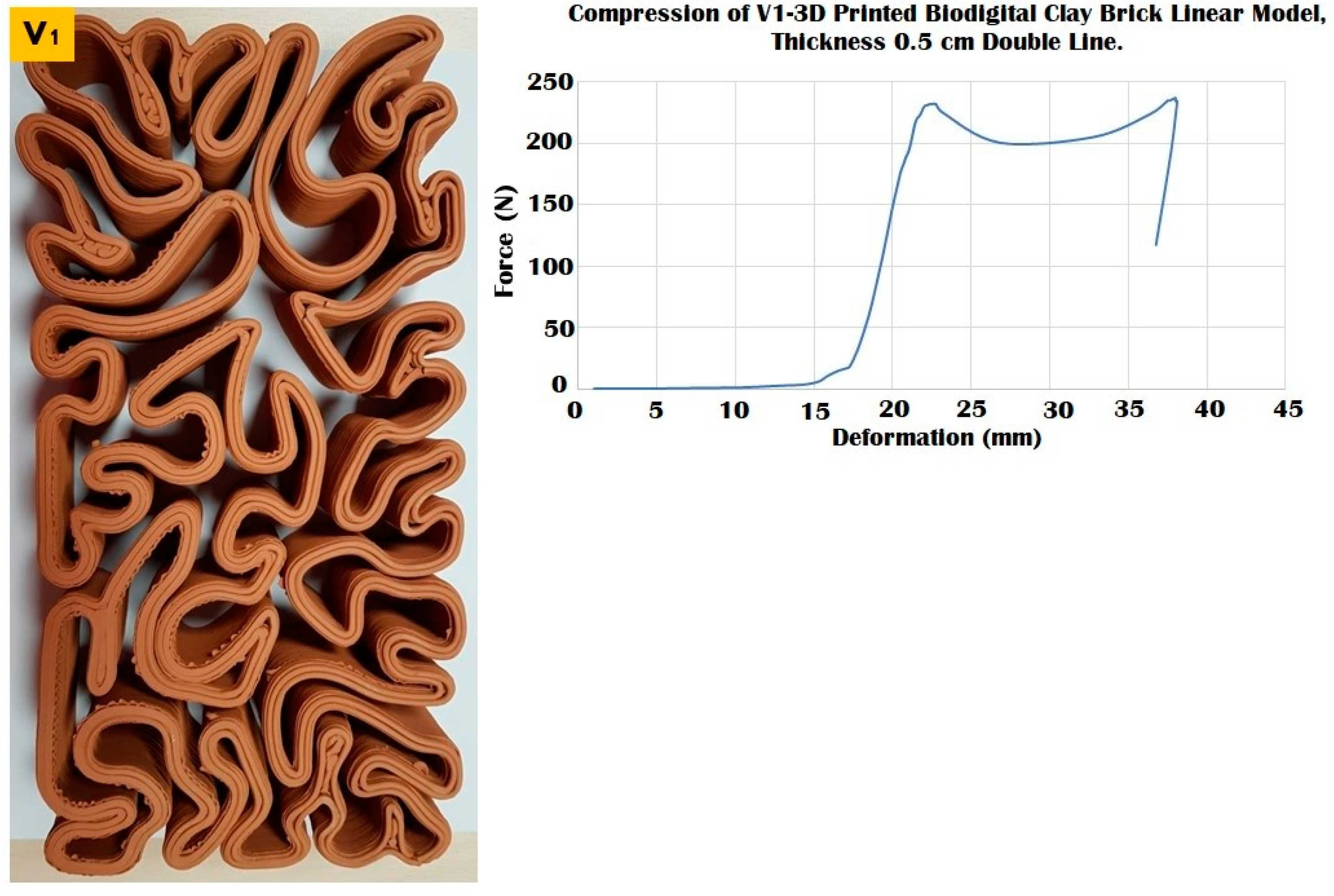

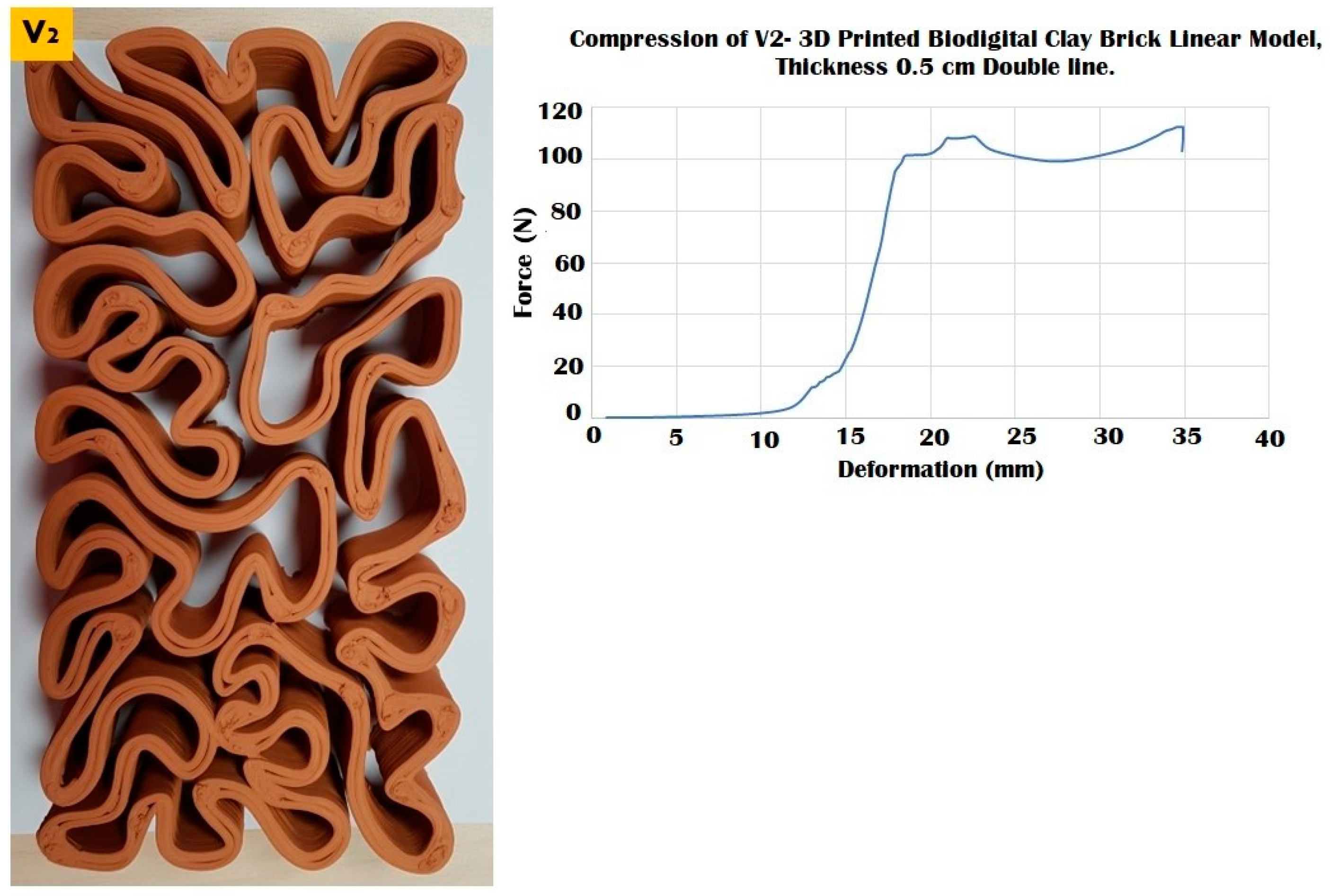

3.2. Elastic 3D Printed Biodigital Clay Bricks

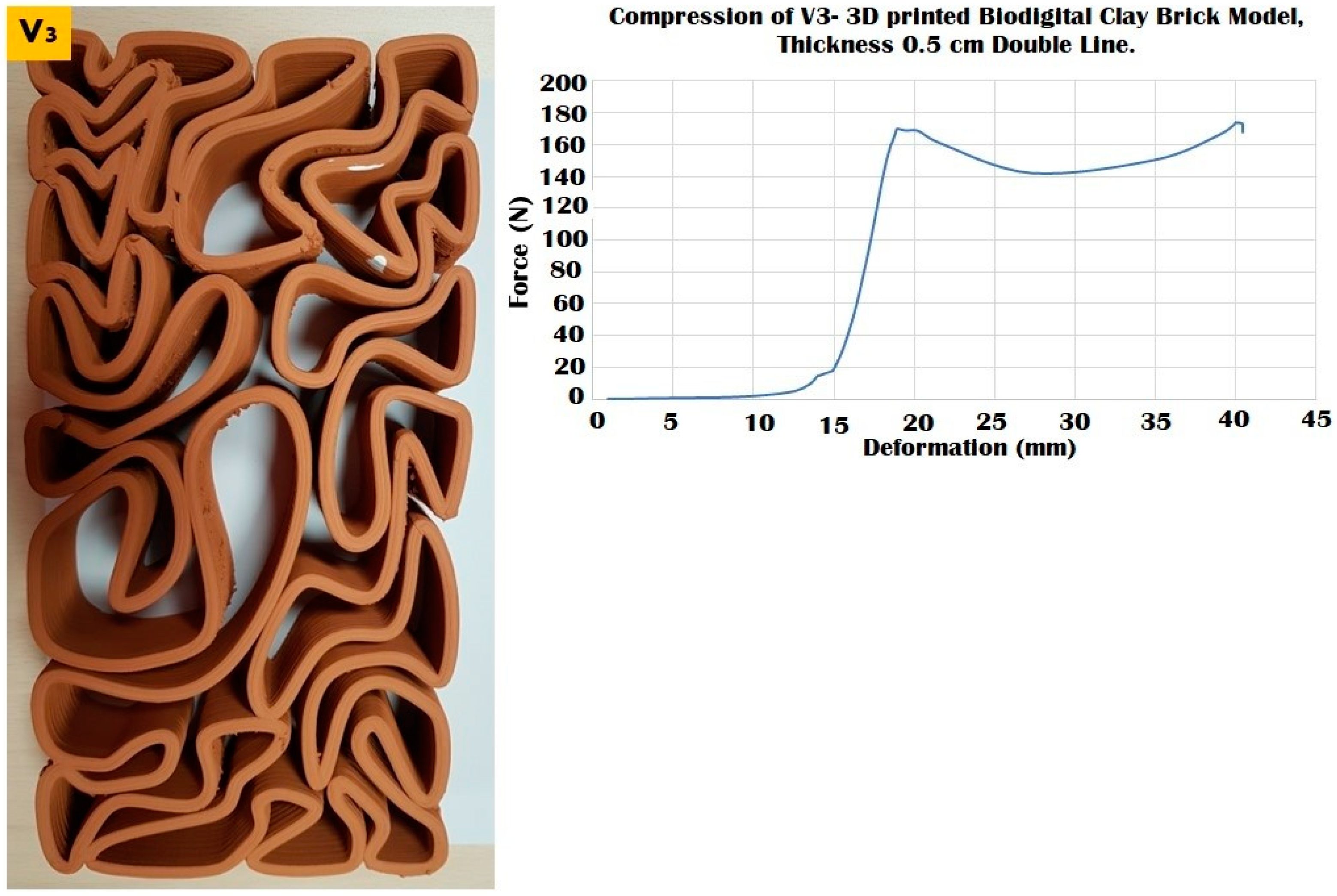

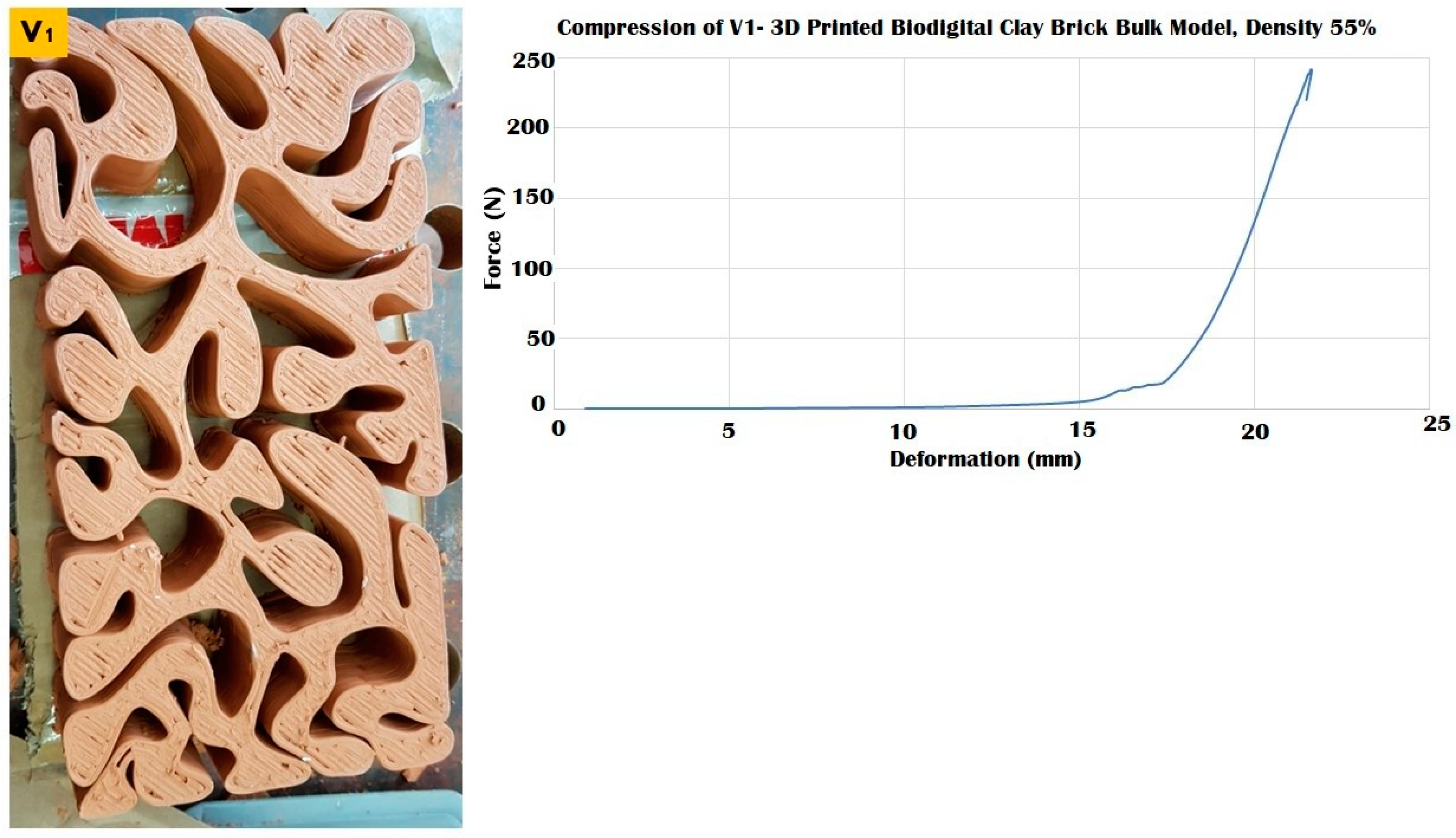

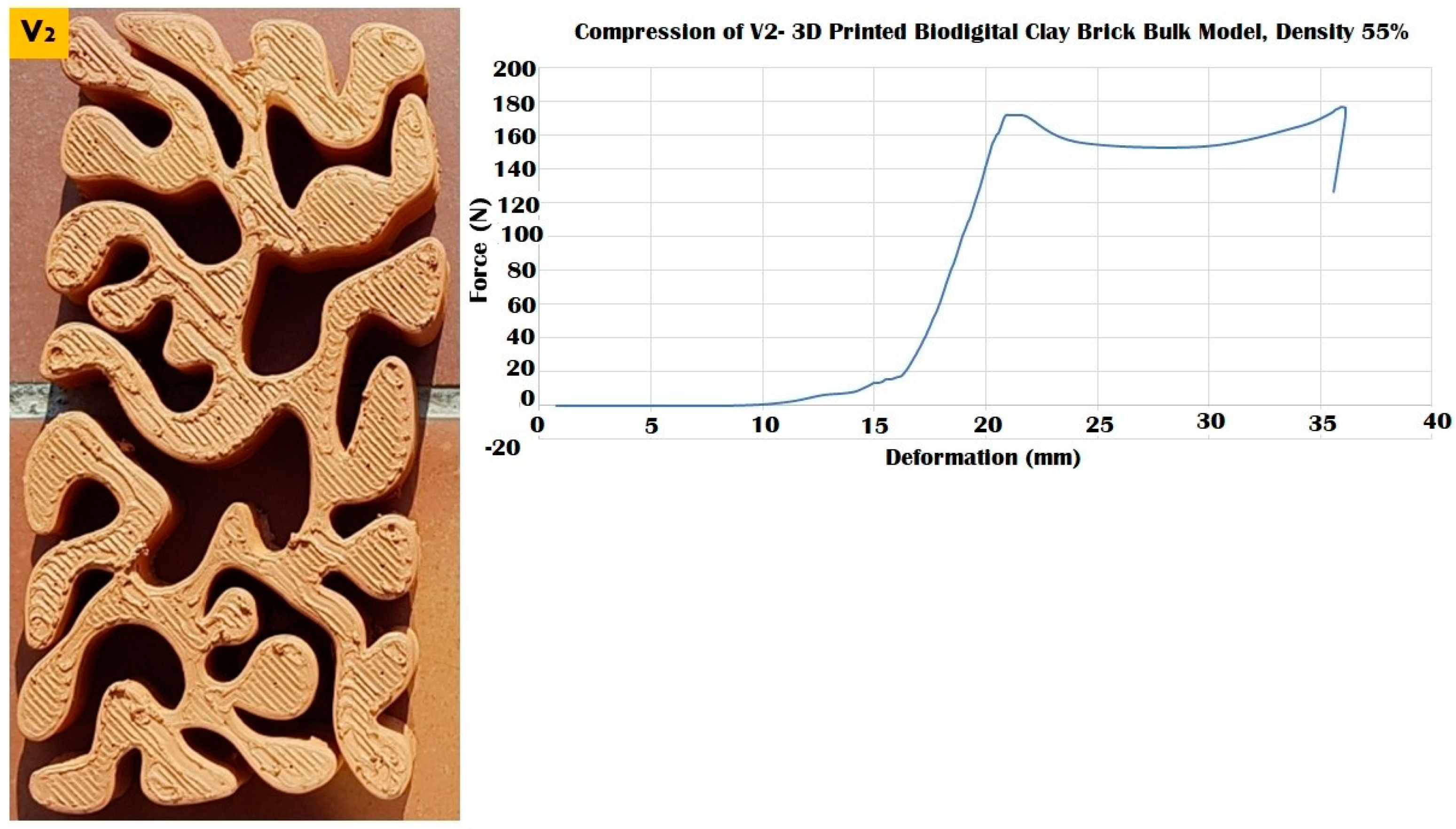

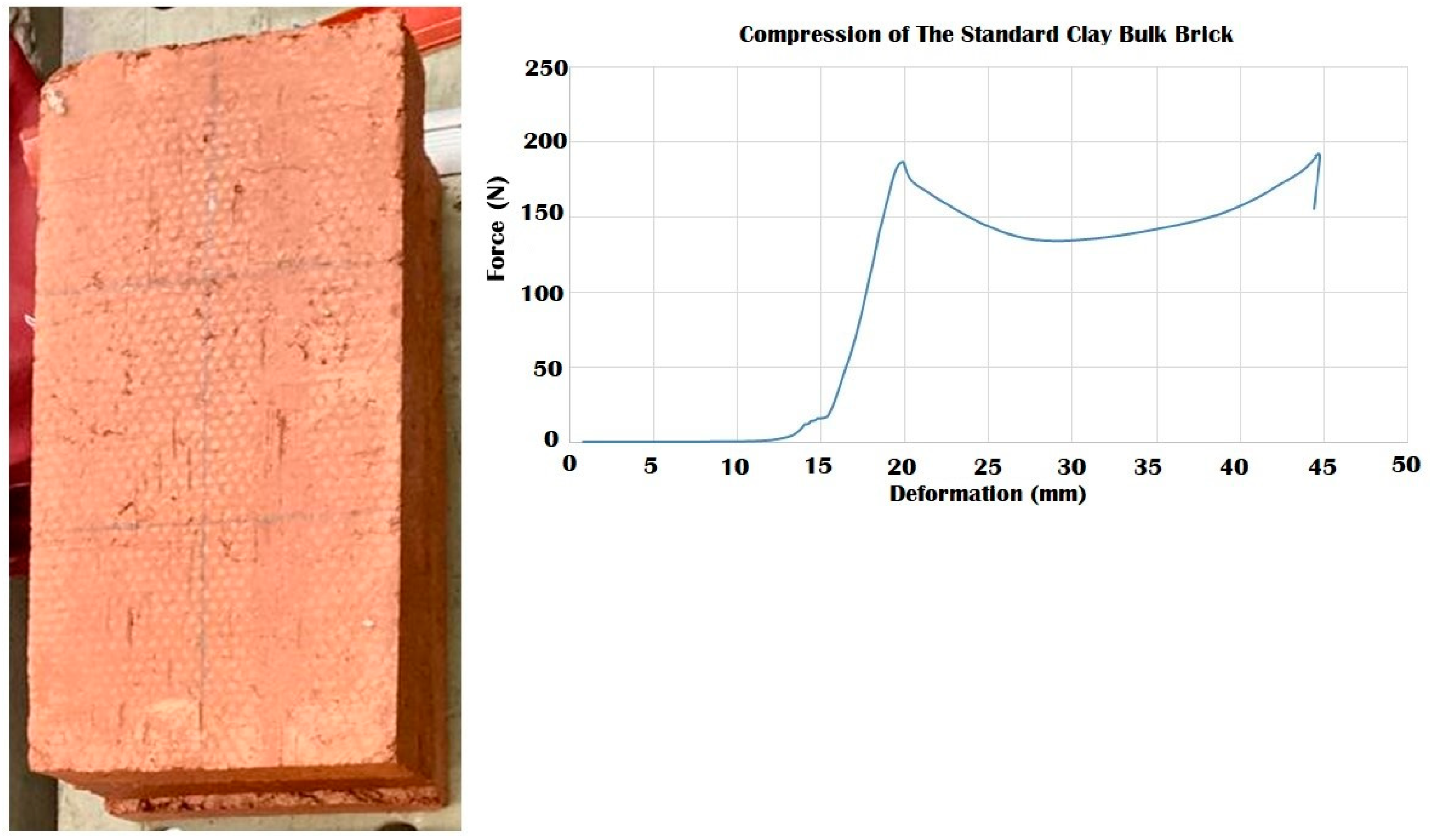

3.3. Durable 3D Printed Biodigital Clay Bricks

3.4. Durability vs. Elasticity “The New Standard”: 3D Printed Biodigital Clay Bricks

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- The Met. 2020. Available online: https://www.metmuseum.org/art/collection/search/544484 (accessed on 22 September 2022).

- Museum of Fine Arts, Boston. Art of Ancient Egypt, Nubia, and the Near East. Available online: https://www.mfa.org/collection/ancient-egypt-nubia-and-the-near-east (accessed on 14 December 2020).

- Ministry of Tourism and Antiquities. Menkaura Triads. Available online: https://egymonuments.gov.eg/collections/menkaura-triads-2/ (accessed on 21 August 2022).

- Teng, W.L. The Menkaure Triad, Numerical Thinking, and Divine Configurations in Ancient Egypt. Armstrong Undergraduate Journal of History (New Edition). 2017. Available online: https://armstronghistoryjournal.wordpress.com/2017/11/16/the-menkaure-triad-numerical-thinking-and-divine-configurations-in-ancient-egypt/ (accessed on 22 September 2022).

- van der Crabben, J. Beauty in Ancient Greek Sculpture—History et Cetera. Available online: https://etc.worldhistory.org/photos/beauty-in-ancient-greek-sculpture/ (accessed on 4 December 2021).

- Kousser, R. Creating the Past: The Vénus de Milo and the Hellenistic Reception of Classical Greece. Am. J. Archaeol. 2005, 109, 227–250. [Google Scholar] [CrossRef][Green Version]

- Spivey, N. 8-Revealing Aphrodite. In Greek Sculpture; Cambridge University Press: Cambridge, UK, 2013; p. 181. [Google Scholar] [CrossRef]

- Gasc-Barbier, M.; Merrien-Soukatchoff, V. Effect of Freezing-Thawing Cycles on the Elastic Waves’ Properties of Rocks. Geosciences 2022, 12, 103. [Google Scholar] [CrossRef]

- Beyhan, F.; Arslan Selçuk, S. 3D Printing in Architecture: One Step Closer to a Sustainable Built Environment. In Lecture Notes in Civil Engineering; Springer: Cham, Switzerland, 2018; pp. 253–268. [Google Scholar] [CrossRef]

- García-Alvarado, R.; Moroni-Orellana, G.; Banda-Pérez, P. Architectural Evaluation of 3D-Printed Buildings. Buildings 2021, 11, 254. [Google Scholar] [CrossRef]

- Hager, I.; Golonka, A.; Putanowicz, R. 3D Printing of Buildings and Building Components as the Future of Sustainable Construction? Procedia Eng. 2016, 151, 292–299. [Google Scholar] [CrossRef]

- Guo, A. 3D printed concrete components and structures: An overview. Sustain. Struct. 2021, 1, 000006. [Google Scholar] [CrossRef]

- Marijnissen, M.P.A.M.; van der Zee, A. 3D Concrete Printing in Architecture—A research on the potential benefits of 3D Concrete Printing in Architecture. In Proceedings of the 35th International Conference on Education and Research in Computer Aided Architectural Design in Europe (eCAADe), Rome, Italy, 20–22 September 2017; Volume 2. [Google Scholar] [CrossRef]

- Abdallah, Y.K.; Estévez, A.T. 3D-Printed Biodigital Clay Bricks. Biomimetics 2021, 6, 59. [Google Scholar] [CrossRef]

- Crawford, A.; In-na, P.; Caldwell, G.; Armstrong, R.; Bridgens, B. Clay 3D printing as a bio-design research tool: Development of photosynthetic living building components. Archit. Sci. Rev. 2022, 65, 185–195. [Google Scholar] [CrossRef]

- 3D-Printed Steel Building Structures. 2014. Available online: https://www.designnews.com/3d-printed-steel-building-structures (accessed on 21 July 2022).

- Amsterdam 3D Printed Steel Bridge. Available online: https://www.arup.com/projects/mx3d-bridge (accessed on 17 June 2020).

- Lesley. How Long Does it Take for Pottery Clay to Dry?—By The Pottery Wheel. 2019. Pottery Tips by the Pottery Wheel. Available online: https://thepotterywheel.com/how-long-does-it-take-for-pottery-clay-to-dry/ (accessed on 22 September 2022).

- Available online: http://www.dwiemach.com (accessed on 22 September 2022).

- Chan, S.S.L.; Pennings, R.M.; Edwards, L.; Franks, G.V. 3D printing of clay for decorative architectural applications: Effect of solids volume fraction on rheology and printability. Addit. Manuf. 2020, 35, 101335. [Google Scholar] [CrossRef]

- ArchDaily. TECLA Technology and Clay 3D Printed House/Mario Cucinella Architects. 2021. Available online: https://www.archdaily.com/960714/tecla-technology-and-clay-3d-printed-house-mario-cucinella-architects. (accessed on 6 August 2022).

- Abdallah, Y.K.; Afsar, S.; Estévez, A.T.; Popov, O. Remote 3D Printing for the Integration of Clay-based Materials in Sustainable Architectural Fabrication. In Renewable Energy for Mitigating Climate Change; CRC Press: Boca Raton, FL, USA, 2021; pp. 133–152. [Google Scholar] [CrossRef]

- Húlan, T.; Štubňa, I.; Ondruška, J.; Csáki, Š.; Lukáč, F.; Mánik, M.; Vozár, L.; Ozolins, J.; Kaljuvee, T.; Trník, A. Young’s Modulus of Different Illitic Clays during Heating and Cooling Stage of Firing. Materials 2020, 13, 4968. [Google Scholar] [CrossRef]

- Kockal, N.U. Properties and microstructure of porous ceramic bodies containing fly ash. J. Build. Phys. 2011, 35, 338–352. [Google Scholar] [CrossRef]

- Aras, A. The change of phase composition in kaolinite- and illite-rich clay-based ceramic bodies. Appl. Clay Sci. 2004, 24, 257–269. [Google Scholar] [CrossRef]

- Brindley, G.W.; Brown, G. Crystal Structures of Clay Minerals and Their X-ray Identification. In Mineralogical Society Monograph, 3rd ed.; Mineralogical Society: London, UK, 1980; ISBN 9780903056083. ISSN 0144-1485. [Google Scholar]

- Chmelík, F.; Trník, A.; Štubňa, I.; Pešička, J. Creation of microcracks in porcelain during firing. J. Eur. Ceram. Soc. 2011, 31, 2205–2209. [Google Scholar] [CrossRef]

- Knapek, M.; Húlan, T.; Minárik, P.; Dobroň, P.; Štubňa, I.; Stráská, J.; Chmelík, F. Study of microcracking in illite-based ceramics during firing. J. Eur. Ceram. Soc. 2016, 36, 221–226. [Google Scholar] [CrossRef]

- Jastrzebski, Z.D. The nature and properties of engineering materials. J. Eng. Mater. Technol. 1988, 110, 294. [Google Scholar] [CrossRef]

- Gorodtsov, V.A.; Lisovenko, D.S. Extreme values of Young’s modulus and Poisson’s ratio of hexagonal crystals. Mech. Mater. 2019, 134, 1–8. [Google Scholar] [CrossRef]

- Vanorio, T.; Prasad, M.; Nur, A. Elastic properties of dry clay mineral aggregates, suspensions and sandstones. Geophys. J. Int. 2003, 155, 319–326. [Google Scholar] [CrossRef]

- Basic Mechanics of Soils. Available online: http://environment.uwe.ac.uk/geocal/soilmech/basic/stiffness.htm (accessed on 22 September 2022).

- Prasad, M.; Kopycinska, M.; Rabe, U.; Arnold, W. Measurement of Young’s modulus of clay minerals using atomic force acoustic microscopy. Geophys. Res. Lett. 2002, 29, 13-1–13-4. [Google Scholar] [CrossRef]

- Pánek, Z.; Figusch, V.; Haviar, M.; Ličko, T.; Šajgalík, P.; Dusza, J. Konštrukčná Keramika; R&D: Bratislava, Slovak, 1992. [Google Scholar]

- Youngovim, O.M.M.T.I.; Keramiki, M.P.T. Relationship between mechanical strength and Young’s modulus in traditional ceramics. Mater. Tehnol. 2011, 45, 375–378. [Google Scholar]

- Jankula, M.; Húlan, T.; Štubňa, I.; Ondruška, J.; Podoba, R.; Šín, P.; Bacík, P.; Trník, A. The influence of heat on elastic properties of illitic clay Radobica. J. Ceram. Soc. Jpn. 2015, 123, 874–879. [Google Scholar] [CrossRef]

- Húlan, T.; Trník, A.; Štubňa, I.; Bačík, P.; Kaljuvee, T.; Vozár, L. Thermomechanical Analysis of Illite from Füzérradvány. Mater. Sci. 2015, 21. [Google Scholar] [CrossRef][Green Version]

- Húlan, T.; Kaljuvee, T.; Štubňa, I.; Trník, A. Investigation of elastic and inelastic properties of Estonian clay from a locality in Kunda during thermal treatment. J. Therm. Anal. Calorim. 2016, 124, 1153–1159. [Google Scholar] [CrossRef]

- Húlan, T.; Štubňa, I.; Shishkin, A.; Ozolins, J.; Csáki, Š.; Bačík, P.; Fridrichová, J. Development of Young’s modulus of natural illitic clay during the heating and cooling stages of firing. Clay Miner. 2019, 54, 229–233. [Google Scholar] [CrossRef]

- Martín-Márquez, J.; Rincón, J.; Ma Romero, M. Effect of microstructure on mechanical properties of porcelain stoneware. J. Eur. Ceram. Soc. 2010, 30, 3063–3069. [Google Scholar] [CrossRef]

- Nikraz, H.; Ullah, M.A.; Ahsan, R.; Haque, S. Shear and Tensile Test of Brick Masonry Unit for Earthquake Safety. In Proceedings of the International Conference on Future Trends in Structural, Civil, Environmental and Mechanical Engineering—FTSCEM 2013, Bangkok, Thailand, 13–14 July 2013; Institute of Research Engineers and Doctors: New York, NY, USA, 2013. ISBN 978-981-07-7021-1. Available online: www.seekdl.org (accessed on 22 September 2022).

- Zimmermann, T.; Strauss, A. Masonry and Earthquakes: Material Properties, Experimental Testing and Design Approaches. In Earthquake-Resistant Structures—Design, Assessment and Rehabilitation; IntechOpen: London, UK, 2012. [Google Scholar] [CrossRef]

- Kasapoğlu, K.E. Earthquake Resistant Brick Design. In Innovative Housing Practices; Elsevier: Amsterdam, The Netherlands, 1989; pp. 147–152. [Google Scholar] [CrossRef]

- Zepeda, J.Á.; Alcocer, S.M.; Flores, L. Earthquake-Resistant Construction with Multi-Perforated Clay Brick Walls. In Proceedings of the 12th World Conference on Earthquake Engineering, Auckland, New Zealand, 30 January–4 February 2000. [Google Scholar]

- Nowak, R.; Kania, T.; Derkach, V.; Orłowicz, R.; Halaliuk, A.; Ekiert, E.; Jaworski, R. Strength Parameters of Clay Brick Walls with Various Directions of Force. Materials 2021, 14, 6461. [Google Scholar] [CrossRef] [PubMed]

- Buchner, T.; Kiefer, T.; Königsberger, M.; Jäger, A.; Füssl, J. Continuum micromechanics model for fired clay bricks: Upscaling of experimentally identified microstructural features to macroscopic elastic stiffness and thermal conductivity. Mater. Des. 2021, 212, 110212. [Google Scholar] [CrossRef]

- Kouris, L.A.S.; Bournas, D.A.; Akintayo, O.T.; Konstantinidis, A.A.; Aifantis, E.C. A gradient elastic homogenisation model for brick masonry. Eng. Struct. 2020, 208, 110311. [Google Scholar] [CrossRef]

- Sciencing. How to Calculate Compressive Strength. Available online: https://sciencing.com/how-8086903-calculate-compressive-strength.html (accessed on 12 October 2020).

| 3DPBDCB Model | Maximum Compressive Force | Apparent Strain (Normal) | Apparent Stress | Compressive Modulus | Elasticity According to Maximum Parallel Force Tolerance. | |

|---|---|---|---|---|---|---|

| ▲L/L0 | F/A | E | Pre-Cracking | Post-Cracking | ||

| V1 Linear | 240 N | 0.82 | 0.0085 | 0.010 | 60 N | 170 N |

| V1 Bulk | 240 N | 0.46 | 0.0087 | 0.018 | ||

| V2 Linear | 110 N | 0.77 | 0.006 | 0.007 | 160 N | - |

| V2 Bulk | 170 N | 0.8 | 0.0032 | 0.004 | ||

| V3 Linear | 170 N | 0.88 | 0.013 | 0.014 | 150 N | 200 N |

| V3 Bulk | 135 N | 0.75 | 0.0058 | 0.007 | ||

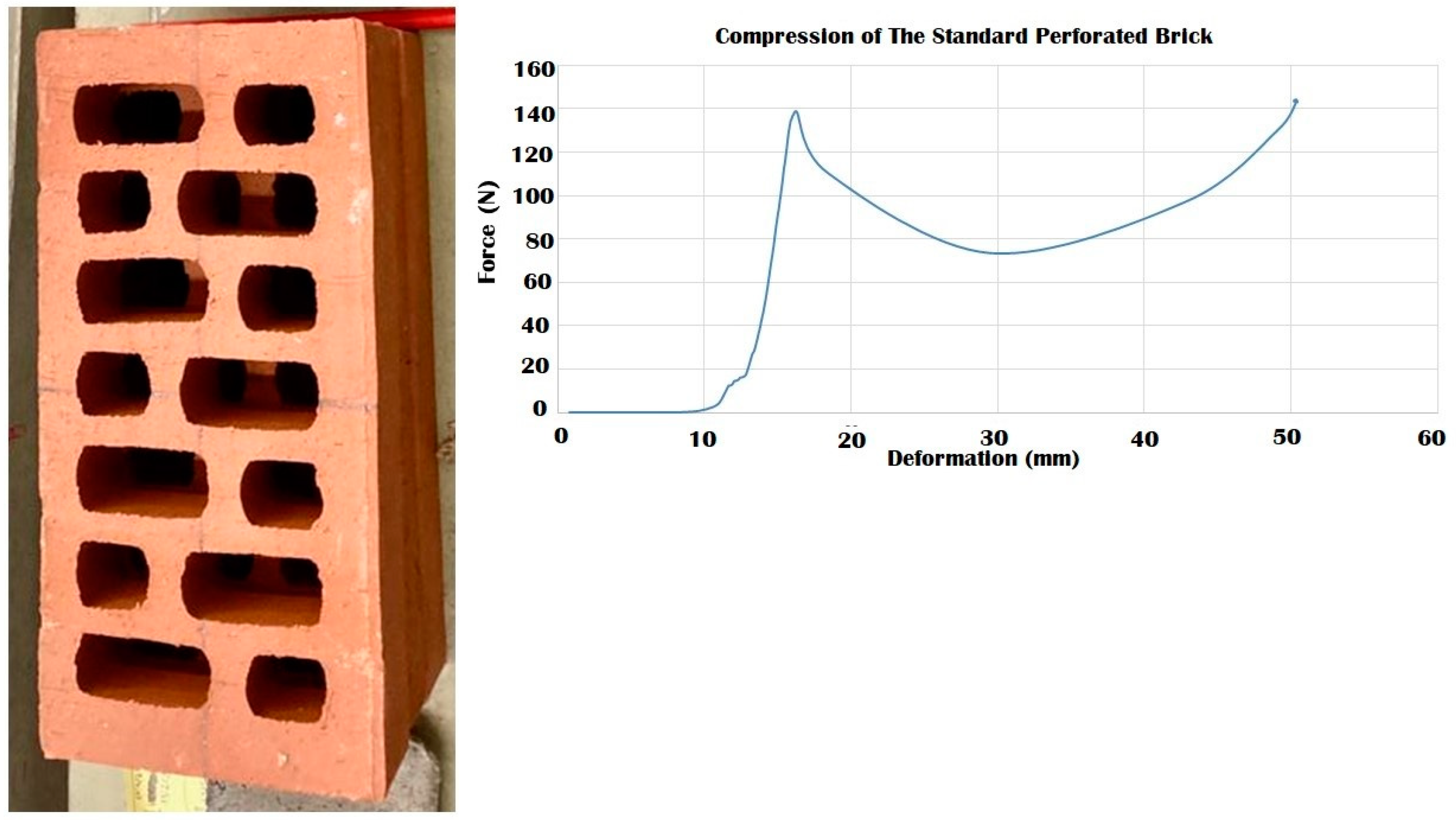

| Standard Bricks | ||||||

| Bulk | 200 N | 0.99 | 0.004 | 0.004 | ||

| Perforated | 140 N | 1.11 | 0.059 | 0.005 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Estévez, A.T.; Abdallah, Y.K. The New Standard Is Biodigital: Durable and Elastic 3D-Printed Biodigital Clay Bricks. Biomimetics 2022, 7, 159. https://doi.org/10.3390/biomimetics7040159

Estévez AT, Abdallah YK. The New Standard Is Biodigital: Durable and Elastic 3D-Printed Biodigital Clay Bricks. Biomimetics. 2022; 7(4):159. https://doi.org/10.3390/biomimetics7040159

Chicago/Turabian StyleEstévez, Alberto T., and Yomna K. Abdallah. 2022. "The New Standard Is Biodigital: Durable and Elastic 3D-Printed Biodigital Clay Bricks" Biomimetics 7, no. 4: 159. https://doi.org/10.3390/biomimetics7040159

APA StyleEstévez, A. T., & Abdallah, Y. K. (2022). The New Standard Is Biodigital: Durable and Elastic 3D-Printed Biodigital Clay Bricks. Biomimetics, 7(4), 159. https://doi.org/10.3390/biomimetics7040159