Effect of Surface Morphology and Texture of Short-Tailed Shrew’s Toe on Tribological Properties of 65Mn Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Materials

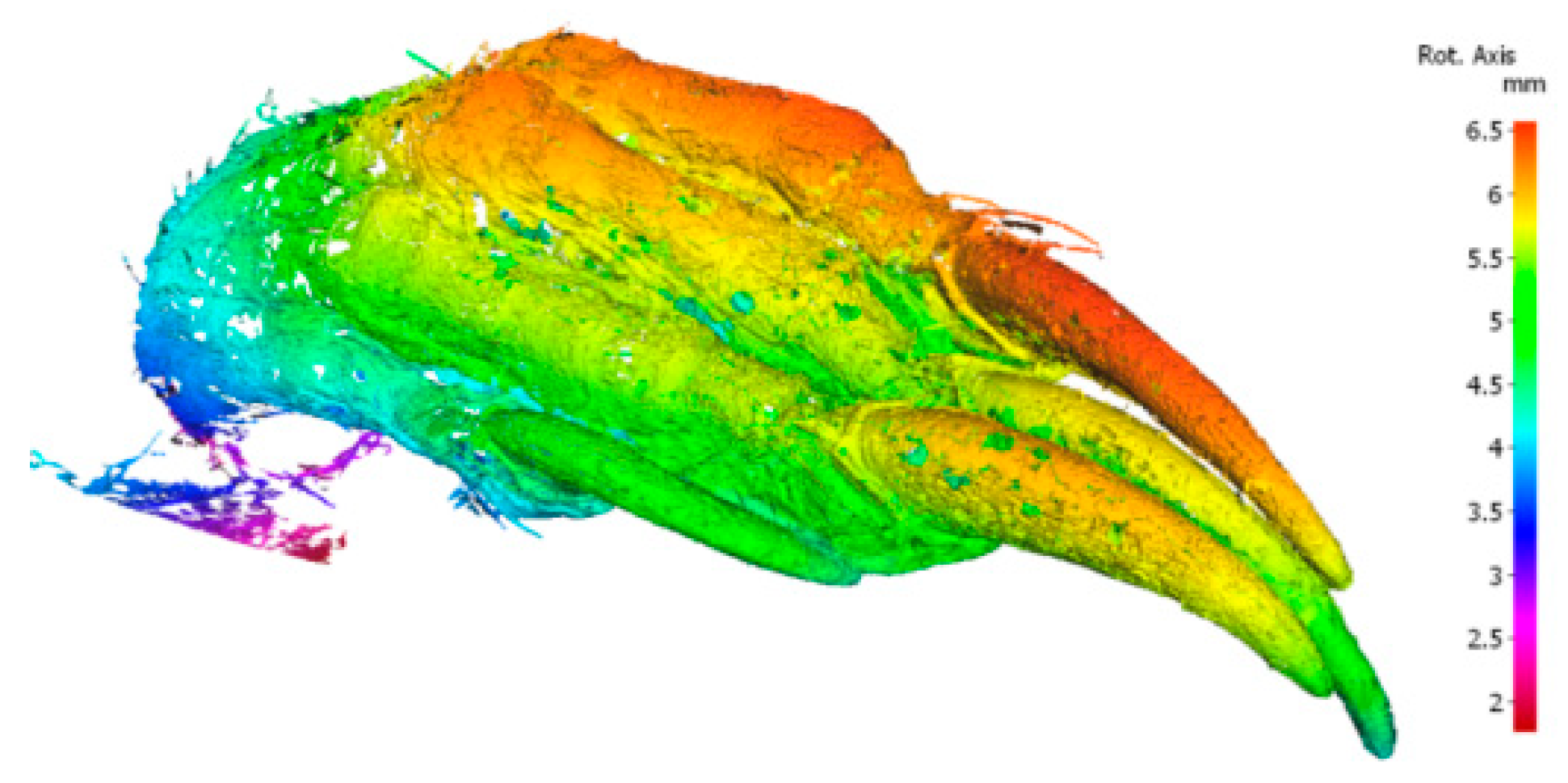

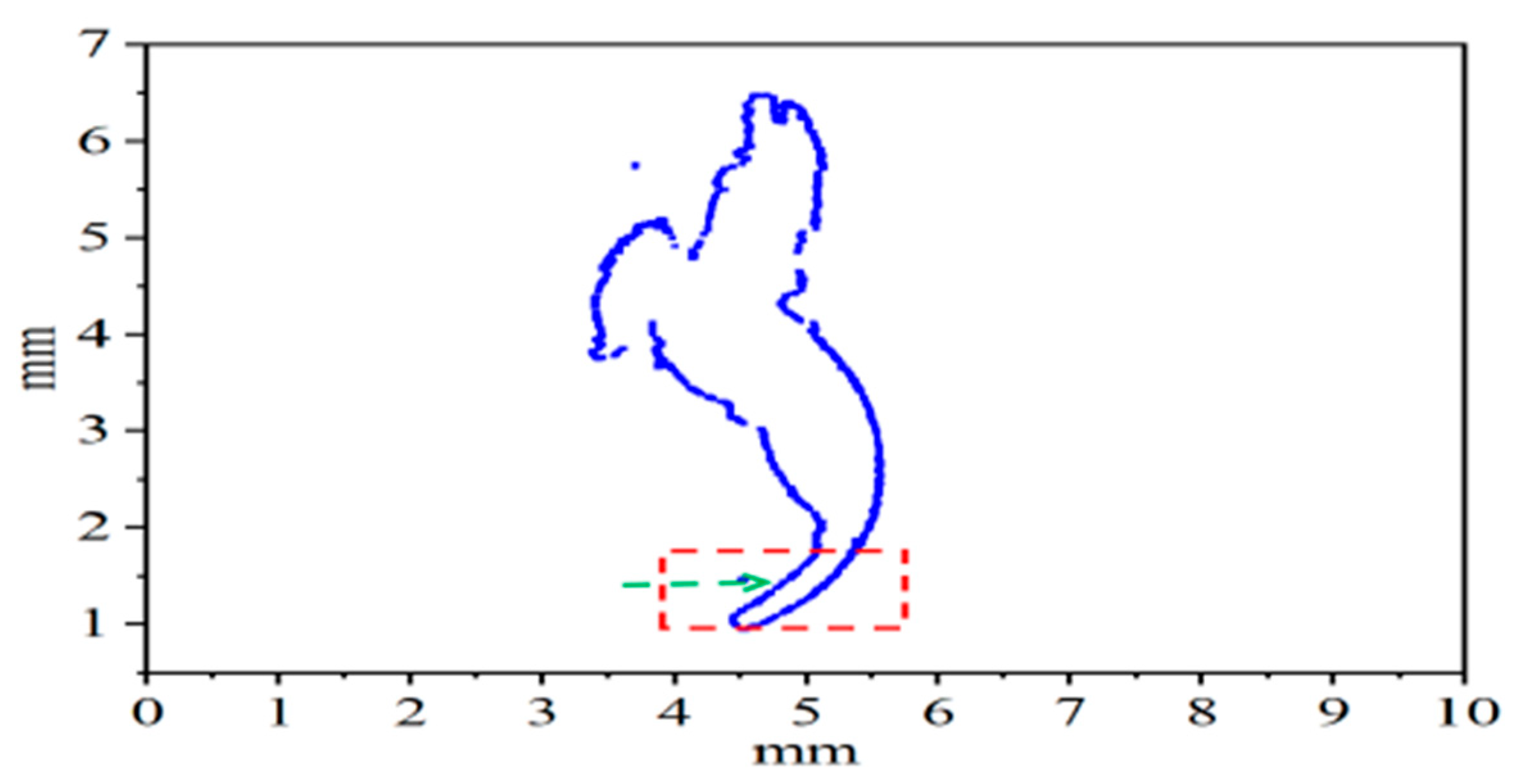

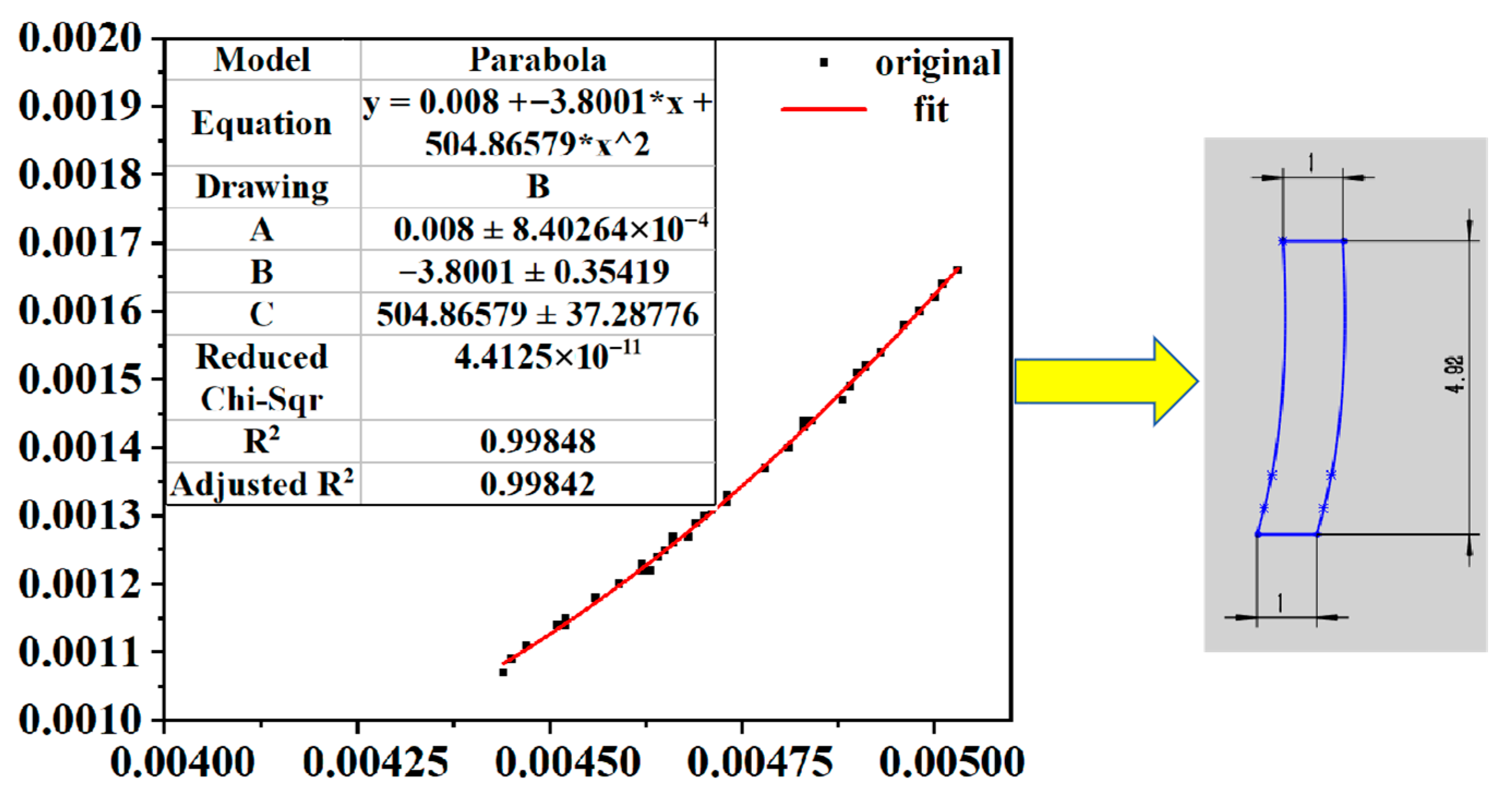

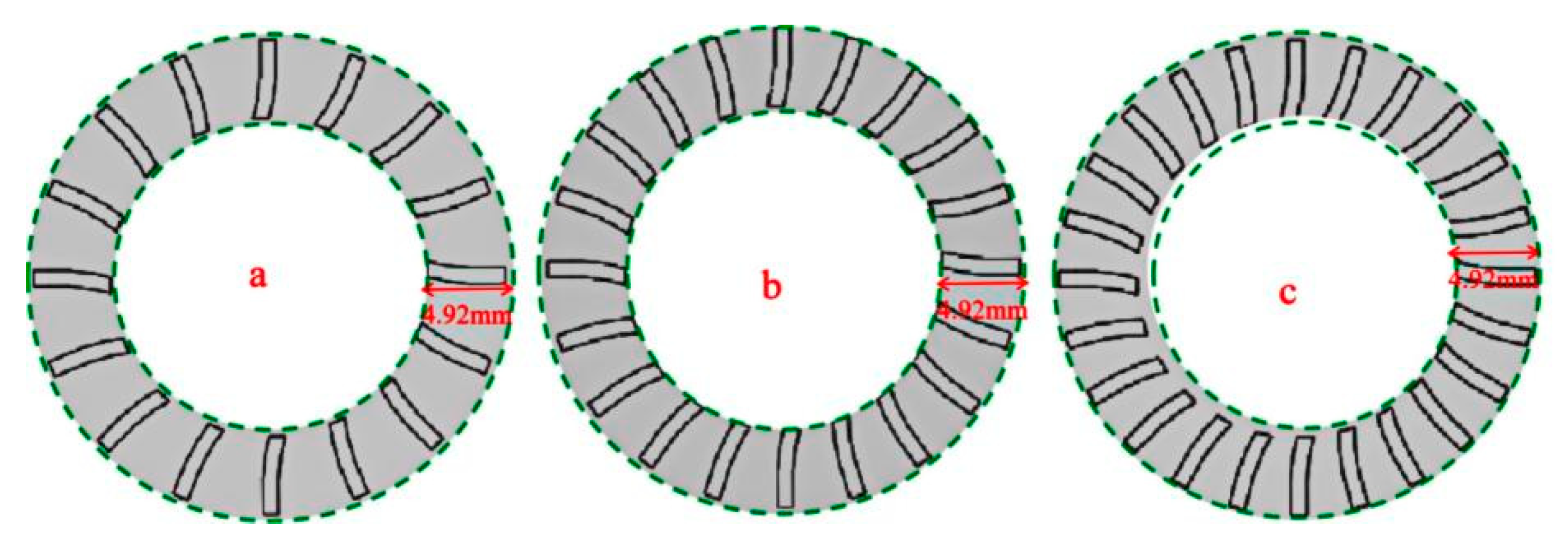

2.2. Study to Select Parameters and Preparation Methods for Bionic Texture Structure

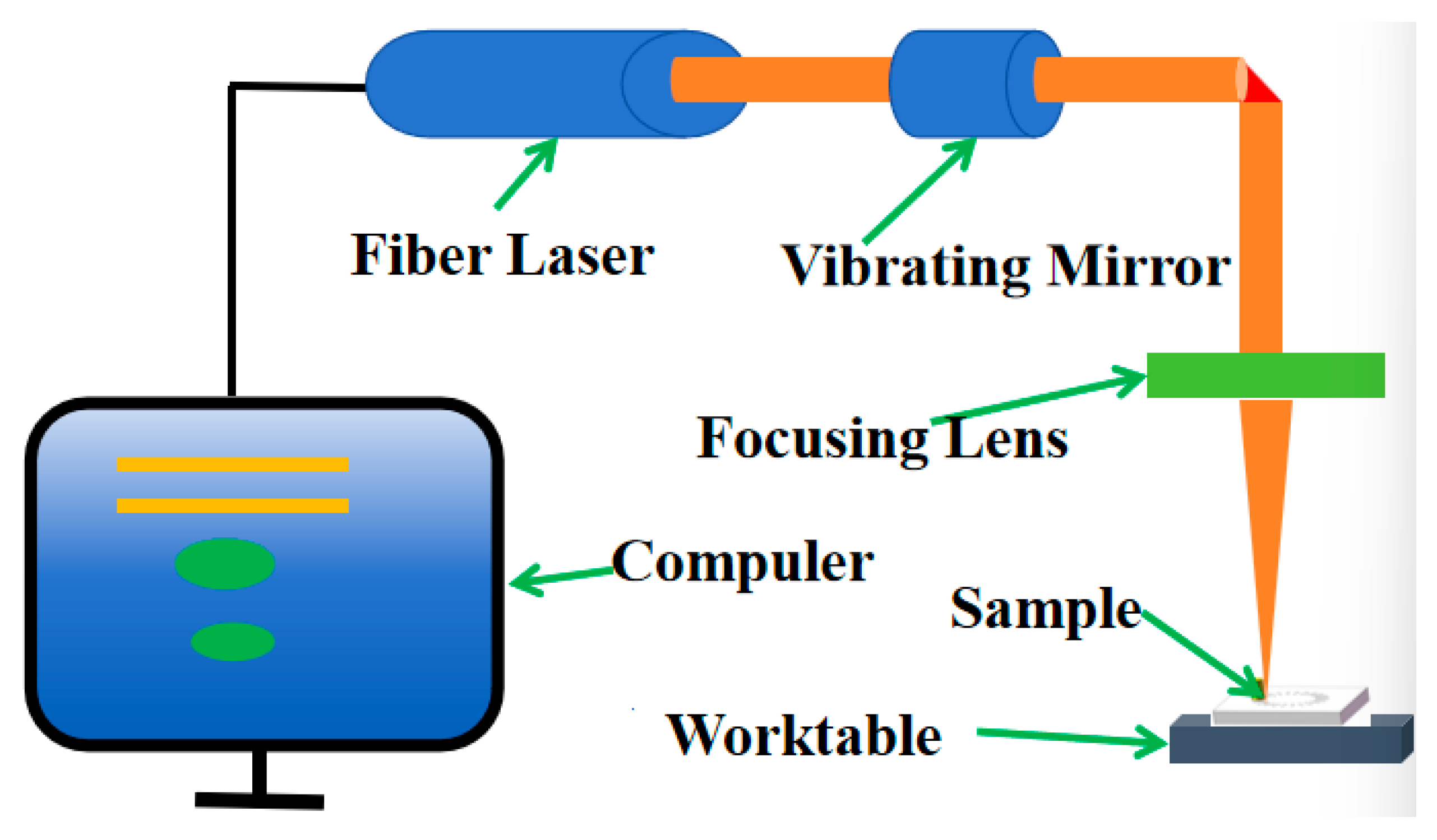

2.3. Preparation of Bionic Texture

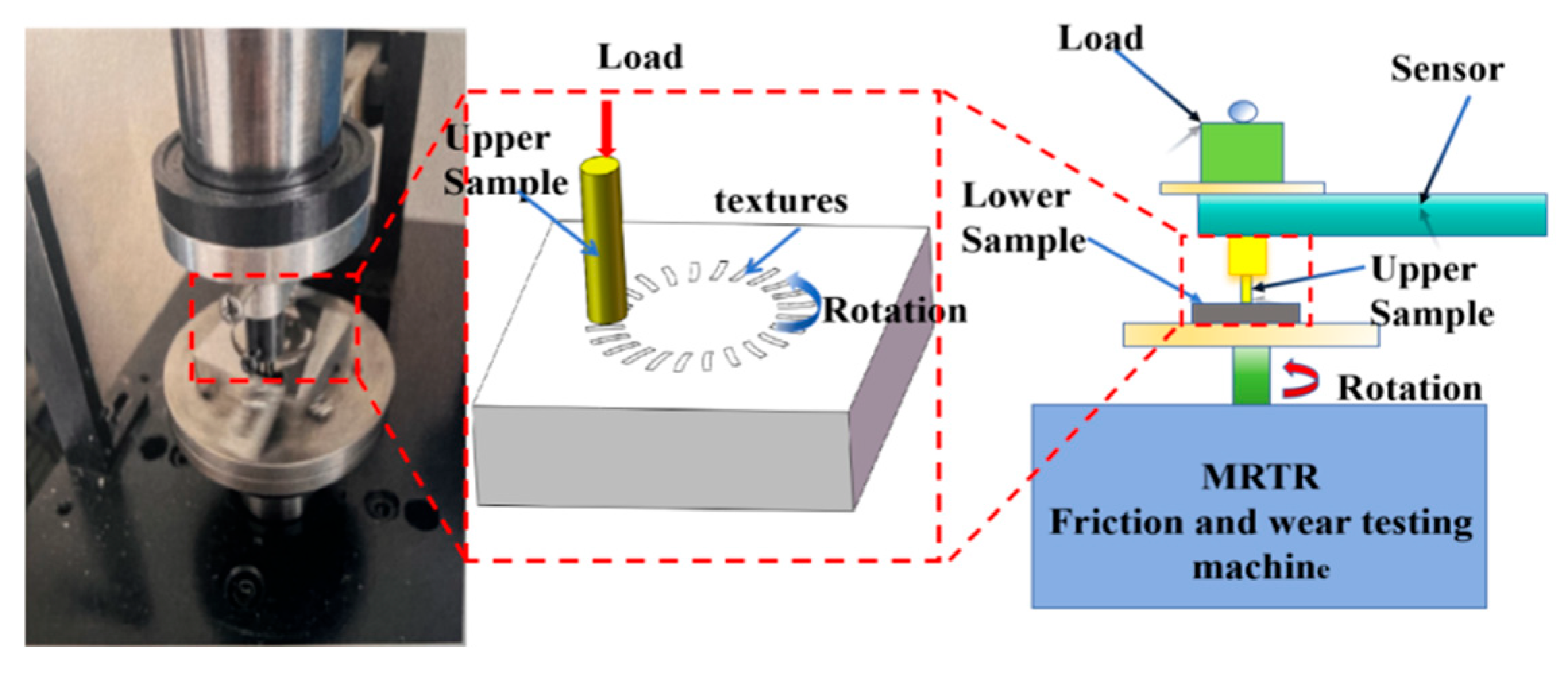

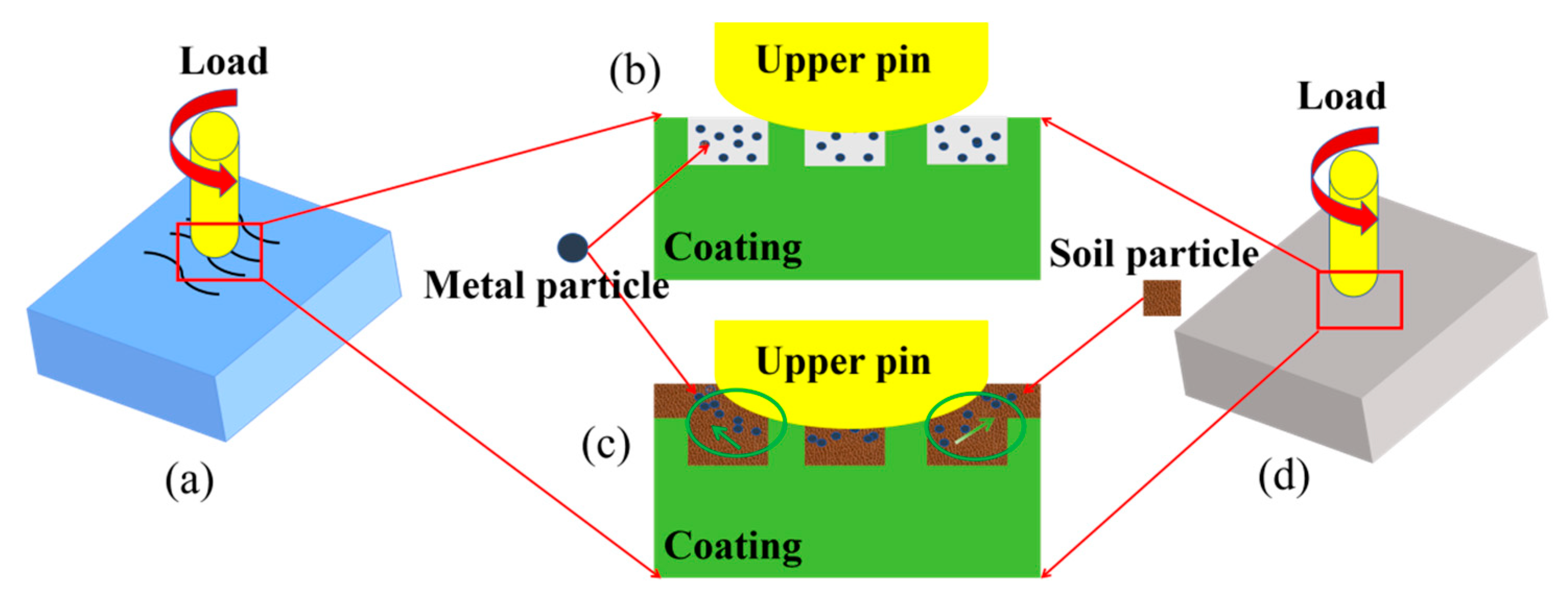

2.4. Friction Wear Test

3. Test Results and Analysis

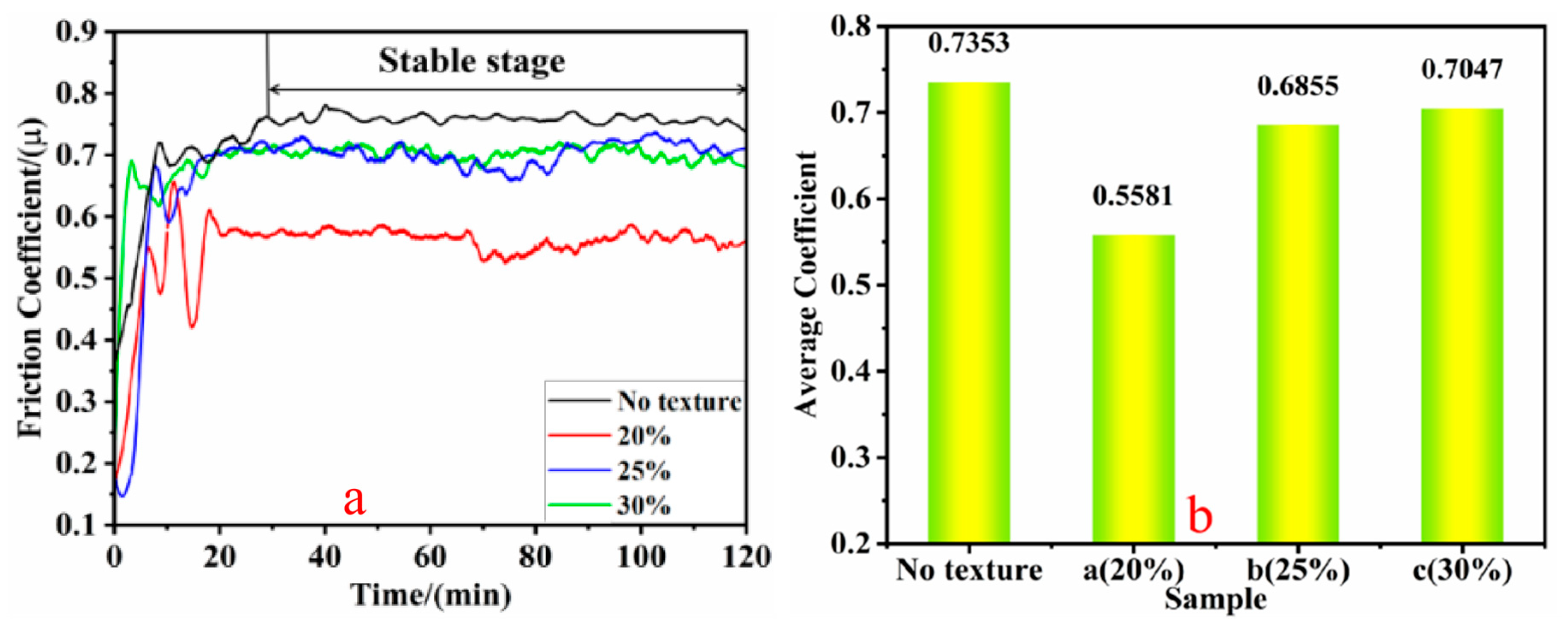

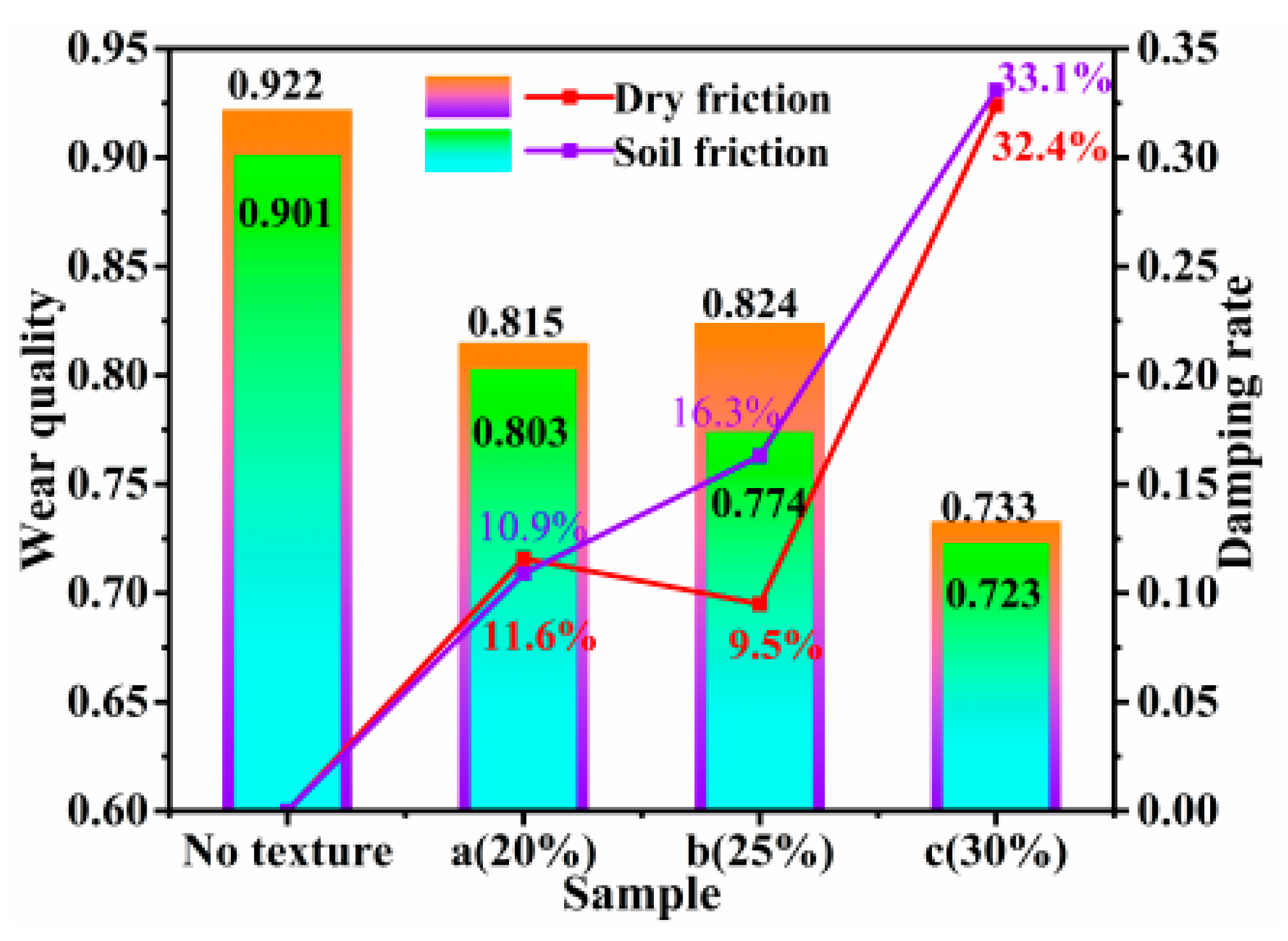

3.1. Surface Friction Properties of 65Mn Steel Under Dry Friction Conditions

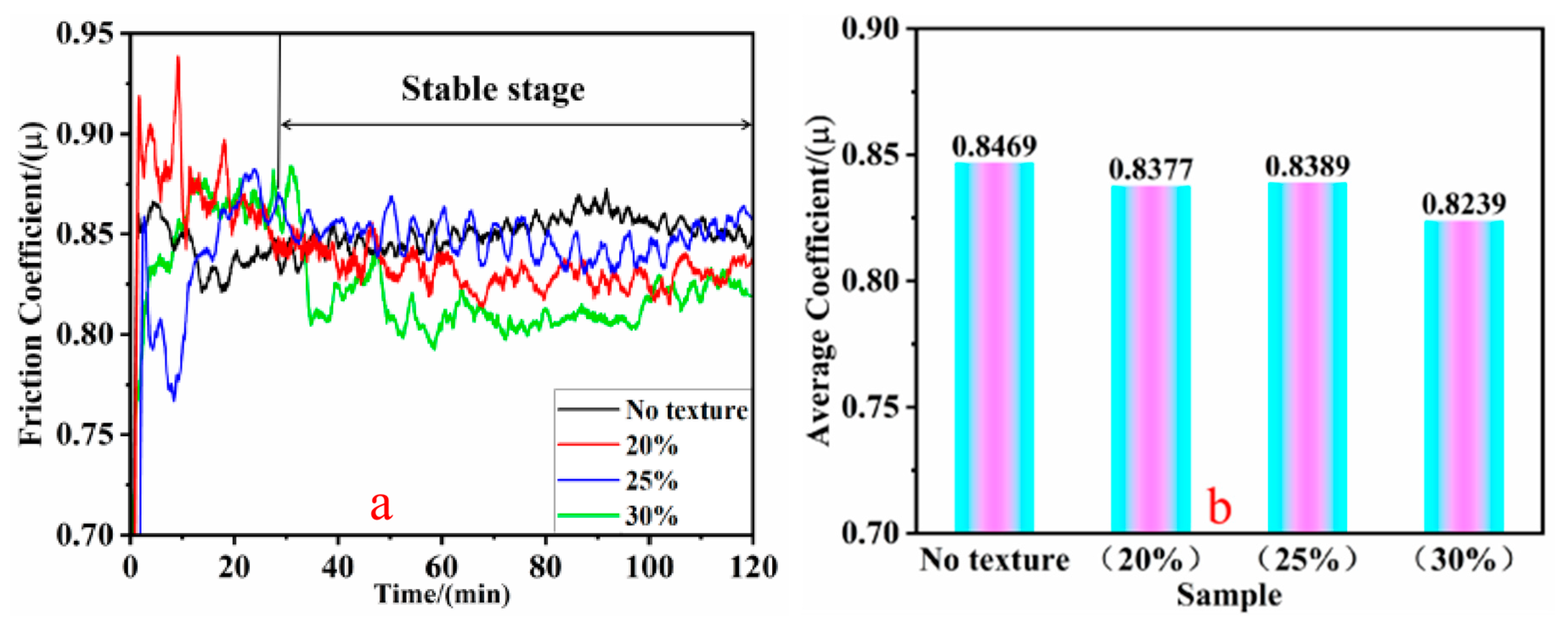

3.2. Surface Friction Properties of 65Mn Steel Under Soil Friction Conditions

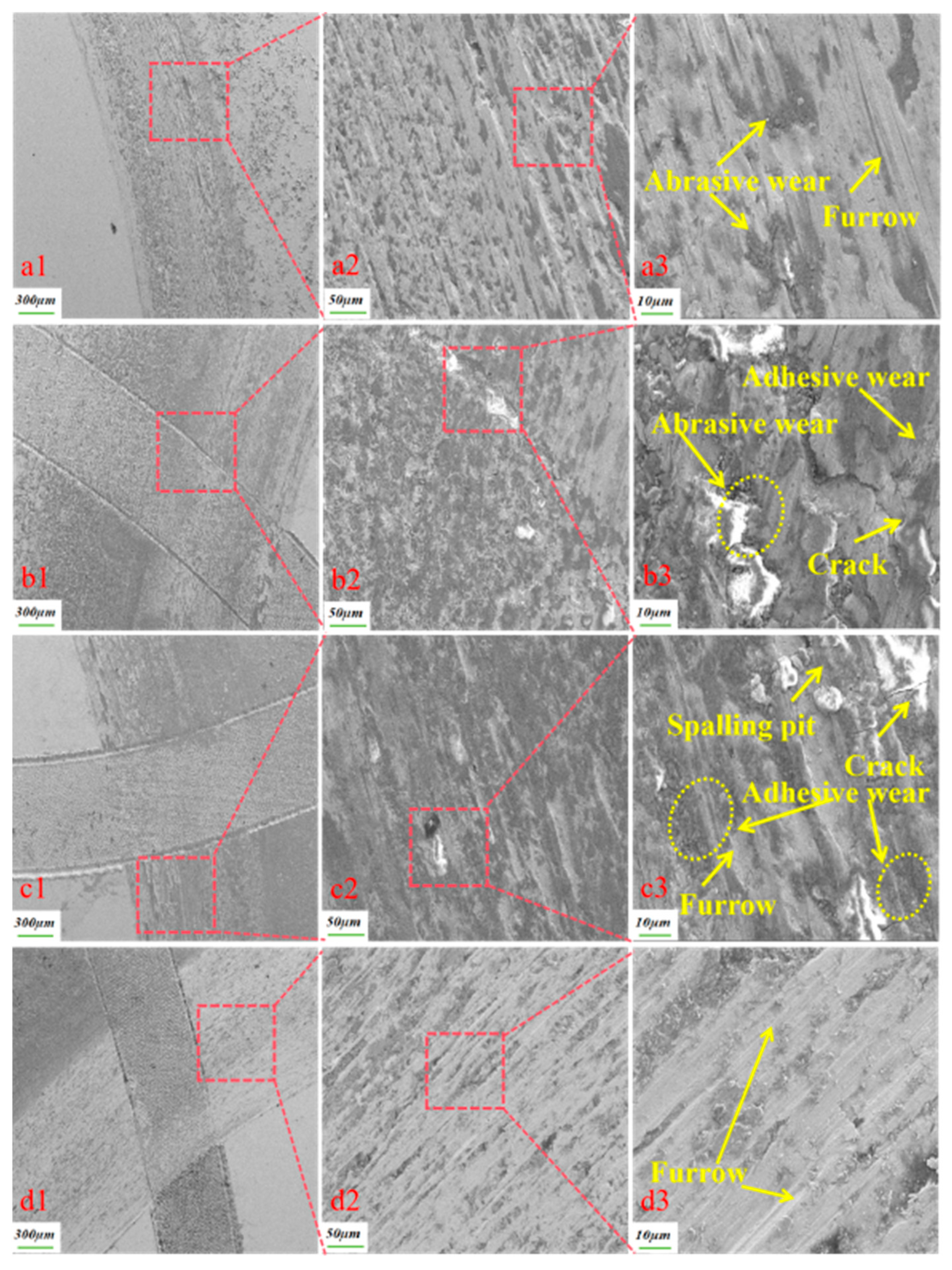

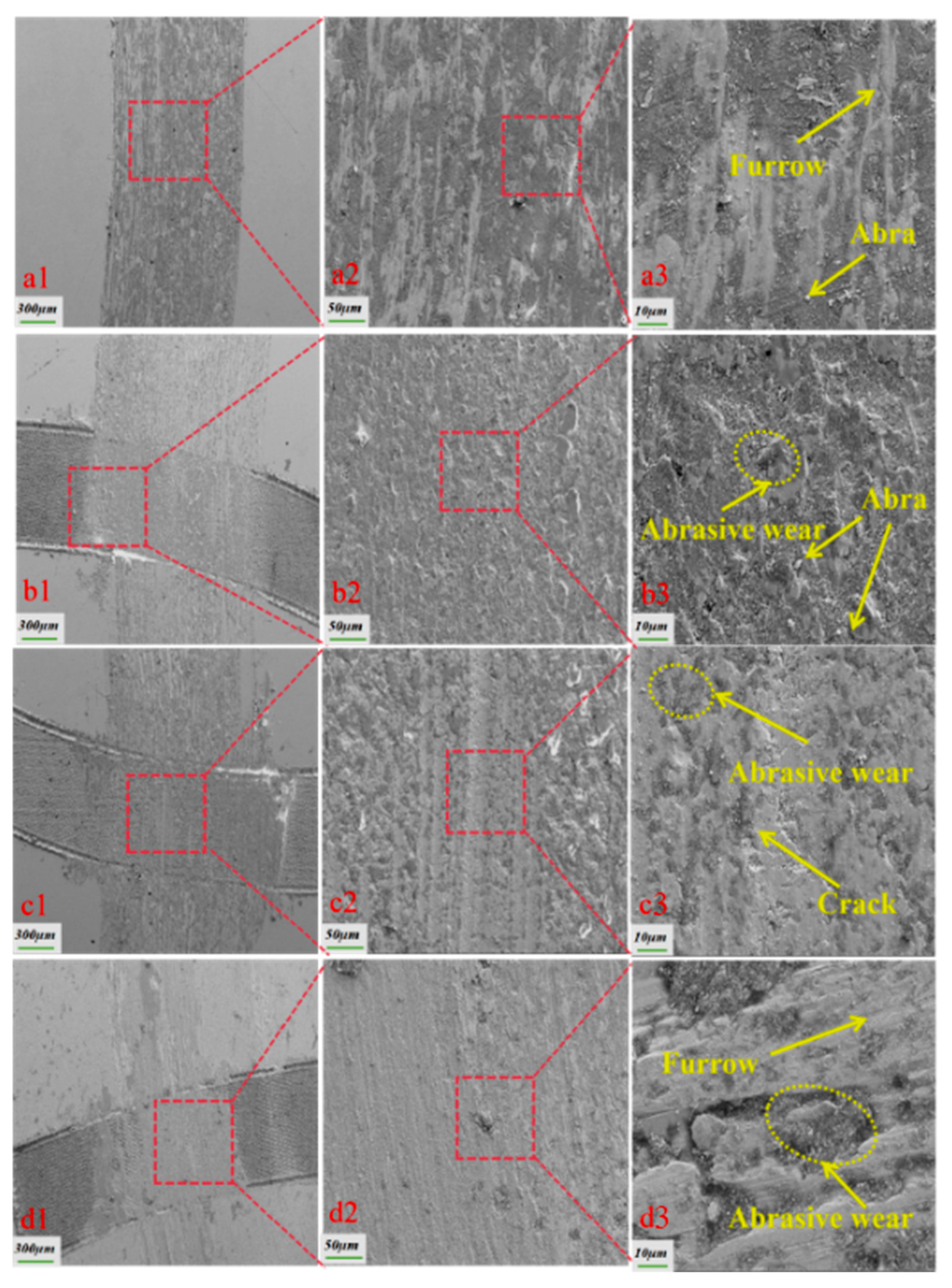

3.3. Sample Wear Morphology Analysis

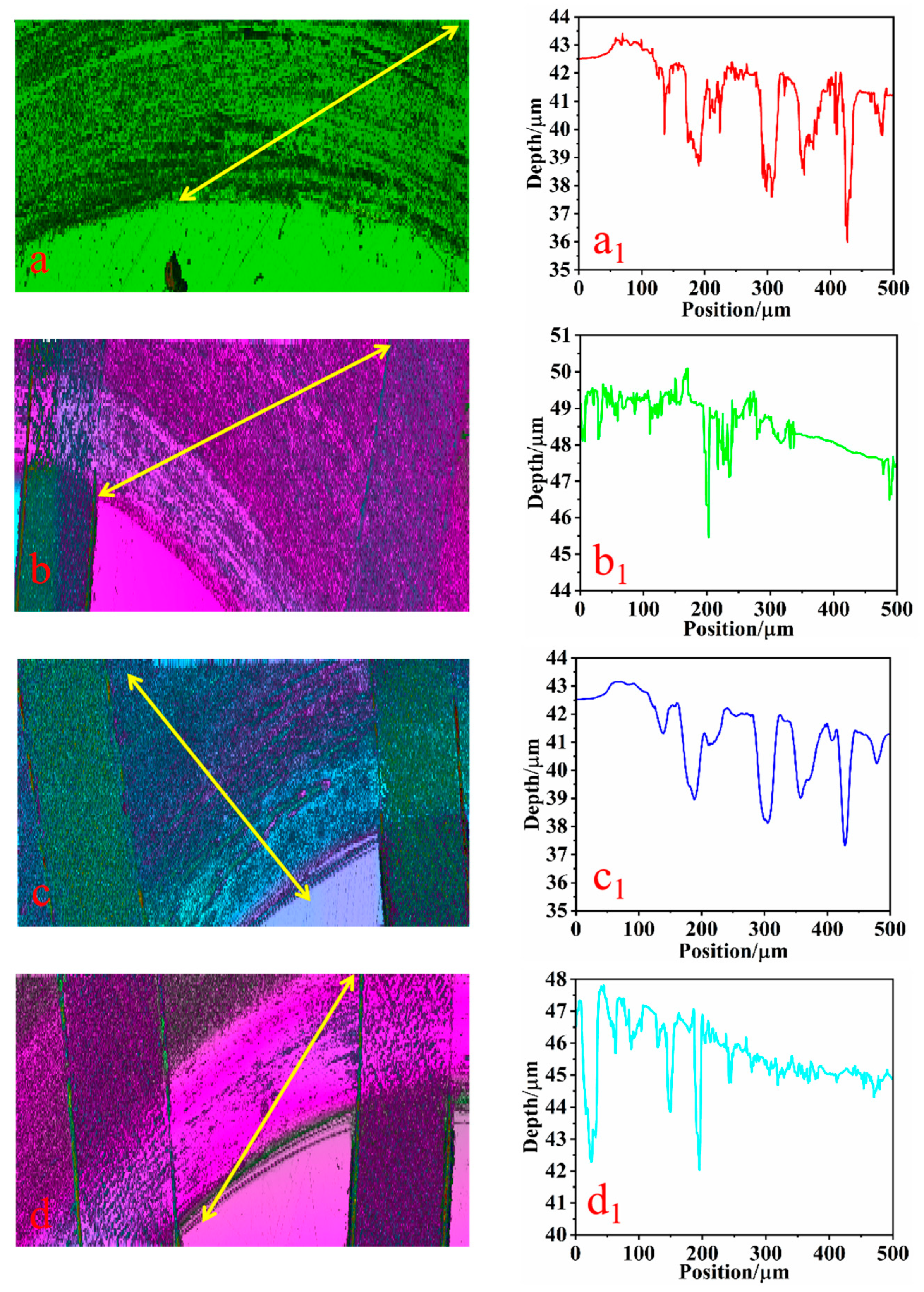

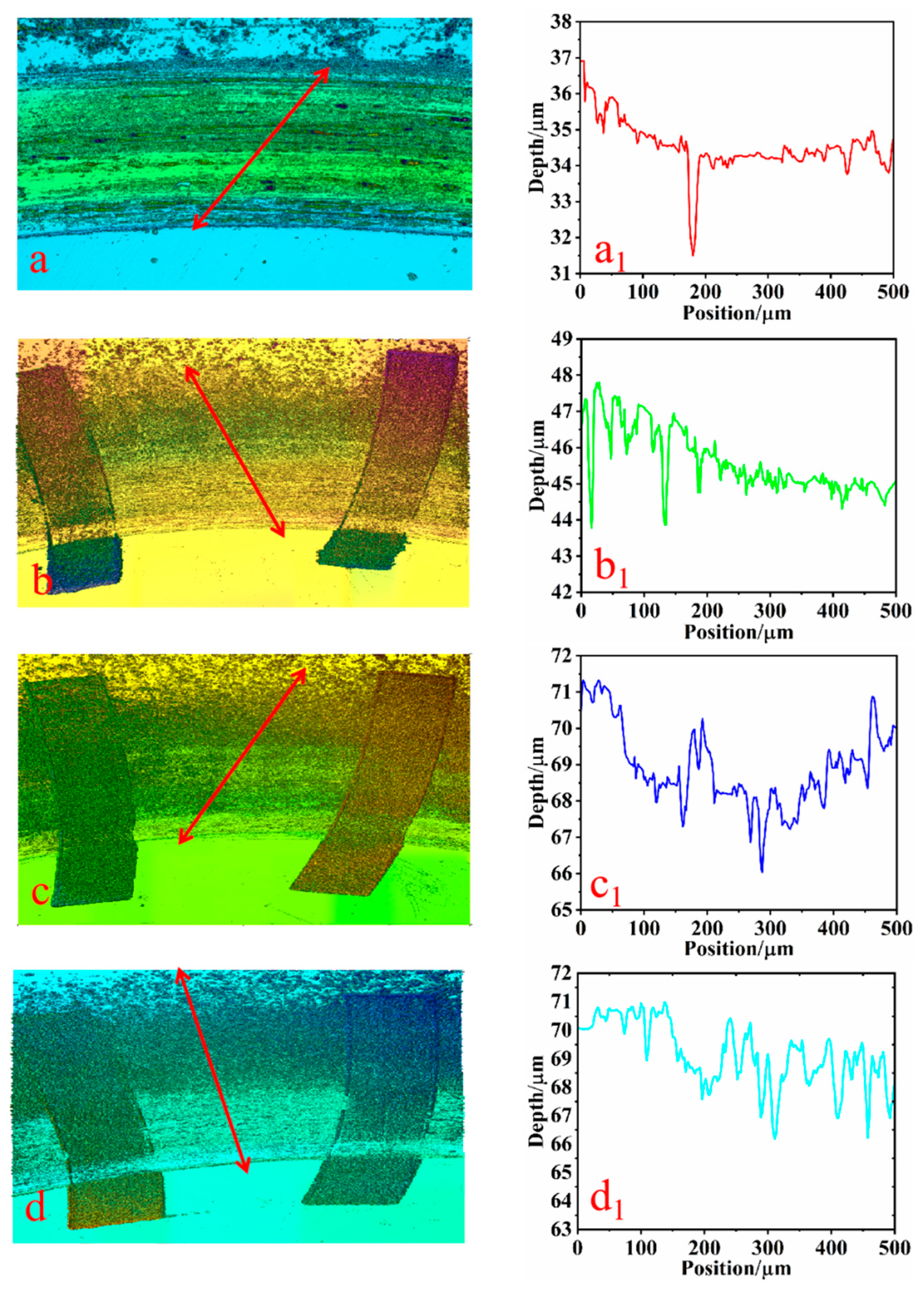

3.4. Three-Dimensional Morphology Analysis of Specimens

3.5. Wear Mechanism Analysis

4. Conclusions

- (1)

- Compared to specimens lacking a bionic texture, those with bionic textures of varying densities applied to their surfaces exhibit superior friction and wear performance. Bionic surface textures can accumulate significant amounts of abrasive material within their surface grooves, with only minimal amounts of abrasive debris adhering to the friction sub-surfaces. This demonstrates that texturing effectively serves to collect abrasive particles.

- (2)

- The friction coefficient was minimized at a distribution density of 20% in dry friction conditions, and it was reduced by 24% compared to the non-bionic texture. Under soil friction conditions, the coefficient of friction was minimized at a distribution density of 30%, and it was reduced by 2.9% compared to the non-bionic texture. This indicates that the processing of a bionic texture on the surface of a specimen can significantly decrease its frictional resistance.

- (3)

- The wear of specimens with bionic textures was significantly reduced compared to those without bionic textures under both conditions. Specifically, wear was reduced by 10.6% at a distribution density of 30% under dry friction conditions and by 19.7% at the same distribution density under soil friction conditions.

- (4)

- Under conditions of soil friction, applying a bionic texture to the surfaces of specimens can effectively reduce frictional wear and enhance the friction wear performance of implements that come into contact with earth. This has excellent potential for application in the agricultural machinery industry in the future.

- (5)

- The texture of the short-tailed shrew’s claw has significant advantages in terms of friction and wear resistance, especially in the field of agricultural machinery, where it has enormous application potential.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Belenkiy, Y.I.; Kretinin, V.I.; Markov, V.A.; Sokolova, V.A. Special features of forestry machines earth cutters wear process. Mater. Today Proc. 2019, 19, 2438–2441. [Google Scholar] [CrossRef]

- Wei, X.; Jiang, Y.-Q.; Yu, L.-J. Microstructure hardness and growth kinetics of 65Mn steel borided layer. Heat Treat. Met. 2021, 46, 110–119. [Google Scholar]

- Jia, H.-L.; Zheng, J.; Zhao, J.-L.; Guo, M.-Z.; Zhong, J.; Wang, Z.-H. Design and parameter optimization of earthworm-like multi-function opener. Trans. Chin. Soc. Agric. Eng. 2018, 34, 62–71. [Google Scholar]

- Zheng, J. Design and Experiment of Earthworm-Like Multi-Function Opener; Jilin University: Changchun, China, 2019. [Google Scholar] [CrossRef]

- Yang, Y.; Tong, J.; Ma, Y.; Li, M.; Jiang, X.; Li, J. Design and testing of a biomimetic soil-cutting blade based on the multi-toed structure of moles. Trans. Chin. Soc. Agric. Mach. 2018, 49, 122–128. [Google Scholar]

- Guo, M.-X.; Guo, Y.; Chen, J.-X. Analysis of Friction Reducing and Leakage Characteristics of Plunger Pair with Pangolin Scale Texture. Lubr. Eng. 2024, 49, 74–81. [Google Scholar]

- Bai, J.; Li, B.; Lu, X.; Chen, J.; Shi, J. Study on Vibration Anti- drag of the Badger Claws Bionic Subsoiler. J. Agric. Mech. Res. 2016, 38, 224–227. [Google Scholar]

- Jia, H.; Wang, W.; Wang, W.; Zheng, J.; Wang, Q.; Zhuang, J. Application of anti-adhesion structure based on earthworm motion characteristics. Soil Tillage Res. 2018, 178, 159–166. [Google Scholar] [CrossRef]

- Chen, D.; Liu, X.; Cui, X.; Zhang, L.; Chen, H. Research Progress and Development Trend of the Drag Reduction Inspired by Fish Skin. Prog. Org. Coat. 2023, 182, 107613. [Google Scholar] [CrossRef]

- Tan, Y.; Liu, S.; Ma, S.C. Application of Bionics Engineering in Innovative design of Agricultural Machinery. In Proceedings of the American Society of Agricultural and Biological Engineers 2020 ASABE Annual International Virtual Meeting, St. Joseph, MI, USA, 13–15 July 2020. [Google Scholar]

- Cui, Y.; Shen, J.; Manladan, S.M.; Geng, K.; Hu, S. Wear resistance of FeCoCrNiMnAlx highentropy alloy coatings at high temperature. Appl. Surf. Sci. 2020, 512, 145736. [Google Scholar] [CrossRef]

- Wu, K.; Xu, Z.; Liu, C.; Zhao, D.; Yin, C.; Ma, B.; Wang, Y. Study on the Friction Reduction and Wear Resistance Characteristics of Biomimetic Microtextures on Plowshare Surfaces Under Water-Soil Solution Lubrication. Surf. Technol. 2024, 53, 112–120+207. [Google Scholar]

- Ma, Y.; Tong, J.; Zhou, J.; Rong, B.; Ren, L. Geometrical and morphological characteristics of the surface of Andrographis paniculata scales and their properties. J. Chin. Electron Microsc. Soc. 2018, 27, 336–340. [Google Scholar] [CrossRef]

- Liu, G.; Wu, X.; Zou, M.; Yan, Y.; Li, J. Experimental study on drag reduction characteristics of bionic earthworm self-lubrication surface. J. Appl. Bionics Biomech. 2019, 2019, 4984756. [Google Scholar] [CrossRef]

- Li, Y.; Feng, X.; Sun, L.; Niu, Y.; Zhang, Y. Effect of laser surface texturing on the friction and wear properties of 45 steel. Surf. Technol. 2018, 47, 147–154. [Google Scholar]

- Zhong, Y.; Zheng, L.; Gao, Y.; Liu, Z. Numerical simulation and experimental investigation of tribological performance on bionic hexagonal textured surface. Trichol. Int. 2019, 129, 151–161. [Google Scholar] [CrossRef]

- Li, G.; Shen, M.; Meng, X.K.; Li, J.Y. Experimental study on friction reduction properties of grooved surface microweave of 316L stainless steel. Funct. Mater. 2015, 46, 2033–2037. [Google Scholar]

- Yang, Z.; Chen, W.; Zhang, Y.; Li, Z.; Yang, J.; Dai, B.; Zhang, J.; Li, D.; Qiu, Z. Tribological properties of MAO coating deposited on aluminum base bearing alloy with different texture shapes. Surf. Coat. Technol. 2024, 492, 131191. [Google Scholar] [CrossRef]

- Wu, Z.; Bao, H.; Xing, Y.; Liu, L. Tribological characteristics and advanced processing methods of textured surfaces: A review. Int. J. Adv. Manuf. Technol. 2021, 114, 1241–1277. [Google Scholar] [CrossRef]

- Wang, M.; Hu, X.; Liu, K.; Fan, X.; Meng, X.; Peng, X.; Wang, J. Study on the effect of laser micro texture arrangement on the tribological properties of aluminum bronze. J. Tribol. 2024, 1–19. [Google Scholar] [CrossRef]

- Wang, X.-B. Design and Experimental Research on Bionic Deep Pine Shovel Based on Discrete Element Method; Sichuan Agricultural Science: Chengdu, China, 2023. [Google Scholar]

- Yang, X.; Chen, W.; Zhang, Y.; Dai, B.; Li, Z.; Yang, J.; Zhang, J.; Li, D.; Qiu, Z. Influence of triangular texture composite MAO coating on the tribological properties of aluminum alloys. Tribol. Int. 2025, 2011, 10243. [Google Scholar] [CrossRef]

- Sui, T.-y.; Cui, Y.-x.; Lin, B.; Zhang, D.-w. Influence of nanosecond laser processed surface textures on the tribological characteristics of diamond films sliding against zirconia bioceramic. Ceram. Int. 2018, 44, 23137–23144. [Google Scholar] [CrossRef]

- Akhtar, M.; Muzamil, M.; Samiuddin, M.; Alsaleh, N.; Khan, R.; Khan, M.A.; Djuansjah, J.; Siddiqui, A.K.; Majeed, A. Post-Wear Surface Morphology Assessment of Selective Laser Melting (SLM) AlSi10Mg Specimens after Heat Exposure to Different Gas Flames. Coatings 2024, 14, 252. [Google Scholar] [CrossRef]

- Muzamil, M.; Iqbal, S.A.; Anwar, M.N.; Samiuddin, M.; Yang, J.; Raza, M.A. Wear Behavior Assessment of New Wire-Arc Additively Manufactured Surfaces on AA6061 and AA5086 Alloys through Multi-Walled Carbon Nanotubes and Ni Particles Inducement. Coatings 2024, 14, 429. [Google Scholar] [CrossRef]

- Milojević, S.; Savić, S.; Mitrović, S.; Marić, D.; Krstić, B.; Stojanović, B.; Popović, V. Solving the Problem of Friction and Wear in Auxiliary Devices of Internal Combustion Engines on the Example of Reciprocating Air Compressor for Vehicles. Teh. Vjesn. 2023, 30, 122–130. [Google Scholar]

- Yuan, S.; Lin, N.; Zou, J.; Liu, Z.; Wang, Z.; Tian, L.; Qin, L.; Zhang, H.; Wang, Z.; Tang, B.; et al. Effect of laser surface texturing (LST) on tribological behavior of double glow plasma surface zirconizing coating on Ti6Al4V alloy. Surf. Coat. Technol. 2019, 368, 97–109. [Google Scholar] [CrossRef]

- Turkdayı, M.; Kavasoğlu, S.Y.; Kovacı, H. Increasing the friction and wear performance of AISI 316L under dry, aqueous and oil lubricated sliding conditions with surface textures fabricated by laser-powder bed fusion (L-PBF). Tribol. Int. 2024, 200, 110135. [Google Scholar] [CrossRef]

- Yang, H.; Wu, X.; Du, S.; Wang, C.; Guo, F.; Lu, H. Synergistic effect of “double pores” texture ontribological properties of AZ31 Mg alloy micro-arc oxide ceramic coatings. Surf. Coat. Technol. 2023, 470, 129875. [Google Scholar] [CrossRef]

- Wang, H.; Lin, N.; Yuan, S.; Liu, Z.; Yu, Y.; Zeng, Q.; Fan, J.; Li, D.; Wu, Y. Structural improvement, material selection and surface treatment for improved tribological performance of friction pairs in axial piston pumps: A review. Tribol. Int. 2024, 198, 109838. [Google Scholar] [CrossRef]

- Cheng, J.; Chen, W.; Li, D.; Chen, H.; Guo, S.; Zhou, Y.; Yuan, H.; Wei, B. Effect of spherical crown texturing and ionized sulfur infiltration on the tribological performance of piston-cylinder liner. Tribol. Int. 2023, 189, 108969. [Google Scholar] [CrossRef]

- Li, Z.; Chen, W.; Li, D.; Yang, J.; Zhang, Y.; Yang, X.; Dai, B.; Zhang, J.; Qiu, Z. Frictional wear properties of different nano La2O3 composite FeCoNiCrMo high-entropy alloy coatings under soil conditions. J. Mater. Res. Technol. 2025, 35, 6874–6888. [Google Scholar] [CrossRef]

| Element | Mn | C | Cr | Cu | Ni | Si | S | P |

|---|---|---|---|---|---|---|---|---|

| Content | 0.90–1.20 | 0.62–0.70 | ≤0.25 | ≤0.25 | ≤0.25 | 0.17–0.37 | ≤0.035 | ≤0.035 |

| Claws and Toes | Fitted Equation | Coefficient of Determination (CD) |

|---|---|---|

| Toe 1 inside | y1n = 0.15571 + (−64.50373 * x) + 6695.13117 * x2 | R2 = 0.95765 |

| Toe 1 outside | y1w = 0.01986 + (−8.61638 * x) + 935.60284 * x2 | R2 = 0.99609 |

| Toe 2 inside | Y2n = 0.00461 + (−2.86875 * x) + 449.06665 * x2 | R2 = 0.98304 |

| Toe 2 outside | Y2w = 0.00905 + (−5.00498 * x) + 684.30525 * x2 | R2 = 0.97772 |

| Toe 3 inside | Y3n = 0.008 + (−3.8001 * x) + 504.86579 * x2 | R2 = 0.99842 |

| Toe 3 outside | Y3w = 0.01999 + (−8.50617 * x) + 951.82364 * x2 | R2 = 0.99643 |

| Equipment | Optical Power | Frequency | Wavelength | Pulse |

|---|---|---|---|---|

| Grace X 355-3 Alaser | 3 W | 30 kHz | 355 nm | 25 Ms |

| Element | C | Cr | Mn | Si | P | S | Ni | Cu |

|---|---|---|---|---|---|---|---|---|

| Content | 0.95–1.05 | 1.30–1.65 | 0.2–0.40 | 0.15–0.35 | ≤0.027 | ≤0.020 | ≤0.030 | ≤0.025 |

| Particle Size (µm) | 2000 | 2000–1000 | 1000–500 | 500–100 | <100 | Total Weight |

|---|---|---|---|---|---|---|

| Measured value (g) | 124.301 | 96.538 | 64.909 | 111.594 | 66.551 | 463.89 |

| Specific gravity | 26.795% | 20.810% | 13.992% | 24.056% | 14.346% | 100% |

| Conditions | Rotation Radius | Load | Rotational Speed | Duration | Texture Density | |||

|---|---|---|---|---|---|---|---|---|

| Dry | 10 mm | 10 N | 200 rpm | 120 min | 0 | 20% | 25% | 30% |

| Soil | ||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhang, J.; Chen, W.; Wang, H.; Qiu, Z.; Wang, W.; Zhang, Y.; Li, D. Effect of Surface Morphology and Texture of Short-Tailed Shrew’s Toe on Tribological Properties of 65Mn Steel. Biomimetics 2025, 10, 631. https://doi.org/10.3390/biomimetics10090631

Zhang Y, Zhang J, Chen W, Wang H, Qiu Z, Wang W, Zhang Y, Li D. Effect of Surface Morphology and Texture of Short-Tailed Shrew’s Toe on Tribological Properties of 65Mn Steel. Biomimetics. 2025; 10(9):631. https://doi.org/10.3390/biomimetics10090631

Chicago/Turabian StyleZhang, Yachao, Jian Zhang, Wengang Chen, Haijun Wang, Zhaoling Qiu, Wen Wang, Yali Zhang, and Dongyang Li. 2025. "Effect of Surface Morphology and Texture of Short-Tailed Shrew’s Toe on Tribological Properties of 65Mn Steel" Biomimetics 10, no. 9: 631. https://doi.org/10.3390/biomimetics10090631

APA StyleZhang, Y., Zhang, J., Chen, W., Wang, H., Qiu, Z., Wang, W., Zhang, Y., & Li, D. (2025). Effect of Surface Morphology and Texture of Short-Tailed Shrew’s Toe on Tribological Properties of 65Mn Steel. Biomimetics, 10(9), 631. https://doi.org/10.3390/biomimetics10090631