Bioinspired Hierarchical Soft Gripper with Hexagonal and Suction Interfaces for Strain-Guided Object Handling

Abstract

1. Introduction

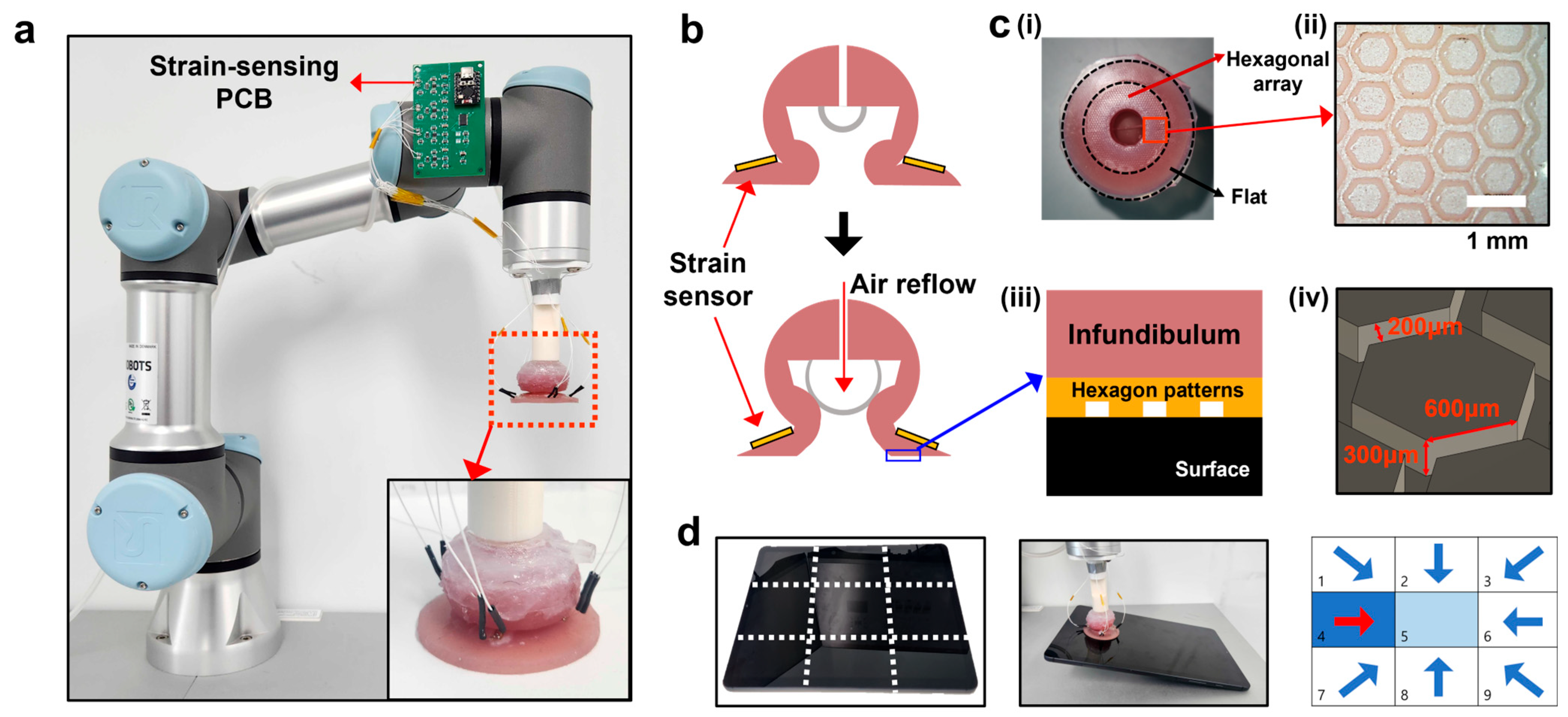

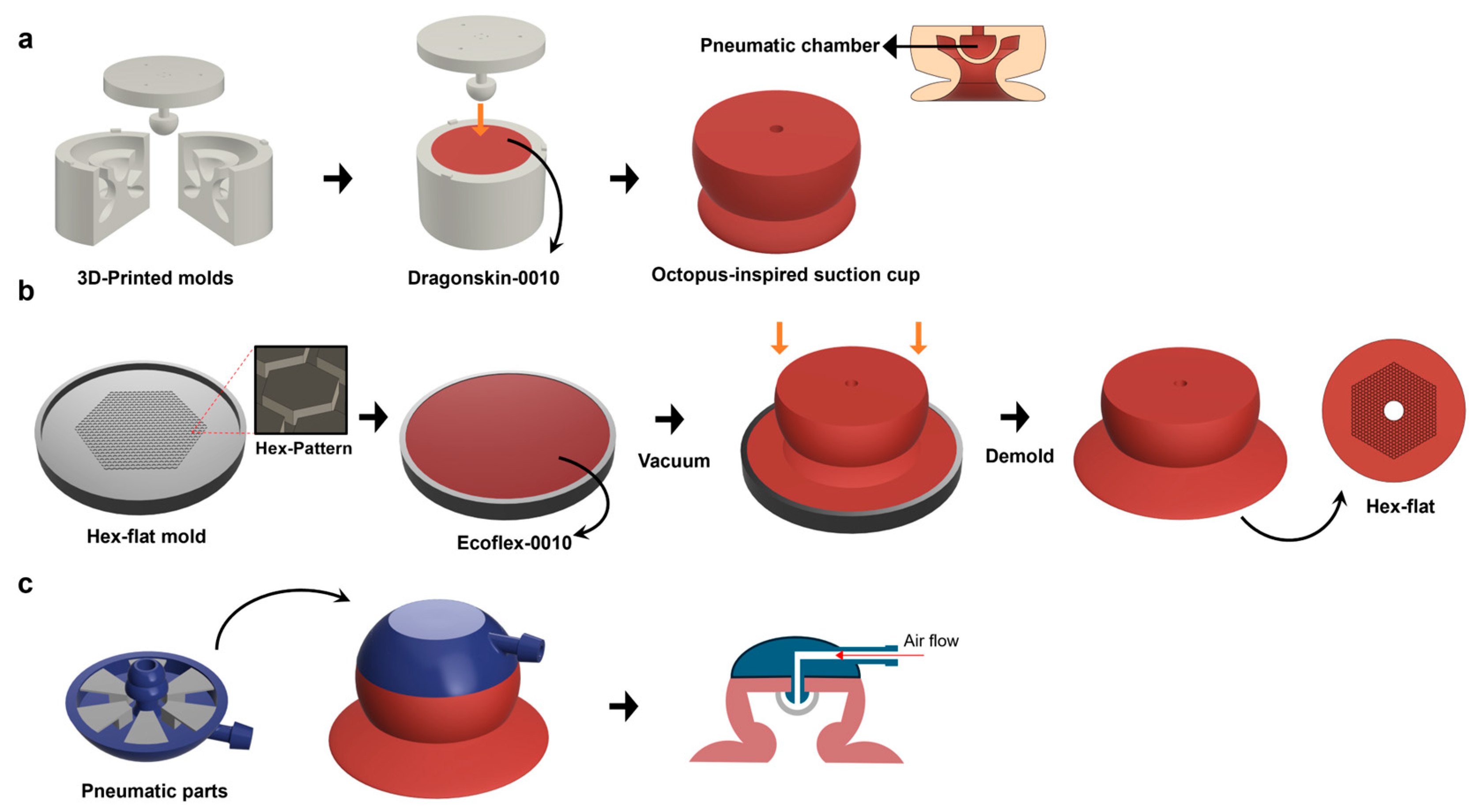

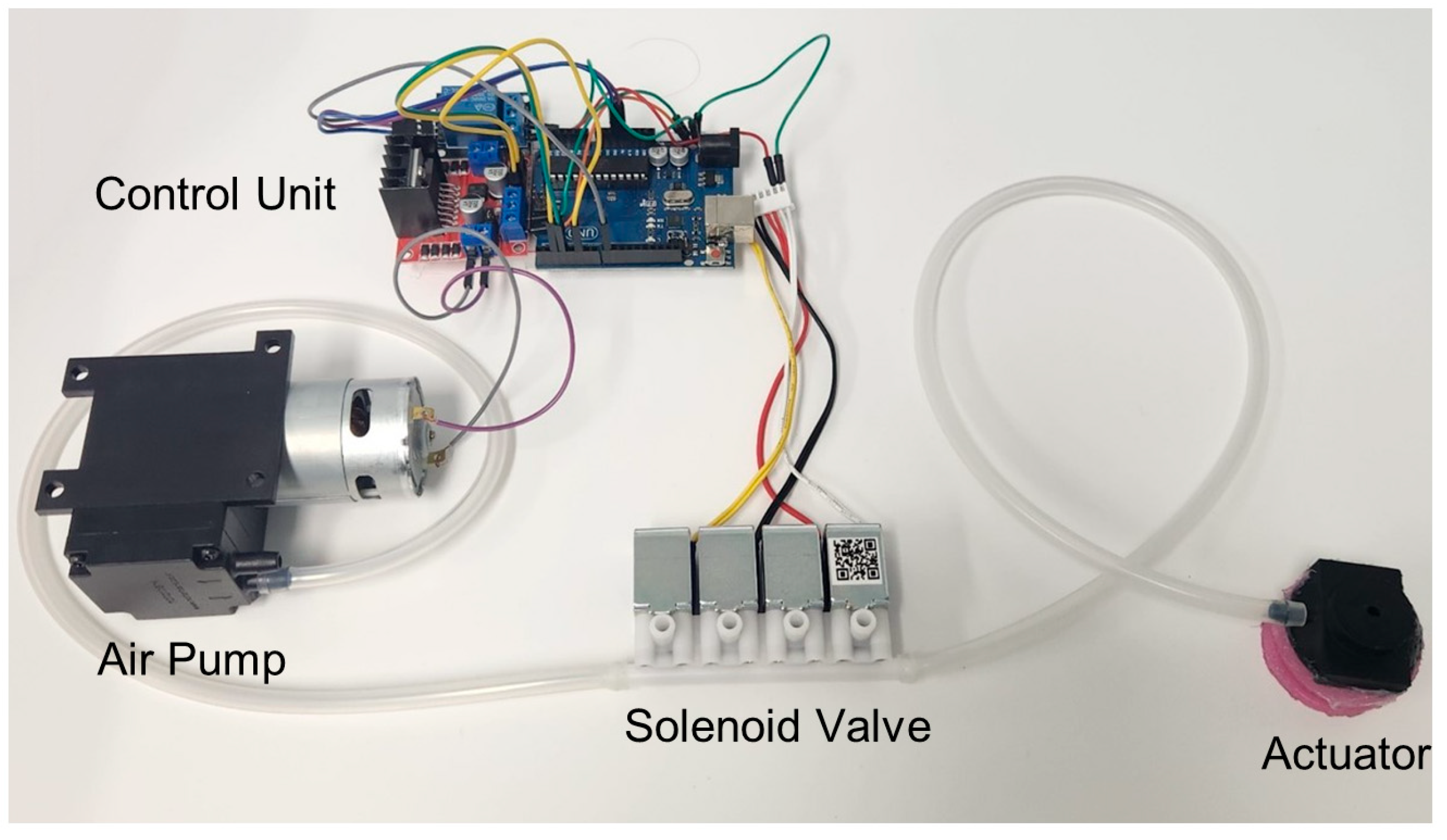

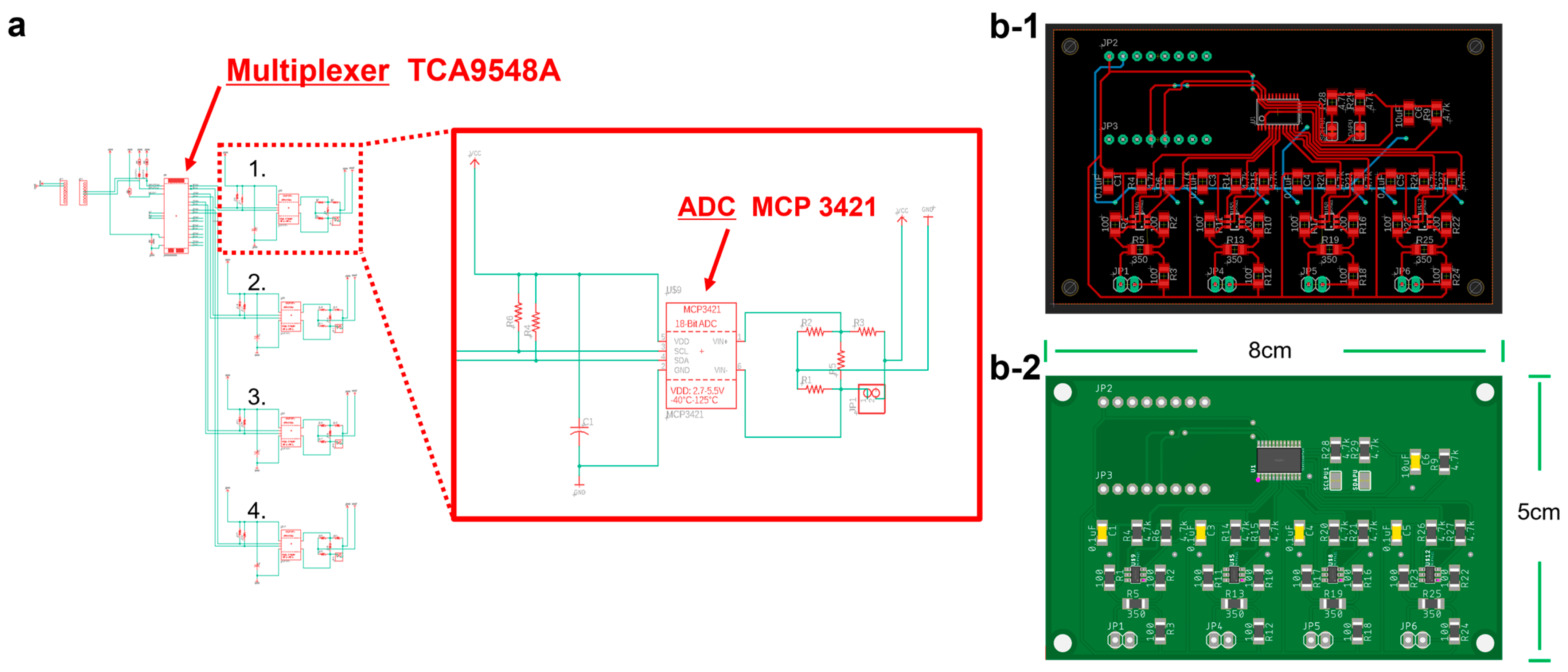

2. Materials and Methods

2.1. Fabrication of Actuator

2.2. Pneumatic System Controlled by PWM

2.3. Design of a PCB for Measuring the Resistance of Strain Gauges

3. Results and Discussion

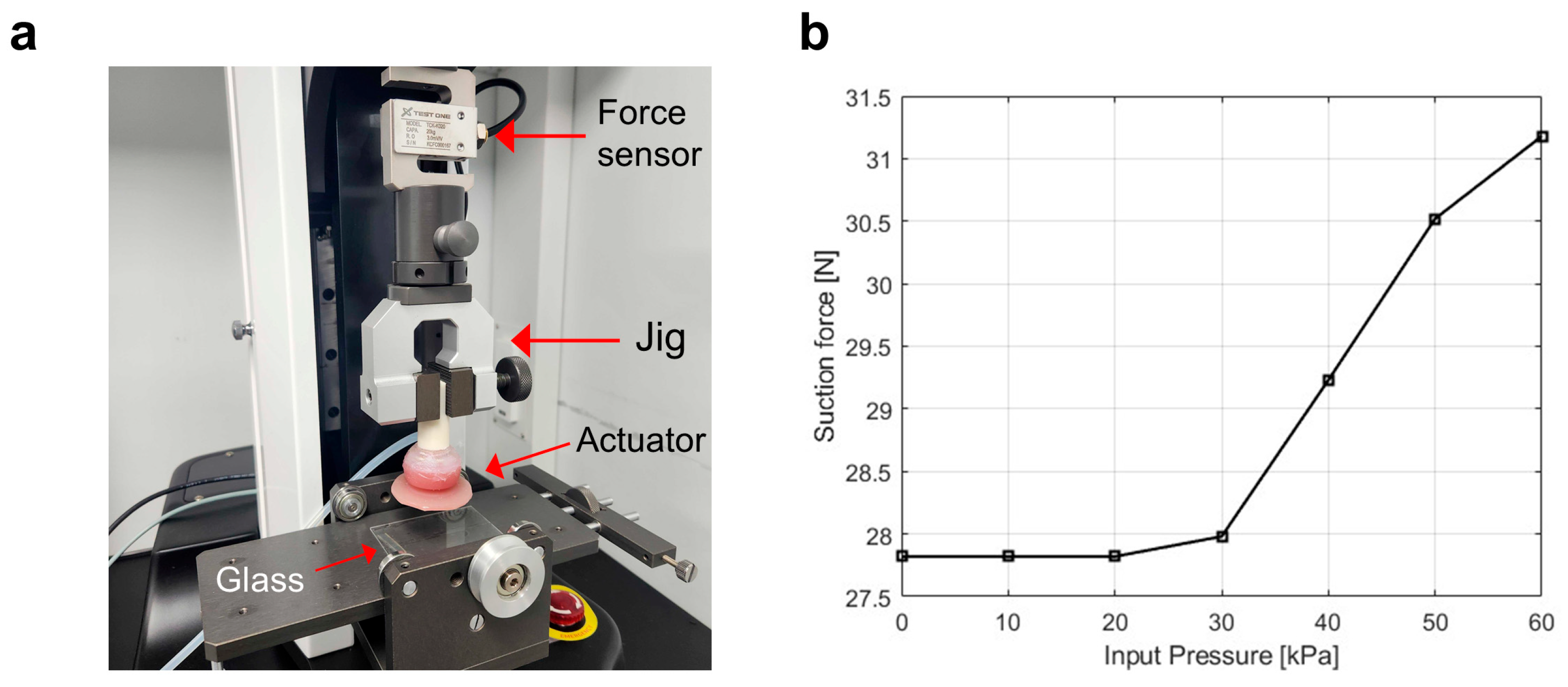

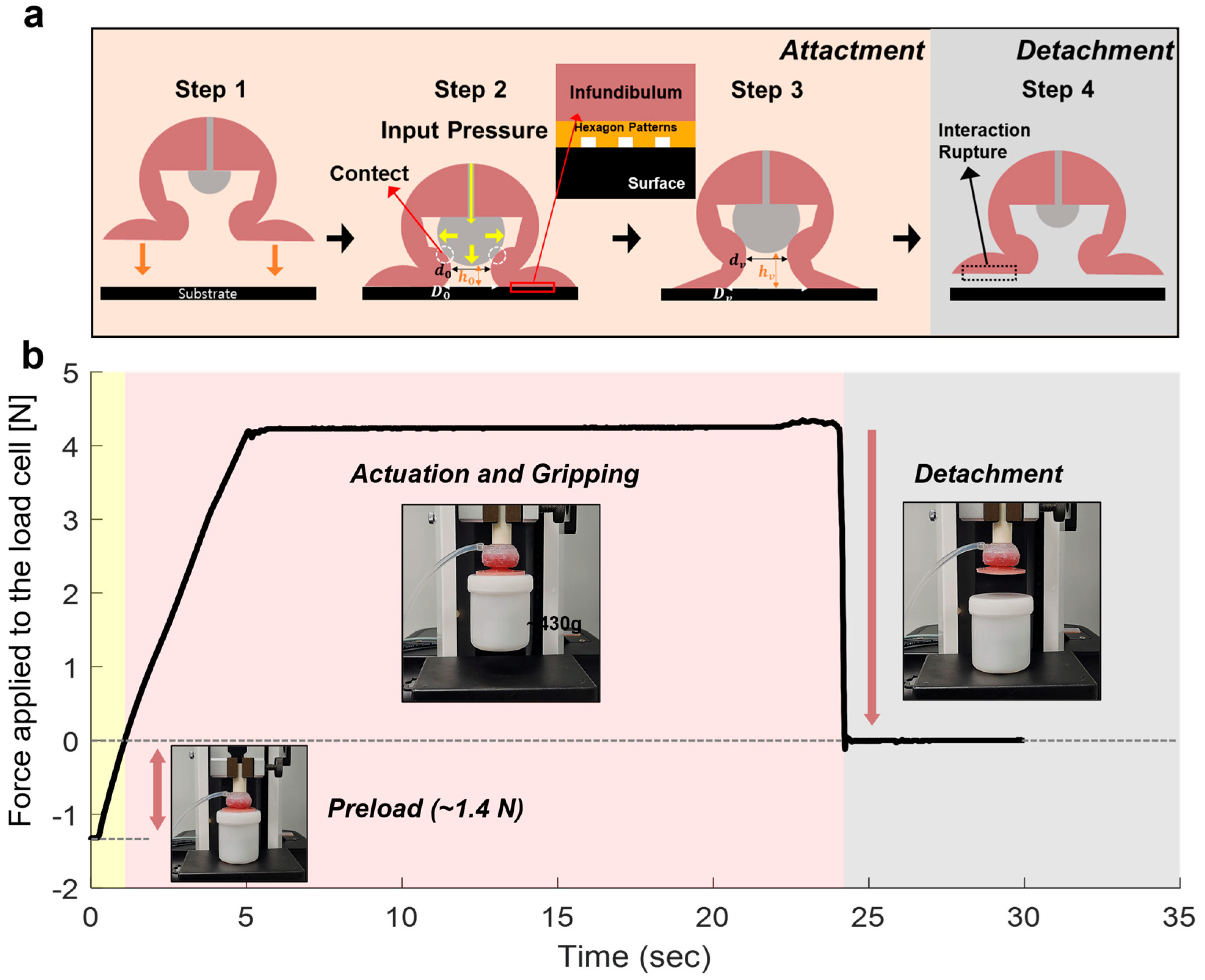

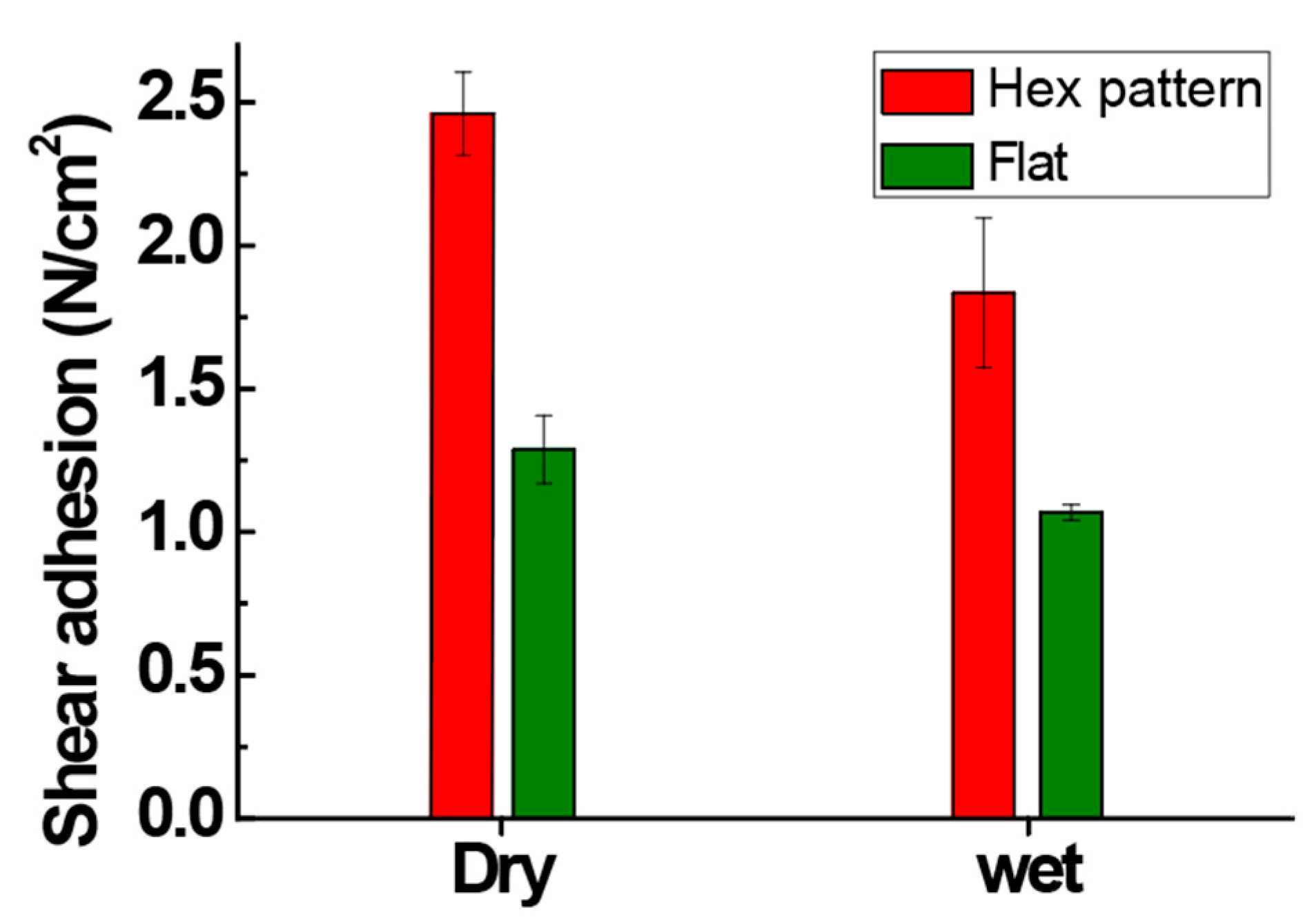

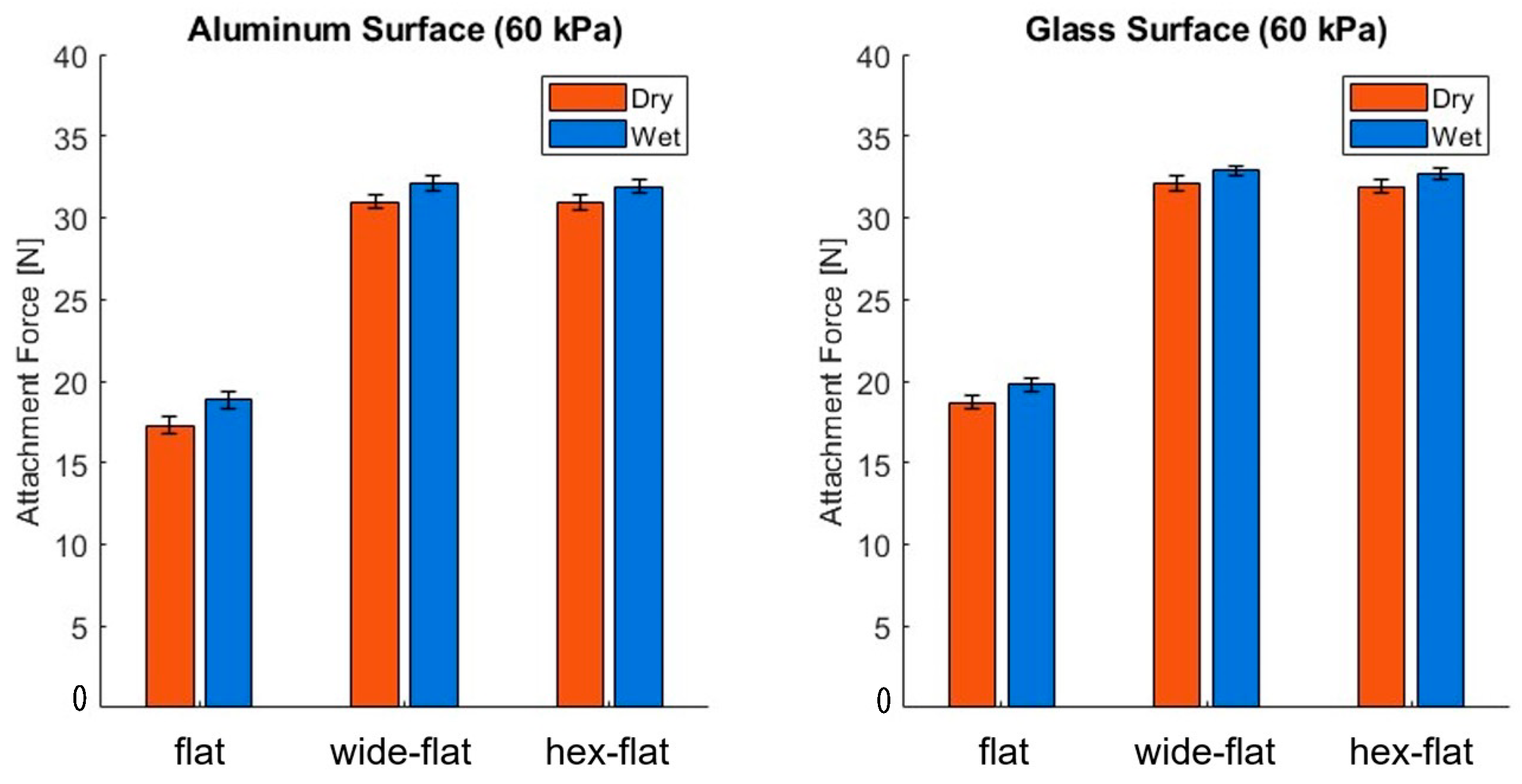

3.1. Adhesion Mechanism and Performance Evaluation

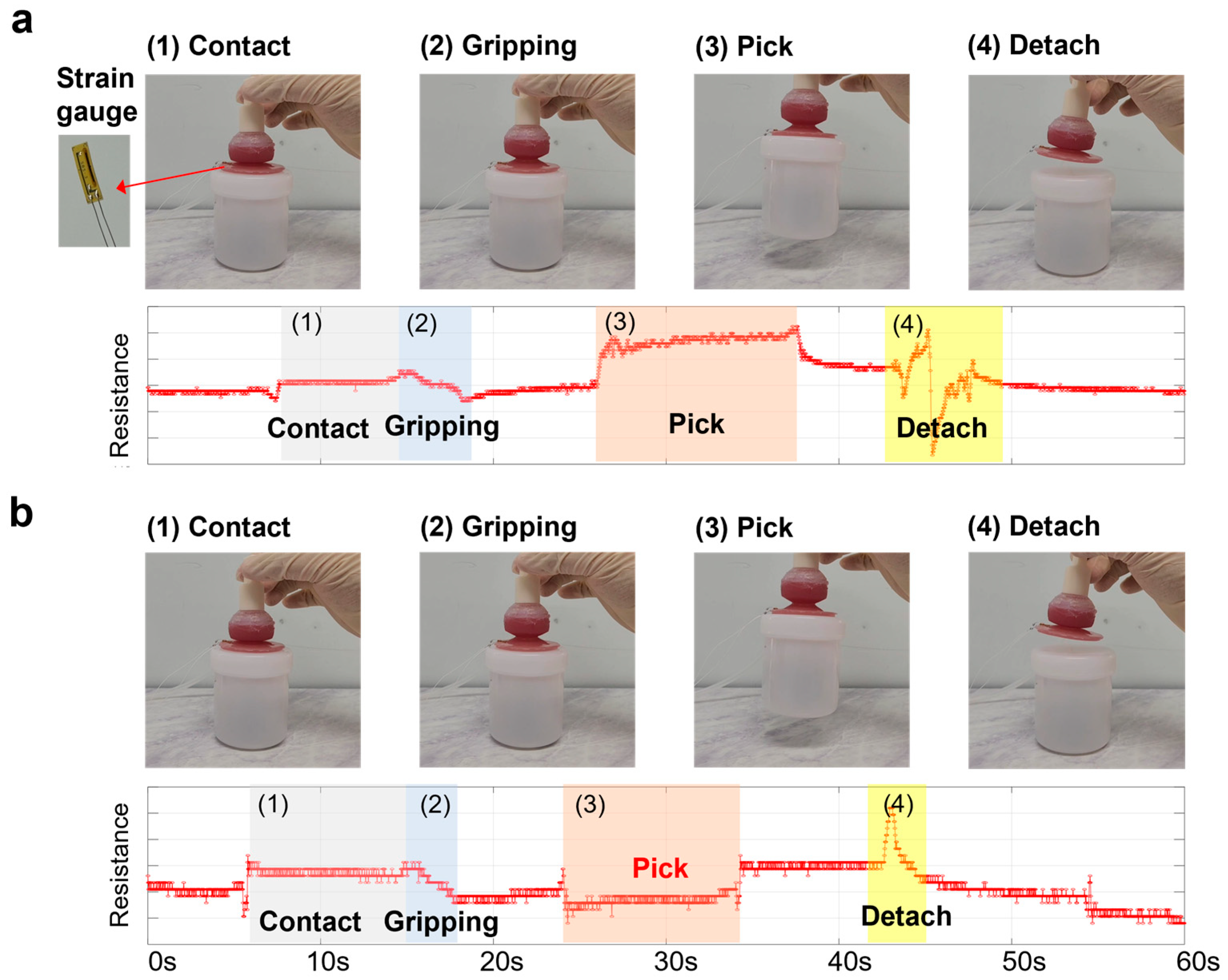

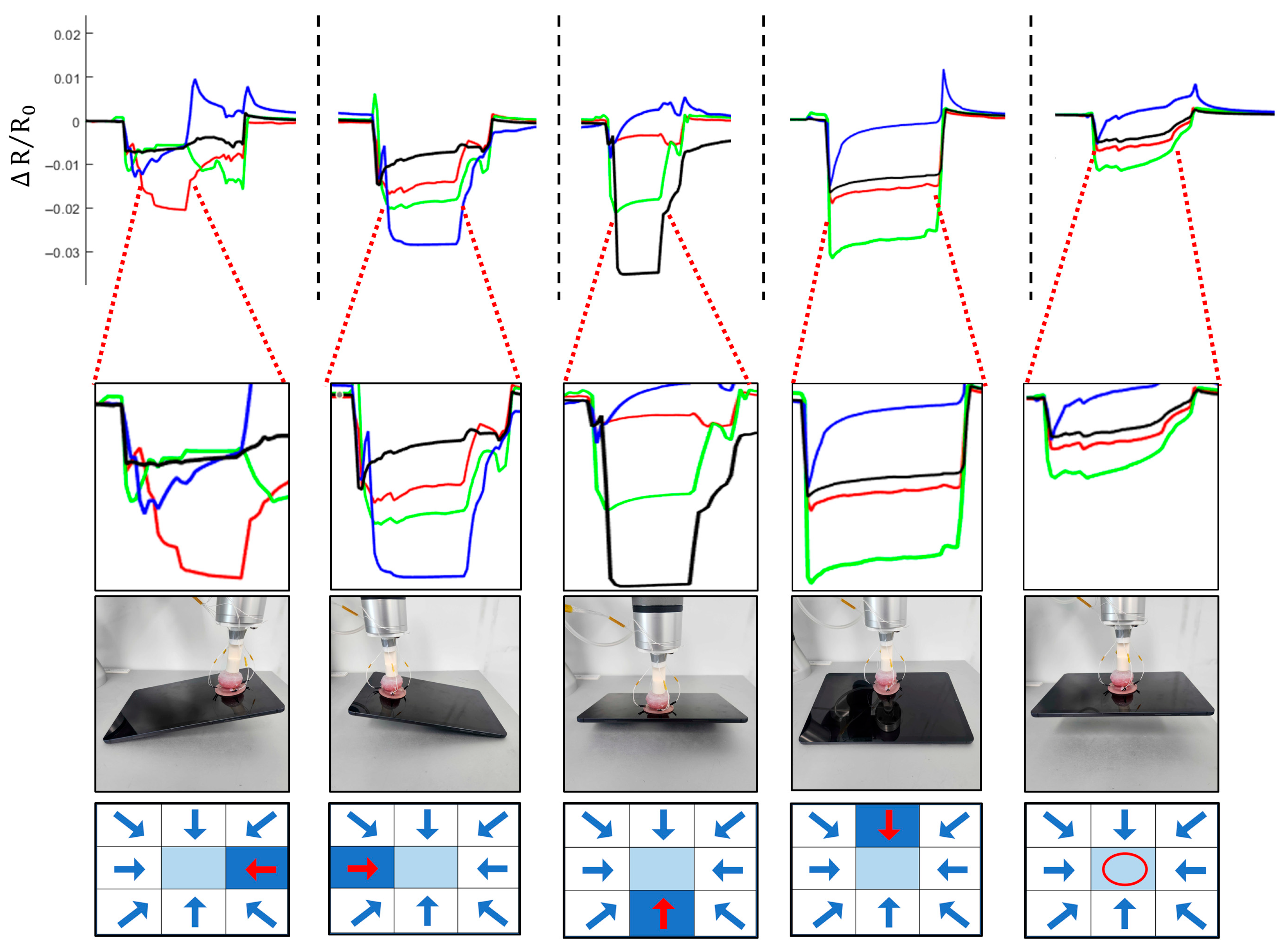

3.2. Strain Gauge-Based Sensing Evaluation During the Gripping Process

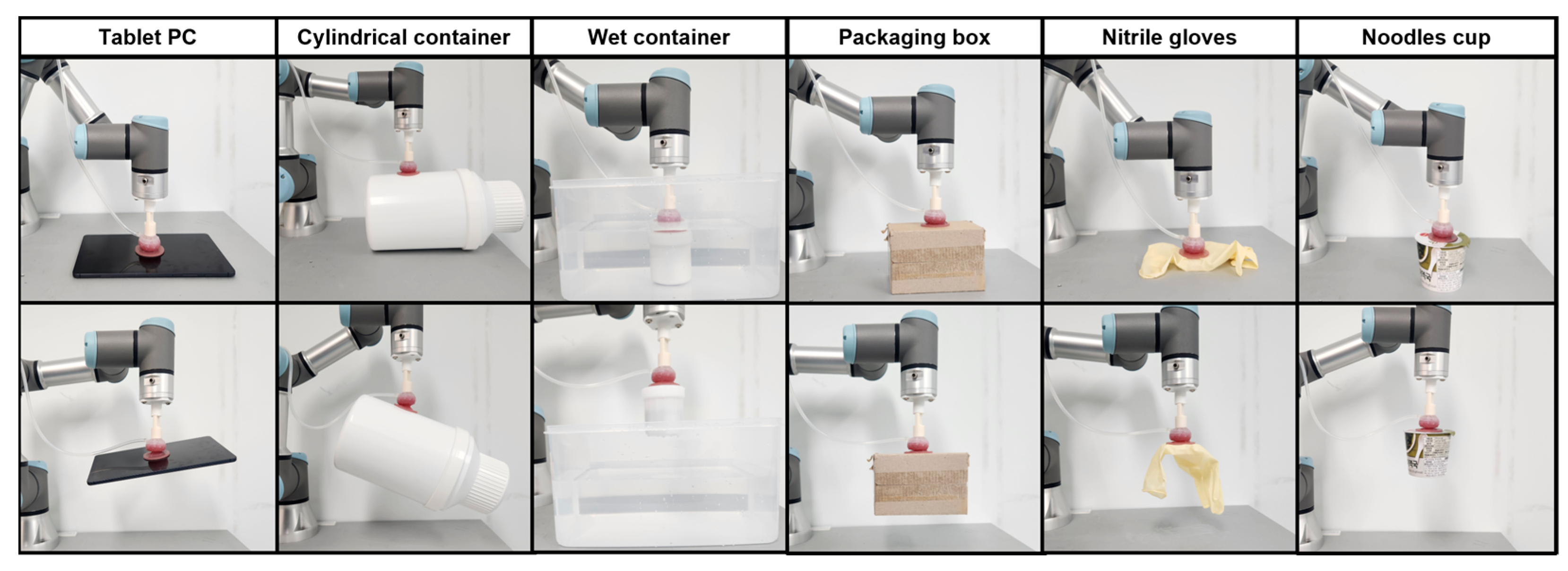

3.3. Application

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AOS | Artificial Octopus Sucker |

| hex-flat | hexagonally arrayed microstructures on a flat elastomer base |

References

- Ghosh, A.; Yoon, C.; Ongaro, F.; Scheggi, S.; Selaru, F.M.; Misra, S.; Gracias, D.H. Stimuli-responsive soft untethered grippers for drug delivery and robotic surgery. Front. Mech. Eng. 2017, 3, 7. [Google Scholar] [CrossRef]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft robotic grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef]

- Yang, G.-Z.; Bellingham, J.; Dupont, P.E.; Fischer, P.; Floridi, L.; Full, R.; Jacobstein, N.; Kumar, V.; McNutt, M.; Merrifield, R. The grand challenges of science robotics. Sci. Robot. 2018, 3, eaar7650. [Google Scholar] [CrossRef] [PubMed]

- Ilievski, F.; Mazzeo, A.D.; Shepherd, R.F.; Chen, X.; Whitesides, G.M. Soft Robotics for Chemists. Angew. Chem. Int. Ed. 2011, 50, 1890–1895. [Google Scholar] [CrossRef] [PubMed]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef]

- Yue, T.; Si, W.; Keller, A.G.; Yang, C.; Bloomfield-Gadêlha, H.; Rossiter, J.M. Bioinspired multi-scale adaptive suction on complex dry surfaces enhanced by regulated water secretion. Proc. Natl. Acad. Sci. USA 2024, 121, e2314359121. [Google Scholar] [CrossRef]

- Giri, A.; Liu, C.; Wang, Z. Design and analysis of a bioinspired positive-pressure soft suction cup for underwater and rough surface applications. IEEE RAS/EMBS BioRob 2022, 2022, 717–722. [Google Scholar]

- Yang, D.Y. Design of a Positive Pressure Octopus-Inspired Suction Cup. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2013. [Google Scholar]

- Amend, J.R.; Brown, E.; Rodenberg, N.; Jaeger, H.M.; Lipson, H. A positive pressure universal gripper based on the jamming of granular material. IEEE Trans. Robot. 2012, 28, 341–350. [Google Scholar] [CrossRef]

- Fujita, K.; Sato, Y.; Ozaki, R.; Sugita, K. Development of a wall climbing robot with a vacuum gripper for non-magnetic surfaces. Adv. Robot. 2018, 32, 605–617. [Google Scholar] [CrossRef]

- Song, S.; Drotlef, D.M.; Son, D.; Koivikko, A.; Sitti, M. Adaptive Self-Sealing Suction-Based Soft Robotic Gripper. Adv. Sci. 2021, 8, 2100641. [Google Scholar] [CrossRef]

- Tsukagoshi, H.; Osada, Y. Soft Hybrid Suction Cup Capable of Sticking to Various Objects and Environments. Actuators 2021, 10, 50. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, X.; Zhang, Y.; Yu, L.; Xu, J.; Zhang, Y.; Li, G.; Guo, J.; Liu, J.; Jiang, Y. Liquid Metal Droplet-Based Flexible and Reconfigurable Smart Adhesion System. ACS Appl. Mater. Interfaces 2019, 11, 35058–35067. [Google Scholar]

- Li, J.; Wang, L.; Wu, X.; Wang, K.; Li, X.; Zheng, Y.; Zhang, H.; Liu, J.; Wu, X.; Jiang, L. A Suction-Based Bioinspired Adhesive Patch with Tunable Stiffness for Widely Versatile Applications. Adv. Mater. 2020, 32, 1907071. [Google Scholar]

- Xie, Z.; Domel, A.G.; An, N.; Green, C.; Gong, Z.; Wang, T.; Knubben, E.M.; Weaver, J.C.; Bertoldi, K.; Wen, L. Octopus arm-inspired tapered soft actuators with suckers for improved grasping. Soft Robot. 2020, 7, 639–648. [Google Scholar] [CrossRef] [PubMed]

- Baik, S.; Kim, D.W.; Park, Y.; Lee, T.-J.; Ho Bhang, S.; Pang, C. A wet-tolerant adhesive patch inspired by protuberances in suction cups of octopi. Nature 2017, 546, 396–400. [Google Scholar] [CrossRef]

- Kier, W.M.; Smith, K.K. The morphology and mechanics of octopus suckers. Integr. Comp. Biol. 2002, 42, 1146–1153. [Google Scholar] [CrossRef]

- Tramacere, F.; Beccai, L.; Kuba, M.; Guglielmelli, E.; Cutkosky, M.R.; Mazzolai, B. Octopus suckers: The role of surface morphology in attachment. J. R. Soc. Interface 2014, 11, 20130816. [Google Scholar] [CrossRef]

- Meloni, S.; Arca, F.; Cannas, M.; Scano, A.; Sanna, S.; Satta, G.; Farina, D.; Porcu, M. Wet adhesion with micro-suckers for transfer printing. Sci. Rep. 2020, 10, 4784. [Google Scholar]

- Wehner, M.; Truby, R.L.; Fitzgerald, D.J.; Mosadegh, B.; Whitesides, G.M.; Lewis, J.A.; Wood, R.J. An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature 2016, 536, 451–455. [Google Scholar] [CrossRef]

- Xie, Z.; Yuan, F.; Liu, J.; Tian, L.; Chen, B.; Fu, Z.; Mao, S.; Jin, T.; Wang, Y.; He, X.; et al. Octopus-Inspired Sensorized Soft Arm for Environmental Interaction. Sci. Robot. 2023, 8, eadh7852. [Google Scholar] [CrossRef]

- Lee, H.J.; Baik, S.; Hwang, G.W.; Song, J.H.; Kim, D.W.; Park, B.-S.; Min, H.; Kim, J.K.; Koh, J.-S.; Yang, T.-H. An electronically perceptive bioinspired soft wet-adhesion actuator with carbon nanotube-based strain sensors. ACS Nano 2021, 15, 14137–14148. [Google Scholar] [CrossRef]

- Cui, E.; Zhou, X.; Liu, Y.; Xue, J.; Xiong, S.; Zhang, D. A Biomimetic Flexible Sliding Suction Cup Suitable for Curved Surfaces. Biomimetics 2025, 10, 137. [Google Scholar] [CrossRef] [PubMed]

- Yue, T.; Bloomfield-Gadêlha, H.; Rossiter, J. Snail-inspired water-enhanced soft sliding suction for climbing robots. Nat. Commun. 2024, 15, 4038. [Google Scholar] [CrossRef]

- Xue, L.; Sanz, B.N.; Luo, A.; Turner, K.T.; Wang, X.; Tan, D.; Zhang, R.; Du, H.; Steinhart, M.; Mijangos, C. Hybrid surface patterns mimicking the design of the adhesive toe pad of tree frog. ACS Nano 2017, 11, 9711–9719. [Google Scholar] [CrossRef] [PubMed]

- Iturri, J.; Xue, L.; Kappl, M.; García-Fernández, L.; Barnes, W.J.P.; Butt, H.J.; del Campo, A. Torrent frog--inspired adhesives: Attachment to flooded surfaces. Adv. Funct. Mater. 2015, 25, 1499–1505. [Google Scholar] [CrossRef]

- Kim, D.W.; Baik, S.; Min, H.; Chun, S.; Lee, H.J.; Kim, K.H.; Lee, J.Y.; Pang, C. Highly permeable skin patch with conductive hierarchical architectures inspired by amphibians and octopi for omnidirectionally enhanced wet adhesion. Adv. Funct. Mater. 2019, 29, 1807614. [Google Scholar] [CrossRef]

- Kim, D.W.; Song, K.I.; Seong, D.; Lee, Y.S.; Baik, S.; Song, J.H.; Lee, H.J.; Son, D.; Pang, C. Electrostatic–mechanical synergistic in situ multiscale tissue adhesion for sustainable residue--free bioelectronics interfaces. Adv. Mater. 2022, 34, 2105338. [Google Scholar] [CrossRef]

- Li, G.; Wong, T.-W.; Shih, B.; Guo, C.; Wang, L.; Liu, J.; Wang, T.; Liu, X.; Yan, J.; Wu, B.; et al. Bioinspired soft robots for deep-sea exploration. Nat. Commun. 2023, 14, 7097. [Google Scholar] [CrossRef]

- Zou, S.; Picella, S.; De Vries, J.; Kortman, V.G.; Sakes, A.; Overvelde, J.T.B. A Retrofit Sensing Strategy for Soft Fluidic Robots. Nat. Commun. 2024, 15, 539. [Google Scholar] [CrossRef]

- Dillard, D.A. Bending of Plates on Thin Elastomeric Foundations. J. Appl. Mech. 1989, 56, 382–386. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Jang, J.; Chang, T.; Jeong, Y.J.; Park, Y.H.; Seo, J.T.; Kim, D.W. Bioinspired Hierarchical Soft Gripper with Hexagonal and Suction Interfaces for Strain-Guided Object Handling. Biomimetics 2025, 10, 510. https://doi.org/10.3390/biomimetics10080510

Lee J, Jang J, Chang T, Jeong YJ, Park YH, Seo JT, Kim DW. Bioinspired Hierarchical Soft Gripper with Hexagonal and Suction Interfaces for Strain-Guided Object Handling. Biomimetics. 2025; 10(8):510. https://doi.org/10.3390/biomimetics10080510

Chicago/Turabian StyleLee, Junho, Junwon Jang, Taeyoung Chang, Yong Jin Jeong, Young Hwan Park, Jeong Tae Seo, and Da Wan Kim. 2025. "Bioinspired Hierarchical Soft Gripper with Hexagonal and Suction Interfaces for Strain-Guided Object Handling" Biomimetics 10, no. 8: 510. https://doi.org/10.3390/biomimetics10080510

APA StyleLee, J., Jang, J., Chang, T., Jeong, Y. J., Park, Y. H., Seo, J. T., & Kim, D. W. (2025). Bioinspired Hierarchical Soft Gripper with Hexagonal and Suction Interfaces for Strain-Guided Object Handling. Biomimetics, 10(8), 510. https://doi.org/10.3390/biomimetics10080510