1. Introduction

Lattice structures are fundamental units for understanding the design, construction, nature, and behavior of material structures. Although lattice structures, like metamaterials, are based on repeating unit cells, they differ from natural crystal lattices in origin and design. Each point of a crystal lattice represents the position of an ion, atom, or molecule; however, lattice structures are engineered materials designed to exhibit properties not found in natural materials. According to Gibson and Ashby Evans [

1], they can be classified as “cellular structures,” which include honeycombs, lattices, and foams. Specifically, a lattice structure is a cellular structure composed of a porous material organized in space in the form of a periodic lattice. Lattice structures are characterized by an interconnected network of edges and faces [

2] and can be closed-cell with isolated pores or open-cell with interconnected pores.

The structural efficiency observed in natural formations such as trabecular bone, fish scales, and honeycombs has motivated engineers to create biomimetic lattice structures that possess high strength-to-weight ratios and energy absorption capabilities. Metals such as Ti 6Al 4V demonstrate high stiffness but exhibit lower impact absorption, whereas polymer-based lattices like TPU provide enhanced flexibility and resilience when subjected to impact loading. The design of various natural structures, including trabecular bone [

3], fish scales [

4], spider webs [

5], honeycombs [

6], mollusk shells [

7], and animal horns [

8], has inspired engineers for centuries to create efficient and durable structures.

The biomimetic design of these lattice structures presents a distinctive combination of versatile properties such as lightweight, mechanical resilience, and energy absorption, rendering them appealing for applications in architecture [

9], aerospace [

10,

11], additive manufacturing [

12,

13], automotive [

14], marine [

15], and biomedical fields [

16]. A biphasic biomimetic bone scaffold has been developed through the bidirectional regulation of endochondral ossification [

17]. The European Aeronautic and Defense Agency optimized a hinge for an Airbus A320 utilizing biomimetic design concepts [

18]. NASA is investigating the application of electroactive polymers as artificial muscles, which play a crucial role in the advancement of biologically inspired technologies [

19].

Considering the fundamental research on lattice structures, the subsequent section examines the latest developments in assessing their deformation properties through both experimental and computational methods. To begin with, we conducted research and gathered information regarding highly regarded journals and frequently cited articles pertaining to the overarching subject of lattice structures (

Table 1).

Verma et al. [

23] conducted a study on the removal of polymer powder-based additive manufacturing during the process. They calculated the total volumetric energy absorbed, energy efficiency of absorption, and the onset of strain for various 3D-printed lattice structures subjected to compression [

24]. The dual-lattice exhibited a greater energy-absorbing capacity at each volume fraction. A lotus root lattice structure (LRLS) was proposed and fabricated using 3D printing technology [

25]. The finite element analysis of LRLS has demonstrated its effectiveness. Additionally, an octagonal lattice structure produced through additive manufacturing has been suggested [

26]. The applicability of a Kelvin lattice structure has been explored for its potential use as a bone scaffold [

27]. An optimization model was introduced for designing the cooling channel in gas turbine blades [

28]. Relationships between heat transfer coefficients were established between a pyramid-type lattice structure (PLS) and a Kagome-type lattice [

28]. Xinwei et al. [

29] employed resonance and Bragg’s scattering to assess the acoustic performance of hybrid lattice structures, discovering that these properties were influenced by the size of the cells. Palomba et al. [

30] examined bamboo samples through impact testing and found that the softer layers of the material exhibited a higher energy absorption capacity. Furthermore, an investigation into the use of lattice structures in marine shipbuilding has been conducted.

Table 2 provides a summary of the reviewed papers detailing specific applications of biomimetics.

There are many obstacles to the widespread commercial application of these structures, primarily due to challenges in manufacturing and the unpredictable nature of fatigue behavior. The majority of the current research has concentrated on existing cellular structures without altering the topography of the cells or taking into account the Poisson ratio. Further investigation is required into the effects of layer design and load-bearing capacities on orientation.

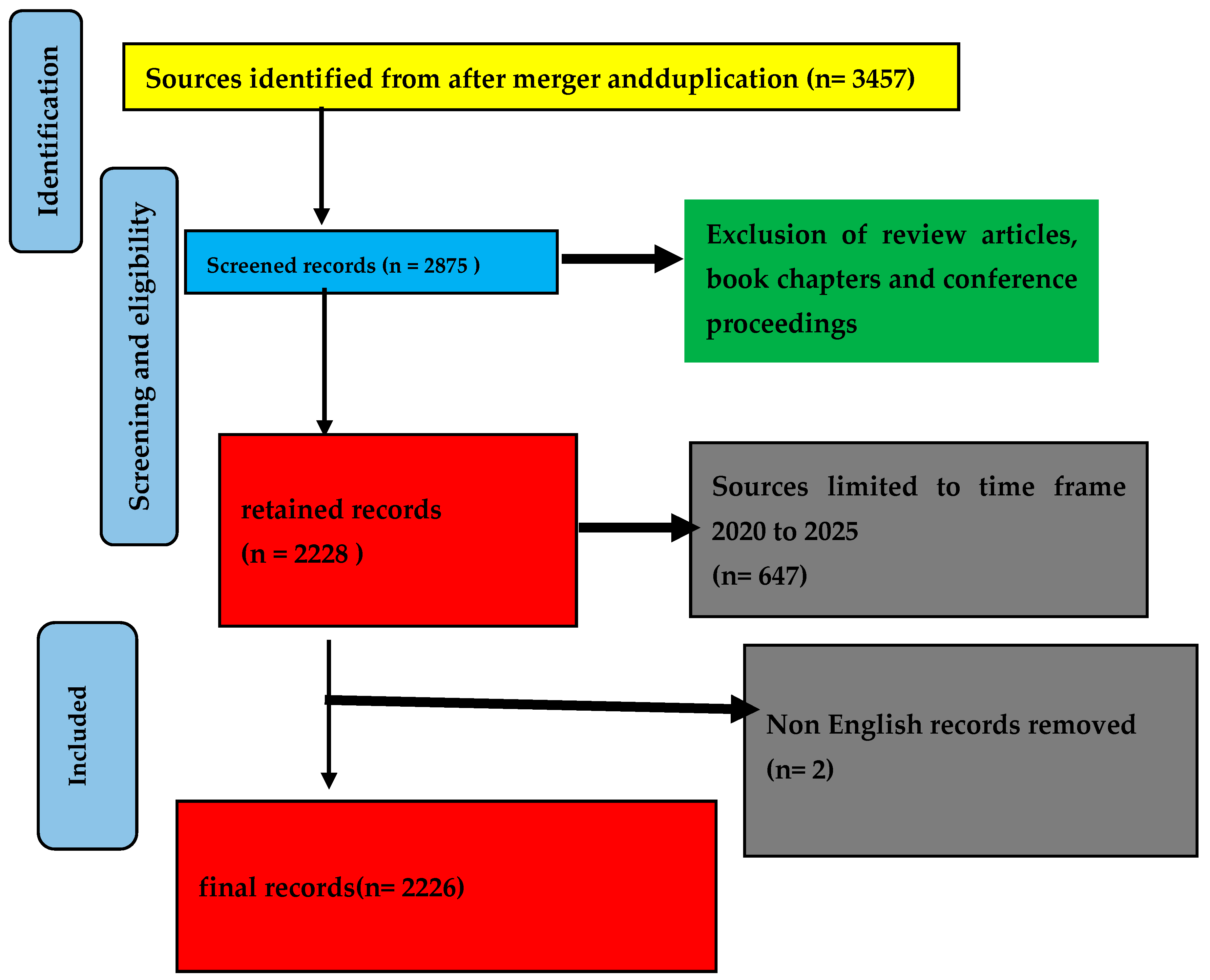

A bibliometric analysis (BA) of lattice structure materials covering the period from 2002 to 2022 was conducted [

33]. A systematic review of 2512 journal articles sourced from the Scopus database revealed a significant bias towards the study of materials [

34]. The Bibliometrix package, applied to 1271 documents from Scopus, indicated a growth rate of 20.8% over the years, with the United States leading in publications, followed by China and the United Kingdom [

35]. Similar findings were observed in recent studies. Research on additive manufacturing for medical applications was most prevalent in the years 2010 and 2012. According to the reviews, there are 2769 pieces of literature related to the theme of 3D printing [

36]. An analysis of keyword frequency revealed that the selective laser melting and fused deposition modeling techniques were the two most frequently studied, accounting for 35.76% and 20.09%, respectively [

37]. A bibliometric analysis of fused deposition modeling (FDM) was performed to gain insights into the trends and research areas [

38].

The landing of the aluminum strut-based Team Indus spacecraft on the Moon in 2020 signified the beginning of a new era in the application of lightweight and structurally sound lattice structures [

39]. A groundbreaking 3D acoustic black hole (ABH) was employed to attain high load-bearing capacity and vibration suppression [

40]. Recently, topology optimization and data-driven techniques have been utilized [

41]. Several challenges, such as computational complexity, material synthesis, and interdisciplinary collaboration, have been recognized in the application of these structures [

42]. These findings suggest that the designated timeframe (2020–2025) is critical or strategic for the current study.

As shown in

Table 1, previous studies have examined various specific elements of these structures; however, there is a lack of a thorough review of recent advancements in these structures designed to emulate biomimetic applications with respect to energy and deformation. Therefore, a comprehensive bibliometric review has been provided based on these criteria. The primary objectives of this analysis are as follows:

Research Question 1 (RQ1). What materials, methods, and thematic areas are most frequently explored in the recent literature on biomimetic lattice structures?

Research Question 2 (RQ2). How has the volume of scientific publications evolved between 2020 and 2025 in relation to deformation and energy absorption in biomimetic lattice design?

Research Question 3 (RQ3). Who are the most influential authors, journals, and countries contributing to this research domain?

Research Question 4 (RQ4). What are the key research gaps and emerging themes that require further investigation in the field?

The primary aim of this work is to offer insights into the most notable contributions and collaborations in the field of lattice structure design over the last five years, as well as to explore the key topics and scholarly articles. This study holds significance as safe design is crucial for maintaining structural integrity. The manuscript is divided into six sections. In

Section 2, we have presented an overview of techniques, methods, and materials for designing these structures. The process of bibliometric analysis is presented in

Section 3. We have tried to identify the most active keywords, journals, researchers, their institutions, collaborations, and countries in

Section 4, which could be advantageous for the relevant scientific community. Additionally, we examined the emergence of new themes that may inspire researchers to explore lesser-known areas in

Section 5. By providing insights into ongoing research and future directions in

Section 6, this review could serve as a vital resource for various industries.

4. Bibliometric Results and Discussions

The analysis procedure in bibliometric research includes statistical, collaboration, co-citation, and co-occurrence analysis. This can be performed using Bibliometrix R-packages [

143].

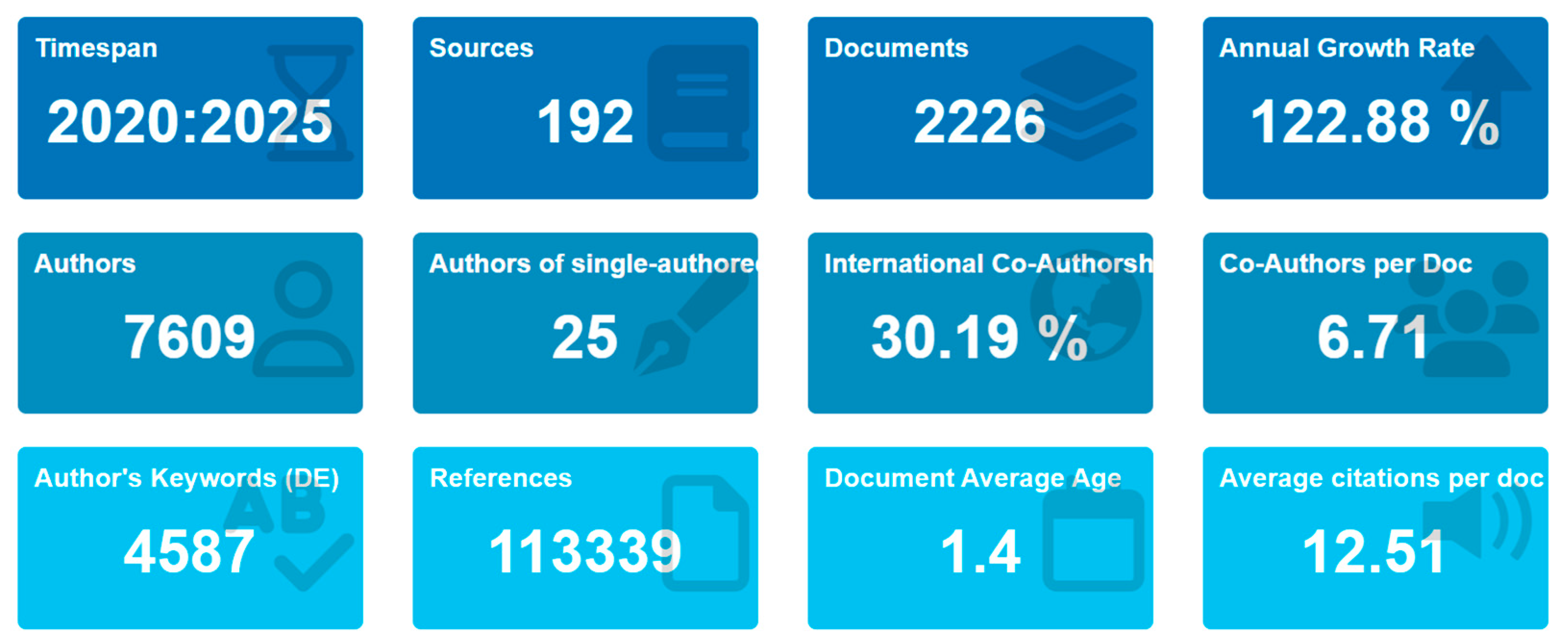

Figure 8 illustrates the summary of merged data extracted, where an impressive annual growth rate of over 122% has been observed. There were about 12 citations for each document authored by about 7609 researchers.

Analysis can be further carried out using version 1.6.20 of VOS viewer for Microsoft Windows systems, which is a software tool developed by Leiden University of the Netherlands [

144]. It uses data in Excel form as input in order to analyze the collaborations and clusters of relationships. The mapping is achieved by connecting various networking nodes having different colors and layouts with high visual outputs.

Figure 9 shows a general layout found in this software tool.

This platform allows for creating, opening, saving, and sharing data. Font and node sizes can also be modified using suitable scaling and size variations. This tool also allows network and density visualization to identify bibliometric coupling in terms of keyword occurrences, key authors, and key affiliating institutions. The distance between nodes represents the frequency of occurrences.

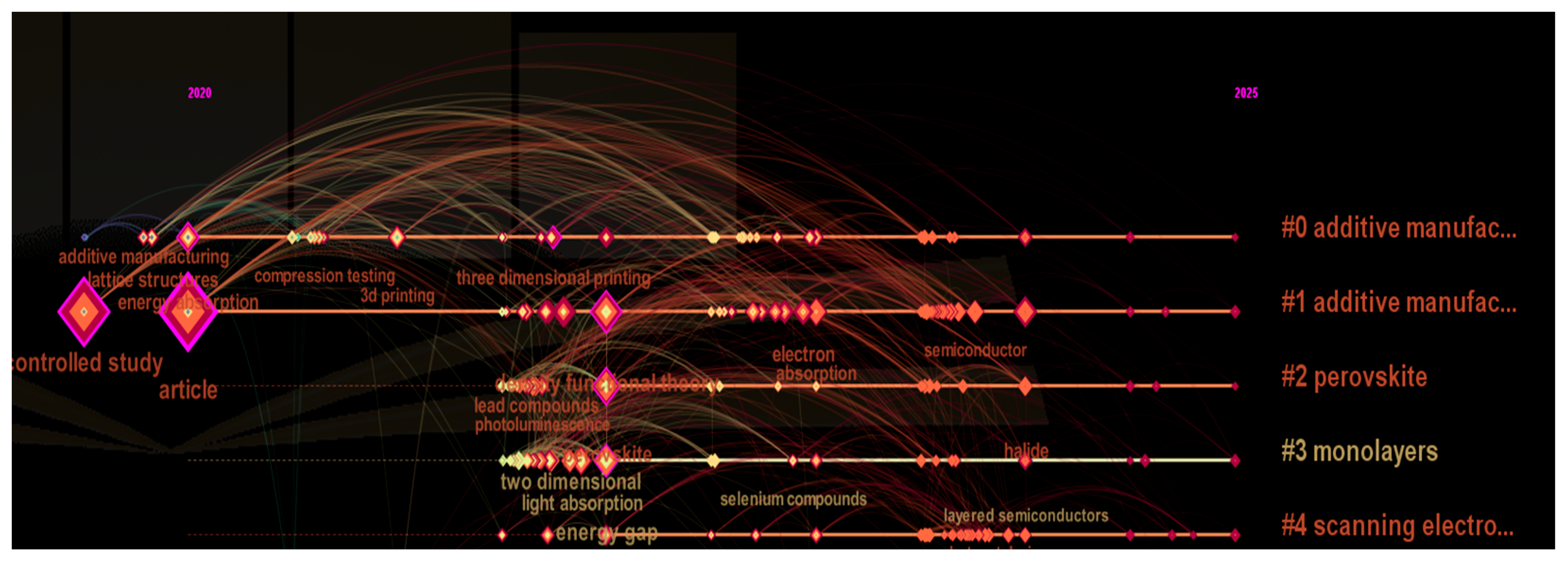

Among other useful tools for generating maps, Cite Space can be used to divide the timeline slice by slice, as seen in

Figure 10. This tool was developed by C. Chen from the University of Drexel, USA [

145].

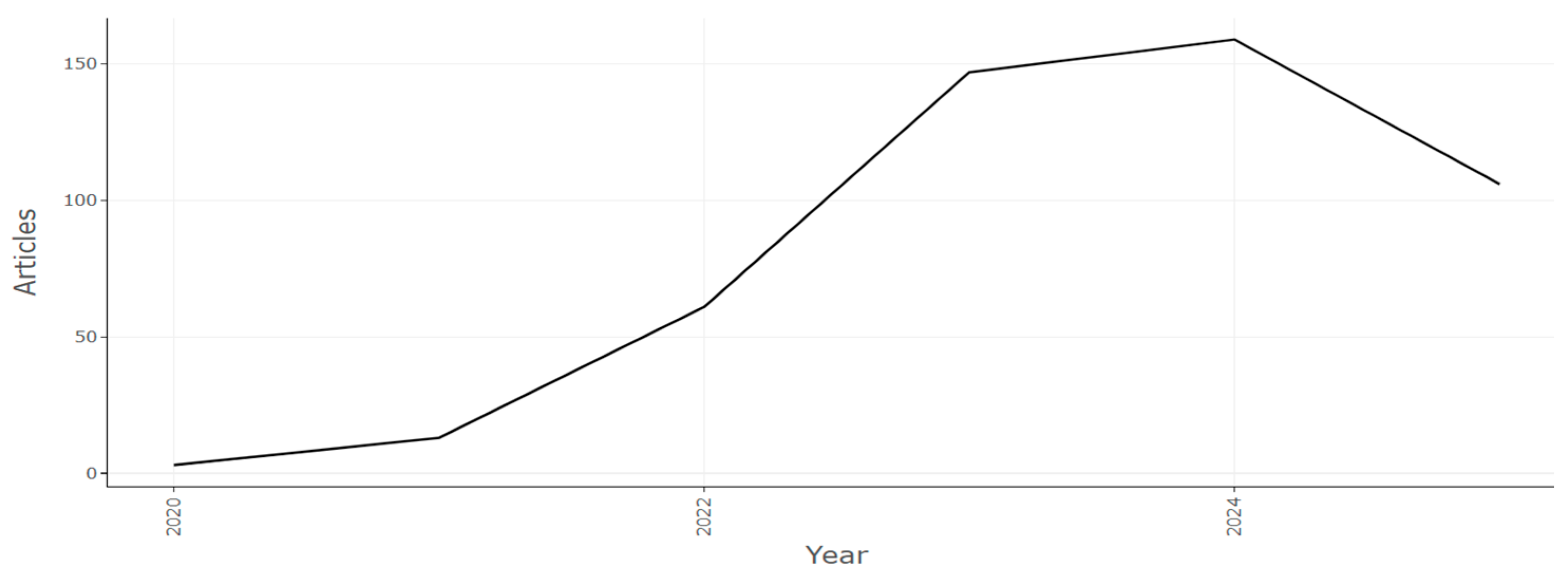

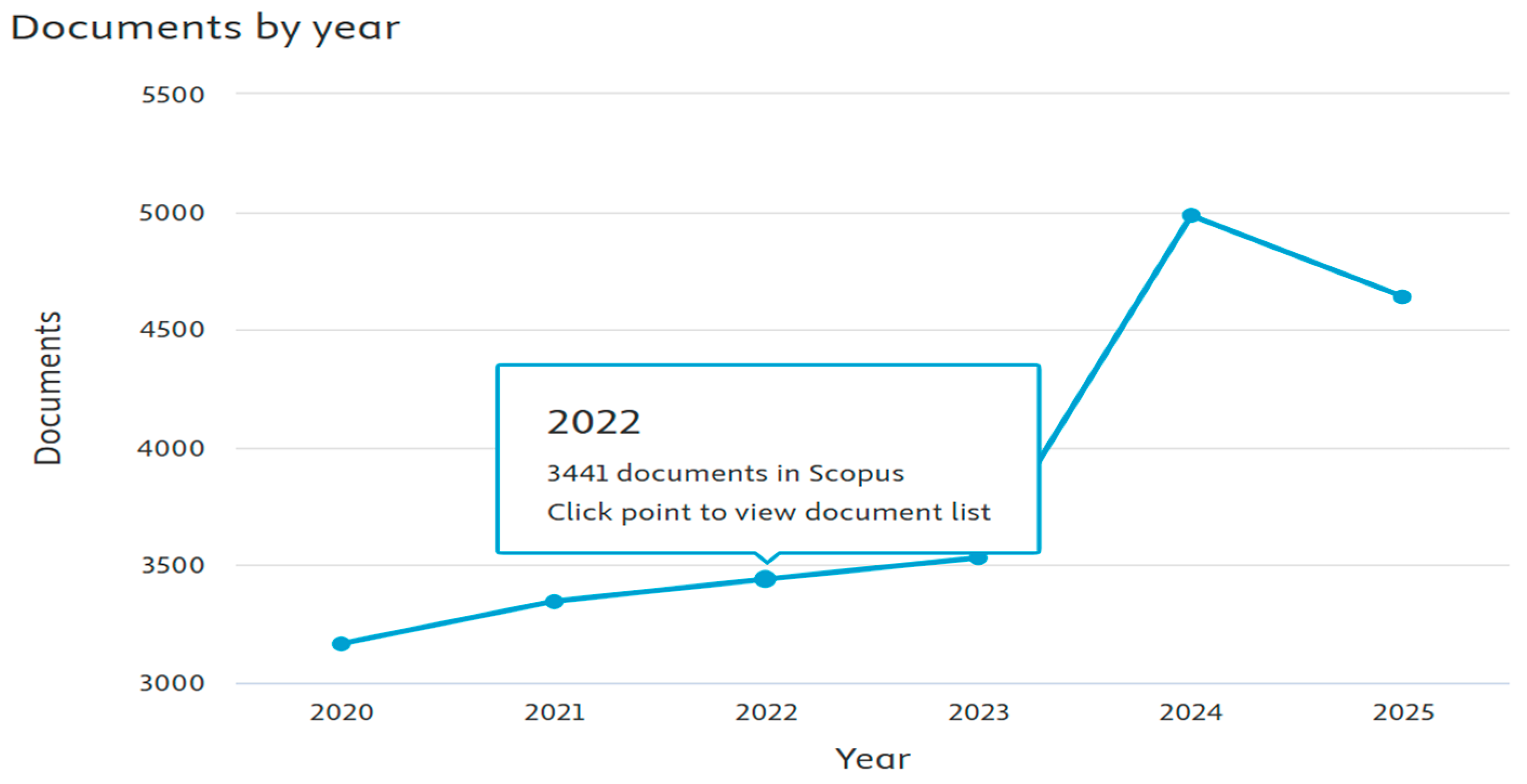

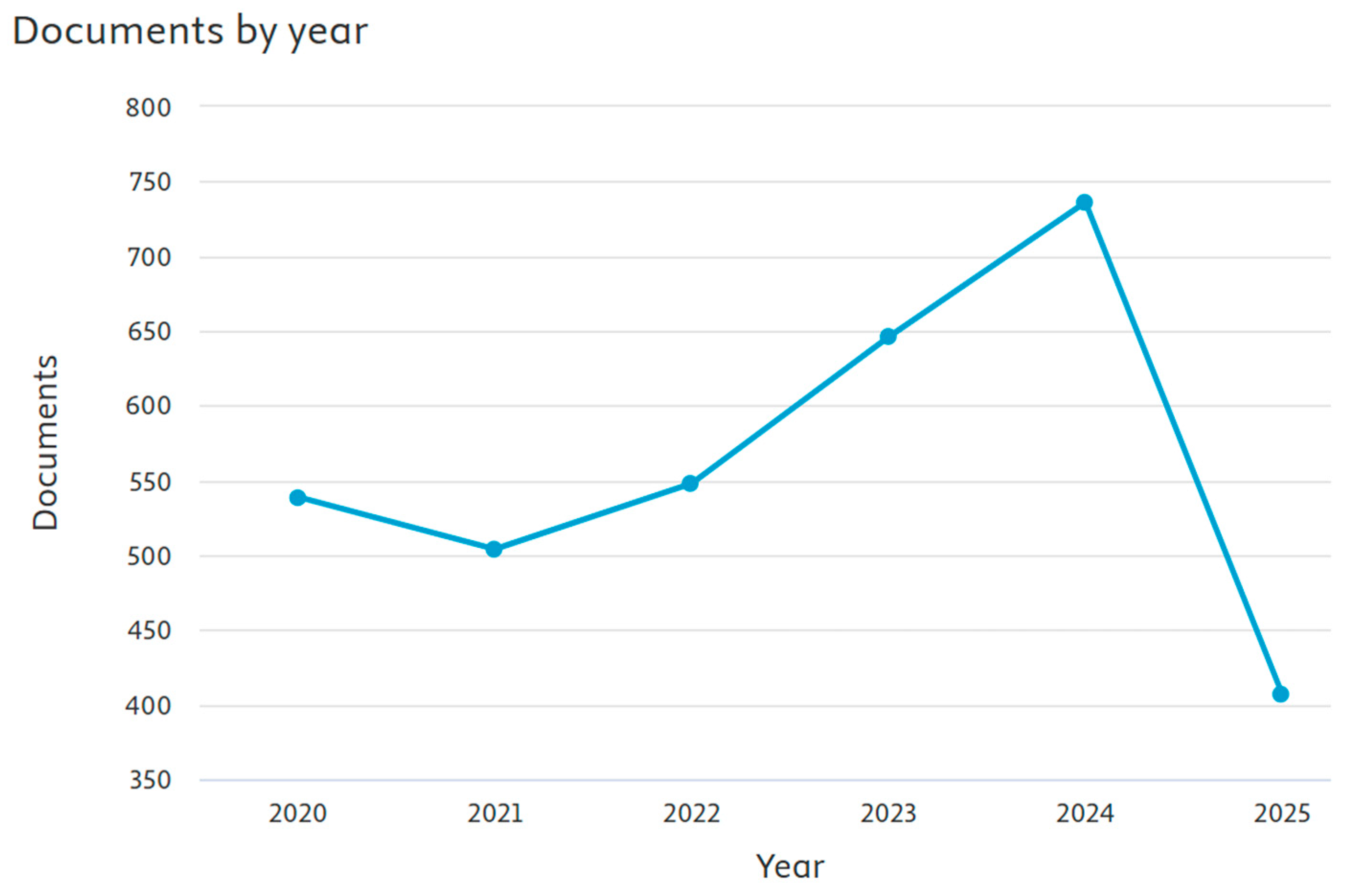

4.1. Trends in Volume of Publications

In this section, we try to explore answers for RQ2. The volume of research publications that are published on a research theme showcases the interest of the scientific community in it. The study of lattice structures has experienced substantial growth during the past few years and created interest in research in the arrangement of particles in crystalline materials, as seen in

Figure 11. The recent surge in electric mobility, safety equipment, and military technology has created renewed interest in materials that will consume much energy and yet serve the same purpose. These materials should have the properties of lightweight, low density, and high energy absorption for crashworthiness, vibration damping, and blast protection applications.

The output increased from almost 1 publication in the year 2020 to over 50 publications in 2022, before it peaked to over 150 publications in the year 2024. There has been a sudden rise in interest in lattice structures owing to their widespread use for different applications [

103]. Particular focus has been on enhancing the design and functionality of low-rise buildings [

104]. This has paved the way for new meta materials that enable customizable multifunctionality [

105].

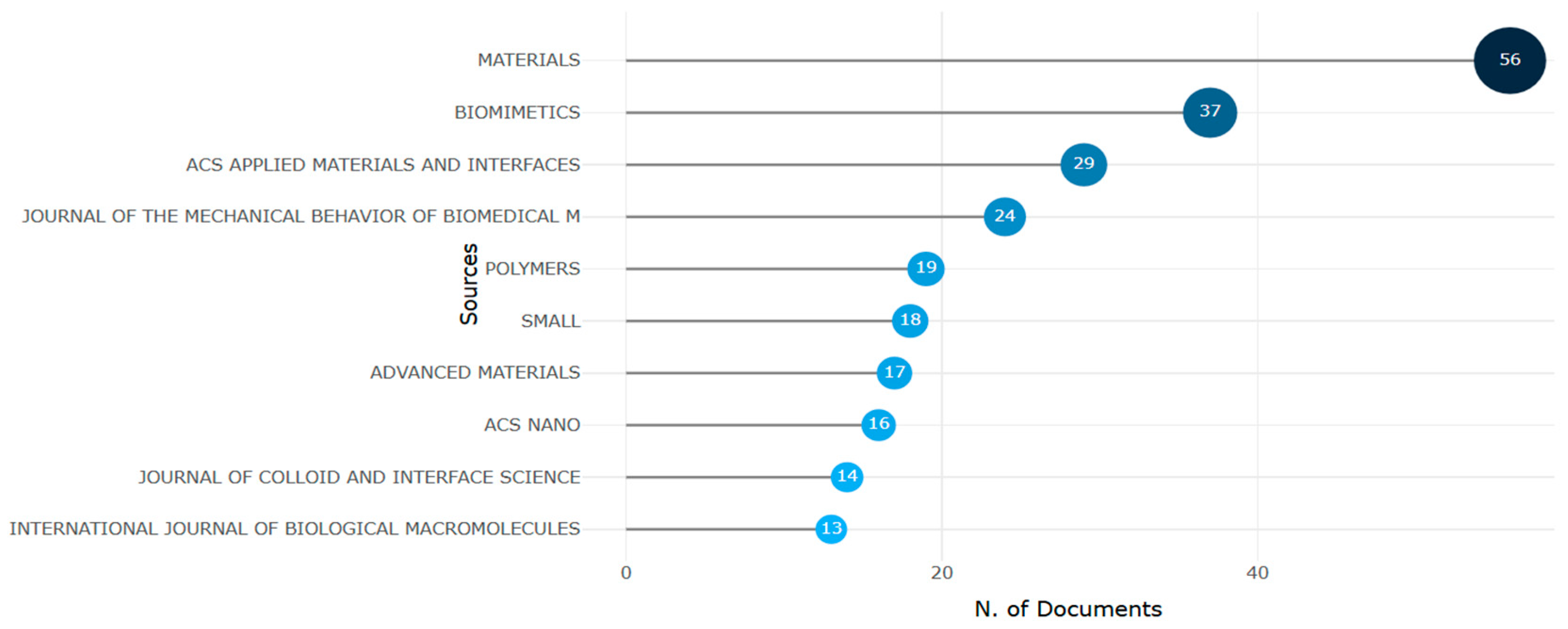

4.2. Sources of Publications

Academic publishers such as Taylor & Francis, Elsevier, Sage, MDPI, and Springer Link publish several high-impact-factor journals after a rigorous peer review process to ensure the scientific soundness, clarity, and novelty of the results. In

Figure 12,

Figure 13,

Figure 14,

Figure 15,

Figure 16,

Figure 17,

Figure 18,

Figure 19,

Figure 20,

Figure 21,

Figure 22,

Figure 23,

Figure 24,

Figure 25,

Figure 26,

Figure 27,

Figure 28,

Figure 29,

Figure 30,

Figure 31,

Figure 32,

Figure 33 and

Figure 34, we try to answer RQ3.

The results of the analysis of the data from Bibliometrix (

Figure 12) confirm that the Materials journal, with 56 publications, was the most promising in this research theme. It was followed by Biomimetics (about 37 articles), ACS Applied Materials and Interfaces (29 articles), Journal of Mechanical Behavior of Biomedical Materials (24 articles), and Small (18 articles).

Table 5 provides more details about the top journals publishing research on this theme.

With an impact factor of 8.851, the Journal of Advanced Materials had the highest SJR score.

Figure 13.

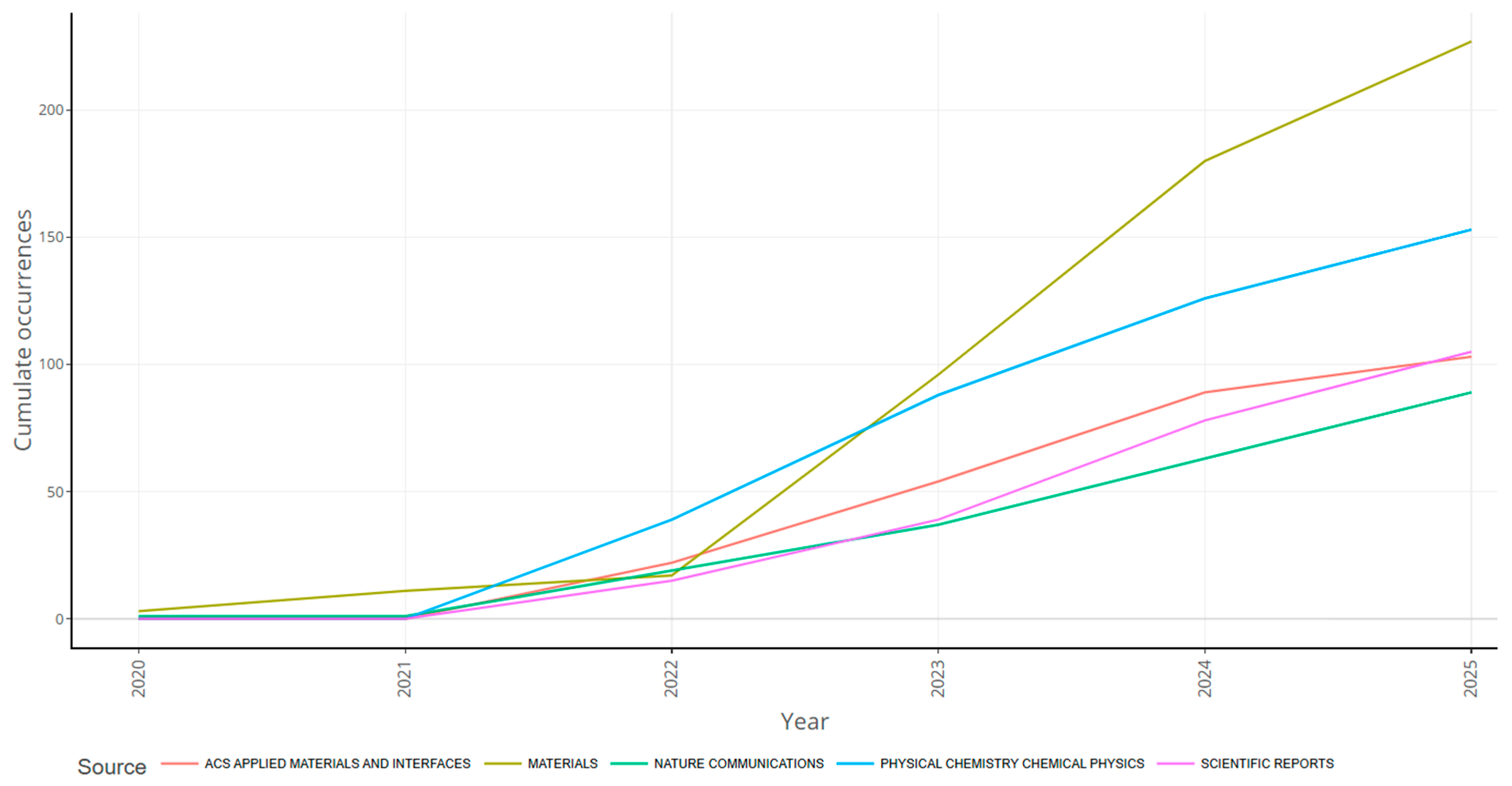

Cumulative production rate in the number of publications (retrieved from Bibliometrix on 7 June 2025).

Figure 13.

Cumulative production rate in the number of publications (retrieved from Bibliometrix on 7 June 2025).

The Journal of Mechanical Behavior of Biomedical Materials is also one of the pioneering sources that focuses on the deformations, damage, and failure of biological materials, with a top Q rank in SJR. With a cumulative publication frequency of over 200 during the last 5 years in a volume of publications (as seen in

Figure 13), this journal (Materials) showed promising trends.

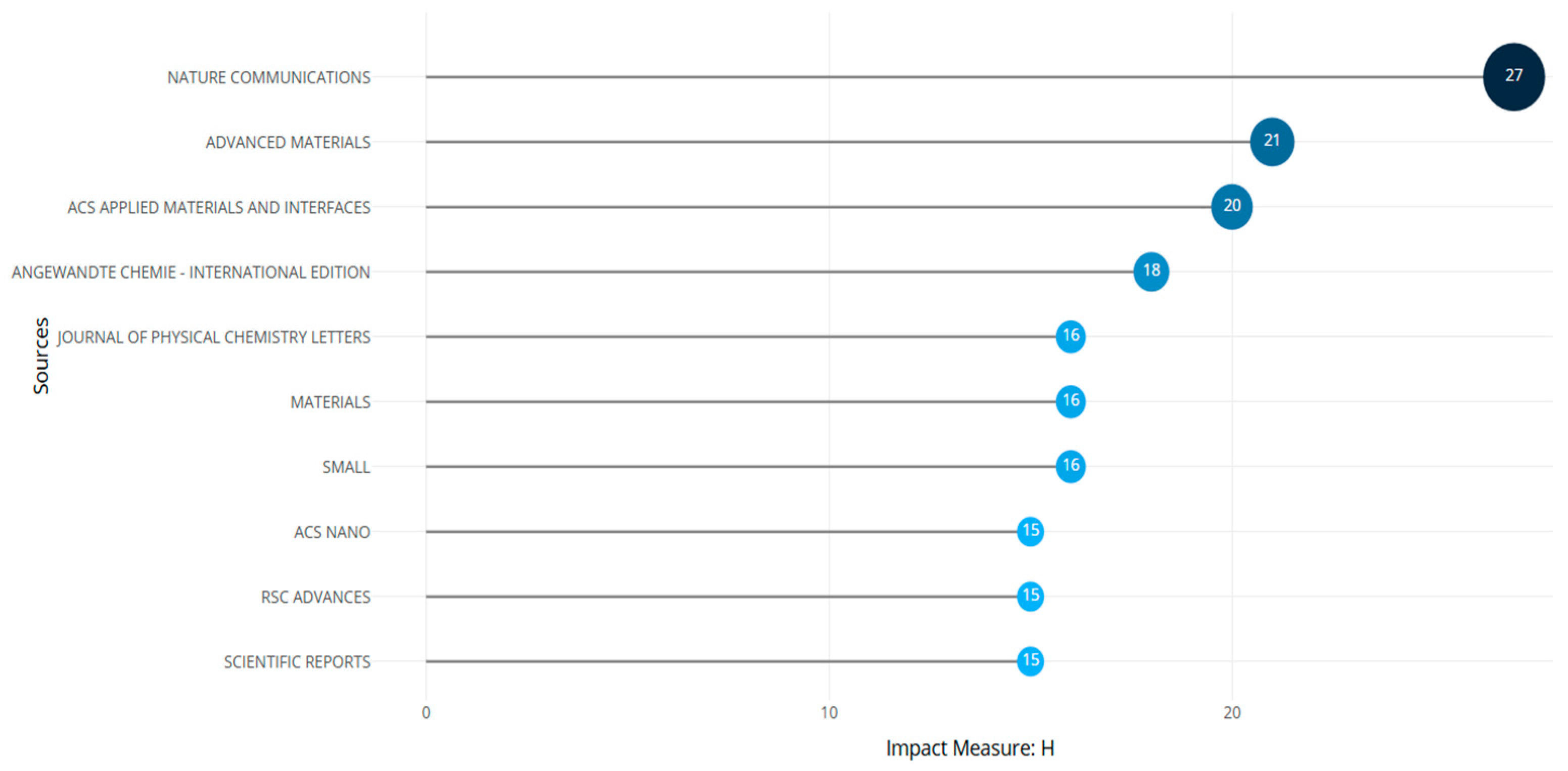

Figure 14.

Local impact factors of sources (retrieved from Bibliometrix on 7 June 2025).

Figure 14.

Local impact factors of sources (retrieved from Bibliometrix on 7 June 2025).

The productivity, impact, and visibility in the scholarly field of a journal are defined by different indicators. Some of these include H and g indices. The local H index of a journal indicates the H number of published articles that are cited at least H times by the local network. The g-index measures the citation performance for a set of articles published in a journal. With a local H factor of 27 and a g factor of 51, the Nature Communications journal was found to be the most prominent source of publication. This was followed by Advanced Materials (H index 21), ACS Applied Materials, Interfaces (H index 20), and Angewandte Chemie (H index 18).

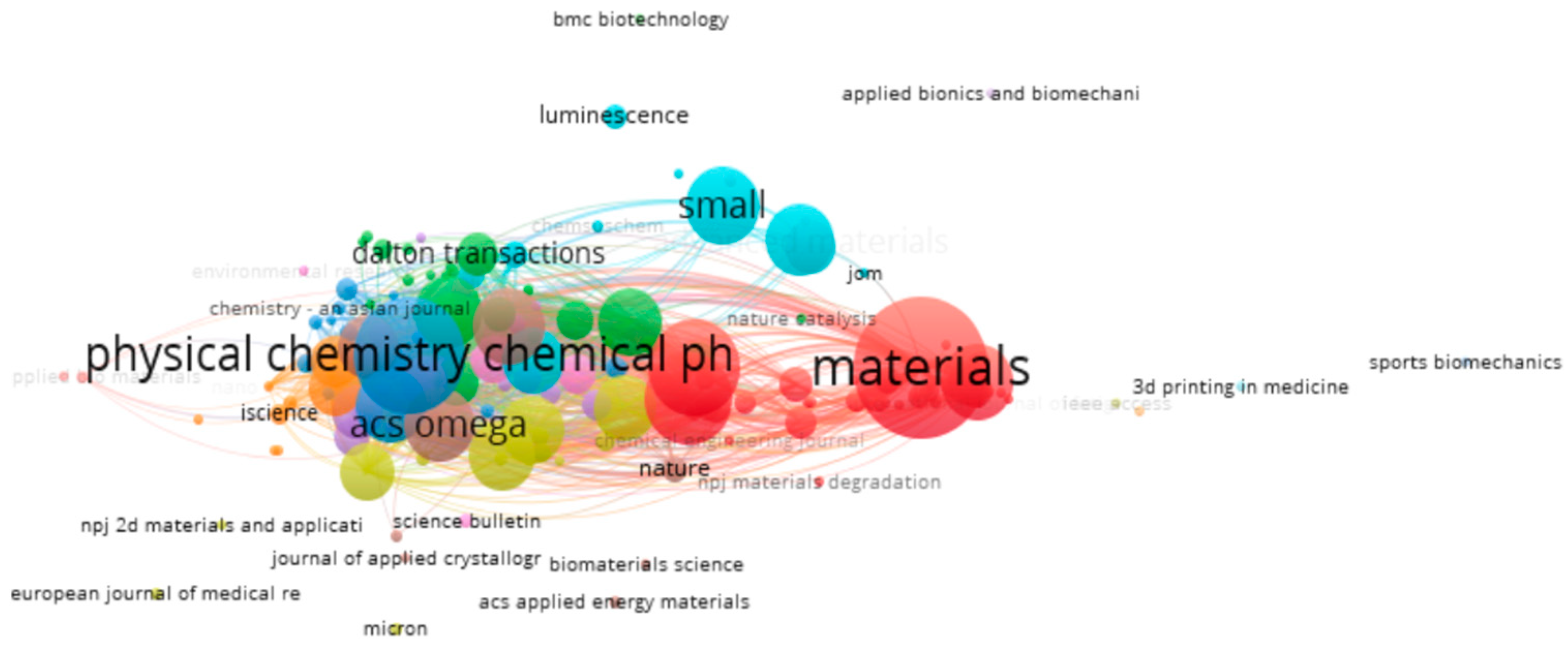

The coupling in bibliometric analysis is used to measure similarity in citations, which could be used to establish a relationship between two documents. Bibliographic coupling takes place when two works cite a common reference in their bibliographies.

Figure 15.

Bibliometric coupling between various journals (retrieved from VOS Viewer on 7 June 2025).

Figure 15.

Bibliometric coupling between various journals (retrieved from VOS Viewer on 7 June 2025).

Figure 15 provides an overview of coupling visualization for various sources. Each source is shown as a circular node, with its size showing its citation count. Sixteen clusters with 4111 links having a strength of 15,1967 connecting 184 items were identified, taking a threshold of one document from one source. Sixty-five journals out of a list of 192 were found to satisfy this threshold. More information about these clusters can be found in

Table 6.

4.3. Publication Subject

Data analysis conducted on the subject of articles is presented in

Figure 16. Materials science-related disciplines account for the largest percentage of about 23.4%, followed by Chemistry of 22.7%, Physics and Astronomy (16.6%), Chemical Engineering (10.9%), and Biochemistry (6.7%). Further, 11 cluster groups were identified from

Figure 14 based on the subject classifications.

Figure 16.

Percentage of publications based on subject area.

Figure 16.

Percentage of publications based on subject area.

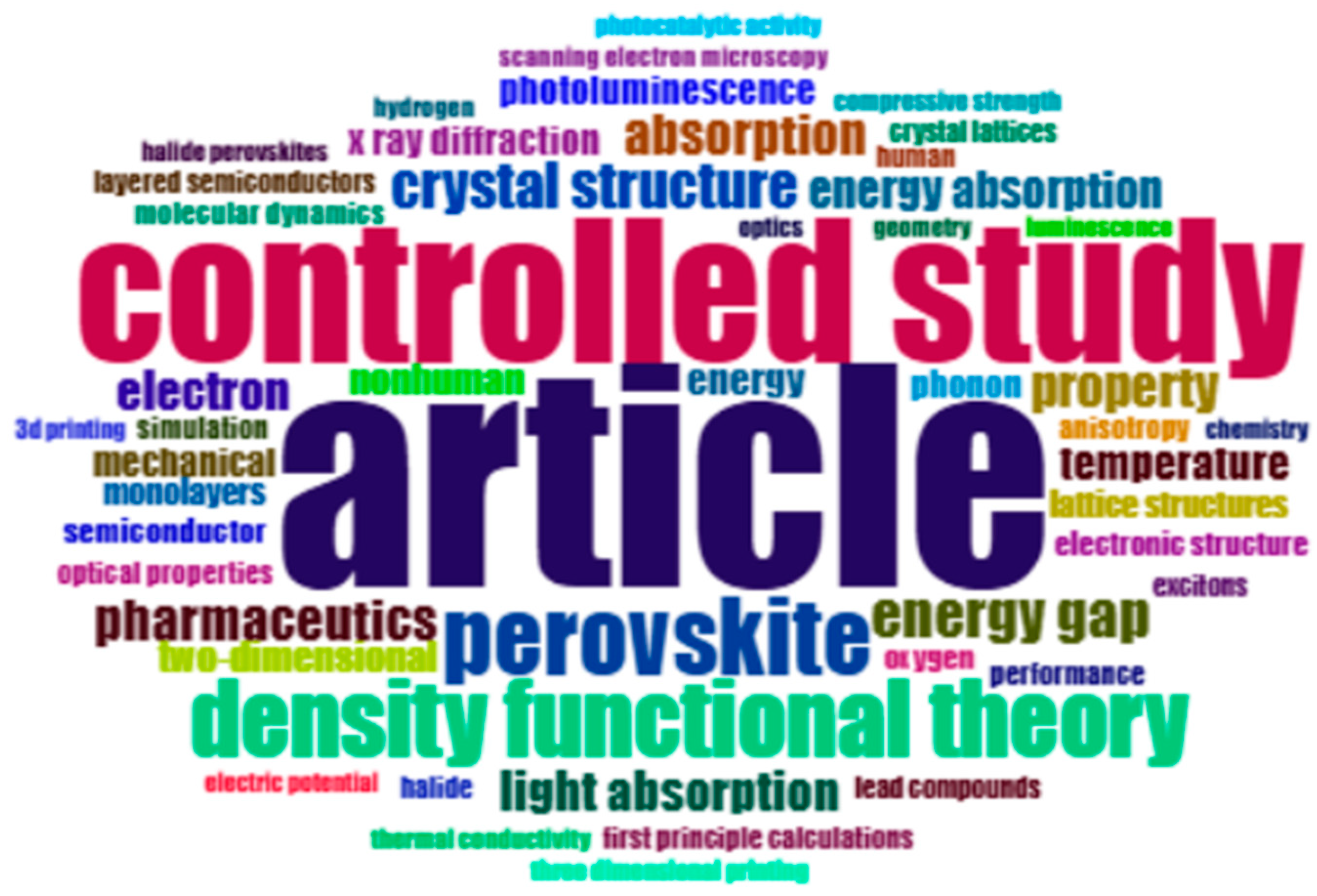

Figure 17.

Word cloud based on keywords of works (retrieved from Bibliometrix on 7 June 2025).

Figure 17.

Word cloud based on keywords of works (retrieved from Bibliometrix on 7 June 2025).

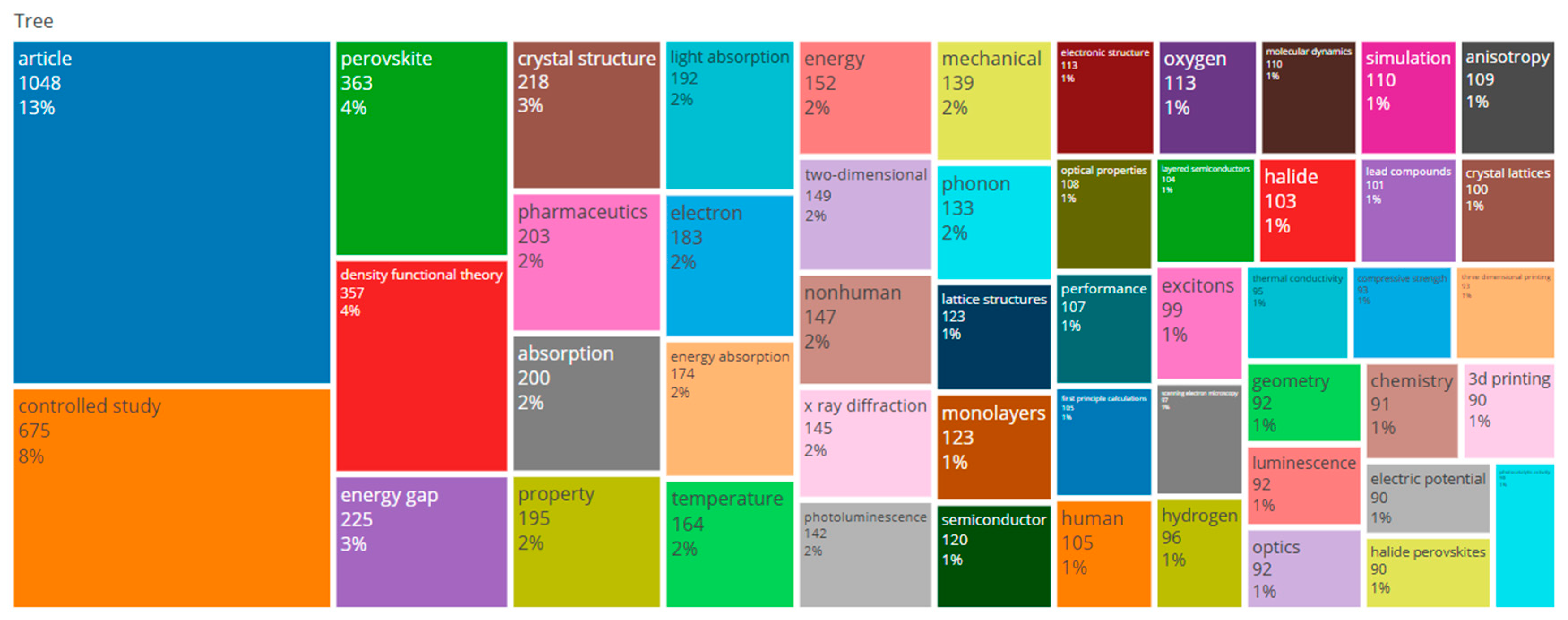

Figure 18.

Tree map of keywords (retrieved from Bibliometrix on 7 June 2025).

Figure 18.

Tree map of keywords (retrieved from Bibliometrix on 7 June 2025).

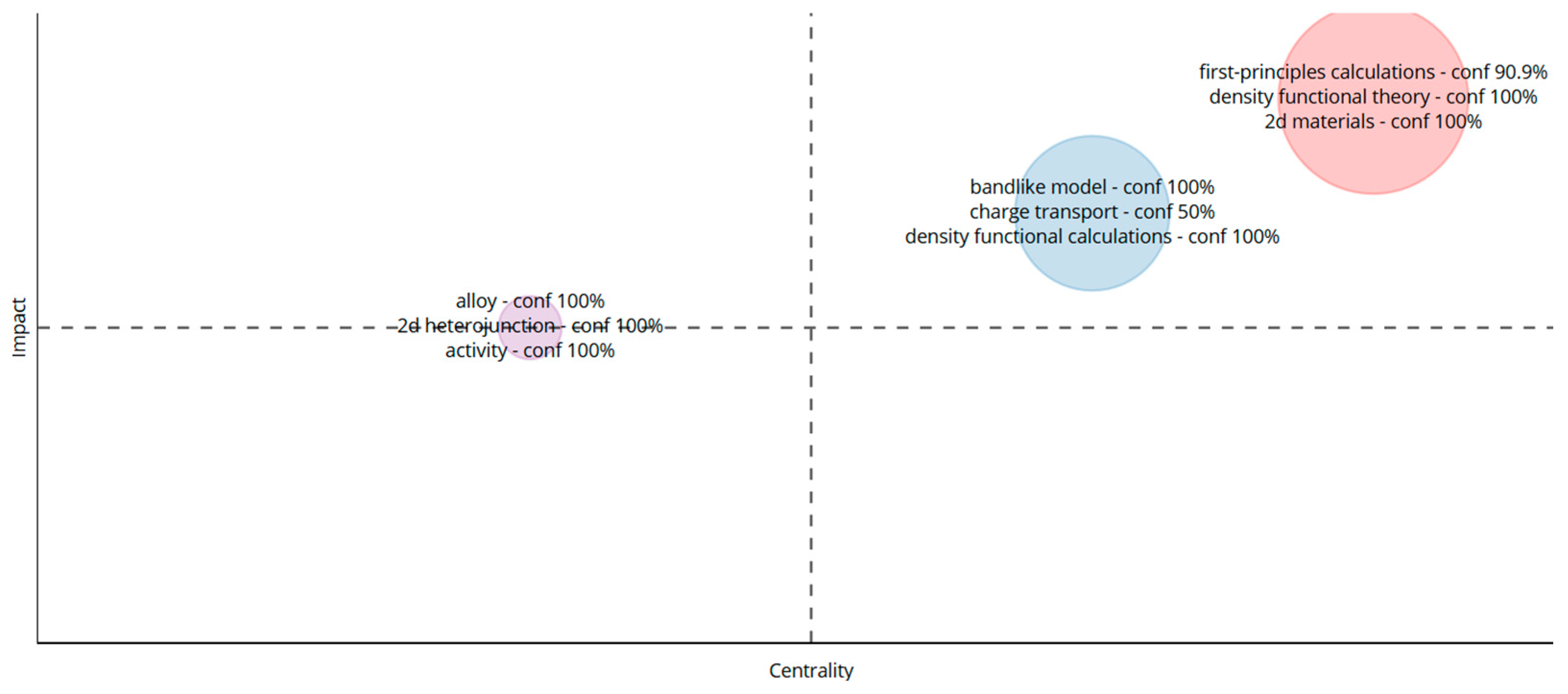

Figure 19.

Matrix of keywords (retrieved from Bibliometrix on 7 June 2025).

Figure 19.

Matrix of keywords (retrieved from Bibliometrix on 7 June 2025).

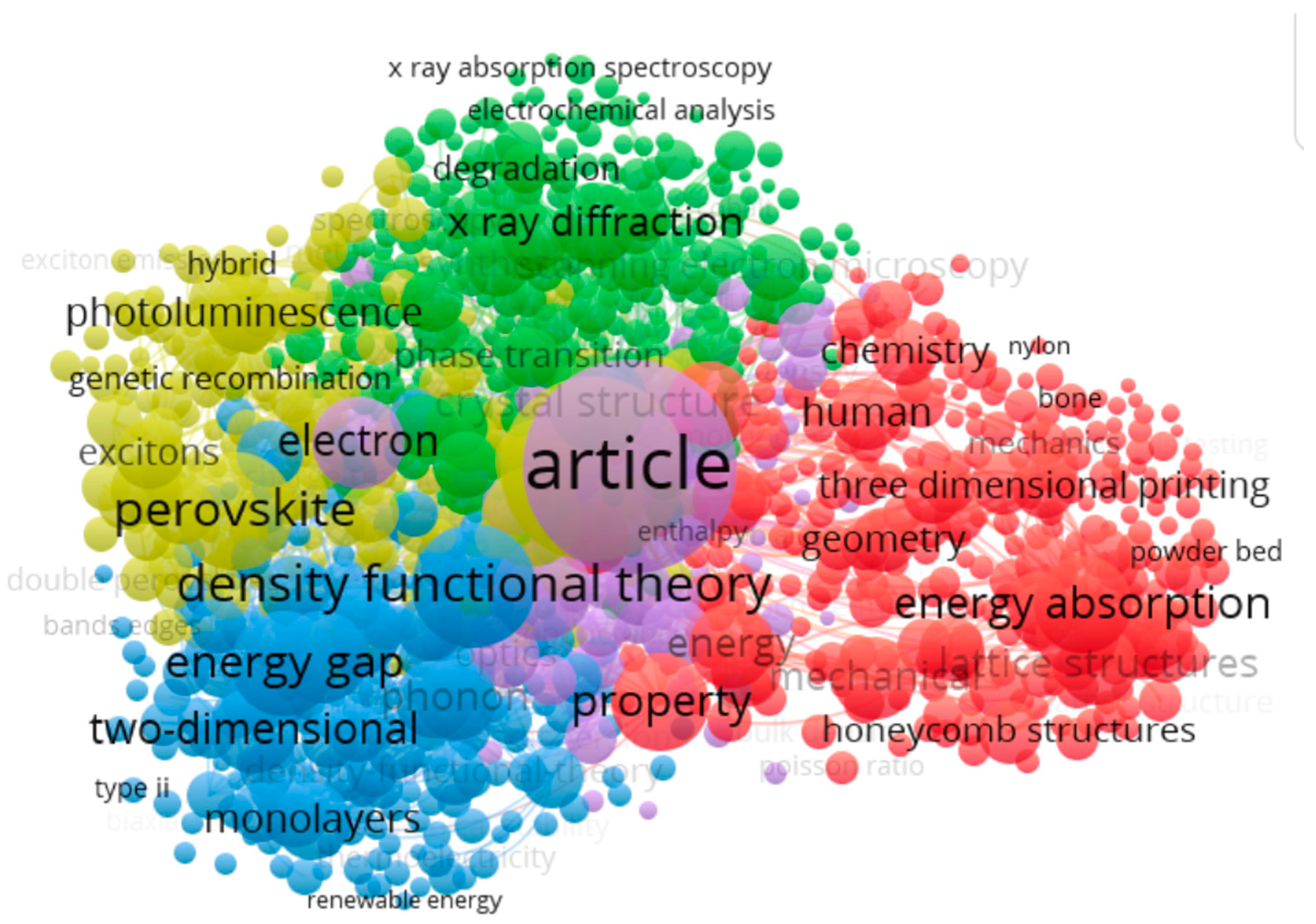

Figure 20.

Bibliometric coupling between the co-occurrence of various keywords (retrieved from VOS Viewer on 7 June 2025).

Figure 20.

Bibliometric coupling between the co-occurrence of various keywords (retrieved from VOS Viewer on 7 June 2025).

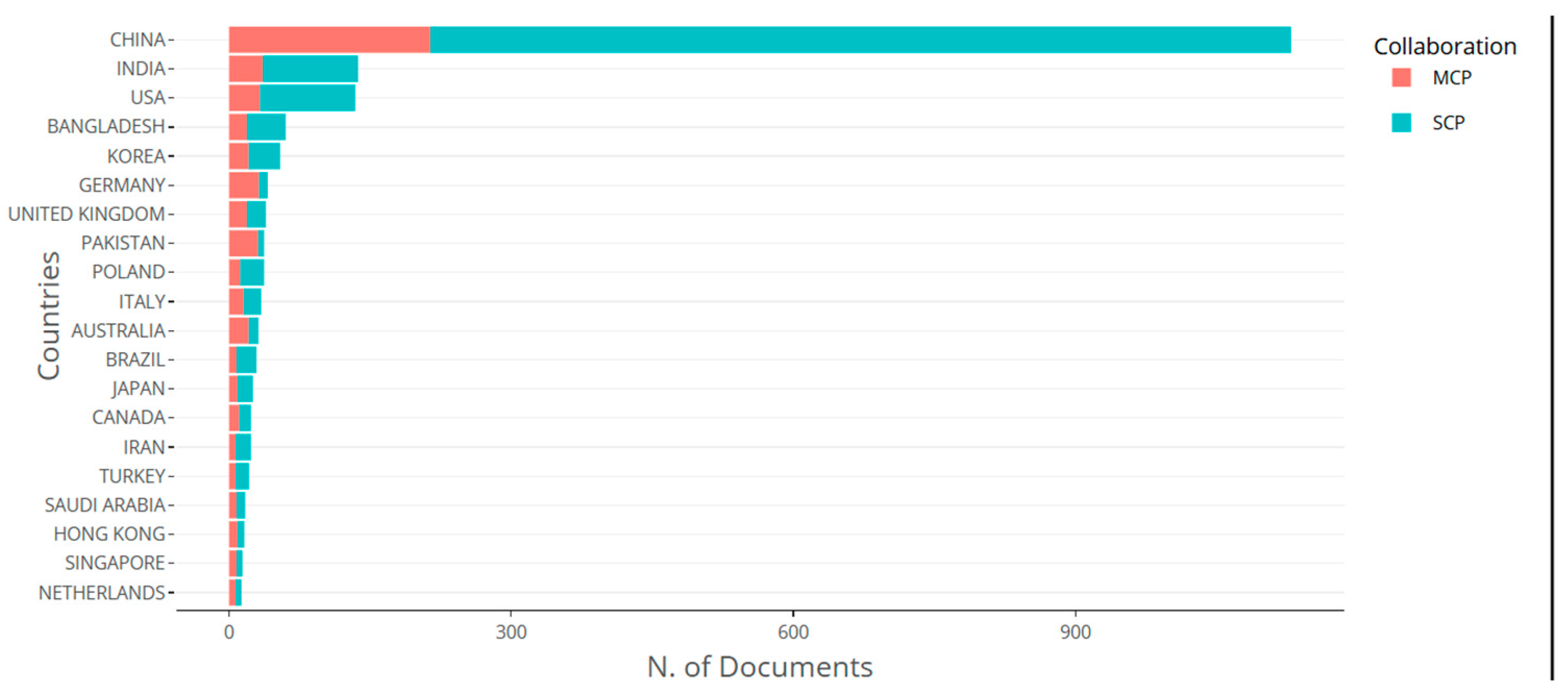

Figure 21.

Country of origin of publications (retrieved from Bibliometrix on 7 June 2025).

Figure 21.

Country of origin of publications (retrieved from Bibliometrix on 7 June 2025).

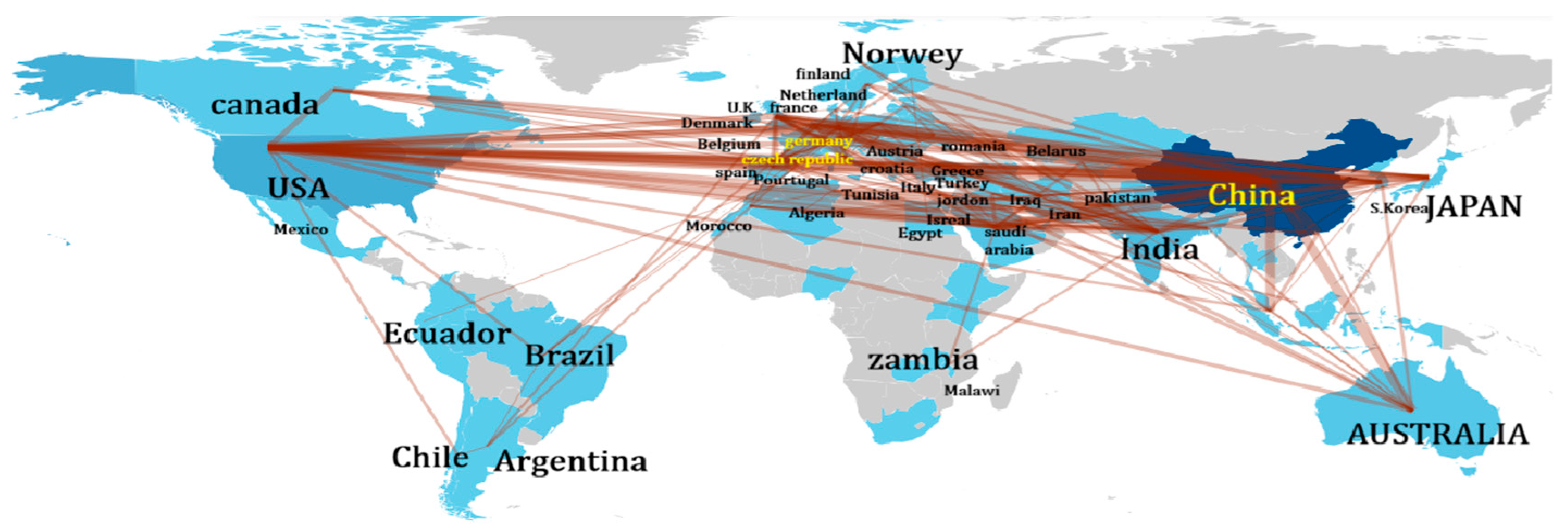

Figure 22.

Collaboration network between various nations (retrieved from Bibliometrix on 7 June 2025).

Figure 22.

Collaboration network between various nations (retrieved from Bibliometrix on 7 June 2025).

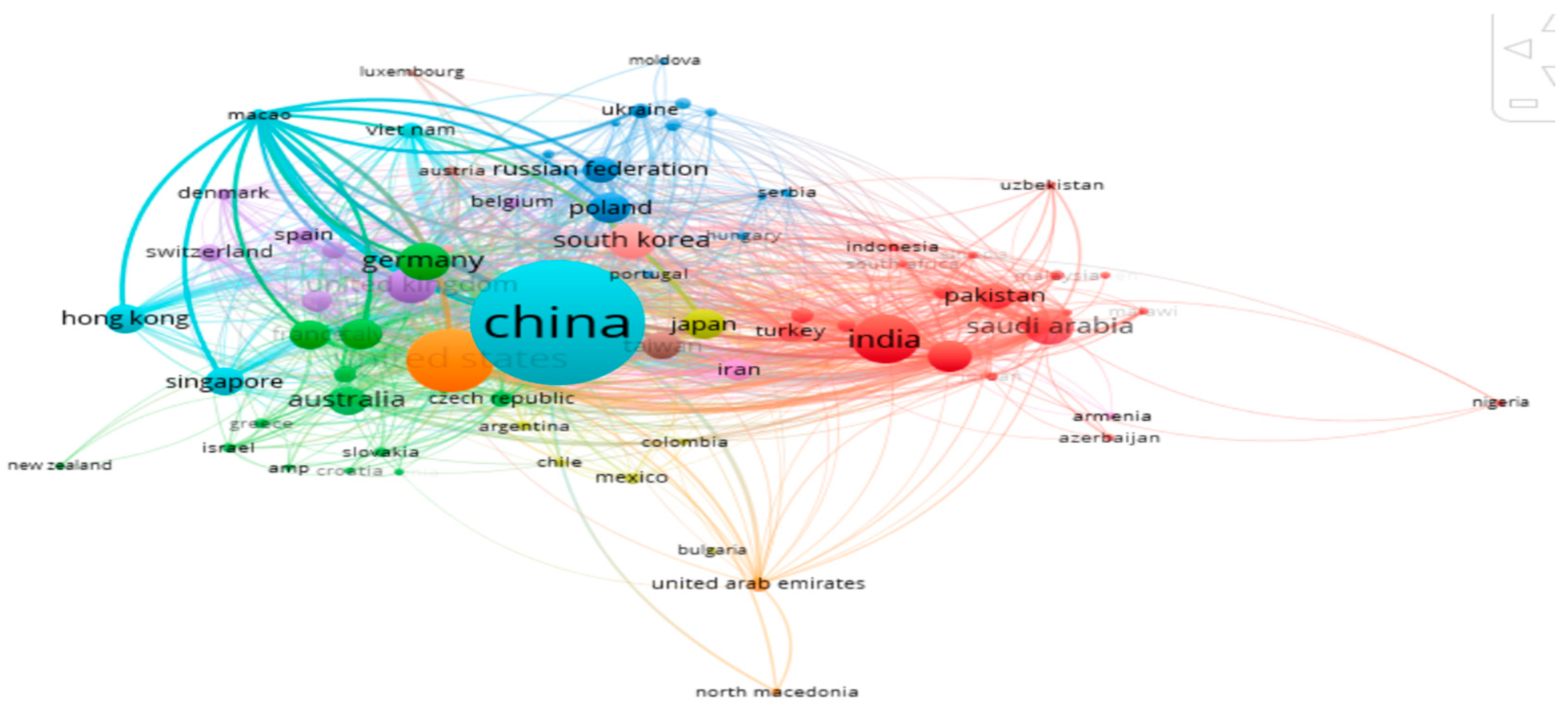

Figure 23.

Bibliometric coupling between various nations of origin of articles (retrieved from VOS on 7 June 2025).

Figure 23.

Bibliometric coupling between various nations of origin of articles (retrieved from VOS on 7 June 2025).

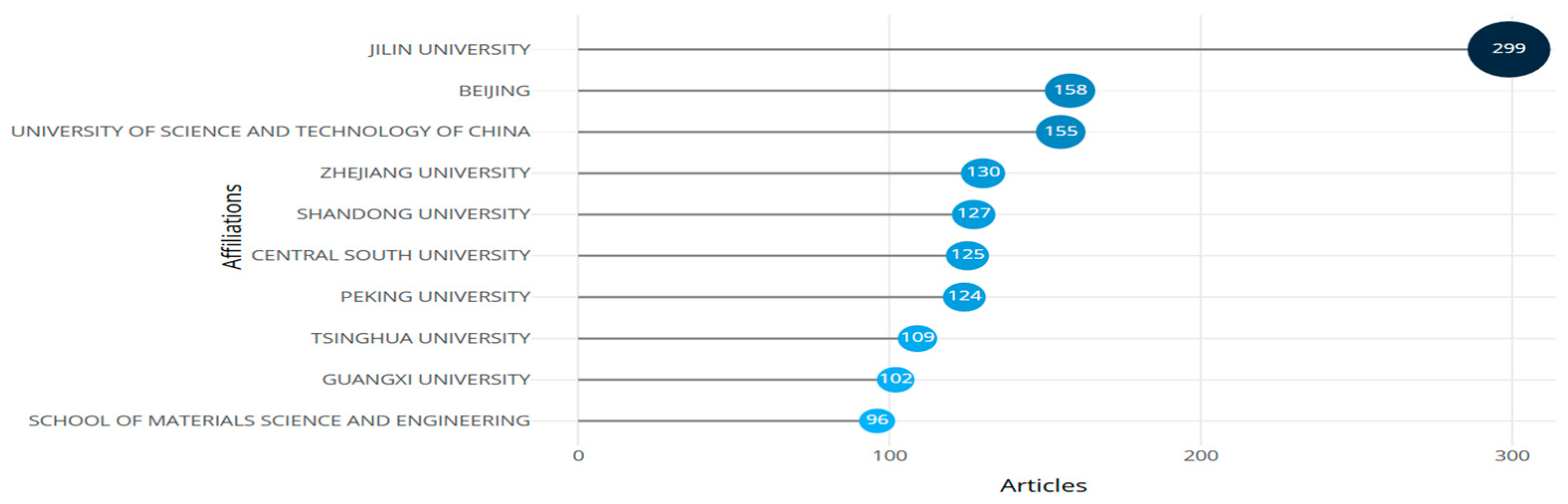

Figure 24.

Trends of prominent affiliating institutions of publications (retrieved from Bibliometrix on 7 June 2025).

Figure 24.

Trends of prominent affiliating institutions of publications (retrieved from Bibliometrix on 7 June 2025).

Figure 25.

Bibliometric coupling between various affiliating institutions (retrieved from VOS Viewer on 7 June 2025).

Figure 25.

Bibliometric coupling between various affiliating institutions (retrieved from VOS Viewer on 7 June 2025).

Figure 26.

Most prominent funding bodies of publications (retrieved on 7 June 2025 from Scopus).

Figure 26.

Most prominent funding bodies of publications (retrieved on 7 June 2025 from Scopus).

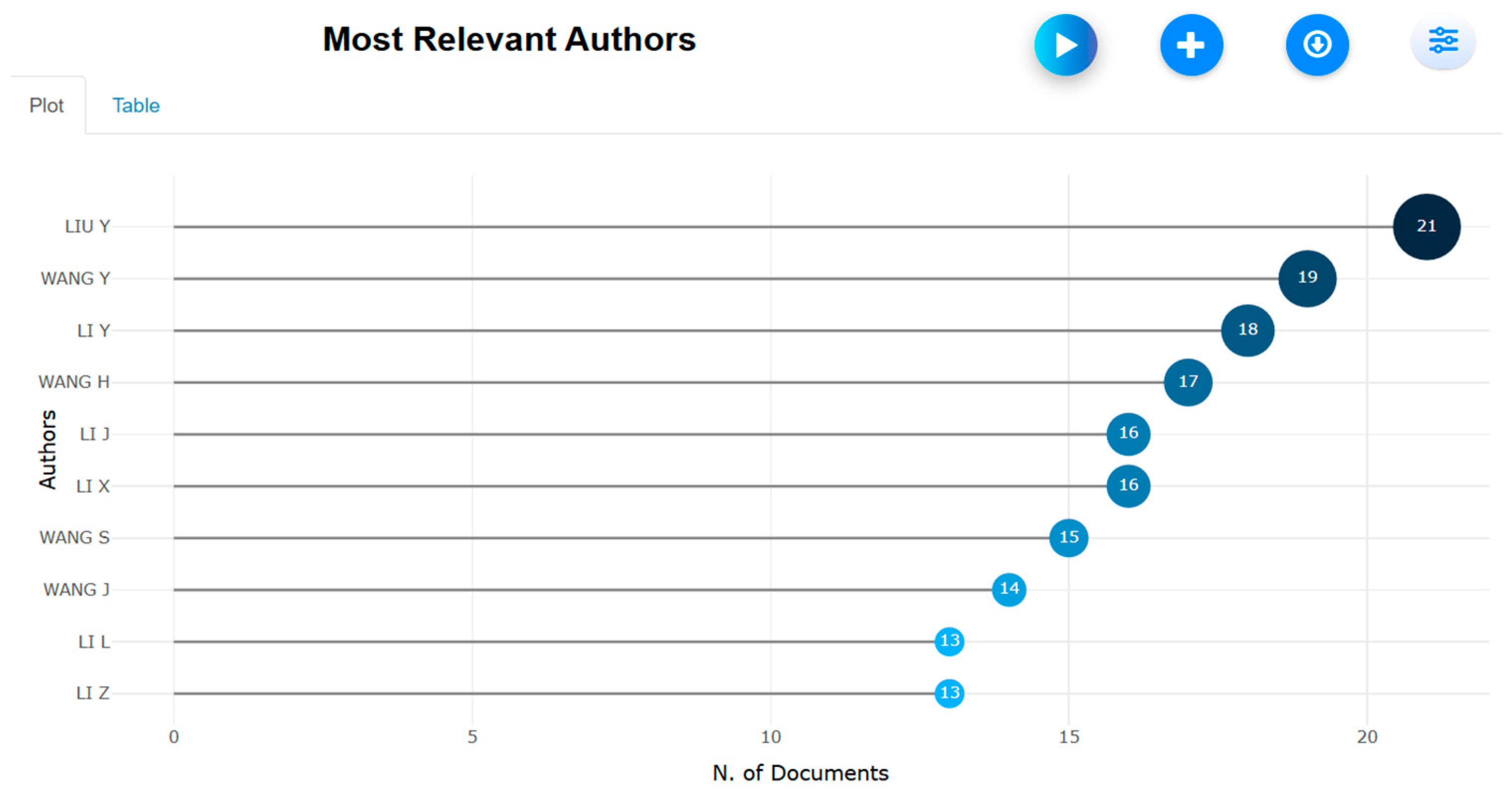

Figure 27.

Most prominent authors (retrieved from Bibliometrix on 7 June 2025).

Figure 27.

Most prominent authors (retrieved from Bibliometrix on 7 June 2025).

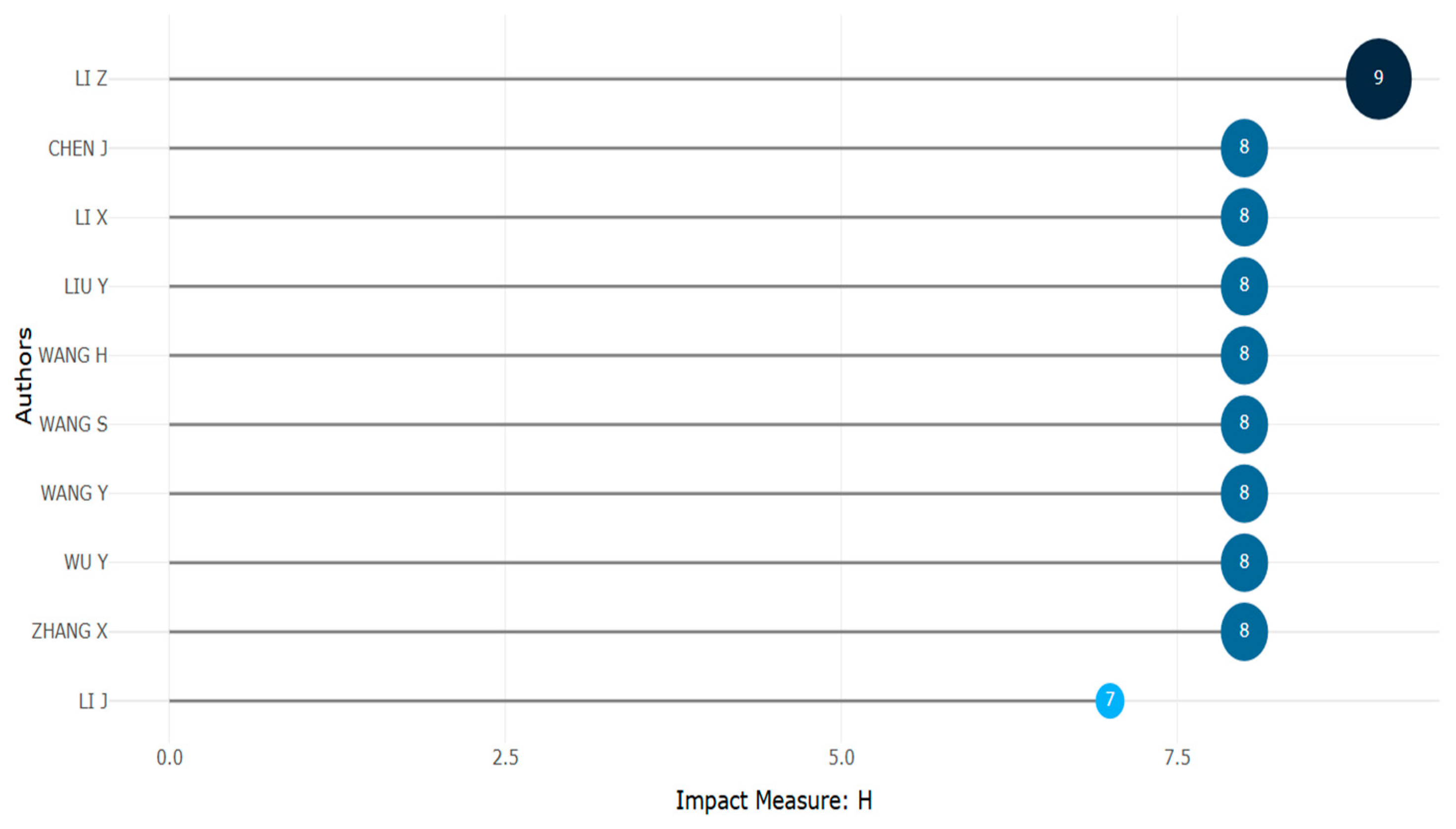

Figure 28.

Local impact factor of authors (retrieved from Bibliometrix on 7 June 2025).

Figure 28.

Local impact factor of authors (retrieved from Bibliometrix on 7 June 2025).

Figure 29.

Number of citations for articles (retrieved from Bibliometrix on 7 June 2025).

Figure 29.

Number of citations for articles (retrieved from Bibliometrix on 7 June 2025).

Figure 30.

Country of origin citing the articles (retrieved from Bibliometrix on 7 June 2025).

Figure 30.

Country of origin citing the articles (retrieved from Bibliometrix on 7 June 2025).

Figure 31.

Most prominent globally cited documents with H index (retrieved from Bibliometrix on 7 June 2025).

Figure 31.

Most prominent globally cited documents with H index (retrieved from Bibliometrix on 7 June 2025).

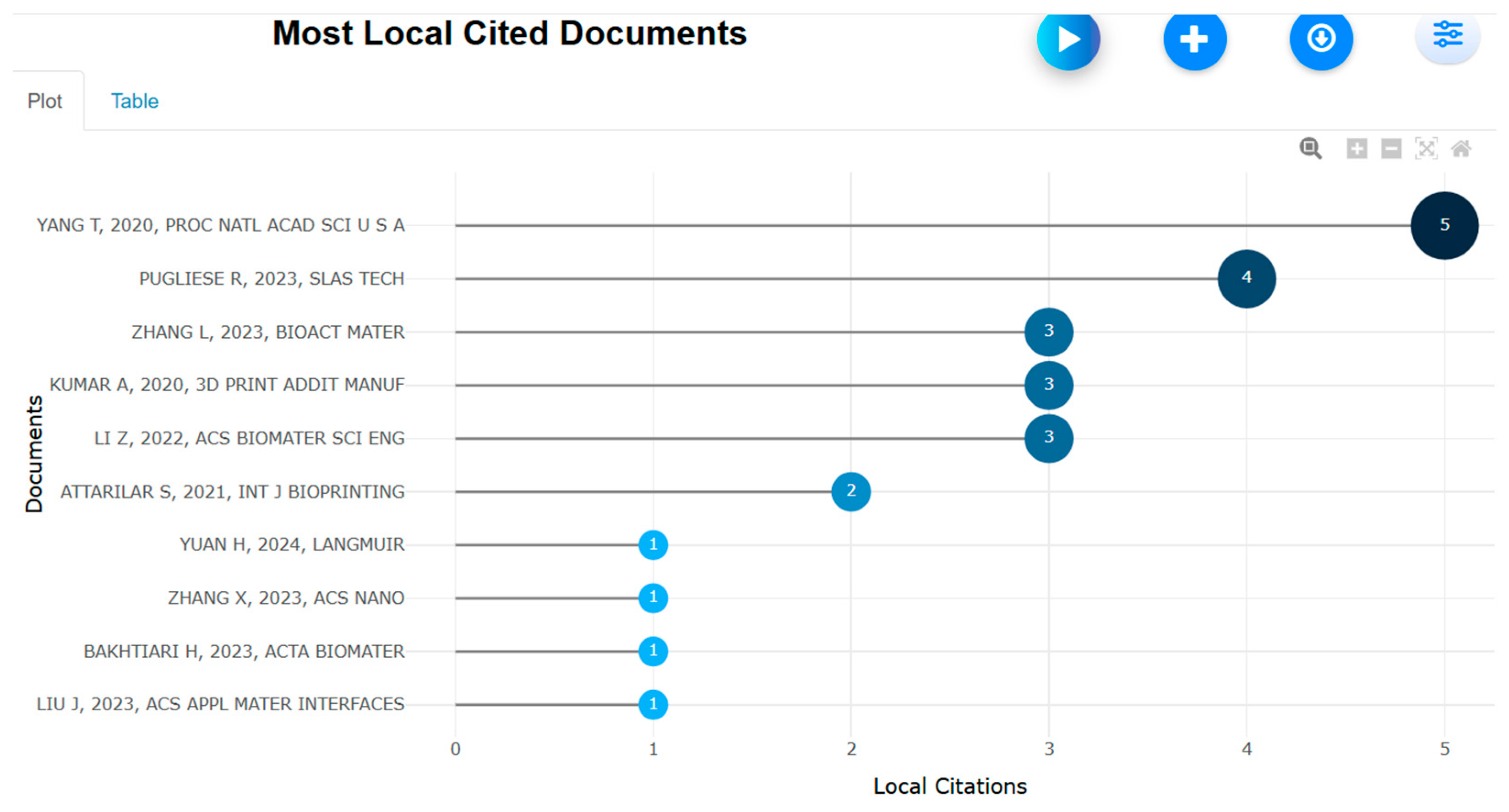

Figure 32.

Most prominent locally cited documents with H index (retrieved from Bibliometrix on 7 June 2025).

Figure 32.

Most prominent locally cited documents with H index (retrieved from Bibliometrix on 7 June 2025).

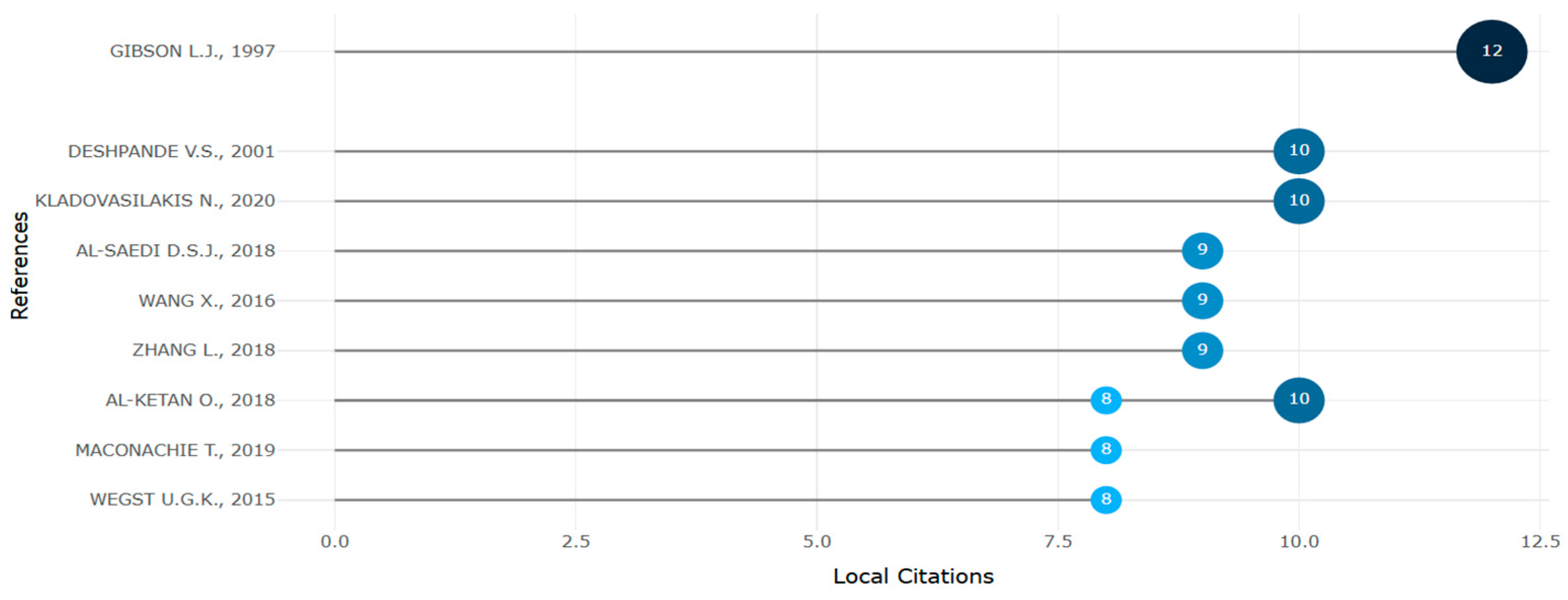

Figure 33.

Most prominent locally cited references (retrieved from Bibliometrix on 7 June 2025).

Figure 33.

Most prominent locally cited references (retrieved from Bibliometrix on 7 June 2025).

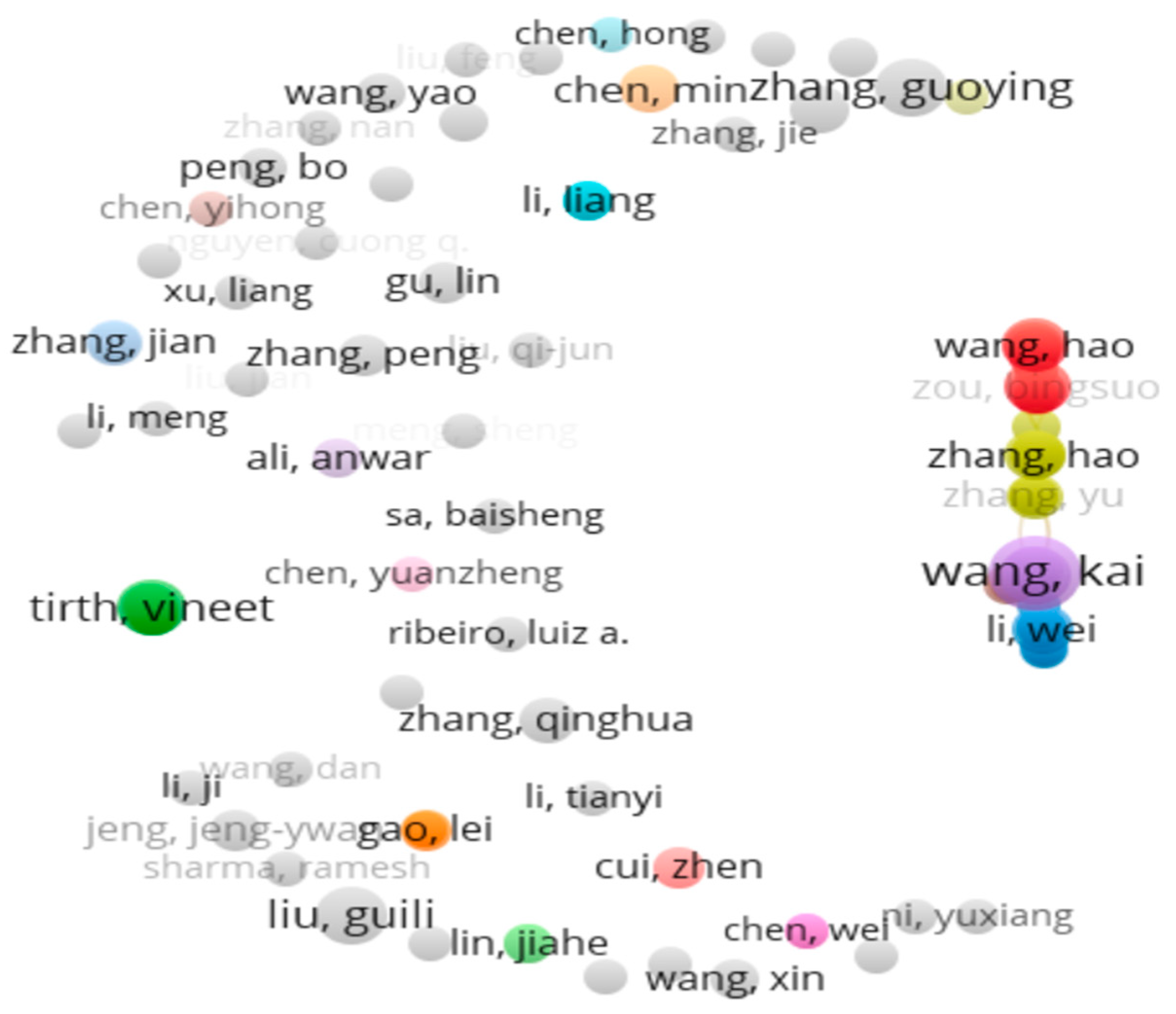

Figure 34.

Co-citation network of authors (retrieved from VOS on 7 June 2025).

Figure 34.

Co-citation network of authors (retrieved from VOS on 7 June 2025).

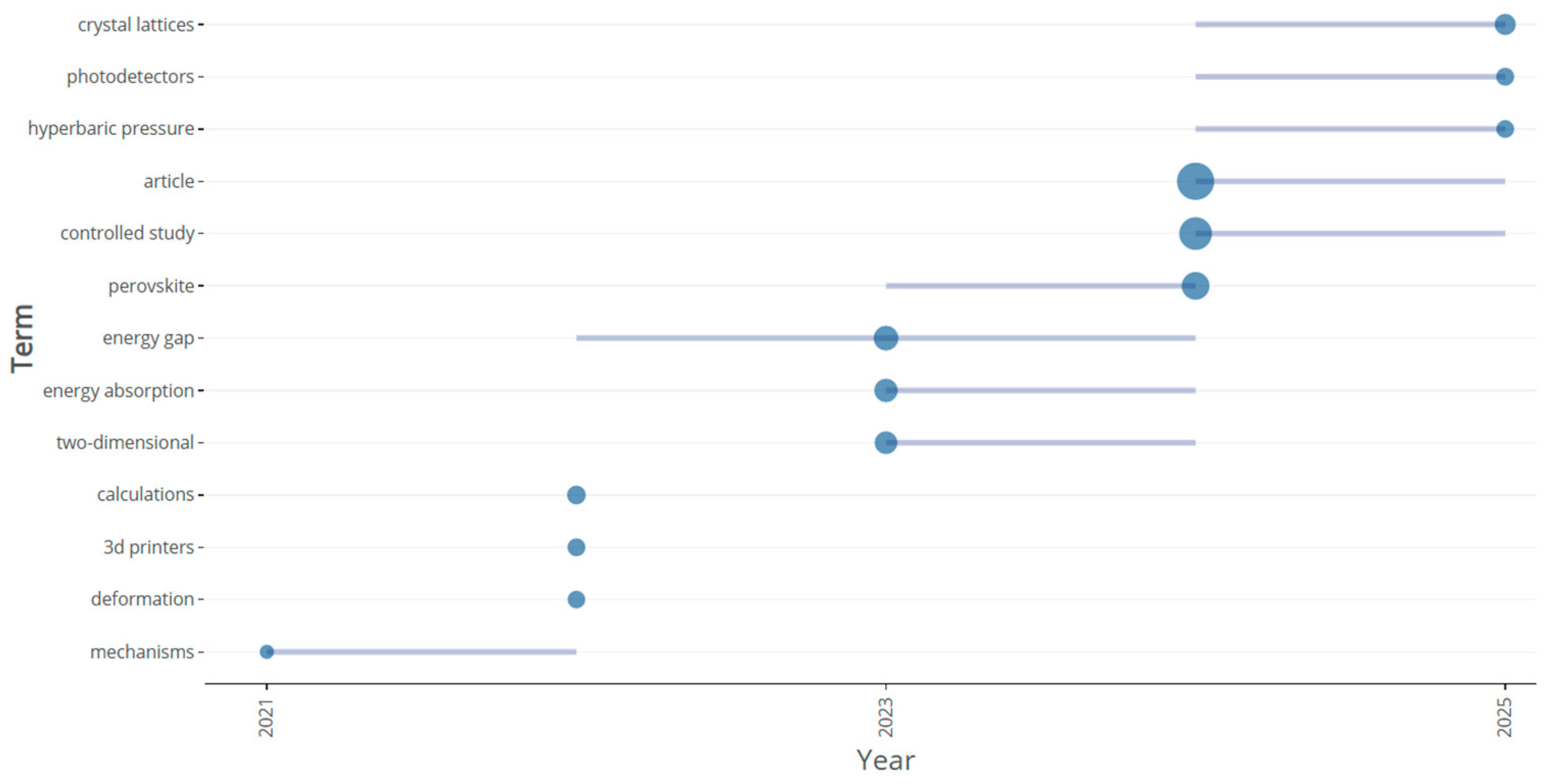

4.4. Occurrence of Keywords

The inclusion of keywords relates to the academic writing of a research work. These words ensure the clarity and ease of visibility of an article for wider audiences.

The analysis of the keywords in

Figure 16 and

Figure 17 shows that some words with higher fonts and unique colors had higher density and frequency of use as compared to others. The relevant keywords included density functional theory (4%), controlled study (8%), and perovskite (4%).

A map of keywords from Bibliometrix data can be used to investigate the impact and probability of occurrence of different words.

Based on the results of

Figure 19, we can divide the Bibliometric matrix into four distinct regions. The data reveal three primary research clusters, with key clusters containing the following words: “2D materials”, “Density functional theory”, and “First principal calculations.”

Next, we again used VOS viewer to display the map of keywords, as shown in

Figure 20 and

Table 7. A list of 4866 keywords was found to satisfy the threshold of minimum occurrence of two times.

Each node is a keyword with its size indicating the occurrence. The link between the nodes shows the co-occurrence. Each color represents a cluster, wherein the nodes and links in that cluster can be used to explain the theme of the cluster.

Further, using the cite score, we identified frequently occurring keywords as shown in

Table 8.

4.5. Affiliation of Publications

The study of the affiliation of key authors in the bibliometric analysis is an important factor, as it helps us to examine research output, patterns in authorship, and rankings of the affiliating institution.

In total, 20 countries were highlighted among the 2226 publications on this research (

Figure 8), with China and the USA publishing the most important scientific productions. This dominance of China (over 1000 articles) may be attributed to resources, advanced equipment, and well-established networks of infrastructure.

Figure 22 shows a map of various collaborating nations. Links between China and the USA had a collaboration frequency of 82. This was followed by links of China with Japan and Singapore, with a frequency of 9.

The coupling between various nations is shown in

Figure 23, taking a minimum of 2 documents from each nation. Ten clusters of 80 items were seen, with the cluster related to China in sea-green color being found to be the strongest one.

Figure 24 shows the background of the most prominent authors publishing research on this theme. Jilin University of China, with 299 articles published as its affiliation, was prominent, followed by the University of Beijing (158 articles) and the University of Science and Technology, China (155 articles). China has maintained its position as a global leader, as evident from its 11th rank in the Global Innovation Index of 2025. A 5.3% year-on-year increase in China’s educational expenditure, reaching USD 890 billion in 2023, advanced equipment, and well-established infrastructure networks have been reported [

146].

The bibliometric coupling of affiliating institutions from

Figure 25 identified 17 clusters with 300 items, with a total of 2746 links of strength 4713. The threshold was taken as a maximum of one article from one institution and one article per institution. About 300 institutions were found to meet the threshold, whose details are tabulated in

Table 9.

Analysis of different funding sources of research papers helps us to understand the role of authors in attracting funds and their impact on research and productivity.

Figure 26 shows that the National Science Foundation had funded a maximum number of articles (about 841). The findings support the previously observed trend, as China was observed to have published the most documents.

4.6. Author Profiles

A study of the profiles of key authors in bibliometric analysis helps us to create collaborative map patterns in publications, citations, authors, and institutions.

The results of

Figure 27 and

Figure 28 show the most prominent author profiles. Ten authors participated actively in the research theme; however, surprisingly, only one of those authors published 20 or more papers. With a list of 21 papers and a local impact factor of 8, Y. Liu was found to be the most promising author.

A lower value of H index for the prominent authors highlights the need for improving the global visibility of research publications.

4.7. Citation of Data

The citation of data is an important indicator of the impact of research. The quantity of citations a publication receives is indicative of its influence. The most important publications in a specific field were identified by citation analysis.

Table 2 presents the top 10 highly cited publications in descending order based on the number of citations. With over 565 citations, the work titled “MXene/Polymer Membranes: Synthesis, Properties, and Emerging Applications” published in ACS Chemistry of Materials, was found to be the most cited article [

147]. This article has shown significant collaboration involving Shenzhen University, the Chinese Academy of Science, Drexel University, and Tsinghua University. This publication shows a significant future scope of collaboration in areas of filtration, electromagnetic interference (EMI) shielding, energy storage devices, and wearable electronics.

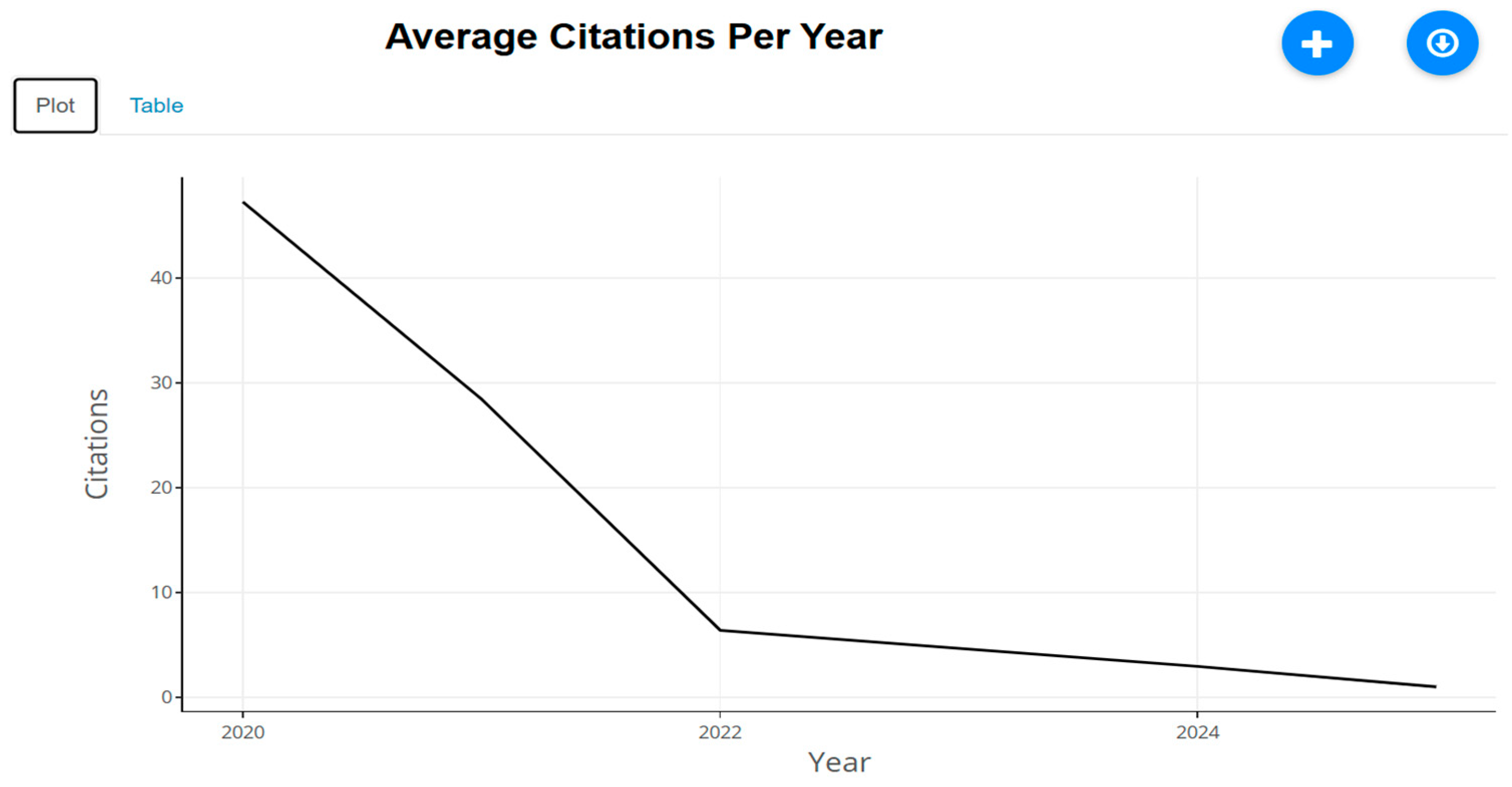

From

Figure 29, it is evident that, after 2022, there has been a notable decrease in the number of citations received for articles. This may be attributed to the disturbance of various academic activities due to pandemic lockdowns.

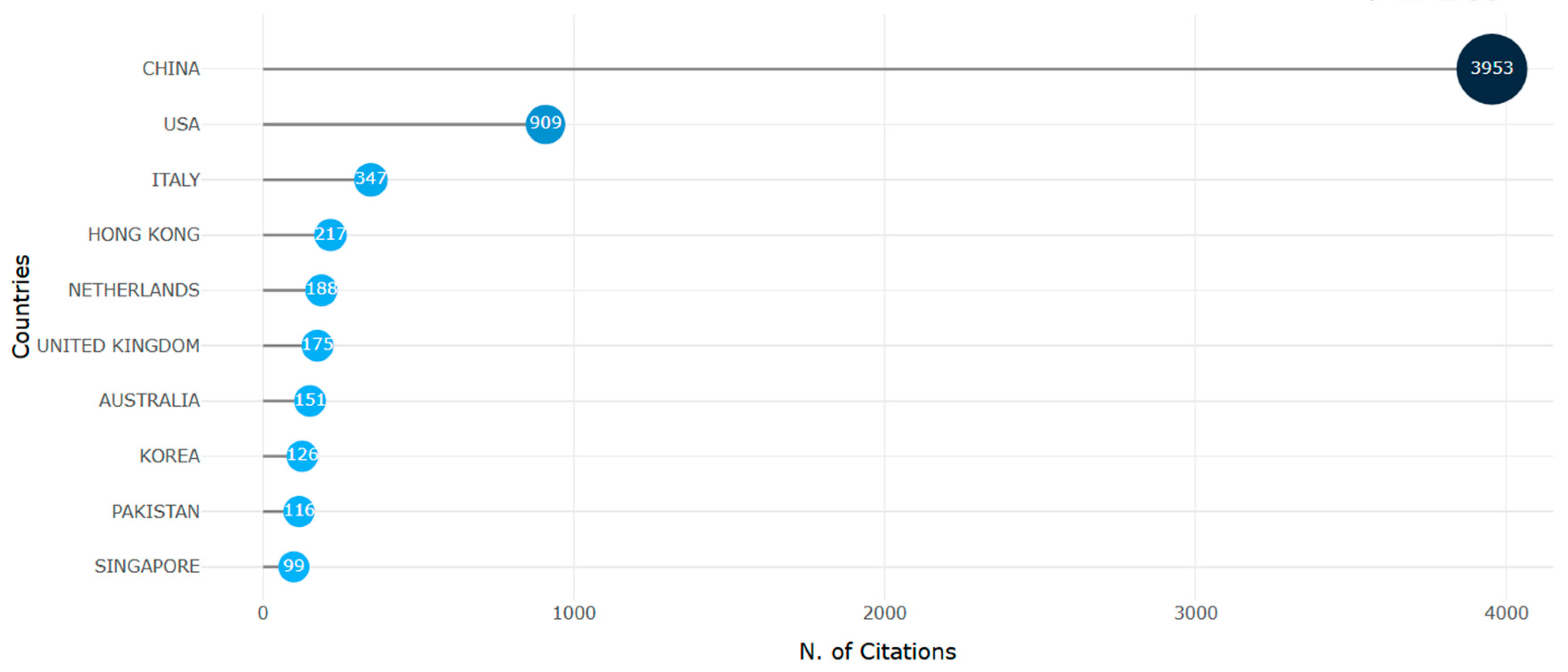

Figure 30 shows that with over 3953 citations, most of the data were cited by Chinese scholars. This emphasizes the need for more international collaborations between China with European and American institutions.

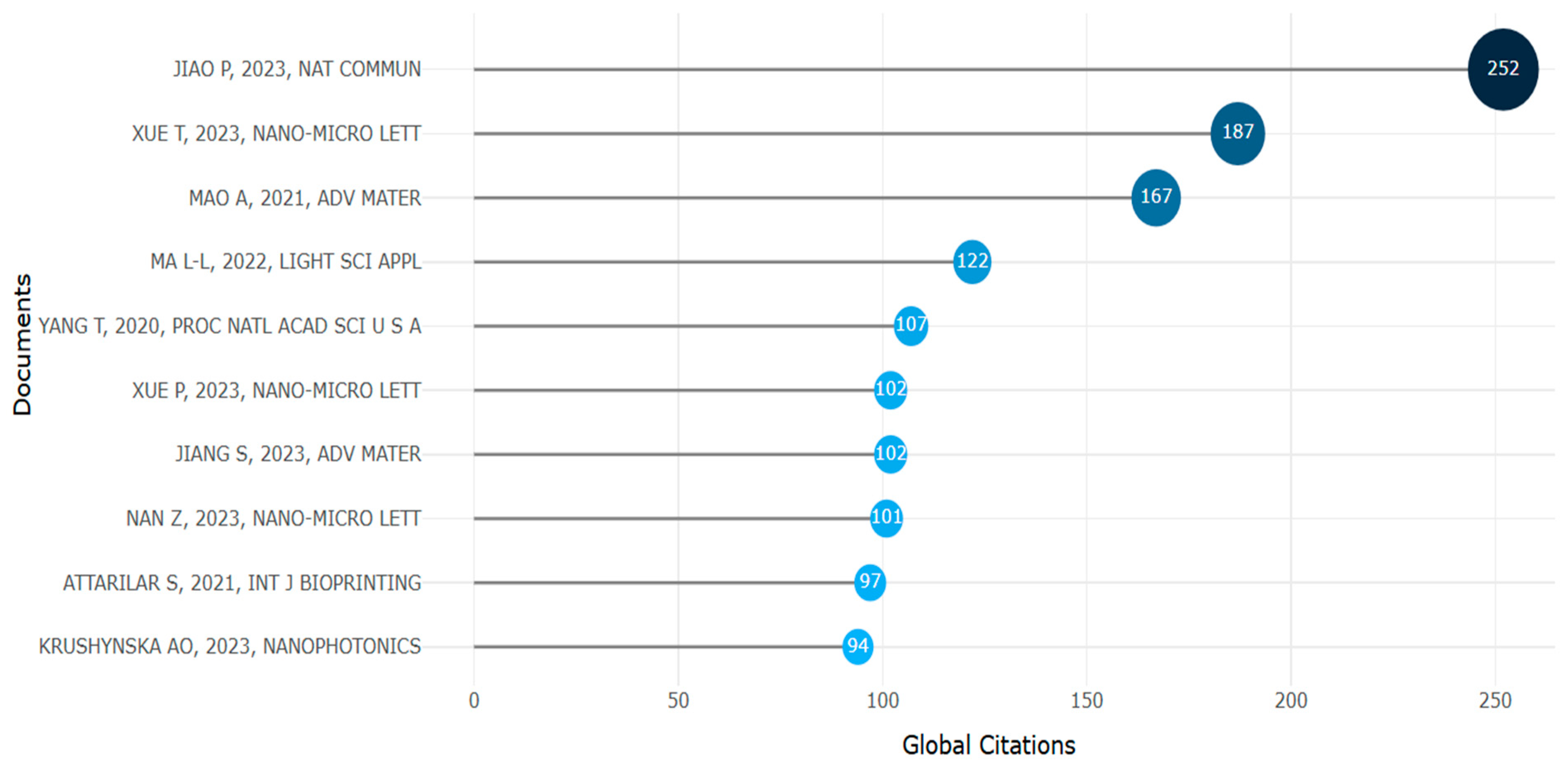

With over 252 reference citations, the most globally cited work was by Jiao et al., as shown in

Figure 31 [

148].

Figure 34 shows the network with the most common authors by co-citations. Each node in the figure represents an article. The articles are ordered by year of publication from newer at the top to older at the bottom, with different colors. The node size depends on the number of citations received from the seed articles and the number of citations of the seed articles. A total of 58 clusters with 105 items were identified, with a minimum of 5 documents from each author as a threshold.

6. Conclusions

This study presents the first comprehensive bibliometric analysis focused exclusively on biomimetic lattice structures engineered for energy absorption and deformation. A curated dataset of 2226 peer-reviewed articles published between 2020 and 2025 was extracted from various databases and analyzed using different bibliometric techniques in order to map keyword co-occurrence, author collaborations, key contributing nations, key affiliating institutions, key authors, and thematic clusters. The results reveal China as the leading contributor in publication volume and institutional partnerships, with strong international collaborations, particularly with European institutions.

Prominent research themes include additive manufacturing, finite element modeling, and the integration of artificial intelligence for design optimization. The leading publication outlets were identified and, in decreasing order of the number of publications, included Materials, Biomimetics, Polymers, and the Journal of Mechanical Behavior of Biomedical Materials. Despite these advances, several critical gaps remain underexplored. These include fatigue performance under dynamic loading, the integration of hybrid or graded materials, and the experimental validation of AI-driven lattice structures.

Despite these promising results, several key challenges remain in the use of lattice structures that are biomimetically designed as a tool for energy absorption. Some of these issues include high strain rates, lattice defects, failure, and deformations. In addition, the lack of regulatory frameworks and the higher costs continue to hinder the large and industrial-scale adoption of these structures. Addressing these challenges will be essential for transitioning bioinspired designs from conceptual models to real-world applications in aerospace, biomedical, and mechanical systems. This analysis not only maps the current research landscape but also underscores a paradigm shift toward data-driven, nature-inspired structural designs. The insights provided here offer a foundation for future interdisciplinary efforts in intelligent materials engineering and guide researchers toward impactful collaboration and innovation. Furthermore, active collaborations between industry, researchers, and policymakers are essential to encourage innovations and market competitiveness.