The Structural Design and Optimization of a Novel Independently Driven Bionic Ornithopter

Abstract

1. Introduction

2. Common Bionic Ornithopter Transmission Structure

2.1. The Single-Gear Crank–Rocker Mechanism

2.2. The Double-Gear Crank–Rocker Mechanism

2.3. The Cross-Shaft Single-Gear Crank Mechanism

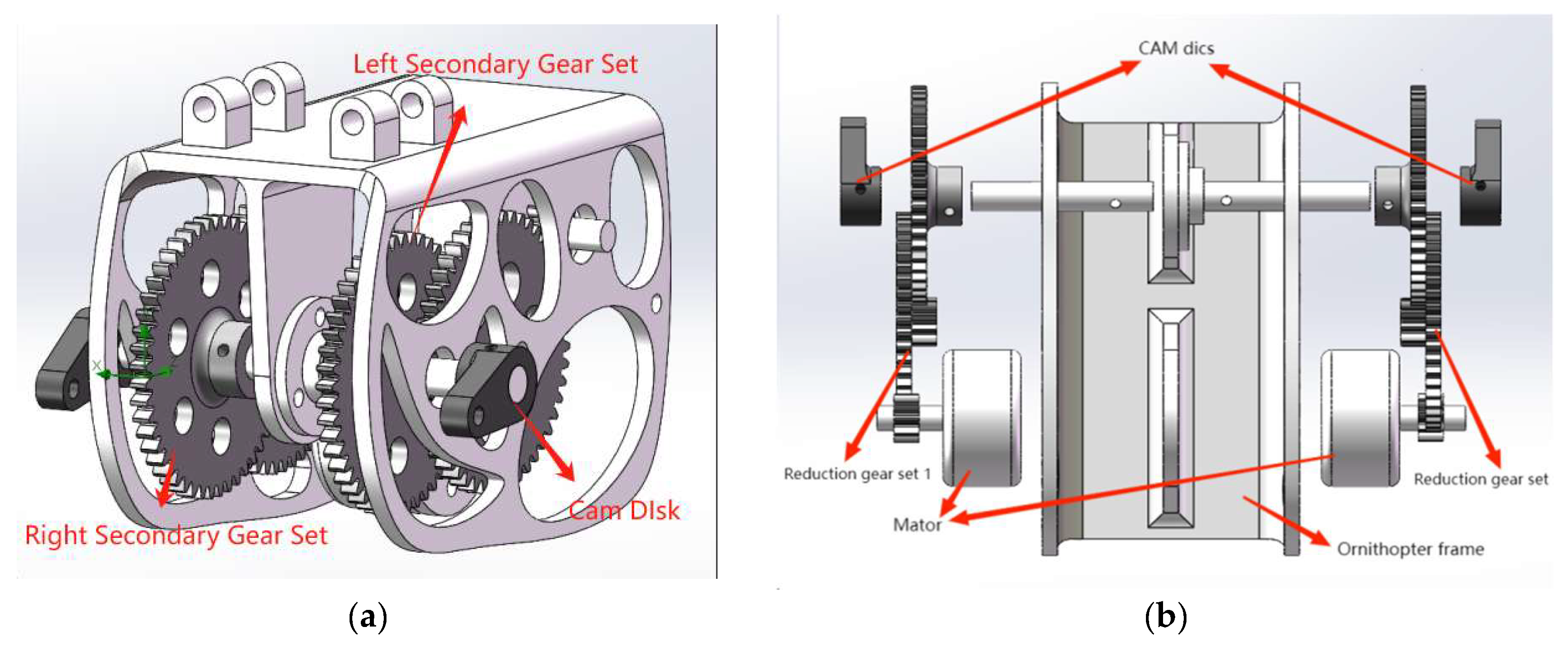

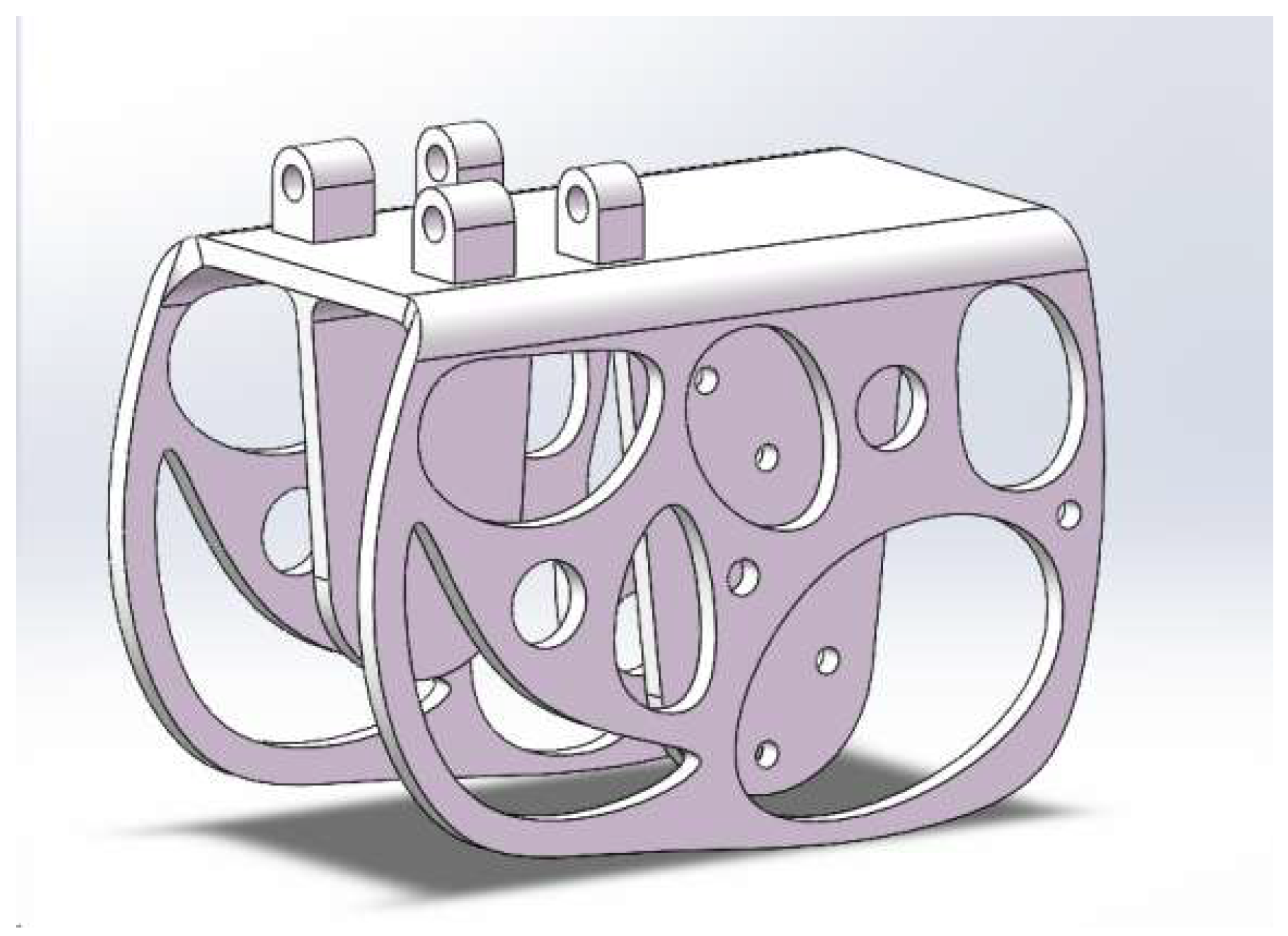

3. A Novel Type of Independently Driven Bionic Ornithopter

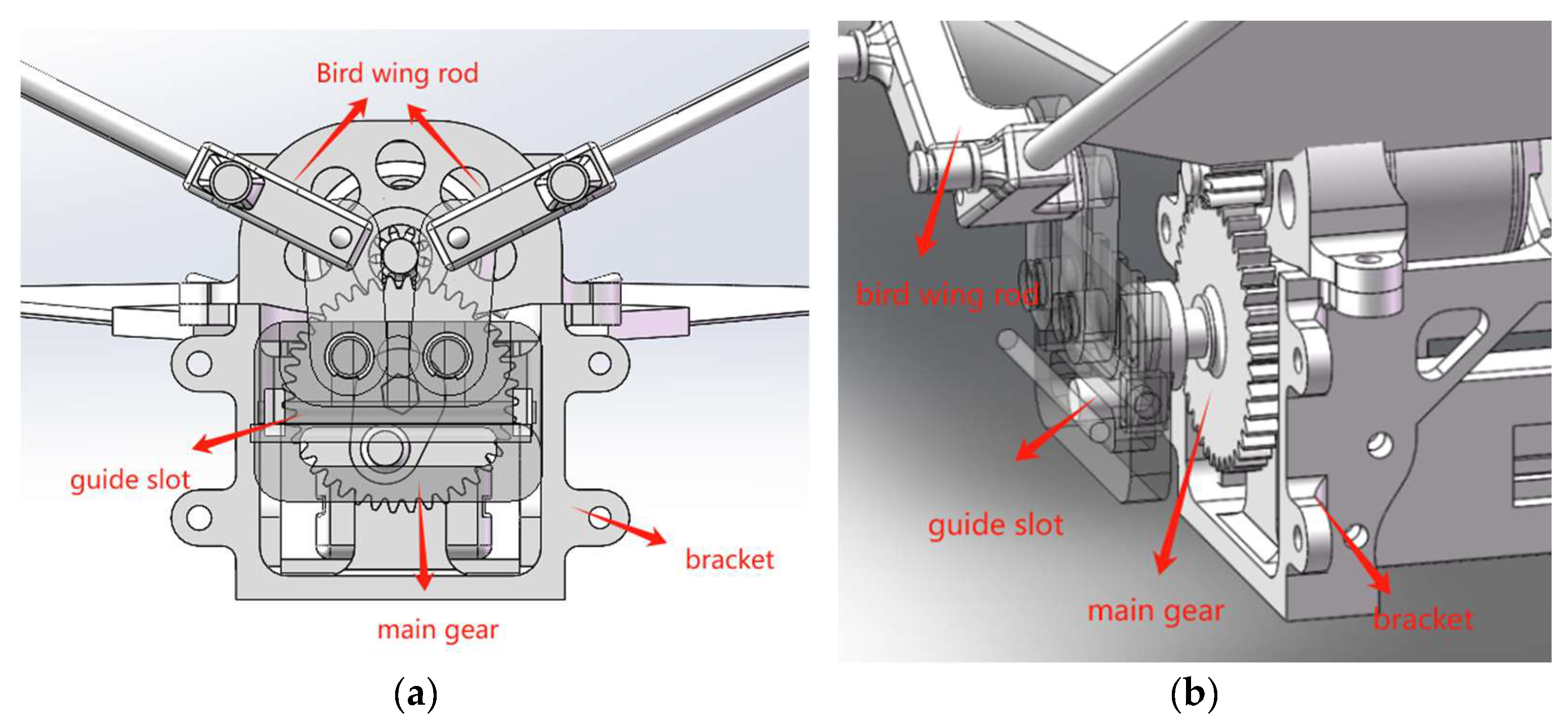

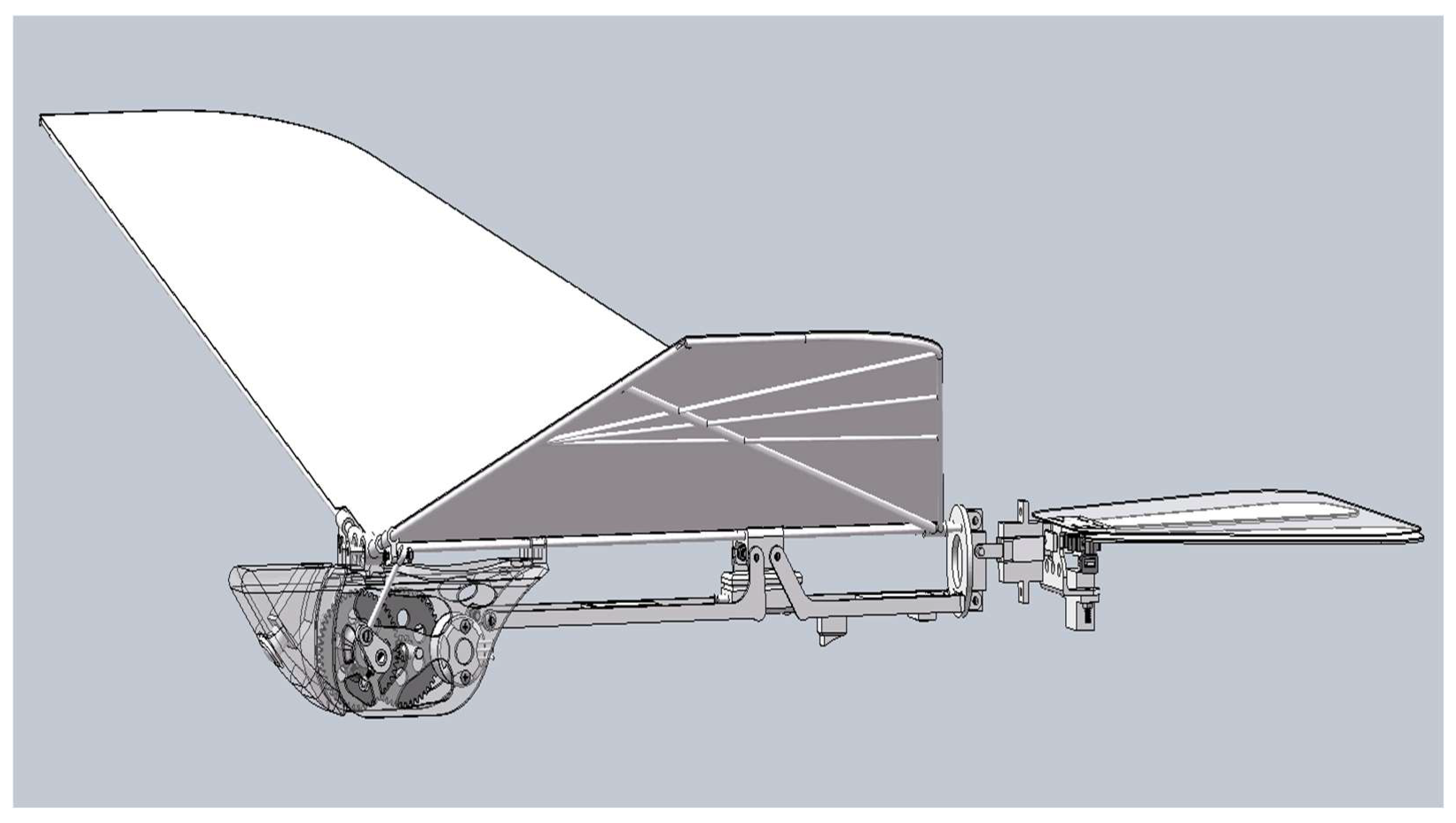

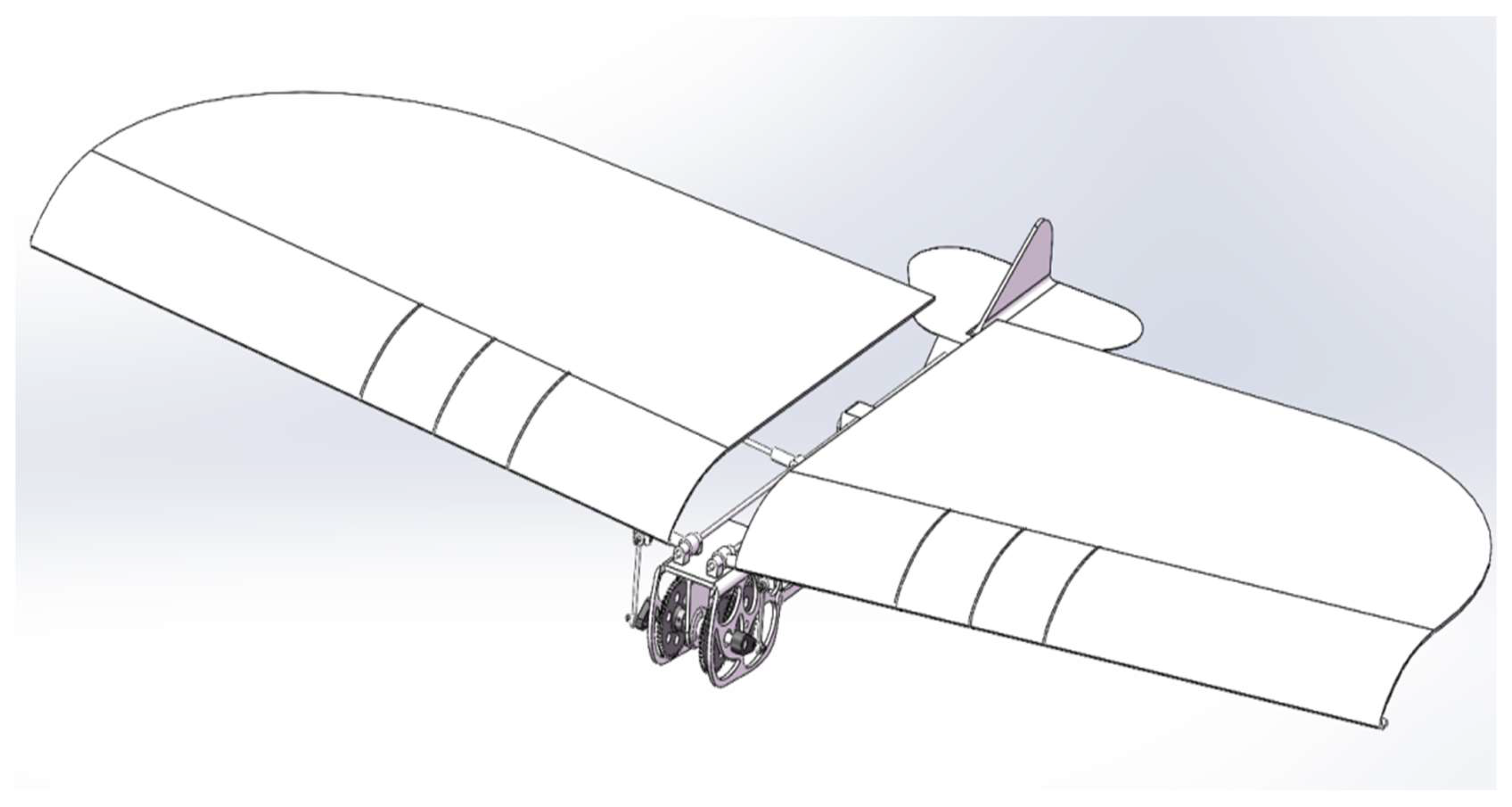

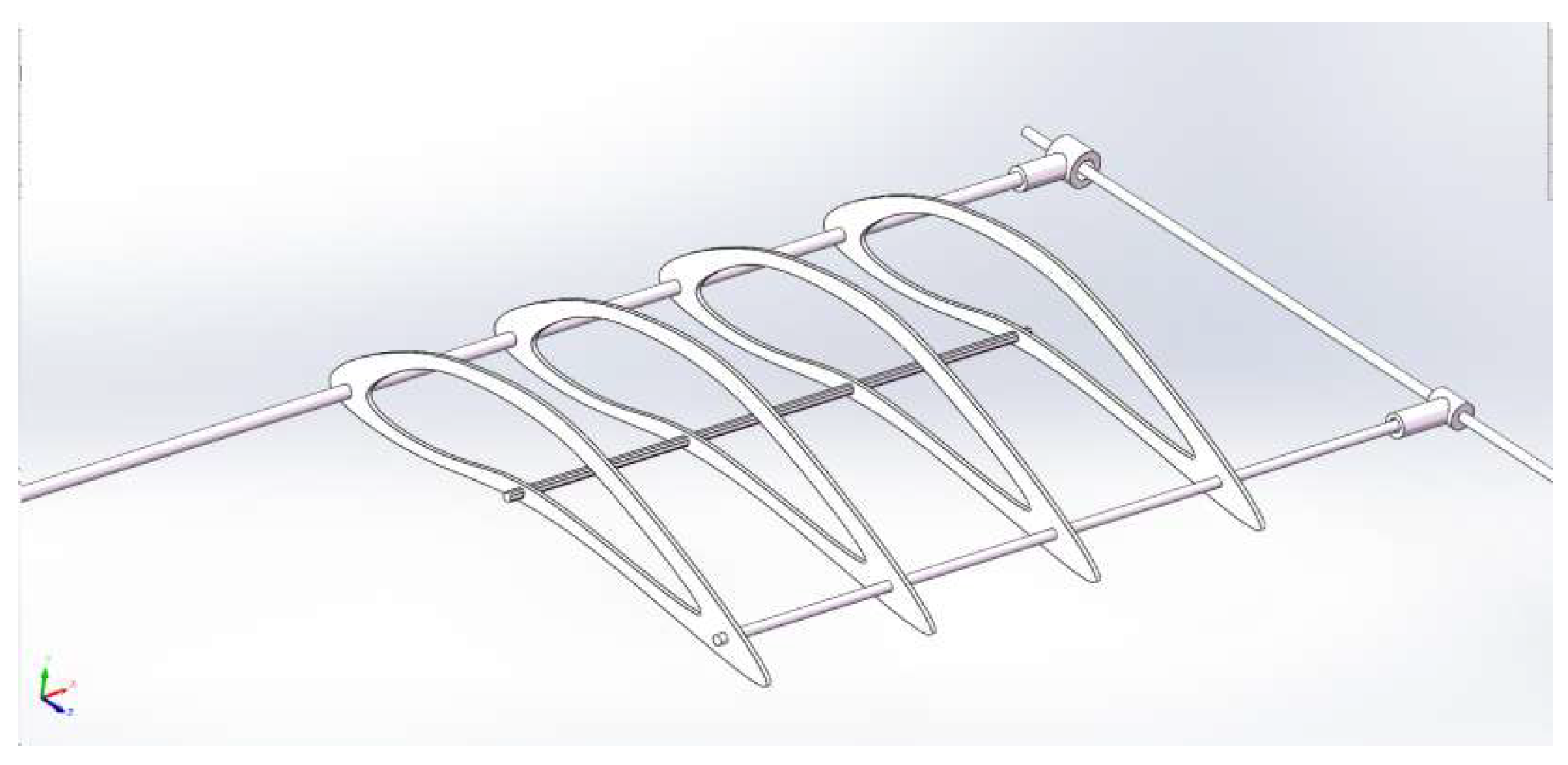

3.1. A Pair of Independently Driven Wings

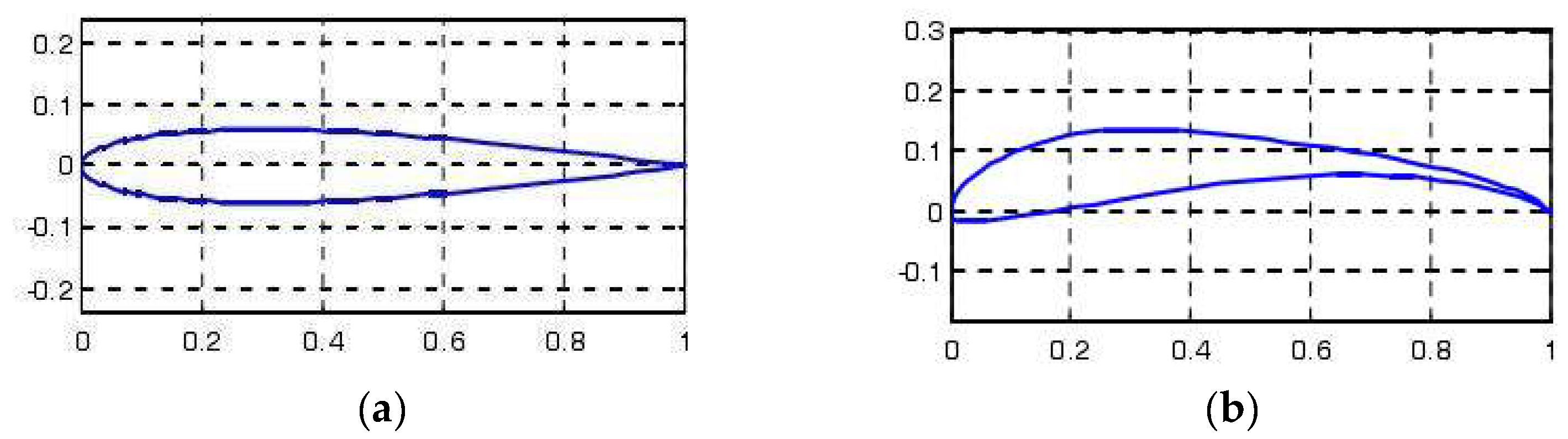

3.2. The Choice of Wing Airfoil

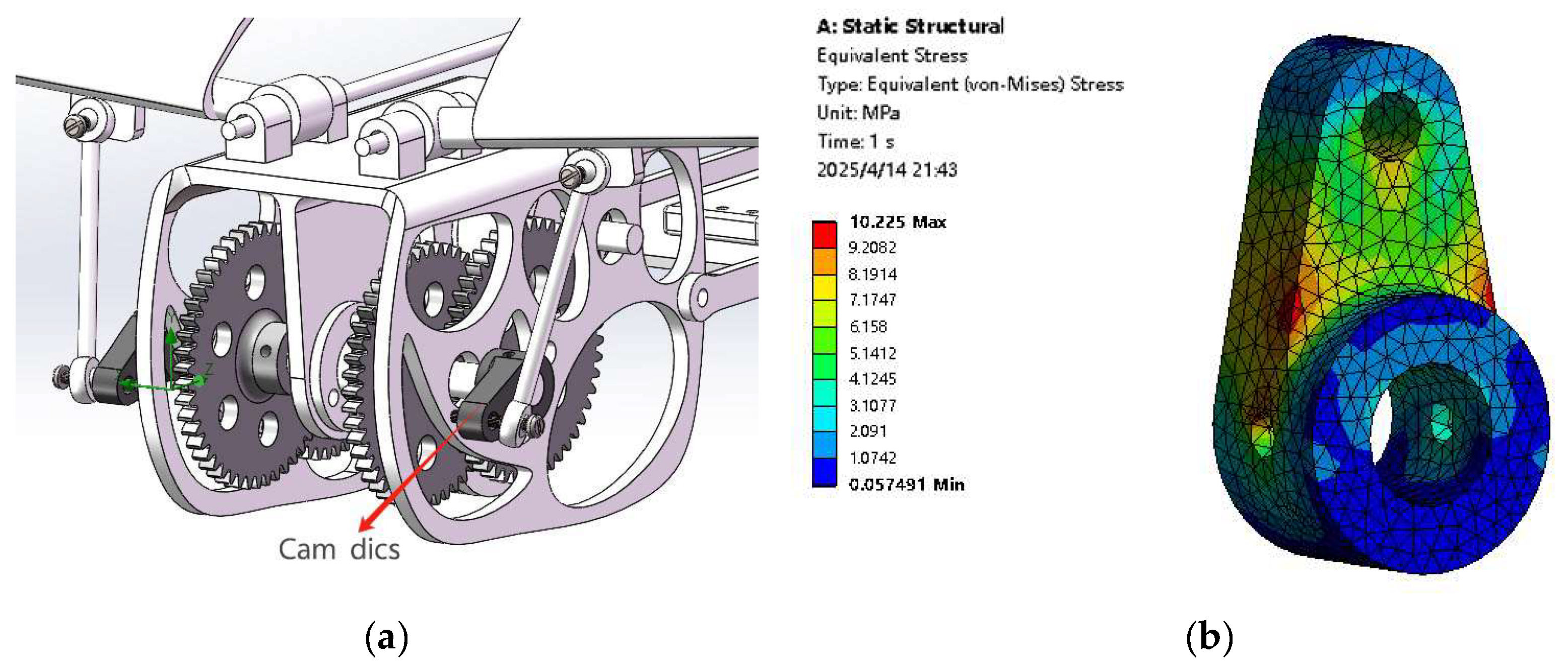

4. Strength Verification and Feasibility Analysis

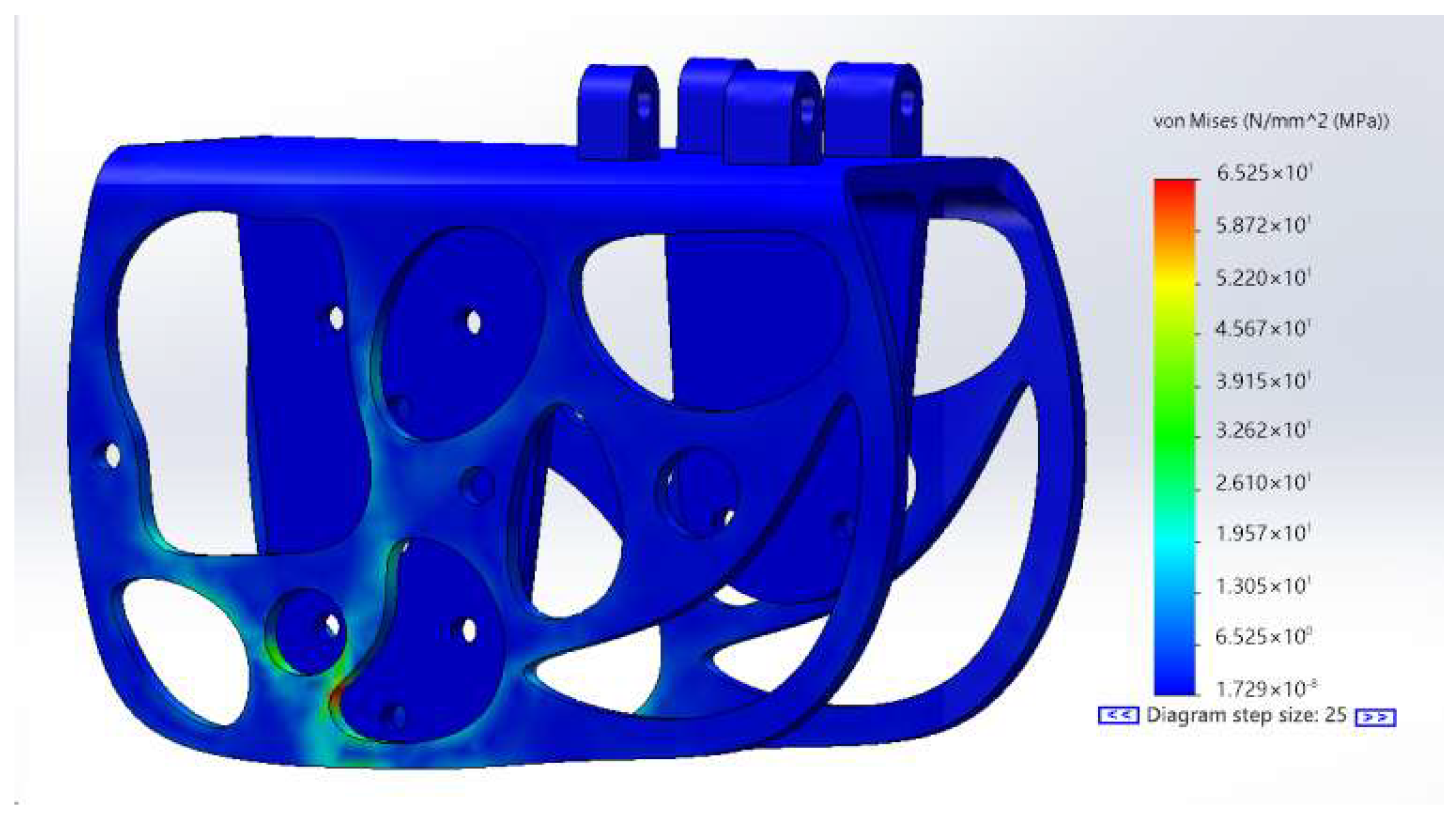

4.1. Simulation Analysis of Frame Drop Test

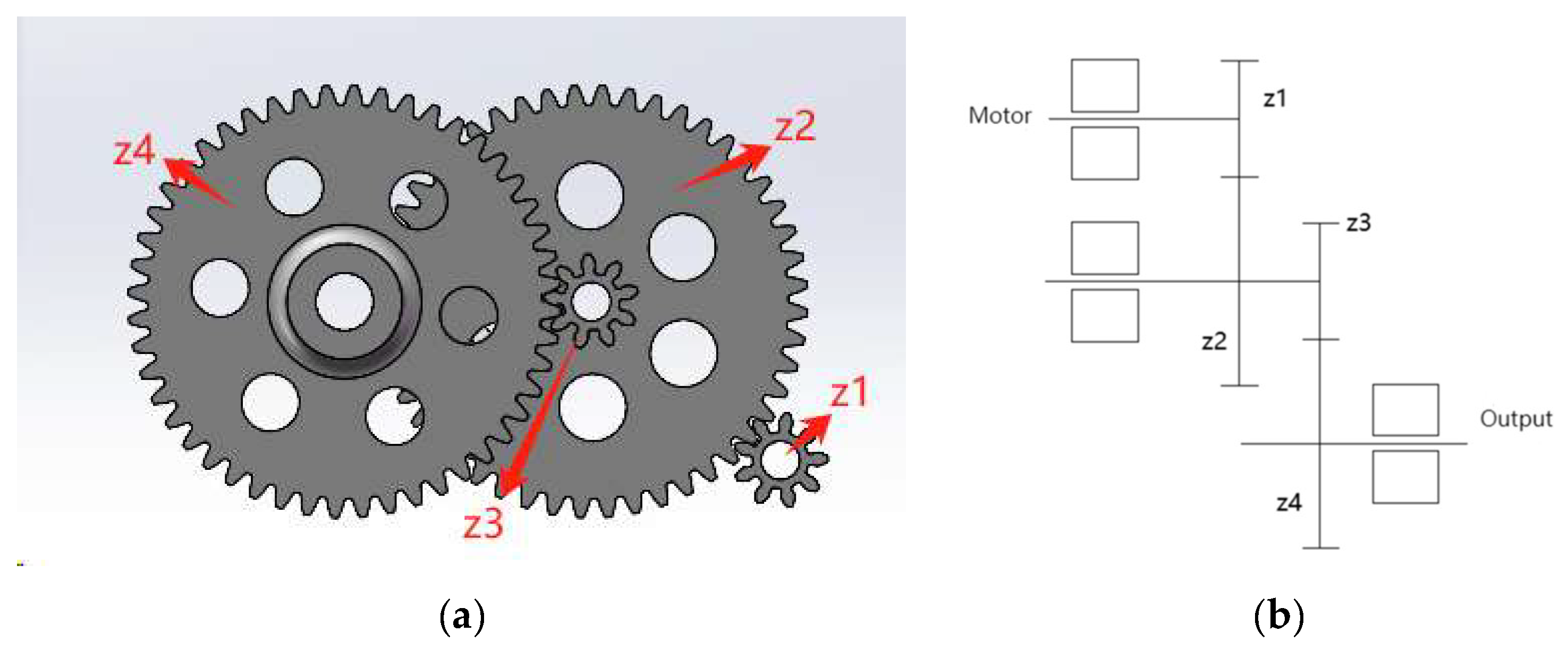

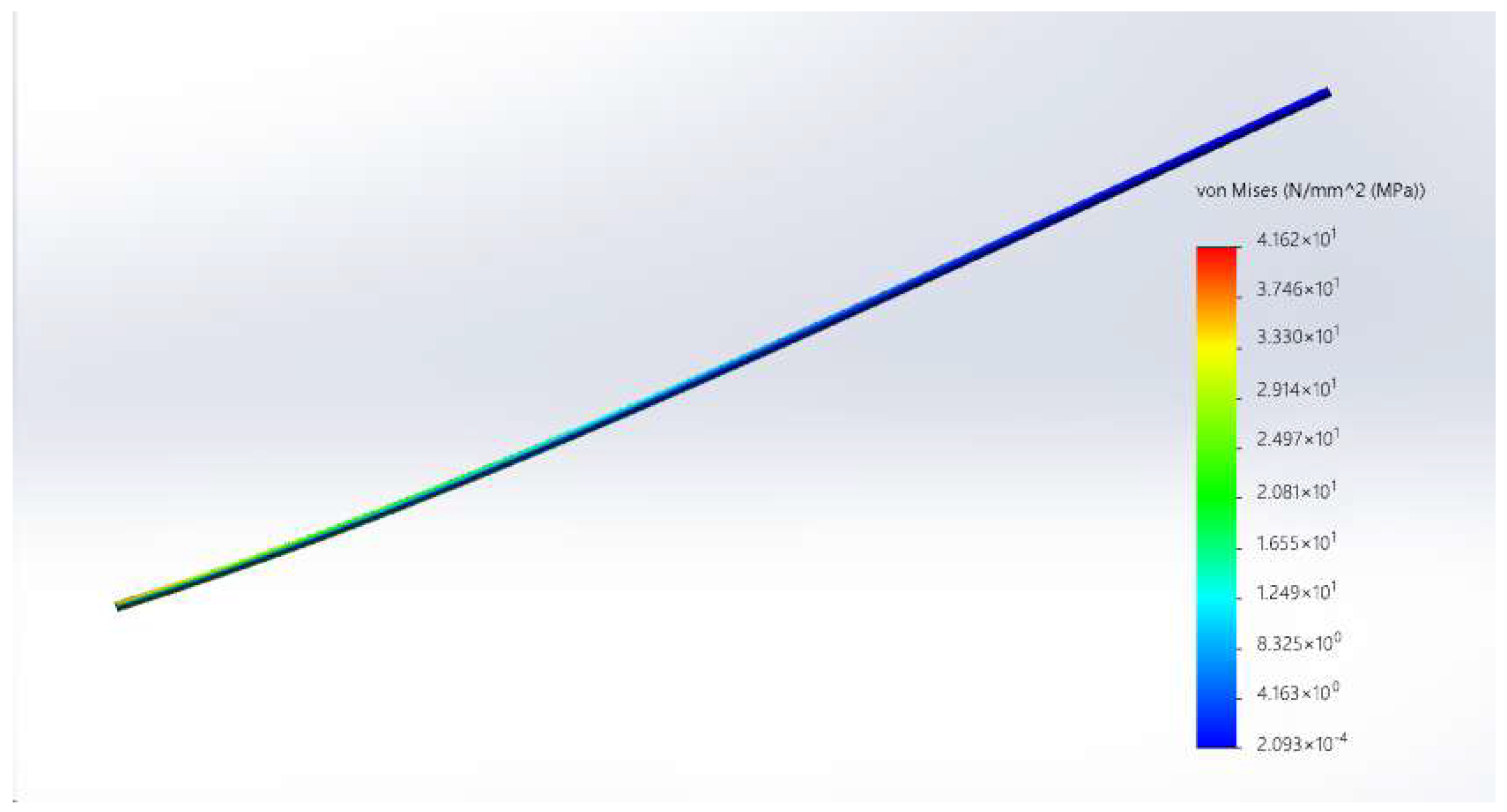

4.2. Gear Design and Strength Verification

4.3. Position Control

5. Simulation Experiment Data Measurement

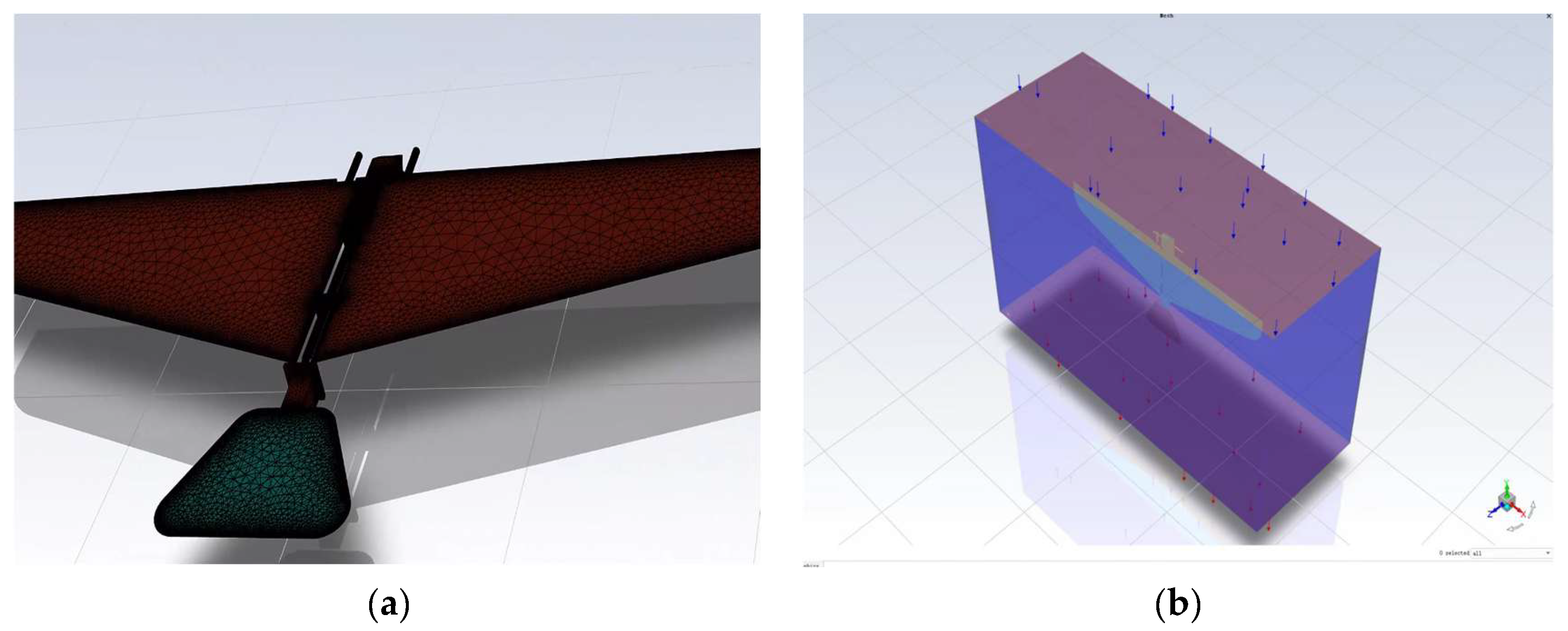

5.1. Parameter Settings and Mesh Generation

5.1.1. Parameter Settings

5.1.2. Mesh Generation

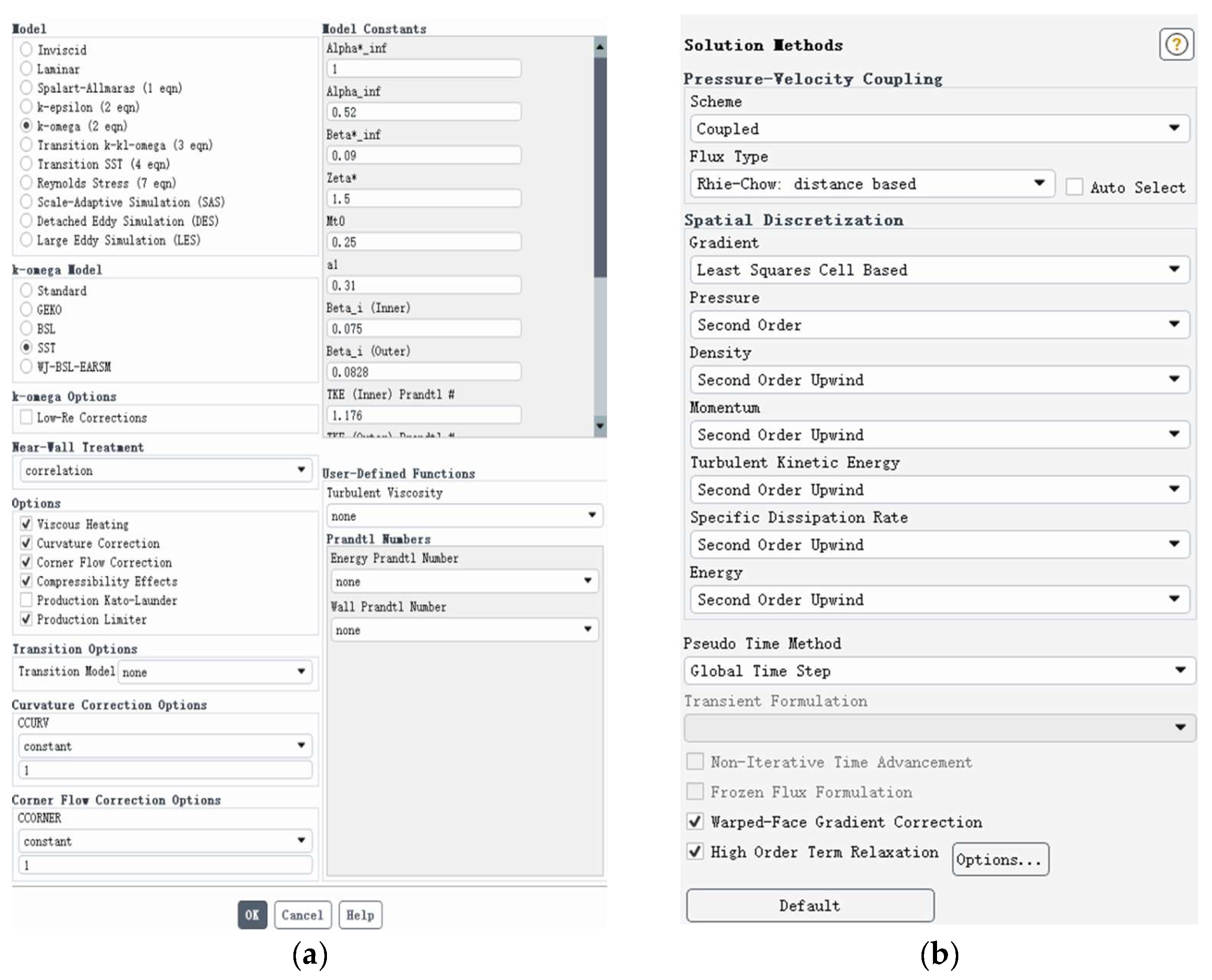

5.2. Key Algorithms and Data Processing in Fluid Simulation Experiments

5.2.1. Turbulence Model

5.2.2. Algorithm Selection

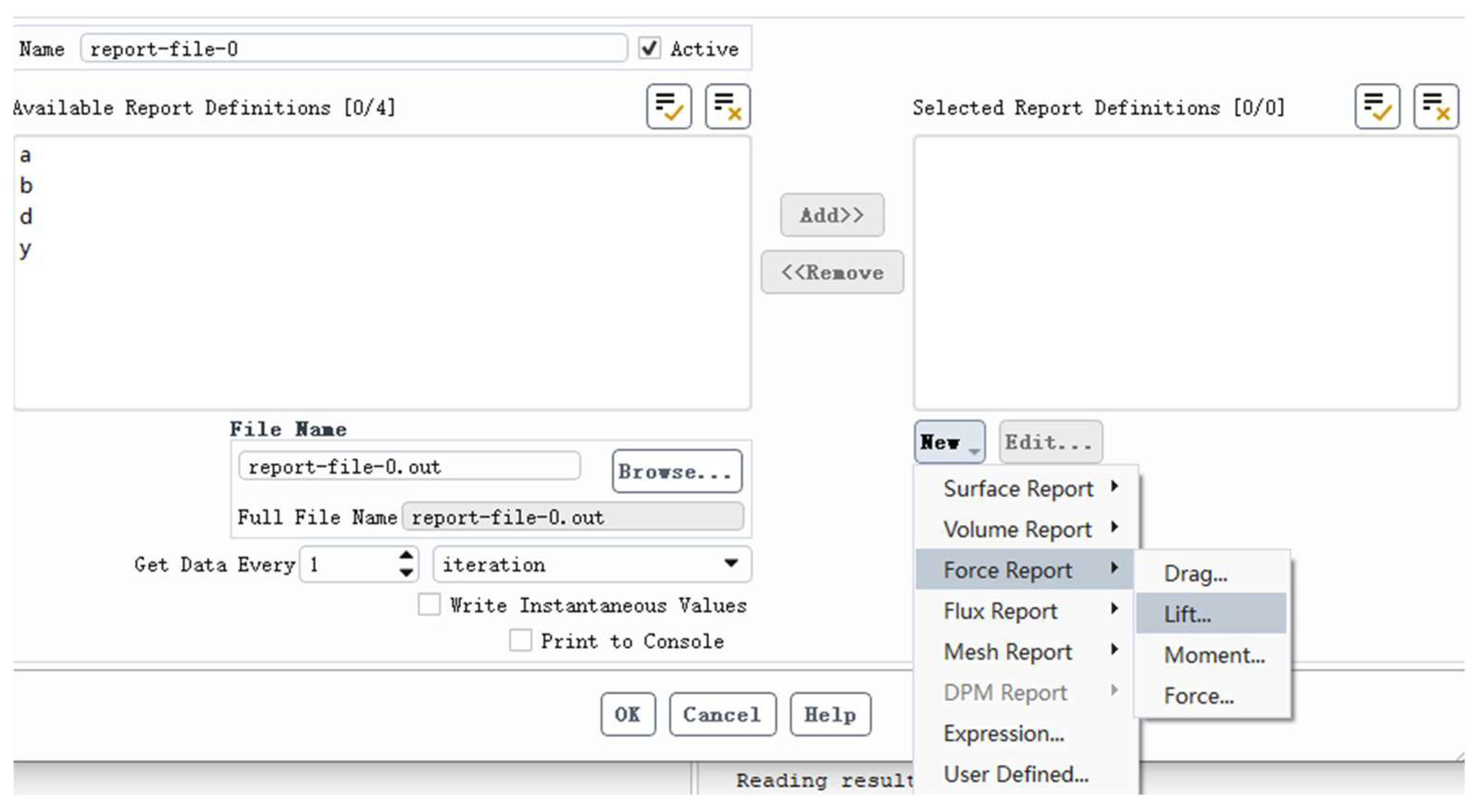

5.2.3. Data Extraction

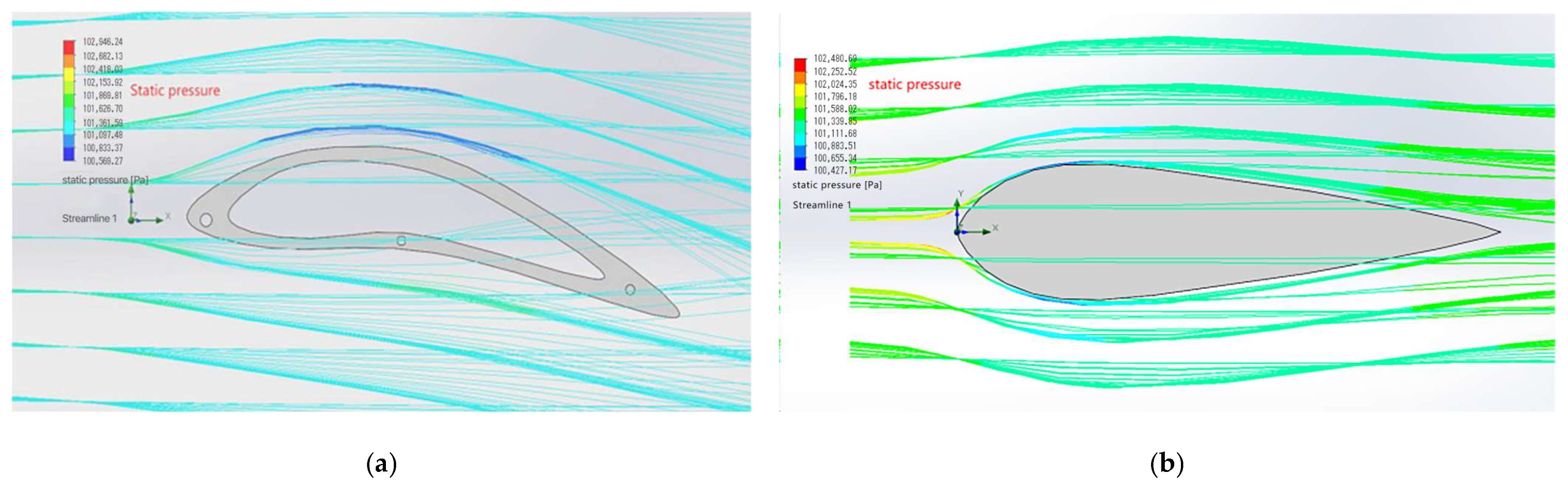

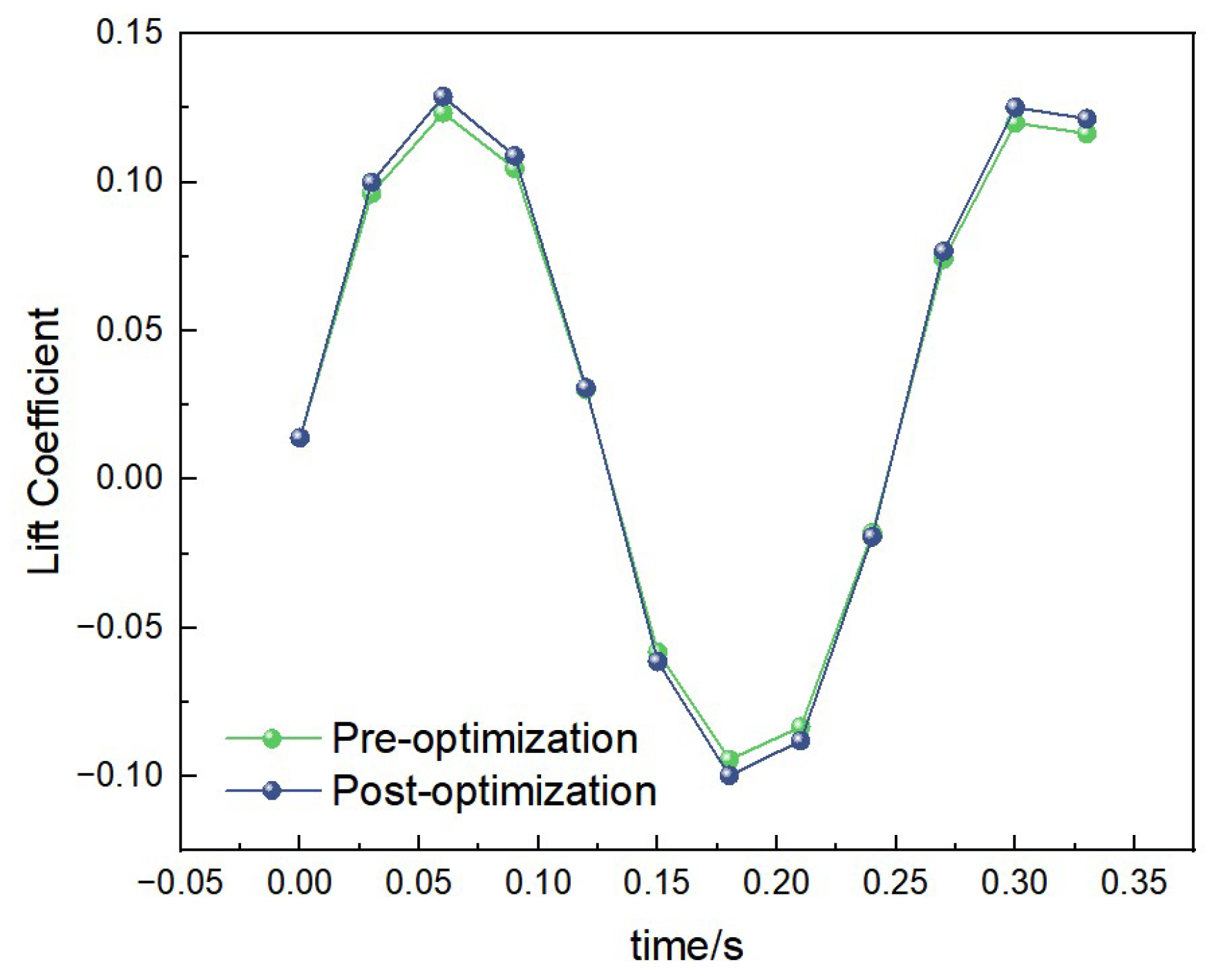

5.3. Aerodynamic Force Calculation of Wings

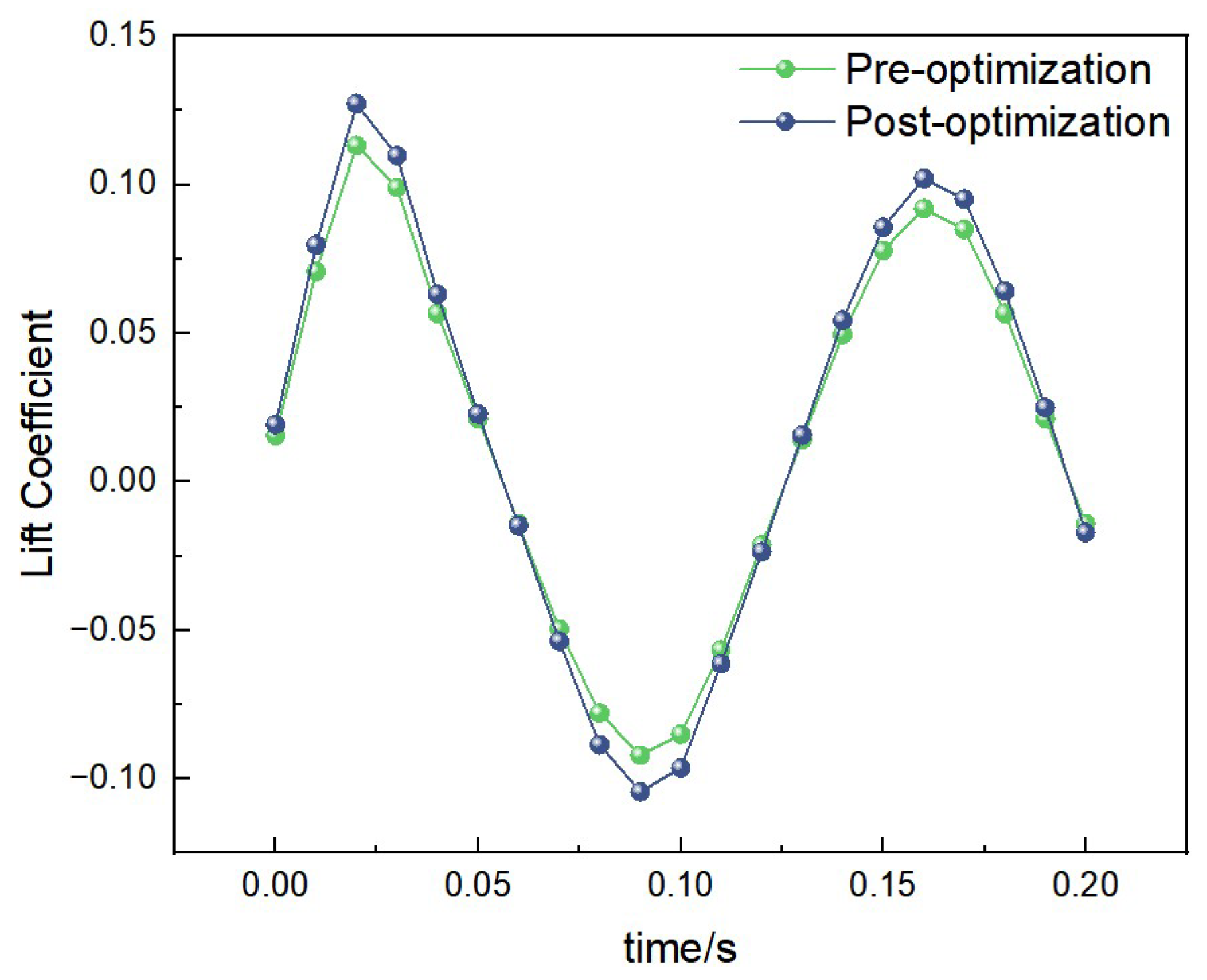

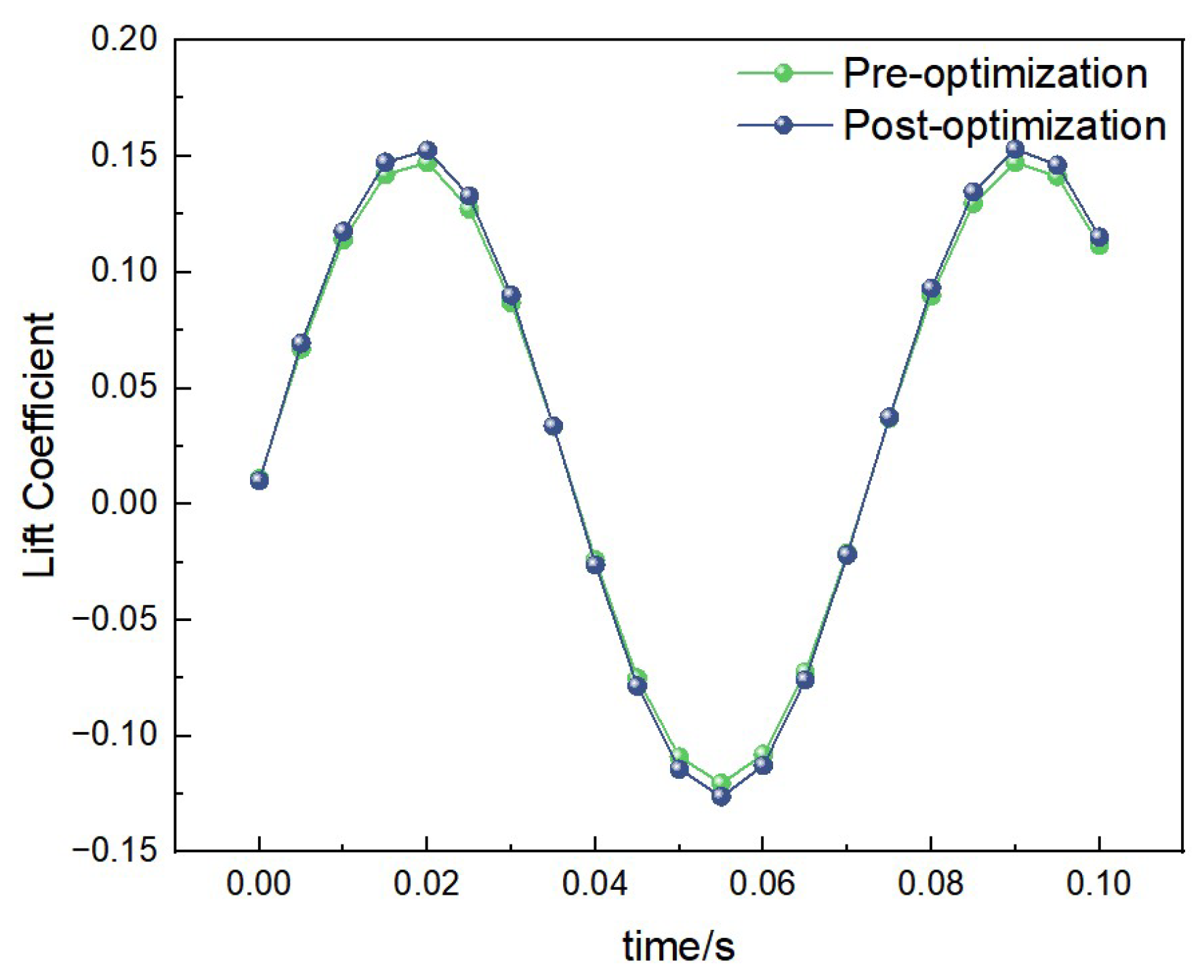

5.3.1. Lift Data

Lift Data Under 1 Hz-1.2 m/s Condition

Lift Data Under 2 Hz-2.5 m/s Condition

Lift Data Under 3.45 Hz-3 m/s Condition

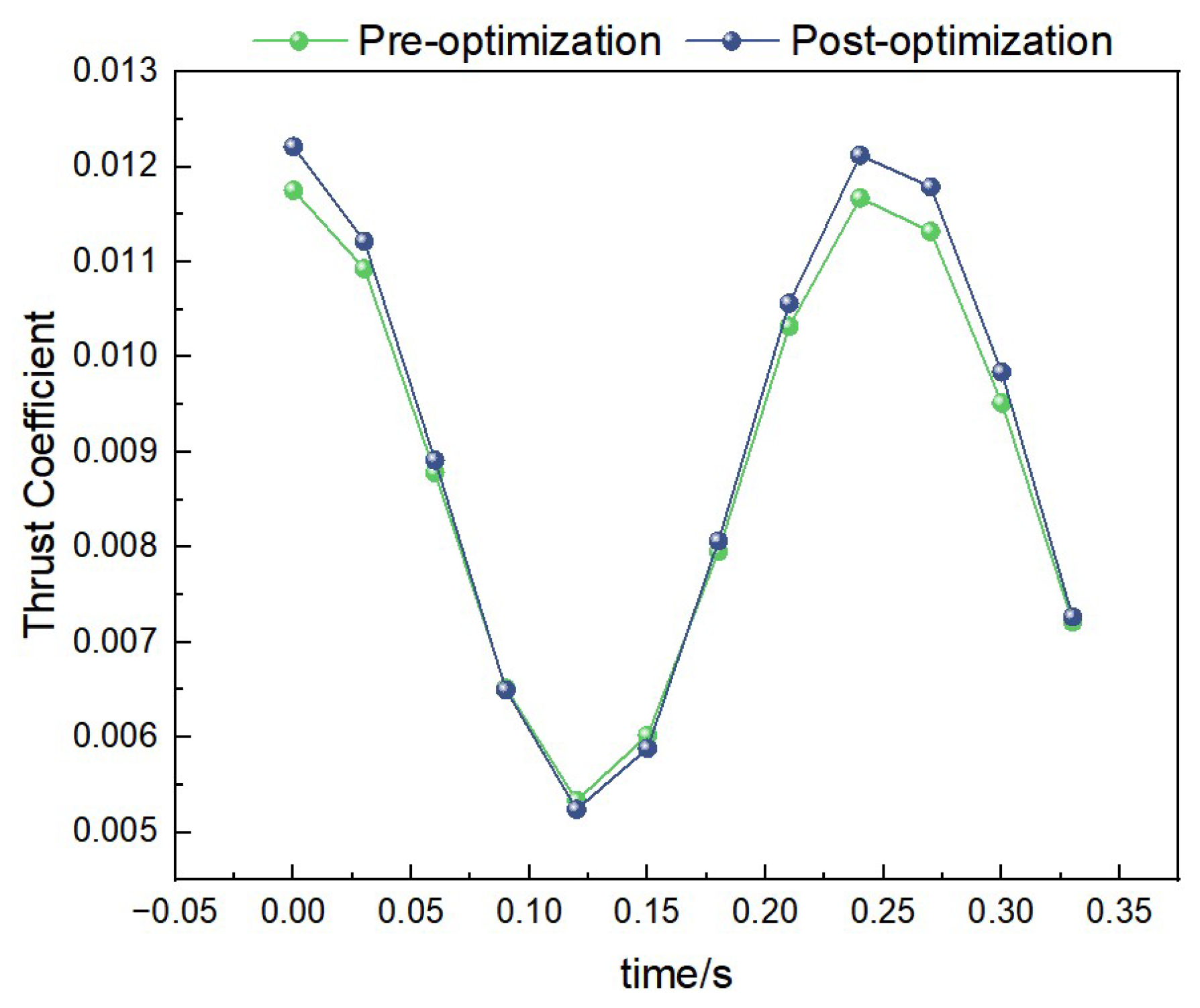

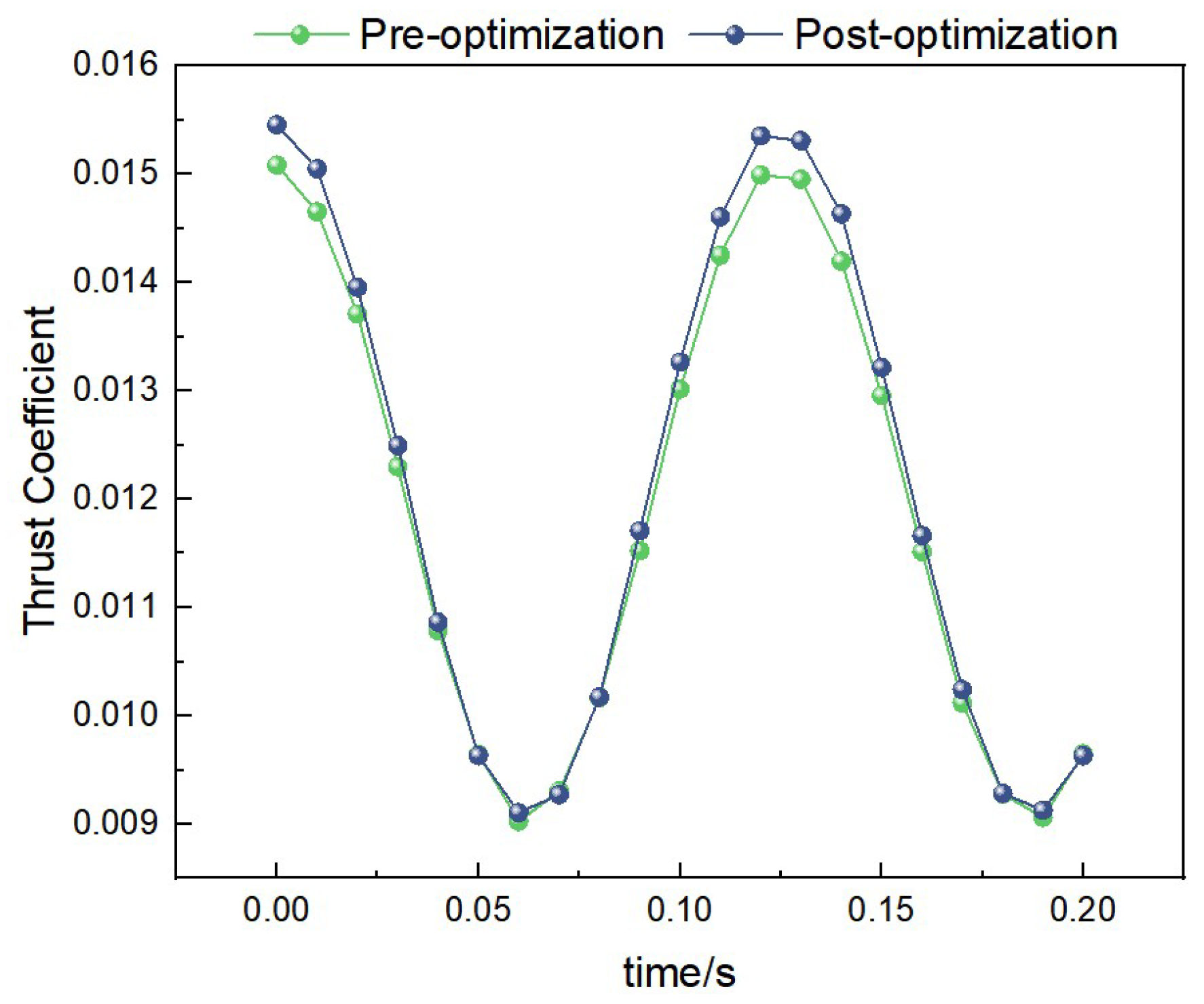

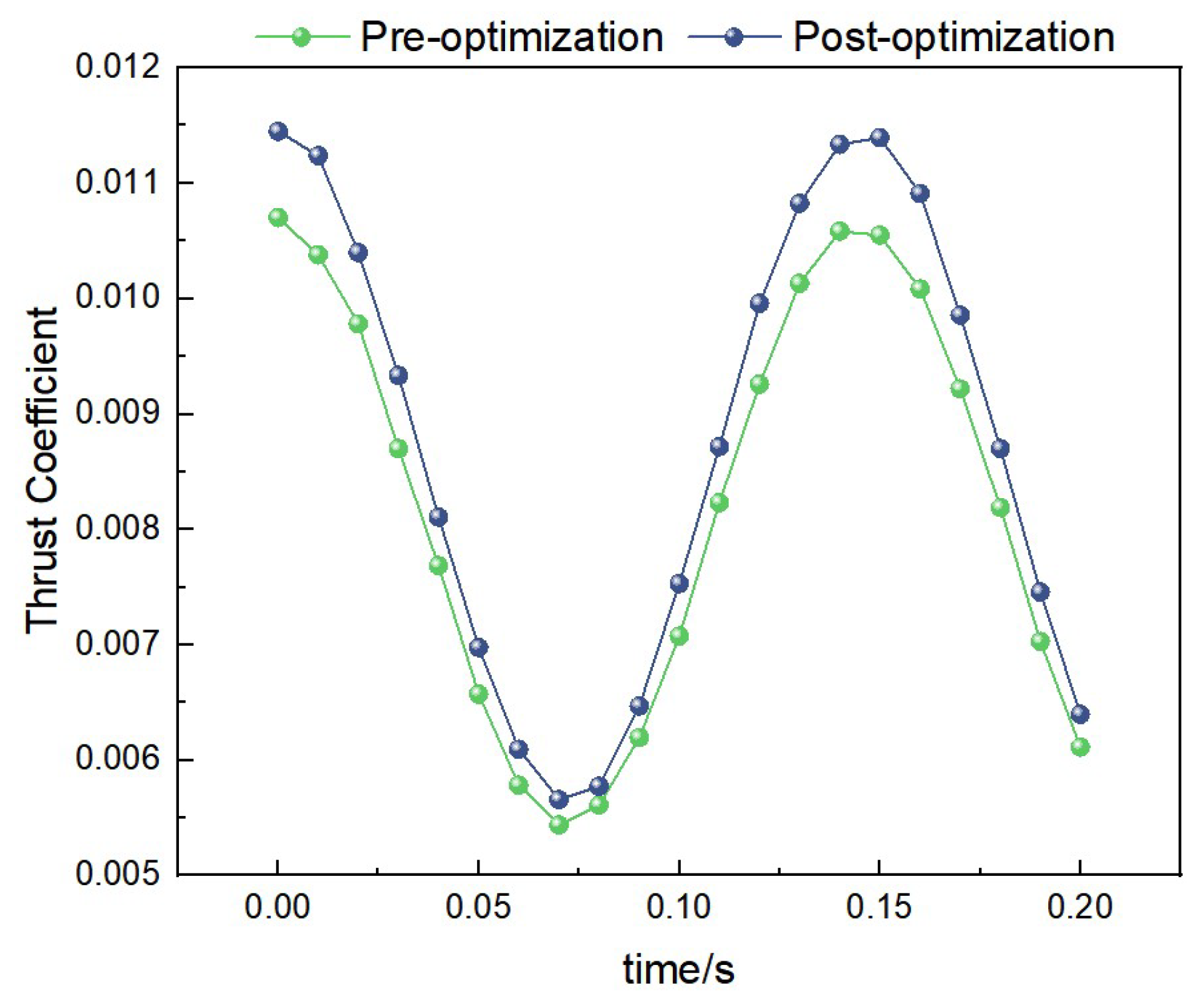

5.3.2. Thrust Data

Thrust Data Under 1 Hz-1.2 m/s Condition

Thrust Data Under 2 Hz-2.5 m/s Condition

Thrust Data Under 3.45 Hz-3 m/s Condition

5.3.3. Comparative Analysis

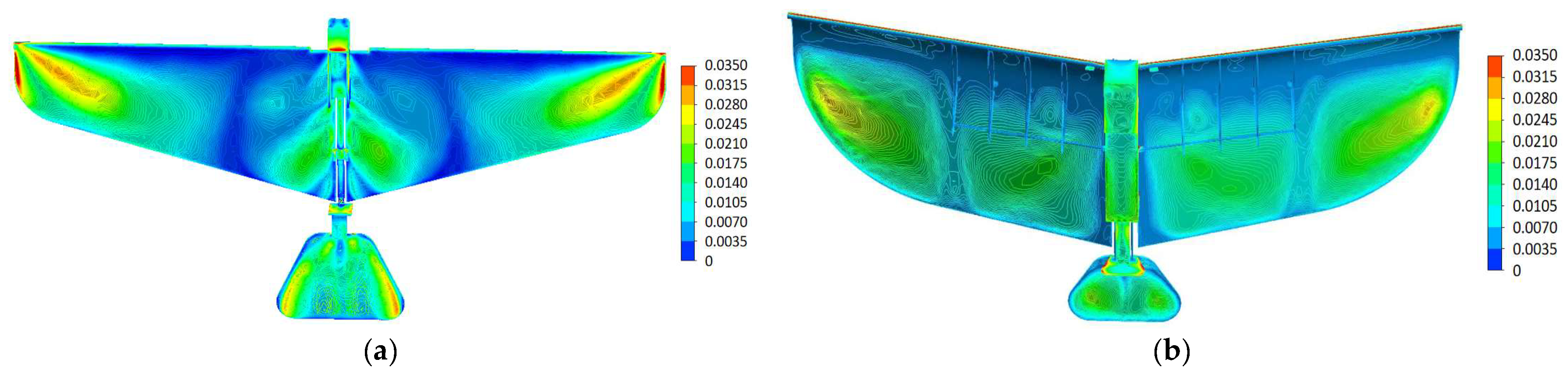

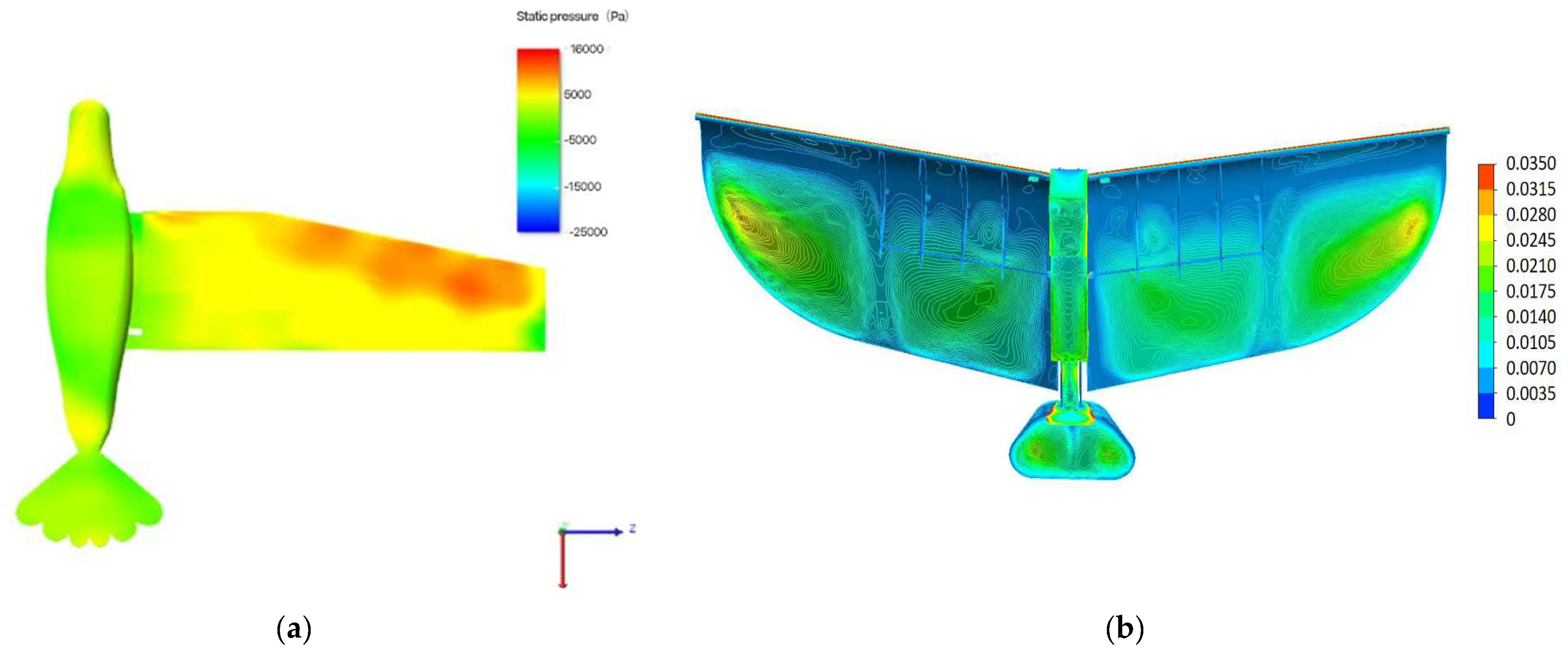

5.4. Stress Cloud Analysis

5.4.1. Stress Distribution Before Optimization

5.4.2. Stress Distribution After Optimization

5.5. Comparison with Existing Designs

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ye, R.; Liu, Z.; Cui, J.; Wang, C.; Wu, Y. Aerodynamic Analysis of Hovering Flapping Wing Using Multi-Plane Method and Quasi-Steady Blade Element Theory. Appl. Sci. 2024, 14, 4258. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, Z.-H.; Wang, J.-H. Research status and development of flapping wing aircraft. J. Ordnance Equip. Eng. 2022, 43, 44–54. [Google Scholar]

- Garg, A.; Anekar, N.; Pawar, R.G.; Ramekar, H.; Tiwari, V.; Padval, A.; Marne, N.; Jadhav, P. Slider-Crank Four-Bar Mechanism-Based Ornithopter: Design and Simulation. In ICT Systems and Sustainability; Lecture Notes in Networks and Systems; Tuba, M., Akashe, S., Joshi, A., Eds.; Springer: Singapore, 2023; Volume 516. [Google Scholar] [CrossRef]

- Yang, W.; Wang, L.; Song, B. Dove: A biomimetic flapping-wing micro air vehicle. Int. J. Micro Air Veh. 2018, 10, 70–84. [Google Scholar] [CrossRef]

- Mu, X.; Xu, S.; Wu, X. Structural Design and Aerodynamic Characteristics of Two Types of Fold-Able Flapping-Wings. In Intelligent Robotics and Applications, Proceedings of the 15th International Conference, ICIRA 2022, Harbin, China, August 1–3 2022; Liu, H., Yin, Z., Liu, L., Jiang, L., Gu, G., Wu, X., Ren, W., Eds.; Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2022; Volume 13455. [Google Scholar] [CrossRef]

- Qiuhong, L.; Jiandong, H.; Chong, W.; Yuan, C.; Bokai, Z. Study on the Aerodynamic Characteristics of Bird-like Flapping Wings Under Multi-degree-of-Freedom Conditions. Int. J. Aeronaut. Space Sci. 2025. [Google Scholar] [CrossRef]

- Neretti, G.; Cristofolini, A.; Borghi, C.A.; Gurioli, A.; Pertile, R. Experimental Results in DBD Plasma Actuators for Air Flow Control. IEEE Trans. Plasma Sci. 2012, 40, 1678–1687. [Google Scholar] [CrossRef]

- Moayedi, H.; Deylami, H.M. Aerodynamic performance improvement of an airfoil using the Gurney flap and fast on-off DBD plasma actuator. Eur. Phys. J. Plus 2024, 139, 28. [Google Scholar] [CrossRef]

- Geißler, W. The single flapping rotor: Detailed physical explanations. CEAS Aeronaut. J. 2023, 14, 787–797. [Google Scholar] [CrossRef]

- Johansson, L.C. Aerodynamic efficiency explains flapping strategies used by birds. Proc. Natl. Acad. Sci. USA 2024, 121, e2410048121. [Google Scholar] [CrossRef] [PubMed]

- Deng, R.-Y.; Ai, Z.-W.; Wu, Y.-C.; Zou, G.-M. Actuator Optimization Design Research of Bird-Imitation Flapping Aero-Craft. Mach. Des. Manuf. 2015, 53, 157–160. [Google Scholar]

- Zhang, J. Structural Optimization Design and Analysis of an Active Deformation Bionic Flapping-Wing Aircraft. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2020. [Google Scholar] [CrossRef]

- Miyasaka, S.; Kang, C.; Aono, H. Experimental Analyses of Aerodynamic Force Generation and Wing Motion Associated with a Single-motor-driven Butterfly-inspired Flapping-wing Robot. Sens. Mater. 2023, 35, 3097–3108. [Google Scholar] [CrossRef]

- Jha, S.K.; Gautam, U.; Pawar, P.; Narayanan, S.; Kumaraswamidhas, L.A. Investigations of Flow Phenomena Over a Flat Plate and NACA0012 Airfoil at High Angles of Attack. Iran J. Sci. Technol. Trans. Mech. Eng. 2020, 44, 985–996. [Google Scholar] [CrossRef]

- Omar, A.A.; Kurban, A.; Jetlawi, M. Numerical Simulation of the Flapping Eagle, Owl and S1223 Airfoils. In Proceedings of the 2023 10th International Conference on Recent Advances in Air and Space Technologies (RAST), Istanbul, Turkiye, 7–9 June 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Imumbhon, J.O.; Alam, M.D.; Cao, Y. Design and Structural Analyses of a Reciprocating S1223 High-Lift Wing for an RA-Driven VTOL UAV. Aerospace 2021, 8, 214. [Google Scholar] [CrossRef]

- Unger, R.; Haupt, M.C.; Horst, P.; Radespiel, R. Fluid-structure analysis of a flexible flapping airfoil at low Reynolds number flow. J. Fluids Struct. 2012, 28, 72–88. [Google Scholar] [CrossRef]

- Li, X.-Z. Aerodynamic Analysis of Flexible Wings and Tail in Multi-Segment Bionic Flapping-Wing Aircraft. Master’s Thesis, Civil Aviation University of China, Tianjin, China, 2018. [Google Scholar]

| The Name of the Parameter | i1 | i2 | ||

|---|---|---|---|---|

| Z1 | Z2 | Z3 | Z4 | |

| Gear modulus | 0.9 | |||

| Number of gear teeth | 9 | 48 | 9 | 48 |

| Gear indexing circle diameter/mm | 8.1 | 43.2 | 8.1 | 43.2 |

| Transmission ratios at all levels | 5.33 | 5.33 | ||

| Total gear ratio | 28.4 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, M.; Wu, R.; Ye, M.; Gao, K.; Chen, B.; Tao, X.; Fan, Z. The Structural Design and Optimization of a Novel Independently Driven Bionic Ornithopter. Biomimetics 2025, 10, 401. https://doi.org/10.3390/biomimetics10060401

Dai M, Wu R, Ye M, Gao K, Chen B, Tao X, Fan Z. The Structural Design and Optimization of a Novel Independently Driven Bionic Ornithopter. Biomimetics. 2025; 10(6):401. https://doi.org/10.3390/biomimetics10060401

Chicago/Turabian StyleDai, Mouhui, Ruien Wu, Mingxuan Ye, Kai Gao, Bin Chen, Xinwang Tao, and Zhijie Fan. 2025. "The Structural Design and Optimization of a Novel Independently Driven Bionic Ornithopter" Biomimetics 10, no. 6: 401. https://doi.org/10.3390/biomimetics10060401

APA StyleDai, M., Wu, R., Ye, M., Gao, K., Chen, B., Tao, X., & Fan, Z. (2025). The Structural Design and Optimization of a Novel Independently Driven Bionic Ornithopter. Biomimetics, 10(6), 401. https://doi.org/10.3390/biomimetics10060401