Design, Modeling, and Experimental Validation of a Bio-Inspired Rigid–Flexible Continuum Robot Driven by Flexible Shaft Tension–Torsion Synergy

Abstract

1. Introduction

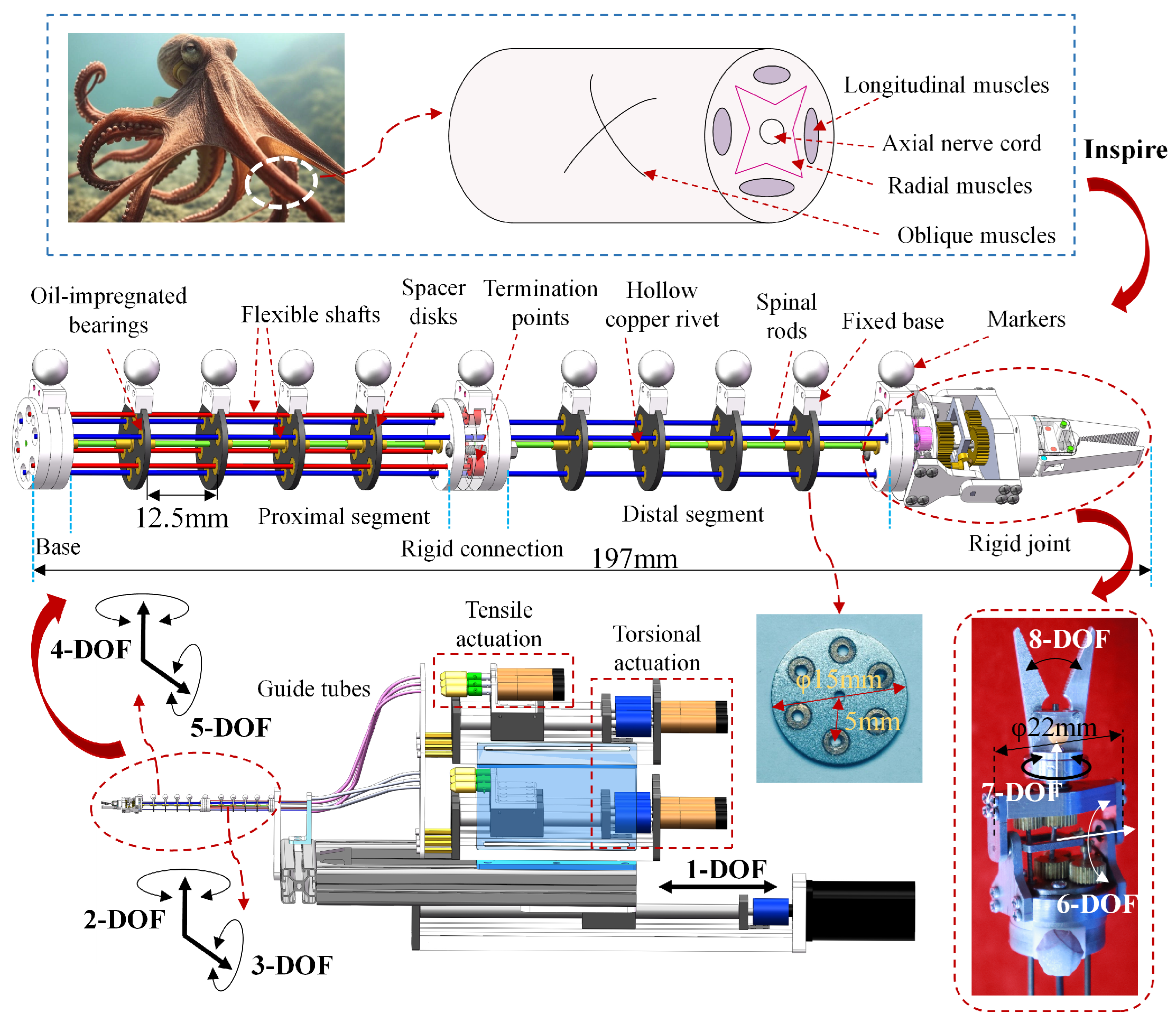

- A novel design is presented for a bio-inspired rigid–flexible continuum robot driven by flexible shaft tension and torsion synergistically, including a two-segment flexible joint driven by flexible shaft tension and a rigid joint driven by flexible shaft torsion.

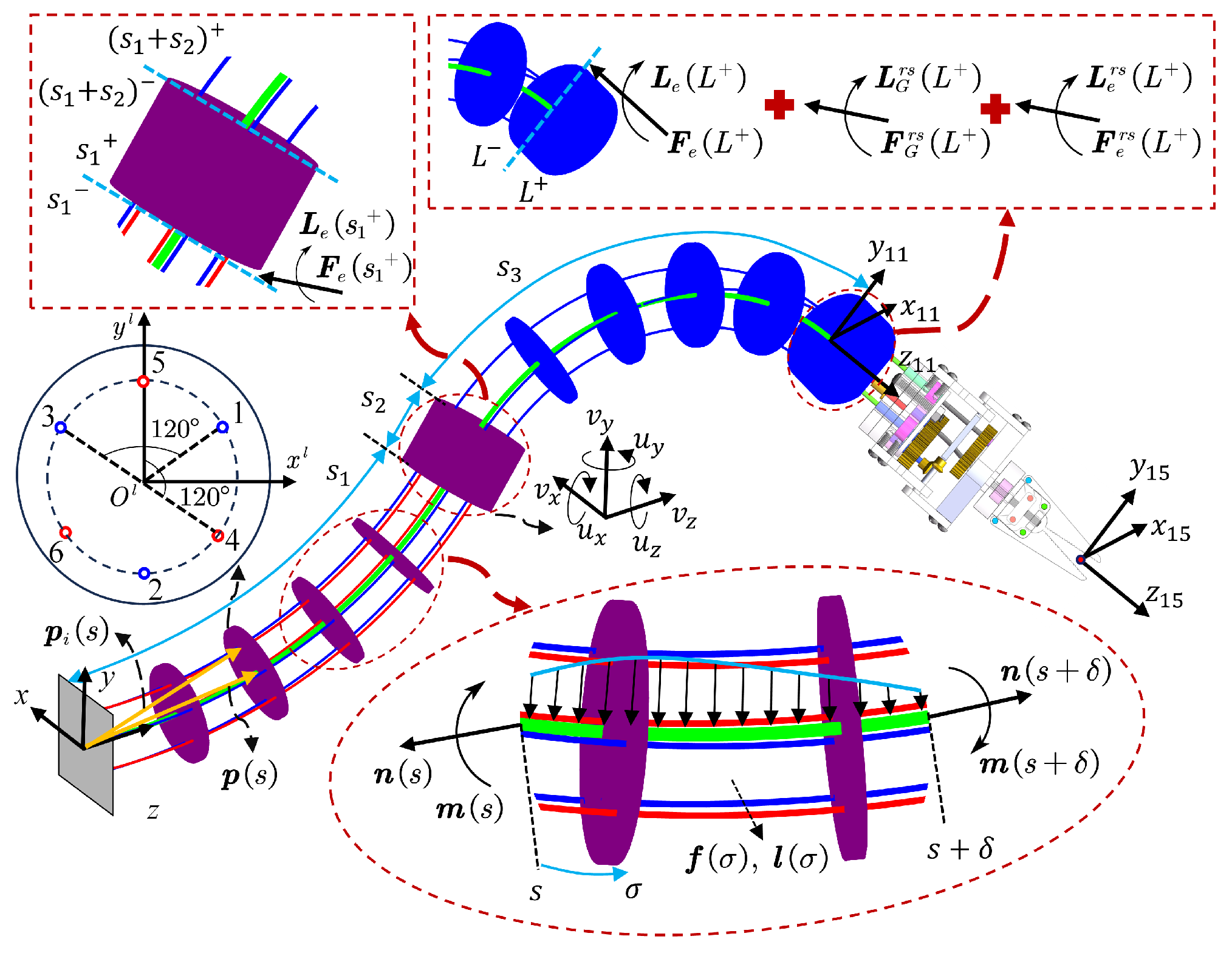

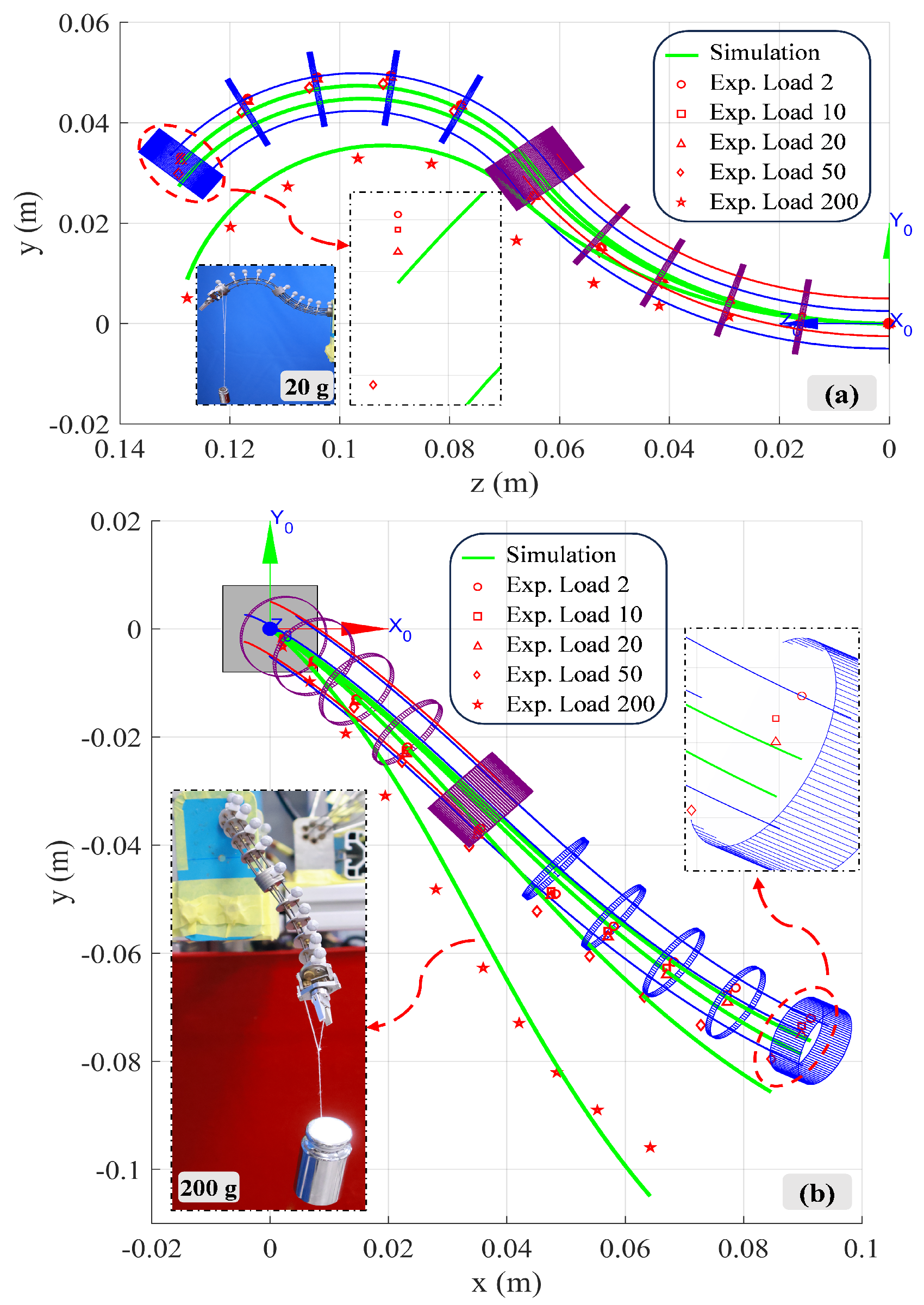

- To characterize the deformation and loading behavior of this hybrid mechanism, a kinetostatic model based on Cosserat rod theory is developed for the coupled “spinal rods + flexible shafts” system, encompassing the double-segment flexible joint, a rigid connecting segment, and the single-segment rigid joint.

- By incorporating models for guide tube friction and the distributed gravity of the spacer disks, a comprehensive kinetostatic model of the bio-inspired rigid–flexible continuum robot is formulated. This model accounts for the effects of flexible shaft tension, the gravity of the flexible shaft, spinal rod, and spacer disk, as well as external forces/moments.

- A physical prototype of the bio-inspired rigid–flexible continuum robot was fabricated. Experimental validations, including assessments of spacer disk mass effects, shape prediction accuracy, and the motion characteristics of the rigid joint, were performed to validate the developed kinetostatic model. The results demonstrate the model’s capability to predict robot deformation driven and controlled by flexible shaft forces, further laying the foundation for precise control of the bio-inspired rigid–flexible continuum robot.

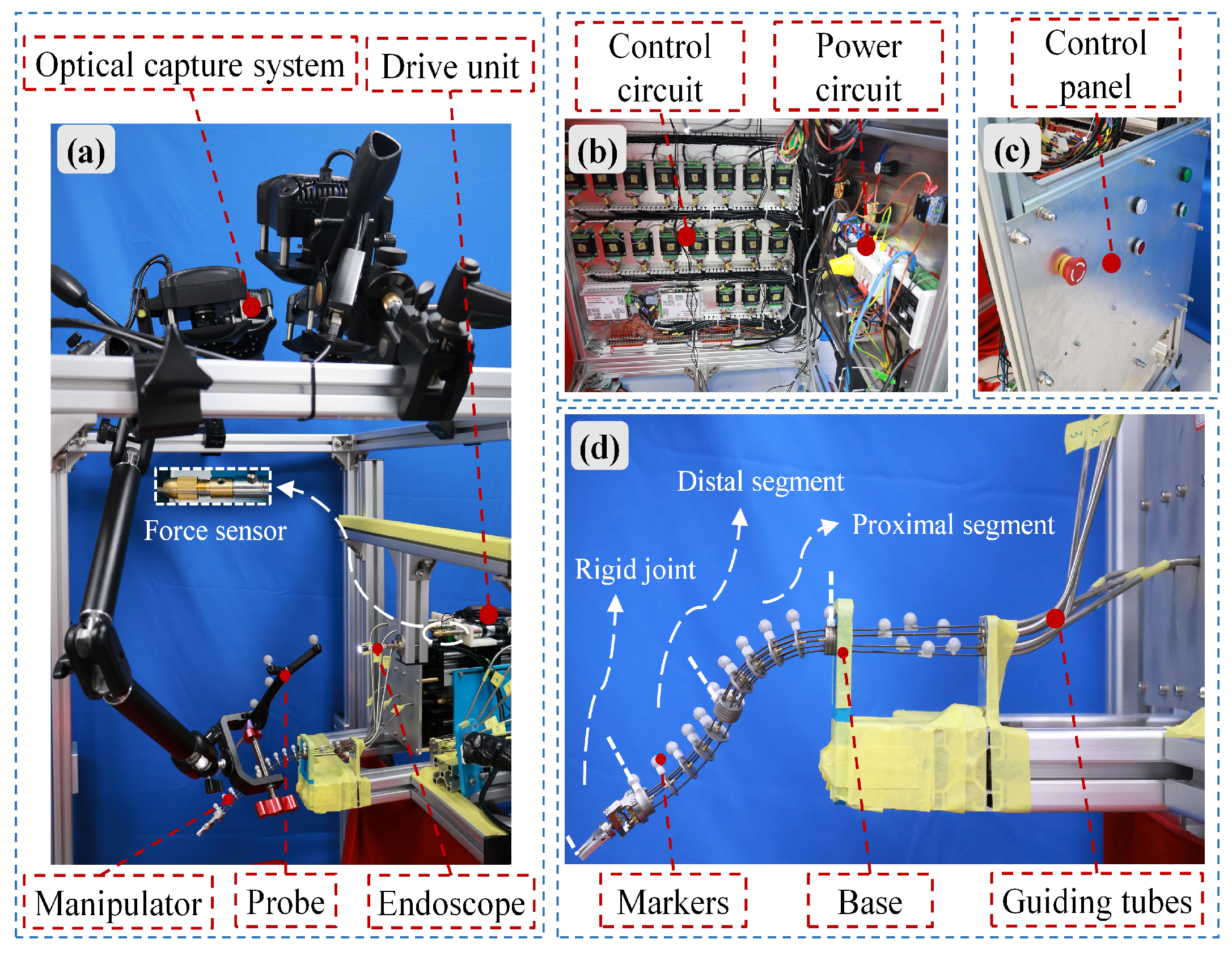

2. System Description

3. Kinetostatic Model of the Bio-Inspired Rigid–Flexible Continuum Robot

- Based on the multiple spacer disk layout scheme, the flexible shaft is treated as a continuous structural constraint. This assumption significantly reduces friction between the flexible shaft and the structure, avoiding the need for detailed solving of the flexible shaft shape, thus simplifying the model complexity of the bio-inspired rigid–flexible continuum robot.

- The flexible shaft is assumed to be non-retractable and to experience negligible friction with the spacer disks, an assumption justified by the use of powder metallurgy oil-impregnated bearings.

- The spinal rod material follows a linear constitutive relationship, and its material properties are assumed to be constant along its length.

- Since the proximal and distal segments of the flexible joints are bolted together, additional forces and moments arising at the interface due to the flexible shafts are ignored in the kinetostatic model.

3.1. Kinematics

3.1.1. Kinematics of Flexible Joints

3.1.2. Rigid Connection Segment Model

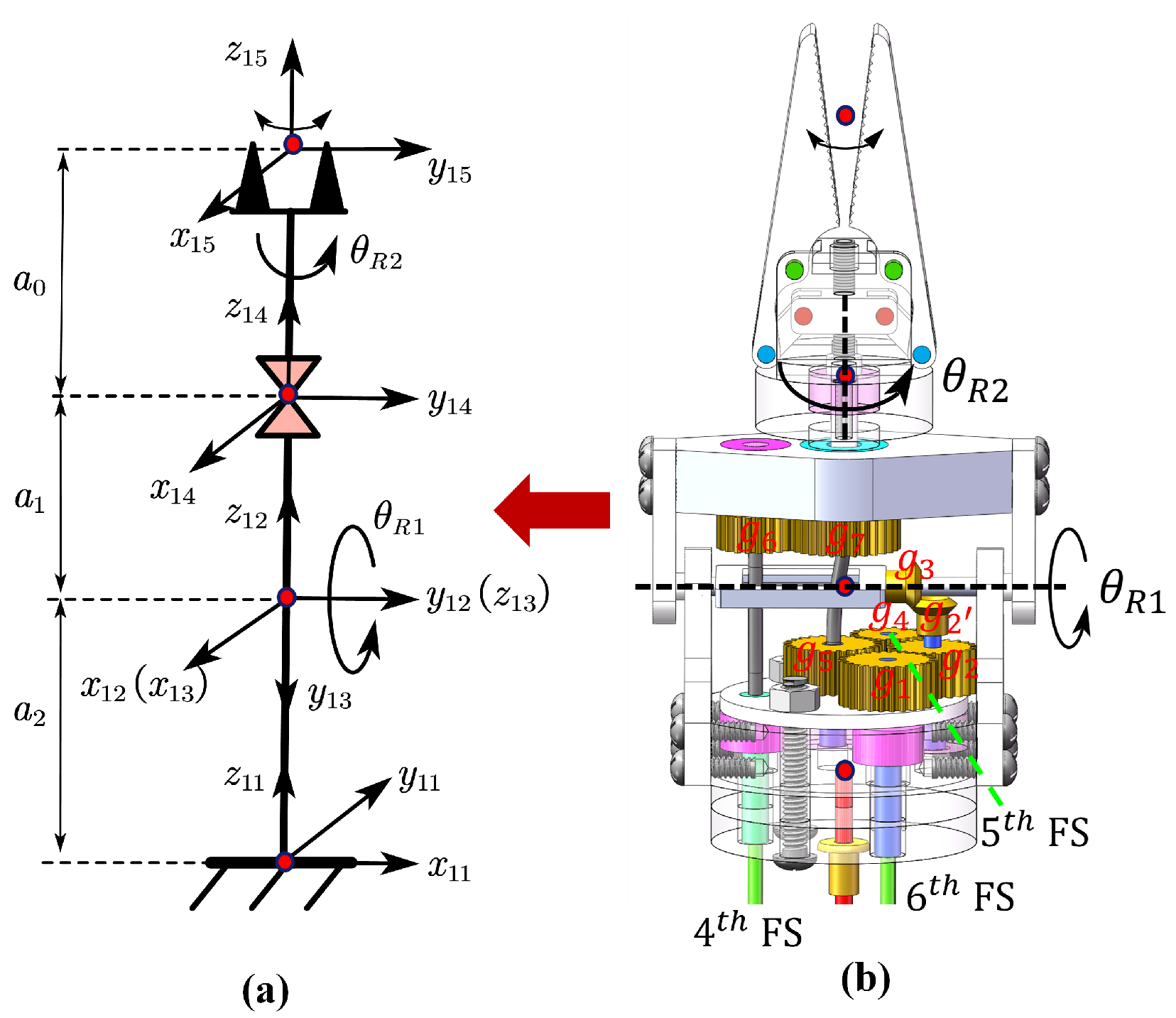

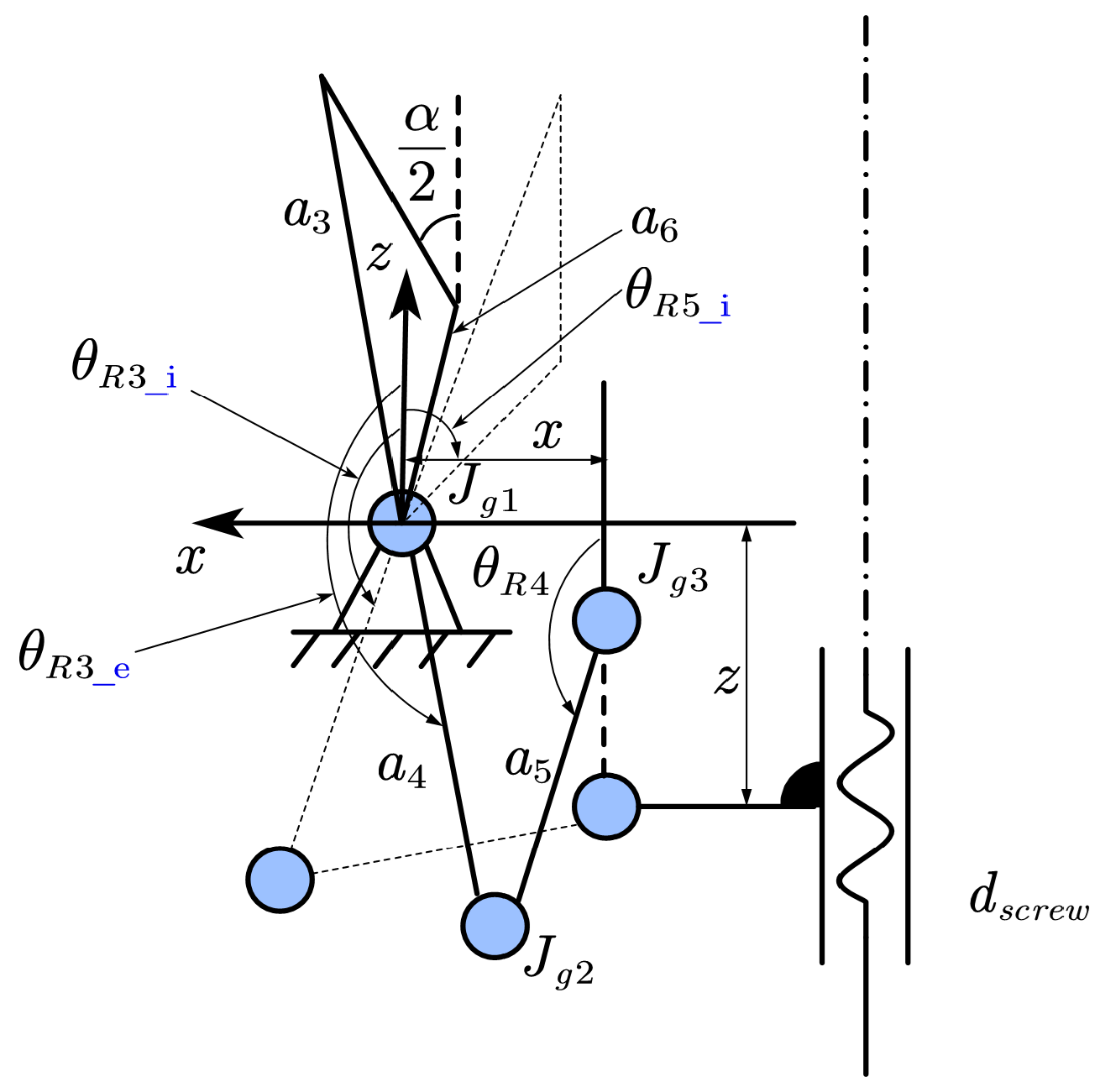

3.1.3. Kinematics of Rigid Joints

3.2. Kinetostatic Model of the Spinal Rods

3.3. Kinetostatic Model of the Continuum Robot

3.4. The Guiding Tubes Model

3.5. Numerical Implementation

4. Experimental Evaluation

4.1. Prototype and Experiment Setup

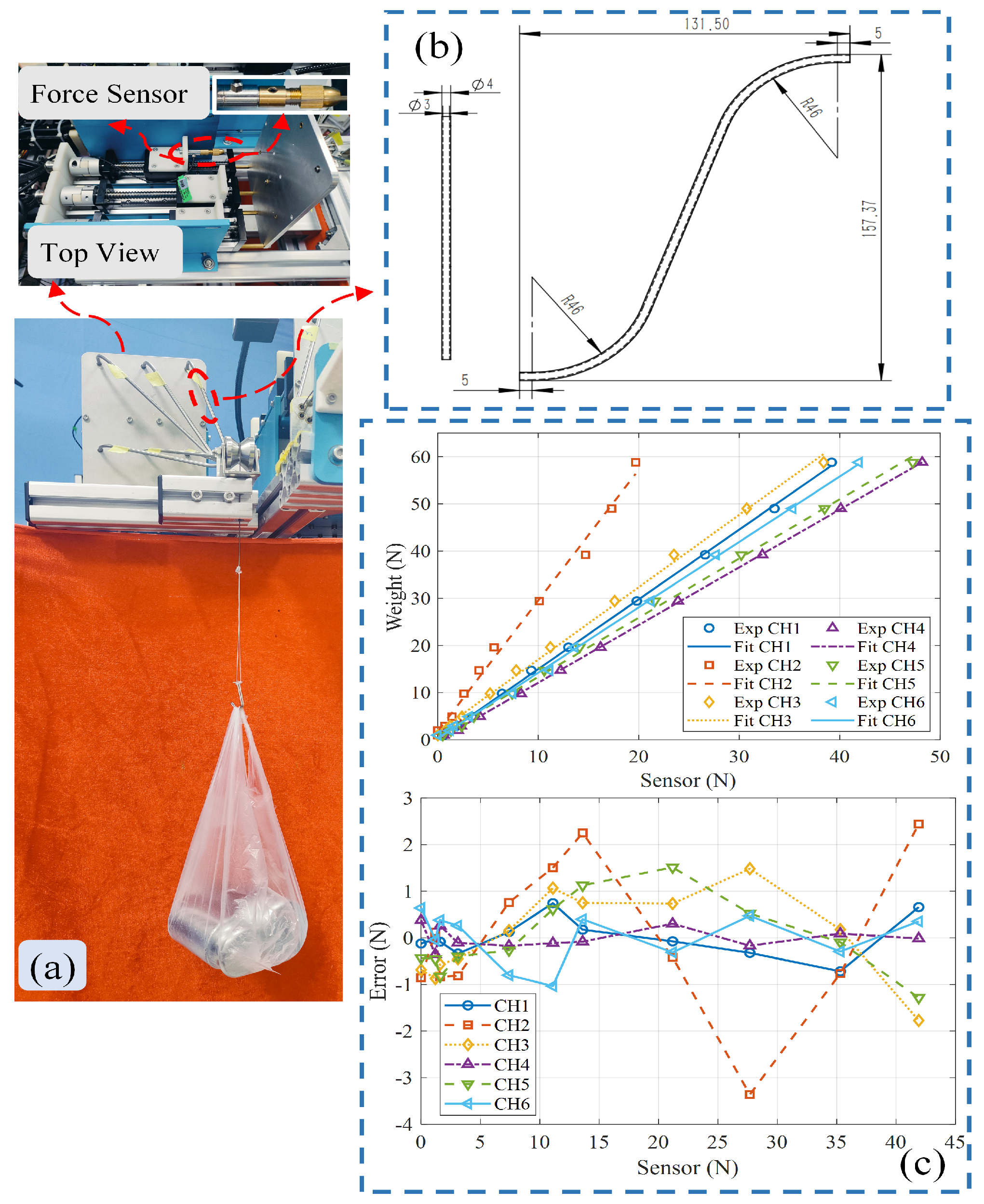

4.2. Parameter Calibration

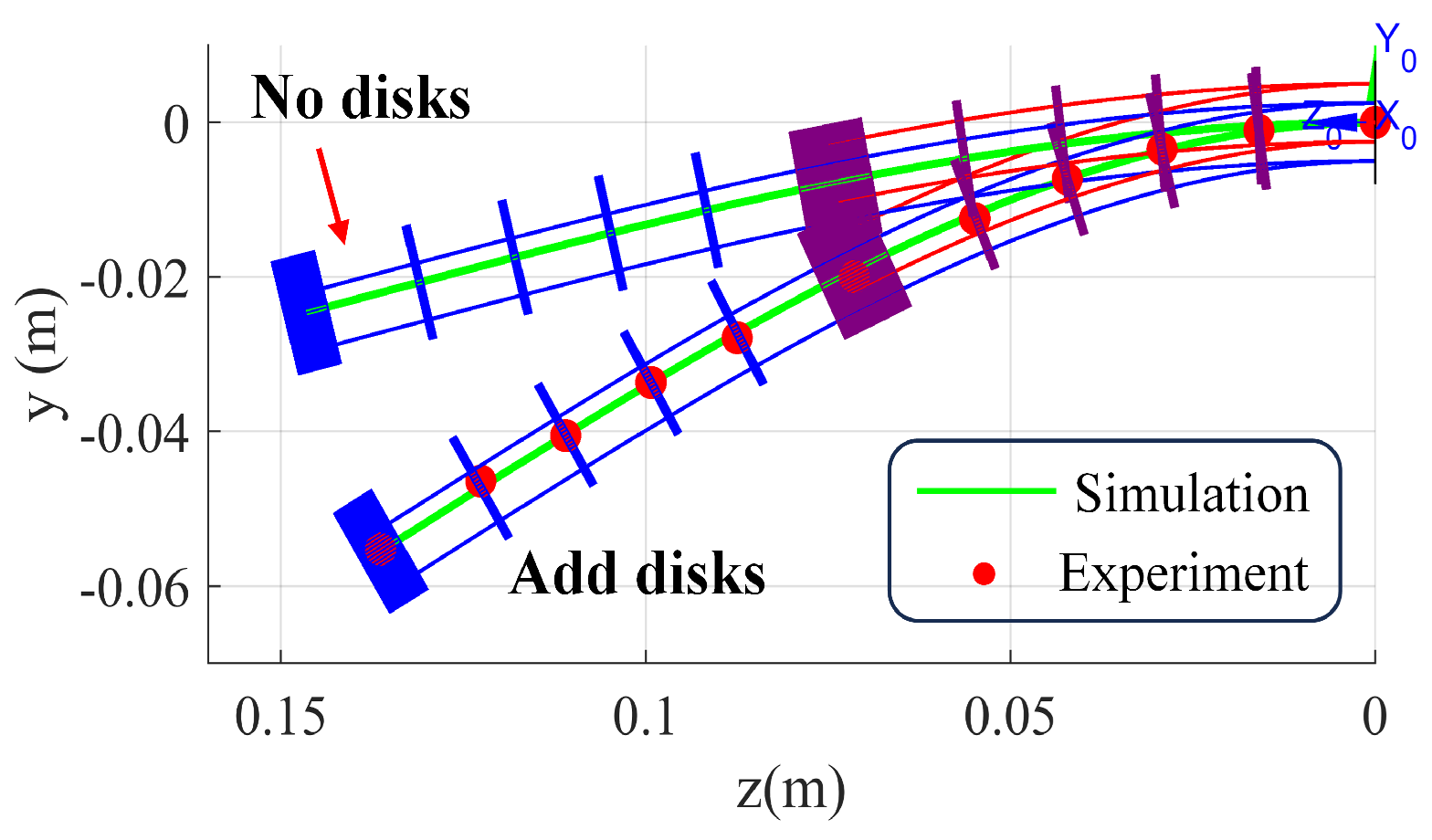

4.3. The Effect of Spacer Disks on Flexible Joints

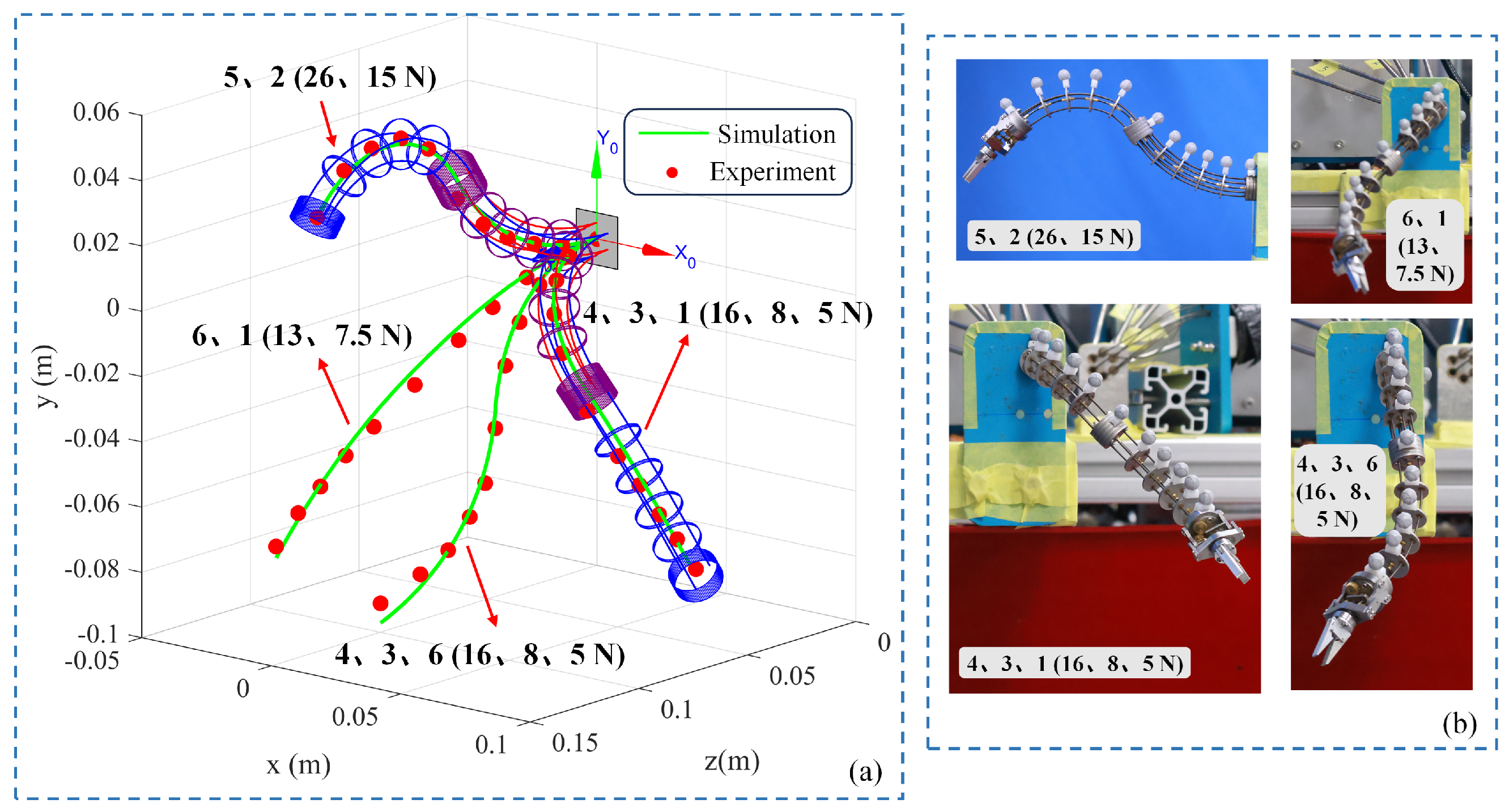

4.4. Shape Perception of Continuum Robot

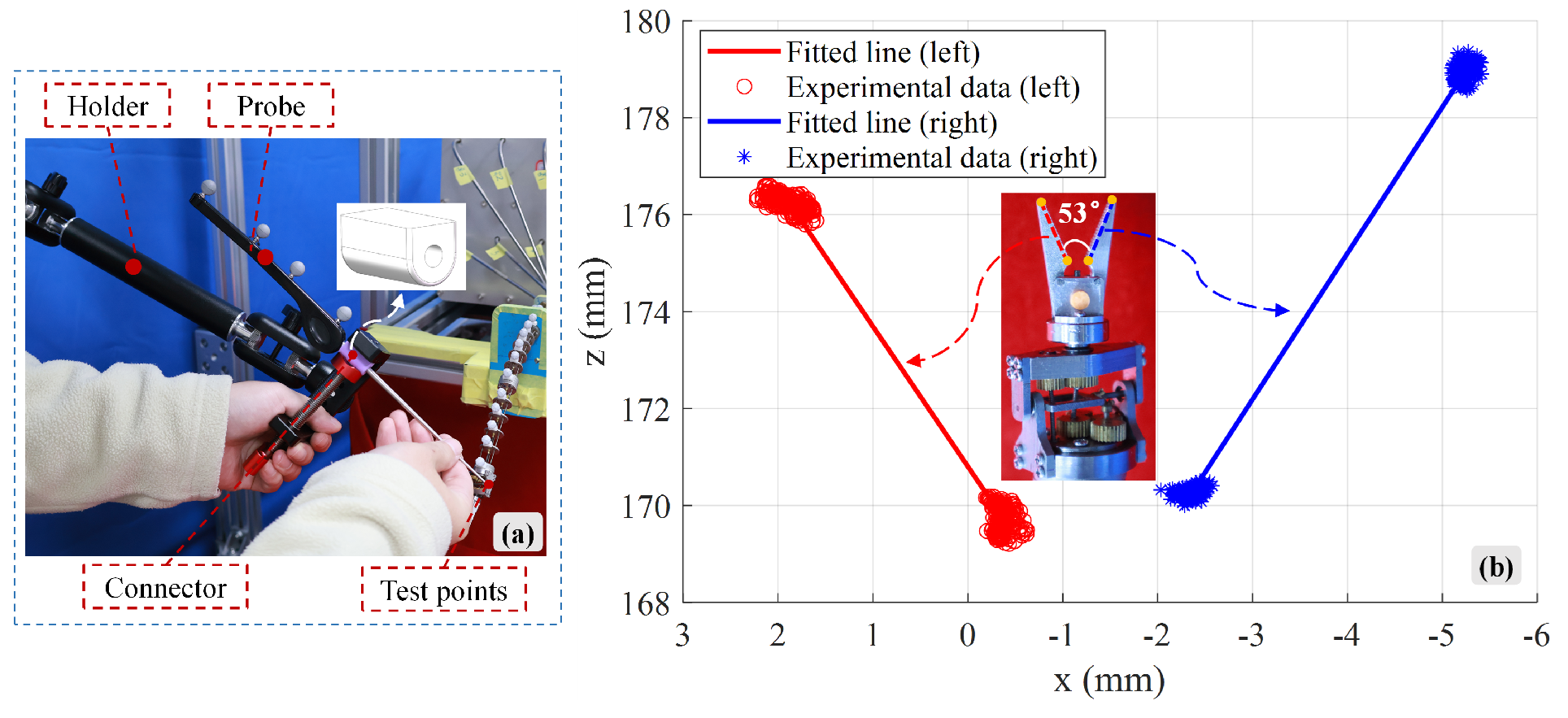

4.5. Rigid Joint Motion Performance

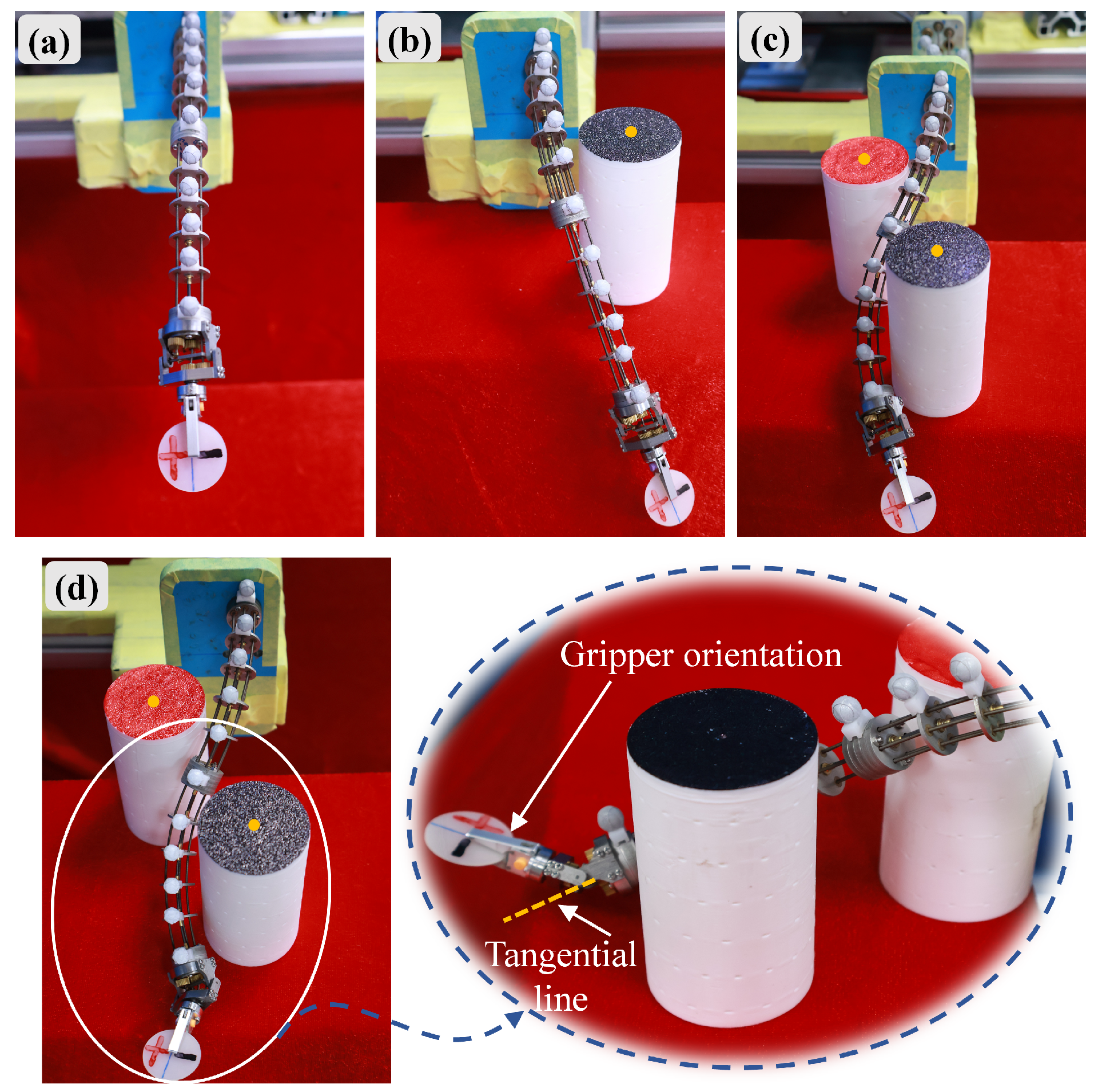

4.6. Multi-Obstacle Environment Omnidirectional Bending and Long-Distance Target Reaching

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Seetohul, J.; Shafiee, M. Snake Robots for Surgical Applications: A Review. Robotics 2022, 11, 57. [Google Scholar] [CrossRef]

- van Veggel, S.; Wiertlewski, M.; Doubrovski, E.L.; Kooijman, A.; Shahabi, E.; Mazzolai, B.; Scharff, R.B.N. Classification and Evaluation of Octopus-Inspired Suction Cups for Soft Continuum Robots. Adv. Sci. 2024, 11, 2400806. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, C.; Liu, Z.; Zhao, R.; An, D.; Wei, Y.; Wu, Z.; Yu, J. Design and Analysis of a Novel Tendon-Driven Continuum Robotic Dolphin. Bioinspiration Biomim. 2021, 16, 065002. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Wang, B.; Xiong, Y.; Zhang, J.; Tong, R.; Meng, Y.; Yu, J. Design and Analysis of a Novel Bionic Tensegrity Robotic Fish with a Continuum Body. Biomimetics 2024, 9, 19. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, L.; Sun, Y.; Chen, X. A Novel Contact-Aided Continuum Robotic System: Design, Modeling, and Validation. IEEE Trans. Robot. 2024, 40, 3024–3043. [Google Scholar] [CrossRef]

- Iqbal, F.; Esfandiari, M.; Amirkhani, G.; Hoshyarmanesh, H.; Lama, S.; Tavakoli, M.; Sutherland, G.R. Continuum and Soft Robots in Minimally Invasive Surgery: A Systematic Review. IEEE Access 2025, 13, 24053–24079. [Google Scholar] [CrossRef]

- Zhang, J.; Fang, Q.; Xiang, P.; Sun, D.; Xue, Y.; Jin, R.; Qiu, K.; Xiong, R.; Wang, Y.; Lu, H. A Survey on Design, Actuation, Modeling, and Control of Continuum Robot. Cyborg Bionic Syst. 2022, 2022, 9754697. [Google Scholar] [CrossRef]

- Riva, G.; Cravero, E.; Briguglio, M.; Capaccio, P.; Pecorari, G. The Flex Robotic System in Head and Neck Surgery: A Review. Cancers 2022, 14, 5541. [Google Scholar] [CrossRef]

- Zhang, L.; Qi, X.; Peng, Y.; Bao, S.; Yuan, J.; Guo, S. Review on Development Status, Challenges and Development Trends of Surgical Robots. In Proceedings of the 2024 IEEE International Conference on Mechatronics and Automation (ICMA), Tianjin, China, 4–7 August 2024; pp. 709–714. [Google Scholar] [CrossRef]

- Oliver-Butler, K.; Till, J.; Rucker, C. Continuum Robot Stiffness Under External Loads and Prescribed Tendon Displacements. IEEE Trans. Robot. 2019, 35, 403–419. [Google Scholar] [CrossRef]

- Janabi-Sharifi, F.; Jalali, A.; Walker, I.D. Cosserat Rod-Based Dynamic Modeling of Tendon-Driven Continuum Robots: A Tutorial. IEEE Access 2021, 9, 68703–68719. [Google Scholar] [CrossRef]

- Shi, J.; Abad, S.A.; Dai, J.S.; Wurdemann, H.A. Position and Orientation Control for Hyperelastic Multisegment Continuum Robots. IEEE/ASME Trans. Mechatron. 2024, 29, 995–1006. [Google Scholar] [CrossRef]

- Yang, C.; Geng, S.; Walker, I.; Branson, D.T.; Liu, J.; Dai, J.S.; Kang, R. Geometric Constraint-Based Modeling and Analysis of a Novel Continuum Robot with Shape Memory Alloy Initiated Variable Stiffness. Int. J. Robot. Res. 2020, 39, 1620–1634. [Google Scholar] [CrossRef]

- Kim, Y.; Zhao, X. Magnetic Soft Materials and Robots. Chem. Rev. 2022, 122, 5317–5364. [Google Scholar] [CrossRef] [PubMed]

- Yuan, H.; Zhou, L.; Xu, W. A Comprehensive Static Model of Cable-Driven Multi-Section Continuum Robots Considering Friction Effect. Mech. Mach. Theory 2019, 135, 130–149. [Google Scholar] [CrossRef]

- Wei, H.; Zhang, G.; Du, F.; Su, J.; Wu, J.; Li, Y.; Song, R. Dexterity Assessment for Wrist Joints of Surgical Robots: A Statics-Based Evaluation Method. IEEE Trans. Instrum. Meas. 2024, 73, 1–11. [Google Scholar] [CrossRef]

- Tan, N.; Gu, X.; Ren, H. Design, Characterization and Applications of a Novel Soft Actuator Driven by Flexible Shafts. Mech. Mach. Theory 2018, 122, 197–218. [Google Scholar] [CrossRef]

- Liu, Q.; Gu, X.; Tan, N.; Ren, H. Soft Robotic Gripper Driven by Flexible Shafts for Simultaneous Grasping and In-Hand Cap Manipulation. IEEE Trans. Autom. Sci. Eng. 2021, 18, 1134–1143. [Google Scholar] [CrossRef]

- Zhang, S.; Li, X.; Sui, D.; Zhang, Q.; Wang, Z.; Zheng, T.; Zhao, J.; Zhu, Y. Design, Modeling and Implementation of a Novel Rigid-Flexible Hybrid Robotic Arm. In Proceedings of the Intelligent Robotics and Applications; Lan, X., Mei, X., Jiang, C., Zhao, F., Tian, Z., Eds.; Springer Nature: Singapore, 2025; pp. 229–243. [Google Scholar] [CrossRef]

- Li, X.; Liu, L.; Huang, P.; Li, B.; Xing, Y.; Wu, Z. A Highly Adaptable Soft Pipeline Robot for Climbing Outside Millimeter-Sized Pipelines. Nano Energy 2025, 134, 110566. [Google Scholar] [CrossRef]

- Paternò, L.; Tortora, G.; Menciassi, A. Hybrid Soft–Rigid Actuators for Minimally Invasive Surgery. Soft Robot. 2018, 5, 783–799. [Google Scholar] [CrossRef]

- Wu, M.; Xu, Y.; Wang, X.; Liu, H.; Li, G.; Wang, C.; Cao, Y.; Guo, Z. Design and Kinematics of a Novel Rigid-Flexible Coupling Hybrid Robot for Aeroengine Blades in Situ Repair. Eng. Comput. 2024, 41, 2504–2533. [Google Scholar] [CrossRef]

- Grazioso, S.; Di Gironimo, G.; Siciliano, B. A Geometrically Exact Model for Soft Continuum Robots: The Finite Element Deformation Space Formulation. Soft Robot. 2019, 6, 790–811. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Wu, B.; Jin, J.; Xu, K. A Variable Curvature Model for Multi-Backbone Continuum Robots to Account for Inter-Segment Coupling and External Disturbance. IEEE Robot. Autom. Lett. 2021, 6, 1590–1597. [Google Scholar] [CrossRef]

- Li, Y.; Yang, F.; Xu, M.; Peng, Y. A High Expansion and Contraction Ratio Tendon-Driven Spiral Soft Robotic Arm Inspired by the Potato Tower. In Mechanics of Advanced Materials and Structures; Taylor & Francis: London, UK, 2025; pp. 1–15. [Google Scholar] [CrossRef]

- Webster, R.J.; Jones, B.A. Design and Kinematic Modeling of Constant Curvature Continuum Robots: A Review. Int. J. Robot. Res. 2010, 29, 1661–1683. [Google Scholar] [CrossRef]

- Roy, R.; Wang, L.; Simaan, N. Modeling and Estimation of Friction, Extension, and Coupling Effects in Multisegment Continuum Robots. IEEE/ASME Trans. Mechatron. 2017, 22, 909–920. [Google Scholar] [CrossRef]

- Awtar, S.; Slocum, A.H.; Sevincer, E. Characteristics of Beam-Based Flexure Modules. J. Mech. Des. 2006, 129, 625–639. [Google Scholar] [CrossRef]

- Chen, Y.; Yao, S.; Meng, M.Q.H.; Liu, L. Chained Spatial Beam Constraint Model: A General Kinetostatic Model for Tendon-Driven Continuum Robots. IEEE/ASME Trans. Mechatron. 2024, 29, 3534–3545. [Google Scholar] [CrossRef]

- Rone, W.S.; Ben-Tzvi, P. Continuum Robot Dynamics Utilizing the Principle of Virtual Power. IEEE Trans. Robot. 2014, 30, 275–287. [Google Scholar] [CrossRef]

- Alessi, C.; Agabiti, C.; Caradonna, D.; Laschi, C.; Renda, F.; Falotico, E. Rod Models in Continuum and Soft Robot Control: A Review. arXiv 2024, arXiv:2407.05886. [Google Scholar] [CrossRef]

- Boyer, F.; Lebastard, V.; Candelier, F.; Renda, F.; Alamir, M. Statics and Dynamics of Continuum Robots Based on Cosserat Rods and Optimal Control Theories. IEEE Trans. Robot. 2023, 39, 1544–1562. [Google Scholar] [CrossRef]

- Xun, L.; Zheng, G.; Kruszewski, A. Cosserat-Rod-Based Dynamic Modeling of Soft Slender Robot Interacting With Environment. IEEE Trans. Robot. 2024, 40, 2811–2830. [Google Scholar] [CrossRef]

- Laschi, C.; Mazzolai, B.; Mattoli, V.; Cianchetti, M.; Dario, P. Design of a Biomimetic Robotic Octopus Arm. Bioinspiration Biomim. 2009, 4, 015006. [Google Scholar] [CrossRef] [PubMed]

- Tekinalp, A.; Naughton, N.; Kim, S.H.; Halder, U.; Gillette, R.; Mehta, P.G.; Kier, W.; Gazzola, M. Topology, Dynamics, and Control of a Muscle-Architected Soft Arm. Proc. Natl. Acad. Sci. USA 2024, 121, e2318769121. [Google Scholar] [CrossRef] [PubMed]

- Bai, H.; Lee, B.G.; Yang, G.; Shen, W.; Qian, S.; Zhang, H.; Zhou, J.; Fang, Z.; Zheng, T.; Yang, S.; et al. Unlocking the Potential of Cable-Driven Continuum Robots: A Comprehensive Review and Future Directions. Actuators 2024, 13, 52. [Google Scholar] [CrossRef]

- Tummers, M.; Lebastard, V.; Boyer, F.; Troccaz, J.; Rosa, B.; Chikhaoui, M.T. Cosserat Rod Modeling of Continuum Robots from Newtonian and Lagrangian Perspectives. IEEE Trans. Robot. 2023, 39, 2360–2378. [Google Scholar] [CrossRef]

- Rucker, D.C.; Webster III, R.J. Statics and Dynamics of Continuum Robots With General Tendon Routing and External Loading. IEEE Trans. Robot. 2011, 27, 1033–1044. [Google Scholar] [CrossRef]

- Till, J.; Aloi, V.; Rucker, C. Real-Time Dynamics of Soft and Continuum Robots Based on Cosserat Rod Models. Int. J. Robot. Res. 2019, 38, 723–746. [Google Scholar] [CrossRef]

- Quaglia, C.; Petroni, G.; Niccolini, M.; Caccavaro, S.; Dario, P.; Menciassi, A. Design of a Compact Robotic Manipulator for Single-Port Laparoscopy. J. Mech. Des. 2014, 136, 105001. [Google Scholar] [CrossRef]

- YS/T 1147-2016; Method for Tension Testing of Nickel-Titanium Superelastic Materials. National Nonferrous Metals Standardization Technical Committee: Beijing, China, 2016.

- GB/T 228.1-2021; Metallic Materials-Tensile Testing-Part 1:Method of Test at Room Temperature. National Steel Standardization Technical Committee: Beijing, China, 2021.

| Link | ||||

|---|---|---|---|---|

| 12 | 0 | |||

| 13 | 0 | 0 | ||

| 14 | 0 | |||

| 15 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, J.; Liu, Q.; Li, P.; Wang, C.; Zhao, X.; Hu, X. Design, Modeling, and Experimental Validation of a Bio-Inspired Rigid–Flexible Continuum Robot Driven by Flexible Shaft Tension–Torsion Synergy. Biomimetics 2025, 10, 301. https://doi.org/10.3390/biomimetics10050301

Dong J, Liu Q, Li P, Wang C, Zhao X, Hu X. Design, Modeling, and Experimental Validation of a Bio-Inspired Rigid–Flexible Continuum Robot Driven by Flexible Shaft Tension–Torsion Synergy. Biomimetics. 2025; 10(5):301. https://doi.org/10.3390/biomimetics10050301

Chicago/Turabian StyleDong, Jiaxiang, Quanquan Liu, Peng Li, Chunbao Wang, Xuezhi Zhao, and Xiping Hu. 2025. "Design, Modeling, and Experimental Validation of a Bio-Inspired Rigid–Flexible Continuum Robot Driven by Flexible Shaft Tension–Torsion Synergy" Biomimetics 10, no. 5: 301. https://doi.org/10.3390/biomimetics10050301

APA StyleDong, J., Liu, Q., Li, P., Wang, C., Zhao, X., & Hu, X. (2025). Design, Modeling, and Experimental Validation of a Bio-Inspired Rigid–Flexible Continuum Robot Driven by Flexible Shaft Tension–Torsion Synergy. Biomimetics, 10(5), 301. https://doi.org/10.3390/biomimetics10050301