Influence of Particle Size and Hot-Pressing Parameters on Mechanical Properties of Bamboo-Based Composite Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Instruments

2.1.1. Experimental Material

2.1.2. Main Instruments

2.2. Experimental Method

2.2.1. Selecting Particles Size of Bamboo Powder and Its Alkali Treatment

2.2.2. Preparation of Zein Solution and Its Ultra-High-Pressure Treatment

2.2.3. Preparation of Bamboo/Zein Composites

2.2.4. Mechanical Property and Water Resistance Tests

2.2.5. Establishing Response Surface Model of Mechanical Properties of Composites

3. Results and Discussion

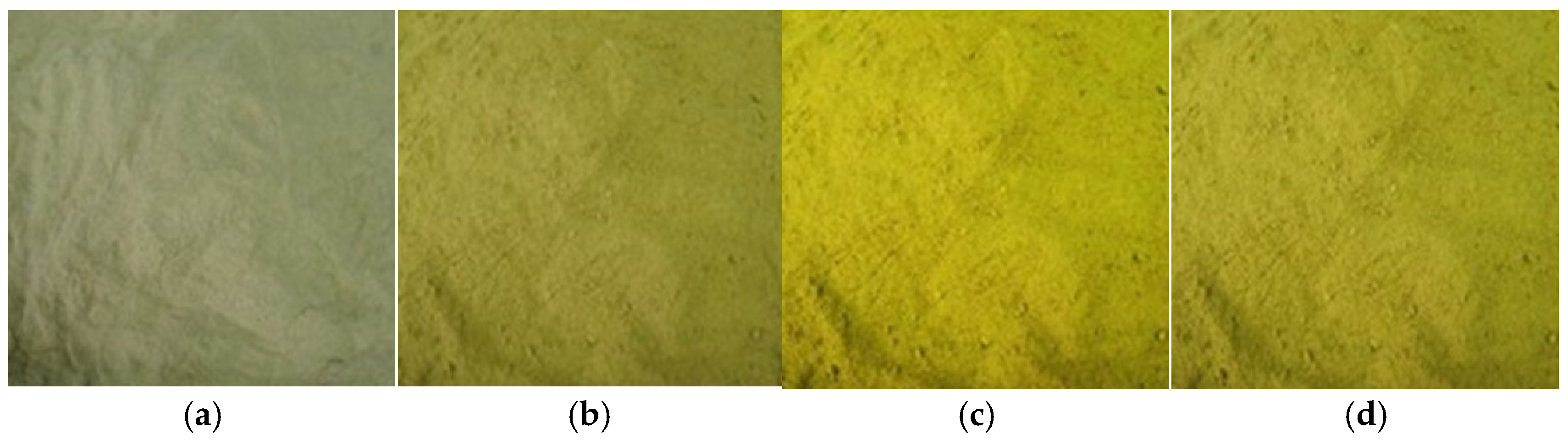

3.1. Appearance Changes of Bamboo Powder Treated with Alkali

3.2. Effect of Particle Size of Bamboo Powder on the Mechanical Properties of Composites

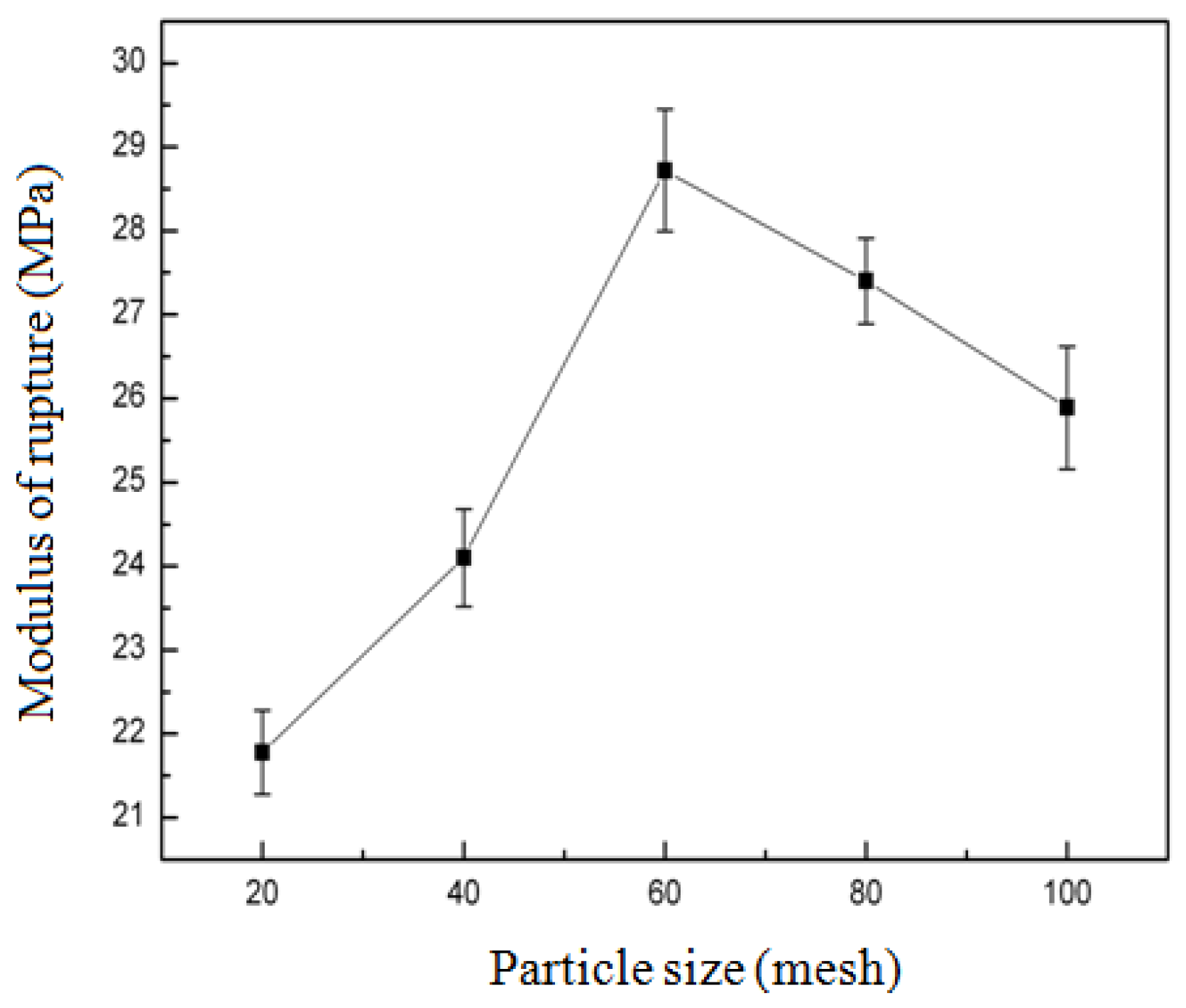

3.2.1. Effect of Particle Size of Bamboo Powder on the Modulus of Rupture (MOR) of Composites

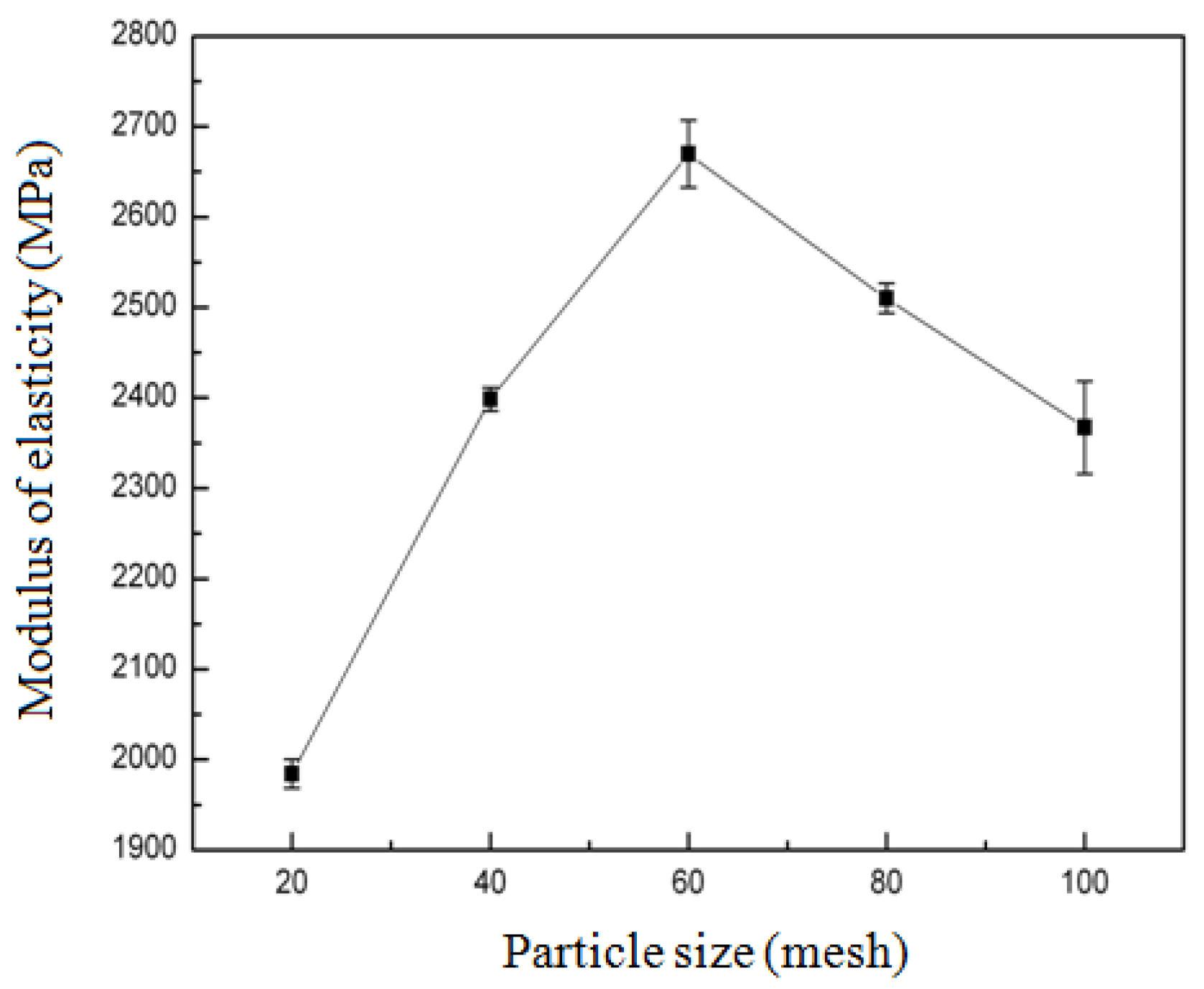

3.2.2. Effect of Particle Size of Bamboo Powder on the Modulus of Elasticity (MOE) of Composites

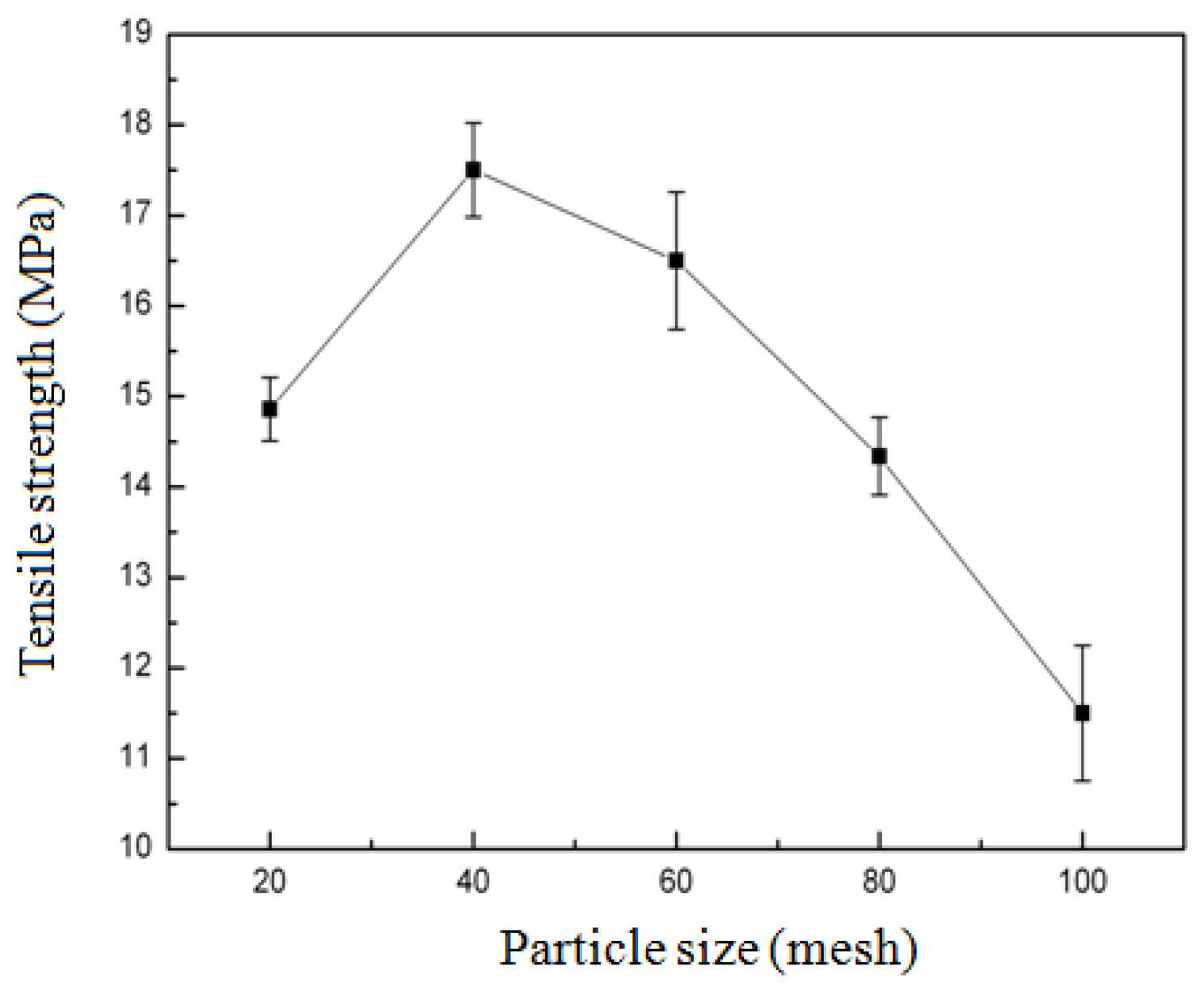

3.2.3. Effect of Particle Size of Bamboo Powder on the Tensile Strength (TS) of Composites

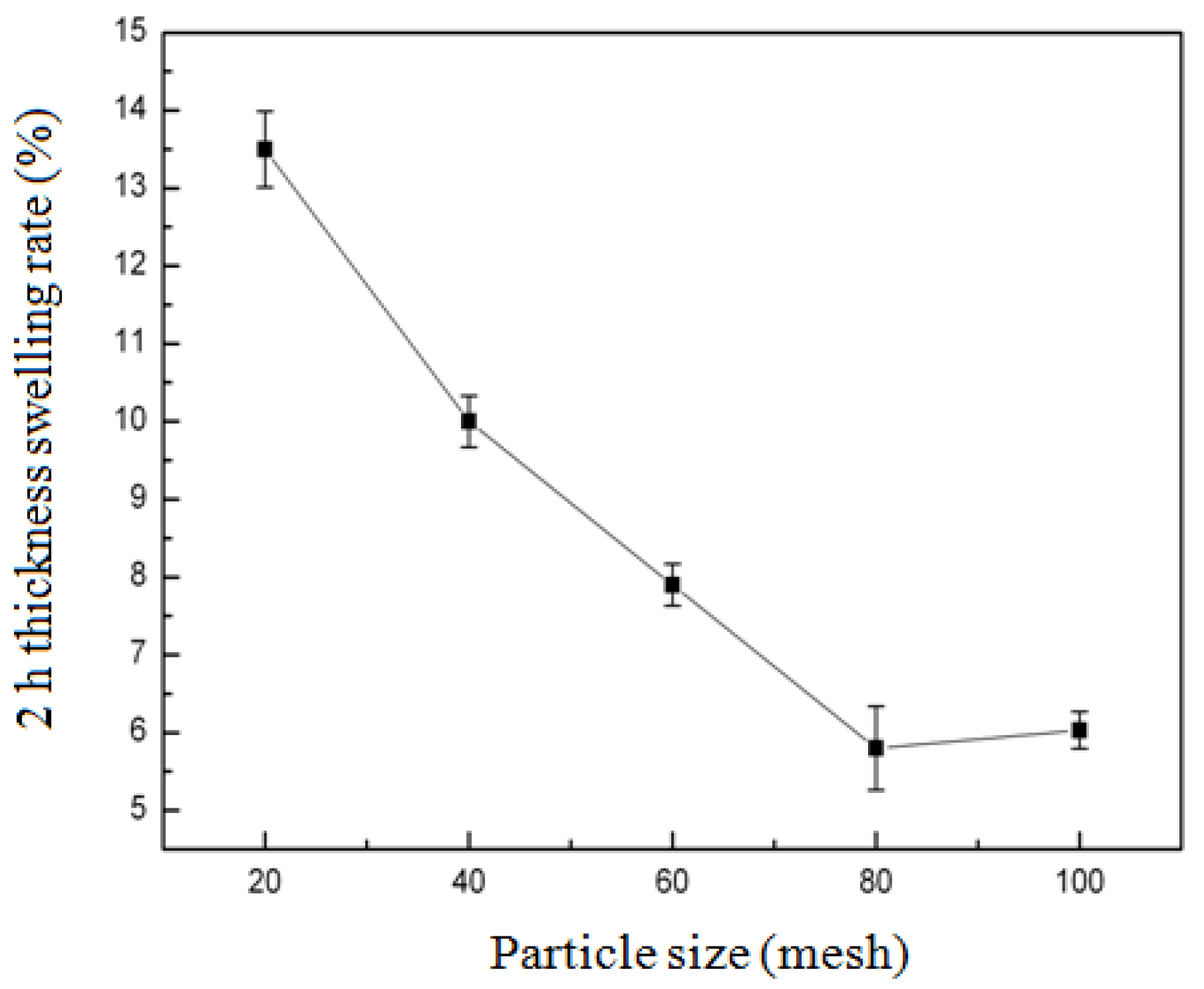

3.2.4. Effect of Particle Size of Bamboo Powder on the 2 h Thickness Swelling Rate (2h-TSR) of Composites

3.3. Influence of Hot-Pressing Parameters on Mechanical Properties of Composites

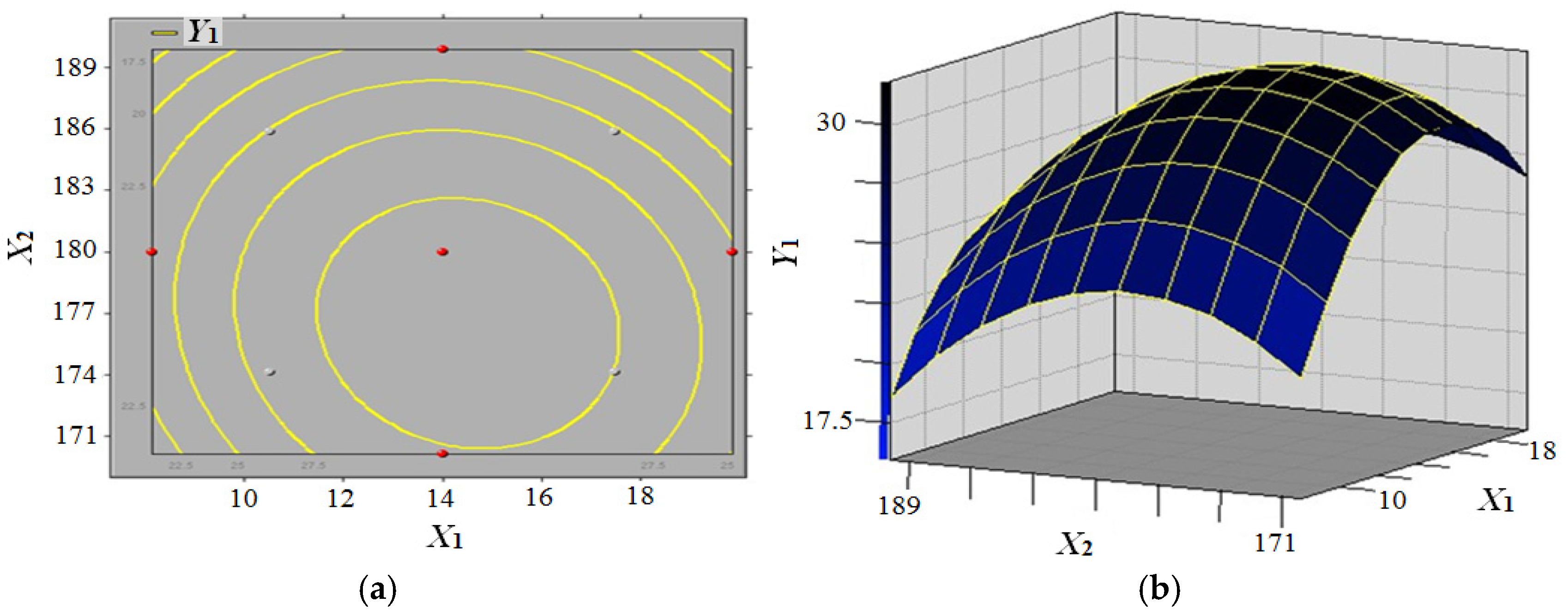

3.3.1. Influence of Moisture Content and Hot-Pressing Parameters on the Modulus of Rupture (MOR) of Composites

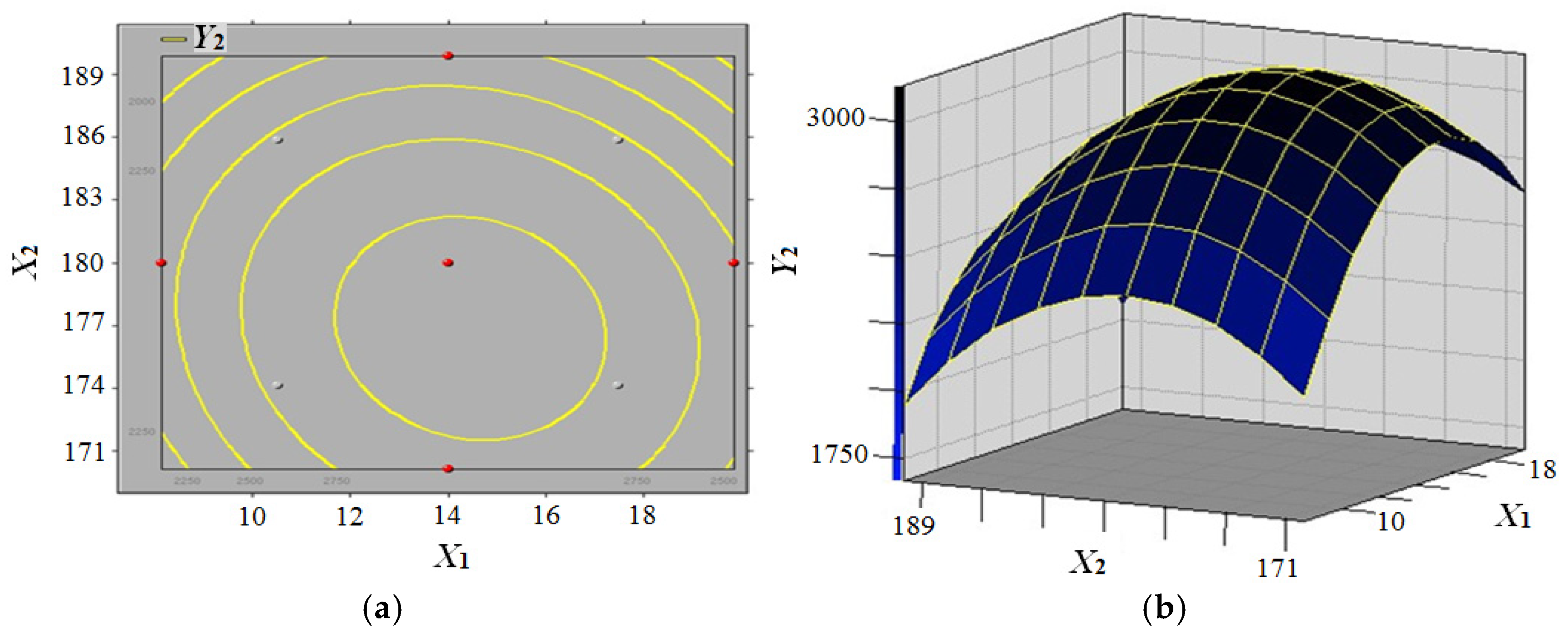

3.3.2. Influence of Moisture Content and Hot-Pressing Parameters on the Modulus of Elasticity (MOE) of Composites

3.3.3. Influence of Moisture Content and Hot-Pressing Parameters on the Tensile Strength (TS) of Composites

3.3.4. Influence of Moisture Content and Hot-Pressing Parameters on the 2 h Thickness Swelling Rate (2h-TSR) of Composites

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, H.; Sheng, K.C.; Chen, J. Mechanical and thermal properties of sodium silicate treated moso bamboo particles reinforced PVC composites. Sci. China Technol. Sci. 2010, 53, 2932–2935. [Google Scholar] [CrossRef]

- Qian, S.; Mao, H.; Sheng, K.; Lu, J.; Luo, Y.; Hou, C. Effect of low-concentration alkali solution pretreatment on the properties of bamboo particles reinforced poly(lactic acid) composites. J. Appl. Polym. Sci. 2013, 130, 1667–1674. [Google Scholar] [CrossRef]

- Kim, S.; Xu, J.Y.; Liu, S. Production of biopolymer composites by particle bonding. Compos. Part A Appl. Sci. Manuf. 2010, 41, 146–153. [Google Scholar] [CrossRef]

- Kim, S. Production of composites by using gliadin as a bonding material. J. Cereal Sci. 2011, 54, 168–172. [Google Scholar] [CrossRef]

- Bull, M.K.; Hayman, M.M.; Stewart, C.M. Effect of prior growth temperature, type of enrichment medium, and temperature and time of storage on recovery of Listeria monocytogenes following high pressure processing of milk. Int. J. Food Microbiol. 2005, 101, 53–61. [Google Scholar] [CrossRef]

- Li, Y.H.; Sun, X.S. Nanocomposites of PLA and surface grafted MgO: Preparation and characterization. J. Biobased Mater. Bioenergy 2011, 5, 452–459. [Google Scholar] [CrossRef]

- Floury, J.; Desrumaux, A.; Axelos, M.A.V. Degradation of methylcellulose during ultra-high pressure homogenization. Food Hydrocoll. 2002, 16, 47–53. [Google Scholar] [CrossRef]

- Chang, R.; Sheng, K.C.; Wang, H. Mechanical properties of particleboard based on zein adhesive. J. Mater. Sci. Eng. 2009, 27, 437–440. [Google Scholar]

- Guessasma, S.; Benseddiq, N.; Lourdin, D. Effective Young’s modulus of biopolymer composites with imperfect interface. Int. J. Solids Struct. 2010, 47, 2436–2444. [Google Scholar] [CrossRef]

- Koseki, S.; Mizuno, Y.; Yamamoto, K. Use of mild-heat treatment following high-pressure processing to prevent recovery of pressure-injured Listeria monocytogenes in milk. Food Microbiol. 2008, 25, 288–293. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, H.T.; Wei, D.Y. Experimental computation process of the surface energy of leaves by acquir-ing drop image information. J. Nanoelectron Optoelectron. 2012, 7, 173–176. [Google Scholar] [CrossRef]

- Li, Y.H.; Sun, X.S. Mechanical and thermal properties of biocomposites from poly(lactic acid) and DDGS. J. Appl. Polym. Sci. 2011, 121, 589–597. [Google Scholar] [CrossRef]

- Neo, Y.P.; Ray, S.; Easteal, A.J. Influence of solution and processing parameters towards the fabrication of electrospun zein fibers with sub-micron diameter. J. Food Eng. 2012, 109, 645–651. [Google Scholar] [CrossRef]

- Panchapakesan, C.; Sozer, N.; Dogan, H. Effect of different fractions of zein on the mechanical and phase properties of zein films at nano-scale. J. Cereal Sci. 2012, 55, 174–182. [Google Scholar] [CrossRef]

- Reddy, N.; Yang, Y.Q. Novel green composites using zein as matrix and jute fibers as reinforcement. Biomass Bioenergy 2011, 35, 3496–3503. [Google Scholar] [CrossRef]

- Jiang, Q.R.; Reddy, N.; Yang, Y.Q. Cytocompatible cross-linking of electrospun zein fibers for the develop-ment of water-stable tissue engineering scaffolds. Acta Biomater. 2010, 6, 4042–4051. [Google Scholar] [CrossRef]

- Luo, Y.C.; Zhang, B.; Cheng, W.H. Preparation, characterization and evaluation of selenite-loaded chi-tosan/TPP nanoparticles with or without zein coating. Carbohydr. Polym. 2010, 82, 942–951. [Google Scholar] [CrossRef]

- Chen, J.; Sheng, K.C.; Chang, R. Influence of γ-irradiation on rheological properties of zein. J. Mater. Sci. Eng. 2011, 29, 263–266. [Google Scholar]

- Anderson, T.J.; Ilankovan, P.; Lamsal, B.P. Two fraction extraction of α-zein from DDGS and its characteri-zation. Ind. Crops Prod. 2012, 37, 466–472. [Google Scholar] [CrossRef]

- Salerno, A.; Zeppetelli, S.; Maio, E.D. Novel 3D porous multi-phase composite scaffolds based on PCL, thermoplastic zein and HA prepared via supercritical CO2 foaming for bone regeneration. Compos. Sci. Technol. 2010, 70, 1838–1846. [Google Scholar] [CrossRef][Green Version]

- John, M.J.; Bellmann, C.; Anandjiwala, R.D. Kenaf–Polypropylene composites: Effect of amphiphilic coupling agent on surface properties of fibres and composites. Carbohydr. Polym. 2010, 82, 549–554. [Google Scholar] [CrossRef]

- Li, Y.H.; Sun, X.S. Preparation and characterization of polymer–inorganic nanocomposites by in situ melt polycondensation of L-lactic acid and surface-hydroxylated MgO. Biomacromolecules 2010, 11, 1847–1855. [Google Scholar] [CrossRef]

- Ahn, B.K.; Sung, J.; Li, Y. Synthesis and characterization of amphiphilic reduced graphene oxide with epox-idized methyl oleate. Adv. Mater. 2012, 24, 2123–2129. [Google Scholar] [CrossRef]

- Wu, Q.D.; Yang, X.C.; Xiang, S.L. Analysis of reed powder by TD-GC/MS. Chin. J. Spectrosc. Lab. 2011, 28, 531–538. [Google Scholar] [CrossRef]

- Wu, Q.D.; Liang, S.; Yi, L. Evaluation on environment friendliness of poplar powder-based composites made by warm self-bonding compaction. J. Chongqing Jiaotong Univ. Nat. Sci. 2012, 31, 528–534. [Google Scholar]

- Huang, J.; Chen, J.L.; Wu, Q.D. Optimization of technical parameters for self-bonding mold forming of poplar powder. J. Northeast. For. Univ. 2012, 40, 81–84. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Zhang, Y.; Wu, Y.; Wang, S.; Li, J.; Chen, Z.; Zhang, Y.; Deng, Y. Biomimetic bamboo-based composites for impact resistance. Compos. Part B Eng. 2022, 245, 110203. [Google Scholar]

- Zhang, Y.; Wang, L.; Liu, H. Bioinspired bamboo fiber-reinforced composites with 3D-printed honeycomb cores for enhanced interfacial bonding. ACS Sustain. Chem. Eng. 2021, 9, 5342–5353. [Google Scholar]

- Li, J.; Xu, T.; Chen, R. Biomimetic bamboo leaf surface-engineered composites with superhydrophobic and self-cleaning properties. Compos. Part B Eng. 2023, 264, 110892. [Google Scholar]

- Wang, H.; Zhang, K.; Zhou, M. Life cycle-assisted design of fully biodegradable bamboo composites with 80% degradation efficiency via enzymatic hydrolysis. Green Chem. 2022, 24, 7021–7034. [Google Scholar]

| Indicators | Parameters | Properties |

|---|---|---|

| Influencing factors | X1 | Moisture content (%) |

| X2 | Press temperature (°C) | |

| X3 | Press time (min) | |

| Response value | Y1 | Modulus of rupture (MOR) (MPa) |

| Y2 | Modulus of elasticity (MOE) (MPa) | |

| Y3 | Tensile strength (TS) (MPa) | |

| Y4 | 2 h thickness swelling rate (2h-TSR) (%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, J.; Sheng, K.; Chen, J.; Ding, X.; Wen, Z.; Li, S. Influence of Particle Size and Hot-Pressing Parameters on Mechanical Properties of Bamboo-Based Composite Materials. Biomimetics 2025, 10, 156. https://doi.org/10.3390/biomimetics10030156

Lu J, Sheng K, Chen J, Ding X, Wen Z, Li S. Influence of Particle Size and Hot-Pressing Parameters on Mechanical Properties of Bamboo-Based Composite Materials. Biomimetics. 2025; 10(3):156. https://doi.org/10.3390/biomimetics10030156

Chicago/Turabian StyleLu, Jun, Kuichuan Sheng, Jie Chen, Xumin Ding, Zichao Wen, and Sha Li. 2025. "Influence of Particle Size and Hot-Pressing Parameters on Mechanical Properties of Bamboo-Based Composite Materials" Biomimetics 10, no. 3: 156. https://doi.org/10.3390/biomimetics10030156

APA StyleLu, J., Sheng, K., Chen, J., Ding, X., Wen, Z., & Li, S. (2025). Influence of Particle Size and Hot-Pressing Parameters on Mechanical Properties of Bamboo-Based Composite Materials. Biomimetics, 10(3), 156. https://doi.org/10.3390/biomimetics10030156