Loong: An Open-Source Platform for Full-Size Universal Humanoid Robot Toward Better Practicality

Abstract

1. Introduction

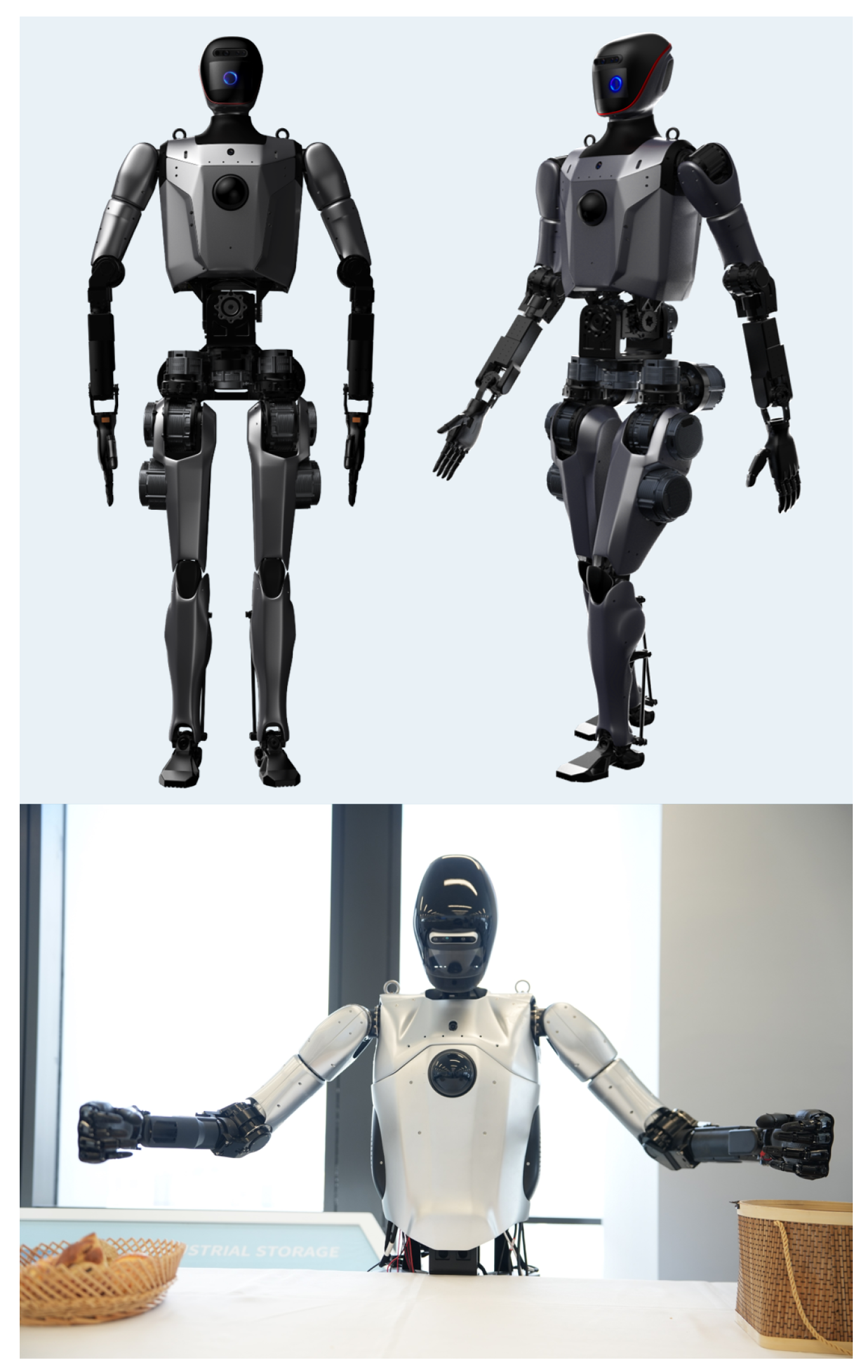

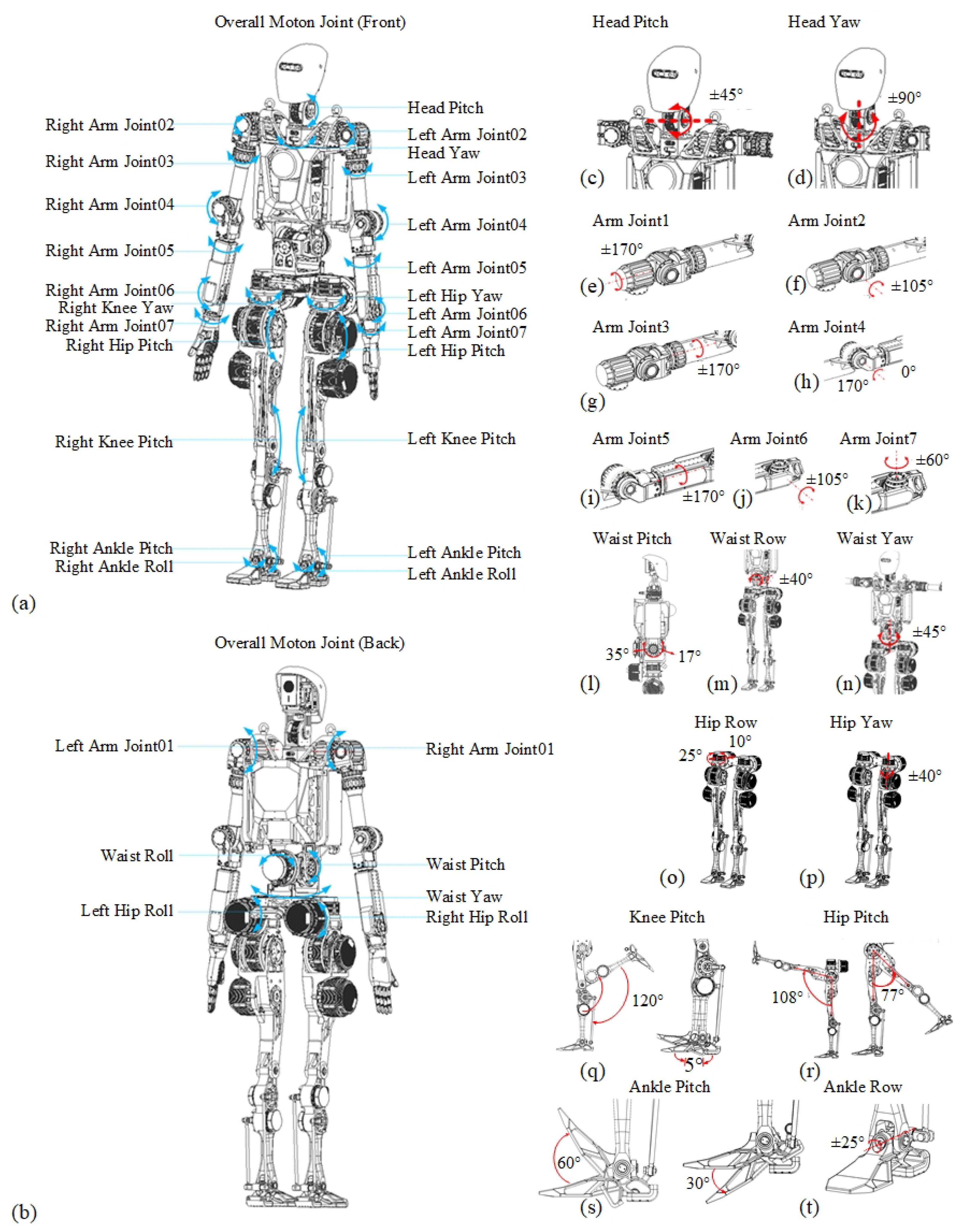

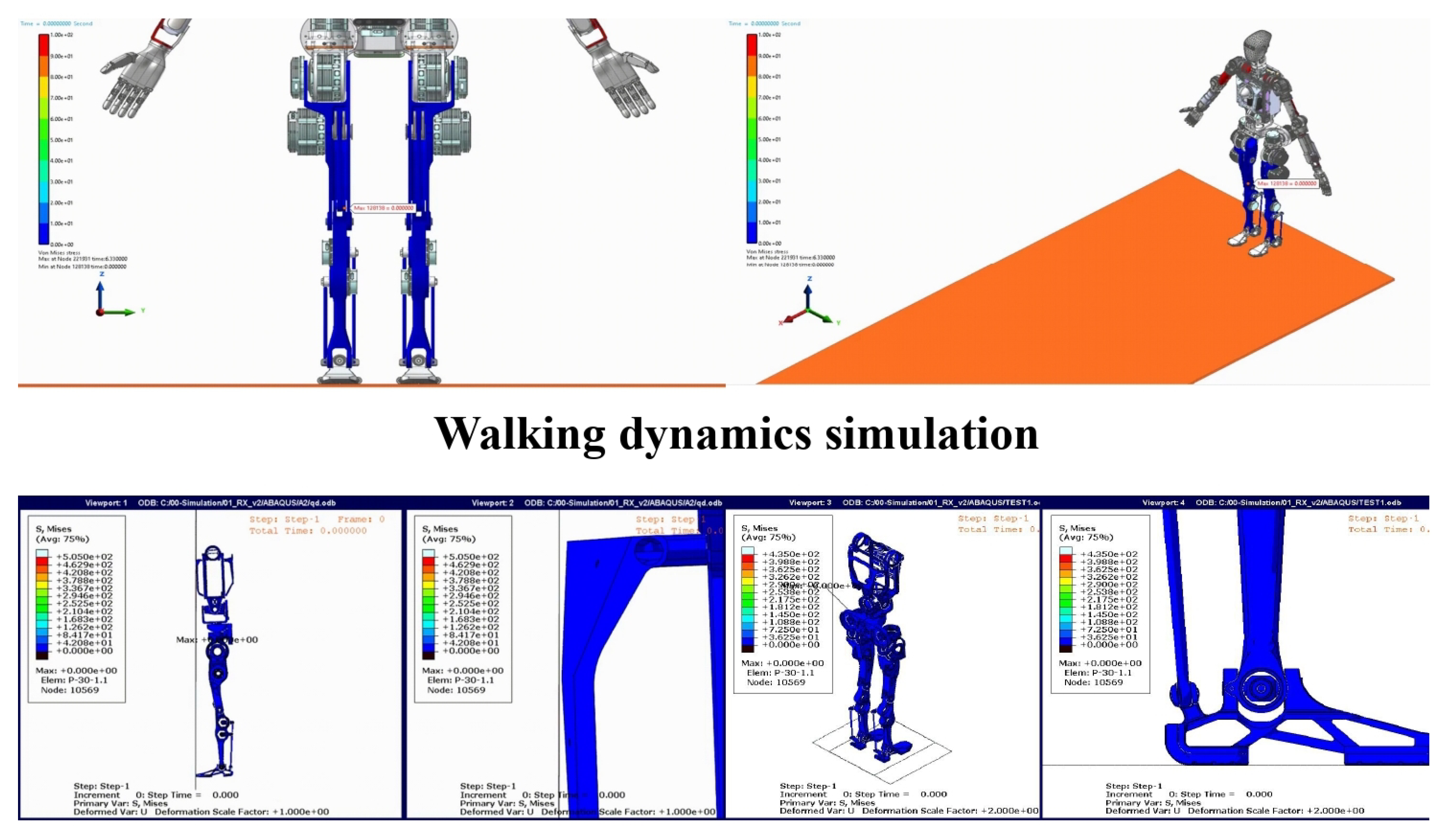

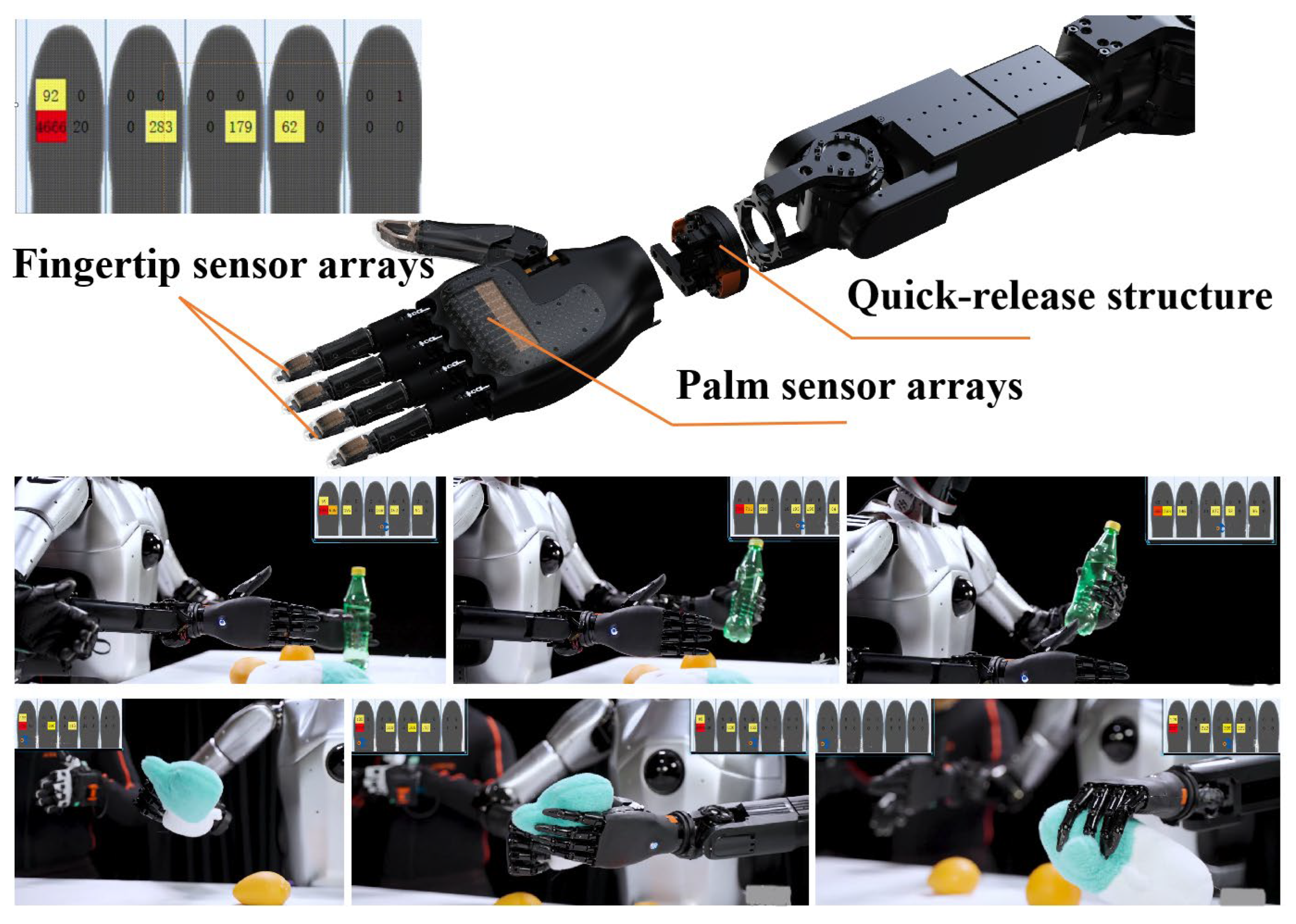

2. Robot Designs

2.1. Overview

2.2. Lightweight Bionic Joints

2.3. Modular System Integration Strategy

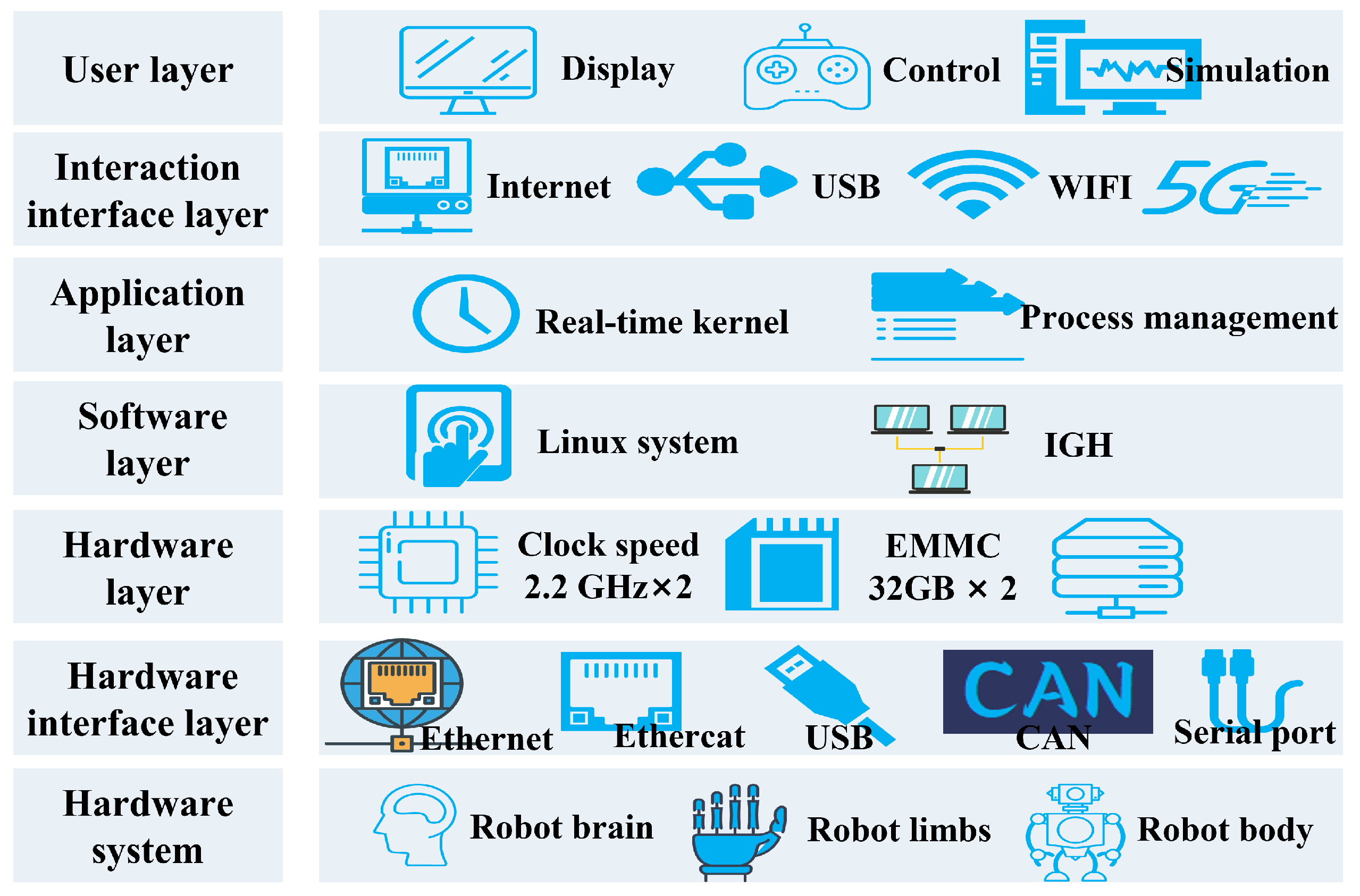

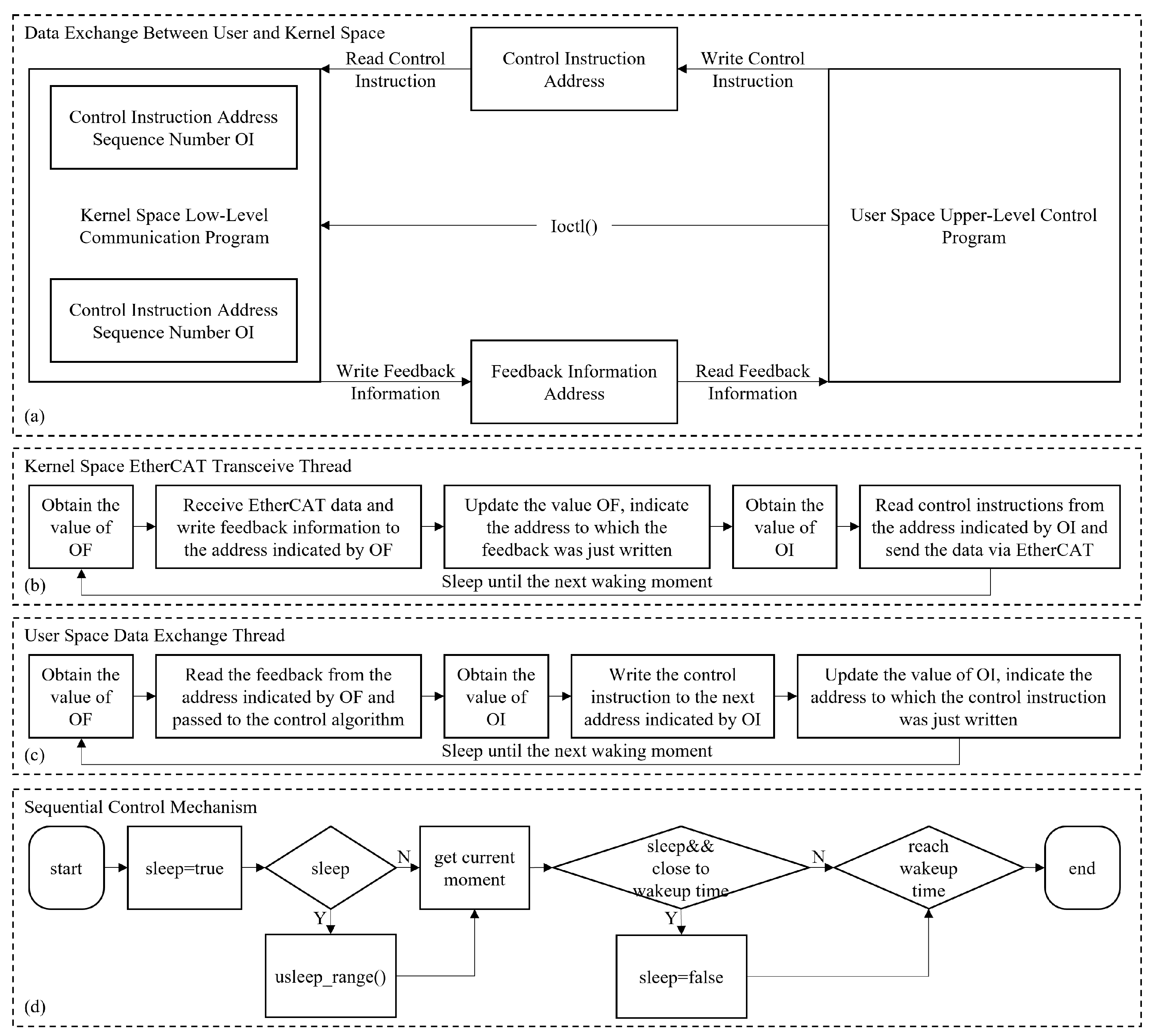

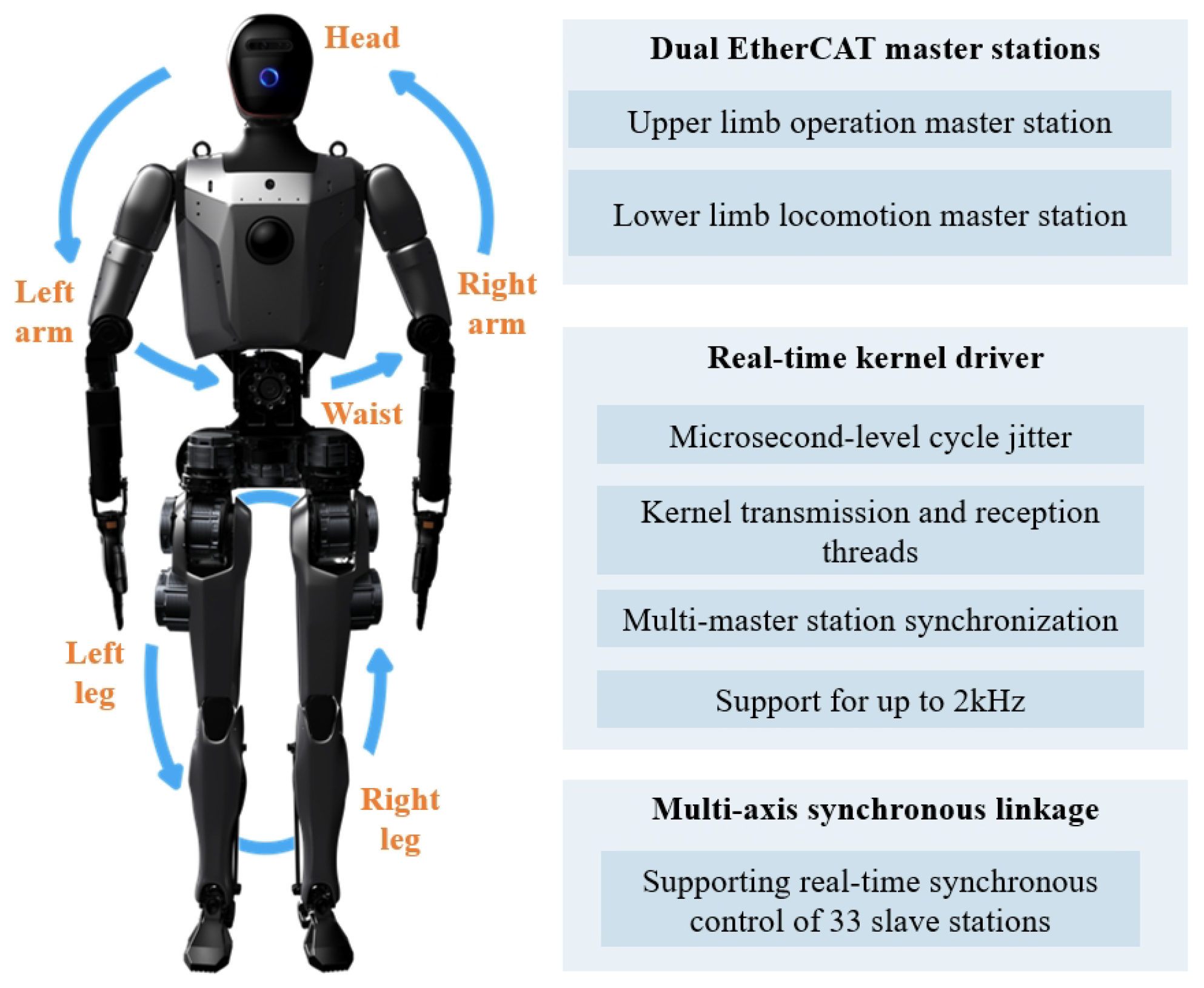

2.4. Multi-Level Control Architecture

3. Experiments and Results

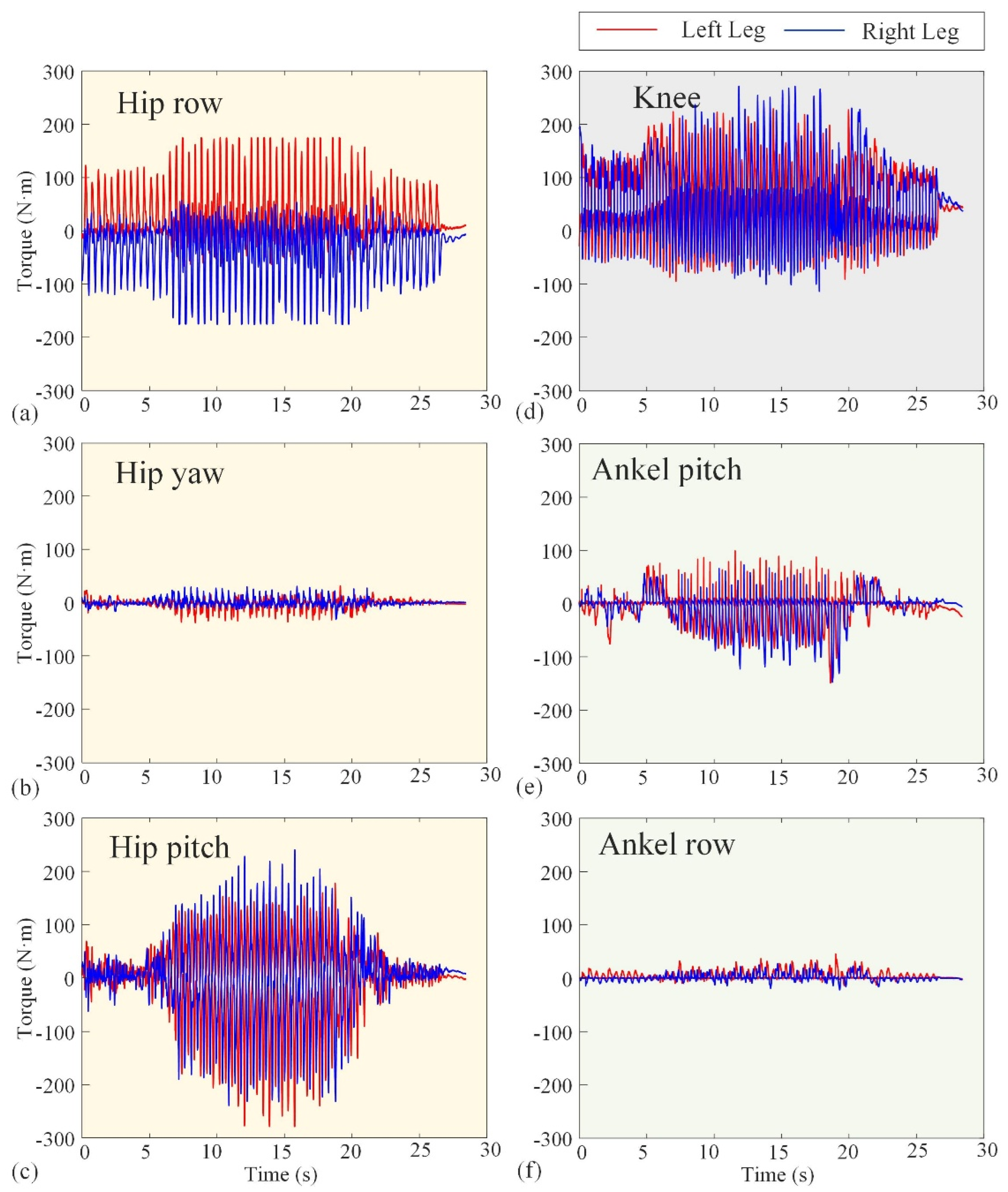

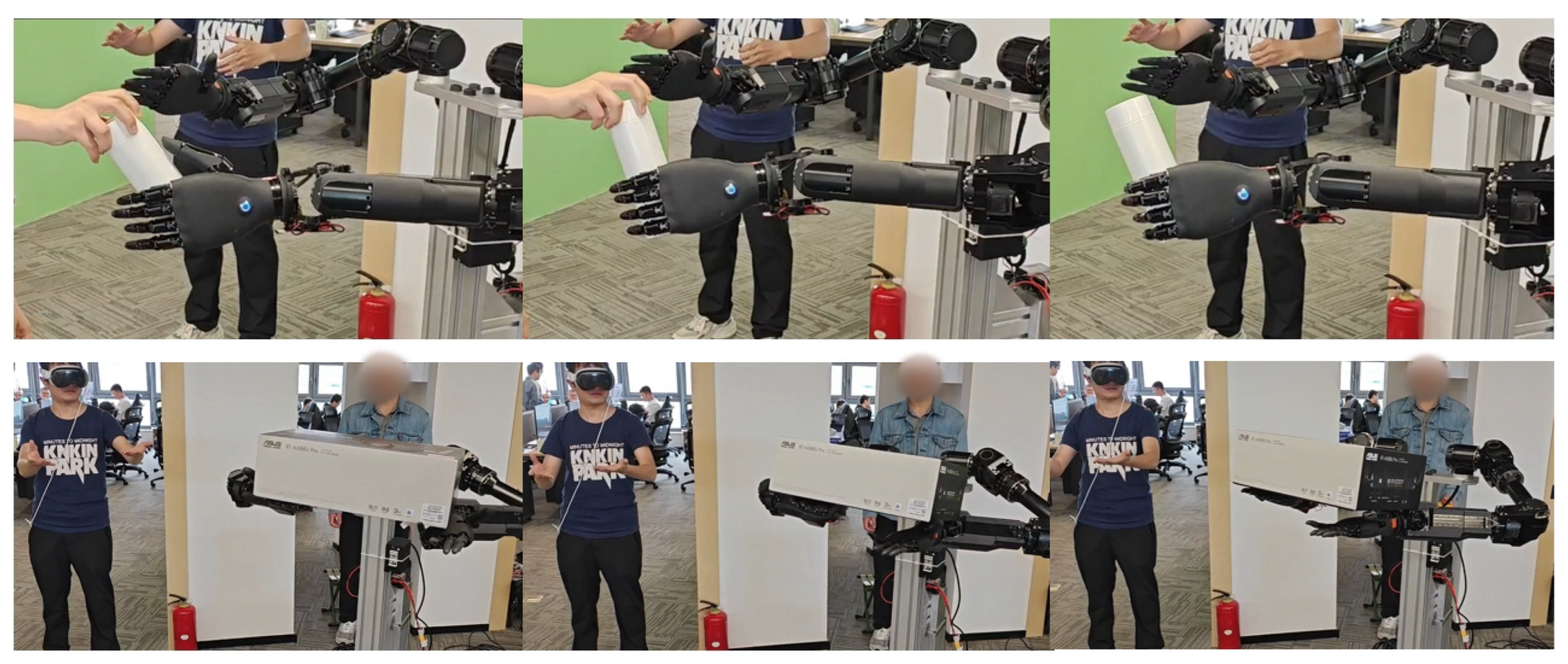

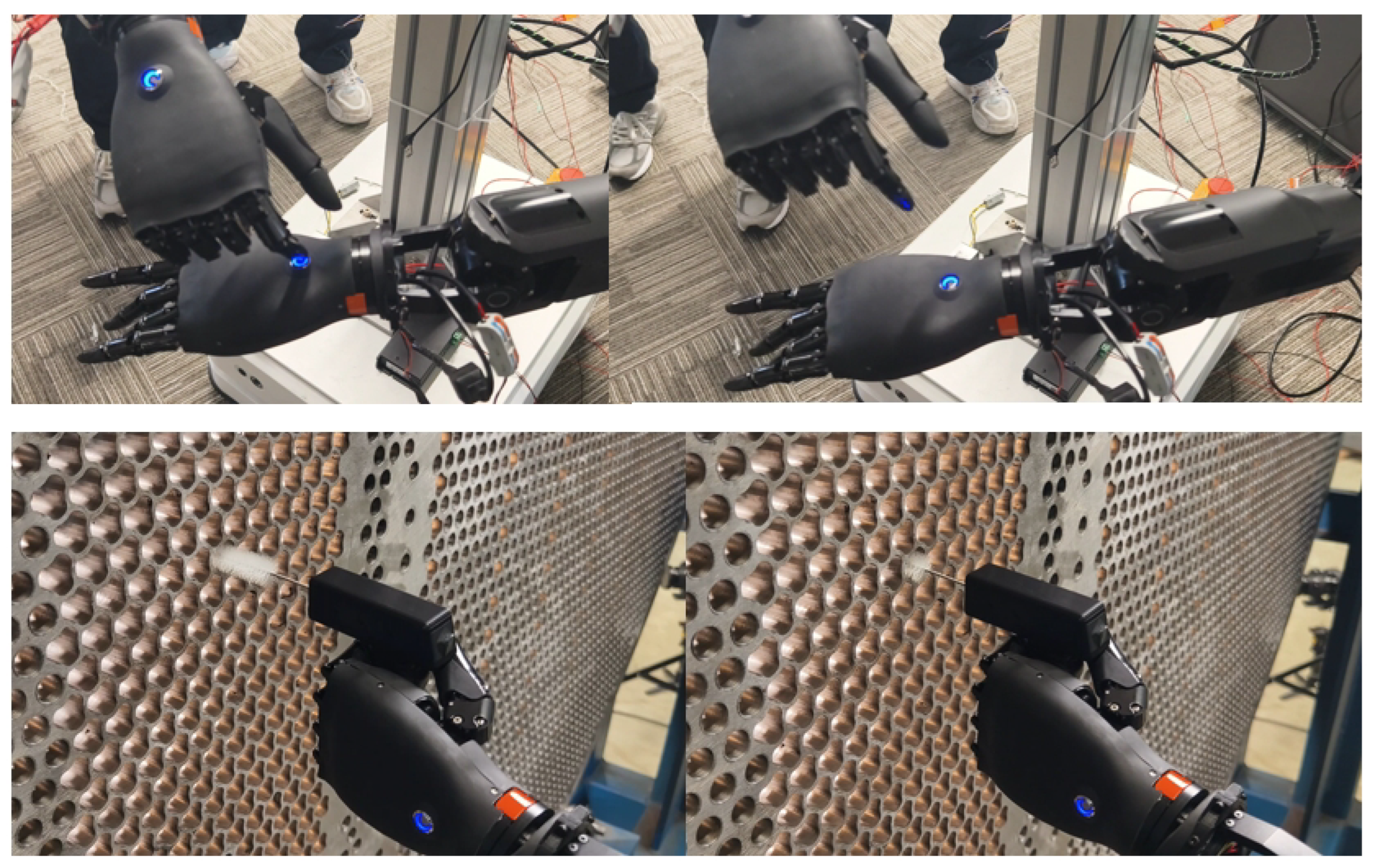

3.1. Basic Performance Testing

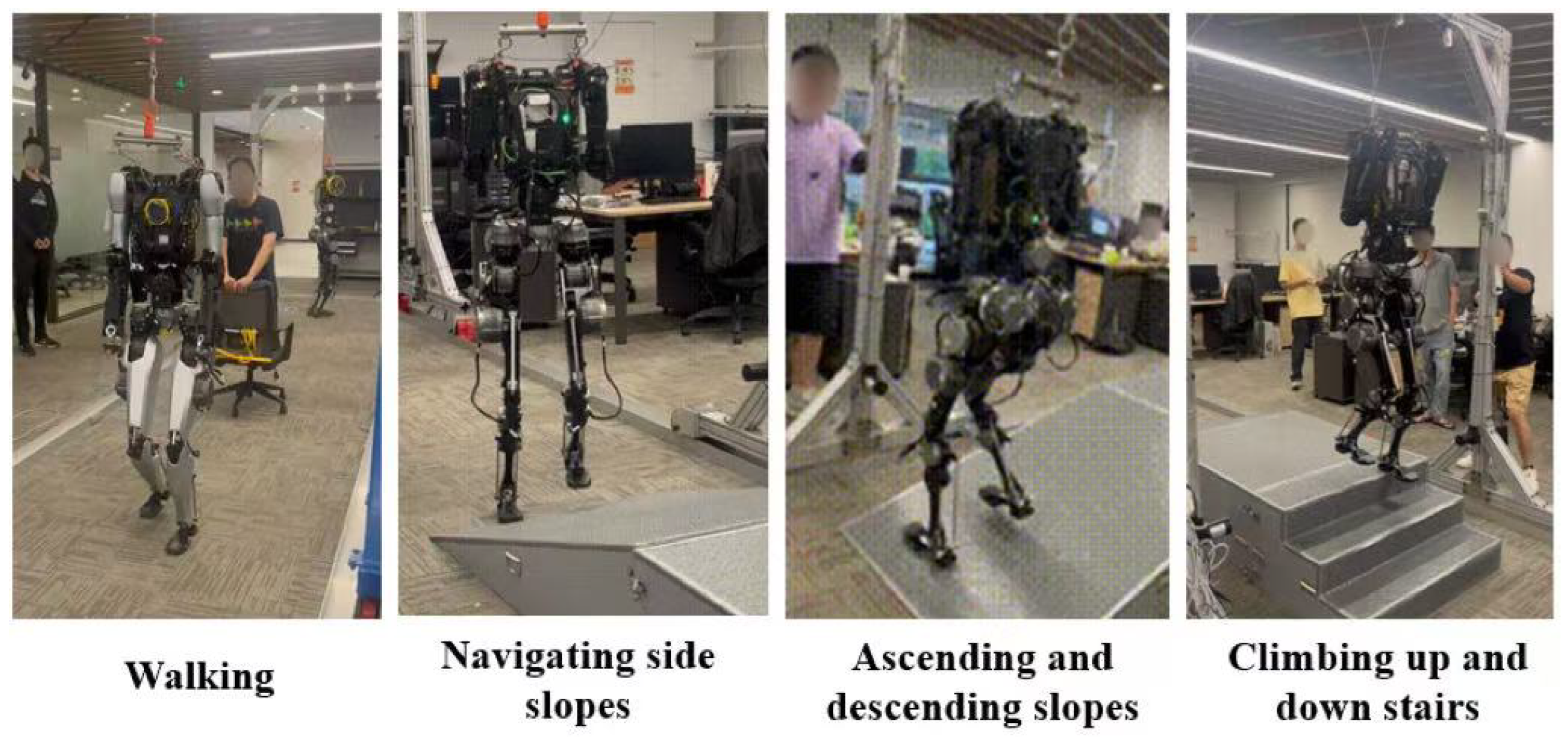

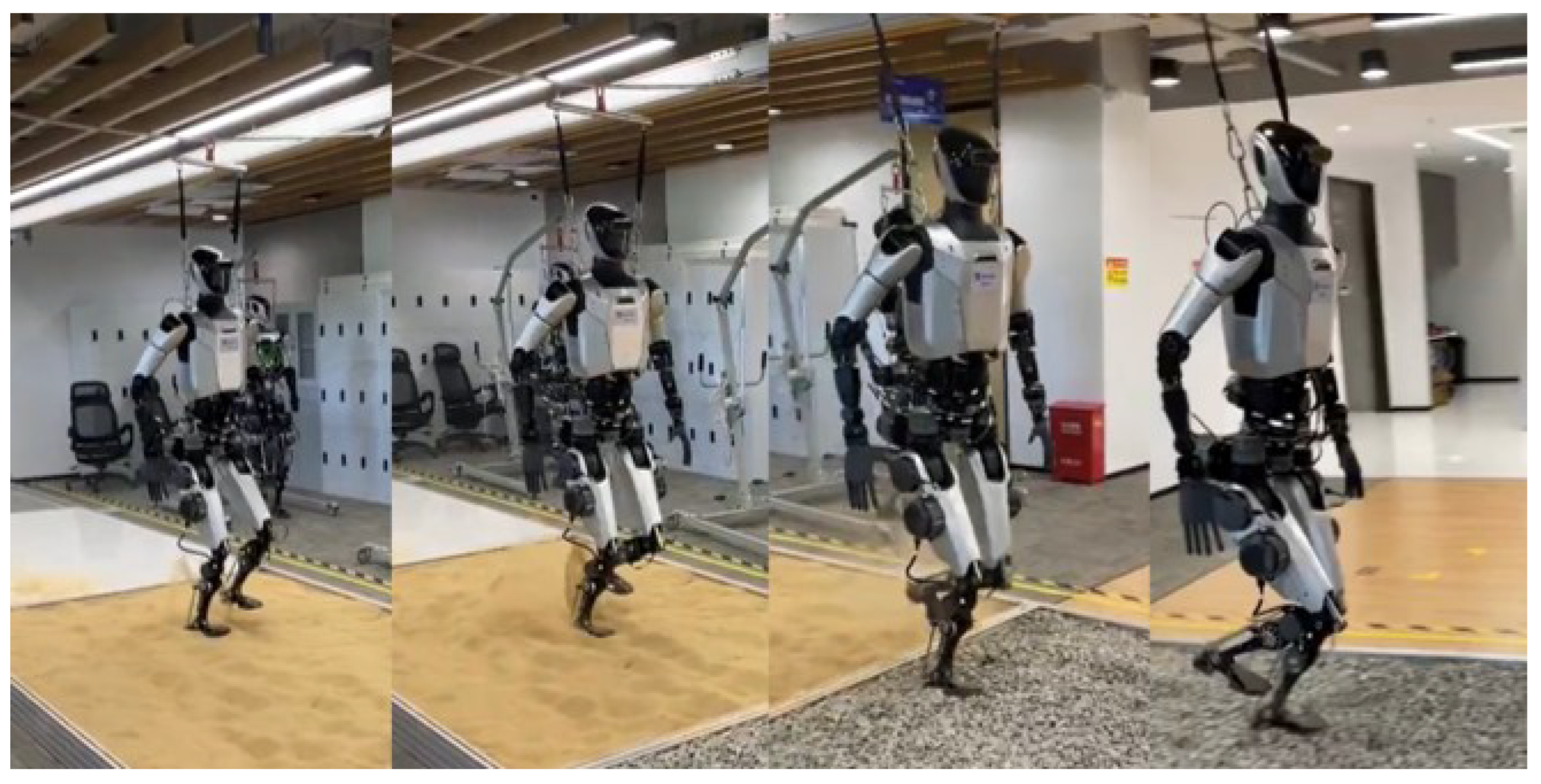

3.2. Motion Scenario Testing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lazaro-Gredilla, M.; Lin, D.; Guntupalli, J.S.; George, D. Beyond Imitation: Zero-Shot Task Transfer on Robots by Learning Concepts as Cognitive Programs. arXiv 2019, arXiv:1812.02788. [Google Scholar] [CrossRef] [PubMed]

- Baines, R.; Patiballa, S.K.; Booth, J.; Ramirez, L.; Sipple, T.; Garcia, A.; Fish, F.; Kramer-Bottiglio, R. Multi-Environment Robotic Transitions Through Adaptive Morphogenesis. Nature 2022, 610, 283–289. [Google Scholar] [CrossRef] [PubMed]

- Vishwanath, A.; Singh, A.; Chua, Y.H.V.; Dauwels, J.; Magnenat-Thalmann, N. Humanoid Co-workers: How Is It Like to Work with a Robot? In Proceedings of the 28th IEEE International Conference on Robot and Human Interactive Communication, New Delhi, India, 14–18 October 2019; pp. 1–6. [Google Scholar]

- Merel, J.; Botvinick, M.; Wayne, G. Hierarchical motor control in mammals and machines. Nat. Commun. 2019, 10, 5489. [Google Scholar] [CrossRef]

- Sathyavenkateshwaren, S.; Malathi, S. Humanoid robot: A survey on communication, tracking and voice recognition. In Proceedings of the 3rd International Conference on Inventive Computation Technologies, Coimbatore, India, 15–16 November 2018; pp. 555–560. [Google Scholar]

- Tong, Y.; Liu, H.; Zhang, Z. Advancements in Humanoid Robots: A Comprehensive Review and Future Prospects. IEEE/CAA J. Autom. Sin. 2024, 11, 301–328. [Google Scholar] [CrossRef]

- Lu, H.; Wu, Z.; Xing, J.; Li, J.; Li, R.; Li, Z.; Shi, Y. BodyGen: Advancing Towards Efficient Embodiment Co-Design. In Proceedings of the International Conference on Learning Representations (ICLR), Singapore, 24–28 April 2025. [Google Scholar]

- Unitree Robotics. Unitree H1: Humanoid Agent AI Avatar. 2024. Available online: https://www.unitree.com/h1 (accessed on 21 November 2024).

- Kaneko, K.; Kaminaga, H.; Sakaguchi, T.; Kajita, S.; Morisawa, M.; Kumagai, I.; Kanehiro, F. Humanoid Robot HRP-5P: An Electrically Actuated Humanoid Robot with High-Power and Wide-Range Joints. IEEE Robot. Autom. Lett. 2019, 4, 1431–1438. [Google Scholar] [CrossRef]

- Boston Dynamics. An Electric New Era for Atlas. 2024. Available online: https://bostondynamics.com/blog/electric-new-era-for-atlas/ (accessed on 21 November 2024).

- UBTECH. Walker-S Industrial Humanoid Service Robot Walk into the Future. 2024. Available online: https://www.ubtrobot.com/en/humanoid/products/WalkerS (accessed on 21 November 2024).

- Tesla. Optimus—Gen 2. 2024. Available online: https://www.youtube.com/watch?v=--KyvVvE7XM (accessed on 21 November 2024).

- Stasse, O.; Thomas, F. An Overview of Humanoid Robots Technologies. In Biomechanics of Anthropomorphic Systems; Springer: Berlin/Heidelberg, Germany, 2019; pp. 281–310. [Google Scholar] [CrossRef]

- Hashimoto, K. Mechanics of Humanoid Robot. Adv. Robot. 2020, 34, 1390–1397. [Google Scholar] [CrossRef]

- Rahman, S.M.M. Generating human-like social motion in a human-looking humanoid robot: The biomimetic approach. In Proceedings of the 2013 IEEE International Conference on Robotics and Biomimetics (ROBIO), Shenzhen, China, 12–14 December 2013; pp. 1377–1383. [Google Scholar] [CrossRef]

- Torricelli, D.; Gonzalez, J.; Weckx, M.; Jiménez-Fabián, R.; Vanderborght, B.; Sartori, M.; Dosen, S.; Farina, D.; Lefeber, D.; Pons, J.L. Human-like compliant locomotion: State of the art of robotic implementations. Bioinspir. Biomimetics 2016, 11, 051002. [Google Scholar] [CrossRef] [PubMed]

- Caldwell, D.; Tsagarakis, N.; Artrit, P.; Canderle, J.; Davis, S.; Medrano-Cerda, G. Biomimetic and smart technology principles of humanoid design. In Proceedings of the 2001 IEEE/ASME International Conference on Advanced Intelligent Mechatronics. Proceedings (Cat. No. 01TH8556), Como, Italy, 8–11 July 2001; Volume 2, pp. 965–970. [Google Scholar] [CrossRef]

- Zhou, T.; Zhou, Z.; Zhang, H.; Chen, W. Modulating Multiarticular Energy during Human Walking and Running with an Unpowered Exoskeleton. Sensors 2022, 22, 8539. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Huang, Q.; Ma, G.; Chen, X.; Zhang, W.; Li, J.; Gao, J. Design and Development of the Humanoid Robot BHR-5. Adv. Mech. Eng. 2014, 6, 852937. [Google Scholar] [CrossRef]

- Taira, T.; Kamata, N.; Yamasaki, N. Design and implementation of reconfigurable modular humanoid robot architecture. In Proceedings of the 2005 IEEE/RSJ International Conference on Intelligent Robots and Systems, Edmonton, AB, Canada, 2–6 August 2005; pp. 3566–3571. [Google Scholar] [CrossRef]

- Sharma, D.; Tokas, K.; Puri, A.; Sharda, K. Shadow Hand. J. Adv. Res. Appl. Sci. 2014, 1, 2–7. [Google Scholar] [CrossRef]

- Pacchierotti, C.; Prattichizzo, D. Cutaneous/Tactile Haptic Feedback in Robotic Teleoperation: Motivation, Survey, and Perspectives. IEEE Trans. Robot. 2024, 40, 978–998. [Google Scholar] [CrossRef]

- Han, M.S.; Harnett, C.K. Journey from Human Hands to Robot Hands: Biological Inspiration of Anthropomorphic Robotic Manipulators. Bioinspir. Biomimetics 2024, 19, 021001. [Google Scholar] [CrossRef] [PubMed]

- Spong, M.W. An historical perspective on the control of robotic manipulators. Annu. Rev. Control. Robot. Auton. Syst. 2022, 5, 1–31. [Google Scholar] [CrossRef]

- Al-Shuka, H.F.N.; Corves, B.; Zhu, W.H.; Vanderborght, B. Multi-level control of zero-moment point-based humanoid biped robots: A review. Robotica 2016, 34, 2440–2466. [Google Scholar] [CrossRef]

- Werner, B.; Yang, L.; Ames, A.D. Architecture Is All You Need: Diversity-Enabled Sweet Spots for Robust Humanoid Locomotion. arXiv 2025, arXiv:2510.14947. [Google Scholar] [CrossRef]

- Zhang, T.; Yue, L.; Zhang, H.; Zhang, L.; Zeng, X.; Song, Z.; Liu, Y.H. Whole-Body Control Framework for Humanoid Robots with Heavy Limbs: A Model-Based Approach. arXiv 2025, arXiv:2506.14278. [Google Scholar]

- Reghenzani, F.; Massari, G.; Fornaciari, W. The Real-Time Linux Kernel: A Survey on PREEMPT_RT. ACM Comput. Surv. 2019, 52, 1–36. [Google Scholar] [CrossRef]

- Kang, S.J. A study on implementation of real-time ethercat master. J. Semicond. Disp. Technol. 2021, 20, 131–136. [Google Scholar]

- Slade, P.; Atkeson, C.; Donelan, J.M.; Houdijk, H.; Ingraham, K.A.; Kim, M.; Kong, K.; Poggensee, K.L.; Riener, R.; Steinert, M.; et al. On human-in-the-loop optimization of human–robot interaction. Nature 2024, 633, 779–788. [Google Scholar] [CrossRef] [PubMed]

| Capability Item | Parameter/Status | Description |

|---|---|---|

| Maximum Moving Speed | Walking: 1 m/s | Safety speed limit (verified in indoor environments) |

| Running: 2 m/s | ||

| Load Capacity | 10 kg | Maximum load capacity under stable walking conditions |

| Terrain Adaptability | Pass | Adaptable to cement/road/gravel/sandy soil surfaces, ground fluctuation tolerance ≥ 5 cm |

| Anti-interference Ability | 50 N thrust | Maintains stability during rhythmic gait walking |

| Slope Traversal Capability | 10° slope | Able to ascend and descend slopes forward under no-load conditions |

| Continuous Walking Time | 40 min | Stable walking at room temperature 23 °C until motor temperature rise reaches 60 °C |

| Emergency Stop System | Dual-mode pass | On-board emergency stop + remote emergency stop |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, L.; Zhang, H.; Xing, B.; Liang, Z.; Sun, Z.; Cheng, J.; Zhou, S.; Song, X.; Li, X.; Zhou, H.; et al. Loong: An Open-Source Platform for Full-Size Universal Humanoid Robot Toward Better Practicality. Biomimetics 2025, 10, 745. https://doi.org/10.3390/biomimetics10110745

Jiang L, Zhang H, Xing B, Liang Z, Sun Z, Cheng J, Zhou S, Song X, Li X, Zhou H, et al. Loong: An Open-Source Platform for Full-Size Universal Humanoid Robot Toward Better Practicality. Biomimetics. 2025; 10(11):745. https://doi.org/10.3390/biomimetics10110745

Chicago/Turabian StyleJiang, Lei, Heng Zhang, Boyang Xing, Zhenjie Liang, Zeyuan Sun, Jingran Cheng, Song Zhou, Xu Song, Xinyue Li, Hai Zhou, and et al. 2025. "Loong: An Open-Source Platform for Full-Size Universal Humanoid Robot Toward Better Practicality" Biomimetics 10, no. 11: 745. https://doi.org/10.3390/biomimetics10110745

APA StyleJiang, L., Zhang, H., Xing, B., Liang, Z., Sun, Z., Cheng, J., Zhou, S., Song, X., Li, X., Zhou, H., Li, Y., & Liu, Y. (2025). Loong: An Open-Source Platform for Full-Size Universal Humanoid Robot Toward Better Practicality. Biomimetics, 10(11), 745. https://doi.org/10.3390/biomimetics10110745