A Soft Exoskeleton for Hand Grip Augmentation and Fall Prevention Assistance in Tower Climbing

Abstract

1. Introduction

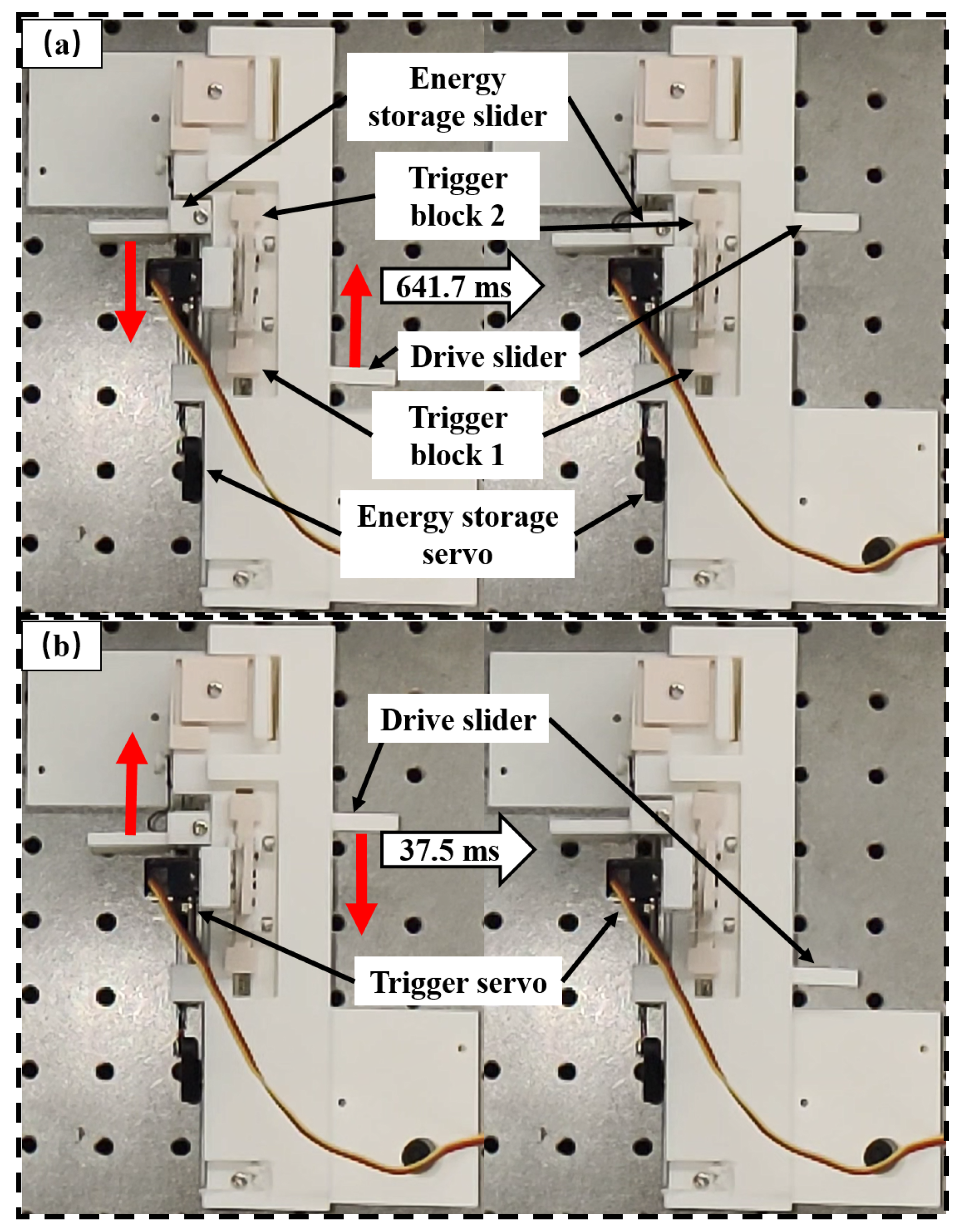

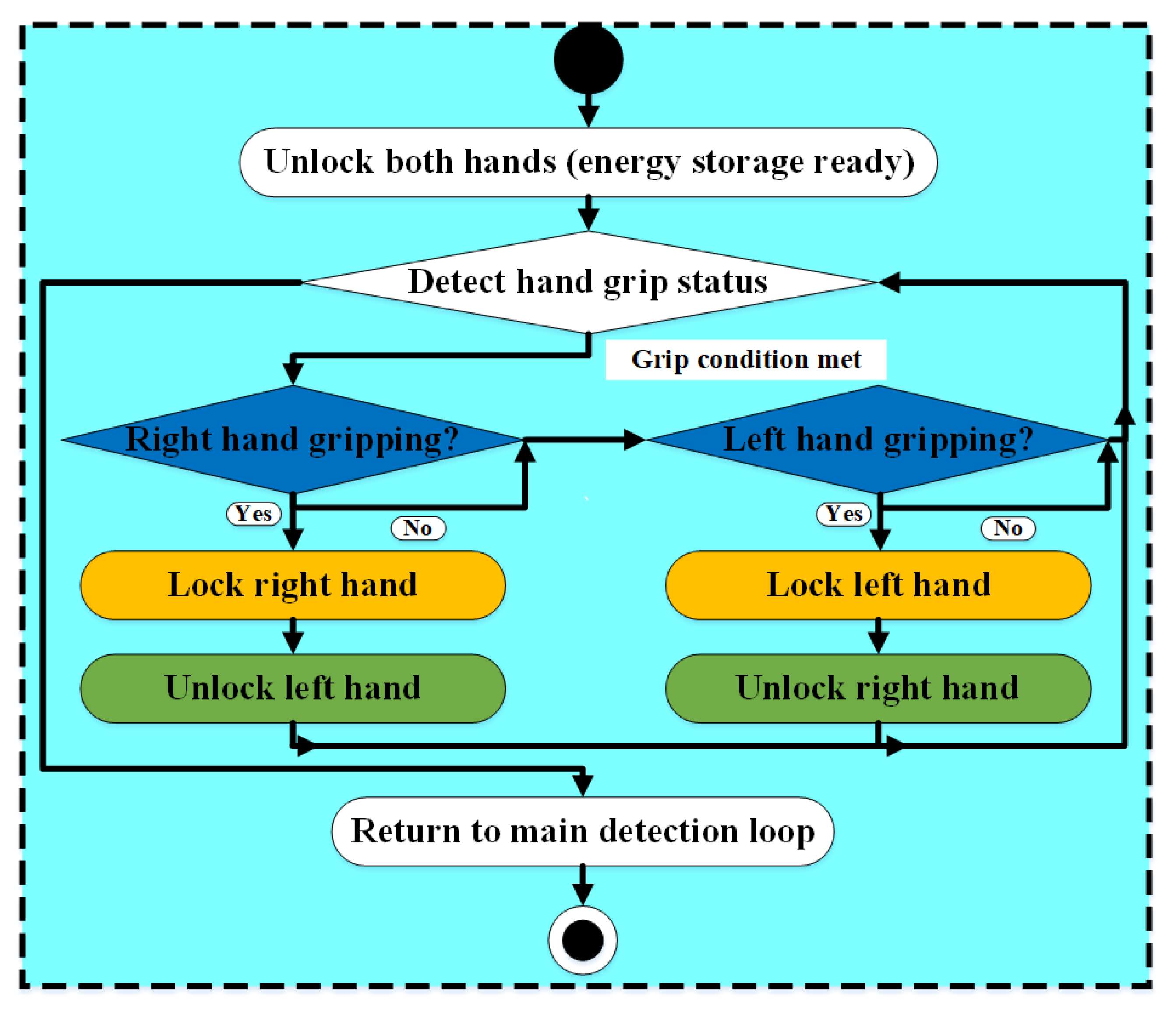

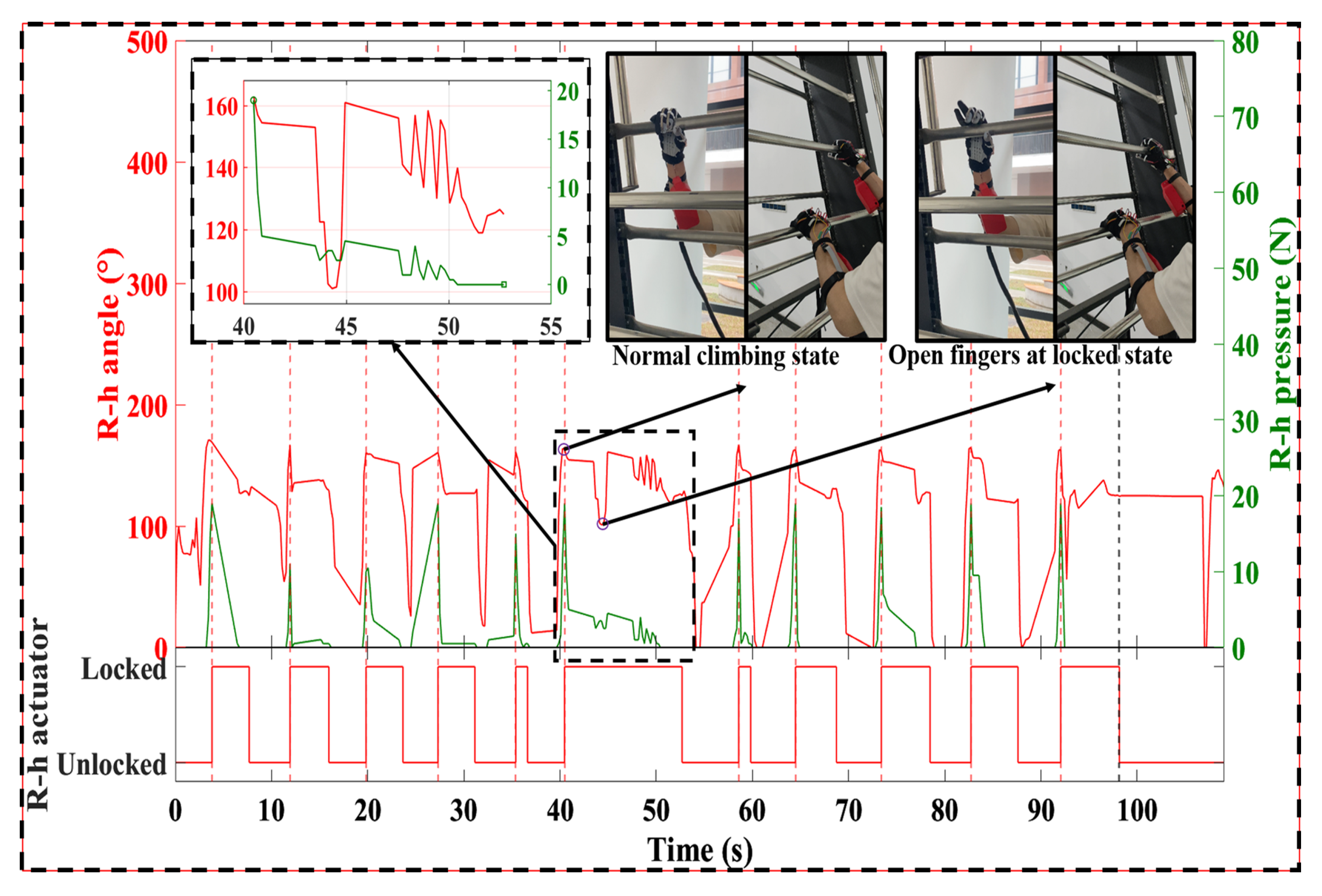

- A compact, stroke-amplified, and fast-response actuator based on a spring energy storage–release mechanism was developed, achieving a locking response time of 37.5 ms—among the fastest reported for exoskeletons. The actuator exhibits high transparency and does not impede natural hand movement during non-locking phases.

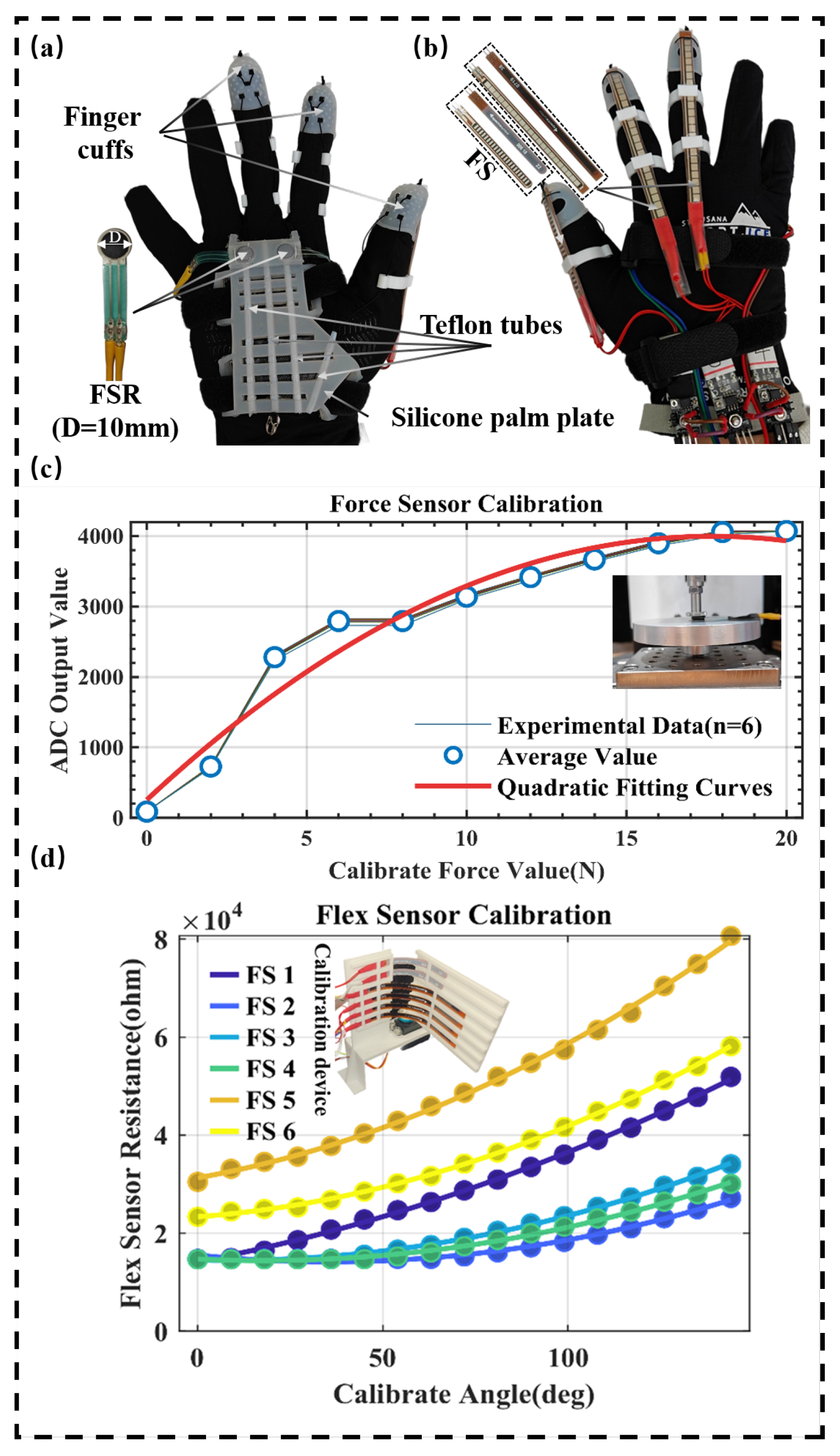

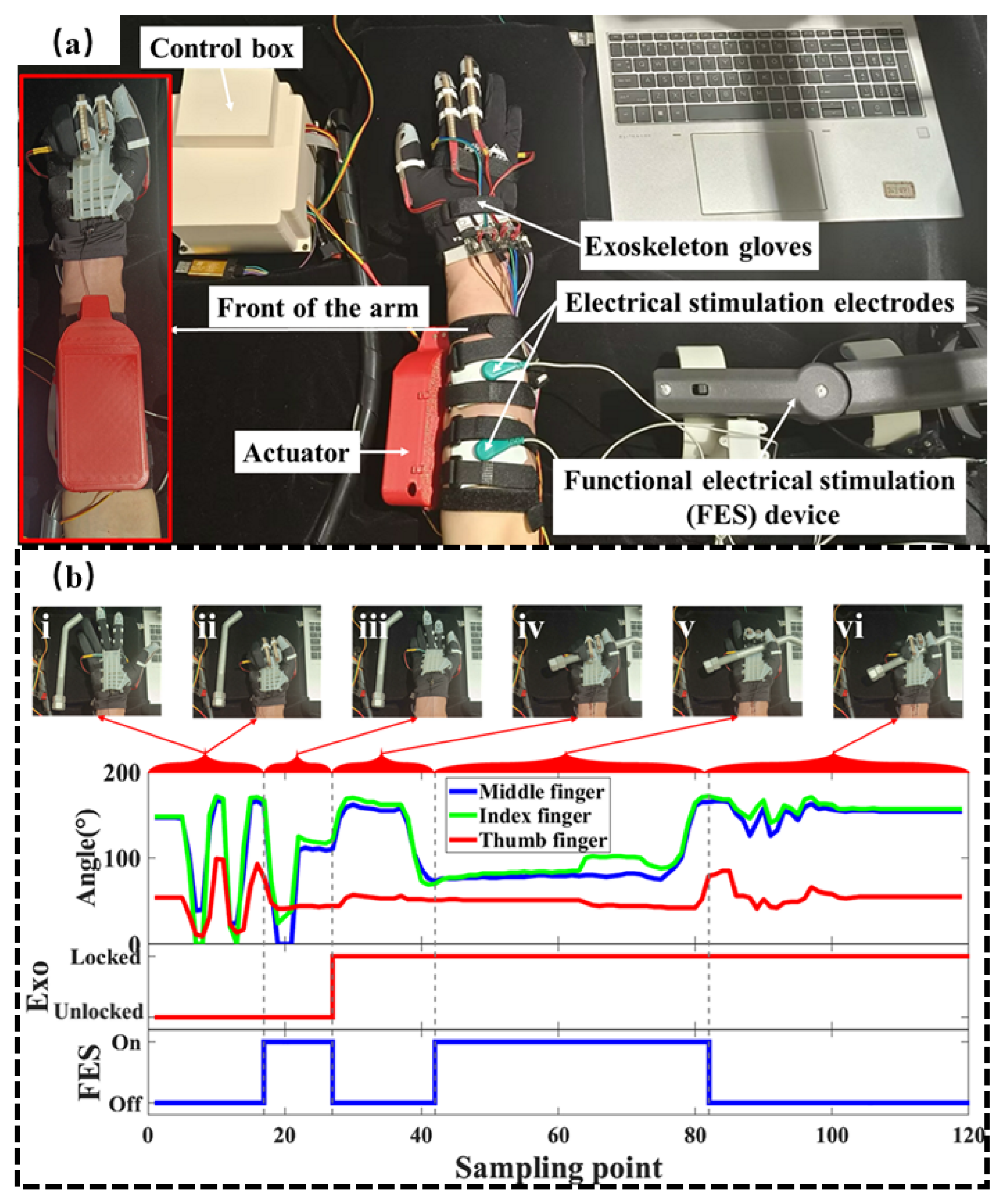

- A dual-sensor fusion module integrating pressure and flexible bending sensors was proposed to reliably detect the user’s handgrip condition in real time, ensuring accurate and robust triggering during climbing activities.

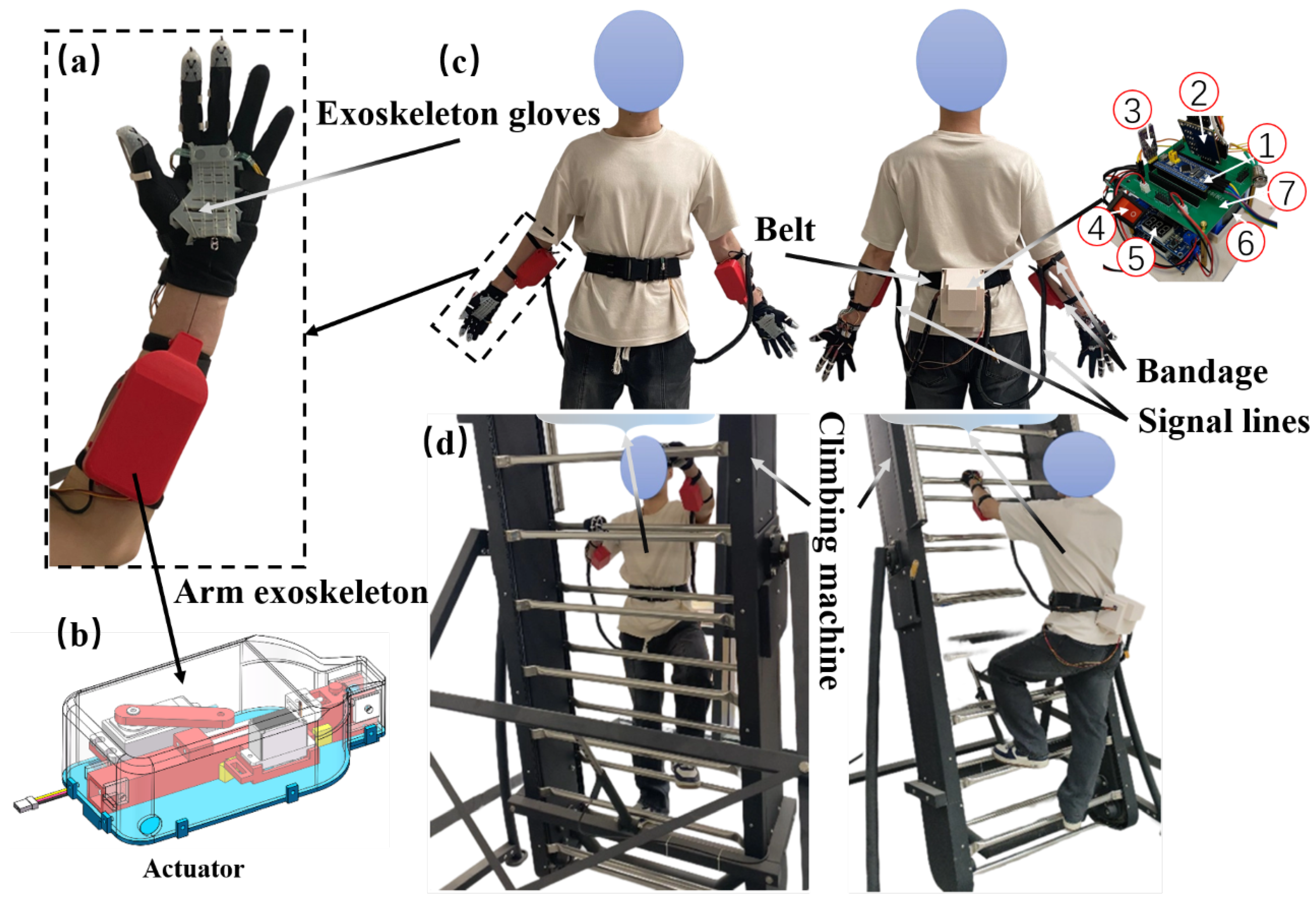

- A soft wearable exoskeleton system was developed and integrated, and its effectiveness in augmenting grip and climbing safety was experimentally validated through functional electrical FES tests and simulated tower climbing tests.

| Reference (Year) | Exoskeleton Type | Actuation/Control | Response Time | Weight | Wearability and Application Focus |

|---|---|---|---|---|---|

| This Study | Upper-limb tower climbing exoskeleton | Spring + servo motor | 37.5 ms | 1.96 kg | Velcro + wrist anchor; wrist–tower non-interference |

| Li et al., 2024 [32] | Climbing hip exoskeleton | GO-M8010 motor + passive joints | Not specified | 3 kg | Load transfer and fatigue relief |

| Li et al., 2025 [38] | Magnetorheological hand exoskeleton | MRG clutch + coil arrays | ms-scale | — | Velcro-based, passive grip enhancement |

| Park et al., 2025 [39] | Human-in-the-loop hip exoskeleton | AK80-9 motor + HIL control | 200 Hz | 3.6 kg | Metabolic optimization in stair ascent |

| Mai et al., 2025 [49] | Non-motorized hand exoskeleton | MR actuators (no external power) | Fast lock | 1.7 kg | Rescue grip aid, passive locking |

| Mahuttanatan et al., 2025 [41] | S-DOT soft anti-slip band | Passive silicone dots | — | Lightweight (<0.2 kg) | Improves skin–surface conformity |

| Moya-Esteban et al., 2025 [50] | Soft back exosuit | Cable + AC servo + 24 V battery | ≈27 ms delay | — | Back support, neuro-mechanical modeling |

2. Development of the Assistive Fall Prevention Exoskeleton System

2.1. Design of the Assistive Fall Prevention Exoskeleton System

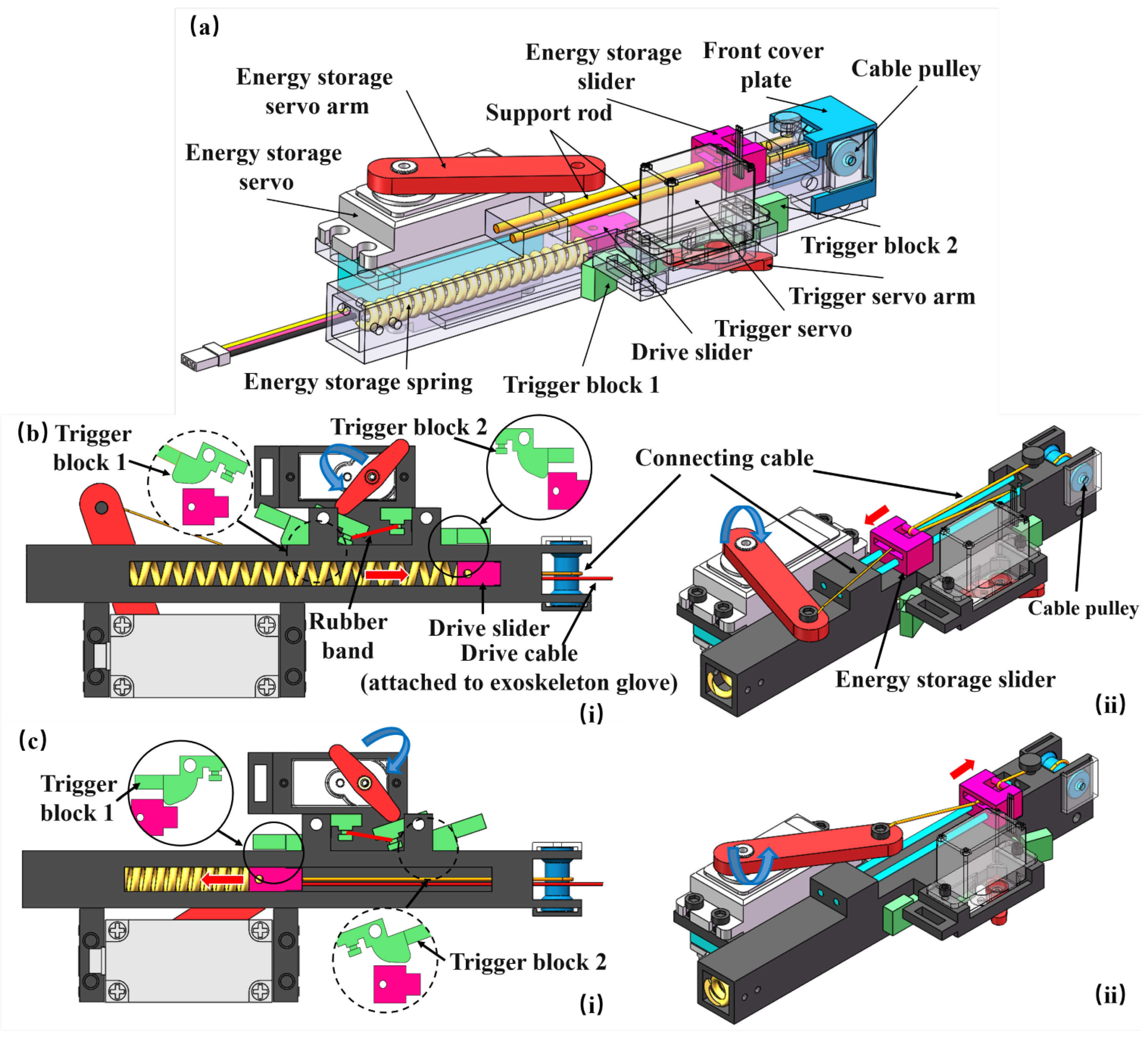

2.2. Actuator Based on Spring Energy Storage–Release Mechanism

2.3. Sensing Module Design and Calibration

2.4. Exoskeleton Glove Design

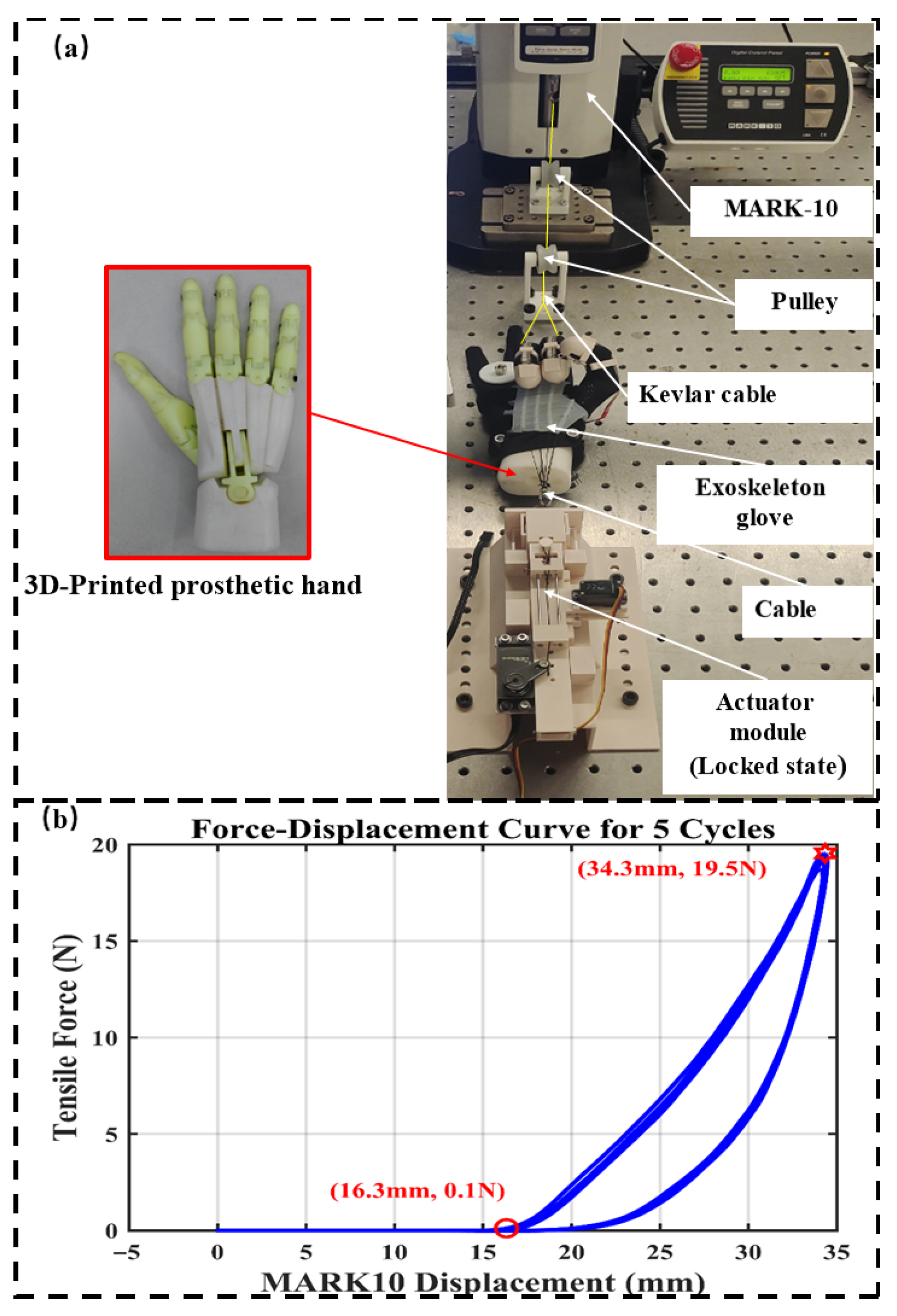

3. System Performance Experiments

3.1. Functional Electrical Stimulation Experiments

3.2. Climbing Experiments

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Z.; Zhang, F.; Yu, J.; Gao, K.; Ma, W. Research on key technologies in ±1100 kV ultra-high voltage DC transmission. High Volt. 2018, 3, 279–288. [Google Scholar] [CrossRef]

- Li, M. Exploration and Practice of Intelligent Operation and Maintenance of Long-distance Ultra-high Voltage Underground Cables Supported by Digital Twin Technology. In Proceedings of the 2023 International Conference on Integrated Intelligence and Communication Systems (ICIICS), Kalaburagi, India, 24–25 November 2023; pp. 1–6. [Google Scholar]

- Li, P.; Wang, J.; Wu, C.; Zhang, S.; Cheng, H.; Dong, M.; Yang, K.; Du, J. Operation and monitoring technology of ultra-high voltage transformer equipment. In Proceedings of the IET Conference Proceedings CP787, Xi’an, China, 21–26 November 2021; IET: Stevenage, UK, 2021; Volume 2021, pp. 2186–2190. [Google Scholar]

- Baszczyński, K. Effects of full body harness design on fall arrest performance. Int. J. Occup. Saf. Ergon. 2021, 27, 938–945. [Google Scholar] [CrossRef] [PubMed]

- Qi, H.; Zhou, Z.; Manu, P.; Li, N. Falling risk analysis at workplaces through an accident data-driven approach based upon hybrid artificial intelligence (AI) techniques. Saf. Sci. 2025, 185, 106814. [Google Scholar] [CrossRef]

- Jachowicz, M.; Owczarek, G. Studies of acceleration of the human body during overturning and falling from a height protected by a self-locking device. Int. J. Environ. Res. Public Health 2022, 19, 12077. [Google Scholar] [CrossRef]

- Brioso, X.; Calderon-Hernandez, C.; Irizarry, J.; Paes, D. Using immersive virtual reality to improve choosing by advantages system for the selection of fall protection measures. In Proceedings of the ASCE International Conference on Computing in Civil Engineering 2019, Atlanta, GA, USA, 17–19 June 2019; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 146–153. [Google Scholar]

- Guo, B.H.; Goh, Y.M. Ontology for design of active fall protection systems. Autom. Constr. 2017, 82, 138–153. [Google Scholar] [CrossRef]

- Hasanzadeh, S.; Esmaeili, B.; Dodd, M.D. Impact of construction workers’ hazard identification skills on their visual attention. J. Constr. Eng. Manag. 2017, 143, 04017070. [Google Scholar] [CrossRef]

- Wang, Z.; Ou, Y.; Li, H.; Zeng, W.; Gao, Q.; Zou, Y.; Li, P. High-altitude fall prevention method and device for power transmission line. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Qingdao, China, 28–30 May 2021; IOP Publishing: Bristol, UK, 2021; Volume 791, p. 012095. [Google Scholar]

- Tang, Y.; Liu, S.; Yang, F.; Li, J. Optoelectronic Data Processing for Investment Prediction in Distribution Networks Using Grey Model Optimization. Adv. Comput. Mater. Sci. Res. 2025, 1, 172–176. [Google Scholar] [CrossRef]

- Jin, X.; Dai, C.; Ji, P.; Wu, S.; Jing, P. Research of fault current limiter for 500 kV power grid. In Proceedings of the 2010 International Conference on Power System Technology, Hangzhou, China, 24–28 October 2010; pp. 1–10. [Google Scholar]

- Kong, C.; Chen, B.; Wang, L.; Hu, J.; Wei, J. Research on the application of double buckle safety fall protection device in transmission line tower climbing operation. J. Phys. Conf. Ser. 2025, 3011, 012048. [Google Scholar] [CrossRef]

- Siviy, C.; Baker, L.M.; Quinlivan, B.T.; Porciuncula, F.; Swaminathan, K.; Awad, L.N.; Walsh, C.J. Opportunities and challenges in the development of exoskeletons for locomotor assistance. Nat. Biomed. Eng. 2023, 7, 456–472. [Google Scholar] [CrossRef]

- Slade, P.; Kochenderfer, M.J.; Delp, S.L.; Collins, S.H. Personalizing exoskeleton assistance while walking in the real world. Nature 2022, 610, 277–282. [Google Scholar] [CrossRef]

- Polygerinos, P.; Wang, Z.; Galloway, K.C.; Wood, R.J.; Walsh, C.J. Soft robotic glove for combined assistance and at-home rehabilitation. Robot. Auton. Syst. 2015, 73, 135–143. [Google Scholar] [CrossRef]

- Mišković, L.; Dežman, M.; Petrič, T. Pneumatic exoskeleton joint with a self-supporting air tank and stiffness modulation: Design, modeling, and experimental evaluation. IEEE/ASME Trans. Mechatron. 2024, 29, 3415–3426. [Google Scholar] [CrossRef]

- Sui, M.; Ouyang, Y.; Jin, H.; Chai, Z.; Wei, C.; Li, J.; Xu, M.; Li, W.; Wang, L.; Zhang, S. A soft-packaged and portable rehabilitation glove capable of closed-loop fine motor skills. Nat. Mach. Intell. 2023, 5, 1149–1160. [Google Scholar] [CrossRef]

- Mora, L.P.; Rodríguez, J.A.; Niño-Suarez, P.A.; Rivera, O.; Avilés, O.F. Exoskeleton Glove with Cable Driven Fingers Actuated by a Differential Mechanism. In Proceedings of the International Symposium on Multibody Systems and Mechatronics; Springer: Cham, Switzerland, 2020; pp. 341–348. [Google Scholar]

- Li, F.; Chen, J.; Ye, G.; Dong, S.; Gao, Z.; Zhou, Y. Soft robotic glove with sensing and force feedback for rehabilitation in virtual reality. Biomimetics 2023, 8, 83. [Google Scholar] [CrossRef]

- Li, F.; Chen, J.; Zhou, Z.; Xie, J.; Gao, Z.; Xiao, Y.; Dai, P.; Xu, C.; Wang, X.; Zhou, Y. Lightweight soft robotic glove with whole-hand finger motion tracking for hand rehabilitation in virtual reality. Biomimetics 2023, 8, 425. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, W.; Guo, T.; Zhou, Y. Smart Flexible Wrist Exoskeleton with Twisted String Actuators and IMU Feedback. In Proceedings of the 2024 7th International Conference on Robotics, Control and Automation Engineering (RCAE), Wuhu, China, 25–27 October 2024; pp. 22–26. [Google Scholar]

- Mudie, K.; Billing, D.; Garofolini, A.; Karakolis, T.; LaFiandra, M. The need for a paradigm shift in the development of military exoskeletons. Eur. J. Sport Sci. 2022, 22, 35–42. [Google Scholar] [CrossRef] [PubMed]

- Liao, H.; Chan, H.H.t.; Liu, G.; Zhao, X.; Gao, F.; Tomizuka, M.; Liao, W.H. Design, control and validation of a novel cabledriven series elastic actuation system for a flexible and portable back-support exoskeleton. IEEE Trans. Robot. 2024, 40, 2769–2790. [Google Scholar] [CrossRef]

- Missiroli, F.; Lotti, N.; Tricomi, E.; Bokranz, C.; Alicea, R.; Xiloyannis, M.; Krzywinski, J.; Crea, S.; Vitiello, N.; Masia, L. Rigid, soft, passive, and active: A hybrid occupational exoskeleton for bimanual multijoint assistance. IEEE Robot. Autom. Lett. 2022, 7, 2557–2564. [Google Scholar] [CrossRef]

- Khatavkar, R.; Nguyen, T.B.; Chen, Y.; Lee, H.; Sun, J. A Hybrid Variable-Stiffness Soft Back Support Device. IEEE Robot. Autom. Lett. 2025, 10, 3238–3245. [Google Scholar] [CrossRef]

- Jeong, J.; Hyeon, K.; Han, J.; Park, C.H.; Ahn, S.Y.; Bok, S.K.; Kyung, K.U. Wrist assisting soft wearable robot with stretchable coolant vessel integrated SMA muscle. IEEE/ASME Trans. Mechatron. 2021, 27, 1046–1058. [Google Scholar] [CrossRef]

- Yang, Z.; Guo, S.; Liu, Y.; Kawanishi, M.; Hirata, H. A task performance-based sEMG-driven variable stiffness control strategy for upper limb bilateral rehabilitation system. IEEE/ASME Trans. Mechatron. 2022, 28, 792–803. [Google Scholar] [CrossRef]

- Proietti, T.; O’Neill, C.; Gerez, L.; Cole, T.; Mendelowitz, S.; Nuckols, K.; Hohimer, C.; Lin, D.; Paganoni, S.; Walsh, C. Restoring arm function with a soft robotic wearable for individuals with amyotrophic lateral sclerosis. Sci. Transl. Med. 2023, 15, eadd1504. [Google Scholar] [CrossRef] [PubMed]

- Gan, L.; Xu, Y.; Cai, Y.; Zhou, Y. A high sensitivity flexible stretchable fiber optic sensor based on the waveguide loss principle. IEEE Trans. Instrum. Meas. 2024, 74, 7000907. [Google Scholar] [CrossRef]

- Guo, T.; Li, Y.; Chen, J.; Wen, X.; Hua, B.; Zhou, Y. Tendon-Driven Anti-Fall Exoskeleton System. In Proceedings of the 2024 International Conference on Intelligent Robotics and Automatic Control (IRAC), Guangzhou, China, 29 November–1 December 2024; pp. 442–447. [Google Scholar]

- Li, M.; Yin, H.; Yang, Z.; Hu, H.; Chen, H.; Fu, Z.; Yang, X.; Guo, Z. The Design and Application of an Assistive Hip Joint Exoskeleton for Tower Climbing. Sensors 2024, 24, 7513. [Google Scholar] [CrossRef]

- Milligan, G.S.; O’Halloran, J.; Tipton, M.J. An ergonomics assessment of three simulated 120 m ladder ascents: A comparison of novice and experienced climbers. Appl. Ergon. 2020, 85, 103043. [Google Scholar] [CrossRef]

- Rodrigue, H.; Wang, W.; Han, M.W.; Kim, T.J.; Ahn, S.H. An overview of shape memory alloy-coupled actuators and robots. Soft Robot. 2017, 4, 3–15. [Google Scholar] [CrossRef]

- Liu, S.; Shen, S.; Li, Y.; Xu, M. Spider-inspired Pneumatic Folding Membrane Soft Actuator. IEEE Robot. Autom. Lett. 2024, 10, 1401–1408. [Google Scholar] [CrossRef]

- Wang, G.; Wang, H.; Gao, W.; Yang, X.; Wang, Y. Jamming enabled variable stiffness wrist exoskeleton for tremor suppression. IEEE Robot. Autom. Lett. 2023, 8, 3693–3700. [Google Scholar] [CrossRef]

- Zhang, J.; Sheng, J.; O’Neill, C.T.; Walsh, C.J.; Wood, R.J.; Ryu, J.H.; Desai, J.P.; Yip, M.C. Robotic artificial muscles: Current progress and future perspectives. IEEE Trans. Robot. 2019, 35, 761–781. [Google Scholar] [CrossRef]

- Li, W.; Mai, X.; Li, Y.; Li, W.; Zhang, S.; Deng, L.; Sun, S. Development of a magnetorheological hand exoskeleton featuring a high force-to-power ratio for enhanced grip endurance. arXiv 2025, arXiv:2503.15915. [Google Scholar]

- Park, D.; An, J.; Lee, D.; Kang, I.; Young, A.J. Human-in-the-loop optimization of hip exoskeleton assistance during stair climbing. IEEE Trans. Biomed. Eng. 2025, 72, 2147–2156. [Google Scholar] [CrossRef]

- Roderick, W.R.; Cutkosky, M.R.; Lentink, D. Bird-inspired dynamic grasping and perching in arboreal environments. Sci. Robot. 2021, 6, eabj7562. [Google Scholar] [CrossRef]

- Mahuttanatan, S.; Tarapongnivat, K.; Asawalertsak, N.; Akkawutvanich, C.; Manoonpong, P. S-DOT: Soft Dot-Structured Surface Pattern for Enhanced Grip and Comfort in Exoskeleton Straps. In Proceedings of the 2025 IEEE 8th International Conference on Soft Robotics (RoboSoft), Lausanne, Switzerland, 22–26 April 2025; pp. 1–8. [Google Scholar]

- Zeiaee, A.; Zarrin, R.S.; Eib, A.; Langari, R.; Tafreshi, R. CLEVERarm: A lightweight and compact exoskeleton for upper-limb rehabilitation. IEEE Robot. Autom. Lett. 2021, 7, 1880–1887. [Google Scholar] [CrossRef]

- Markin, V.S.; Volkov, A.G.; Jovanov, E. Active movements in plants: Mechanism of trap closure by Dionaea muscipula Ellis. Plant Signal. Behav. 2008, 3, 778–783. [Google Scholar] [CrossRef]

- Müller, U.K.; Kranenbarg, S. Power at the tip of the tongue. Science 2004, 304, 217–219. [Google Scholar] [CrossRef]

- Xu, Z.; Liang, J.; Zhou, Y. Manta Ray-Inspired Soft Robotic Swimmer for High-speed and Multi-modal Swimming. In Proceedings of the 2024 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Abu Dhabi, United Arab Emirates, 14–18 October 2024; pp. 235–240. [Google Scholar]

- Zhou, Y.; Xu, Z. Mechanically prestressed pneumatically driven bistable soft actuators. J. Mech. Robot. 2024, 16, 051006. [Google Scholar] [CrossRef]

- Pal, A.; Goswami, D.; Martinez, R.V. Elastic energy storage enables rapid and programmable actuation in soft machines. Adv. Funct. Mater. 2020, 30, 1906603. [Google Scholar] [CrossRef]

- Tang, Y.; Chi, Y.; Sun, J.; Huang, T.H.; Maghsoudi, O.H.; Spence, A.; Zhao, J.; Su, H.; Yin, J. Leveraging elastic instabilities for amplified performance: Spine-inspired high-speed and high-force soft robots. Sci. Adv. 2020, 6, eaaz6912. [Google Scholar] [CrossRef] [PubMed]

- Mai, X.; Yang, J.; Li, L.; Zi, B.; Zhang, S.; Gong, X.; Li, W.; Yun, G.; Sun, S. Non-motorized Hand Exoskeleton for Rescue and Beyond: Substantially Elevating Grip Endurance and Strength. IEEE Trans. Robot. 2025, 41, 4761–4775. [Google Scholar] [CrossRef]

- Moya-Esteban, A.; Refai, M.I.; Sridar, S.; van der Kooij, H.; Sartori, M. Soft back exosuit controlled by neuro-mechanical modeling provides adaptive assistance while lifting unknown loads and reduces lumbosacral compression forces. Wearable Technol. 2025, 6, e9. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Chen, Y.; Liu, S.; Xie, L. Design and Performance Verification of a Hybrid Robotic System for Hand and Wrist Rehabilitation. In Proceedings of the 2024 IEEE International Conference on Cybernetics and Intelligent Systems (CIS) and IEEE International Conference on Robotics, Automation and Mechatronics (RAM), Hangzhou, China, 8–11 August 2024; pp. 99–104. [Google Scholar]

- Jensen, R.C.; Holland, C.J. Ladder safety: A taxonomy of limb-movement patterns for three points of control. Int. J. Environ. Res. Public Health 2020, 17, 2897. [Google Scholar] [CrossRef] [PubMed]

- Cole, K.J.; Abbs, J.H. Grip force adjustments evoked by load force perturbations of a grasped object. J. Neurophysiol. 1988, 60, 1513–1522. [Google Scholar] [CrossRef] [PubMed]

- Cutkosky, M.R. On grasp choice, grasp models, and the design of hands for manufacturing tasks. IEEE Trans. Robot. Autom. 1989, 5, 269–279. [Google Scholar] [CrossRef]

- Wu, J.Z.; Sinsel, E.W.; Warren, C.M.; Welcome, D.E. An evaluation of the contact forces on the fingers when squeezing a spherical rehabilitation ball. Bio-Med. Mater. Eng. 2018, 29, 629–639. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, S.; Chen, Z.; Gan, L.; Ling, J.; Huang, H.; Chen, J.; Zhou, Y. A Soft Exoskeleton for Hand Grip Augmentation and Fall Prevention Assistance in Tower Climbing. Biomimetics 2025, 10, 721. https://doi.org/10.3390/biomimetics10110721

Fu S, Chen Z, Gan L, Ling J, Huang H, Chen J, Zhou Y. A Soft Exoskeleton for Hand Grip Augmentation and Fall Prevention Assistance in Tower Climbing. Biomimetics. 2025; 10(11):721. https://doi.org/10.3390/biomimetics10110721

Chicago/Turabian StyleFu, Shaojian, Zuyuan Chen, Lu Gan, Jingqi Ling, Hao Huang, Junkai Chen, and Yitong Zhou. 2025. "A Soft Exoskeleton for Hand Grip Augmentation and Fall Prevention Assistance in Tower Climbing" Biomimetics 10, no. 11: 721. https://doi.org/10.3390/biomimetics10110721

APA StyleFu, S., Chen, Z., Gan, L., Ling, J., Huang, H., Chen, J., & Zhou, Y. (2025). A Soft Exoskeleton for Hand Grip Augmentation and Fall Prevention Assistance in Tower Climbing. Biomimetics, 10(11), 721. https://doi.org/10.3390/biomimetics10110721