Application of Near-Miss Management Systems: An Exploratory Field Analysis in the Italian Industrial Sector

Abstract

1. Introduction

2. Materials and Methods

2.1. Background and Motivation of the Study

2.2. Research Method

3. Results

3.1. Company Type and Safety Organization Analysis

3.2. NMMS Adoption: Tools and Methods Adopted

3.3. NMMS Adoption: Outlined Criticalities and Benefits

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thoroman, B.; Goode, N.; Salmon, P. System thinking applied to near misses: A review of industry-wide near miss reporting systems. Theor. Issues Ergon. Sci. 2018, 19, 712–737. [Google Scholar] [CrossRef]

- Haas, E.J.; Yorio, P.L. The role of risk avoidance and locus of control in workers’ near miss experiences: Implications for improving safety management systems. J. Loss Prev. Process Ind. 2019, 59, 91–99. [Google Scholar] [CrossRef] [PubMed]

- International Labour Organization (ILO). Investigation of Occupational Accidents and Diseases—A Practical Guide for Labour Inspectors; International Labour Office: Geneva, Switzerland, 2014. [Google Scholar]

- ISO 45001:2018; Occupational Health and Safety Management Systems—Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland, 2018.

- Jones, S.; Kirchsteiger, C.; Bjerke, W. The importance of near miss reporting to further improve safety performance. J. Loss Prev. Process Ind. 1999, 12, 59–67. [Google Scholar] [CrossRef]

- Bragatto, P.A.; Agnello, P.; Ansaldi, S.; Pittiglio, P. Weak signals of potential accidents at “Seveso” establishments. In Safety, Reliability and Risk Analysis: Theory, Methods and Applications (4 Volumes + CD-ROM); CRC Press: Boca Raton, FL, USA, 2008; p. 137. [Google Scholar]

- Brizon, A.; Wybo, J.L. The life cycle of weak signals related to safety. Int. J. Emerg. Manag. 2009, 6, 117–135. [Google Scholar] [CrossRef]

- Andriulo, S.; Gnoni, M.G. Measuring the effectiveness of a near-miss management system: An application in an automotive firm supplier. Reliab. Eng. Syst. Saf. 2014, 132, 154–162. [Google Scholar] [CrossRef]

- Heinrich, H.W. Industrial Accident Prevention; McGraw-Hill: New York, NY, USA, 1959. [Google Scholar]

- Van der Schaaf, T.W. Near Miss Reporting in the Chemical Process Industry. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 1992. [Google Scholar]

- Zhou, Z.; Li, C.; Mi, C.; Qian, L. Exploring the Potential Use of Near miss Information to Improve Construction Safety Performance. Sustainability 2019, 11, 1264. [Google Scholar] [CrossRef]

- Demich, B.; Haas, E.J.; McGuire, J. The use of workers’ near miss reports to improve organizational management. Min. Eng. 2020, 72, 40–42. [Google Scholar]

- Westreich, S.; Perlman, Y.; Winkler, M. Analysis and Implications of the Management of Near-miss events: A Game Theoretic Approach. Reliab. Eng. Syst. Saf. 2021, 212, 107645. [Google Scholar] [CrossRef]

- Bugalia, N.; Maemura, Y.; Ozawa, K. A system dynamics model for near miss reporting in complex systems. Saf. Sci. 2021, 142, 105368. [Google Scholar] [CrossRef]

- Van der Schaaf, T.W.; Lucas, D.A.; Hale, A.R. Near Miss Reporting as a Safety Tool; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Marks, E.; Mckay, B.; Awolusi, I. Using Near Misses to Enhance Safety Performance in Construction. In Proceedings of the ASSE Professional Development Conference and Exposition, Dallas, TX, USA, 7–10 June 2015. [Google Scholar]

- Gnoni, M.G.; Tornese, F.; Guglielmi, A.; Pellicci, M.; Campo, G.; De Merich, D. Near miss management systems in the industrial sector: A literature review. Saf. Sci. 2022, 150, 105704. [Google Scholar] [CrossRef]

- Muermann, A.; Oktem, U. The near-miss management of operational risk. J. Risk Financ. 2002, 4, 25–36. [Google Scholar] [CrossRef]

- De Leo, F.; Elia, V.; Gnoni, M.G.; Tornese, F. Integrating safety-I and safety-II approaches in near miss management: A critical analysis. Sustainability 2023, 15, 2130. [Google Scholar] [CrossRef]

- Zerguine, H.; Jalaludin, J.; Tamrin SB, M. Behaviour based safety approach and factors affecting unsafe behaviour in construction sector: A review. Asia Pac. Environ. Occup. Health J. 2016, 2, 1–12. [Google Scholar]

- Baldissone, G.; Comberti, L.; Bosca, S.; Murè, S. The analysis and management of unsafe acts and unsafe conditions. Data collection and analysis. Saf. Sci. 2019, 119, 240–251. [Google Scholar] [CrossRef]

- Phimister, J.R.; Oktem, U.; Kleindorfer, P.R.; Kunreuther, H. Near-miss incident management in the chemical process industry. Risk Anal. Int. J. 2003, 23, 445–459. [Google Scholar] [CrossRef] [PubMed]

- Fabiano, B.; Currò, F. From a survey on accidents in the downstream oil industry to the development of a detailed near miss reporting system. Process Saf. Environ. Prot. 2012, 90, 357–367. [Google Scholar] [CrossRef]

- Williamsen, M. Near miss reporting: A missing link in safety culture. Prof. Saf. 2013, 58, 46–50. [Google Scholar]

- Haas, E.J.; Demich, B.; McGuire, J. Learning from Workers’ Near miss Reports to Improve Organizational Management. Min. Metall. Explor. 2020, 37, 873–885. [Google Scholar] [CrossRef]

- Drupsteen, L.; Wybo, J.L. Assessing propensity to learn from safety-related events. Saf. Sci. 2015, 71, 28–38. [Google Scholar] [CrossRef]

- Teizer, J.; Cheng, T. Proximity hazard indicator for workers-on-foot near miss interactions with construction equipment and geo-referenced hazard areas. Autom. Constr. 2015, 60, 58–73. [Google Scholar] [CrossRef]

- Simone, F.; Ansaldi, S.M.; Agnello, P.; Patriarca, R. Industrial safety management in the digital era: Constructing a knowledge graph from near misses. Comput. Ind. 2023, 146, 103849. [Google Scholar] [CrossRef]

- Bhattacherjee, A. Social Science Research: Principles, Methods, and Practices; Textbooks Collection 3; University of South Florida: Tampa, FL, USA, 2012. [Google Scholar]

- De Merich, D.; Gnoni, M.G.; Malorgio, B.; Micheli, G.J.L.; Piga, G.; Sala, G.; Tornese, F. A Cloud-Based Tool for Integrating Occupational Risk Assessment Within Management Systems for SMEs. Safety 2020, 6, 47. [Google Scholar] [CrossRef]

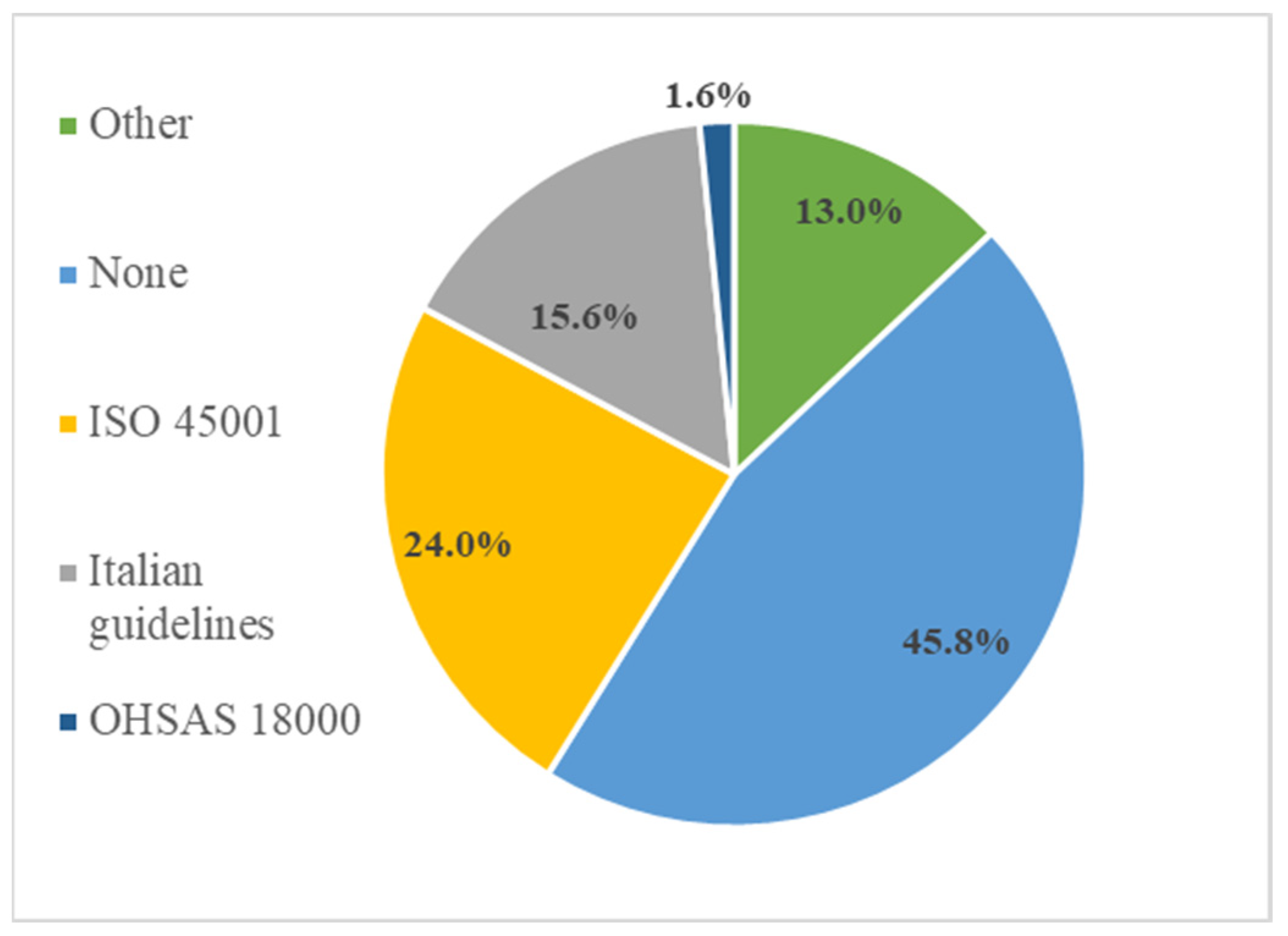

| Company Size | Companies NOT Adopting SMS | Companies Adopting Standardized SMS | Companies Adopting Other Types of SMS | Total |

|---|---|---|---|---|

| Micro | 17 (65%) | 4 (15%) | 5 (19%) | 26 |

| Small | 44 (47%) | 36 (39%) | 13 (14%) | 93 |

| Medium | 20 (42%) | 23 (48%) | 5 (10%) | 48 |

| Large | 7 (28%) | 16 (64%) | 2 (8%) | 25 |

| Total | 88 (45.83%) | 79 (41.14%) | 25 (13.02%) | 192 |

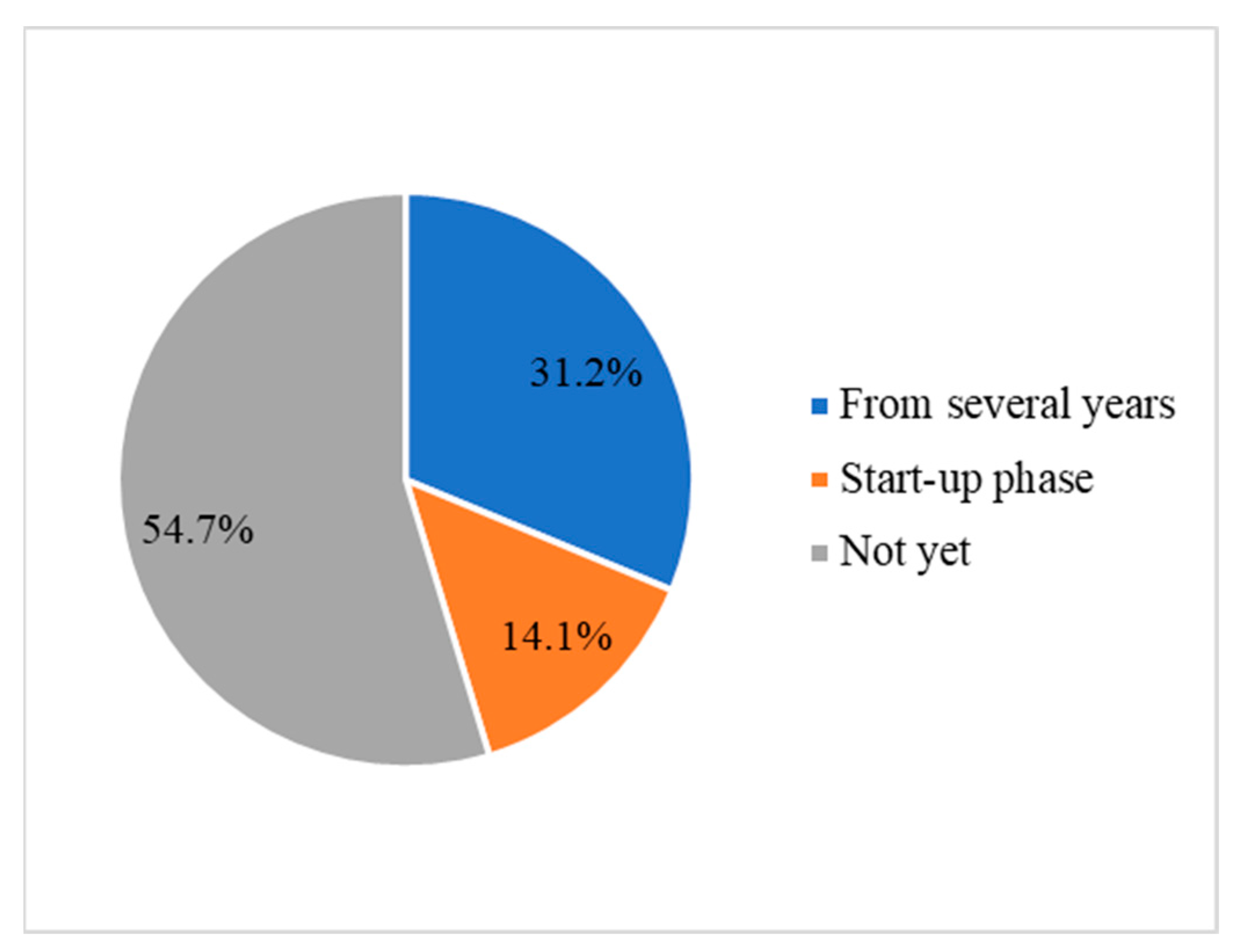

| Company Size | NMS Not Yet Adopted | Start Up Phase | Adopted from Several Years | Total |

|---|---|---|---|---|

| Micro | 23 (88.5%) | 3 (11.5%) | 0 | 26 |

| Small | 63 (67.7%) | 8 (8.6%) | 22 (23.7%) | 93 |

| Medium | 17 (35.4%) | 10 (20.8%) | 21 (43.8%) | 48 |

| Large | 2 (8.0%) | 6 (24.0%) | 17 (68.0%) | 25 |

| Total | 105 | 27 | 60 | 192 |

| Collected Event Type | N° of Companies |

|---|---|

| Only Near miss | 26 (29.89%) |

| Near miss, Unsafe act, Unsafe conditions | 32 (36.78%) |

| Near miss and Unsafe act | 4 (4.60%) |

| Near miss and Unsafe condition | 10 (11.49%) |

| Other | 15 (17.24%) |

| Responsibility to Report Event | Company Size | ||||

|---|---|---|---|---|---|

| Micro | Small | Medium | Large | Total | |

| Worker directly involved in the event | 1 | 11 | 8 | 12 | 32 (36.78%) |

| Worker who is responsible for the collection process | 1 | 10 | 13 | 3 | 27 (31.03%) |

| Company owner | 0 | 1 | 1 | 0 | 2 (2.30%) |

| Health and safety manager | 1 | 4 | 5 | 3 | 13 (14.94%) |

| Other | 0 | 4 | 4 | 5 | 13 (14.94%) |

| Adopted Cause Analysis Method | N° of Companies |

|---|---|

| 5 WHYS Method to Identify Root Causes of Incidents | 8 (9.20%) |

| Ishikawa Diagram | 4 (4.60%) |

| Company checklist | 6 (6.90%) |

| Italian method for analyzing fatal injury | 4 (4.60%) |

| Structured Interview | 8 (9.20%) |

| Internal company risk assessment model | 42 (48.28%) |

| Other | 15 (17.24%) |

| Company Size | |||||

|---|---|---|---|---|---|

| Micro | Small | Medium | Large | Total | |

| Training and information meetings | 2 | 15 | 11 | 6 | 34 (39.08%) |

| Company Bulletin Board | 0 | 5 | 4 | 2 | 11 (12.64%) |

| E-newsletter | 0 | 3 | 4 | 5 | 12 (13.79%) |

| Company Module | 0 | 1 | 3 | 1 | 5 (5.75%) |

| No diffusion | 0 | 0 | 1 | 2 | 3 (3.45%) |

| Other | 1 | 6 | 8 | 7 | 22 (25.29%) |

| NMMS Process Involved in Digitalization | N° of Companies |

|---|---|

| Collection | 10 (11.49) |

| Analysis | 3 (3.45%) |

| Collection and analysis | 13 (14.94%) |

| Collection, analysis, and diffusion | 6 (6.90%) |

| No software tool adopted | 51 (58.62%) |

| Other | 4 (4.60%) |

| Outlined Benefits | N° of Companies |

|---|---|

| Enhanced safety (less injuries, more control, prevention and risk identification) | 48 (55.17%) |

| More awareness and attention among workers | 14 (16.09%) |

| Control and improvement of processes and procedures | 10 (11.49%) |

| Improved work conditions | 4 (4.60%) |

| Not yet observed | 4 (4.60%) |

| Other | 4 (4.60%) |

| No answer | 3 (3.45%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agnusdei, G.P.; Gnoni, M.G.; Tornese, F.; De Merich, D.; Guglielmi, A.; Pellicci, M. Application of Near-Miss Management Systems: An Exploratory Field Analysis in the Italian Industrial Sector. Safety 2023, 9, 47. https://doi.org/10.3390/safety9030047

Agnusdei GP, Gnoni MG, Tornese F, De Merich D, Guglielmi A, Pellicci M. Application of Near-Miss Management Systems: An Exploratory Field Analysis in the Italian Industrial Sector. Safety. 2023; 9(3):47. https://doi.org/10.3390/safety9030047

Chicago/Turabian StyleAgnusdei, Giulio Paolo, Maria Grazia Gnoni, Fabiana Tornese, Diego De Merich, Armando Guglielmi, and Mauro Pellicci. 2023. "Application of Near-Miss Management Systems: An Exploratory Field Analysis in the Italian Industrial Sector" Safety 9, no. 3: 47. https://doi.org/10.3390/safety9030047

APA StyleAgnusdei, G. P., Gnoni, M. G., Tornese, F., De Merich, D., Guglielmi, A., & Pellicci, M. (2023). Application of Near-Miss Management Systems: An Exploratory Field Analysis in the Italian Industrial Sector. Safety, 9(3), 47. https://doi.org/10.3390/safety9030047