Abstract

This paper presents a conceptual framework with the application of the structural equation modeling (SEM) method for improving safety in the surface mining industry. The focus of the study is to address the essential components of occupational safety and assess them to develop significant linkages because they are often addressed individually. In this study, the risk (accident causation) factors were examined for continuous improvement based on the risk management process and the application of engineering, education, and enforcement. Data collected from mine employees were utilized to evaluate the framework using SEM. The final structure model showed good fit indices, including chi-square to a degree of freedom (x2/df) equal to 2.545, root mean square error of approximation (RMSEA) of 0.034 with a probability of 1.0, and a valid framework path. All the factors had a significant positive effect on workplace conditions and workers’ commitment, except machinery, which had a positive non-significant effect on workplace conditions. The effects of the mediated factors of worker commitment and workplace conditions on the number of accidents were β = −0.76 and β = −0.145, respectively, and the effects on job satisfaction were β = 0.31 and β = 0.433. The research concluded that any risk factor reduction can improve safety in the mining industry; however, the correlation of all factors’ effects magnifies the influence of a single factor. Furthermore, the conceptual framework is recommended for identifying the factors that need modification in order to manage hazards and improve safety in the workplace.

1. Introduction

Mining is one of the most physically demanding industries, with a high rate of accidents and injuries [1]. These mining injuries and accidents are complicated and often include several technological, societal, and individual elements [2]. Improper mine design, inadequately maintained equipment, unexpected geological conditions, incompetent management, or a combination of these difficulties can all lead to unsafe working conditions [3]. There is always the possibility of an accident occurring in an unsafe work environment; however, accidents and injuries do not always result from unsafe conditions; thus, it is essential to understand the factors that lead from a risky situation to an injury [4]. In addition, unsafe acts are the actions and decisions of workers that directly influence the occurrence of an accident in a socio-technical system and have been the subject of discourse in various models and theories [5,6]. However, many scholars perceive that the role of humans in accidents and errors can be a consequence of failure in the process that influences human behavior and causes unwanted events [7,8,9]. Therefore, a comprehensive accident analysis approach based on systematic research can identify a number of contributing factors that led to the accident as well as prospective changes that can minimize future losses [10,11]. Various factors and methods have been used for risk assessment, but efforts to achieve zero incidents in the workplace will continue [12,13]. There is a need to focus on methodologies that investigate the effect of the crucial factors that contribute to accidents and injuries, as well as those that prevent the occurrence of accidents. In this research, various risky but modifiable factors have been compiled from the literature; however, age, years of experience, and occupation are excluded from the investigation because they are unchangeable in nature [3,14]. The following modifiable workplace factors examined in safety research are considered, with a focus on how they interact with one another in the workplace.

1.1. Personal Protective Equipment (PE)

PPE is one of the most important factors in the safety process and serves as a barrier between workers and potential harm [15]. Workers that use PPE incur relatively few injuries, while the lack of PPE is a great indicator of injuries [16,17].

1.2. Machinery and Equipment (Me)

Machine safety remains a top priority for mining operations, as the majority of serious accidents are related to machine operation or maintenance [18]. Poor maintenance and improper use of machinery and equipment lead to accidents [19]. Risk related to mining equipment varies depending on the work environment, mine design, machine specifications, and human aspect [20].

1.3. Training (Tr)

One of the most important aspects of preventing workplace accidents is training [21]. The purpose of safety training is to provide employees with the ability to deal with risks at work and complete work safely [22]. Training is important because it motivates employees to maintain a safe workplace, resulting in reduced injuries.

1.4. Law Implementation (Lw)

Compliance with safety regulations enhances workplace safety [23]. Infractions of laws and regulations, as well as a lack of enforcement of the law, are responsible for the higher frequency of mine accidents [24].

1.5. Management Commitment (MC)

Management commitment is important in the workplace and helps to promote safety [25]. The employees’ impressions of their management’s adherence to safety policies, practices, and safety motivation can be used to gauge management’s commitment to safety [26]. The lack of a supporting environment suggests insufficient management commitment to safety [25].

1.6. Workers Commitment (WC)

Worker commitment plays an important part in the mine environment. The commitment of employees to safety raises workplace safety, which is connected to management commitment through fostering a safe environment [27,28].

1.7. Workplace Safety Condition (WP)

The workplace must be risk-free and provide a safe and secure environment for workers [29]. Risks in mines are associated with falling rocks, slipping from a height, improper drilling and shot-firing, using excavators, loaders, dumpers, and other equipment incorrectly, and hazards with electricity and haulage, which are potential sources of injury [30,31,32]. Enhancing safety performance can improve safety in the workplace [33]. An increase in workplace safety would result from improvements in management and supervisors’ safety practices, safety initiatives, co-workers’ safety, and work safety [34].

1.8. Number of Injuries/Accidents (Ac)

The core problem in the mining sector is that miners are exposed to a higher frequency of accidents. Despite substantial progress in safety, mining is still the sector where accidents happen most frequently [35]. Working conditions, mining procedures, geological conditions, individual miner characteristics, and mine act violations are only a few of the many elements that lead to accidents and injuries in coal mines and affect mining worker safety [36].

1.9. Job Satisfaction (JS)

A supportive administration and a secure workplace promote job satisfaction, which further strengthens employees’ commitment [37,38]. Job satisfaction is a key aspect of maintaining a safe working environment, and employees who are satisfied with their occupations maintain favorable attitudes toward their jobs [39].

Numerous frameworks and models have been developed for assessing and managing risk in industries, reducing the frequency and severity of accidents; however, endeavors to ensure workplace safety persist [23,40]. The research carried out so far has encompassed several factors of accident for analysis, but they are mostly explored independently [13,29,41,42,43]. The primary purpose of this research is to identify risk factors and their combined impact on the complex mine’s environment.

The key assumption of this study is that there is a relationship among the risk factors, and these factors have either positive or negative effects on the mine environment. Proper identification and assessment of these risk factors are crucial for reducing accidents in the workplace. In this paper, a framework is proposed to illustrate the important relationships among workplace conditions, training, law implementation, equipment, workers and management commitment, their accident experience, and other outcomes such as job satisfaction for continuous safety improvement in the workplace. The distribution and potency of associations between these factors are assessed using structural equation modeling. The primary objective is to establish the relationship between the factors that require additional consideration for safety in the workplace. The research aims to better understand the systemic factors that lead to an increase in the frequency of injuries and fatalities in the surface mining industry of Pakistan.

2. Materials and Methods

2.1. Conceptual Framework and Hypothesis

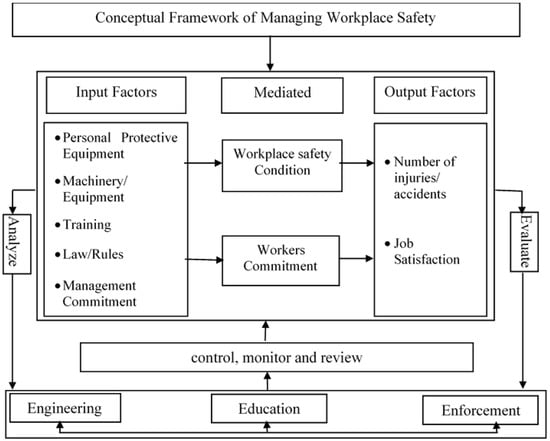

In this research, a conceptual framework for the management of surface mines’ hazards was established for continual improvement in the workplace, as shown in Figure 1. The factors for the framework were identified from research related to workplace safety [34,44,45]. To determine the relationship between the factors in the framework, the data were gathered from mine workers through a questionnaire. The framework analysis was based on the 3 E’s slogan (engineering, education, and enforcement) concept, which was put forth by the National Safety Council of the United States in 1974 for occupational safety [46]. The engineering component is concerned with controlling physical risks, education is concerned with training and motivating employees, and enforcement is concerned with putting the legislation into practice so that the task is carried out properly [45]. The risk management system employs a continuous process of analysis, evaluation, control, monitoring, and review to address potential incidents and achieve workplace safety [47].

Figure 1.

Conceptual framework.

In the framework, the observed factors were identified as input factors (PE, Me, Tr, Lw, and MC), mediated factors (WP and WC), and output factors (Ac and JS). This classification is significant in analyzing the effects of factors in a system. Three hypotheses were established in order to assess the influence/path of the observed factors on one another in the conceptual framework.

Hypothesis 1 (H1):

It is hypothesized that all the input, mediated, and output factors are significantly correlated.

Hypothesis 2 (H2):

It is hypothesized that all the input and mediated factors have a significant relationship with accidents and job satisfaction. An increase or decrease in any factor will increase or decrease the output factor according to the situation.

Hypothesis 3 (H3):

It is hypothesized that the more important factors, such as worker commitment and workplace conditions, will serve as effective mediators. The input factors have a significant relationship with mediators, and mediators have significant relationships with output factors. A safe workplace is expected to have minimal risks and incidents, and committed employees are more satisfied with their jobs and perform better in terms of safety.

In order to verify the path of the factors, the proposed hypotheses were tested with a structural equation modeling technique based on a questionnaire survey.

2.2. Questionnaire Survey

A questionnaire survey was carried out for data collection from the mines’ employees. After obtaining approval from the relevant committee members and explaining the purpose of the research to mine workers, informed consent was obtained, and data were collected. Behavioral decision studies illustrate that humans are vulnerable to several biases, some of which are due to cognitive errors [48,49]. To lessen bias in the decision, a large sample of employees from all occupations, including supervisors in the mine, was set as the target respondent group. Fifteen hundred questionnaires were distributed, in which 1300 respondents gave their opinion about observed factors of the framework. A five-point Likert scale was used to ask the respondents to rate each statement, with 1 for “strongly disagree” and 5 for “strongly agree”. The scores obtained from the statements were utilized for exploratory factor analysis (EFA) and structural equation modeling (SEM) [50]. For SEM, code/identification numbers were assigned to the statement regarding factors. For example, Ac_1 represented statement No. 1 concerning the accident experience of the workers in the questionnaire survey and so on.

3. Data Analysis and Results

Structural Equation Modelling is a procedure for exploring structural relationships. To confirm factorial validity in SEM, confirmatory factor analysis (CFA) was used [51,52]. Prior to applying SEM, exploratory factor analysis (EFA) was performed in which all of the acquired data were verified with Skewness and Kurtosis for outliers, irregular answers, and missing values, and each case was fixed with the median of close-by points. In order to ascertain the dimensionality of the factors, SPSS v25 was used to conduct a factor analysis on each reflective indicator [53]. To produce a clear pattern of the factor loading, the Kaiser–Mayer–Olkin (KMO) and Bartlett tests were used for description, and maximum likelihood was used as an extraction mode and consisted of Eigenvalues more than 1. A Scree plot was used for factor determination, Promax rotation was used for factor correlation, and a coefficient display format with absolute values less than 0.3 was also utilized [54].

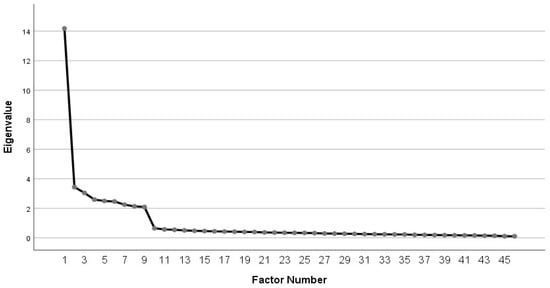

The Scree plot produced nine factors, as shown in Figure 2. KMO was used to determine the variance shared by the indicators, and a score greater than 0.7 was considered favorable. Bartlett tests with a value less than 0.05 were considered significant [54]; the findings which verify the acceptability of data for analysis are shown in Table 1. Cronbach’s alpha was used to determine the internal consistency (reliability) of factors. Table 2 lists all of Cronbach’s alpha results that were more than 0.70 for each group of factors, showing satisfactory reliability. In Table 2, the commonalities and the pattern matrix are also provided. In commonality, the variance is calculated; values closer to one indicate that more variation is explained by the extracted factor, whereas values close to zero indicate a weak match [53]. The pattern matrix’s factors showed unidimensionality, and each item significantly contributed to its estimated factors. The factor correlation matrix depicts either a positive or negative correlation of factors, shown in Table 3.

Figure 2.

Scree plot for extracted factor Eigenvalues.

Table 1.

Kaiser–Meyer–Olkin (KMO) and Bartlett test.

Table 2.

Communalities, Cronbach’s alpha, and pattern matrix for the factors.

Table 3.

Factor correlation matrix.

3.1. Measurement Model

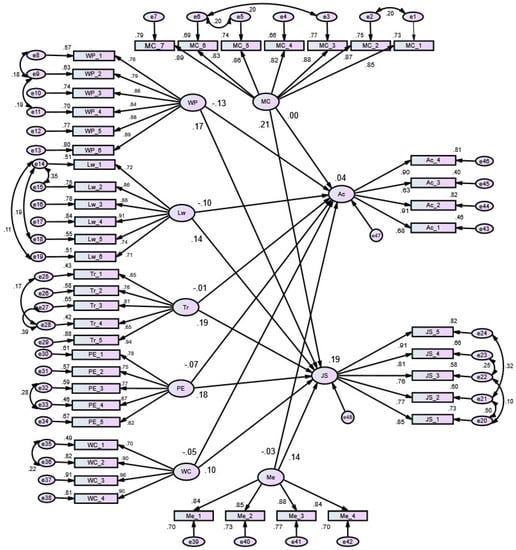

The structural equation modeling (SEM) technique is defined in two sub-models: the measurement model and the structure model. The measurement model supported the nine factors obtained with EFA and confirmed the goodness of fit using confirmatory factor analysis (CFA) with the mathematical tool (Analysis of Moment Structure) SPSS version 23, as shown in Figure 3. The overall model fit was assessed using a number of fit indices, particularly the chi-square (x2/df), comparative fit index (CFI), incremental-fit index (IFI), Tucker–Lewis index (TLI), Parsimony Comparative fit index (PCFI), root mean square error of approximation (RMSEA), and probability of close fit (PLCLOSE) [55]. All factors had factor loadings greater than the acceptable threshold of 0.5, as shown in Figure 3 [56]. The results are summarized in Table 4, which shows that the model fit the data well. The model’s reliability, convergent, and discriminant validity tests yielded results that were within acceptable bounds, as shown in Table 5. The regression weights, standardized regression weights, covariances, correlations, and variances are provided in the Supplementary Materials.

Figure 3.

Measurement model.

Table 4.

Goodness of fit.

Table 5.

Composite reliability, average variance extracted, convergent, and discriminant validity.

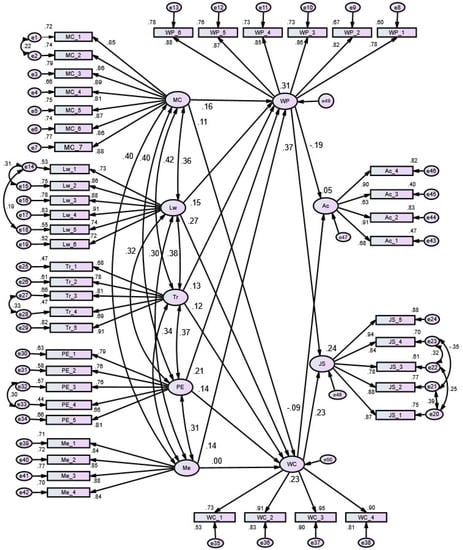

3.2. Structural Model

A structure model was constructed to indicate the path among the factors in accordance with the hypothesis, H2, for factors estimated by the measurement model [57]. The initial structure model was tested by rearranging the pathways, as presented in Figure 4. The results produced by the initial structure model are provided in Table 6, Model 1. The results reveal that all the effects of the exogenous factors on Ac and JS factors were either negative or positive with a value of p < 0.05, respectively, excluding the effects (non-Significant) of the factors MC on Ac with p = 0.902, Tr on Ac with p = 0.793, WC on Ac with p = 0.096, and Me on Ac with p = 0.282.

Figure 4.

Initial structural equation modeling.

Table 6.

Model fit indices.

The analysis of the initial model indicates that the proposed hypothesis, H2, is not completely verified. A number of model runs were carried out with different paths in order to demonstrate the relationships in the framework and improve the overall model fit. The structural equation model provided in Figure 5 with good fit indices (Table 6) was considered the final model, which also verified the path in the framework. All the factors had a significant positive effect on WP and WC except Me on WC. The effect of factors WC on Ac was standardized to β = −0.76, p < 0.05, and the effect on JS was standardized to β = 0.31, p < 0.05; the effect of factors WP on Ac was standardized to β = −0.14, p < 0.05, and the effect on JS was standardized to β = 0.433, p < 0.05. The regression weights, standardized regression weights, covariances, correlations, and variances of the initial and final structure equation models are provided in the Supplementary Materials.

Figure 5.

Final structural equation model.

4. Discussion

This study provides a comprehensive framework for managing risks and effective safety improvements in surface mines. All potential causes of mine accidents were investigated to assess their relevance to accident causation as researchers suggested that the interactions between elements and the attitude of the individual that comes from those relationships constitute the core of a system; hence, the system as a whole must be investigated [58]. Data acquired from the mine sites were used to evaluate the framework with the SEM technique. SEM was used since it enables a variety of tests for determining the good fit of the data acquired for examination. Following exploratory factor analysis to verify the dataset’s validity and reliability, the measurement model was subjected to confirmatory factor analysis. The formulated hypothesis H1 was verified by generating a measurement model and yielded acceptable model fit indices. All the factors exhibited significant relationships with one another, indicating how these factors interact with one another in a mine environment.

Then, to determine the effects of independent factors (PE, Me, Tr, Lw, MC, WP, and WC) on the dependent factors (Ac and JS), an initial structure model was generated. Numerous independent factors had no visible direct significant effects on the dependent factors, according to the data analysis. The model yielded not well-fitted statistics and partially verified hypothesis H2. The results imply that worker dedication alone cannot prevent accidents if workplace safety parameters are not satisfied. Similarly, providing machinery, training, and enforcing laws will not minimize accidents until the workplace is safe and employees are committed to safety.

Since the initial structural model’s results are partially satisfactory, the use of mediators is necessary for a well-fitting model. The final structural equation model produced model fit indices and supported the path given in the developed framework. A significant positive correlation among the input factors ranging from 0.30 to 0.43 was achieved. All the input factors had a significant positive effect on the mediated factor except the factor Me to WC, which was found positive and non-significant (the result of the machinery was non-significant because, in this study, workers were not satisfied with the situation of all the factors except machinery/equipment). The mediators WC and WP had a significant positive effect on output factor JS and a significant negative effect on factor Ac, which was also specified by several researchers [1,59]. This indicates that by improving working conditions and increasing employee dedication, mine sites will experience higher job satisfaction and fewer accidents [28,38,60]. Similarly, the most essential influencing factors, such as safety training, proper equipment, and regulation execution, imply that these elements are critical in minimizing unfavorable outcomes since they increase employee awareness, improve job abilities, and extend professional potential [58]. The findings indicate that all the framework variables are interrelated, and the correlation of all factors’ impacts amplifies the importance of any single factor by emphasizing interactions between the contributory factors.

Appropriate solutions to prevent accidents are achievable if all causes and relevant factors are identified [61]. To increase workplace safety, approaches should be based on engineering, education, and enforcement. Considering engineering principles, workers must have access to modern, safe PPE and equipment. Workplace injuries can be reduced by mandating the use of personal protective equipment. The use, training, and monitoring of PPE among workers should be continuous and mandatory [16,17]. Similarly, a reduction in machinery-related accidents may be attained by enhancing operator training. Regular evaluations of the efficacy of training and remediation programs should be conducted with established procedures for identifying and addressing defects [18,62]. Workers need both technical and safety training to be able to recognize and prevent any risks in the workplace. This study revealed that management levels, both individually and collectively, affected workers’ safety behavior. Management should be committed to workplace safety and compliance with all regulations and laws to improve workers’ behavior. Since workplace and human factors influence occupational accidents, behavioral and organizational approaches to mine safety ought to be regarded as complementary rather than as alternatives [49,63]. Thus, all risk variables must be addressed and monitored for safety improvement, and importance must be given to the most influential factors.

This study included several methodological limitations. One of the limitations of this study was the incorporation of nine factors sourced from the literature that were deemed essential for ensuring safety in mining environments but may exhibit variability if implemented in a singular workplace. Another limitation pertained to the fact that all accidents were grouped together, despite the possibility that minor and serious accidents may have distinct associations with certain environments. This research can be extended in the future by examining the relationship among manageable factors based on different mining methods.

5. Conclusions

In this study, a conceptual framework for managing workplace risks in the surface mining industry was designed on the most pertinent factors of the mine environment. The relationship between the factors was derived from the formulated hypotheses and was analyzed with SEM using data acquired from mine workers.

This study found that each independent factor, such as personal protective equipment, machinery and equipment, management commitment, law enforcement, training, workplace conditions, and workers’ commitment, has a significant weak effect on each dependent factor, i.e., the number of accidents and job satisfaction. This finding indicates that the outcome of a single factor is weaker; for example, if training is provided, but workers are not committed, the effect will be low. The final structural equation model verified that the effects of correlated factors significantly strengthen the influence of any single factor.

The final structural model further demonstrates that the majority of the unsafe conditions in the mine environment are caused by independent factors and that these conditions should be improved through continuous evaluation, the use of engineering solutions, the provision of education and training, and the strict enforcement of the law. A safe workplace can be achieved by providing proper training, protective equipment, and machinery and enforcing laws and policies. Workers’ and management commitment can be improved by providing safe workplaces and safety training. This framework is suggested for evaluating workplace safety and identifying factors that need improvement in order to increase safety. Additional research is recommended to further elaborate on the risk factors for safety in mines.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/safety9020031/s1.

Author Contributions

Conceptualization, S.S.; methodology, S.S. and S.R.; software, S.S.; validation, S.S., S.R., and I.A.; formal analysis, S.S.; investigation, S.S. and S.R.; resources, S.S.; data curation, S.S. and I.A.; writing—original draft preparations, writing—review and editing, S.S., S.R., and I.A.; visualization, S.S.; supervision, S.R.; project administration, S.S. and I.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

This study was approved by the Institutional Research Committee at the University of Engineering and Technology in Peshawar, Pakistan (PCD/HEC 25694).

Informed Consent Statement

Mentioned in the questionnaire.

Data Availability Statement

Supporting data are attached as Supplementary Materials.

Acknowledgments

The authors are thankful for the administrative support provided by the University of Engineering and Technology in Peshawar, Pakistan.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chatterjee, S. Development of uncertainty-based work injury model using Bayesian structural equation modelling. Int. J. Inj. Contr. Saf. Promot. 2014, 21, 318–327. [Google Scholar] [CrossRef] [PubMed]

- Paul, P.S. Predictors of work injury in underground mines—An application of a logistic regression model. Min. Sci. Technol. 2009, 19, 282–289. [Google Scholar] [CrossRef]

- Maiti, J.; Chatterjee, S.; Bangdiwala, S.I. Determinants of work injuries in mines—An application of structural equation modelling. Inj. Control Saf. Promot. 2004, 11, 29–37. [Google Scholar] [CrossRef] [PubMed]

- Khanzode, V.V.; Maiti, J.; Ray, P.K.; Tewari, V.K. Injury severity assessment for underground coalmine workers. Appl. Ergon. 2010, 41, 242–250. [Google Scholar] [CrossRef]

- Shappell, S.; Wiegmann, D.A. The Human Factors Analysis and Classification System—HFACS. 2000. Available online: https://www.nifc.gov/fireInfo/fireInfo_documents/humanfactors_classAnly.pdf (accessed on 12 October 2022).

- Wang, J.; Yan, M. Application of an improved model for accident analysis: A case study. Int. J. Environ. Res. Public Health 2019, 16(15), 2756. [Google Scholar] [CrossRef]

- Leveson, N.G. Engineering a Safer World Systems Thinking Applied to Safety; The MIT Press: Cambridge, MA, USA; London, UK, 2011; Volume 33. [Google Scholar] [CrossRef]

- Mosey, D. Looking beyond operator—Putting people in the mix. NEI Magazine, 2014. Available online: http://www.neimagazine.com/features/featurelooking-beyond-the-operator-4447549/ (accessed on 29 April 2023).

- Dekker, S.; Cilliers, P.; Hofmeyr, J.H. The complexity of failure: Implications of complexity theory for safety investigations. Saf. Sci. 2011, 49, 939–945. [Google Scholar] [CrossRef]

- Leveson, N.G. Applying systems thinking to analyze and learn from events. Saf. Sci. 2011, 49, 55–64. [Google Scholar] [CrossRef]

- Joe-Asare, T.; Amegbey, N.; Stemn, E. Human Factor Analysis Framework for Ghana’s Mining Industry. Ghana Min. J. 2020, 20, 60–76. [Google Scholar] [CrossRef]

- Wang, Y.; Griffis, F. The Theory of Zero Incident Safety Management. J. Civ. Constr. Environ. Eng. 2018, 3, 83–98. [Google Scholar] [CrossRef]

- Ajith, M.M.; Ghosh, A.K.; Jansz, J. Risk Factors for the Number of Sustained Injuries in Artisanal and Small-Scale Mining Operation. Saf. Health Work 2020, 11, 50–60. [Google Scholar] [CrossRef]

- Maiti, J.; Bhattacherjee, A. Evaluation of Risk of Occupational Injuries among Underground Coal Mine Workers through Multinomial Logit Analysis. J. Safety Res. 1999, 30, 93–101. [Google Scholar] [CrossRef]

- Chimamise, C.; Gombe, N.T.; Tshimanga, M.; Chadambuka, A.; Shambira, G.; Chimusoro, A. Factors associated with severe occupational injuries at mining company in Zimbabwe, 2010: A cross-sectional study. Pan. Afr. Med. J. 2014, 14, 5. [Google Scholar] [CrossRef] [PubMed]

- Izudi, J.; Ninsiima, V.; Alege, J.B. Use of Personal Protective Equipment among Building Construction Workers in Kampala, Uganda. J. Environ. Public Health 2017, 2017, 5. [Google Scholar] [CrossRef] [PubMed]

- Sehsah, R.; El-Gilany, A.H.; Ibrahim, A.M. Personal protective equipment (Ppe) use and its relation to accidents among construction workers. Med. Del Lav. 2020, 111, 285–295. [Google Scholar] [CrossRef]

- Ruff, T.; Coleman, P.; Martini, L. Machine-related injuries in the US mining industry and priorities for safety research. Int. J. Inj. Contr. Saf. Promot. 2011, 18, 11–20. [Google Scholar] [CrossRef]

- Groves, W.A.; Kecojevic, V.J.; Komljenovic, D. Analysis of fatalities and injuries involving mining equipment. J. Safety Res. 2007, 38, 461–470. [Google Scholar] [CrossRef]

- Kumar, R.; Ghosh, A.K. The accident analysis of mobile mine machinery in Indian opencast coal mines. Int. J. Inj. Contr. Saf. Promot. 2014, 21, 54–60. [Google Scholar] [CrossRef]

- Chan, D.W.M.; Chan, A.P.C.; Choi, T.N.Y. An empirical survey of the benefits of implementing pay for safety scheme (PFSS) in the Hong Kong construction industry. J. Safety Res. 2010, 41, 433–443. [Google Scholar] [CrossRef]

- Bae, H.; Simmons, D.R.; Polmear, M. Promoting the Quarry Workers’ Hazard Identification through Formal and Informal Safety Training. Saf. Health Work 2021, 12, 317–323. [Google Scholar] [CrossRef]

- Luo, T. Safety climate: Current status of the research and future prospects. J. Saf. Sci. Resil. 2020, 1, 106–119. [Google Scholar] [CrossRef]

- Sherin, S.; Zahid -Ur-rehman, E.D.; Hussain, S.; Mohammad, N.; Raza, S. Hazards identification and risk analysis in surface mines of Pakistan using fault tree analysis technique. Min. Miner. Depos. 2021, 15, 119–126. [Google Scholar] [CrossRef]

- Aliabadi, M.M.; Aghaei, H.; Kalatpour, O.; Soltanian, A.R.; SeyedTabib, M. Effects of human and organizational deficiencies on workers’ safety behavior at a mining site in Iran. Epidemiol. Health 2018, 40, e2018019. [Google Scholar] [CrossRef] [PubMed]

- McGonagle, A.K.; Essenmacher, L.; Hamblin, L.; Luborsky, M.; Upfal, M.; Arnetz, J. Management Commitment to Safety, Teamwork, and Hospital Worker Injuries. J. Hosp. Adm. 2016, 5, 46–52. [Google Scholar] [CrossRef] [PubMed]

- Joshi, A.; Miller, S.P.; Whalen, M.; Heimdahl, M.P.E. A proposal for model-based safety analysis. In Proceedings of the AIAA/IEEE Digital Avionics Systems Conference, Forth Worth, TX, USA, 25–28 October 2005; Volume 2. [Google Scholar] [CrossRef]

- Zohar, D. Safety Climate: Conceptualization, Measurement, and Improvement. In The Oxford Handbook of Organizational Climate and Culture; Schneider, B., Barbera, K.M., Eds.; Oxford University Press: Oxford, UK, 2014; pp. 317–334. [Google Scholar] [CrossRef]

- Naji, G.M.A.; Isha, A.S.N.; Mohyaldinn, M.E.; Leka, S.; Saleem, M.S.; Rahman, S.M.N.B.S.A.; Alzoraiki, M. Impact of safety culture on safety performance; mediating role of psychosocial hazard: An integrated modelling approach. Int. J. Environ. Res. Public Health 2021, 18, 8568. [Google Scholar] [CrossRef] [PubMed]

- Ural, S.; Demirkol, S. Evaluation of occupational safety and health in surface mines. Saf. Sci. 2008, 46, 1016–1024. [Google Scholar] [CrossRef]

- Michelo, P.; Bråtveit, M.; Moen, B.E. Occupational injuries and fatalities in copper mining in Zambia. Occup. Med. 2009, 59, 191–194. [Google Scholar] [CrossRef]

- Kasap, Y.; Subası, E. Risk assessment of occupational groups working in open pit mining: Analytic Hierarchy Process. J. Sustain. Min. 2017, 16, 38–46. [Google Scholar] [CrossRef]

- Wirth, O.; Sigurdsson, S.O. When workplace safety depends on behavior change: Topics for behavioral safety research. J. Safety Res. 2008, 39, 589–598. [Google Scholar] [CrossRef]

- Opoku, F.K.; Kosi, I.; Degraft-arthur, D. Enhancing Workplace Safety Culture in the Mining Industry in Ghana. Ghana J. Dev. Stud. 2020, 17, 23–48. [Google Scholar] [CrossRef]

- Elenge, M.; Leveque, A.; De Brouwer, C. Occupational accidents in artisanal mining in Katanga, D.R.C. Int. J. Occup. Med. Environ. Health 2013, 26, 265–274. [Google Scholar] [CrossRef]

- Mangal, A.; Paul, P.S.; Mishra, K. A before Math Analysis of Mine Accident and Safety Research—A Bayesian Structural Equation Modelling Approach. In Proceedings of the International Conference on Deep Excavation, Energy Resources and Production, Kharagpur, India, 24–26 January 2017; Volume 2017, pp. 1–8. [Google Scholar]

- Bushiri, C.P. The Impact of Working Environment on Employees’ Performance: The Case of Institute of Finance Management in Dar Es Salaam Region. Master’s Thesis, Human Resource Management Open University, Dar es Salaam, Tanzania, 2014; p. 88. [Google Scholar]

- Saidi, N.S.A.; Michael, F.L.; Sumilan, H.; Lim, S.L.O.; Jonathan, V.; Hamidi, H.; Ahmad, A.I.A. The Relationship between Working Environment and Employee Performance. J. Cogn. Sci. Hum. Dev. 2019, 5, 14–22. [Google Scholar] [CrossRef]

- Paul, P.S.; Maiti, J. The role of behavioral factors on safety management in underground mines. Saf. Sci. 2007, 45, 449–471. [Google Scholar] [CrossRef]

- Machfudiyanto, R.A.; Latief, Y. A conceptual framework to development of construction safety culture in Indonesia. In Proceedings of the IOP Conference Series Earth and Environmental Science, Yogyakarta, Indonesia, 14–15 November 2017. [Google Scholar] [CrossRef]

- Zhang, M.; Kecojevic, V.; Komljenovic, D. Investigation of haul truck-related fatal accidents in surface mining using fault tree analysis. Saf. Sci. 2014, 65, 106–117. [Google Scholar] [CrossRef]

- Sanmiquel, L.; Bascompta, M.; Rossell, J.M.; Anticoi, H.F.; Guash, E. Analysis of Occupational Accidents in Underground and Surface Mining in Spain Using Data-Mining Techniques. Int. J. Environ. Res. Public Health 2018, 15, 462. [Google Scholar] [CrossRef]

- Maiti, J.; Bhattacherjee, A. A causal model for evaluation of mine safety. Inst. Min. Metall. Trans. Sect. A Min. Technol. 2000, 109, 55–59. [Google Scholar] [CrossRef]

- Akyuz, E. A marine accident analysing model to evaluate potential operational causes in cargo ships. Saf. Sci. 2017, 92, 17–25. [Google Scholar] [CrossRef]

- Vierendeels, G.; Reniers, G.; van Nunen, K.; Ponnet, K. An integrative conceptual framework for safety culture: The Egg Aggregated Model (TEAM) of safety culture. Saf. Sci. 2018, 103, 323–339. [Google Scholar] [CrossRef]

- Swuste, P.; van Gulijk, C.; Zwaard, W. Safety metaphors and theories, a review of the occupational safety literature of the US, UK and The Netherlands, till the first part of the 20th century. Saf. Sci. 2010, 48, 1000–1018. [Google Scholar] [CrossRef]

- BS ISO31000; 2018 BSI Standards Publication Risk Management—Guidelines. BSI: London, UK, 2018; p. 26, ISBN 978-0-539-08191-6. Available online: https://www.ashnasecure.com/uploads/standards/BS%20ISO%2031000-2018.pdf (accessed on 10 November 2022).

- Montibeller, G.; von Winterfeldt, D. Cognitive and Motivational Biases in Decision and Risk Analysis. Risk Anal. 2015, 35, 1230–1251. [Google Scholar] [CrossRef]

- Komljenovic, D.; Loiselle, G.; Kumral, M. Organization: A new focus on mine safety improvement in a complex operational and business environment. Int. J. Min. Sci. Technol. 2017, 27, 617–625. [Google Scholar] [CrossRef]

- Chinda, T.; Suanmali, S.; Ammarapala, V. Structural Equation Model of Safety Implementation and Productivity in the Textile Industry. Thammasat Int. J. Sci. Technol. 2017, 22, 46–60. [Google Scholar] [CrossRef]

- Hidayat, R.; Norul, S.S.A.; Zulnaidi, H. Exploratory and Confirmatory Factor Analysis of Achievement Goals for Indonesian Students in Mathematics Education Programmes. Eurasia J. Math. Sci. Technol. Educ. 2018, 14, 12. [Google Scholar] [CrossRef]

- Mphahlele, P.; Els, C.; De Beer, L.T.; Mostert, K. Investigating strengths and deficits to increase work engagement: A longitudinal study in the mining industry. SA J. Hum. Resour. Manag. 2018, 16, 1–16. [Google Scholar] [CrossRef]

- Plucker, J.A. Exploratory and Confirmatory Factor Analysis in Gifted Education: Examples with Self-Concept Data. J. Educ. Gift. 2003, 27, 20–35. [Google Scholar] [CrossRef]

- Koyuncu, İ.; Kılıç, A.F. The use of exploratory and confirmatory factor analyses: A document analysis. Educ. Sci. 2019, 44, 361–388. [Google Scholar] [CrossRef]

- Xu, S.; Zou, P.X.W.; Luo, H. Impact of Attitudinal Ambivalence on Safety Behaviour in Construction. Hindawai Adv. Civ. Eng. 2018, 2018, 12. [Google Scholar] [CrossRef]

- Amponsah-Tawiah, K.; Jain, A.; Leka, S.; Hollis, D.; Cox, T. Examining psychosocial and physical hazards in the Ghanaian mining industry and their implications for employees’ safety experience. J. Safety Res. 2013, 45, 75–84. [Google Scholar] [CrossRef]

- Rashed, F.; Deluyi, A.H.M.; Dauda, K. Developing a mathematical model of entrepreneurship based on transformational leadership behavior. J. Teknol. 2015, 72, 13–19. [Google Scholar] [CrossRef]

- Zhang, Y.; Shao, W.; Zhang, M.; Li, H.; Yin, S.; Xu, Y. Analysis 320 coal mine accidents using structural equation modeling with unsafe conditions of the rules and regulations as exogenous variables. Accid. Anal. Prev. 2016, 92, 189–201. [Google Scholar] [CrossRef]

- Akbari, H.; Kashani, M.M.; Asadi, Z.; Kaveh, M.; Saberi, H. The Relationship between Job Satisfaction and the Incidence of Unsafe Acts in Metal Smelting Industry Workers in 2017. Int. Arch. Heal. Sci. 2019, 6, 127–131. [Google Scholar] [CrossRef]

- Raziq, A.; Maulabakhsh, R. Impact of Working Environment on Job Satisfaction. Procedia Econ. Financ. 2015, 23, 717–725. [Google Scholar] [CrossRef]

- Sanmiquel, L.; Freijo, M.; Edo, J.; Rossell, J.M. Analysis of work related accidents in the Spanish mining sector from 1982–2006. J. Safety Res. 2010, 41, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Kecojevic, V.; Komljenovic, D.; Groves, W.; Radomsky, M. An analysis of equipment-related fatal accidents in U.S. mining operations: 1995–2005. Saf. Sci. 2007, 45, 864–874. [Google Scholar] [CrossRef]

- Dominic, P.; Psychol, C.C.; State, E. The Impact of Management’ s Commitment on Employee Behavior: A Field Study. In Proceedings of the American Society of Safety Engineers Middle East Chapter, 7th Professional Development Conference & Exhibition, Manama, Kingdom of Bahrain, 18–22 March 2006. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).