Estimating Safety Outcomes of Increased Organisational Safety Management in Trucking Companies

Abstract

:1. Introduction

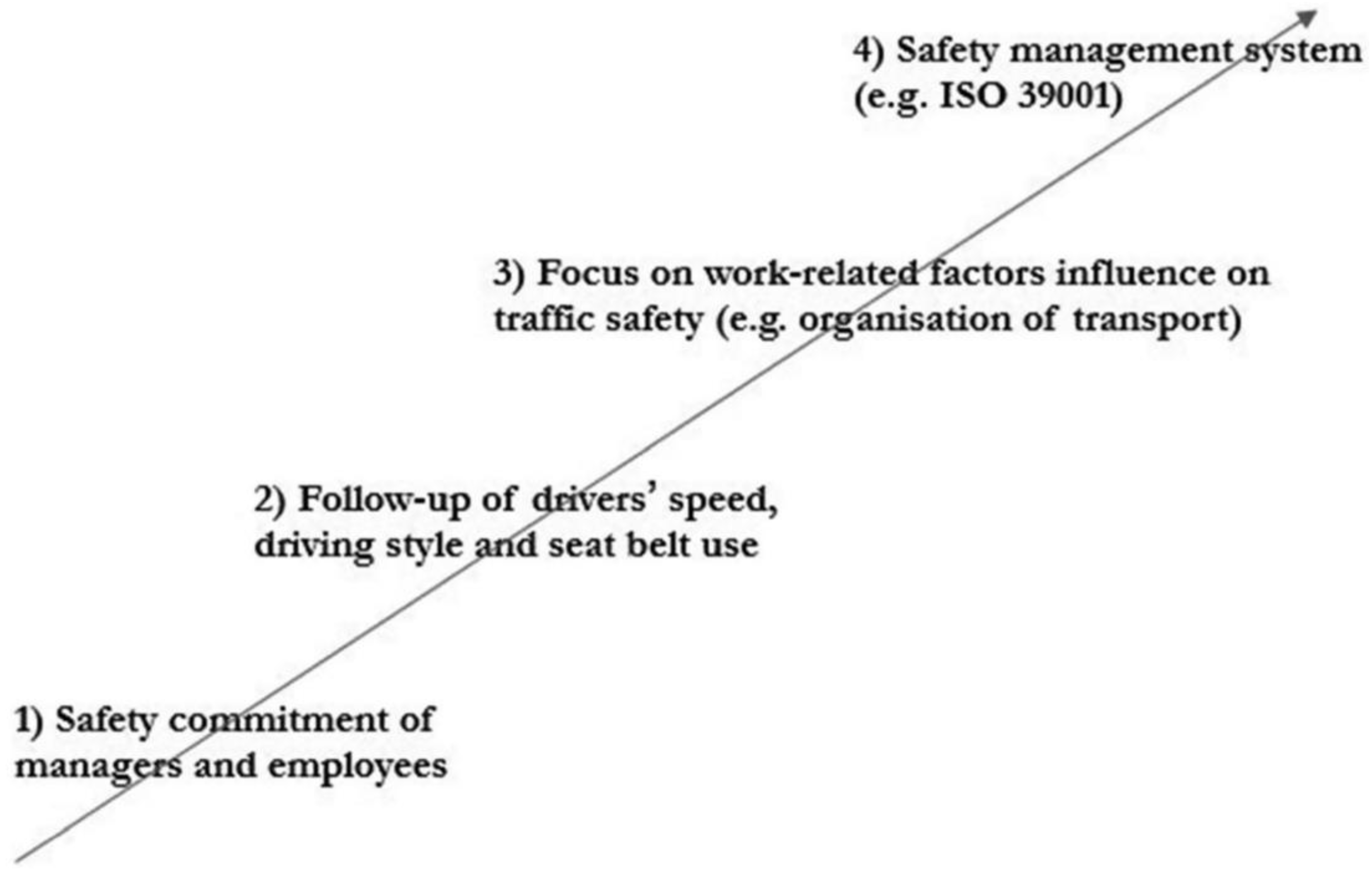

2. The Safety Ladder for Companies Involved in Road Transport of Goods

3. Methods

3.1. Focus on Employed Drivers in Norwegian Companies

3.2. Mapping HGV Fatalities and Injuries Involving Employed Drivers

3.3. The Current Prevalence of Organisational Safety Management

3.4. Outcomes of Organisational Safety Management

3.5. Example Calculations of Potential Given Prevalence and Effects

4. Results

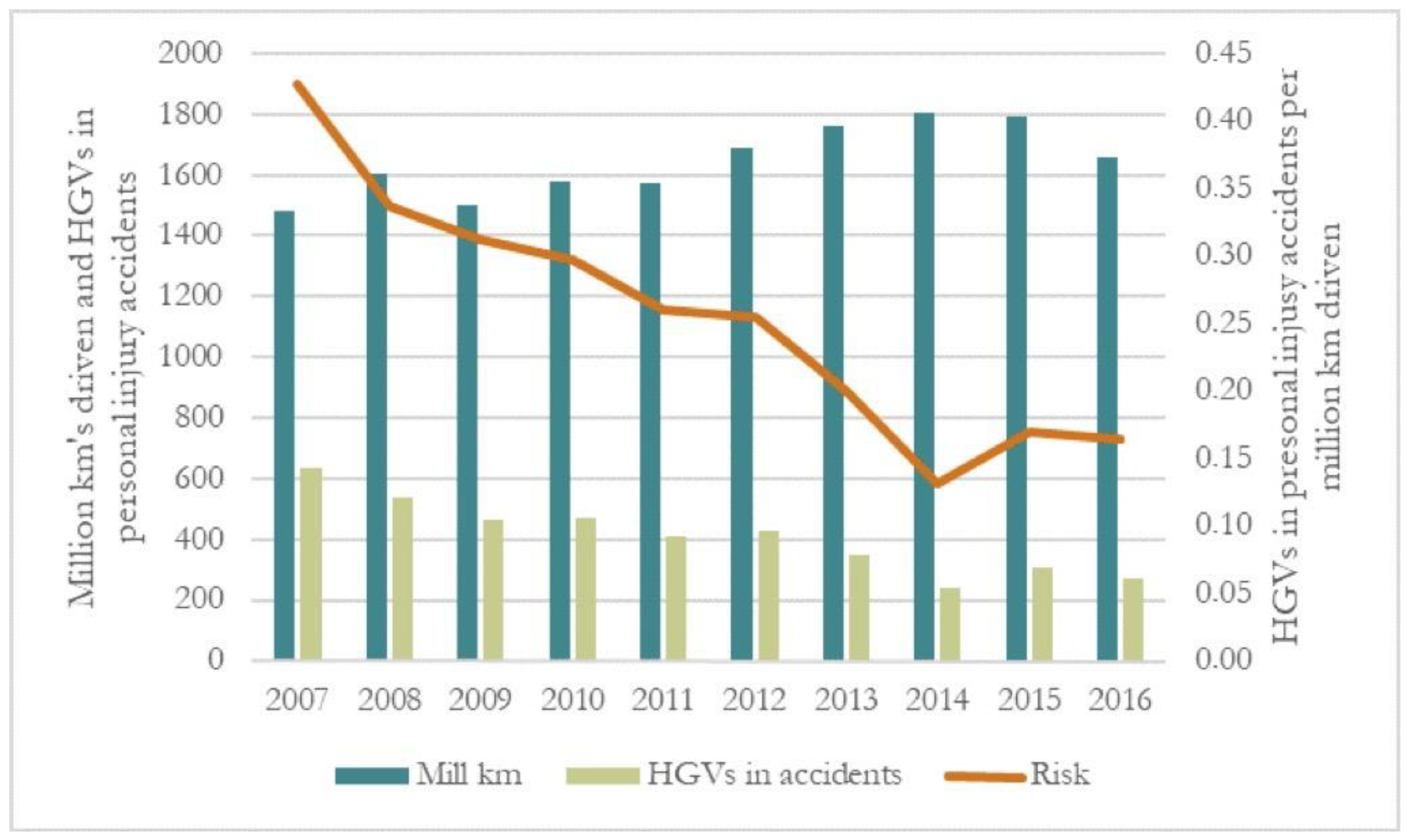

4.1. Exposure, HGV Fatalities, and Injuries Involving Employed Drivers

4.2. Prevalence of Organisational Safety Management Measures

4.3. Effects of Organisational Safety Management Measures

4.4. Estimating the Potential for Avoiding Accidents and Injuries

4.4.1. The Basis of the Example Calculations

4.4.2. The Relationship between Personal Injury Accidents and Property Damage Accidents

4.4.3. Level 1: Managers’ and Employees’ Safety Commitment

4.4.4. Level 2: Organisational Focus on Speed, Driving Style, and Seat Belt Use

4.4.5. Level 3: Focus on the Importance of Work-Related Factors for Road Safety

4.4.6. Level 4: Implementing a Safety Management System

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Evgenikos, P.; Yannis, G.; Folla, K.; Bauer, R.; Machata, K.; Brandstaetter, C. Characteristics and causes of heavy goods vehicles and buses accidents in Europe. Transp. Res. Procedia 2016, 14, 2158–2167. [Google Scholar] [CrossRef] [Green Version]

- Eurostat. 2018. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Road_freight_transport_statistics#Growth_in_EU_road_freight_transport_for_the_fifth_consecutive_year (accessed on 21 December 2020).

- Hovi, I.B.; Caspersen, E.; Wangsness, P.B. Godstransportmarkedets Sammensetning og Utvikling TØI Rapport 1363/2014; Transportøkonomisk Institutt: Oslo, Norway, 2014. [Google Scholar]

- ERSO. 2018. Available online: https://ec.europa.eu/transport/road_safety/sites/roadsafety/files/pdf/statistics/dacota/bfs20xx_hgvs.pdf (accessed on 21 December 2020).

- NHTSA, 2019. Available online: https://crashstats.nhtsa.dot.gov/Api/Public/ViewPublication/812663 (accessed on 21 December 2020).

- Langeland, P.E.; Phillips, R.O. Tunge Kjøretøy og Trafikkulykker—Norge Sammenliknet Med Andre Land i Europa. TØI Rapport 1494/2016; Transportøkonomisk Institutt: Oslo, Norway, 2016. [Google Scholar]

- Banks, T.D. An Investigation into How Work-Related Road Safety Can Be Enhanced. Ph.D. Thesis, Queensland University of Technolohy, Brisbane, Australia, 2008. [Google Scholar]

- Gregersen, N.P.; Brehmer, B.; Morén, B. Road safety improvement in large companies. An experimental comparison of different measures. Accid. Anal. Prev. 1996, 28, 297–306. [Google Scholar] [CrossRef] [Green Version]

- Mooren, L.; Grzebieta, R.; Williamson, A.; Olivier, J.; Friswell, R. Safety management for heavy vehicle transport: A review of the literature. Saf. Sci. 2014, 62, 79–89. [Google Scholar] [CrossRef]

- Mooren, L.; Williamson, A.; Friswell, R.; Olivier, J.; Grzebieta, R.; Magableh, F. What are the differences in management characteristics of heavy vehicle operators with high insurance claims versus low insurance claims? Saf. Sci. 2014, 70, 327–338. [Google Scholar] [CrossRef]

- Zohar, D. The effects of leadership dimensions, safety climate, and assigned priorities on minor injuries in work groups. J. Organ. Behav. 2002, 23, 75–92. [Google Scholar] [CrossRef]

- Wills, A.R.; Watson, B.; Biggs, H.C. Comparing safety climate factors as predictors of work-related driving behavior. J. Saf. Res. 2006, 37, 375–383. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, Y.H.; Zohar, D.; Robertson, M.M.; Garabet, A.; Lee, J.; Murphy, L.A. Development and validation of safety climate scales for lone workers using truck drivers as exemplar. Transp. Res. Part F 2013, 17, 5–19. [Google Scholar] [CrossRef] [Green Version]

- Thomas, M.J.W. A Systematic Review of the Effectiveness of Safety Management Systems; No. AR-2011-148; Australian Transport Safety Bureau: Canberra, Australia, 2012.

- Elvik, R.; Høye, A.; Vaa, T.; Sørensen, M. The Handbook of Road Safety Measures, 2nd ed.; Emerald Insight: Bingley, UK, 2009. [Google Scholar]

- Antonsen, S. The relationship between culture and safety on offshore supply vessels. Saf. Sci. 2009, 47, 1118–1128. [Google Scholar] [CrossRef]

- Nævestad, T.-O. Culture, Crises and Campaigns: Examining the Role of Safety Culture in the Management of Hazards in a High Risk Industry. Ph.D. Thesis, University of Oslo, Oslo, Norway, 2010. [Google Scholar]

- Nævestad, T.O.; Phillips, R.O.; Elvebakk, B. Traffic accidents triggered by drivers at work–A survey and analysis of contributing factors. Transp. Res. Part F Traffic Psychol. Behav. 2015, 34, 94–107. [Google Scholar] [CrossRef] [Green Version]

- Newnam, S.; Watson, B. Work-related driving safety in light vehicle fleets: A review of past research and the development of an intervention framework. Saf. Sci. 2011, 49, 369–381. [Google Scholar] [CrossRef] [Green Version]

- IATA. Creating a Positive Safety Culture. Best Practices to Align with Annex 19’s New Recommendations. 2019. Available online: https://go.updates.iata.org/safety-culture?_ga=2.26439165.1941341082.1571071913-370565390.1570852392 (accessed on 21 December 2020).

- ERA. European Railway Agency Safety Unit Application Guide for the Design and Implementation of a Railway Safety Management System Developing and Improving Safety Culture in the Organisation; Publications Office of the European Union: Luxembourg, 2013. [Google Scholar]

- Lappalainen, F.J.; Kuronen, J.; Tapaninen, U. Evaluation of the ISM Code in the Finnish shipping companies. J. Marit. Res. 2014, 9, 23–32. [Google Scholar]

- T-OPhillips, R.O.N.; Elvebakk, B. The safety ladder: Developing an evidence-based safety management strategy for small road transport companies. Transp. Rev. 2017, 38, 372–393. [Google Scholar] [CrossRef]

- Steen, J.; Bråten, R.M.; Jordfald, B.; Dotterud Leiren, M.; Nævestad, T.-O.; Skollerud, K.H.; Sternberg, H.; Tranvik, T. Arbeidsforhold I Gods og Turbil. Fafo Rapport 2014:58; Fafo: Oslo, Norway, 2014. [Google Scholar]

- European Commission. Road freight transport vademecum. In European Commission, Directorate General Energy and Transport, Directorate E—Inland Transport, Unit E.1—Land Transport Policy; European Commission: Brussels, Belgium, 2009. [Google Scholar]

- Nævestad, T.O.; Blom, J.; Phillips, R.O. Safety culture, safety management 1162 and accident risk in trucking companies. Transp. Res. Part F Traffic Psychol. Behav. 2020, 73, 325–347. [Google Scholar] [CrossRef]

- Arboleda, A.; Morrow, P.C.; Crum, M.R.; Shelley, M.C., II. Management practices as antecedents of safety culture within the trucking industry: Similarities and differences by hierarchical level. J. Saf. Res. 2003, 34, 189–197. [Google Scholar] [CrossRef]

- Goettee, D.; Spiegel, W.; Tarr, R.; Campanian, C.; Grill, L. Overview of Federal Motor Carrier Safety Administration Safety Training Research for New Entrant Motor Carriers; The SAGE Corporation, Motor Carrier Services: Washington, DC, USA, 2015. [Google Scholar]

- Hickman, J.S.; Geller, E.S. Self-management to increase safe driving among short-haul truck drivers. J. Organ. Behav. Manag. 2003, 23, 1–20. [Google Scholar] [CrossRef]

- Hickman, J.S.; Hanowski, R.J. Use of a video monitoring approach to reduce at-risk driving behaviors in commercial vehicle operations. Transp. Res. Part F Traffic Psychol. Behav. 2011, 14, 189–198. [Google Scholar] [CrossRef]

- Musicant, O.; Lotan, T.; Toledo, T. Safety correlation and implications of an in-vehicle data recorder on driver behavior. In Proceedings of the TRB Conference, Washington, DC, USA, 21–25 January 2007. [Google Scholar]

- Myers, L.A.; Russi, C.S.; Will, M.D.; Hankins, D.G. Effect of an onboard event recorder and a formal review process on ambulance driving behaviour. Emerg. Med. J. 2012, 29, 133–135. [Google Scholar] [CrossRef]

- Olson, R.; Anger, W.K.; Wipfli, D.L.; Gray, M. A new health promotion model for lone workers: Results of the safety & health involvement for truckers (SHIFT) pilot study. J. Occup. Environ. Med. 2009, 51, 1233–1246. [Google Scholar]

- Toledo, T.; Musicant, O.; Lotant, T. In-vehicle data recorders for monitoring and feedback on drivers’ behavior. Transp. Res. Part C 2008, 16, 320–331. [Google Scholar] [CrossRef]

- Wouters, I.J.; Bos, J.M. Traffic accident reduction by monitoring driver behaviour with in-car data recorders. Accid. Anal. Prev. 2000, 32, 643–650. [Google Scholar] [CrossRef]

- Newnam, S.; Oxley, J. A program in safety management for the occupational driver: Conceptual development and implementation case study. Saf. Sci. 2016, 84, 238–244. [Google Scholar] [CrossRef]

- Salminen, S. Two interventions for the prevention of work-related road accidents. Saf. Sci. 2008, 46, 545–550. [Google Scholar] [CrossRef]

- Feyer, A.-M.; Williamson, A.; Friswell, R. Balancing work and rest to combat driver fatigue: An investigation of two-up driving in Australia. Accid. Anal. Prev. 1997, 29, 541–553. [Google Scholar] [CrossRef]

- Gander, P.H.; Marshall, N.S.; Bolger, W.; Girling, I. An evaluation of driver training as a fatigue countermeasure. Transp. Res. Part F Traffic Psychol. Behav. 2005, 8, 47–58. [Google Scholar] [CrossRef]

- Moore-Ede, M.; Heitmann, A.; Guttkuhn, R.; Trutschel, U.; Aguirre, A.; Croke, D. Circadian alertness simulator for fatigue risk assessment in transportation: Application to reduce frequency and severity of truck accidents. Aviat. Space Environ. Med. 2004, 75, A107–A118. [Google Scholar] [PubMed]

- Wallington, D.; Murray, W.; Darby, P.; Raeside, R.; Ison, S. Work-related road safety: Case study of British Telecommunications (BT). Transp. Policy 2014, 32, 194–202. [Google Scholar] [CrossRef]

- Murray, W.; Ison, S.; Gallemore, P.; Nijjar, H.S. Effective Occupational Road Safety Programs A Case Study of Wolseley. Transp. Res. Rec. 2009, 2096, 55–64. [Google Scholar] [CrossRef]

- Murray, W.; White, J.; Ison, S. Work-related road safety: A case study of Roche Australia. Saf. Sci. 2012, 50, 129–137. [Google Scholar] [CrossRef]

- Naveh, E.; Marcus, A. Financial performance, ISO 9000 standard and safe driving practices effects on accident rate in the U.S. motor carrier industry. Accid. Anal. Prev. 2007, 39, 731–742. [Google Scholar] [CrossRef]

- Nævestad, T.-O.; Bjørnskau, T. Kartlegging av Sikkerhetskultur i tre Godstransportbedrifter.Oslo: TØI Rapport 1300/2014; Transportøkonomisk Institutt: Oslo, Norway, 2014. [Google Scholar]

- Naveh, E.; Katz-Navon, T. A Longitudinal Study of an Intervention to Improve Road Safety Climate: Climate as an Organisational Boundary Spanner. J. Appl. Psychol. 2015, 100, 216–226. [Google Scholar] [CrossRef]

- Flin, R.; Mearns, K.; O’Connor, P.; Bryden, R. Measuring safety climate: Identifying the common features. Saf. Sci. 2000, 34, 177–192. [Google Scholar] [CrossRef]

- Guldenmund, F.W. The nature of safety culture: A review of theory and research. Saf. Sci. 2000, 34, 215–257. [Google Scholar] [CrossRef]

- Elvik, R.; Høye, A. Potensialet for å Redusere Antall drepte og Hardt Skadde i Trafikken Fram til 2030, TØI Rapport, 1645/2018; Transportøkonomisk Institutt: Oslo, Norway, 2018. [Google Scholar]

- Fourie, C.; Holmes, A.; Hildritch, C.; Bourgeois-Bougrine, S.; Jackson, P. Interviews with Operators, Regulators and Researchers with Experience of Implementing Fatigue Risk Management Systems. In Road Safety Research Report; Department for Transport: London, UK, 2010. [Google Scholar]

- Grayson, G.B.; Helman, S. Work-related road safety: A systematic review of the literature on the effectiveness of interventions. In IOSH Research Report 11.3; Institute of Occupational Safety and Health: Wigston, UK, 2011. [Google Scholar]

| Level | “How Well Do the Statements Match the Trucking Companies in Your District? Enter the Answer as a Percentage. Make Your Best Guess on the Basis of Your Impression” |

|---|---|

| Level 0 | The management does not talk about traffic safety and has not introduced any special measures aimed at it. |

| Level 1 | Management often talks about road safety and gives the impression of having a personal commitment to road safety. |

| Level 2 | The company’s heavy vehicles have a speed limiter of approximately 80 km/h. The company’s heavy vehicles have a speed limiter of approximately 85 km/h. |

| The management has a strong focus on drivers’ seat belt use, and gives warnings about lacking seat belt use. | |

| The company has a fleet management system, and drivers receive systematic feedback on speed and driving style. The company has driver training focusing on driver limitations, with the goal that drivers should be more critical of their own abilities, so that they drive more carefully. | |

| Level 3 | When planning a transport assignment, the company focuses on minimising drivers’ stress, time pressure, and fatigue. |

| The company has group discussions that identify workplace risks, relevant measures, and where drivers commit to change behaviour. | |

| Level 4 | The company has a functioning system for reporting nonconformities and incidents. |

| The company has a system for risk assessment of work tasks and activities. | |

| The company has introduced a safety management system, e.g., Quality and Environment on the Road 1, ISO:9001, ISO:39001. |

| Rental Transport (>1 Employee) | Rental Transport Self-Employed | Transport for Own Account | ||||

|---|---|---|---|---|---|---|

| Share | Mill km | Share | Mill km | Share | Mill km | |

| 2007 | 57% | 940 | 11% | 186 | 32% | 522 |

| 2008 | 54% | 963 | 10% | 185 | 36% | 632 |

| 2009 | 57% | 951 | 11% | 181 | 32% | 537 |

| 2010 | 55% | 971 | 11% | 185 | 34% | 600 |

| 2011 | 56% | 969 | 10% | 176 | 34% | 600 |

| 2012 | 59% | 1101 | 10% | 189 | 31% | 583 |

| 2013 | 59% | 1156 | 10% | 190 | 31% | 613 |

| 2014 | 59% | 1173 | 9% | 179 | 33% | 652 |

| 2015 | 61% | 1222 | 9% | 172 | 30% | 598 |

| 2016 | 66% | 1214 | 9% | 171 | 25% | 458 |

| Avg. | 58% | 1022 | 10% | 181 | 31% | 550 |

| Reg. Country | 2007 | 2008 | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Unregistered | 115 | 112 | 64 | 43 | 13 | 16 | 42 | 24 | 27 | 23 | 479 |

| Norway | 602 | 501 | 463 | 484 | 443 | 464 | 355 | 318 | 246 | 282 | 4158 |

| Foreign | 69 | 62 | 54 | 75 | 65 | 71 | 62 | 42 | 39 | 30 | 569 |

| Total | 786 | 675 | 581 | 602 | 521 | 551 | 459 | 384 | 312 | 335 | 5206 |

| Study/Country | Method/Sample | Which Level in the Safety Ladder | Is Effect on Accident Estimated? | Strengths/Weaknesses |

|---|---|---|---|---|

| Studies addressing level 1 | ||||

| Arboleda et al. 2003 [27] (USA) | 116 U.S. haulier companies. Studies the relationship between four aspects of safety culture and management practices. | Level 1: management focus on safety; Level 3: focus on training to avoid fatigue, organisation of transport and employee involvement. | Does not look at impact on accidents. Finds significant relationships between safety culture and, e.g., employee involvement and management commitment to safety. | Large sample, but only looks at relationships. |

| Goette et al. 2015 [28] (USA) | Cross-sectional design using a test group and a matched control group; “dose–response” | Level 1 and 3: manager training with the goal of working to develop a safety culture. | Yes, the companies that participated in the training had 42% fewer accidents than more experienced companies. | Potential self-selection bias. |

| Studies addressing level 2 | ||||

| Hickman and Geller 2003 [29] (USA): Drivers’ self-management for safety | Evaluate effects on self-management on driver safety behaviour. No control; 33 short haul truck drivers. | Level 2: driving style and speed. | No, looks at behaviour as outcome measures: speeding reduced by 30% and extreme braking incidents by 64% during intervention. | Low numbers, drivers may adjust behaviour merely in response to being monitored. |

| Hickman and Hanowski 2011 [30] (USA): Coaching of behaviour based on cameras and fleet management technology. | Quasi-experimental design, with 4-week baseline with monitoring equipment in place but not activated and 13-week intervention with monitoring, analysis, and feedback. | Level 2: driving style and speed. | No, looks at behaviour as outcome measures. Reduction in recorded safety related events. | No control group. |

| Musicant et al. 2007 [31] (Israel) IVDR | Prospective pre-/post-intervention study. IVDR (in-vehicle data recorder). 103 drivers from six companies. 70 of the drivers use IVDR feedback for average 9 months. | Level 2: driving style and speed. | Yes. A 44% reduction in the accident rate and 38% in the rate of at fault accidents. | Unclear how the feedback mechanism worked and how much of the participants’ reactions are due to the measure vs. that they are being studied/have fitted equipment. |

| Myers et al. 2012 [32]: DriveCam onboard event recorder recording external and internal video before and after g-forces are triggered | Analysis of events triggered over time since intervention began. 54 ambulances fitted with DriveCam. | Level 2: driving style: camera triggered by g-forces. Review of events and feedback. | No. The outcome measure was incidents, specified as the number of times the camera is triggered. Significant decrease in events over time. | Descriptive study of the process in the organisation. No control group. |

| Olson et al. 2009 [33] (USA): Safe driving competition, with computer-based training, motivational interviewing, and behavioural self-monitoring. | Single group pre-/post-test quasi-experimental design; no control. 29 truck drivers from 4 companies. | Level 2: driving style and speed. | No. The outcome measures are behaviour and incidents. Significant reductions in hard braking events. | Possible self-selection? |

| Toledo et al. 2008 [34]: Feedback to drivers based on “in-vehicle data recorder” (IVDR) | Prospective pre-/post-intervention evaluation, with IVDR installed but not generating feedback during the 8-week pre-intervention (blind profile). 191 pickup trucks. | Level 2. Fleet management with feedback. | Yes, 38% decrease in accident rate. | The study also finds a 19% overall reduction in accident risk in the study period. |

| Wouters and Bos 2000 [35]: Driver feedback on time driven, speed, acceleration, braking, and fuel use, based on-vehicle data recorder (IVDR) | Prospective ABA pre-/post-intervention design, with “pseudo-experimental” treatment group and matched control group. 7 experimental and 7 matched control vehicle fleets in various sectors and traffic environments. | Level 2. Fleet management with feedback. | On average, 20% decrease in accident rate, but the effects vary between the different samples included. | Wide variation in effect among fleets, with some showing increase in accidents. Study does not account for method of feedback used. |

| Studies addressing level 3 | ||||

| Gregersen et al. 1996 (Sweden) [8]: Driver training, campaign information, group discussions, group bonus to avoid accidents | Compare effects of 4 organisational safety measures on accident risks and costs. Quasi-experimental prospective design, with measures of treatment and control groups for 2-year period before, at start, and the 2-year period following intervention. 5 groups of company drivers (n = 900–1000 in each group); 4 test groups, and 1 control group. | Level 2 driver training; level 3 group discussions aimed at uncovering workplace risks and implementing measures. | Significant reductions in accident risks were largest in the driver training and group discussion (in both cases reduced from 0.16 to 0.08) groups. | 10–20% dropout rates. Did not account for accident seriousness. Ultimately, conclusions about specific, tailor-made measures cannot be generalised to all instances. |

| Newnam and Oxley 2016 [36] (Australia) | Pre–post study (N = 36) without control group. 8 respondents in post-study. | Level 2 driver training; Level 3: manager training to increase risk understanding associated with driver stress, fatigue, pressure. | No. Finds improved safety climate. | Relatively low numbers in the pre-post groups. No control group. |

| Salminen 2008 [37] (Sweden): Group discussion and 1-day course in anticipatory driver training, e.g., on ice, in dark | Evaluates effect of each intervention type on safety. (1) 172 electrician driving vans and lorries, an average of 278 km/wk. (2) 179 electricians driving 276 km/week on average. | Level: 3 group discussions aimed at uncovering workplace risk and taking action. | 72% reduction in traffic accidents of group discussions. Training provided a 50% increase in accidents. | No exposure measures and no control group. Results from the audits are difficult to transfer to other settings and compare. |

| Mooren et al. 2014a [9] (International) | Review of the literature on safety management interventions and studies focusing on correlations between management practices and outcomes. | Level 1: management focus; level 3: organisation of transport. | Yes, some of the reviewed studies include this. Management commitment, safety training, and work scheduling are each robustly linked to safety outcomes across three different study designs. | Concludes that robust knowledge is lacking on the safety outcomes of OSM practices in the haulier industry. |

| Feyer et al. 1997 [38] (Australia): “Fatigue management” | Study focusing on 37 long-distance HGV drivers on long-distance trips. | Level 3: Organisation of transport. | No. The outcome measure is fatigue. Overnight rests and assignments with two drivers in the truck (“two-up driving”) reduce fatigue. | Mostly relevant for long-distance drivers. |

| Gander, et al. 2005 [39]: “Fatigue management training” | Quasi-experimental pre-/post-study of training without control group 275 heavy-vehicle drivers and 350 light-vehicle drivers. | Level 2/3: training drivers to develop better strategies to avoid fatigue. | No. Finds increased knowledge about strategies to avoid fatigue, etc. Effects on fatigue, behaviour, or accidents were not studied. | The study does not examine whether, or how, the training may influence other safety measures. |

| Moore-Ede et al. 2004 [40] (USA): Organisation of transport based on assessment of risk of fatigue (through computer program) | 500 power-unit trucking fleet, with around 800 U.S. truck drivers involved in study. | Level 3: technology and system for assessing driver fatigue and using it as a management tool. | Yes. Significant fall in fatigue scores Associated with 23% reduction in accident rates | Relatively comprehensive alignment of predictions and changes in variables used, but no control group. |

| Studies addressing level 4 | ||||

| Wallington et al. [41] 2014 (UK): Comprehensive program | Case study of long-term trends in accidents, and insurance claims in British Telecom with 95,000 workers in the period 2001–2012. | Level 4 (and probably the others as well): most of the measures are about SMS on level 4 (and probably also the others). | Not quite. Looks at insurance claims related to accidents. Finds a 50% reduction of such accidents. “Property damage”. | The accident rates also declined significantly in the UK in the study period (2001–2012). Analyses do not control for this. Does not examine the effects of specific measures. |

| Murray et al. 2012 [42] (Australia): Comprehensive program, based on the “Haddon Matrix” | Case study describing program events from 2005 to 2009, with evaluation of associated outcomes. Roche. | Level 4: SMS (probably covers all levels.). | Not quite. 56% reduction in insurance claims, and accident costs were 55% lower in 2009 than in 2004. | Does not account for national trends in accident statistics, or pin down effect of individual interventions. |

| Murray, et al. 2009 [43] (UK) | Descriptive case study. Wolseley, UK, branch of international heating and plumbing distributor, with 7000 drivers. | Level 4: SMS (probably covers all levels.) | Not quite. Examines insurance claims. Almost halving of accidents with blame (third-party accidents) per vehicle. | Inspiring, but lacks detail on individual measures, so it is hard to link effects and measures. Does not account for external influences. |

| Mooren et al. 2014b [10] (Australia) | Questionnaire on safety management for 50 organisations with heavy vehicles. Focus on associations between vehicle insurance claim rates and safety management practices. | All the levels are covered more or less in the survey of companies. | No. Organisations with low insurance costs focus more on proactive risk assessment. | Surprising that higher claimers more often than low claimers were reported to have more policies and some accreditation, and more in-vehicle monitoring. |

| Naveh and Marcus 2007 [44] (USA) | Retrospective analysis of data 2 y pre-/2 y post-certification (ISO:9002), comparing performance to matched groups of trucking companies who did not become certified in the test period. | Level 4: safety management (ISO 9000), and level 2, focus on driver behaviour. | Yes, personal injury and salvage incidents. Test companies: 28/40 showed significant increase in safety performance. 18/40 matched controls showed improvements in safety performance. | Unique study, but little consideration of internal mechanisms involved. No exposure figures. |

| Thomas 2012 [14] (International) | Literature review focusing both on SMS in transport and to all sectors. | Level 4: SMS, and level 1 due to management’s focus on safety. | Over 2000 studies found; 37 were relevant, and 19 studies estimated the effect of SMS on objective safety measures (e.g., accidents behaviours). Some indicate positive results. | Most studies include several SMS elements, and it is hard to determine the importance of specific SMS elements. Focuses on transport in general. |

| Nævestad and Bjørnskau 2014 [45] (Norway) | Survey data and interviews in three goods companies with a high safety level. | Examines all the levels. | Examines accident risk but focuses on the relationship between 10 common management practices and risk. | Only case study which examines correlations. No control groups. Does not study the effects of measures (before–after–control). |

| Naveh and Katz-Navon 2015 [46] (Israel) Safety Climate Intervention | Longitudinal pre-/post-test-controlled experiment, with baseline survey administration for 3 months prior to t1 (=start of intervention) and at t2, 12 months afterwards. | The safety culture intervention consists of level 1: systematic and daily management focus on safety, level 3: for example in organising transport, and level 4, i.e., SMS components. | No. Concludes that safety climate mediates the effect of the intervention on fines for traffic violations. | The analysis controls for several relevant factors, e.g., gender, experience, exposure, and whether the driver is professional. |

| Time Period | HGVs | Accidents | Personal Injuries | Fatalities | Seriously Injured | Minor Injuries | |

|---|---|---|---|---|---|---|---|

| 1 | 2012–2016 Only trucking companies (58%) | 222 | 216 | 302 | 24 | 36 | 242 |

| 2 | 2012–2016 Including transport for own account (90%) | 334 | 326 | 456 | 37 | 55 | 365 |

| 3 | 2012–2016 All accidents with Nor. Reg. HGVs in Nor. | 353 | 364 | 510 | 41 | 61 | 408 |

| 4 | 2012–2016 All accidents with all HGVs in Norway | 408 | 397 | 556 | 45 | 67 | 445 |

| Annual Average in the Period | Million km | Personal Injury Accidents | Property Damages | Risk Personal Injury | Risk Property Damage | Ratio Personal vs. Property | |

|---|---|---|---|---|---|---|---|

| 1 | 2012–2016 (trucking companies) | 1173 | 216 | 9397 | 0.18 | 8.0 | 0.02 |

| 2 | 2012–2016 (including transp. for own account) | 1741 | 334 | 13,928 | 0.18 | 8.0 | 0.02 |

| Period | Pers. Injury Accidents | Property Damages | Personal Injuries | Killed or Seriously Injured | Minor Pers. Injuries | ||

|---|---|---|---|---|---|---|---|

| Estimate | Reduction | ||||||

| 1 | 2012–2016 (baseline 58%) | 216 | 9397 | 302 | 60 | - | 242 |

| 2 | 2012–2016 (20% red.) | 168 | 7518 | 236 | 47 | 13 | 189 |

| 3 | 2012–2016 (20% red. in 50%) | 189 | 8439 | 265 | 53 | 7 | 212 |

| 4 | 2012–2016 (20% red. in 90%) | 177 | 7706 | 248 | 50 | 10 | 198 |

| 5 | 2012–2016 (baseline 90%) | 334 | 14,030 | 456 | 91 | - | 365 |

| 6 | 2012–2016 (20% red. in 50%) | 301 | 12,627 | 421 | 84 | 7 | 337 |

| 7 | 2012–2016 (20% red. in 90%) | 274 | 11,505 | 383 | 77 | 14 | 307 |

| Period | Pers. Injury Accidents | Property Damages | Personal Injuries | Killed or Seriously Injured | Minor Pers. Injuries | ||

|---|---|---|---|---|---|---|---|

| Estimate | Reduction | ||||||

| 1 | 2012–2016 (baseline 58%) | 216 | 9397 | 302 | 60 | - | 242 |

| 2 | 2012–2016 (41% red. in 51%) | 164 | 7499 | 230 | 46 | 14 | 184 |

| 3 | 2012–2016 (41% red. in 90%) | 130 | 5921 | 182 | 36 | 24 | 145 |

| 4 | 2012–2016 (baseline 90%) | 334 | 13,666 | 456 | 91 | - | 365 |

| 5 | 2012–2016 (41% red. in 51%) | 243 | 10,808 | 340 | 68 | 23 | 272 |

| 6 | 2012–2016 (41% red. in 90%) | 194 | 8623 | 272 | 54 | 37 | 217 |

| Period | Pers. Injury Accidents | Property Damages | Personal Injuries | Killed or Seriously Injured | Minor Pers. Injuries | ||

|---|---|---|---|---|---|---|---|

| Estimate | Reduction | ||||||

| 1 | 2012–2016 (baseline 58%) | 216 | 9397 | 302 | 60 | - | 242 |

| 2 | 2012–2016 (59% red. in 60%) | 133 | 6062 | 186 | 37 | 23 | 149 |

| 3 | 2012–2016 (59% red. in 92%) | 94 | 4290 | 132 | 26 | 34 | 105 |

| 4 | 2012–2016 (baseline 90%) | 334 | 14,030 | 456 | 91 | - | 365 |

| 5 | 2012–2016 (59% red. in 60%) | 199 | 8828 | 278 | 56 | 35 | 222 |

| 6 | 2012–2016 (59% red. in 92%) | 141 | 6415 | 197 | 39 | 52 | 158 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nævestad, T.-O.; Phillips, R.; Hovi, I.B.; Jordbakke, G.N.; Elvik, R. Estimating Safety Outcomes of Increased Organisational Safety Management in Trucking Companies. Safety 2022, 8, 36. https://doi.org/10.3390/safety8020036

Nævestad T-O, Phillips R, Hovi IB, Jordbakke GN, Elvik R. Estimating Safety Outcomes of Increased Organisational Safety Management in Trucking Companies. Safety. 2022; 8(2):36. https://doi.org/10.3390/safety8020036

Chicago/Turabian StyleNævestad, Tor-Olav, Ross Phillips, Inger Beate Hovi, Guri Natalie Jordbakke, and Rune Elvik. 2022. "Estimating Safety Outcomes of Increased Organisational Safety Management in Trucking Companies" Safety 8, no. 2: 36. https://doi.org/10.3390/safety8020036

APA StyleNævestad, T.-O., Phillips, R., Hovi, I. B., Jordbakke, G. N., & Elvik, R. (2022). Estimating Safety Outcomes of Increased Organisational Safety Management in Trucking Companies. Safety, 8(2), 36. https://doi.org/10.3390/safety8020036