A Cloud-Based Tool for Integrating Occupational Risk Assessment Within Management Systems for SMEs

Abstract

1. Introduction

2. Occupational Health and Safety Management in SMEs: A Literature Analysis

- -

- -

- -

- -

- -

- There is wide awareness in academia about how poorly OHS is currently managed in SMEs, and specific studies confirm this trend in several countries (evidence from Europe, Asia and North America). However, not many attempts to propose new models/approaches for OHS evaluation and management that fit the needs of SMEs exist. In fact, the literature confirms that most of the existing tools and methods for OHS management are originally designed for LEs and are not always suitable for SMEs.

- Several barriers complicate the actual implementation of OHS practices in SMEs. Among these, little resources and time dedicated to promoting a safety culture, ineffective information, unawareness of management and employees, and the internal resistance to change seem to be the most diffused. All of these factors indicate the need for some kind of support to SMEs in the safety management process.

- On the other hand, some drivers can support effective OHS management in SMEs: the legislative pressure raising in several countries, the possibility to increase competitiveness with respect to other companies, as well as the aim to improve internal efficiency and safety.

- Evidence shows that the adoption of OHSMS in SMEs has a positive impact on safety conditions in the workplace, allowing better internal information sharing, and that involving employees in safety management processes is a crucial factor for increasing safety effectiveness.

- Cost-effectiveness often represents a crucial factor for the management that faces the decision of adopting an OHSMS in SMEs. Therefore, enterprises need to perceive the economic benefits in order to be inclined to adopt a formal management system.

3. Methods

3.1. Phase 1: Barriers’ and Drivers’ Identification

3.1.1. The Survey Analysis

3.1.2. The Focus Group and Follow Up Interview Analysis

3.2. Phase 2: The Operational Guideline Development

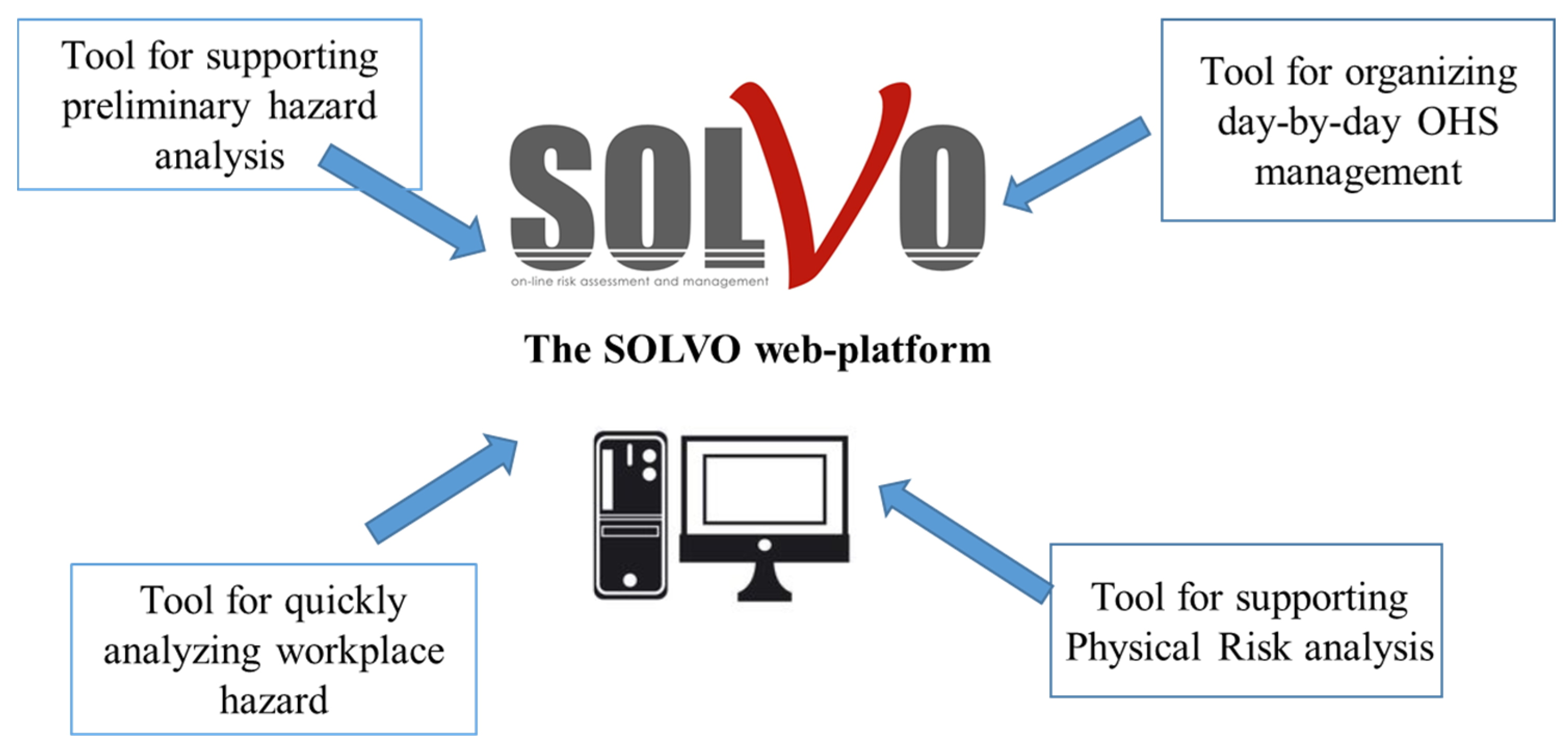

- A tool for preliminary hazard analysis: the main idea is to provide updated information about the most recurring hazards in a specific company, thus aiming to support a more effective risk assessment process based on real data, usually not available at an individual company level. This information is provided by historical data about injures: the main source is the national database INFORMO, where data (industrial context, injury dynamic and main causes) about mortal injuries occurred in Italian companies are collected by the National Authority. This sample will provide to SMEs updated knowledge about most critical factors outlined in an industrial context similar to theirs. A searching form—based on multiple parameters—allows us to provide these data to the users of the tool;

- A tool for fastly analyzing workplace hazard: the idea is to define a standardized logic to analyze all SME processes and workplaces with an increasing level of details. Thus, the process under consideration is analyzed based on a three-level standard schema: at first, hazards defined at plant level are analyzed and, next, hazards at job-shop and working areas, respectively. The aim is to provide a standardized and common way to describe and analyze each specific organization adopted by a single SME from a safety point of view;

- A tool for supporting physical risk analysis: the aim is to use a simplified procedure (compared to the traditional ones based, e.g., on complex risk evaluation), to analyze critical risks for defining prevention and protection activities to be developed. The proposed procedure is based on a simplified logic: if a specific hazard is outlined for the level in analysis—i.e., plant, job-shop and working area—the risk level is defined as “present” thus, allowing a fast risk estimation. Consequently, every time a risk is defined as present, organizational (e.g., training, maintenance) as well as technical (e.g., re-layout, machine modification) interventions, must be adopted to control and manage the risks. Legislative and technical standards could be used to define the most effective actions to be planned. Risks that require a deeper analysis—e.g., manual handling of loads, ergonomics risks—could be evaluated using specific guidelines. The aim is to provide to SMEs a fast tool for risk assessment that provide effective results for their specific conditions;

- Tools for analyzing organizing OHS management system: the tool will provide a simple guideline to organize and apply an OHS management system in SME. Basic pillars are a performance measurement system based on both quantitative indicators and organizational procedures (e.g., audits), a responsibility.

4. Results: The SOLVO Prototype

- The business owner or the safety manager (indicated through by the Italian acronym ADDL): the person in charge of the risk analysis and assessment process at the workplace level, as well as risk level control in daily operations;

- The safety consultant (defined by the acronym CONS): the person who actually carries out a risk analysis for several companies as a third party—under the authorization of each company employer. The CONS user can visualize data concerning the companies he/she manages, but cannot share them with external users.

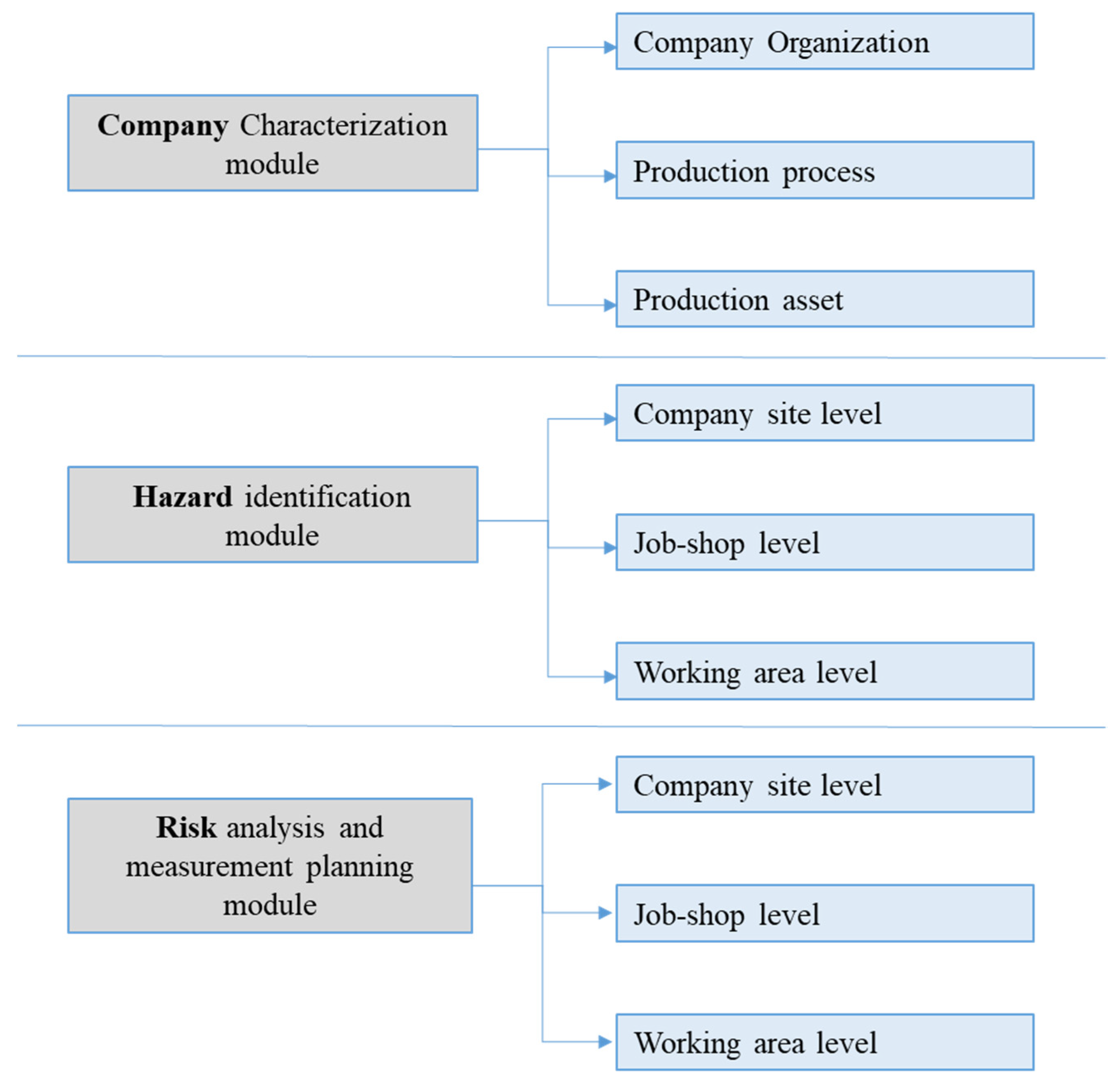

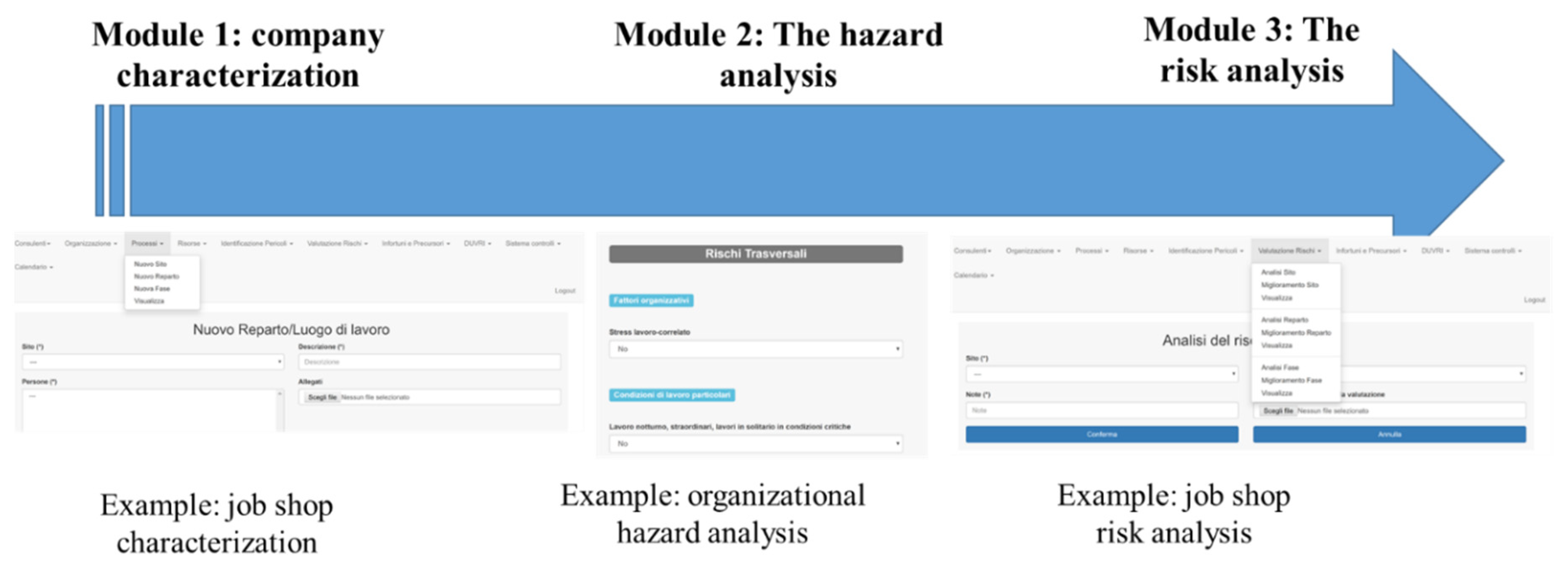

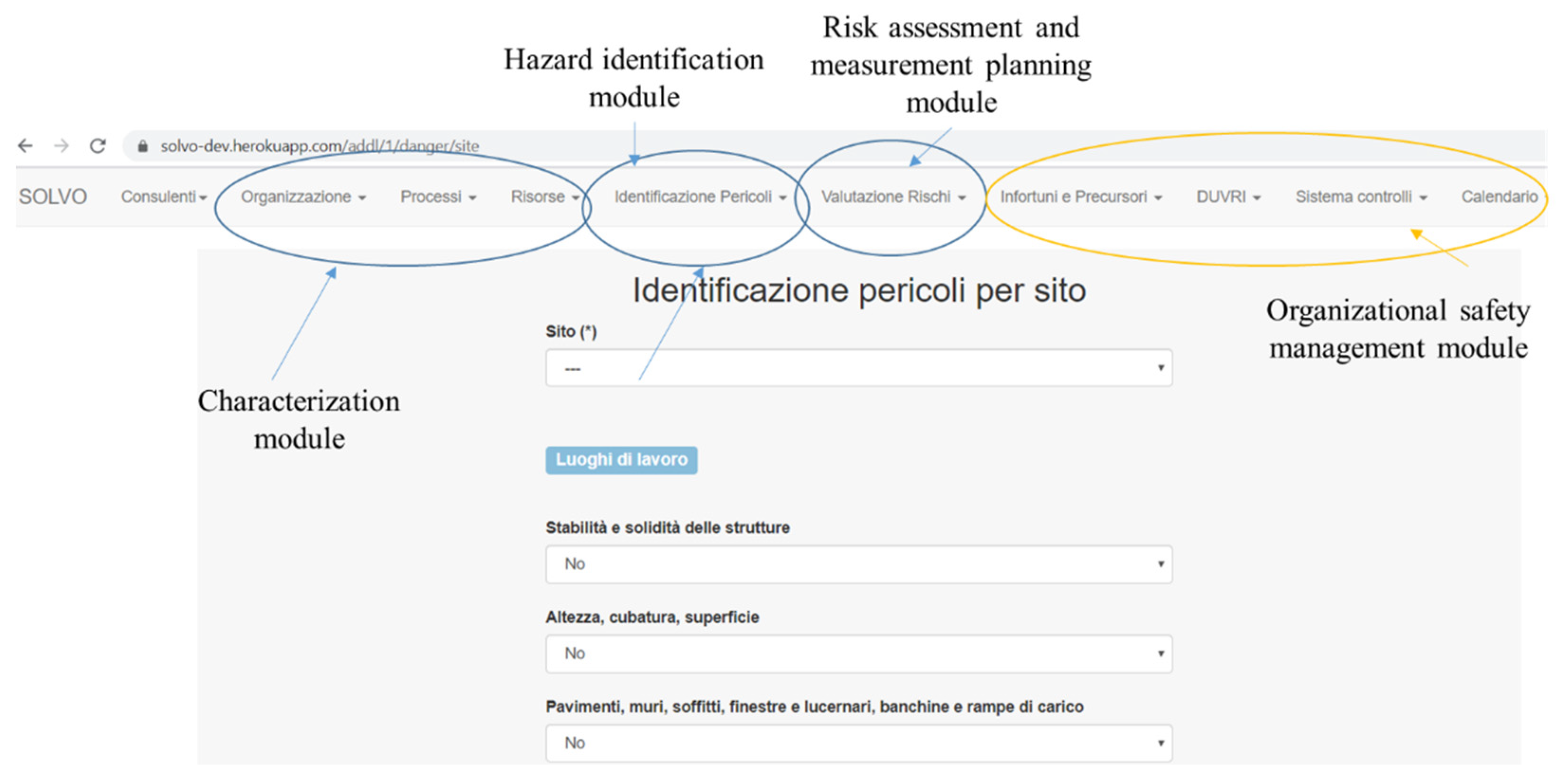

- The company characterization module defines the main data of the workplace that can influence the presence of hazards for workers. The description of the production process and the workplace is defined based on three main levels: company plant site, job-shop and working area. The plant site is the entire building where all activities and processes of the company take place, and is divided into departments (job-shops), which are in turn composed by single working areas. After filling out the company site-level data, the workplace can be composed of several job-shop areas, each one divided into one or more working areas. Next, company employees, equipment and materials (substances) have to be allocated in each of the workplace levels introduced.

- The hazard analysis module: a simplified and guided method allows the user to identify the hazards based on a set of hazard categories defined for the plant size, the job-shop and working areas previously identified. For each category, a set of hazards typically characterizing the area are defined. The hazard selection is developed starting from these lists. Therefore, the activity of hazard identification consists of the evaluation of the presence or absence of a set of specific hazards. This simplified hazard identification procedure is based on predefined lists of potential hazards and does not require the quantification of each hazard.

- The module for risk analysis and measurement planning: for each of the hazards identified, some standardized prevention and/or protection measures are identified, which can be related to the training of employees, the adoption of PPE, procedural or technical intervention or periodic medical control. Considering also the specific prescription regulated by the current legislation, the user can detail every measure that has to be adopted by the company to mitigate each risk. Next to this, the implementation plan of each intervention, including details such as date and responsibilities, is also defined in order to provide a scheduling for each deadline.

- a planning module;

- a collection module for injury and precursor (near-miss) events;

- a module for supporting internal audit and safety control;

- a module for supporting the company in managing documents for external procurement risk analysis process.

5. Conclusions

- it proposes a tool fitting the specific needs of SMEs, designed starting from an accurate field analysis to meet their necessities and expectations, which can support them not only in the phase of risk assessment (which is the only one strictly regulated by Italian legislation), but also in other safety management activities which are usually optional for SMEs, contributing to improving management and workers’ awareness and information sharing, enhancing prevention and safety conditions in the workplace.

- the cost-effectiveness of the tool: the project allowed the design and test of a web-based open-source software based on the framework elaborated, which is integrated with institutional databases from INAIL and can support SMEs, on one side facilitating the risk assessment process and the production of the DVR, on the other side enabling OHS management activities and promoting the diffusion of a safety culture.

- The integration with institutional databases and the support from INAIL can also represent an appealing factor for SMEs, which are facilitated to comply with the current Italian legislation on safety management.

Author Contributions

Funding

Conflicts of Interest

References

- Champoux, D.; Brun, J.-P. Occupational health and safety management in small size enterprises: An overview of the situation and avenues for intervention and research. Saf. Sci. 2003, 41, 301–318. [Google Scholar] [CrossRef]

- Muller, P.; Julius, J.; Herr, D.; Koch, L.; Peycheva, V.; McKiernan, S. Annual Report on European SMEs 2016/2017. Focus on Self-Employment; European Commission: Luxembourg, 2017. [Google Scholar]

- Ansori, N.; Widyanti, A.; Sutalaksana, I.Z. Safety Outcomes in small-size and medium-size metal enterprises in Indonesia: Are they different? In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 16–19 December 2018; pp. 93–97. [Google Scholar]

- Bluff, E. How SMEs respond to legal requirements to provide information, training, instruction and supervision to workers about work health and safety matters. Saf. Sci. 2019, 116, 45–57. [Google Scholar] [CrossRef]

- Salguero-Caparrós, F.; Pardo-Ferreira, M.D.C.; Martínez-Rojas, M.; Rubio-Romero, J.C. Management of legal compliance in occupational health and safety. A literature review. Saf. Sci. 2020, 121, 111–118. [Google Scholar] [CrossRef]

- Legg, S.; Olsen, K.; Laird, I.; Hasle, P. Managing safety in small and medium enterprises. Saf. Sci. 2015, 71, 189–196. [Google Scholar] [CrossRef]

- Masi, D.; Cagno, E. Barriers to OHS interventions in small and medium-sized enterprises. Saf. Sci. 2015, 71, 226–241. [Google Scholar] [CrossRef]

- Tremblay, A.; Badri, A. Assessment of occupational health and safety performance evaluation tools: State of the art and challenges for small and medium-sized enterprises. Saf. Sci. 2018, 101, 260–267. [Google Scholar] [CrossRef]

- Walters, D.; Wadsworth, E. European Agency for Safety and Health at Work. In Context and Arrangements for Occupational Safety and Health in Micro and Small Enterprises in the EU: SESAME Project; Publications Office: Luxembourg, 2016. [Google Scholar]

- Arocena, P.; Nuñez, I. An empirical analysis of the effectiveness of occupational health and safety management systems in SMEs. Int. Small Bus. J. Res. Entrep. 2010, 28, 398–419. [Google Scholar] [CrossRef]

- Hasle, P.; Kines, P.; Andersen, L.P. Small enterprise owners’ accident causation attribution and prevention. Saf. Sci. 2009, 47, 9–19. [Google Scholar] [CrossRef]

- Micheli, G.J.L.; Gnoni, M.G.; De Merich, D.; Sala, G.; Rosso, A.; Tornese, F.; Piga, G.; Malorgio, B. Barriers, drivers and impact of a simplified occupational safety and health management system in micro and small enterprises. Adv. Intell. Syst. Comp. 2018, 791, 81–90. [Google Scholar] [CrossRef]

- Masi, D.; Cagno, E.; Micheli, G.J. Developing, implementing and evaluating OSH interventions in SMEs: A pilot, exploratory study. Int. J. Occup. Saf. Ergon. 2014, 20, 385–405. [Google Scholar] [CrossRef]

- Garnica, G.B.; Barriga, G.D.C. Barriers to occupational health and safety management in small Brazilian enterprises. Production 2018, 28. [Google Scholar] [CrossRef]

- Wang, Q.; Mei, Q.; Liu, S.; Zhang, J. Analysis of managing safety in small enterprises: Dual-effects of employee prosocial safety behavior and government inspection. BioMed Res. Int. 2018, 2018, 1–12. [Google Scholar] [CrossRef]

- Zhang, J.; Mei, Q.; Liu, S.; Wang, Q. Study on the influence of government intervention on the occupational health and safety (OHS) services of small- and medium-sized enterprises (SMEs). BioMed Res. Int. 2018, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Hasle, P.; Limborg, H.J. A review of the literature on preventive occupational health and safety activities in small enterprises. Ind. Heal. 2006, 44, 6–12. [Google Scholar] [CrossRef] [PubMed]

- MacEachen, E.; The Small Business Systematic Review Team; Kosny, A.; Scott-Dixon, K.; Facey, M.; Chambers, L.; Breslin, C.; Kyle, N.; Irvin, E.; Mahood, Q. Workplace health understandings and processes in small businesses: A systematic review of the qualitative literature. J. Occup. Rehabil. 2010, 20, 180–198. [Google Scholar] [CrossRef] [PubMed]

- Cagno, E.; Micheli, G.J.; Masi, D.; Jacinto, C. Economic evaluation of OSH and its way to SMEs: A constructive review. Saf. Sci. 2013, 53, 134–152. [Google Scholar] [CrossRef]

- Floyde, A.; Lawson, G.; Shalloe, S.; Eastgate, R.; D’Cruz, M. The design and implementation of knowledge management systems and e-learning for improved occupational health and safety in small to medium sized enterprises. Saf. Sci. 2013, 60, 69–76. [Google Scholar] [CrossRef]

- Schulte, P.A.; Cunningham, T.R.; Guerin, R.J.; Hennigan, B.; Jacklitsch, B.L. Components of an occupational safety and health communication research strategy for small- and medium-sized enterprises. Ann. Work. Expo. Health 2018, 62, S12–S24. [Google Scholar] [CrossRef]

- Nowrouzi-Kia, B.; Nadesar, N.; Casole, J. Systematic review: Factors related to injuries in small- and medium-sized enterprises. Int. J. Crit. Illn. Inj. Sci. 2019, 9, 57–63. [Google Scholar] [CrossRef]

- Walker, D.; Tait, R. Health and safety management in small enterprises: An effective low cost approach. Saf. Sci. 2004, 42, 69–83. [Google Scholar] [CrossRef]

- Cagno, E.; Micheli, G.J.; Jacinto, C.; Masi, D. An interpretive model of occupational safety performance for small- and medium-sized enterprises. Int. J. Ind. Ergon. 2014, 44, 60–74. [Google Scholar] [CrossRef]

- Farina, E.; Bena, A.; Dotti, A. Impact on safety of a preventive intervention in metalworking micro-enterprises. Saf. Sci. 2015, 71, 292–297. [Google Scholar] [CrossRef]

- Bianchini, A.; Donini, F.; Pellegrini, M.; Saccani, C. An innovative methodology for measuring the effective implementation of an occupational health and safety management system in the European Union. Saf. Sci. 2017, 92, 26–33. [Google Scholar] [CrossRef]

- Tremblay, A.; Badri, A. A novel tool for evaluating occupational health and safety performance in small and medium-sized enterprises: The case of the Quebec forestry/pulp and paper industry. Saf. Sci. 2018, 101, 282–294. [Google Scholar] [CrossRef]

- Zocca, R.; Lima, T.M.; Gaspar, P.; Charrua-Santos, F. Kaizen Approach for the systematic review of occupational safety and health procedures in food industries. In Advances in Intelligent Systems and Computing; Springer Science and Business Media LLC: Cham, Switzerland, 2018; Volume 876, pp. 722–727. [Google Scholar]

- Fabiano, B.; Currò, F.; Pastorino, R. A study of the relationship between occupational injuries and firm size and type in the Italian industry. Saf. Sci. 2004, 42, 587–600. [Google Scholar] [CrossRef]

- Micheli, G.J.; Cagno, E. Dealing with SMEs as a whole in OHS issues: Warnings from empirical evidence. Saf. Sci. 2010, 48, 729–733. [Google Scholar] [CrossRef]

- Lehtinen, S. Activities and ways of organizing better occupational health and safety in small workplaces: Special focus on information. Ind. Heal. 2006, 44, 13–16. [Google Scholar] [CrossRef]

- Gopang, M.A.; Nebhwani, M.; Khatri, A.; Marri, H.B. An assessment of occupational health and safety measures and performance of SMEs: An empirical investigation. Saf. Sci. 2017, 93, 127–133. [Google Scholar] [CrossRef]

- Santos, G.; Barros, S.; Mendes, F.; Lopes, N. The main benefits associated with health and safety management systems certification in Portuguese small and medium enterprises post quality management system certification. Saf. Sci. 2013, 51, 29–36. [Google Scholar] [CrossRef]

- Jaroenroy, T. and Chompunth, C., An alternative integrated occupational health, safety and environmental management system for small and medium-sized enterprises (SMEs) in Thailand. Int. J. Geomate 2019, 17. [Google Scholar] [CrossRef]

- Cagno, E.; Micheli, G.J.; Perotti, S. Identification of OHS-related factors and interactions among those and OHS performance in SMEs. Saf. Sci. 2011, 49, 216–225. [Google Scholar] [CrossRef]

- Surienty, L. OSH Implementation in SMEs in Malaysia: The role of management practices and legislation. In Proceedings of the Advances in Intelligent Systems and Computing; Springer Science and Business Media LLC: Cham, Switzerland, 2019; Volume 819, pp. 650–671. [Google Scholar]

- Diugwu, I.A. Re-Strategising for effective health and safety standards in small and medium-sized enterprises. Open J. Saf. Sci. Technol. 2011, 1, 115–128. [Google Scholar] [CrossRef]

- Bonafede, M.; Corfiati, M.; Gagliardi, D.; Boccuni, F.; Ronchetti, M.; Valenti, A.; Marinaccio, A.; Iavicoli, S. OHS management and employers’ perception: Differences by firm size in a large Italian company survey. Saf. Sci. 2016, 89, 11–18. [Google Scholar] [CrossRef]

- Sinclair, R.C.; Cunningham, T.R.; Schulte, P.A. A model for occupational safety and health intervention diffusion to small businesses. Am. J. Ind. Med. 2013, 56, 1442–1451. [Google Scholar] [CrossRef]

- Boustras, G.; Hadjimanolis, A.; Economides, A.; Yiannaki, A.; Nicolaides, L. Management of health and safety in micro-firms in Cyprus-Results from a nationwide survey. Saf. Sci. 2015, 79, 305–313. [Google Scholar] [CrossRef]

- Unnikrishnan, S.; Iqbal, R.; Singh, A.; Nimkar, I.M. Safety management practices in small and medium enterprises in India. Saf. Heal. Work. 2015, 6, 46–55. [Google Scholar] [CrossRef] [PubMed]

- Jahangiri, M.; Azmon, H.; Daneshvar, A.; Keshmiri, F.; Khaleghi, H.; Besharati, A.; Daneshvar, S.; Hassanipour, S.; Malakoutikhah, M.; Besharati, M. Occupational health problems and safety conditions among small and medium-sized enterprises: A cross-sectional study in Shiraz, Iran. Ann. Glob. Health 2019, 85, 51. [Google Scholar] [CrossRef]

- Cantonnet, M.L.; Aldasoro, J.C.; Iradi, J. New and emerging risks management in small and medium-sized Spanish enterprises. Saf. Sci. 2019, 113, 257–263. [Google Scholar] [CrossRef]

- Segarra-Cañamares, M.; Villena Escribano, B.; González García, M.; Romero Barriuso, A.; Rodríguez Sáiz, A. Occupational risk-prevention diagnosis: A study of construction SMEs in Spain. Saf. Sci. 2017, 92, 104–115. [Google Scholar] [CrossRef]

- Mashwama, N.; Aigbavboa, C.; Thwala, W.D.D. Occupational health and safety challenges among small and medium sized enterprise contractors in South Africa. In Advances in Intelligent Systems and Computing; Springer Science and Business Media LLC: Cham, Switzerland, 2019; Volume 792, pp. 68–76. [Google Scholar]

- Dumitrescu, A.; Deselnicu, D.C. Risk assessment in manufacturing SMEs’ labor system. Procedia Manuf. 2018, 22, 912–915. [Google Scholar] [CrossRef]

- Sun, J.; Liu, C.; Yuan, H. Evaluation of risk management maturity: Measurable proactive indicators suitable for Chinese small and medium-sized chemical enterprises. IOP Conf. Ser. Earth Environ. Sci. 2019, 242, 042006. [Google Scholar] [CrossRef]

- Fera, M.; Macchiaroli, R. Appraisal of a new risk assessment model for SME. Saf. Sci. 2010, 48, 1361–1368. [Google Scholar] [CrossRef]

- Reinhold, K.; Järvis, M.; Tint, P. Practical tool and procedure for workplace risk assessment: Evidence from SMEs in Estonia. Saf. Sci. 2015, 71, 282–291. [Google Scholar] [CrossRef]

- De Merich, D.; Gnoni, M.G.; Malorgio, B.; Micheli, G.J.L.; Piga, G.; Rosso, A.; Sala, G.; Tornese, F. A new model proposal for occupational health and safety management in small and medium enterprises. In 23rd Summer School “Francesco Turco”; Industrial Systems Engineering: Palermo Italy, 2018; pp. 101–107. [Google Scholar]

- Gnoni, M.G.; Saleh, J.H. Near-miss management systems and observability-in-depth: Handling safety incidents and accident precursors in light of safety principles. Saf. Sci. 2017, 91, 154–167. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Merich, D.; Gnoni, M.G.; Malorgio, B.; Micheli, G.J.L.; Piga, G.; Sala, G.; Tornese, F. A Cloud-Based Tool for Integrating Occupational Risk Assessment Within Management Systems for SMEs. Safety 2020, 6, 47. https://doi.org/10.3390/safety6040047

De Merich D, Gnoni MG, Malorgio B, Micheli GJL, Piga G, Sala G, Tornese F. A Cloud-Based Tool for Integrating Occupational Risk Assessment Within Management Systems for SMEs. Safety. 2020; 6(4):47. https://doi.org/10.3390/safety6040047

Chicago/Turabian StyleDe Merich, Diego, Maria Grazia Gnoni, Brunella Malorgio, Guido J. L. Micheli, Giusi Piga, Guido Sala, and Fabiana Tornese. 2020. "A Cloud-Based Tool for Integrating Occupational Risk Assessment Within Management Systems for SMEs" Safety 6, no. 4: 47. https://doi.org/10.3390/safety6040047

APA StyleDe Merich, D., Gnoni, M. G., Malorgio, B., Micheli, G. J. L., Piga, G., Sala, G., & Tornese, F. (2020). A Cloud-Based Tool for Integrating Occupational Risk Assessment Within Management Systems for SMEs. Safety, 6(4), 47. https://doi.org/10.3390/safety6040047