1. Introduction

Operating industrial machinery is associated with occupational hazards, and the safety of machine operators is thus a paramount concern both for companies and for legislative bodies. Laws and regulation have been enforced by most countries, stipulating the safety requirements for newly built machines or for ones already being exploited.

A literature review regarding the assessment of risks related to industrial machines, presented in Reference [

1], highlights the fact that the manufacturing industry was responsible for 63% of non-fatal injuries in the US during 1992–2001. The conclusion recommends, among others, the implementation of a positive safety culture to decrease injuries among machine operators. Additionally, a comprehensive survey of behavioral safety in manufacturing was presented in Reference [

2]. The conclusion pointed out that behavioral interventions are successful in an industry with a high risk of injury. In Reference [

3], a study was performed on medium- and small-sized manufacturing companies with regards to work environment factors, as seen by managers and safety delegates. The results show that the perceptions differ significantly between two professional roles. In Reference [

4], an analytic hierarchy process (AHP)-based methodology was used for the hierarchization of safety devices for industrial machinery. The presented approach made no distinction between the types of industrial machinery considered (machine tools or other kinds of equipment). Furthermore, AHP combined with fuzzy methods (fuzzy AHP) was proposed in Reference [

5] to study the factors affecting the safety of work systems in manufacturing organizations.

Moving parts of machines are considered an important source of risk. A quantification of risks associated with operating, maintaining, cleaning, and clearing a machine with moving parts was presented in Reference [

6]. Another study regarding accidents involving moving parts of machinery was presented in Reference [

7]. It was highlighted that the lack and bypassing of guards, unsafe working methods, and easy access to moving parts are the most encountered causes of accidents.

In the context of automatically controlled machines, which are nowadays widely used in the industry, risks associated with machine control functions have also been studied [

8]. The results highlighted that the safety-related part of the control system must be considered, and that wrong choices in this regard could lead to reduced safety and multiple costs. The emergency stop feature, seen as a control system for machineries, was evaluated from the point of view of the safety performance level in Reference [

9]. The work presented in Reference [

10], which targeted machine tools from the metalworking industry from small enterprises, revealed that safeguards protecting the working area from moving elements were absent or inadequate in a large percentage of the machines considered. Additionally, automated installation is not necessarily without safety problems, as revealed by the research presented in Reference [

11]. There are some safety parameters of machines, such as reduced speeds, which are designed for the control mode of hazardous elements only in reduced risk conditions. A study presented in Reference [

12] revealed that machine operators usually switched to the reduced speed regime without applying the other required safety conditions.

The construction industry has also been the subject of numerous safety analyses. The work from Reference [

13] presented a fuzzy approach for assessing the occupational hazards in this industry. Fuzzy logic methods were used to process the subjective assessment of experts. Other approaches based upon the use of fuzzy logic methods for the assessment of safety risks in the construction industry were presented in References [

14,

15]. Fuzzy logic methods were also used for assessing safety performance in the Indian construction industry [

16] by predicting various types of accidents using a fuzzy inference engine. Special attention has also been given to industrial robots, seen as a special category of industrial machines. The robotic structure represents an entire assembly of automatically moving elements, and thus safety issues have frequently been tackled in the literature [

17,

18].

The approach presented in this paper targets a special category of industrial machinery, namely, computer numerical control (CNC) machine tools. Designed to machine parts from metal workpieces, these technological systems work in a fully automatic way, moving their mobile elements at high speeds. Considering the demanding process of metal removal (cutting metal chips) for which these machines are designed, high forces and torques are also involved in their exploitation. Consequently, safety devices and systems are fitted on CNC machine tools during or after the construction phase. The methodology presented here is intended to evaluate the efficiency of such safety systems by means of a specific multi-criteria decision-making tool, the AHP.

2. Materials and Methods

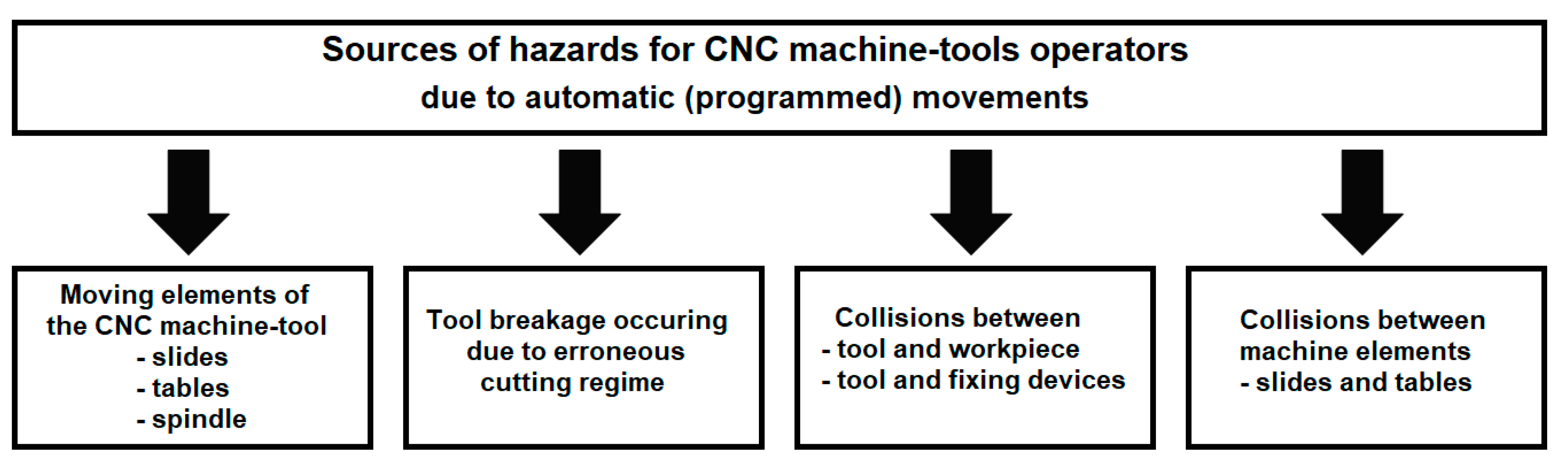

CNC machine tools are complex systems for machining parts by means of cutting processes in a fully automatic way. The machining process is controlled by a machining code, also called the NC program, which is designed by trained programmers using computer-aided manufacturing (CAM) software. Even though CNC machine tools are fully automatic, a CNC operator is needed to set-up and monitor the machine. Thus, the CNC operator could be subject to several hazards which could occur during the exploitation of the machine tool. The most important sources of hazards which can affect the safety of the CNC operator could be considered as (

Figure 1):

Moving elements of the machine (machine slides, rotating tables, rotating main spindle) which move automatically under the control of the NC program;

Tool breakage occurring due to an erroneous cutting regime (higher cutting depths and speeds than are allowable), which can project tool fragments outside the working space of the machine;

Collisions between tools and the workpiece and tools and fixing devices, occurring at high positioning speeds, which can project moving debris outside the working space of the machine. These collisions can occur due to erroneous programming or erroneous setup operations (fixing the workpiece in other positions than the one considered in the programming stage);

Collisions between machine elements due to erroneous programming (related to multi-axis machining operations). In this case, not only should tools and workpieces be checked for collisions, but machining slides should also be checked for collisions against the rotating axes (rotating tables).

To protect the CNC operator, the following categories of safety devices (hardware and software) were taken into consideration by the proposed approach:

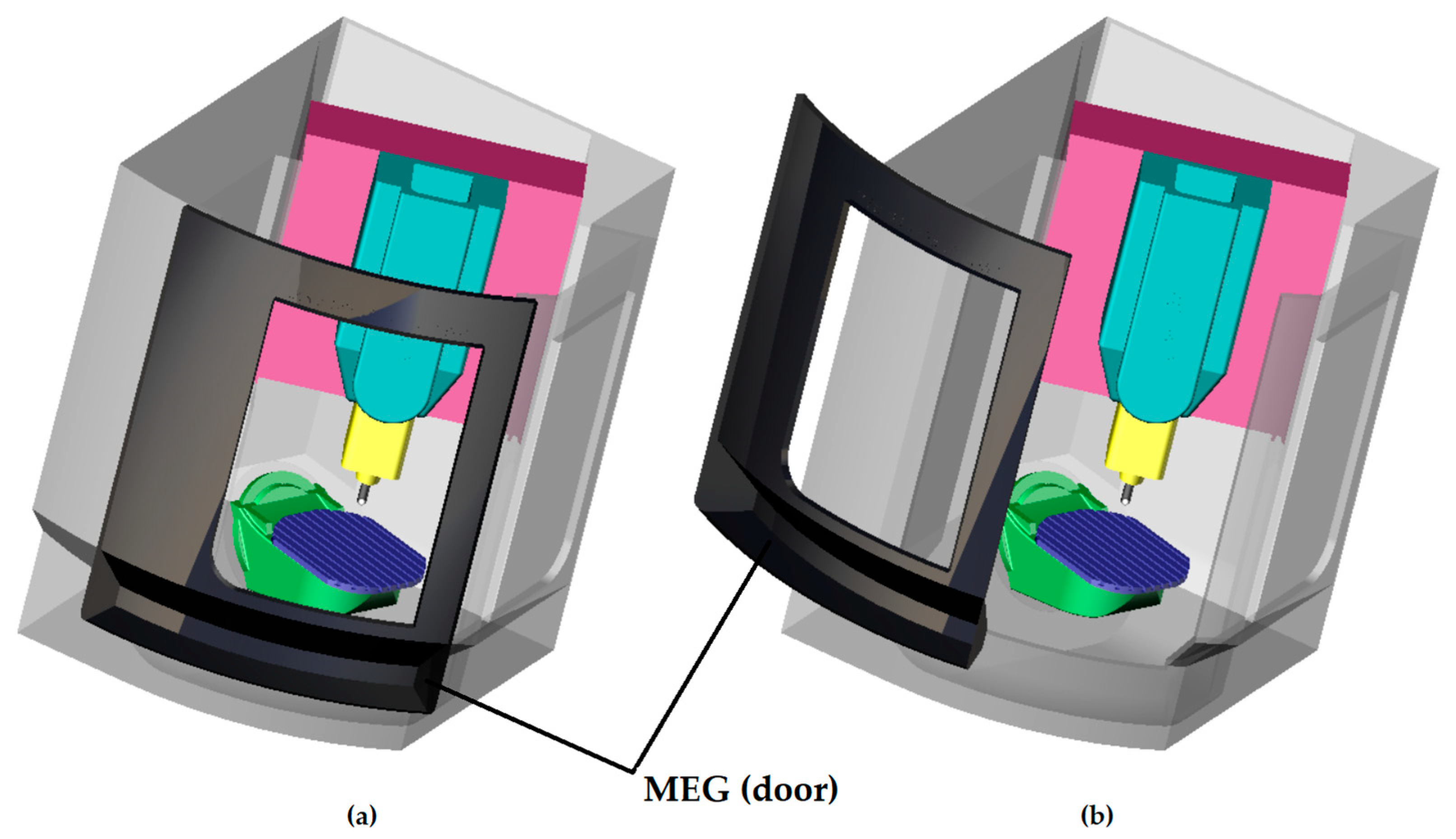

Movable enclosing guards (MEGs): This category includes mobile devices (doors) which limit the access to the working space of a machine (

Figure 2). Usually, these devices have two positions: closed (which is associated with safety) and opened (which is considered unsafe). Also, MEGs are equipped with interlocking mechanisms (for example, if the door is not closed, the main spindle will not start, nor will the rapid movements of the machine slides be enabled).

Manually operated controls (MOC): This category includes safety switches. These devices are used to stop any movement of the machine tool when pressed. An emergency stop is a good example of such a device. The “cycle stop” button, present on most of the commercially available CNC controllers’ operator panels, could also be included in this category. The main difference between the two is that an emergency stop requires a complete restart of the machine after being pressed, while the “cycle stop” button allows the machining process to be resumed from the sequence before stopping it. A special mention must be made here: the emergency stop cancels any motion of the machine tool, while the “cycle stop” button only stops the motions which are programmed in the NC code. For example, the emergency stop stops both the movement of the machine slides and the rotation of the main spindle, while the “cycle stop” button only stops the movements of the machine slides, without stopping the spindle.

Override controls (OVC): This category includes special control switches (potentiometric buttons), present on the CNC operator panel. These switches allow the user to reduce the programmed feed rates of the machine slides and the speed of the main spindle. Although their intended function is not a protective one, usually in the initial stages of testing a machining code (CNC program), these buttons set reduced values for the abovementioned feed rates and speed, thus allowing the user to avoid machining hazards until the CNC program is certified to be safe by all points of view.

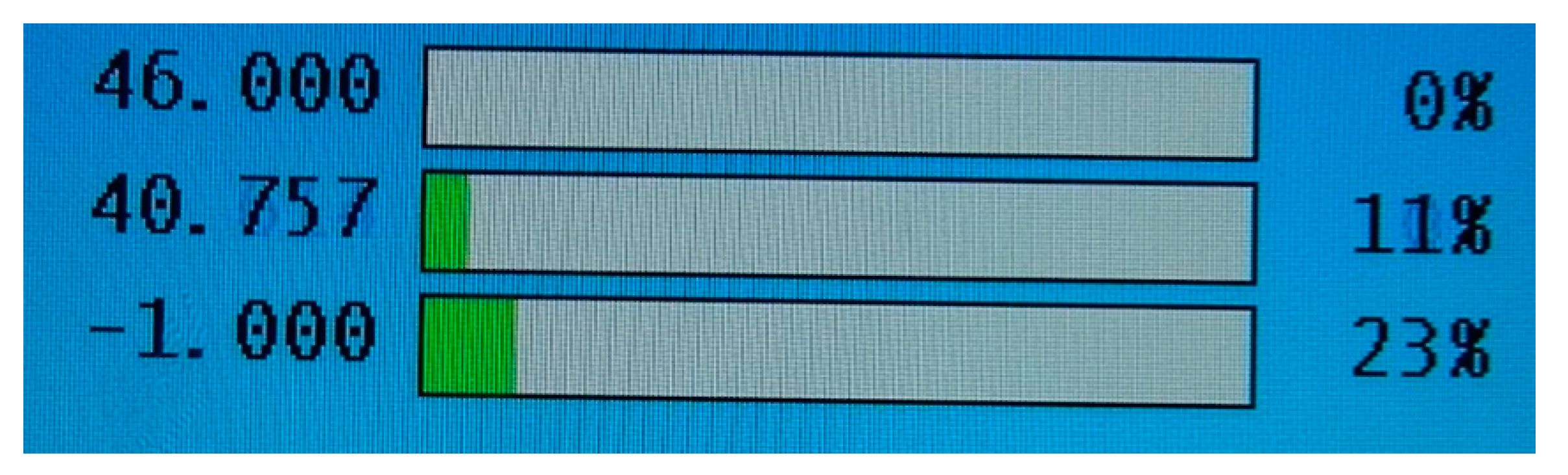

Internal sensors (INS): This category includes sensors fitted on a machine during its manufacturing phase which stop the movements of the machining slides if some situations occur. An example is current sensors that can detect whether the amount of current required by the feed motor on each axis (feed drive) exceeds the maximal value (corresponding to the maximum motor torque), thus indicating that the resistant torque has increased above the rated torque of the motor. In this scenario, the current sensors will issue a stop command on the corresponding feed drive. In

Figure 3, a screenshot from a CNC panel with current sensors is presented; the percentages of the required rated torque of the feed motor (on each axis) are displayed on the left side of the figure. If the percentages exceed 100%, the current sensor will issue a stop command. Another example of an INS are the position sensors on each axis which measure the instantaneous tracking error (difference between programmed and current position). If the tracking error exceeds an allowable value (several hundredths of millimeters), which can signal a problem (obstacle due to an ongoing collision), the sensors will issue a stop command.

External sensors (EXS): This category includes sensors fitted on a machine after it has been manufactured. Examples of this kind of equipment are tool-monitoring sensors, which automatically monitor tools for fracture using acoustic emission and/or force measuring. If a dull cutting edge or even a tool fracture is detected, the sensors will issue a stop command for the main spindle unit and the machine slides.

Software implemented protection (SIP): This category includes special software features included in the operating system of modern CNC controllers. For example, some CNC controllers are able to check the syntax of the CNC program and simulate the relative movements of the tools. However, most of them are not able to simulate either the workpiece or the process of removing the material between the workpiece and the final part. Thus, syntax errors can be detected. However, the simulation has limitations with regards to avoiding collisions between tools and workpiece. Another software feature related to safety is the possibility of identifying programming mistakes (which are not syntax errors), because their syntax is correct. An example of such a mistake is to program machining movements (using G1/G2/G3 commands) without starting the main spindle (using M3/M4). Such a mistake could lead to tool breakage and could not be identified by a simple syntax checker included in the software, but by a complex software feature which checks not only the syntax but also the flowchart of the NC code.

To evaluate the considered safety devices, five criteria were proposed (

Figure 4):

C1—effectiveness: seen as a measure of how effective a safety device is in preventing hazards and/or protecting the machine operator from the sources of hazards;

C2—reliability: seen as the capability of a safety device to operate without failures. It also takes into consideration the capability of the device to operate in the harsh environment specific to metal-cutting processes (high torques and forces, vibrations and noise, contact with metal chips and cooling fluids, rough manipulation);

C3—costs: seen as costs related to purchasing a safety device in the machine tool construction phase or fitting it to the machine at a later stage. It also takes into consideration the cost related to maintenance and upgrade;

C4—tampering avoidance: seen as a measure by which a safety device can avoid being bypassed, removed, or made ineffective, intentionally, by the machine operator;

C5—ease of operation: seen as a measure of user friendliness, i.e., of how easily and intuitively a safety device can be used by the machine operator.

3. Results

An evaluation of six safety devices was made using the AHP method introduced by References [

19,

20]. The approach is based on pairwise comparisons by comparing elements

i and

j. As result, the value

aij was obtained. A given hierarchization criterion was used for making the comparison:

The work presented here uses the judgement scale proposed by Saaty [

19] for the pairwise comparisons: 1—equally important; 3—weakly more important; 5—strongly more important; 7—demonstrably more important; 9—absolutely more important. The values in-between (2, 4, 6, and 8) represent compromise judgements.

The pairwise comparisons were conducted in a joint team composed of the authors of this paper and experts (manufacturing engineers and safety specialists) from COMPA S.A. (Sibiu, Romania;

www.compa.ro), a large manufacturing company and supplier of machined parts for the automotive industry. Both manufacturing engineers and operators from COMPA were involved in the pairwise comparison required by AHP. Workshops were organized with the engineers in order to discuss and evaluate the safety devices. The opinions of the machine tool operators were gathered and processed by means of questionnaires. The information processed from questionnaires was used as input for the workshops.

The five criteria for evaluating the safety device were compared pairwise against each other. The comparison results were synthesized in the preference matrix A, presented in

Table 1.

To illustrate the proposed approach, it will be explained below how the first line of

Table 1 was generated:

Effectiveness (C1), a measure of how effective a safety device is in protecting the machine operator, is weakly more important than reliability (C2), which expresses the ability of the safety device to operate without failures;

Effectiveness (C1) expresses in the highest degree the main purpose of a safety device, so it was considered to be strongly more important than the costs related to the device’s purchase (C3);

Effectiveness (C1) was also considered to be strongly more important than the capability to avoid being made ineffective, intentionally, by the machine operator (C4);

Finally, effectiveness (C1) was considered to be weakly more important than ease of operation (C5).

Following the AHP approach, the next step involved the normalization of the preference matrix A by generating the matrix B according to the following relation:

Table 2 presents the normalized matrix

B. In the last column of matrix B, the eigenvector w—calculated as the arithmetic averages from the row of the normalized comparison matrix, according to Equation (3)—was placed.

The next step involved a consistency check [

19,

20,

21] of the comparisons by calculating the maximal eigenvalue according to the following equations:

is the matrix’s largest eigenvalue and

CI is the consistency index [

19,

20].

By using the random consistency index table (presented in

Table 3) introduced in Reference [

20], the consistency ratio (CR) may be calculated (for a 5-dimensional matrix, the

r coefficient is 1.12).

According to the result presented in Equation (5), the value of the CR was found to be smaller than 10% (8.1055 %). This certifies the fact that the pairwise comparisons which were made in the process of structuring the matrices A and B were consistent [

19,

21].

According to Equation (5), the pairwise comparisons for the evaluation of the considered criteria were consistent, since the CR for the comparison matrix was less than 10%.

The next step of the AHP involved the evaluation of the safety devices, taking into consideration the proposed criteria. The evaluation for each one is presented in

Table 4,

Table 5,

Table 6,

Table 7,

Table 8,

Table 9 and

Table 10. In the last column of each table, the eigenvectors are introduced.

At this moment, using the data from

Table 4,

Table 5,

Table 6,

Table 7 and

Table 8, the user can build matrix C. In the columns of matrix C, one has the eigenvectors resulting from the pairwise comparison of the four alternatives. The order of the columns within matrix C takes into consideration the order of the criteria determined in

Table 2: C1, C2, C5, C4, and C3. By performing the multiplication of matrix C and the vector w, the preference vector x for the SIC analyzed alternatives is obtained. The multiplication is presented in Equation (6).

Analyzing the results from Equation (6), it can be stated that the AHP method determines manually operated controls (MOCs) as the best safety device.

Sensitivity Analysis

To test the robustness of the AHP results, a sensitivity analysis was suggested in Reference [

22]. This analysis is based on the change of the weights, while maintaining the previously determined ranking order. This can be made by introducing a coefficient ≥0 and transforming the matrix A into the matrix

. According to Reference [

22], if > 1 more dispersed weights are obtained, and if ≤ 1, the weights become more concentrated without affecting the previously determined ranking order.

Table 9 shows the weight values obtained for coefficients = 0.5, 0.7, 0.9, 1.0, 1.1, 1.3, and 1.5 (these values were proposed in Reference [

23]).

Table 10 presents the simulation results of the calculation of the preference vector

x for the weights from

Table 9.

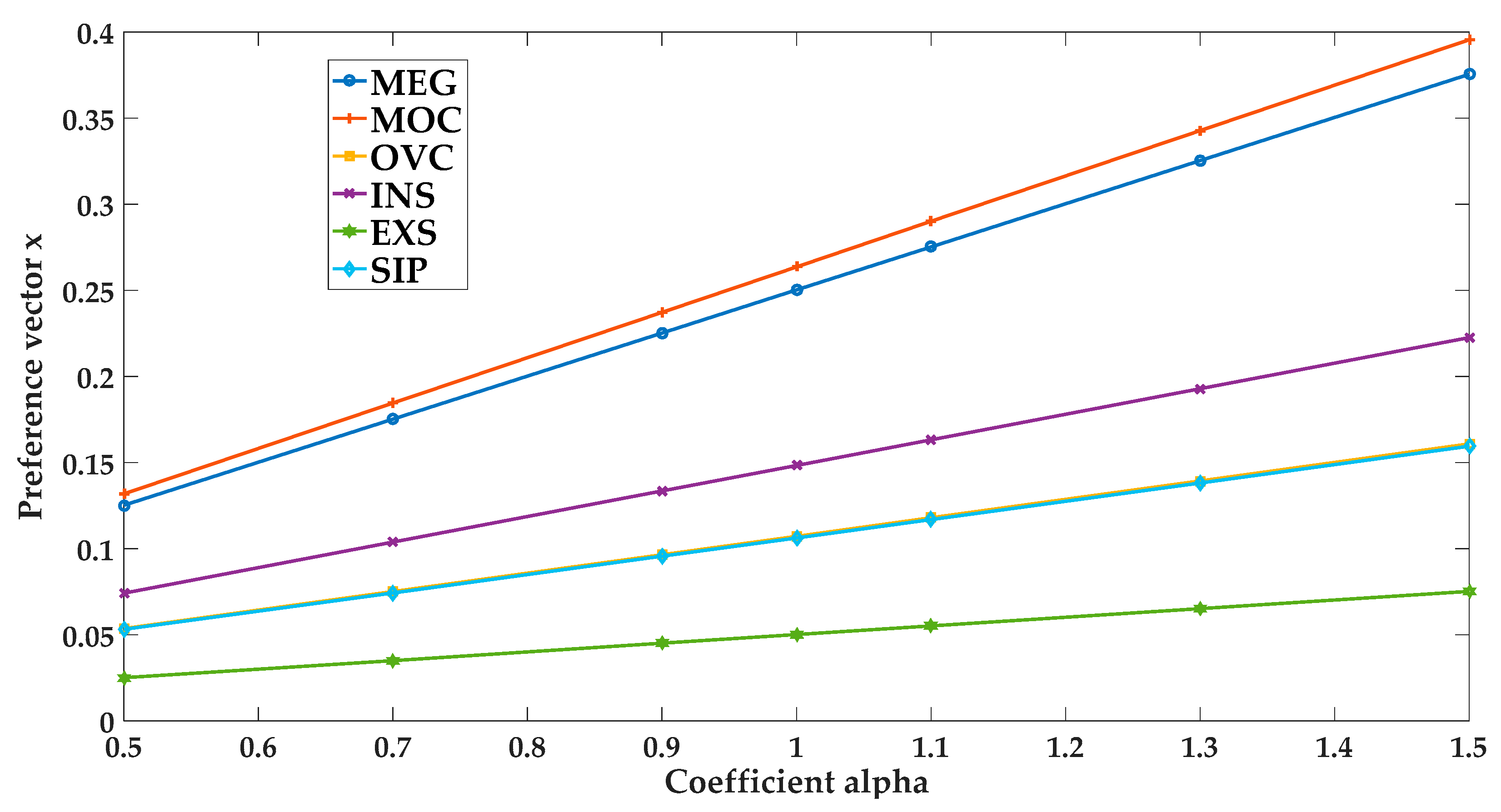

A graphical representation of the results of the sensitivity analysis is presented in

Figure 5. From the figure, one may notice that the changes in the weights do not affect the order of the preference vectors

x. As a result, it can be stated that MOC is the best safety device alternative for the entire range of the sensitivity analysis. From

Figure 5, it can also be noticed that the graphical representations of the evolution of coefficient for OVC and SIP are very close to each other, without influencing the results of the analysis.

4. Discussion

As result of running the AHP, the analyzed safety devices were hierarchized as follows: (1) MOC; (2) MEG; (3) INS; (4) OVC; (5) SIP; (6) EXS.

In first place are MOC (manually operated controls), which are simple, classical safety devices. Consequently, it can be stated that classical safety devices, which are present in practically every type of industrial machine (either machine tool or otherwise, and either automatic or otherwise) are by far better than the other solutions. Modern solutions, related with the computer control capabilities of the CNC machine tools, are in third place (internal sensors) and in fifth place (software implemented protection). A possible explanation for these results could be the fact that internal sensors usually come as standard devices on CNC machine tools, while software-implemented protection is usually provided as supplementary options. This leads to higher costs for the latter, and machine operators are not very familiar with them. On the other hand, it is encouraging that modern systems, which intervene automatically by stopping the machining process, are in third place. These internal sensors are designed primarily for avoiding technological issues (avoiding the use of inadequate feeds or cutting depths), and their use as safety devices comes only indirectly, a fact that could explain why these modern safety devices are not better placed in this hierarchy. The situation may change in the future when a new class of internal sensors is designed specifically for safety purposes. The AHP placed the external sensors in last place, a fact which could be explained by taking into consideration their costs, the training required for the operators to make use of them, and their considered reduced user friendliness (due to the constructive complexity).

5. Conclusions

It is noticeable that the results of the analysis presented here relied heavily on the experience of the users from the manufacturing company involved in the research, and could consequently be affected by subjectivity. However, COMPA S.A., the company used as a benchmark for this approach, has an endowment of more than 200 CNC machine tools, and thus the knowledge base related with their exploitation existing at the company level is significant. Nevertheless, further research must be conducted to increase the degree of generality of the results.

Further research will try to consider a larger amount of data (by involving more companies) and will use fuzzy methods in combination with AHP to deal with subjectivity problems. Another direction targeted by future research will be the inclusion in the study of other sources of hazards, such as cooling systems and/or hybrid cutting systems (which are equipped in the most modern CNC machine tools).