Industrial Safety Strategies Supporting the Zero Accident Vision in High-Risk Organizations: A Scoping Review

Abstract

1. Introduction

2. State of the Art

3. Materials and Methods

3.1. Study Design

3.2. Inclusion and Exclusion Criteria

3.3. Search Strategy

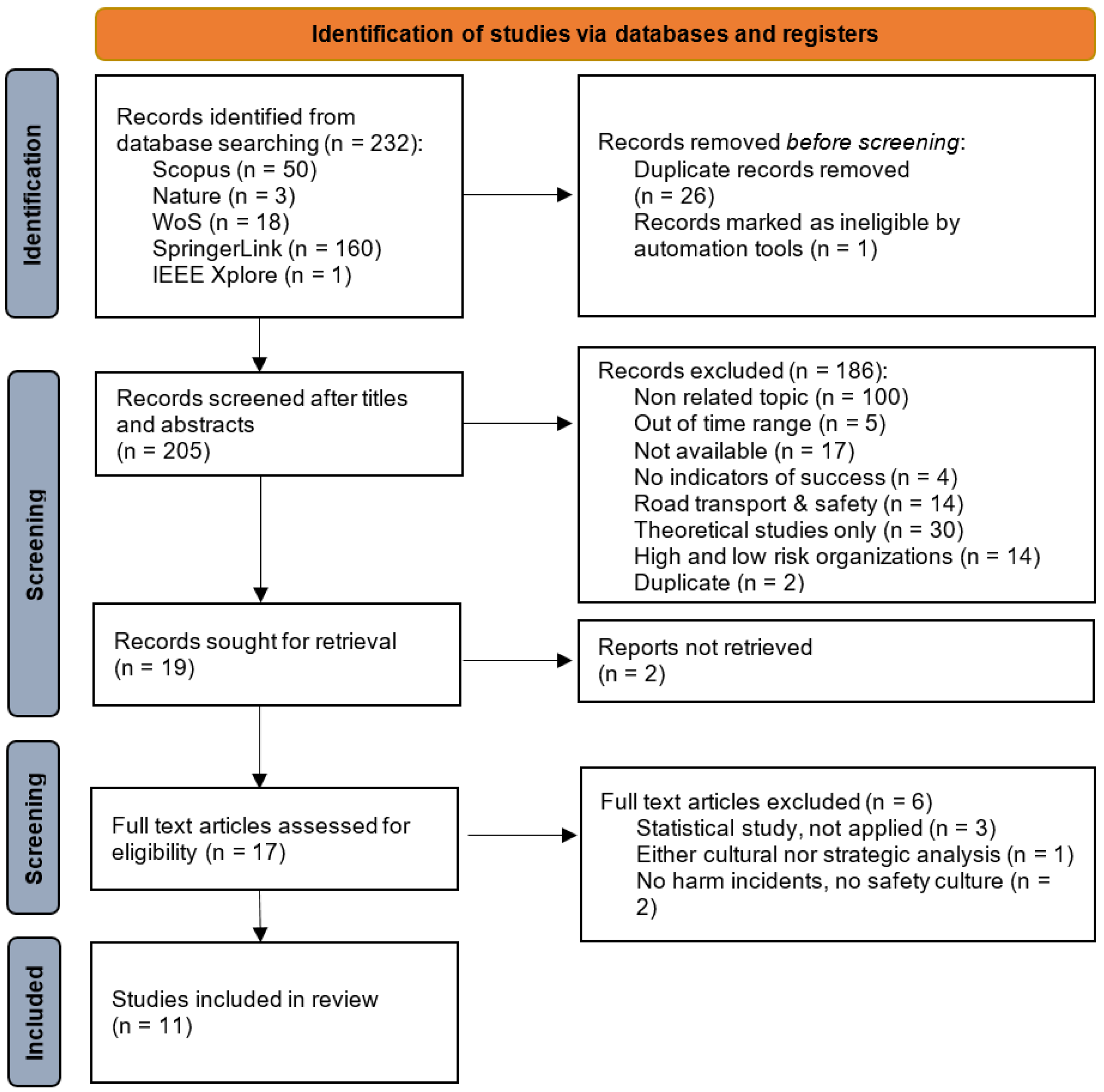

3.4. Study Selection Process

3.5. Data Extraction

4. Results

4.1. Description of Included Studies

4.2. Organizational Cultural Impact and Occupational Risk Management Policies

4.3. Comparison of Cultural Change Approaches in Proposed and Traditional Models

4.4. Evaluation of the Transition Toward a Zero-Accident Culture

4.5. Analysis of Practical Implementation

4.6. Evidence of Clear Success Indicators in the Proposed Models

4.7. Review of Methodologies

4.8. Comparative Synthesis and International Benchmarks

4.9. Contributions of the Selected Studies to the Review

5. Discussion

5.1. Differences Between the Zero Accident Vision and Zero Accident Culture

5.2. Near-Miss Reporting as a Proactive Contribution to ZAV

5.3. Safety Excellence as a Corporate Strategy

5.4. Values, Goals, and Strategic Realism

5.5. Roles, Leadership, and Organizational Commitment

5.6. Measurement and Performance Assessment

5.7. Conceptual Clarity and Consistency of Criteria

5.8. Technical Competence of Personnel

5.9. Implications for Practice

5.10. Integration of the Five Pillars into OHS Management Systems

5.11. Limitations and Future Work

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schulte, P.A.; Iavicoli, I.; Fontana, L.; Leka, S.; Dollard, M.F.; Salmen-Navarro, A.; Salles, F.J.; Olympio, K.P.K.; Lucchini, R.; Fingerhut, M.; et al. Occupational Safety and Health Staging Framework for Decent Work. Int. J. Environ. Res. Public Health 2022, 19, 10842. [Google Scholar] [CrossRef]

- Albert, L.; Routh, C. Designing Impactful Construction Safety Training Interventions. Safety 2021, 7, 42. [Google Scholar] [CrossRef]

- Moradi, A.; Yazdi, M. Mastering the Landscape of Occupational Health and Safety: Regulations, Best Practices, and Avoiding Pitfalls. In Safety-Centric Operations Research: Innovations and Integrative Approaches: A Multidisciplinary Approach to Managing Risk in Complex Systems; Yazdi, M., Ed.; Springer Nature: Cham, Switzerland, 2025; pp. 151–167. ISBN 978-3-031-82934-5. [Google Scholar]

- Ranganathan, P.; Sujatha, S. Occupational Accidents and Need for Worker Safety in Manufacturing and High Risk Industries—An Explorative Study with Solutions. Int. J. Prof. Bus. Rev. 2022, 7, e0670. [Google Scholar] [CrossRef]

- Debelu, D.; Mengistu, D.A.; Tolera, S.T.; Aschalew, A.; Deriba, W. Occupational-Related Injuries and Associated Risk Factors Among Healthcare Workers Working in Developing Countries: A Systematic Review. Health Serv. Res. Manag. Epidemiol. 2023, 10, 23333928231192834. [Google Scholar] [CrossRef] [PubMed]

- Rabbani, U.; Fatmi, Z. Incidence, Patterns and Associated Factors for Occupational Injuries among Agricultural Workers in a Developing Country. Med. J. Islam. Repub. Iran 2018, 32, 88. [Google Scholar] [CrossRef] [PubMed]

- Duarte, J.; Marques, A.T.; Santos Baptista, J. Occupational Accidents Related to Heavy Machinery: A Systematic Review. Safety 2021, 7, 21. [Google Scholar] [CrossRef]

- Trinh, M.T.; Feng, Y. A Maturity Model for Resilient Safety Culture Development in Construction Companies. Buildings 2022, 12, 733. [Google Scholar] [CrossRef]

- The Lloyd’s Register Foundation. Engineering Safer Workplaces: Global Trends in Occupational Safety and Health; The Lloyd’s Register Foundation: London, UK, 2024. [Google Scholar] [CrossRef]

- Glebova, E.V.; Volokhina, A.T.; Vikhrov, A.E. Assessment of the efficiency of occupational safety culture management in fuel and energy companies. J. Min. Inst. 2023, 259, 68–78. [Google Scholar] [CrossRef]

- Gidiagba, J.O.; Olurin, J.O.; Ehiaguina, V.E.; Ndiwe, T.C.; Ojo, G.G.; Ogunjobi, O.A. Safety, Quality Control, And Sustainability in Construction: Exploring the Nexus—A Review. Eng. Herit. J. 2023, 7, 72–93. [Google Scholar]

- Ahamad, M.A.; Arifin, K.; Abas, A.; Mahfudz, M.; Cyio, M.B.; Khairil, M.; Ali, M.N.; Lampe, I.; Samad, M.A. Systematic Literature Review on Variables Impacting Organization’s Zero Accident Vision in Occupational Safety and Health Perspectives. Sustainability 2022, 14, 7523. [Google Scholar] [CrossRef]

- Abebe, H.G.; Hansson, S.O.; Edvardsson Björnberg, K. Arguments Against Vision Zero: A Literature Review. In The Vision Zero Handbook; Springer: Cham, Switzerland, 2023; pp. 107–149. ISBN 978-3-030-76505-7. [Google Scholar]

- Rosencrantz, H.; Edvardsson, K.; Hansson, S.O. Vision Zero—Is It Irrational? Transp. Res. Part A Policy Pract. 2007, 41, 559–567. [Google Scholar] [CrossRef]

- Zwetsloot, G.I.J.M.; Kines, P.; Wybo, J.-L.; Ruotsala, R.; Drupsteen, L.; Bezemer, R.A. Zero Accident Vision Based Strategies in Organisations: Innovative Perspectives. Saf. Sci. 2017, 91, 260–268. [Google Scholar] [CrossRef]

- ISO 45001:2018; Occupational Health and Safety Management Systems—Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland, 2018.

- Narain, J.; Meena, M.L.; Dangayach, G.S.; Patnaik, A. Adopting Zero Accident Vision in India: A Conceptual Framework. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1017, 012006. [Google Scholar] [CrossRef]

- Parshina, V.; Marushchak, T.; Kuznetsova, E.; Davydov, A. Motivational Elements of the Human Factor for the Implementation of the “Vision Zero” Concept in Railway Transport. Transp. Res. Procedia 2021, 54, 191–199. [Google Scholar] [CrossRef]

- Sankar, S.S.; Anandh, K.S.; Rajendran, S.; Ibrahim, C.K.I.C.; Szóstak, M. Examining the Relative Importance and Association between Safety Leadership Styles and Factors Affecting Organizational Safety Climate. Buildings 2023, 13, 2062. [Google Scholar] [CrossRef]

- Rahim, H.; Dapari, R.; Che Dom, N.; Mohd Noor, M.I. Decoding Stakeholder Priorities of Safety Culture Preferences in the Oil and Gas Industry. Sci. Rep. 2024, 14, 20735. [Google Scholar] [CrossRef]

- Tsichla, K.; Adam, K. The Εvolution of Health and Safety Training Needs of the Mining Sector in Greece and EU. Mater. Proc. 2022, 5, 136. [Google Scholar] [CrossRef]

- Ordysiński, S. The Role of Trust in Occupational Safety: Research Results. Int. J. Occup. Saf. Ergon. 2024, 30, 741–753. [Google Scholar] [CrossRef]

- Wu, Z.; Yin, B.; Ning, P. The Influence of Team Human Capital on Safety Performance of Engineering Project Team: The Mediating Role of Safety Citizenship Behavior. IEEE Access 2021, 9, 65560–65573. [Google Scholar] [CrossRef]

- Twaalfhoven, S.F.M.; Kortleven, W.J. The Corporate Quest for Zero Accidents: A Case Study into the Response to Safety Transgressions in the Industrial Sector. Saf. Sci. 2016, 86, 57–68. [Google Scholar] [CrossRef]

- Chambergo-Michilot, D.; Diaz-Barrera, M.E.; Benites-Zapata, V.A. Revisiones de alcance, revisiones paraguas y síntesis enfocada en revisión de mapas: Aspectos metodológicos y aplicaciones. Rev. Peru. Med. Exp. Salud Pública 2021, 38, 136–142. [Google Scholar] [CrossRef]

- Tricco, A.C.; Lillie, E.; Zarin, W.; O’Brien, K.K.; Colquhoun, H.; Levac, D.; Moher, D.; Peters, M.D.J.; Horsley, T.; Weeks, L.; et al. PRISMA Extension for Scoping Reviews (PRISMA-ScR): Checklist and Explanation. Ann. Intern. Med. 2018, 169, 467–473. [Google Scholar] [CrossRef]

- Chandler, E.; Bryden, R.; Paul, T.; Roddy, S. An Approach to Process Safety Management. In Proceedings of the SPE International Conference and Exhibition on Health, Safety, Security, Environment, and Social Responsibility, Stavanger, Norway, 11–13 April 2016. [Google Scholar]

- Akintola, A.; Barlow, J.; Cooke, E.; Fynn, W.; Hansen, H.; Heim, M.; Jackson, R.; Mennes, S.; Pendrey, D.; Perkins, B.; et al. Construction Site Safety Standardisation. In Proceedings of the SPE International Conference and Exhibition on Health, Safety, Security, Environment, and Social Responsibility, Stavanger, Norway, 11–13 April 2016. [Google Scholar]

- Jain, A.; Leka, S.; Zwetsloot, G.I.J.M. Mainstreaming Health, Safety and Well-Being. In Managing Health, Safety and Well-Being: Ethics, Responsibility and Sustainability; Jain, A., Leka, S., Zwetsloot, G.I.J.M., Eds.; Springer: Dordrecht, The Netherlands, 2018; pp. 175–220. ISBN 978-94-024-1261-1. [Google Scholar]

- Egbeocha, J.O.; Reginald-Ugwuadu, O.G.; Oluchi, E.; Ebisike, R.C.; Obanya, P. Entrenching Process Safety Culture in The Face of Shifting Demography—a Key to Sustaining Goal Zero Performance in Well Operations. In SPE Nigeria Annual International Conference and Exhibition; SPE: Lagos, Nigeria, 2015. [Google Scholar]

- Molyneux, J. Industrial Perspective on the Seminar: The Viewpoint of a Mining Expert. In Beyond Safety Training: Embedding Safety in Professional Skills; Bieder, C., Gilbert, C., Journé, B., Laroche, H., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 97–101. ISBN 978-3-319-65527-7. [Google Scholar]

- Mazur, A. Model of OHS Management Systems in an Excellent Company. In Proceedings of the Universal Access in Human-Computer Interaction. Access to the Human Environment and Culture; Antona, M., Stephanidis, C., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 456–467. [Google Scholar]

- Sudarsan, J.S.; Nithiyanantham, S. Optimization of Safety in Indian Construction Industry Learning from Expert Survey. Int. J. Pavement Res. Technol. 2022, 15, 539–546. [Google Scholar] [CrossRef]

- Häkkinen, K. Safety Management—From Basic Understanding Towards Excellence. In Integrated Occupational Safety and Health Management: Solutions and Industrial Cases; Väyrynen, S., Häkkinen, K., Niskanen, T., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 7–15. ISBN 978-3-319-13180-1. [Google Scholar]

- Franceschini, L.; Maugeri, P.; Chiantella, P.; Buccarelli, A.; Grillo, R. Safety Pact. In Proceedings of the SPE Kuwait Oil & Gas Show and Conference, Mishref, Kuwait, 13–16 October 2019. [Google Scholar]

- Nguyen, N.; Meesmann, U.; Truong, N.-L.; Trinh, V.-H. VISION ZERO—Tools for Safety, Health, and Well-Being Management and the Application in the Vietnamese Coal Mining Industry. Inżynieria Miner. 2021, 1, 365–372. [Google Scholar] [CrossRef]

- Hethmon, T. 3—Zero Harm Coal Mining. In Advances in Productive, Safe, and Responsible Coal Mining; Hirschi, J., Ed.; Woodhead Publishing: Cambridge, UK, 2019; pp. 31–51. ISBN 978-0-08-101288-8. [Google Scholar]

- World Health Organization. How WHO Is Funded. Available online: https://www.who.int/about/funding (accessed on 16 September 2025).

- International Labour Organization. Regular Budget Assessed Income. Available online: https://www.ilo.org/about-ilo/how-ilo-works/organizational-structure-international-labour-office/financial-management/regular-budget-assessed-income (accessed on 16 September 2025).

- World Health Organization. WHO/ILO Joint Estimates of the Work-Related Burden of Disease and Injury, 2000–2016: Global Monitoring Report. Available online: https://www.who.int/publications/i/item/9789240034945 (accessed on 16 September 2025).

- World Health Organization. WHO/ILO Joint Estimates of the Work-Related Burden of Disease and Injury, 2000–2016: Technical Report with Data Sources and Methods. Available online: https://www.who.int/publications/i/item/9789240034921 (accessed on 16 September 2025).

- Pega, F.; Náfrádi, B.; Momen, N.C.; Ujita, Y.; Streicher, K.N.; Prüss-Üstün, A.M.; Descatha, A.; Driscoll, T.; Fischer, F.M.; Godderis, L.; et al. Global, Regional, and National Burdens of Ischemic Heart Disease and Stroke Attributable to Exposure to Long Working Hours for 194 Countries, 2000–2016: A Systematic Analysis from the WHO/ILO Joint Estimates of the Work-Related Burden of Disease and Injury. Environ. Int. 2021, 154, 106595. [Google Scholar] [CrossRef] [PubMed]

- Hulshof, C.T.J.; Pega, F.; Neupane, S.; van der Molen, H.F.; Colosio, C.; Daams, J.G.; Descatha, A.; Kc, P.; Kuijer, P.P.F.M.; Mandic-Rajcevic, S.; et al. The Prevalence of Occupational Exposure to Ergonomic Risk Factors: A Systematic Review and Meta-Analysis from the WHO/ILO Joint Estimates of the Work-Related Burden of Disease and Injury. Environ. Int. 2021, 146, 106157. [Google Scholar] [CrossRef] [PubMed]

- International Labour Organization. Quick Guide on Sources and Uses of Statistics on Occupational Safety and Health, 1st ed.; International Labour Organization: Geneva, Switzerland, 2020; ISBN 978-92-2-033702-8. [Google Scholar]

- Dong, X.S.; Largay, J.A.; Choi, S.D.; Wang, X.; Cain, C.T.; Romano, N. Fatal Falls and PFAS Use in the Construction Industry: Findings from the NIOSH FACE Reports. Accid. Anal. Prev. 2017, 102, 136–143. [Google Scholar] [CrossRef] [PubMed]

- Reason, J. Safety Paradoxes and Safety Culture. Inj. Control. Saf. Promot. 2000, 7, 3–14. [Google Scholar] [CrossRef]

- Dekker, S. The Field Guide to Human Error Investigations; Routledge: London, UK, 2017; ISBN 978-1-315-20277-8. [Google Scholar]

- Elvik, R. How Would Setting Policy Priorities According to Cost–Benefit Analyses Affect the Provision of Road Safety? Accid. Anal. Prev. 2003, 35, 557–570. [Google Scholar] [CrossRef]

- Locke, E.A.; Latham, G.P. Building a Practically Useful Theory of Goal Setting and Task Motivation. A 35-Year Odyssey. Am. Psychol. 2002, 57, 705–717. [Google Scholar] [CrossRef]

- Zhang, Q.; Xi, Y.; Xuan, S.; Hu, S. The Influence Path of Safety Culture on Pilot’s Safety Behavior. In Proceedings of the 2021 6th International Conference on Transportation Information and Safety (ICTIS), Wuhan, China, 22–24 October 2021; pp. 811–815. [Google Scholar]

- Astuti, P.N.; Djunaidi, Z.; Alfiyyah, A. Assessing Safety Culture Maturity in Indonesia’s Petrochemical Producer. Indones. J. Occup. Saf. Health 2025, 14, 142–151. [Google Scholar]

- Cram, R.S.; Sime, J.-A. Behaviour, the Final Frontier—A Proven Approach to Changing Organizational Behaviour. In SPE/IADC Middle East Drilling Technology Conference and Exhibition; SPE: Muscat, Oman, October 2011. [Google Scholar]

- Galloway, S.M. The Power of Tribes & the Case for SAFETY STRATEGY. Prof. Saf. 2024, 69, 16–18. [Google Scholar]

- Misan, A.; Lada, S.; Omar, P.M.F.F.A. The Relationship between Strategic Management Performance and Safety: Bibliometric Review Analysis. Labu. Bull. Int. Bus. Financ. 2023, 21, 31–49. [Google Scholar] [CrossRef]

- Ajmal, M.; Isha, A.; Nordin, S. Safety Management Practices and Occupational Health and Safety Performance: An Empirical Review. Jinnah Bus. Rev. 2021, 9, 15–33. [Google Scholar] [CrossRef]

- Kalteh, H.O.; Mortazavi, S.B.; Mohammadi, E.; Salesi, M. The Relationship between Safety Culture and Safety Climate and Safety Performance: A Systematic Review. Int. J. Occup. Saf. Ergon. 2021, 27, 206–216. [Google Scholar] [CrossRef] [PubMed]

- Jilcha, K. Vision Zero for Industrial Workplace Safety Innovative Model Development for Metal Manufacturing Industry. Heliyon 2023, 9, e21504. [Google Scholar] [CrossRef] [PubMed]

- Vandeskog, B. Safety Is the Preservation of Value. J. Saf. Res. 2024, 89, 105–115. [Google Scholar] [CrossRef] [PubMed]

- Mathis, T.L. STEPS to Safety Culture Excellence. In Proceedings of the ASSE Professional Development Conference and Exposition, Las Vegas, NV, USA, 22–28 June 2013. [Google Scholar]

- Rahim, N.A.; Husin, N.; Juhari, J.; Daud, S.R.; Ahmad, K.S.; Masdek, N.R.N.M. Improving Safety Performance by Influence Safety Management Practices and Safety Culture: A Conceptual Framework. Int. J. Acad. Res. Bus. Soc. Sci. 2023, 13, 1868–1879. [Google Scholar] [CrossRef]

- Sharman, A. From Accidents to Zero: A Practical Guide to Improving Your Workplace Safety Culture, 2nd ed.; Routledge: London, UK, 2016; ISBN 978-1-315-58326-6. [Google Scholar]

- Tay, H.H. Key Factors of near Miss Reporting Behaviour at Work and the Interaction of Safety Climate: A Review Based on Reciprocal Safety Model. Int. J. Reliab. Saf. 2025, 19, 1–21. [Google Scholar] [CrossRef]

- Slil, E.; Iyiola, K.; Alzubi, A.; Aljuhmani, H.Y. Impact of Safety Leadership and Employee Morale on Safety Performance: The Moderating Role of Harmonious Safety Passion. Buildings 2025, 15, 186. [Google Scholar] [CrossRef]

- Chiu, C.-Y.; Nahrgang, J.D.; Bartram, A.; Wang, J.; Tesluk, P.E. Leading the Team, but Feeling Dissatisfied: Investigating Informal Leaders’ Energetic Activation and Work Satisfaction and the Supporting Role of Formal Leadership. J. Organ. Behav. 2021, 42, 527–550. [Google Scholar] [CrossRef]

- Benson, C.; Obasi, I.C.; Akinwande, D.V.; Ile, C. The Impact of Interventions on Health, Safety and Environment in the Process Industry. Heliyon 2024, 10, e23604. [Google Scholar] [CrossRef] [PubMed]

- Broadribb, M.P. Leading by Example: Culture, Leadership, and Accountability. Process Saf. Prog. 2024, 43, 437–440. [Google Scholar] [CrossRef]

- Yazdi, M. The Impact of Leadership on Fostering a Safety-Oriented Organizational Culture. In Safety-Centric Operations Research: Innovations and Integrative Approaches: A Multidisciplinary Approach to Managing Risk in Complex Systems; Yazdi, M., Ed.; Springer Nature: Cham, Switzerland, 2025; pp. 31–50. ISBN 978-3-031-82934-5. [Google Scholar]

- Sangwa, S.; Mutabazi, P. Compliance as the New Competence: How Obedience Cultures Erode Innovation and Leadership Ethics in Global Workplaces; SSRN: Amsterdam, The Netherlands, 2025. [Google Scholar]

- Shen, L. Safety Performance Evaluation System: A Brief Review. In Proceedings of the 2024 9th International Conference on Social Sciences and Economic Development (ICSSED 2024), Beijing, China, 22–24 March 2024; Magdalena, R., Majoul, B., Singh, S.N., Rauf, A., Eds.; Atlantis Press International BV: Dordrecht, The Netherlands, 2024; Volume 289, pp. 866–872. [Google Scholar]

- Nkrumah, E.N.K.; Liu, S.; Doe Fiergbor, D.; Akoto, L.S. Improving the Safety–Performance Nexus: A Study on the Moderating and Mediating Influence of Work Motivation in the Causal Link between Occupational Health and Safety Management (OHSM) Practices and Work Performance in the Oil and Gas Sector. Int. J. Environ. Res. Public Health 2021, 18, 5064. [Google Scholar] [CrossRef] [PubMed]

- Kazmi, M. Measuring Process Safety Culture and Identifying Gaps Through PSM Element Focused Interviews. In Proceedings of the SPE International Health, Safety, Environment and Sustainability Conference and Exhibition, Abu Dhabi, United Arab Emirates, 10–12 September 2024. [Google Scholar]

- Ravi, D.; Tawfik, D.S.; Sexton, J.B.; Profit, J. Changing Safety Culture. J. Perinatol. 2021, 41, 2552–2560. [Google Scholar] [CrossRef]

- Jääskeläinen, A.; Tappura, S.; Pirhonen, J. The Path toward Successful Safety Performance Measurement. J. Saf. Res. 2022, 83, 181–194. [Google Scholar] [CrossRef]

- Curcuruto, M.; Griffin, M.A. Upward Safety Communication in the Workplace: How Team Leaders Stimulate Employees’ Voice through Empowering and Monitoring Supervision. Saf. Sci. 2023, 157, 105947. [Google Scholar] [CrossRef]

- van der Sluis, L.E.C. Leadership for Risk Management: Navigating the Haze with Modern Techniques; Future of Business and Finance; Springer International Publishing: Cham, Switzerland, 2021; ISBN 978-3-030-69406-7. [Google Scholar]

- Bayram, M. Safety Training and Competence, Employee Participation and Involvement, Employee Satisfaction, and Safety Performance: An Empirical Study on Occupational Health and Safety Management System Implementing Manufacturing Firms. Alphanumeric 2019, 7, 301–318. [Google Scholar] [CrossRef]

- Akande, A.; Bobek, V.; Krakkai, A.; Ternullo, G.; Horvat, T. The Fundamentals of Human Behavior in Organizations: Attitudes, Values, and Workplace Success. In Organizational Behavior: Current Science, Models, and Applications; Akande, A., Ed.; Springer Nature: Cham, Switzerland, 2025; pp. 57–108. ISBN 978-3-031-85803-1. [Google Scholar]

- Kothari, A.; Boyko, J.A.; Conklin, J.; Stolee, P.; Sibbald, S.L. Communities of Practice for Supporting Health Systems Change: A Missed Opportunity. Health Res. Policy Syst. 2015, 13, 33. [Google Scholar] [CrossRef]

- Tusseyev, M.; Torybayeva, J.; Ibragim, K.; Gurbanova, A.; Nazarova, G. Ensuring the Safety of Learning and Teaching Environments. World J. Educ. Technol. Curr. Issues 2021, 13, 1029–1039. [Google Scholar] [CrossRef]

- International Labour Organization (ILO). Safety and Health at the Heart of the Future of Work Building on 100 Years of Experience, 1st ed.; International Labour Organization: Geneva, Switzerland, 2019; ISBN 978-92-2-133152-0. [Google Scholar]

- Drupsteen, L. Improving Organisational Safety through Better Learning from Incidents and Accidents. Ph.D. Thesis, Aalborg University, Centre for Industrial Production (CIP), Copenhagen, Denmark, 2014. [Google Scholar]

- Haleem, A.; Javaid, M.; Singh, R.P. Encouraging Safety 4.0 to Enhance Industrial Culture: An Extensive Study of Its Technologies, Roles, and Challenges. Green Technol. Sustain. 2025, 3, 100158. [Google Scholar] [CrossRef]

- Zwetsloot, G.; Leka, S.; Kines, P.; Jain, A. Vision Zero: Developing Proactive Leading Indicators for Safety, Health and Wellbeing at Work. Saf. Sci. 2020, 130, 104890. [Google Scholar] [CrossRef]

- Hesham, M.; Hosny, G.; Mahmoud, E.; Ghatas, Z. Developing an Integrated Model for Improving Occupational Health and Safety Performance in Some Industries Using Safety Standards. Discov. Public Health 2025, 22, 338. [Google Scholar] [CrossRef]

| Category | Keywords | Sample Combinations | |

|---|---|---|---|

| Type of industry |

|

|

|

| Vision Zero and variants |

|

|

|

| Safety culture and strategy |

|

|

|

| Search Type | Search String |

|---|---|

| Exploratory | (“high-risk industries” OR “high-hazard industries” OR “hazardous” OR “dangerous”) AND (“Vision Zero” OR “zero accidents” OR “zero harm” OR “zero injury” OR “Goal Zero” OR “injury-free workplace”) NOT (“road safety” OR “transport safety” OR “road transport safety” OR “traffic safety” OR “safety on the road”) |

| Focused | (“high-risk industries” OR “high-hazard industries” OR “hazardous” OR “dangerous”) AND (“Vision Zero” OR “zero accidents” OR “zero harm” OR “zero injury” OR “Goal Zero” OR “injury-free workplace”) AND (“safety culture” OR “safety strategies” OR “safety programs” OR “organizational safety” OR “leadership in safety”) NOT (“road safety” OR “transport safety” OR “road transport safety” OR “traffic safety” OR “safety on the road”) |

| Reference | Practical Application | Cultural Transition Assessment | Clear Success Indicators | Comparison with Other Models | Cultural and Political Impact | Methodology |

|---|---|---|---|---|---|---|

| Chandler, E. et al. (2016) [27] | Yes | Comprehensive | Yes | Yes | High | Applied methodologies with practical relevance |

| Akintola, A. et al. (2016) [28] | Yes | Not applicable | No | Yes | Low | Applied methodologies with practical relevance |

| Egbeocha, J.O. et al. (2015) [30] | Yes | Moderate | Yes | Partial | Medium | Intervention study |

| Molyneux, J. (2018) [31] | Yes | Moderate | Partial | No | Medium | Practical case study |

| Jain, A. et al. (2018) [29] | Yes | Comprehensive | Yes | Yes | High | Mixed-method case study |

| Mazur, A. (2015) [32] | Yes | Moderate | Yes | Yes | High | Audits and Lean approach |

| Sudarsan, J.S. and Nithiyanantham, S. (2021) [33] | Yes | Basic | No | Partial | Medium | Direct intervention |

| Häkkinen, K. (2015) [34] | Yes | Not applicable | No | Yes | Low | Applied methodologies with practical relevance |

| Franceschini, L. et al. (2019) [35] | Yes | Moderate | Partial | Yes | Medium–High | Qualitative study with strategic analysis |

| Nguyen, N. et al. (2021) [36] | Yes | Moderate | Partial | No | Medium | Mixed-method study with regional focus |

| Hethmon, T. (2018) [37] | Yes | Moderate | Partial | Yes | Medium | Normative case study |

| Source | 5.1. Differences Between ZAV and ZAC | 5.2. Near-Miss Reporting | 5.3. Safety Excellence | 5.4. Values, Goals, and Realism | 5.5. Roles, Leadership, and Commitment | 5.6. Measurement & Assessment | 5.7. Conceptual Clarity | 5.8. Technical Competence |

|---|---|---|---|---|---|---|---|---|

| WHO/ILO Global Monitoring Report [40] | Does not address ZAV/ZAC; focuses on global quantification of risks and burdens. Gap in cultural dimension. | Does not mention near misses; concentrates on mortality and exposures. Preventive gap. | Provides global metrics as strategic baseline, but without detailing corporate strategies. | Links safety with SDG 8.8; lacks concreteness in organizational goals. | Emphasizes public policies and national systems, not direct corporate leadership. | Strong contribution: robust methodology, disaggregated by sex, age, and region. | Defines risk–outcome pairs with high consistency; limited by missing data for certain risks. | Does not address workforce competence; highlights need for national statistical capacities. |

| WHO/ILO Technical Report [41] | Does not address cultural vision, methodological focus. Gap in ZAV→ZAC transition. | Does not include near misses; focused on exposures and diseases. | Provides inputs for prevention plans; does not discuss corporate strategic excellence. | Linked to SDG 8.8; no explicit focus on realistic corporate goals. | Highlights institutional alliances (WHO/ILO); does not address organizational leadership. | Large database, microsimulation, systematic reviews; global standard for measurement. | Transparent methodology; limited in occupational and sectoral disaggregation. | Emphasizes need for statistical and methodological expertise rather than operational skills. |

| Pega et al. [42] | Does not mention ZAV/ZAC; shows impact of long hours, integrating chronic risks into “zero accident” goals. | Focuses on medical outcomes (IHD, stroke); does not address near misses. | Demonstrates that long hours deteriorate health; calls for excellence policies regulating work time. | Notes unrealistic goals when excessive hours are ignored; links prevention with labor justice. | Recommendation of working time regulations and enforcement; require leadership. | Uses systematic reviews and surveys; defines ≥55 h/week as occupational risk. | Provides clear criteria for causality; acknowledges methodological limitations. | Reinforces need for expertise in policy design and occupational epidemiology. |

| Hulshof et al. [43] | Does not discuss ZAV/ZAC; high prevalence of ergonomic risks shows insufficiency of vision without sustained safety culture. | Does not analyze near misses; highlights need to integrate them in ergonomics. | Recommends including ergonomic management in safety excellence strategies. | Limited global representativeness; challenge for universal goals and values. | Highlights WHO/ILO and expert roles; without institutional commitment risks remain underrated. | Limitations in self-reports; calls for more objective ergonomic metrics. | Recognizes bias and indirectness; initial framework to include MSD in global burden. | Highlights need for skills in ergonomic measurement and occupational epidemiology. |

| ILO Quick Guide [44] | Does not address ZAV/ZAC; stresses comparable statistics as basis for policies. | The warning about the lack of information suggests integrating near misses into the indicators. | Recommends reliable data to prioritize preventive strategies by sector/occupation. | Links statistics with SDG 8.8; calls for contextual interpretation at national level. | Requires inter-institutional cooperation; leadership critical in data and management. | Core: data quality, comparability, time series, disaggregation. | Calls for coherent indicator frameworks and joint interpretation. | Emphasize statistical, sampling, and harmonization competencies. |

| Dong et al. [45] | Demonstrates that ZAV is insufficient without ZAC: without PFAS use culture, zero falls is unattainable. | Focuses on fatalities, not nearly misses; near-miss data could have anticipated failures. | Reinforces need for effective technical measures: PFAS availability and use. | Shows that zero accident goals are unrealistic without real access to fall protection. | Highlights shared responsibility: leaders, workers, and regulators. | Provides detailed data on falls and PFAS use, useful for performance evaluation. | Defines clear analysis criteria; conceptual consistency applicable to construction. | Demonstrates need for technical skills in PFAS installation, use, and supervision. |

| Study | ZAV vs. ZAC | Near-Miss Reporting | Safety Excellence as Strategy | Values & Strategic Realism | Leadership & Commitment | Performance Measurement | Conceptual Clarity | Technical Competence |

|---|---|---|---|---|---|---|---|---|

| Chandler, E. et al. [27] | Differentiates vision vs. culture in PSM adoption | Incident learning systems | Frames excellence via structured PSM pillars | Regulatory vs. practical balance | Managerial support critical | KPIs for compliance & learning | Defines PSM as systemic | Strong process safety base |

| Akintola, A. et al. [28] | Implicit ZAC through harmonized practices | Reporting barriers in construction | Excellence via standardized procedures | Practical feasibility vs. ideals | Site managers’ leadership central | Audits & checklists | Simplifies models for practice | Focus on site hazards |

| Jain, A. et al. [29] | Sustaining ZAV across workforce demographics | Near-miss vital for cultural adaptation | Excellence via long-term reinforcement | Adapts to workforce diversity | Leaders shape cultural transfer | Metrics adapted to turnover | Clarifies “Goal Zero” | Competence = demographic-tailored training |

| Egbeocha, J.O. et al. [30] | Critiques Zero Harm vs. fatality precursors | Skepticism on minor injury stats | Strategy = fatality root cause focus | Emphasizes realistic, site-specific goals | Managerial alignment crucial | Tracks precursors, not frequency | Questions about Bird’s Pyramid | Behavioral influence prioritized |

| Molyneux, J. [31] | ZAV integrated into mainstream business | Implied via integrated reporting | Excellence = embedding HSW in core | Strong CSR/value alignment | Leadership drives embedding | Integrated indicators | Systemic conceptual model | Technical competence secondary |

| Mazur, A. [32] | Aligns ZAV/ZAC with excellent standards | Incident registration as input | OHS excellence linked to TQM | Realism via continuous improvement | Leadership as EFQM enabler | Balanced scorecards & audits | Clarifies OHS-MS/EFQM links | Technical rigor in OHS-MS |

| Sudarsan, J.S. & Nithiyanantham, S. [33] | ZAC aligned via expert consensus | Highlights under-reporting | Excellence = optimized safety culture | Realism in developing economy | Managerial priority essential | Suggests quantifiable indices | Clarifies safety constructs | Technical insights from expert survey |

| Häkkinen, K. [34] | Moves from basic safety to ZAV/ZAC integration | Stresses near-miss systems | Excellence = proactive safety maturity | Strategic realism emphasized | Leaders as cultural drivers | Uses leading indicators | Conceptual model of maturity | Technical detail in system design |

| Franceschini, L. et al. [35] | Promotes shared ZAV commitment | Pact requires open reporting | Excellence via collective agreements | Embeds shared values | Collective & visible leadership | Joint monitoring mechanisms | Pact clarifies cultural meaning | Technical detail less emphasized |

| Nguyen, N. et al. [36] | Applies ZAV via ISSA 7 Golden Rules | Near-miss reporting integrated in Rule 2 | Excellence = embedding Golden Rules | Realism through national adaptation | Leadership central in Rules 1 & 7 | Rule 3: targets & metrics | Rules clarify scope of ZAV | Competence via Rule 6 (training) |

| Hethmon, T. [37] | Explores realism of Zero Harm ambition | Warns of under-reporting risk | Strategy = integrated systems, culture, leadership | Stresses realistic definitions of harm | Leadership as culture driver | Differentiates injuries vs. illnesses | Clarifies scope of “harm” | Technical competence in mining systems |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blanco-Juárez, J.; Buele, J. Industrial Safety Strategies Supporting the Zero Accident Vision in High-Risk Organizations: A Scoping Review. Safety 2025, 11, 101. https://doi.org/10.3390/safety11040101

Blanco-Juárez J, Buele J. Industrial Safety Strategies Supporting the Zero Accident Vision in High-Risk Organizations: A Scoping Review. Safety. 2025; 11(4):101. https://doi.org/10.3390/safety11040101

Chicago/Turabian StyleBlanco-Juárez, Jesús, and Jorge Buele. 2025. "Industrial Safety Strategies Supporting the Zero Accident Vision in High-Risk Organizations: A Scoping Review" Safety 11, no. 4: 101. https://doi.org/10.3390/safety11040101

APA StyleBlanco-Juárez, J., & Buele, J. (2025). Industrial Safety Strategies Supporting the Zero Accident Vision in High-Risk Organizations: A Scoping Review. Safety, 11(4), 101. https://doi.org/10.3390/safety11040101