Abstract

This article discusses the possibilities and methods for rescuing people from abandoned mine workings and the cooperation of the components of the Integrated Rescue System of the Slovak Republic when carrying out rescue work in underground spaces, specifically the Bankov mine. Additionally, the basic legislative restrictions on the level of rescue work that can be performed in underground spaces in Slovakia and abroad are characterized. In the study itself, exercises in a mining environment were designed and tested by rescuers from the fire and rescue corps of the Slovak Republic, while several methods for rescuing people from underground spaces using climbing equipment were tested. Since the research setting was an abandoned mine, the rescue methods were carried out with regard to the maximum achievable safety of the firefighters. With the demise of the Mine Rescue Service in the Slovak Republic in 2025, rescue activities passed into the hands of the fire and rescue corps, and it is therefore necessary to determine the best method for rescue from mining spaces that can be performed by firefighters when the priority is the rescue time: the most important factor for saving human life. Using the analysis of the data obtained in this study, the most effective method specifically for rescuing people from underground spaces was determined. Based on the information obtained, proposals and measures were established to make rescue work in underground spaces more efficient. The research met all standards set for firefighters, and all rescuers agreed to publish this research.

1. Introduction

Increasing security is an essential part of improving the standard of living in our society. Therefore, various institutions should be as interested as possible in reducing the risks of extraordinary events that can have a negative impact on their operation and security [1].

A specific case is mining works, which, in most cases in the Slovak Republic, are a relic from the last century. However, the consequences of mining activities remain and due to the negative financial efficiency, it is increasingly difficult for the owners of the aforementioned mines to secure old mine workings. These abandoned mine workings sometimes become the target of adrenaline enthusiasts who participate in “urbex” (urban exploration) [2,3].

Unauthorized persons in underground spaces have an increased risk of injury, becoming lost, becoming stuck, suffocating, or succumbing to other threats to life and health. In such cases, rescue activities are carried out. According to the original legislative framework, these activities were the responsibility of the Mining Rescue Service; however, due to a change in legislation, the aforementioned rescue service has been abolished in the territory of the Slovak Republic, and all rescue activities have been transferred to the fire and rescue corps. Since firefighters have not yet encountered the aforementioned rescue methods during their work since the demise of the Mining Rescue Service, it is necessary to define the best method for the aforementioned type of rescue and extraction from the aforementioned mining works [3,4,5,6].

1.1. History of the Bankov Mine

The history of magnesite mining in the vicinity of Košice (Slovak Republic) dates back to the 19th century, and there is a significant magnesite deposit in the city of Košice, located in the north of the Košice Region, in the current recreational area of Bankov, which can be classified as part of the Ochtín Formation. The structure of the deposit is in a zone of clastics, euryptives, and carbonate rocks and is tectonically composed of several deposit parts, namely, the calcareous type of magnesite, the siliceous type of magnesite, and bedrock built up of bench-shaped limestones, chloritic slates, and diabases. The overlying layer of the deposit is made up of Neogene rocks of gravel formation, conglomerates, and also graphitic slates [7,8,9].

Since the beginning of magnesite mining in the northern area of Košice, several mining companies have succeeded each other. The first was the German–Hungarian Magnesite Joint Stock Company, which, in 1910, began construction of a plant located on the Hornád River. In the interwar period, the company was bought by Dr. Weiser and Bayern, who founded a joint stock company named Herkulesové závody. At that time, the central location was also rented by the Austrian company Veitscher, which later merged with the company Západočeské továrni. This subsequently resulted in the merger of Západočeské továrni with Spojená Gemerská magnezitka and, later, Herkulesové závody in 1928. In the period after World War II, production began to expand, and a new plant was established, which caused the cessation of mining in the old plant. In 1967, the transition to underground mining took place, which was carried out on the following eight horizons:

- Horizon I—275 m above sea level: open chamber, divided into K110, K111, K131, K141, and K142 (part of the chambers is currently inaccessible due to collapse).

- Horizon II—245 m above sea level: the Banisko deposit section has two chambers, K231 and K232, which were liquidated, and the Bankov deposit section has chambers K262, K263, K268, K271, and K275, which were also all liquidated.

- Horizon III—200 m above sea level: the Banisko deposit section has chambers K339-K342 and K344, and the Bankov deposit section has chambers K339-K375. Only chamber K344 has been preserved.

- Horizon IV—150 m a.s.l.: the Banisko deposit has chambers K439-K443, with chamber K439 being mined and the others partially mined, and the Bankov deposit has chambers K468-K475, where chambers K464 and K465 were partially prepared for mining, but mining did not take place.

- Horizon V—100 m above sea level: in the Bankov deposit section, chambers K568-K575 were established, with mining only in chambers K571-K575 and chamber K573 being liquidated.

- Horizon VI—50 m a.s.l.: mining was carried out only in the Medvedza deposit using outcrop mining at sites V601-V602.

- Horizon VII—0 m a.s.l.: during the excavation of the pit east from the level of Horizon IV to the level of Horizon VIII, stops were driven out for the impact point of Horizon VII, which was ultimately not excavated.

- Horizon VIII—50 m a.s.l.: a pumping station was created here, and water corridors were set up. Due to the completion of mining, preparations for mining in this horizon were also completed [10,11,12,13].

1.2. Risks in Mining and Underground Areas

There are general risks that characterize any type of underground space, but some risks are also associated with the operation of technological equipment in mines. Despite the fact that entry of unauthorized persons into inaccessible mining or underground spaces is generally prohibited, many cases have been recorded in which such entries have occurred, with people entering such areas either out of curiosity and/or seeking an extreme experience or for enrichment through theft of the material stored in old mining or underground works [14,15,16].

The risks and hazards can be defined as follows, according to the scientific literature:

- (a)

- Accidents, injuries, and traumas: most often, these complications occur due to a lack of experience, insufficient equipment, and overestimation of the abilities of persons entering such premises. Even apparently minor injuries and accidents can be life-threatening due to other factors affecting the injured person. The impossibility of independent evacuation from the premises often means a complex and time-consuming rescue operation is required [17,18].

- (b)

- Falling objects: falling objects are also a cause of light and heavy injuries. In mining areas, these might include stones of different sizes, weights, and shapes or objects such as metal evacuation and access ladders or structures, which might be heavily corroded, have reduced load-bearing capacity, or have come loose from their support points, all of which can endanger life and health [19,20].

- (c)

- Entrapment: entering confined spaces can be fatal because, once a person is trapped in such a narrow and inaccessible space, it is very difficult to free them. Due to the nature of entrapment in these spaces, it is also almost impossible for the trapped person to call for help [21].

- (d)

- Loss of orientation: especially in large underground works, becoming lost and losing orientation are difficulties not only for the lost person but also for the rescue services that carry out the survey and search for the person. Even an experienced person can have problems with orientation in large underground works, especially if the access roads are poorly marked or not marked at all [22,23,24].

- (e)

- Falls: falls are a relatively common type of accident in underground spaces, especially if there are unsecured, difficult-to-see vertical shafts, sinkholes, etc. [25].

- (f)

- Floods and flood areas: in some underground spaces, sudden rainfall can cause flooding of access roads and the trapping of a person/people underground. In this situation, the danger arises not only from drowning but also from hypoxia, hypothermia, or exhaustion, with the person being unable to leave the flooded space and reach safety due to several factors [26,27,28].

- (g)

- Discharge of batteries in lamps (the lack of spare batteries in lamps, or their discharge or sudden failure, without the possibility of using a backup light source): moving in an underground space without adequate lighting leads to immediate loss of orientation, to an increased risk of injury, tripping, and falling, and, ultimately, to complete exhaustion [29].

- (h)

- Hypothermia: humidity, wind flow, and cold are factors that adversely affect the body temperature of a person trapped in an underground space. Hypothermia is one of the main life-threatening factors for injured people in general [30].

- (i)

- Air: dangerous chemicals and their concentrations in the air of underground spaces can be very dangerous, especially if they are colorless, odorless gases such as CO or CO2, the concentration of which can be significantly increased in underground spaces [31,32].

- (j)

- Communication: this mainly concerns communication with people underground. In the event of a person becoming lost or injured, it is impossible for them to call for help from underground due to the lack of a signal to connect to the emergency call line. Also, communication inside such spaces is only possible via voice or visual means [33].

2. Materials and Methods

The main part of the presented research comprises the method of a specific experiment involving rescuing an injured person from an underground mine space using climbing equipment performed by members of the fire and rescue service of the Slovak Republic. When conducting the research and the rescue itself, specific parameters were measured, such as the time to reach the firefighters who would perform the rescue, the time to survey and assess the situation, the time to reach the injured person and make contact with them, and, ultimately, the time to rescue the person. As can be seen, the priority was time, the most important parameter in rescues, and it was mainly used to determine the most efficient rescue method in the specified space for the purpose of drafting methodological guidelines for the fire and rescue service.

Three different rescue methods using climbing techniques were examined under the same testing conditions. First, risks and threats to responding firefighters were identified. Then, during the rescue itself, concentrations of life-threatening gases were measured using Dräger personal meters. In addition, humidity, temperature, and wind speed were also measured with an anemometer. The studied rescue methods are currently used for rescue by the fire and rescue service of the Slovak Republic on the surface, but, due to the aforementioned change in legislation, it is now necessary to create a methodology for rescue from underground spaces.

The possibilities of using the forces and resources of the fire and rescue corps and the possibility of using special technical and technological means, which the fire and rescue corps possesses, have also been analyzed. Subsequently, comparison and evaluation were used to assess the research findings, and the results were also analyzed by means of an experiment comparing them with the standard procedure with respect to the applicable legislative standards and methodological procedures. Several evaluation criteria were empirically selected for the evaluation of the individual methods based on the experience of the intervention commanders and the commanders of the climbing groups. The calculation method for determining the most effective rescue method involved a combination of point evaluation based on the measured results and weight evaluation by the evaluation criteria. In determining the weight of the individual criteria, paired evaluation using Fuller’s triangle was utilized.

2.1. The Theme and Scenario of the Rescue Performed

The scenario comprises the rescue of a person (maintenance employee) who fell during a normal premises inspection of a mining site and is stuck in part of a vertical ventilation shaft. They have suffered injuries to the lower limbs (open fracture of the femur), pelvic injury, injury to the spine, and multiple head injuries but are able to communicate. When counting employees, colleagues notice his absence and alert the emergency line.

Despite the physiological indicators, anatomical injuries, and injury mechanism, the injured person remains positive. Despite their safety training, employees move without warning around the space where mining activities are carried out, where some injuries may of course occur. The rescue activities intended to save a person were designed during the normal daily operations of the fire and rescue corps, which take place from 7:00 to 16:00 [34].

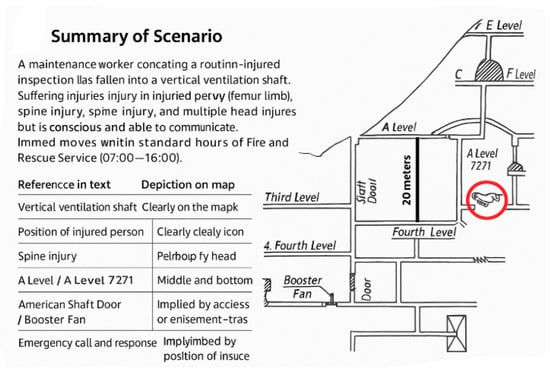

Figure 1 shows a drawing of the position of the injured person and the location of the emergency.

Figure 1.

Sketch of the emergency scene (source: elaborated by authors).

The simulated scenario involves the rescue of a maintenance employee who, during a scheduled inspection of the vertical ventilation shaft, slipped and fell to a position partway down the shaft. The injured person fell down to rest on a sloped ledge located 20 m vertically below the shaft’s top portal and 4 m laterally from the central axis, adjacent to the junction with an abandoned lateral inspection drift. The ledge is inclined at approximately 25°, covered with loose debris, and bordered on one side by the remains of a corroded ladder segment in a partially collapsed condition.

From the victim’s location:

- The vertical distance to the nearest intact landing above is approximately 12 m.

- The vertical distance to the bottom of the shaft is approximately 72 m.

- The horizontal distance from the victim to the drift wall is 1.2 m.

- The shaft diameter at this depth is 7.1 m, consistent with the upper section but narrowing below.

- The shaft has several slope changes, with a slight deviation towards the northeast at ~35 m depth, creating a partial overhang above the victim’s position. This overhang restricts direct vertical access and increases the likelihood of rock or debris dislodgement during rope operations.

The hazards at the site include the deteriorated ladder structure, unstable rock fragments above the victim, and the risk of further collapse of the inspection drift wall. The victim’s injuries include an open fracture of the femur, pelvic trauma, spinal injury, and multiple head contusions. Despite these, the individual remains conscious and communicative, although experiencing hypothermia due to the ambient temperature of 3.9 °C and wind gusts up to 13.2 km/h recorded at the shaft mouth.

The rescue was staged during normal working hours of the fire and rescue corps (07:00–16:00). The access route to the shaft portal is via the surface crater, leading to the secured entrance of Horizon VI and the portal to the ventilation shaft. Figure 1 presents the full layout, including the vertical and horizontal dimensions, reference points, and the exact location of the victim relative to the shaft’s top portal, intact platforms, and shaft bottom. These details are critical for justifying the rescue method selection, calculating access times, and assessing operational risks.

2.2. Characteristics of the Space

The space in the scenario is a vertical ventilation shaft that is about 7 m wide and about 100–150 m deep, to which the outlets of horizontal shafts are directed. The vertical shaft has a slope in certain places where a person may become stuck in the event of a fall and has an evacuation ladder with stair landings, which is in an emergency state and cannot possibly be used. These aspects complicate the intervention because of the potential for collapse and more complex access to the injured person. The shaft can be accessed from the crater that remained after the surface mining. There is an entrance to Horizon VI in the crater, which is currently secured against the entry of unauthorized persons (by a heap of clay and stones overlying the concrete plate), and, behind it, is a portal for entrance to the vertical ventilation shaft (shown in Figure 2).

Figure 2.

Entry to the vertical shaft square area (source: elaborated by authors).

After entering the portal, it is possible to reach a walled entrance area where there is an integrated hole in the door with a free accessory door and, behind it, a small area of approximately 25 m2 with unpaved stairs and a slope towards the shaft. The entrance portal to the vertical shaft is bounded on the side by an iron railing in an emergency state.

This space is shown in Figure 3.

Figure 3.

The surface with a railing bounding the vertical shaft (source: elaborated by authors).

Behind the ventilation shaft, there is another horizontal shaft, to which there is access from the right side of the entrance. However, access to this horizontal shaft is not protected by a railing, and there is a risk of overcoming the ventilation shaft when overcoming this length (Figure 4).

Figure 4.

View of the vertical ventilation shaft in which the evacuation ladder in an emergency state is integrated (source: elaborated by authors).

2.3. Meteorological Conditions at the Scene of the Event

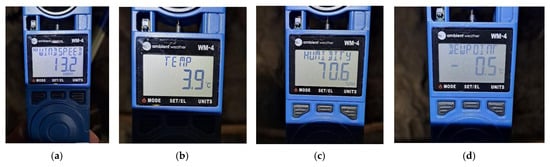

On the days when the climbing group exercised in the Bankov mine, weather changes and meteorological conditions were minimal. Factors that could affect the effectiveness of the intervention, both for the intervening firefighters and for the injured person, were measured on-site. Wind speed, air humidity, temperature, and the dew point were measured. The measurement of these values was performed using the Ambient Weather WM-4, which is part of the equipment of the fire and rescue corps.

The Ambient Weather WM-4 is a comprehensive handheld wind meter, directional compass, comfort index monitor, and psychrometer, all in one compact, portable, rugged package [35]. It measures wind speed, wind direction, temperature, relative humidity, and compass direction and calculates the wind gust, dew point, wet bulb and dry bulb temperature, Delta T, wind chill, and comfort index [36].

The measured values are shown in Figure 5, where Figure 5a is the maximum speed of the pudding wind in the ventilation shaft, Figure 5b is the temperature in the ventilation shaft, Figure 5c is the humidity in the ventilation shaft, and Figure 5d is the dew point in the ventilation shaft.

Figure 5.

(a) Maximum speed of the pudding wind in the ventilation shaft, (b) temperature in the ventilation shaft, (c) humidity in the ventilation shaft, (d) dew point in the ventilation shaft (source: elaborated by authors).

Figure 5 shows that the conditions at the scene were not extreme, especially in terms of air temperature and humidity, but the wind speed, which reached a maximum of 13.2 km/h, was a complicating factor. The temperature at the site of the incident was 3.9 °C, the humidity was 70.6%, and the dew point was −0.5 °C.

All these conditions are particularly dangerous for an injured person, who, as a result of their injuries, would lose a significant amount of heat through evaporation, which would deepen hypothermia. In this case, it is necessary to provide thermal comfort for the injured person as soon as possible in order to at least partially prevent the development of the so-called “lethal diamond”, where hypothermia, disseminated intravascular coagulopathy, and developing acidosis and hypocalcemia are just some of the complications [37].

The effect of wind on an injured person during rescue operations is an often underestimated but significant factor that can significantly affect the course of the rescue and the condition of the injured person. Strong or cold wind accelerates body heat loss, thereby increasing the risk of hypothermia, especially in injuries associated with blood loss, immobility, or wet clothing. Research in the field of thermoregulation has shown that windy conditions can reduce the effective skin temperature by up to several degrees Celsius, dramatically shortening the time required for the development of hypothermic symptoms. In addition to having physiological consequences, wind also affects communication between rescuers, the stability of climbing and aerial systems, and the effectiveness of protective equipment. In difficult terrain conditions, it is therefore essential to take wind speed and direction into account when planning and executing a rescue, including quickly wrapping the injured person in thermal insulation materials and protecting them from further cooling [38,39].

2.4. Hazardous Substances in the Air

When rescuing people from abandoned mine areas using climbing equipment, the presence of hazardous substances in the air is a significant problem. These substances can be the result of chemical leaks, putrefactive processes, insufficient ventilation, or previous industrial activity, and their identification is often challenging, as the areas are often difficult to access, and air monitoring is limited. The presence of toxic gases such as carbon monoxide, hydrogen sulfide, or volatile organic compounds can endanger not only the person being rescued but also the rescuers. When using climbing equipment, the risk increases due to limited mobility and the time required for the intervention [40,41,42].

The equipment of the fire and rescue service was also used to measure the concentrations of dangerous gases at the scene that could endanger the firefighters. We focused mainly on the values of carbon monoxide, carbon dioxide, and sulfur, as well as their lower explosion limits. The values that had to be observed were, of course, also the values of air oxygen.

The listed values were measured with the MAB3-0EC1123-021 MultiRAE Lite Pumped Portable Multi-gas Monitor, the optimal one-to-six gas monitor for personal protection and leak detection applications. The manufacturer of the MAB3-0EC1123-021 MultiRAE Lite Pumped Portable Multi-gas Monitor is RAE Systems, Inc. (a Honeywell brand), and city: San Jose, California, country of origin: United States of America. The MultiRAE Lite is available in pumped and diffusion versions and features the broadest selection of sensor options in its class. It can be configured to exactly meet the detection needs and compliance requirements of various countries, industries, and applications, and its optional wireless capability improves safety by providing commanders and safety officers with real-time access to instrument readings and alarm statuses from any location for better situational awareness and faster incident response [43,44].

Figure 6 shows the measured values of hazardous gases. No increased concentrations of CO, CO2, or H2S were measured in the area. The air oxygenation value was at the level of 20.9%, which means that the area was sufficiently ventilated, with no hazardous substances in the air, which ensured that the rescuers did not have to use autonomous breathing apparatus during the rescue. However, the wind speed at its maximum reached more than 13.2 km/h, which could swirl up mining dust. Its macroscopic particles could be inhaled by the officers during the intervention without protection for the upper respiratory tract, and this could cause later health complications.

Figure 6.

Measured values of hazardous gases in the ventilation shaft (source: elaborated by authors).

2.5. Access Options to the Event Location

Access to the scene from the fire station in Košice is mostly via paved access roads, which are shown in Figure 6. There are several access options, but Figure 7 shows the shortest possible route. In some places on the access road, there are problem points at the transition from a paved asphalt road to an unpaved forest road approximately 3 m in width. Figure 7 shows the unpaved access road that runs along the perimeter of the crater left after surface mining to its bottom. Here, there is access to Horizon VI and the portal to the ventilation shaft where the person was to be rescued. In some sections, the slope of the access road is greater than 10%, and since it is an unpaved forest road, the access is not suitable for heavy rescue vehicles. For this reason, the following vehicles were used: a Nissan Navara (manufacturer: Nissan Motor Corporation, country: Japan, city: Yokohama), Polaris Ranger XP 900 quad bikes and Polaris Ranger XP 800 six-wheelers (manufacturer: Polaris Inc., country: United States, city: Medina, Minessota). The aforementioned fire trucks were purchased by the Ministry of the Interior of the Slovak Republic.

Figure 7.

Illustration of the shortest possible route along paved roads from the Košice Požiarnická fire station (source: elaborated by authors).

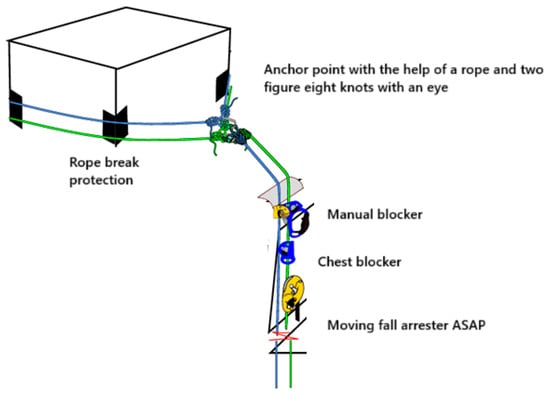

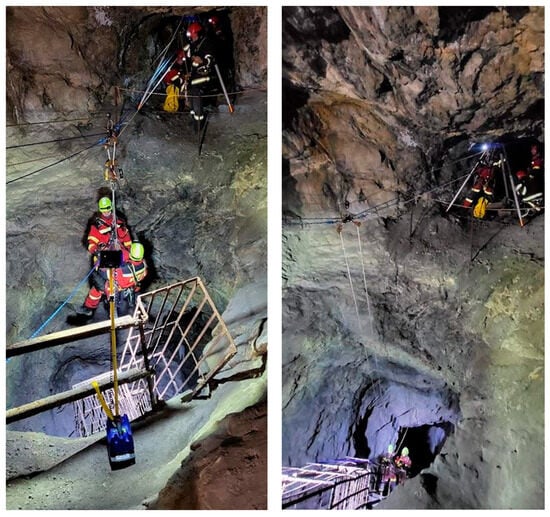

2.6. Rescue Method Using a Simple Cableway

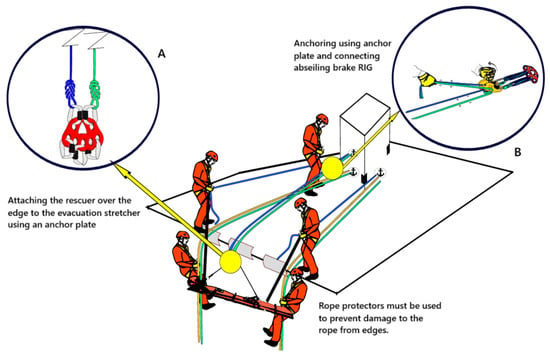

This method is based on the creation of a simple ropeway leading over the edge using a double rope technique. After creating an anchor point and preparing a reconnaissance group of climbers, reconnaissance and rapid assessment of the situation are carried out, and the basic actions required to stabilize the person’s health and determine the possibility of rescue based on the available number of rescuers, resources, and time urgency, calculated according to the person’s health, are performed (Figure 8) [45,46,47,48].

Figure 8.

Graphical representation of anchor anchoring and bridging the edge of the ventilation shaft (source: elaborated by authors).

The procedure for the rescue operation using a simple cableway was as follows:

- -

- The fire brigade arrives at the scene, and a quick survey and evaluation of the situation are performed by the commander of the intervention.

- -

- The climbers are prepared, and anchoring points and a cableway are created, as shown in Figure 8. Subsequently, a means to arrest falling is connected to the safety rope and to the working rope connection, which allows for subsequent control of functionality.

- -

- After reaching the edge when descending using ascenders, the rescuer proceeds in such a way that the chest block is as close to the edge as possible.

- -

- The rescuer inserts the rope into the rappel device under the chest block.

- -

- The chest block is then unfastened (by standing in the climbing harness), and the rope is pulled into the rappel device.

- -

- After stepping into the rappel device, the rescuer places the hand block with the climbing harness (without a personal positioning loop) behind the edge in the direction of descent and adjusts its length.

- -

- Then, after standing in the climbing harness, pulling on the hand block, and pulling the rope into the rappel device, the rescuer safely climbs over the edge.

- -

- Upon reaching the injured person, a rapid assessment of health is performed and the method of rescue is determined—in this case, pulling out the injured person in a stretcher using a simple cableway tracking over the edge of the ventilation shaft.

- -

- Meanwhile, additional climbers, transport stretchers, and fixatives are prepared, and the climber is connected to the entire string to connect the evacuation stretcher.

- -

- A third climber is clipped together with the evacuation stretcher to the injured person, and the immobilization and loading of the injured person into the stretcher begin.

- -

- Subsequently, using the pulley system, the injured person and climbers begin to pull out. In this case, it is necessary to provide other firefighters for roping to pull out the stretcher with the injured person and the climbers.

- -

- The stretcher is transferred over the edge as shown in Figure 9 (utilizing at least two rescuers below the edge, two rescuers above the edge, and one rescuer to ensure the strengthening of the stretcher using the anchoring point).

Figure 9. Graphical representation of the passage over the edge with evacuation stretcher from the ventilation shaft area ((A)—representation of the anchoring plate to which the evacuation stretcher is connected, (B)—representation of the plates for connecting the stretcher) (source: elaborated by authors).

Figure 9. Graphical representation of the passage over the edge with evacuation stretcher from the ventilation shaft area ((A)—representation of the anchoring plate to which the evacuation stretcher is connected, (B)—representation of the plates for connecting the stretcher) (source: elaborated by authors). - -

- After pulling them into a safe space, firefighters disconnect the injured person from the chain of evacuation stretcher connection and transport them to the ambulance of the firefighting team [45,46,47,48].

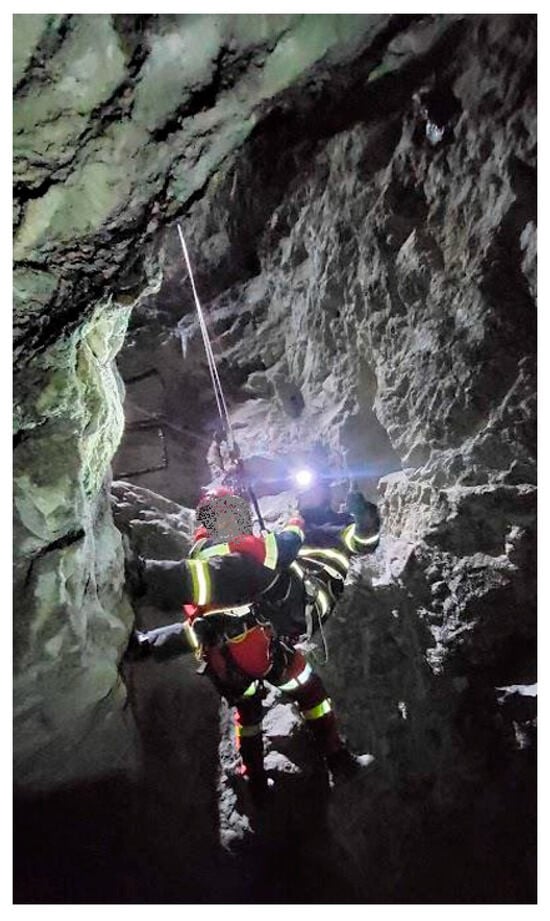

Figure 10 shows the survey conducted using a simple cableway.

Figure 10.

Survey performed by an exploratory group using a simple cableway (source: elaborated by authors).

The advantages of the rescue method using a simple cableway include the following:

- -

- A quick technical development of a climbing group;

- -

- Less demand on the material and technical equipment of the fire brigade;

- -

- Suitability for every first-response fire department in Slovakia [45,46,47,48].

The disadvantages of the rescue method using a simple ropeway include the following:

- -

- Great physical demands on the responding firefighters;

- -

- Discomfort for the rescued person;

- -

- Significant time consumption;

- -

- Significantly extended time spent pulling the person out of the ventilation shaft;

- -

- Risk of damage or failure of technical equipment when it is loaded over the edge of the ventilation shaft;

- -

- Limitation in the direction of pulling out the injured person;

- -

- Significant difficulty in crossing the edge due to the presence of a railing;

- -

- A higher number of firefighters required at the rescue site;

- -

- Increased wear and tear on climbing equipment and their subsequent earlier retirement from use [45,46,47,48].

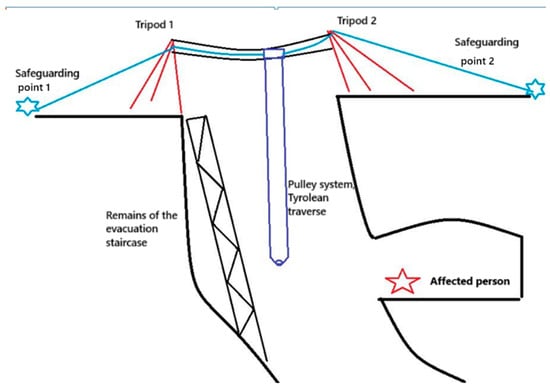

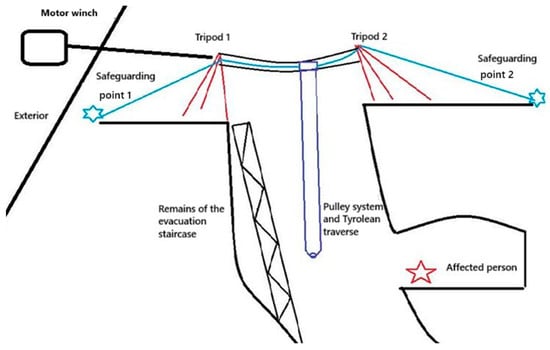

2.7. Rescue Using a Tyrolean Traverse

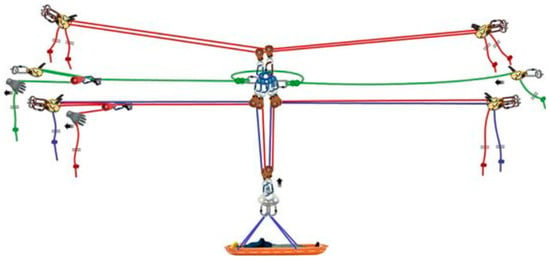

This method is based on handling the load (in this case, an evacuation stretcher) in both vertical and horizontal directions. However, this method of rescue is more time-consuming and requires more anchorages, traverses, tools, and a greater number of climbers to assemble the rope system. After a survey using a simple ropeway was conducted by two climbers and the rescue method was determined to be a Tyrolean traverse, the person could be rescued faster and more safely. Figure 11 shows a diagram of the anchoring and creation of a Tyrolean traverse.

Figure 11.

Diagram of anchoring and creating a Tyrolean traverse (source: elaborated by authors).

Figure 12 shows a diagram of how to create anchor points using two tripods and a Tyrolean traverse.

Figure 12.

Diagram of creating anchor points using two tripods and a Tyrolean traverse (source: elaborated by authors).

The sequence of rescue steps using a Tyrolean traverse is as follows:

- -

- The fire brigade arrives at the scene, and a rapid survey and assessment of the situation are performed by the incident commander.

- -

- Climbers are prepared, and anchor points and ropes are arranged as shown in Figure 13. Subsequently, a device for arresting falls is connected to the safety rope, the rappelling device is connected to the working rope, and a subsequent functionality check is performed.

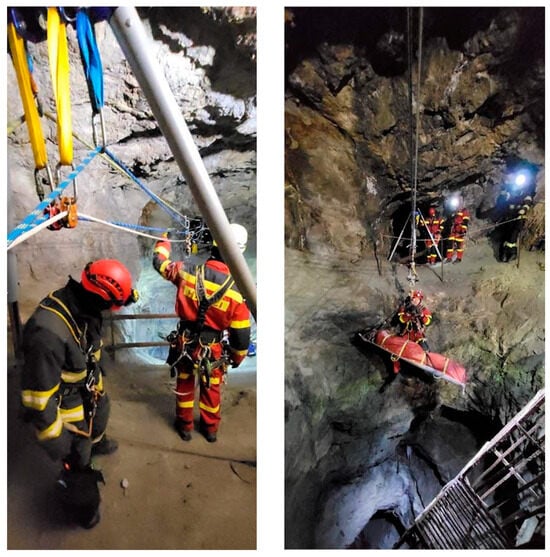

Figure 13. Rappelling to an injured person using a Tyrolean traverse (left) and rappelling to the injured person and immobilization in the ventilation shaft (right) (source: elaborated by authors).

Figure 13. Rappelling to an injured person using a Tyrolean traverse (left) and rappelling to the injured person and immobilization in the ventilation shaft (right) (source: elaborated by authors). - -

- The climbers approach the edge and, after going over the edge, rappel in a controlled manner towards the injured person.

- -

- Upon reaching the injured person, a rapid assessment of their health is performed and the rescue method determined—in this case, pulling the injured person out with a stretcher using a Tyrolean traverse.

- -

- After a rapid initial assessment and determination of the method for freeing the person, the climbing group can already create a Tyrolean traverse during the survey, and it is necessary to install two tripods on opposite sides of the ventilation shaft.

- -

- While the tripods are being set up, other climbers form a rope traverse and evacuation system, to which the evacuation stretcher is connected.

- -

- After the system is anchored, a quick load check is performed, and the stretcher is lowered with a climber to the injured person.

- -

- After reaching the evacuation stretcher, immobilization, and loading of the injured person into the evacuation stretcher and subsequent fixation against falling begin.

- -

- Using the pulley system, the injured person and the climbers begin pulling out. In this case, too, it is necessary to provide additional firefighters to pull the ropes, to pull out the stretcher with the injured person and the climbers.

- -

- Subsequently, after pulling out above the level of the edge of the ventilation shaft, the horizontal evacuation of the injured person is continued via the Tyrolean traverse towards the edge of the vertical shaft and towards a safe area.

- -

- After pulling out to a safe area, the firefighters ensure the disconnection of the injured person from the chain of the evacuation stretcher connection and transport them to the fire rescue service ambulance.

The advantages of the Tyrolean traverse rescue method are as follows:

- -

- Less physical strain for the responding firefighters;

- -

- Greater comfort and less stress for the injured person during transport to the surface;

- -

- Lower risk of secondary injuries to the injured person;

- -

- Lower risk of forces acting on the ropes or rope system (the rope does not go over the sharp edges of the ventilation shaft);

- -

- More space for manipulating the stretcher during the loading of the injured person and also during transport;

- -

- Faster evacuation time for the injured person, without the need to overcome the edge of the ventilation shaft.

The disadvantages of the Tyrolean traverse rescue method are as follows:

- -

- Longer time to create a rope traverse;

- -

- More climbing gear;

- -

- More complex system assembly;

- -

- More climbers needed to assemble the system and operate it.

2.8. Rescue Using a Tyrolean Traverse and Motor Winch

This method is identical to the previous rescue method using a Tyrolean traverse, but instead of the forces required to pull the rope using a hoist and a larger number of firefighters, a motor winch is used. The method of assembling the traverse system and the number of tools used are identical to the previous procedure, but the change in this case is that the rope is wound with the injured person.

This method significantly reduces the efforts of the responding firefighters, requires a smaller number of firefighters at the scene of the intervention, and also requires a shorter time to rescue the person.

After a survey using a simple ropeway is conducted by two climbers and the rescue method determined to be a Tyrolean traverse, the person could be rescued faster, more comfortably, and more effectively by the responding firefighters.

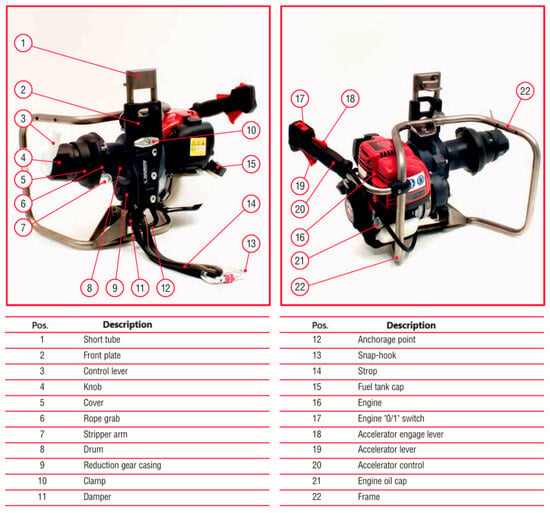

Figure 14 shows a motor winch used by the Harken fire and rescue department.

Figure 14.

Harken motor winch [49].

Figure 15 shows a diagram of the anchor points created using two tripods and a Tyrolean traverse using a motorized winch.

Figure 15.

Diagram of anchor points created using two tripods and a Tyrolean traverse using a motorized winch (source: elaborated by authors).

The procedure for the rescue operation using the Tyrolean traverse method and a motorized winch is as follows:

- -

- The fire brigade arrives at the scene, and a rapid survey and assessment of the situation are performed by the incident commander.

- -

- Climbers are prepared, and anchor points and ropes are arranged as shown in Figure 16. Subsequently, a device to arrest falls is connected to the safety rope, a rappelling device is connected to the working rope, and a subsequent functionality check is performed.

Figure 16. Assembling the Tyrolean traverse, anchoring using two tripods, connecting the rope to the motor winch (left), and evacuation of a person on a stretcher using the Tyrolean traverse method and a motor winch (right) (source: elaborated by authors).

Figure 16. Assembling the Tyrolean traverse, anchoring using two tripods, connecting the rope to the motor winch (left), and evacuation of a person on a stretcher using the Tyrolean traverse method and a motor winch (right) (source: elaborated by authors). - -

- Climbers approach the edge and, after going over the edge, rappel in a controlled manner toward the injured person.

- -

- Upon reaching the injured person, a rapid assessment of their health condition is performed and the rescue method determined—in this case, pulling the injured person out on a stretcher using a Tyrolean traverse with the use of a motor winch.

- -

- After the rapid initial assessment and determination of the method for freeing the person during the survey, the climbing group can create a Tyrolean traverse, where it is necessary to install two tripods on opposite sides of the ventilation shaft.

- -

- While the tripods are being set up, other climbers form a rope traverse and an evacuation system, to which the evacuation stretcher is attached.

- -

- In the area in front of the shaft, another firefighter prepares a motor winch, and, together with the climbing group preparing the rescue system, they create a rope system.

- -

- Subsequently, after anchoring the system, a quick load check is carried out, and the stretcher is lowered together with a climber to the injured person.

- -

- Once the evacuation stretcher reaches the injured person, the individual is immobilized and loaded into the evacuation stretcher, where they are subsequently secured to prevent falling.

- -

- Using the motor winch, the extraction of the injured person and the climbers is started. In this case, the firefighters are relieved of the physically demanding extraction of the injured person.

- -

- Subsequently, after being pulled above the level of the edge of the ventilation shaft, the horizontal evacuation of the injured person continues via the Tyrolean traverse towards the edge of the vertical shaft and towards a safe area.

- -

- After they are pulled to a safe area, firefighters ensure that the injured person is disconnected from the evacuation stretcher connection chain and transport them to the fire rescue service ambulance vehicle.

The advantages of the Tyrolean traverse rescue method using a motor winch are as follows:

- -

- Much less physical strain for the responding firefighters;

- -

- Greater comfort and less stress for the injured person during the extraction to the surface;

- -

- Less risk of secondary injuries for the injured person;

- -

- Less risk of forces acting on the ropes or rope system (the rope does not go over the sharp edges of the ventilation shaft);

- -

- More space for manipulating the stretcher during the loading of the injured person and also during extraction;

- -

- Faster evacuation of the injured person than in the case without a motor winch (smooth evacuation without stopping), and no need to overcome the edge of the ventilation shaft.

The disadvantages of the Tyrolean traverse rescue method using a motor winch are as follows:

- -

- Longer time to create a rope traverse;

- -

- More climbing equipment and use of longer ropes;

- -

- More complex system assembly;

- -

- The winch can only be used outdoors;

- -

- The winch can only be used at the location of the motor winch.

3. Results

In this chapter, the methods used in rescuing the person from the ventilation shaft of the Bankov mine will be recalculated in terms of time. During the rescue, all three methods described in Chapter 2 were used, and the rescuers had the opportunity to try all methods. A survey conducted by the survey climbing group was required in all scenarios and was always the same as the standard.

3.1. Calculation and Evaluation

The basic calculation of the time from the beginning of the event to its end was performed for all three methods. Specifically, t_event is the time of the event development, and t_survey is the time of the first survey by the climbing group. We then determined this time according to Equation (1) [50,51]:

where

t_event = t_obs + t_report + t_call + t_d1 [min]

t_obs is the time from the expected occurrence of the emergency to the injured person being observed (or being heard screaming for help, etc.), which mainly depends on the circumstances and whether the person is alone or with someone else [min];

t_report is the time from the observation of the event to the alarm being declared to the emergency line, which depends on the telecommunications capabilities in the given area [min];

t_call is the call handling time for the emergency line operator, which depends mainly on the correct localization of the event location [min];

td1 is the time from the alarm to the arrival of the first fire brigade to the scene of the incident (usually the arrival of the first fire brigade is counted) [min].

The arrival time of the first fire brigade is determined according to Equation (2) [50,51]:

where

t_d1 = t_depard + t_drive [min]

t_depard is the departure time of the fire brigade (or other rescue service) [min];

t_drive is the driving time of the fire brigade (or other rescue service) [min].

The fire brigade’s travel time is determined based on Equation (3) [51,52]:

where

t_drive = (60 × L)/vj [min]

L is the distance in km;

vj is the average vehicle speed in kmh−1 (45 kmh−1).

After the unit arrives, reconnaissance is carried out by at least two climbers, i.e., a reconnaissance group. The preparation of the reconnaissance group consists of certain steps, which subsequently determine the reconnaissance time, i.e., t_survey, which is calculated according to Equation (4) [52]:

where

t_survey = t_gear + t_anchor + t_reach1 + t_eval [min]

t_gear is the climbers’ dressing time [min];

t_anchor is the cable car anchoring time [min];

t_reach1 is the time taken by the search team to reach the injured person [min];

t_evalv is the time taken for examination and determination of rescue method [min].

Subsequently, the time course of the intervention of the firefighters and climbers is measured, i.e., the climbing rescue time, according to Equation (5) [53]:

where

t_rescue_total = t_setup + t_survey + t_climb [min]

t_setup is the time to build a ropeway according to the specific rescue method [min];

t_survey is the time taken for exploration by the reconnaissance climbing group [min];

t_climb is the climbing time [min].

“The time of climbing activity” is understood to include all climbing actions from attaching the climber(s) to the rope to evacuating the person to the surface and handing them over to the emergency medical service. This time is determined according to Equation (6) [53]:

where

t_climb = t_reach2 + t_immob + t_load + t_extract [min]

t_reach2 is the time from the next climber connecting to the rope to reaching the injured person [min];

t_immob is the time of immobilization of the injured person [min];

t_load is the time loading the injured person into the transport device [min];

t_extract is the time of the rescue (evacuation) of the injured person [min].

In Table 1, based on calculations and intervention measurements, the event development time is defined according to Equations (1) and (2).

Table 1.

Event development time (source: elaborated by authors).

Table 2 shows the exploration time taken by the exploration climbing group according to Equation (4).

Table 2.

Exploration time taken by the reconnaissance climbing group (source: elaborated by authors).

While the basic survey is being carried out by the survey climbing group, other climbers are building the ropeway, and this time, tvld, includes the actual construction of the ropeway, anchoring, preparing the evacuation equipment, preparing the next climber, and checking or preparing the other equipment.

The measured times for building the cable car were as follows:

Method 1: tvld1 = 5 min;

Method 2: tvld1 = 17 min;

Method 3: tvld1 = 17 min.

The total rescue time was calculated from the arrival of the fire brigade to the evacuation of the person and their transfer to the fire rescue ambulance. Some actions were performed simultaneously because, during the initial survey by the survey climbing group, performed approximately just after reaching the injured person, the leader of the climbing group could determine which method of rescue was appropriate given the situation.

Table 3 shows the times for the individual sections of the climbing rescue action, which result in the climbing activity time for the three different rescue methods.

Table 3.

Calculated climbing activity times according to individual methods (source: elaborated by authors).

As can be observed from Table 3, after adding up the partial times, the most time-efficient climbing activity was achieved by Method 3, i.e., rescuing a person using a Tyrolean traverse and a motorized winch. The second most time-efficient rescue method was the rescue using a Tyrolean traverse without a motorized winch. The longest rescue, according to the climbing activity time, was the rescue using the simple rescue method. Although the time difference between Method 2 and Method 3 is less significant, the need to develop the physical strength of the responding firefighters in rescue Method 2 is much greater, and thus the rescue is more demanding for the responding firefighters.

The total climbing rescue time from the arrival of the fire brigade at the scene of the incident to the rescue of the person was also calculated using three different methods. This time included the time of the first survey performed by the survey climbing group, the time of building the ropeway, and the climbing activity time determined according to the calculations in Table 3. In this case, the first survey and the construction of the ropeway were carried out simultaneously.

Table 4 shows the calculation of the climbing rescue time according to the individual rescue methods.

Table 4.

Calculation of climbing rescue time according to individual rescue methods (source: elaborated by authors).

Table 4 shows that the most time-efficient climbing rescue method was the Tyrolean traverse rescue method using a motorized winch. Conversely, the least time-efficient climbing rescue method was the simple ropeway rescue method.

3.2. Multi-Criteria Evaluation of the Effectiveness of the Methods Used

Based on the results obtained from the rescue of a person from the Bankov mine using climbing activities performed by firefighters, it was necessary to determine which rescue method was the most effective. Several criteria were evaluated:

- -

- Climbing rescue time t_rescue_total [min]—K1;

- -

- Amount of force [number of firefighters]—K2;

- -

- Amount of climbing equipment [number]—K3;

- -

- Difficulty of intervention according to the responders [scale 1–10, with 1 being least difficult and 10 the most difficult]—K4;

- -

- Difficulty of building a ropeway [scale 1–10, with 1 being the least difficult and 10 being the most difficult]—K5;

- -

- Comfort for the rescued person [scale 1–10, with 1 being the least comfortable and 10 being the most comfortable]—K6.

These criteria were chosen because time is the most important factor in the general activities of the fire and rescue service and in rescue situations, and the priority is always saving lives. The amount of technical equipment required has a significant impact on the rescue time and also the number of rescuers. Other criteria are also important for the activity and the rescue itself.

Table 5 shows the determination of parameters according to criteria based on the rescue method used.

Table 5.

Determination of parameters according to criteria based on the rescue method used (source: elaborated by authors).

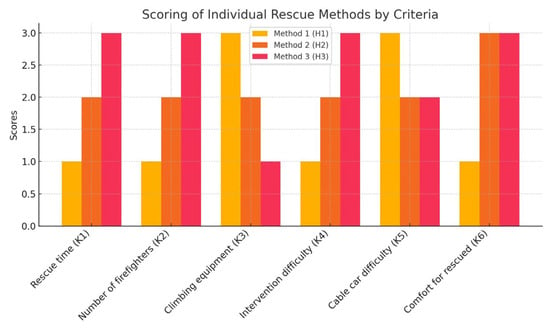

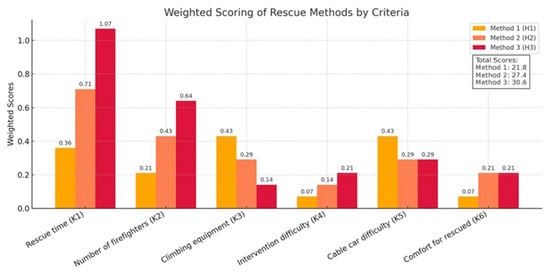

In addition to the above calculations, it is necessary to determine which method was the most effective in this case. Given that the criteria by which the individual rescue methods were evaluated have been determined, these methods were evaluated based on a point rating. The points were determined on a scale of 1–3 points, with 1 point being the least effective and 3 points being the most effective, and all methods were evaluated according to the individual criteria. A point overview of the evaluation of methods according to the criteria is shown in Scheme 1.

Scheme 1.

Scoring of individual rescue methods according to specified criteria (source: elaborated by authors).

Based on the sum of the points obtained by the individual rescue methods, it was found that the most points were obtained by Method 3, i.e., the rescue using a Tyrolean traverse and a motor winch, which received 15 points. The second method received 13 points, and the method using a simple cable car was the least effective, receiving 10 points.

After the selection of the criteria, it is possible to proceed to their evaluation from the point of view of their significance for the decision-maker. To determine criteria preferences, it is possible to determine the weights of the criteria based on pairwise comparison, a method characterized by determining the preferential relations of pairs of criteria. The simplest modification of this method, also called Fuller’s triangle, involves determining the pairwise criterion as the number of its preferences with respect to all other criteria. For each pair of criteria, the decision-maker determines whether they prefer the criterion indicated in the row or the criterion indicated in the column.

However, some criteria are more important when performing an intervention; therefore, the paired evaluation method for the selection of criteria was chosen, on the basis of which the weight of the individual criteria was determined. To determine the weight of the individual criteria, the Fuller triangle was applied, based on which a paired evaluation of the individual criteria was created. The criteria were compared with each other so that each criterion was compared with every other without repetition. In the paired evaluation, the most important of the pair of criteria will always be selected, considering a rescue of a similar type (Table 6).

Table 6.

Fuller’s triangle for selecting and summing more important criteria (source: elaborated by authors).

In Table 6, the victories of individual criteria within the pairwise evaluation are highlighted in gray. According to Table 6, the most victories are achieved by the total rescue time, while the least important criteria are the comfort of the rescued person and the difficulty of the intervention.

Subsequently, according to the number of victories of individual criteria, their weight was determined and was multiplied by the number of points from Table 6 for the specific method. The result is the sum of the values, i.e., the total score for each method according to Equation (7):

where

CSj is the total method score;

Hij is the method score for Mj for criterion Ki;

n is the number of criteria.

Subsequently, the number of times each criterion was more important was determined. Based on the number of wins of the criterion, this number is divided by the total number of wins of the criteria, and the weight of the given criterion is determined according to Equation (8):

where

Wi is the weight of the criterion;

Si is the number of wins of the Ki criterion;

Sj is the number of wins of the criteria Kn.

Scheme 2 shows the overall score for the methods using a normative weighted evaluation according to individual criteria.

Scheme 2.

Evaluation of methods by criteria (K1–K6) (source: elaborated by authors).

Based on the product of the criteria weight and the criteria score of the individual methods and their subsequent sum, the total score of the individual methods was calculated. Method 1 achieved a total score of 1.81, Method 2 achieved 2.39, and Method 3 achieved the highest score of 2.57 terms of overall effectiveness. Therefore, Method 3 (Tyrolean traverse with motor winch) was the most effective, followed by Method 2 (Tyrolean traverse without motor winch), while Method 1 (simple ropeway) was the least effective.

4. Discussion

The issue of rescuing people from difficult-to-access terrain is still a current topic being addressed by many scientific institutions in Slovakia and abroad. Although some threats have been known for many years and the risks of an emergency are reduced by preventive measures, it is not possible to completely eliminate these risks, and these facts are an aggravating factor for emergency response commanders on the scene of an emergency. Although there are many recommended procedures for rescuing people, animals, property, and the environment, each emergency is unique, and the conditions of the intervention are always different. In some cases, the intervention commander cannot even apply the recommended procedures from the method sheets due to their outdatedness or their absence, or due to a specific type of event. This creates a very difficult situation for the incident commander, because, when making decisions, he must take into account the safety of all persons involved in eliminating the consequences of the emergency, as well as the safety of the persons affected by the emergency. He must create conditions for rescuing people as soon as possible using the appropriate material means and by selecting the appropriate work procedures.

Furthermore, the intervention commander must know his options for securing forces and resources, material and technical equipment, and specialists, whether in the field of mountaineering activities, medical activities, or any other specializations suitable for eliminating the consequences of an emergency within the jurisdiction of the fire and rescue service of the Slovak Republic.

The issue of rescuing people in non-functional mine workings is also topical. People often visit them for adrenaline or to enrich themselves by stealing the materials that are still available in the mines. As already mentioned, one of the decisive factors in a rescue operation is time. This factor significantly limits the success and efficiency of resolving an emergency.

Until recently, in Slovakia, rescue activities in closed mine workings have been deployed by the Mine Rescue Service. However, from April 1, 2025, the above activity comes under the responsibility of the fire and rescue service, and it is necessary to identify and devise the most effective methods for rescue in the abovementioned areas.

All three described and tested rescue methods have their specificities, and, on the surface, they are performed routinely. Underground, however, as mentioned, there are specific conditions, and, based on the results, it was determined that the use of the Tyrolean traverse method with a motor drive is currently the most effective for the aforementioned type of rescue.

Other Methods for Rescue from Mining Areas

As determined by Lei Shang et al. (2025), the use of a mine rescue robot is ineffective for fall or slip rescues in deep mines due to the slope and approach [54].

Felix Lehnen’s research describes rescue methods, specifically in the paper “Mine Rescue Management a Concept for Long-Lasting Missions based on Case Study Analysis and Disaster Management Approaches” (2016), which defines rescue case studies. However, climbing techniques are absent from the mentioned case studies [55].

In his research, Moshood Onifade (2021) describes rescue activities carried out by mine rescue teams, but the discussed activities also do not focus on the use of climbing equipment [56].

Numerous studies and global methodologies, such as the Mine Rescue Manual by Chris Enright (2015), and the work of Kowalski-Trakofler et al. (2008), Perry (2003), Saleh (2011), and many others, provide scientific knowledge regarding risks and emergency management in mining areas. This scientific knowledge provides solutions to these disasters in some ways, but the possibility of performing interventions and rescues using climbing techniques is not mentioned [57,58,59,60].

In addition to the above, methodologies and methods for saving older data are presented, which gives room for innovative solutions, such as the use of climbing technology.

The research conducted in this article fills a gap in the field of mine rescue, as traditional rescue methodologies in fire department training involve urban environments and confined spaces, while the area of abandoned mine rescue using climbing techniques remains largely unexplored and under-researched. This study provides new insights into a highly specialized and high-risk operational context that bridges multiple disciplines.

Unlike active mines, these locations typically lack access to modern infrastructure, communication systems, and security monitoring. Rescue operations in such conditions require not only technical expertise but also adaptive strategies rooted in uncertainty and improvisation. This research fills a critical gap by addressing the operational requirements for safely navigating and performing rescue operations in such degraded underground environments.

5. Conclusions

The presented article is dedicated to the underground rescue activities of firefighters. A brief description of the abandoned Bankov mine is also provided, characterizing the individual risks to firefighters.

This research investigated the complex and highly specialized field of rescue from abandoned mine shafts performed by firefighters using climbing techniques and addressed an important but often overlooked aspect of emergency response. The research was directly carried out in the abandoned Bankov mine.

By focusing on rescue techniques based on climbing, this study demonstrated how rope systems, vertical access methods, and tactical anchoring systems can be effectively adapted to the underground environment. The findings highlight the importance of integrating the single-rope technique (SRT), multi-directional traction systems, and confined-space climbing protocols into firefighter training programs for mine incidents. These techniques not only improve the ability to reach and extract trapped personnel but also improve the overall safety of the rescue team during such high-risk missions.

The research further highlighted a broader systemic gap: the lack of standardized procedures and specialized training for rescue from abandoned mines, particularly when the rescuers themselves are in distress. This work contributes to addressing this gap by providing a basis for the future development of a rescue doctrine, specialized training curricula, and equipment guidelines tailored to this unique operational scenario.

Ultimately, this study confirms the need for continued innovation and inter-disciplinary collaboration in the rescue services. Incorporating climbing techniques into underground rescue not only improves the survival of firefighters in mine shaft incidents but also strengthens the overall resilience and preparedness of fire and rescue units facing the growing challenges presented by abandoned industrial sites.

The rescue itself and the evaluation show that firefighters can perform rescue work even in exposed conditions, such as underground spaces. The fire and rescue service of the Slovak Republic also has great potential for training additional firefighters who could specialize in underground rescue work, as several specialized modules have already been designed to facilitate rescue and liquidation work in specific emergencies.

The results of this work show that, for a specific proposed emergency in an underground space, firefighters would be able to perform an effective intervention with the help of their material and technical resources and their forces and means.

The most effective method of rescuing a person is using a Tyrolean traverse and a motor winch; conversely, the method of rescuing a person using a simple ropeway is more time-consuming and also requires greater physical effort.

The article pointed out the limitations of not only the fire and rescue service of the Slovak Republic but also other components of the Integrated Rescue System for performing underground rescue work in the Slovak Republic. In addition, it pointed out the possibilities for improving this situation and proposed specific measures to make rescue work more efficient.

It was also proven that firefighters can perform a certain type of intervention in a mining environment independently, which significantly improves the availability of help for people in danger and accelerates the rescue process. The availability of help is an indicator of the level of safety for a society.

The results suggest that certain legislative frameworks need to be adopted in the field of rescuing people using climbing equipment. The presented research can be used to create methodologies for rescue in underground spaces, where the aforementioned rules and regulations are currently absent.

Author Contributions

Each author (M.S., M.B., M.K., M.Š. and A.Š.) equally contributed to this publication. Conceptualization, M.B. and M.K.; methodology, M.B.; software, M.K.; validation, M.Š. and A.Š.; formal analysis, A.Š.; investigation, M.Š. and M.S.; resources, M.B.; data curation, M.K.; writing—original draft preparation, M.Š. and M.S.; writing—review and editing, M.B. and M.K.; visualization, M.Š.; supervision, M.B.; project administration, M.K., M.S. and A.Š.; funding acquisition, M.Š. and A.Š. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by the Scientific Grant Agency of the Ministry of Education, Science, Research, and Sport of the Slovak Republic and the Slovak Academy of Sciences as part of the research project VEGA: 1/0431/25: “Research and development of new methods based on the principles of modelling, logistics and simulation in solving technological and environmental problems with regard to the economic efficiency and safety of raw material extraction” and as part of the research project VEGA 1/0430/22 “Research, development and concept creation of new solutions based on TestBed in the context of Industry 4.0 to streamline production and logistics for Mining 4.0”.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki and approved by the Ethics Committee) of the Technical University of Košice (protocol code 51362/2025 and approval on 25 August 2025).

Informed Consent Statement

Informed consent was obtained from all participants involved in this study.

Data Availability Statement

The data presented in this article are available on request from the corresponding author.

Acknowledgments

The authors would like to thank the anonymous referees for their valuable comments that improved the quality of the manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Hildebrandt, R.; Marszowski, R.; Lubosik, Z.; Jarosławska-Sobór, S. Transforming underground coal mine workings into critical cyber security facilities in the perspective of the European Green Deal plan. Sci. Pap. Silesian Univ. Technol. Organ. Manag. Ser. 2023, 182, 79–97. [Google Scholar] [CrossRef]

- Chaplygina, A.B.; Filatova, O.V.; Litvin, L.M.; Nykyforov, V.V. The main factors and prospects for the restoration of biodiversity in technogenic territories (on the example of the Poltava Mining and Processing Plant). Biosyst. Divers. 2023, 31, 100–112. [Google Scholar] [CrossRef]

- Delmastro, C.; Lavagno, E.; Schranz, L. Underground urbanism: Master Plans and Sectorial Plans. Tunn. Undergr. Space Technol. 2016, 55, 103–111. [Google Scholar] [CrossRef]

- Rak, J.; Tomášek, P.; Svoboda, P. Design of a Spatial Data Model for the Sustainability of Population Sheltering Processes in the Czech Republic. Sustainability 2021, 13, 13503. [Google Scholar] [CrossRef]

- Vicar, D.; Tomek, M.; Safarik, Z.; Strohmandl, J. Selected Aspects of Providing Humanitarian Aid Czech Republic. Krízový Manažment 2016, 15, 57–63. [Google Scholar] [CrossRef]

- Tomašková, M.; Pokorný, J.; Krajňák, J.; Balážiková, M. Assessment of Risk Factors of Critical Points in Forest Firefighting in Difficult-to-Access Sites. Fire 2025, 8, 11. [Google Scholar] [CrossRef]

- Szurgacz, D.; Trzop, K.; Gil, J.; Zhironkin, S.; Pokorný, J.; Gondek, H. Numerical Study for Determining the Strength Limits of a Powered Longwall Support. Processes 2022, 10, 527. [Google Scholar] [CrossRef]

- Pach, G.; Różański, Z.; Wrona, P.; Niewiadomski, A.; Zapletal, P.; Zubíček, V. Reversal Ventilation as a Method of Fire Hazard Mitigation in the Mines. Energies. 2020, 13, 1755. [Google Scholar] [CrossRef]

- Sedlák, V.; Hofierka, J.; Gallay, M.; Kaňuk, J. Specific solution of 3D deformation vector in mine subsidence: A case study of the Košice-Bankov abandoned magnesite mine, Slovakia. Arch. Min. Sci. 2018, 63, 511–531. [Google Scholar] [CrossRef]

- Hronček, P.; Gregorová, B.; Tometzová, D.; Molokáč, M.; Hvizdák, L. Modeling of Vanished Historic Mining Landscape Features as a Part of Digital Cultural Heritage and Possibilities of Its Use in Mining Tourism (Case Study: Gelnica Town, Slovakia). Resources 2020, 9, 43. [Google Scholar] [CrossRef]

- Sejkora, J.; Biagioni, C.; Števko, M.; Musetti, S.; Peterec, D. Tetrahedrite-(Cu), Cu12Sb4S13, from Bankov near Košice, Slovak Republic: A new member of the tetrahedrite group. Mineral. Mag. 2024, 88, 392–399. [Google Scholar] [CrossRef]

- Sedlák, V.; Poljakovič, P. Particularities of Deformation Processes Solution with GIS Application for Mining Landscape Reclamation in East Slovakia. J. Geogr. Cartogr. 2018, 4, 508. [Google Scholar] [CrossRef]

- Pavolová, H.; Čulková, K.; Šimková, Z.; Seňová, A.; Kudelas, D. Contribution of Mining Industry in Chosen EU Countries to the Sustainability Issues. Sustainability 2022, 14, 4177. [Google Scholar] [CrossRef]

- Miao, D.; Lv, Y.; Yu, K.; Liu, L.; Jiang, J. Research on coal mine hidden danger analysis and risk early warning technology based on data mining in China. Process Saf. Environ. Prot. 2023, 171, 1–17. [Google Scholar] [CrossRef]

- Su, G.; Hu, E. Research on coal mine safety risk evolution and key hidden dangers under the perspective of complex network. Sci. Rep. 2024, 14, 20624. [Google Scholar] [CrossRef]

- Naeini, S.A.B.; Badri, A. Identification and categorization of hazards in the mining industry: A systematic review of the literature. Int. Rev. Appl. Sci. Eng. 2023, 15, 1–19. [Google Scholar] [CrossRef]

- Sanmiquel, L.; Bascompta, M.; Rossell, J.M.; Anticoi, H.F.; Guash, E. Analysis of Occupational Accidents in Underground and Surface Mining in Spain Using Data-Mining Techniques. Int. J. Environ. Res. Public Health 2018, 15, 462. [Google Scholar] [CrossRef] [PubMed]

- Stojadinović, S.; Svrkota, I.; Petrović, D.; Denić, M.; Pantović, R.; Milić, V. Mining injuries in Serbian underground coal mines—A 10-year study. Injury 2012, 43, 2001–2005. [Google Scholar] [CrossRef] [PubMed]

- Singo, J.; Isunju, J.B.; Moyo, D.; Bose-O’Reilly, S.; Steckling-Muschack, N.; Mamuse, A. Accidents, Injuries, and Safety among Artisanal and Small-Scale Gold Miners in Zimbabwe. Int. J. Environ. Res. Public Health 2022, 19, 8663. [Google Scholar] [CrossRef]

- Qiang, X.; Li, G.; Fan, C.; Zhao, W.; Wang, Q. The Full Lifecycle Evolution Model of Accidents: A Case Study of Underground Metal Mines in China. Appl. Sci. 2025, 15, 4004. [Google Scholar] [CrossRef]

- Longoni, L.; Papini, M.; Brambilla, D.; Arosio, D.; Zanzi, L. The risk of collapse in abandoned mine sites: The issue of data uncertainty. Open Geosci. 2016, 8, 246–258. [Google Scholar] [CrossRef]

- Colas, E.; Kukla, P.A.; Amann, F.; Back, S. Geological and mining factors influencing further use of abandoned coal mines—A multi-disciplinary workflow towards sustainable underground storage. J. Energy Storage 2025, 108, 115101. [Google Scholar] [CrossRef]

- Ngwenyama, P.L.; Webber-Youngman, R.C.W. The Development of User Requirements as a Framework for the Design and Evaluation of a Fit-for-Purpose Missing Person Locator System for Underground Mines. Min. Metall. Explor. 2023, 40, 2205–2225. [Google Scholar] [CrossRef]

- Patri, A.; Nayak, A.; Jayanthu, S. Wireless communication systems for underground mines—A critical appraisal. Int. J. Eng. Trends Technol. 2013, 4, 3149–3153. [Google Scholar]

- Badri, A.; Nadeau, S.; Gbodossou, A. A mining project is a field of risks: A systematic and preliminary portrait of mining risks. Int. J. Saf. Secur. Eng. 2012, 2, 145–166. [Google Scholar] [CrossRef]

- Sun, Z.; Qi, Q.; Liu, Y. Vulnerability Assessment of Mine Flooding Disaster Induced by Rainstorm Based on Tri-AHP. Sustainability 2022, 14, 16731. [Google Scholar] [CrossRef]

- Karalidis, K.; Louloudis, G.; Roumpos, C.; Mertiri, E.; Pavloudakis, F. Flood Detection in Complex Surface Mining Areas Using Satellite Data for Sustainable Management. Mater. Proc. 2023, 15, 1. [Google Scholar] [CrossRef]

- Ignacy, D. Comprehensive method of assessing the flood threat of artificially drained mine subsidence areas for identification and sustainable repair of mining damage to the aquatic environment. Water Resour. Ind. 2021, 26, 100153. [Google Scholar] [CrossRef]

- Li, T.; Zhang, H. Design of Charge and Discharge Performance Inspection System for Lead-Acid Battery in Coal Mine. Highlights Sci. Eng. Technol. 2024, 81, 769–773. [Google Scholar] [CrossRef]

- Taggart, S.M.; Girard, O.; Landers, G.J.; Wallman, K.E. Heat exposure as a cause of injury and illness in mine industry workers. Ann. Work Expo. Health 2024, 68, 325–331. [Google Scholar] [CrossRef]

- Luo, G. Calculation of Required Air Volume and Verification of Ventilation Capacity for Mines. Front. Comput. Intell. Syst. 2023, 4, 119–123. [Google Scholar] [CrossRef]

- Wrona, P.; Różański, Z.; Pach, G.; Niewiadomski, A.P.; Markowska, M.; Król, A.; Król, M.; Chmiela, A. Selected Meteorological Factors Influencing Gas Emissions from an Abandoned Coal Mine Shaft—Results of In Situ Measurements. Sustainability 2025, 17, 3875. [Google Scholar] [CrossRef]

- Bazargur, B.; Bataa, O.; Budjav, U. Reliability Study for Communication System: A Case Study of an Underground Mine. Appl. Sci. 2023, 13, 821. [Google Scholar] [CrossRef]

- Bedford, M.; Foster, P.; Markowska, M.; Kruczek, M.; Zawadzki, P.; Nguyen, P.M.V.; Wrana, A.; Skalny, A.; Janson, E.; Łabaj, P.; et al. TEXMIN Handbook. A Guide to Managing the Risks Posed to Working and Abandoned Mining Facilities, and to the Surrounding Environment, Caused by Climate Change, 1st ed.; Central Mining Institute (GIG): Katowice, Poland; University of Exeter: Exeter, UK, 2023; p. 155. ISBN 978-83-65503-45-9. [Google Scholar]

- Mcingani, I.; Meyer, E.L.; Overen, O.K. The Impact of Ambient Weather Conditions and Energy Usage Patterns on the Performance of a Domestic Off-Grid Photovoltaic System. Energies 2024, 17, 5013. [Google Scholar] [CrossRef]

- Liu, K.; Murao, R. Reliability and validity assessment of working memory measurements. Appl. Psycholinguist. 2025, 46, e3. [Google Scholar] [CrossRef]

- Oprita, B.; Olaru, I.; Botezatu, L.; Diaconu, A.E.; Oprita, R. Management of Severe Hypothermia: Challenges and Advanced Strategies. J. Clin. Med. 2025, 14, 1584. [Google Scholar] [CrossRef]

- Błażejczyk, K.; Havenith, G.; Szymczak, R.K. Simulations of the human heat balance during Mount Everest summit attempts in spring and winter. Int. J. Biometeorol. 2024, 68, 351–366. [Google Scholar] [CrossRef] [PubMed]

- Krzyżewska, A.; Dobek, M.; Domżał-Drzewicka, R.; Rząca, M. Emergency interventions due to weather-related hypothermia. Weather 2017, 72, 8–12. [Google Scholar] [CrossRef]

- Grocott, M.P.; Martin, D.S.; Levett, D.Z.; McMorrow, R.; Windsor, J.; Montgomery, H.E. Arterial Blood Gases and Oxygen Content in Climbers on Mount Everest. N. Engl. J. Med. 2009, 360, 140–149. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Gao, J.; Zhao, F.; Liu, Y. A Search-and-Rescue Robot System for Remotely Sensing the Underground Coal Mine Environment. Sensors 2017, 17, 2426. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Fu, G.; Nieto, A. A comparative study of gas explosion occurrences and causes in China and the United States. Int. J. Min. Reclam. Environ. 2016, 30, 269–278. [Google Scholar] [CrossRef]

- Payus, C.M.; Vasu Thevan, A.T.; Sentian, J. Impact of school traffic on outdoor carbon monoxide levels. City Environ. Interact. 2019, 4, 100032. [Google Scholar] [CrossRef]

- Gurbanov, E.; Aslanova, S. Study of the area, environmental conditions of the “Binagadineft” NGCI mines in the Absheron peninsula of the Republic of Azerbaijan, and study of vegetation-soil cover contaminated by oil and oil products. Adv. Stud. Biol. 2025, 17, 11–17. [Google Scholar] [CrossRef]

- STN EN 353-1+A1; Slovak Technical Standard. Personal Protective Equipment Against Falls from a Height. Part 1: Guided Type Arresting Devices on Fixed Anchor Lines. SUTN: Bratislava, Slovakia, 2018.

- STN EN 354; Slovak Technical Standard. Personal Protective Equipment Against Falls from a Height. Fasteners. SUTN: Bratislava, Slovakia, 2018.

- STN EN 358; Slovak Technical Standard. Personal Protective Equipment for Work Positioning and Prevention of Falls from a Height. Belts and Connecting Devices for Work Positioning and Prevention of Falls. SUTN: Bratislava, Slovakia, 2019.

- STN EN 795; Slovak Technical Standard. Personal Protective Equipment Against Falls from a Height. Anchoring Devices. SUTN: Bratislava, Slovakia, 2013.

- Harken Power Seat PWRS-G Instruction Manual. Rev. 04 FT PWRS-G_07-07-2023. 2023. Available online: https://gallery.harkenindustrial.com/gallery/3e3fe761-e6a8-4295-9594-3e4941929560.pdf (accessed on 5 July 2025).

- Betuš, M.; Konček, M.; Šofranko, M.; Čambal, J.; Ondov, M. Methods of Extinguishing Fires in Objects with High Voltage. Fire 2023, 6, 442. [Google Scholar] [CrossRef]

- Betuš, M.; Seňová, A.; Behúnová, A.; Burachok, I.; Terzieva, G.T. Optimizing Emergency Response in Healthcare Facilities: Integration of Firefighting Technologies and Tactical Evacuation Strategies. Fire 2025, 8, 77. [Google Scholar] [CrossRef]

- Betuš, M.; Konček, M.; Šofranko, M.; Rosová, A.; Szücs, M.; Horizralová, K. Causes of Slope Deformations in Built-Up Areas and the Elimination of Emergencies with Regard to Population Protection. Geosciences 2025, 15, 74. [Google Scholar] [CrossRef]

- Presidium of the Fire and Rescue Service Home Page. Tactical-Methodical Procedure for Carrying out Interventions No. 110. Rescue from Heights and Free Depths. Available online: https://elearnhazz-sk.webnode.sk/subory-na-stiahnutie/metodicke-listy/ (accessed on 18 May 2025).

- Shang, L.; Wang, H.; Si, H.; Li, Y.; Pan, T. Investigating the Obstacle Climbing Ability of a Coal Mine Search-and-Rescue Robot with a Hydraulic Mechanism. Appl. Sci. 2022, 12, 10485. [Google Scholar] [CrossRef]

- Lehnen, F. Mine Rescue Management. A Concept for Long-Lasting Missions Based on Case Study Analysis and Disaster Management Approaches. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2016. Available online: https://publications.rwth-aachen.de/record/657470/files/657470.pdf (accessed on 6 July 2025).

- Onifade, M. Towards an emergency preparedness for self-rescue from underground coal mines. Process Saf. Environ. Prot. 2021, 149, 946–957. [Google Scholar] [CrossRef]

- Enright, C.; Ferriter, R.L. Mine Rescue Manual: A Comprehensive Guide for Mine Rescue Team Members; SME: Eaglewood, CO, USA, 2014; Available online: https://1url.cz/rJVcw (accessed on 6 July 2025).

- Kowalski-Trakofler, K.M.; Vaught, C.; Brnich, M.J. Expectations Training for Miners Using Self-Contained Self-Rescuers in Escapes from Underground Coal Mines. J. Occup. Environ. Hyg. 2008, 5, 671–677. [Google Scholar] [CrossRef]

- Perry, R.W.; Lindell, M.K. Preparedness for emergency response: Guidelines for the emergency planning process. Disasters 2003, 27, 336–350. [Google Scholar] [CrossRef]