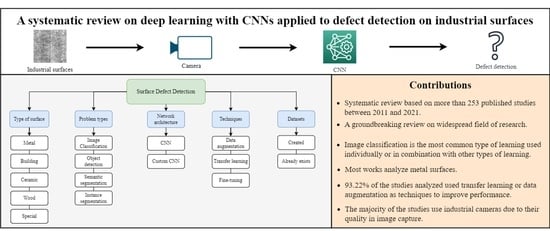

A Systematic Review on Deep Learning with CNNs Applied to Surface Defect Detection

Abstract

:1. Introduction

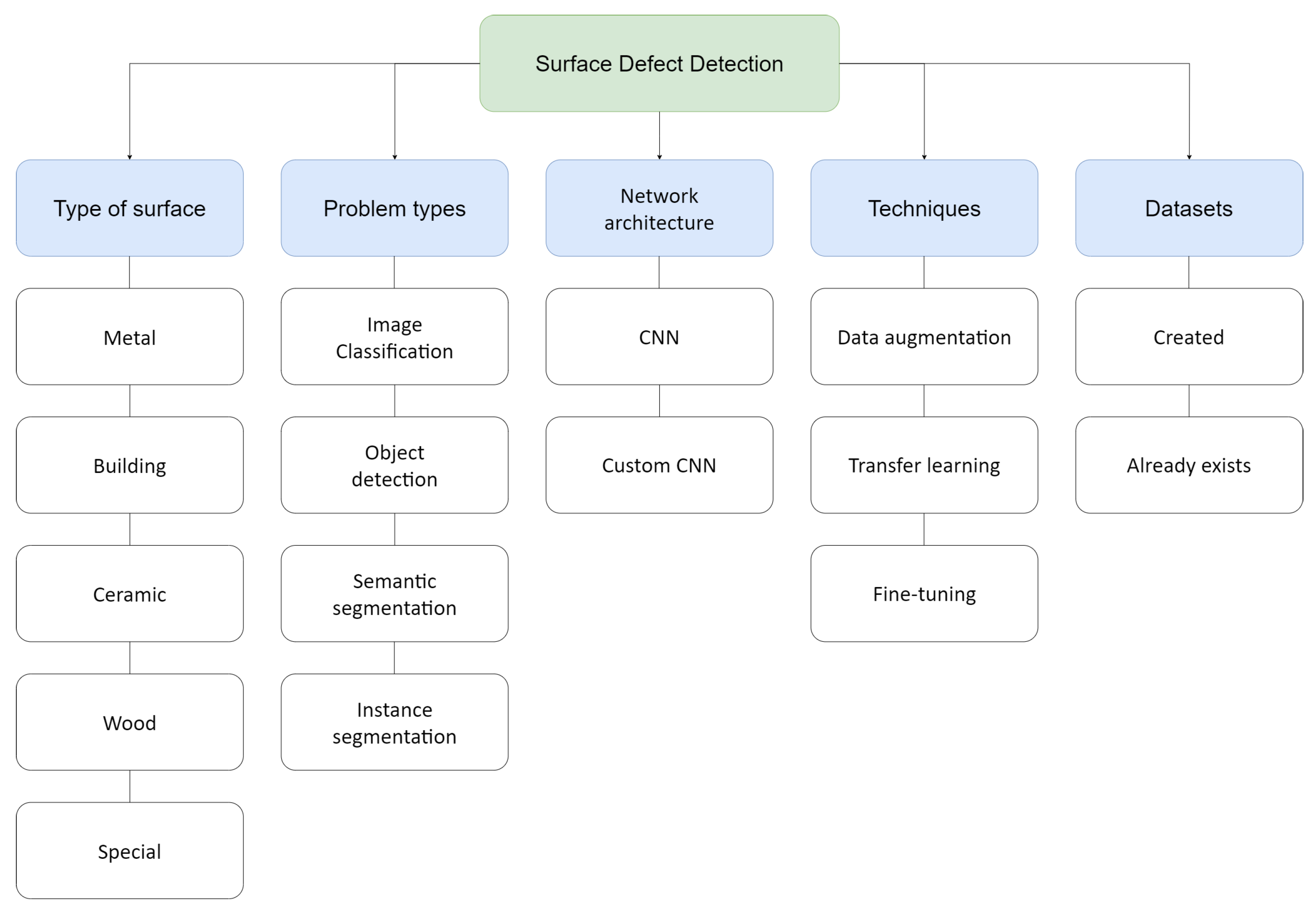

1.1. Research Relevance

1.2. Research Questions

- RQ1: Which are the most used types of surfaces in defect detection?

- RQ2: What are the main problem types for surface defect detection?

- RQ3: Which is the type of network architecture most used for each type of surface defect detection?

- RQ4: What techniques were used to improve performance in studies regarding surface defect detection?

- RQ5: Which is the most used type of dataset?

- RQ6: How did the number of studies evolve over the years?

1.3. Contributions

- A comparison between techniques is made by the type of material, which will guide researchers when searching specifically for a specific material or to perceive the main trends in the industry;

- The studies were classified by type of learning, to easily understand what is being used in each study reviewed;

- The proposal of a taxonomy for machine learning and surface defect detection.

1.4. Review Structure

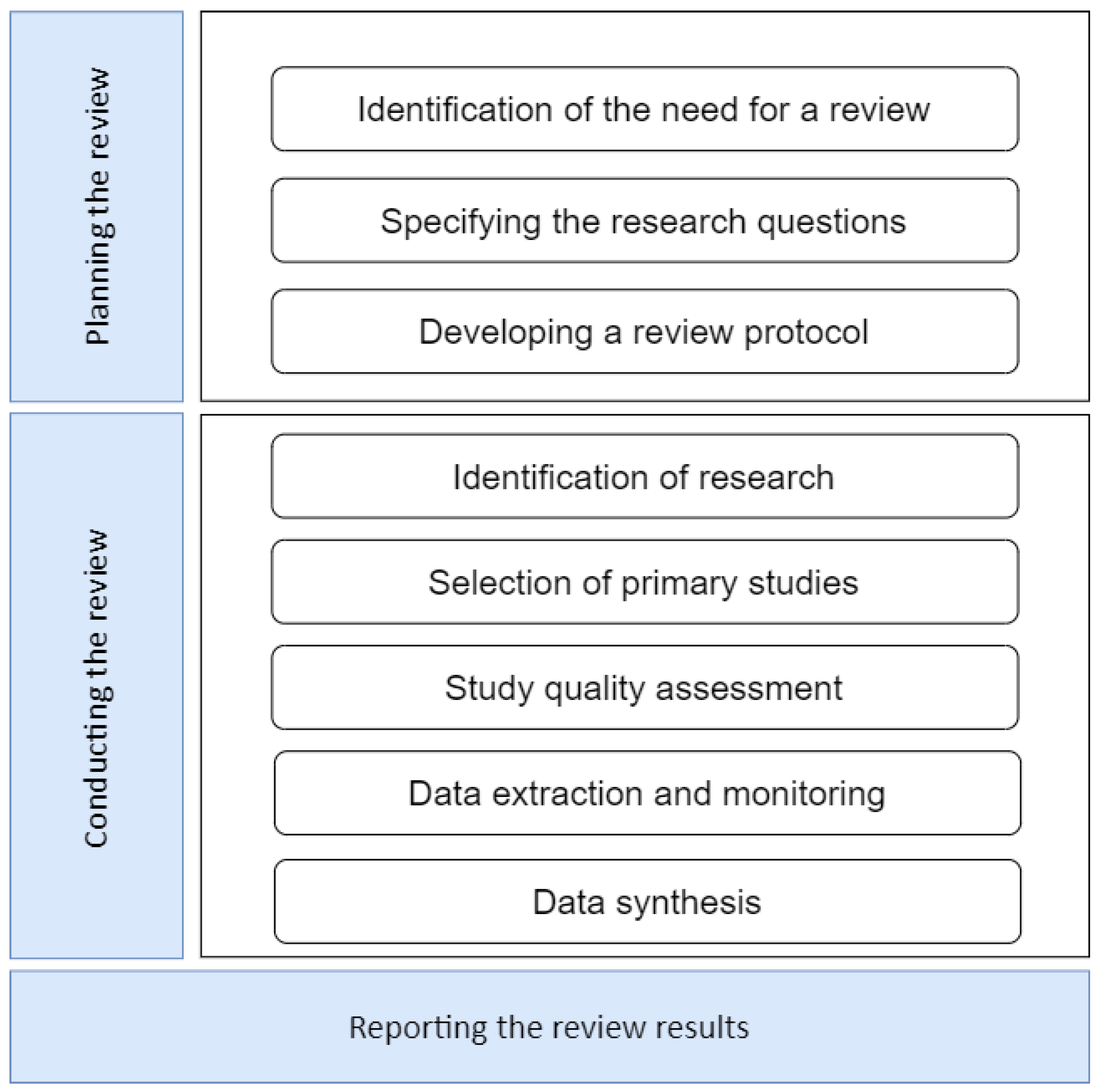

2. Methods

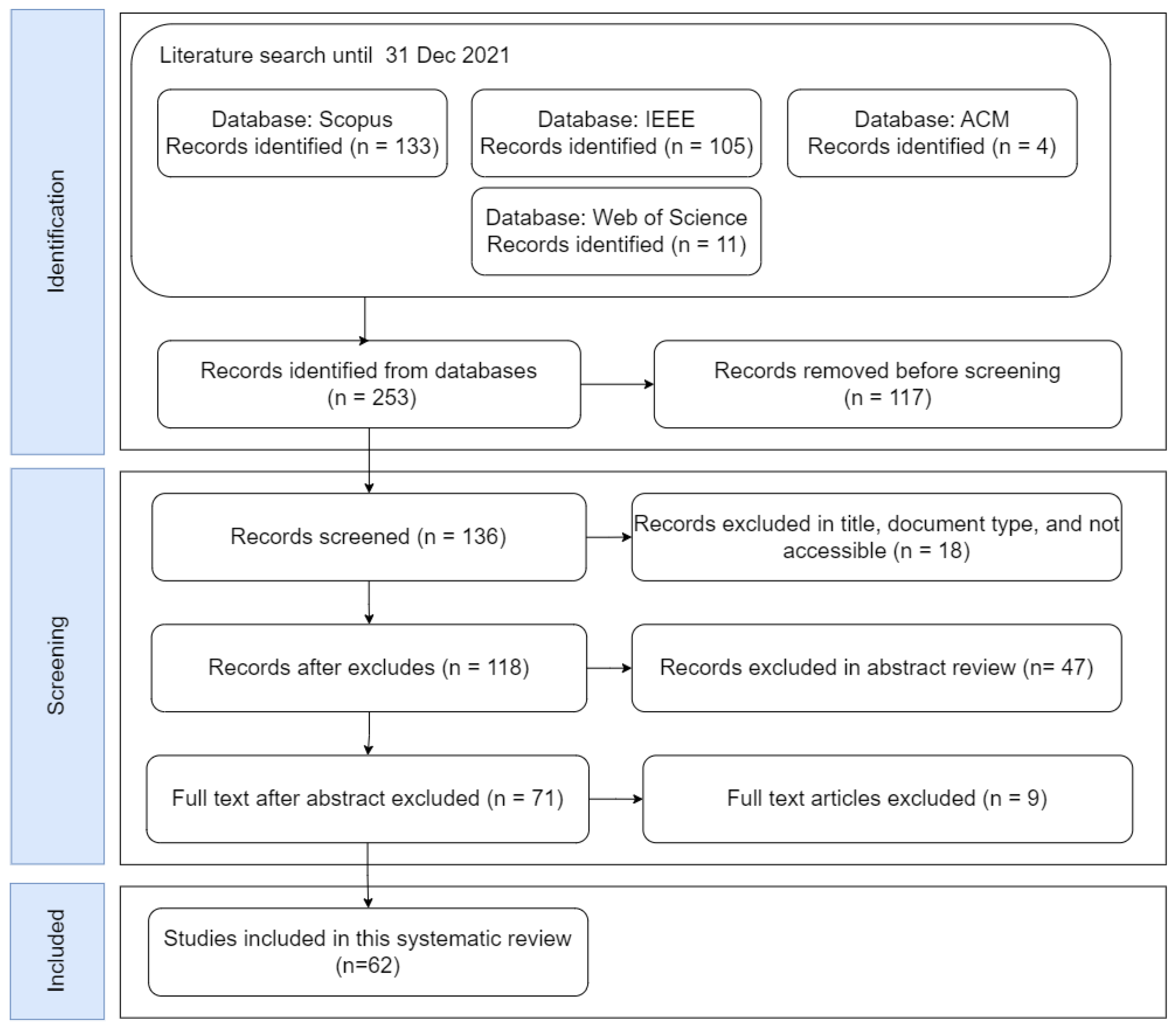

2.1. Literature Search

2.2. Eligibility Criteria

- Empirical studies using CNNs for surface defect detection;

- Empirical studies using supervised learning for surface defect detection;

- Empirical studies combining CNNs and other commonly used machine learning techniques;

- Review studies, conference papers, and articles;

- Studies between 2011 and 2021;

- Studies in English;

- Final published versions.

- Studies without empirical analysis or results of the use of CNNs;

- Studies using CNN techniques in a context other than surface defect detection;

- Studies using CNNs with datasets not based on images;

- Studies with only abstracts;

- Articles in press.

2.3. Study Selection

2.4. Study Quality Assessment

3. Results

3.1. Study Characteristics

3.2. Applications of CNNs in Defects Detection

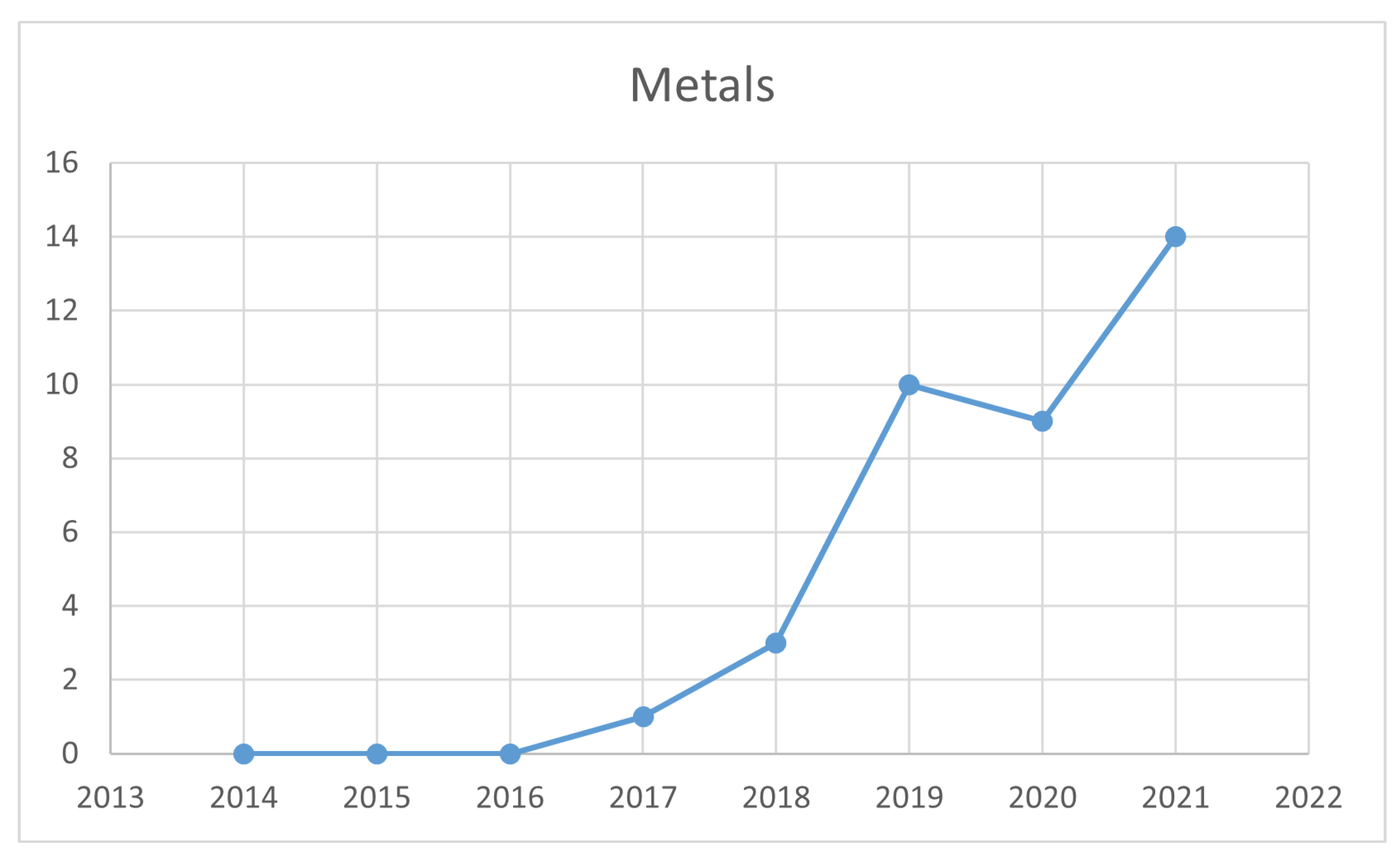

3.2.1. Metal

3.2.2. Building

3.2.3. Ceramic

3.2.4. Wood

3.2.5. Special

4. Discussion

4.1. Research Questions

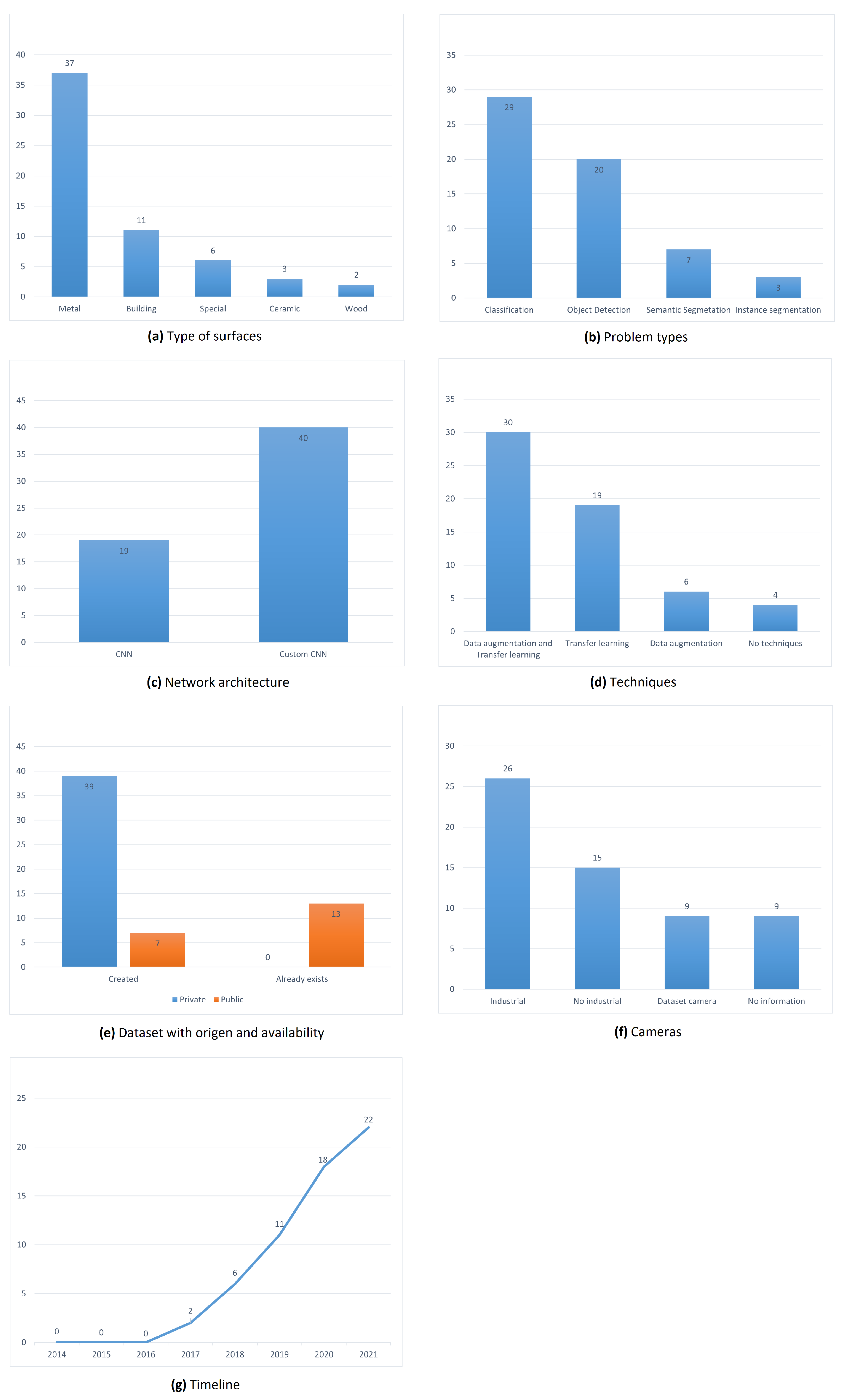

4.1.1. RQ1: Which Are the Most Used Types of Surfaces in Defect Detection?

4.1.2. RQ2: What Are the Main Problem Types for Surface Defect Detection?

- P1: image classification;

- P2: object detection;

- P3: semantic segmentation;

- Instance segmentation.

4.1.3. RQ3: Which Is the Type of Network Architecture Most Used for Each Type of Surface Defect Detection?

4.1.4. RQ4: What Techniques Were Used to Improve Performance in Studies Regarding Surface Defect Detection?

- DA: data augmentation;

- TL: transfer learning.

4.1.5. RQ5: What Type of Dataset Is the Most Used?

4.1.6. RQ6: How Did the Number of Studies Evolve over the Years?

4.2. Learned Lessons

- In industry, metal surfaces are the most used, being in 62.71% of primary studies, even though this type of surface is difficult to study because the light is reflected and it is not easy to obtain superior-quality datasets at the beginning;

- According to problem types, image classification is the most used type of learning individually or in combination, because there is a lot of information and its computational cost is less high than the other problem types. It is followed by object detection and finally by semantic segmentation together with instance segmentation, which have the highest computational cost and take the longest time to compute;

- Using techniques to improve performance is common in this type of study, due to the difficulty of creating datasets with large numbers of images. A total of 93.22% of the studies use at least one technique to improve performance; it can be transfer learning or data augmentation. Individually, transfer learning is the most popular among researchers;

- The number of studies conducted on surface defect detection with CNNs is increasing every year because it provides better results in the industry, helps reduce costs, and increases the speed of production when implemented in a factory. These technological solutions not only offer these benefits but also have the potential to bring about significant changes in the industrial sector. By harnessing these advancements, businesses can gain a substantial competitive edge over their counterparts;

- To create datasets, industrial cameras are the most used and showed better results due to their ability to capture better-quality images than conventional cameras or web cameras. However, in conditions of difficult access to study sites, the authors used various types of cameras;

- The traditional networks have already been tested with several experiments and studies. However, to obtain more and more accurate results, current studies are focused on modifying these networks or creating complementary methods to improve defect detection. We note that this trend is growing, especially on surfaces with the largest number of studies.

5. Conclusions and Future Work

- Researchers must diligently screen articles containing extensive information on image capture. Often, in this domain, data from one source can be reused in another, making data reuse feasible. In this scenario, it is noteworthy that only 15.25% of the studies did not reveal information about the use of cameras for their datasets. Therefore, existing modules created for image capture can be used as a guide;

- Some studies withhold relevant information within their datasets, especially the quantity of generated images. This omission restricts essential data access for researchers or professionals in need of using such information for real-world applications or comparing new network architectures. Therefore, utilizing existing datasets as a guide for constructing our dataset proves to be a prudent approach;

- Researchers about to conduct flaw detection studies must first focus on the type of surface they are going to study. If there is no information regarding the surface sought, similar surfaces must be used because defects are repeated on most surfaces;

- Researchers who possess limited experience in this field should initiate their endeavors by conducting experiments on metal surfaces, leveraging the wealth of existing data. Subsequently, they can transition to their specific area of interest or the surface type they are studying.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Study No. | Reference | Score 1 | Score 2 | Final Score | Study No. | Reference | Score 1 | Score 2 | Final Score |

|---|---|---|---|---|---|---|---|---|---|

| DDA1 | [6] | 7 | 8 | 7.5 | DDA32 | [83] | 7.5 | 8.5 | 8 |

| DDA2 | [9] | 4.5 | 6 | 5.25 | DDA33 | [85] | 8.5 | 6.5 | 7.5 |

| DDA3 | [31] | 7.5 | 6 | 6.75 | DDA34 | [29] | 9 | 7.5 | 8.25 |

| DDA4 | [33] | 8 | 9 | 8.5 | DDA35 | [30] | 7.5 | 7.5 | 7.5 |

| DDA5 | [35] | 8.5 | 8.5 | 8.5 | DDA36 | [32] | 7 | 6.5 | 6.75 |

| DDA6 | [37] | 8 | 8 | 8 | DDA37 | [34] | 8 | 7.5 | 7.75 |

| DDA7 | [39] | 8.5 | 8.5 | 8.5 | DDA38 | [36] | 8 | 8 | 8 |

| DDA8 | [41] | 7 | 7 | 7 | DDA39 | [38] | 7 | 8 | 7.5 |

| DDA9 | [43] | 6 | 5.5 | 5.75 | DDA40 | [40] | 6.5 | 6 | 6.25 |

| DDA10 | [45] | 5.5 | 5.5 | 5.5 | DDA41 | [42] | 8.5 | 8.5 | 8.5 |

| DDA11 | [47] | 7.5 | 8 | 7.75 | DDA42 | [44] | 8 | 8 | 8 |

| DDA12 | [86] | 4 | 3.5 | 3.75 | DDA43 | [46] | 8 | 8 | 8 |

| DDA13 | [49] | 6 | 6 | 6 | DDA44 | [48] | 7 | 8 | 7.5 |

| DDA14 | [96] | 2 | 3 | 2.5 | DDA45 | [50] | 5 | 5.5 | 5.25 |

| DDA15 | [51] | 7 | 7 | 7 | DDA46 | [52] | 6 | 5 | 5.5 |

| DDA16 | [53] | 7 | 7 | 7 | DDA47 | [54] | 8.5 | 8.5 | 8.5 |

| DDA17 | [55] | 6.5 | 6.5 | 6.5 | DDA48 | [56] | 7 | 7.5 | 7.25 |

| DDA18 | [57] | 5.5 | 5.5 | 5.5 | DDA49 | [58] | 6.5 | 6.5 | 6.5 |

| DDA19 | [59] | 7 | 6.5 | 6.75 | DDA50 | [60] | 6 | 7.5 | 6.75 |

| DDA20 | [61] | 8 | 8 | 8 | DDA51 | [62] | 6.5 | 6.5 | 6.5 |

| DDA21 | [63] | 6.5 | 6 | 6.25 | DDA52 | [64] | 7.5 | 7.5 | 7.5 |

| DDA22 | [65] | 6.5 | 6.5 | 6.5 | DDA53 | [66] | 4 | 8 | 6 |

| DDA23 | [67] | 6.5 | 7 | 6.75 | DDA54 | [68] | 3.5 | 6 | 4.75 |

| DDA24 | [69] | 6.5 | 7 | 6.75 | DDA55 | [70] | 7.5 | 7.5 | 7.5 |

| DDA25 | [71] | 5.5 | 6.5 | 6 | DDA56 | [72] | 7.5 | 7.5 | 7.5 |

| DDA26 | [73] | 7 | 8.5 | 7.75 | DDA57 | [74] | 8 | 8 | 8 |

| DDA27 | [97] | 2.5 | 5 | 3.75 | DDA58 | [76] | 8 | 8 | 8 |

| DDA28 | [75] | 7.5 | 8.5 | 8 | DDA59 | [78] | 8 | 7.5 | 7.75 |

| DDA29 | [77] | 5.5 | 8.5 | 7 | DDA60 | [80] | 8 | 8 | 8 |

| DDA30 | [79] | 5.5 | 6.5 | 6 | DDA61 | [82] | 7.5 | 7.5 | 7.5 |

| DDA31 | [81] | 5 | 5.5 | 5.25 | DDA62 | [84] | 7.5 | 7.5 | 7.5 |

References

- Bhatt, P.M.; Malhan, R.K.; Rajendran, P.; Shah, B.C.; Thakar, S.; Yoon, Y.J.; Gupta, S.K. Image-Based Surface Defect Detection Using Deep Learning: A Review. J. Comput. Inf. Sci. Eng. 2021, 21, 040801. [Google Scholar] [CrossRef]

- Gong, Y.; Lin, Z.; Wang, J.; Gong, N. Bringing machine intelligence to welding visual inspection: Development of Low-Cost portable embedded device for welding quality control. In Proceedings of the IS and T International Symposium on Electronic Imaging Science and Technology, Burlingame, CA, USA, 28 January–1 February 2018; pp. 2041–2045. [Google Scholar] [CrossRef]

- Blug, A.; Carl, D.; Höfler, H. Inspecting rapidly moving surfaces for small defects using CNN cameras. In Proceedings of the Videometrics, Range Imaging, and Applications XII, and Automated Visual Inspection, Munich, Germany, 14–16 May 2013; Volume 8791, pp. 302–312. [Google Scholar] [CrossRef]

- Huang, X.Q.; Luo, X.B. A real-time algorithm for aluminum surface defect extraction on non-uniform image from CCD camera. In Proceedings of the 2014 International Conference on Machine Learning and Cybernetics, Lanzhou, China, 13–16 July 2014; Volume 2, pp. 556–561. [Google Scholar] [CrossRef]

- Prakash, N.; Manconi, A.; Loew, S. Mapping Landslides on EO Data: Performance of Deep Learning Models vs. Traditional Machine Learning Models. Remote Sens. 2020, 12, 346. [Google Scholar] [CrossRef]

- Kou, X.; He, Y.; Qian, Y. An improvement and application of a model conducive to productivity optimization. In Proceedings of the 2021 IEEE International Conference on Power Electronics, Computer Applications, ICPECA 2021, Shenyang, China, 22–24 January 2021; pp. 1050–1053. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Y. Deep learning based crack damage detection technique for thin plate structures using guided lamb wave signals. Smart Mater. Struct. 2019, 29, 015032. [Google Scholar] [CrossRef]

- Ramezani, S.; Hasanzadeh, R.P. Defect detection in metallic structures through AMR C-scan images using deep learning method. In Proceedings of the 4th International Conference on Pattern Recognition and Image Analysis, IPRIA 2019, Tehran, Iran, 6–7 March 2019; pp. 135–140. [Google Scholar] [CrossRef]

- He, H.; Yuan, M.; Liu, X. Research on Surface Defect Detection Method of Metal Workpiece Based on Machine Learning. In Proceedings of the 2021 IEEE 6th International Conference on Intelligent Computing and Signal Processing, ICSP 2021, Xi’an, China, 9–11 April 2021; pp. 881–884. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. Int. J. Surg. 2021, 88, 105906. [Google Scholar] [CrossRef]

- Kitchenham, B.; Kitchenham, B.; Charters, S. Guidelines for Performing Systematic Literature Reviews in Software Engineering. 2007. Available online: https://www.researchgate.net/profile/Barbara-Kitchenham/publication/302924724_Guidelines_for_performing_Systematic_Literature_Reviews_in_Software_Engineering/links/61712932766c4a211c03a6f7/Guidelines-for-performing-Systematic-Literature-Reviews-in-Software-Engineering.pdf (accessed on 26 July 2023).

- Wen, J.; Li, S.; Lin, Z.; Hu, Y.; Huang, C. Systematic literature review of machine learning based software development effort estimation models. Inf. Softw. Technol. 2012, 54, 41–59. [Google Scholar] [CrossRef]

- Dolling, O.R.; Varas, E.A. Artificial neural networks for streamflow prediction. J. Hydraul. Res. 2010, 40, 547–554. [Google Scholar] [CrossRef]

- Cichy, R.M.; Kaiser, D. Deep Neural Networks as Scientific Models. Trends Cogn. Sci. 2019, 23, 305–317. [Google Scholar] [CrossRef]

- Eligüzel, N.; Çetinkaya, C.; Dereli, T. Comparison of different machine learning techniques on location extraction by utilizing geo-tagged tweets: A case study. Adv. Eng. Inform. 2020, 46, 101151. [Google Scholar] [CrossRef]

- Tulbure, A.A.; Tulbure, A.A.; Dulf, E.H. A review on modern defect detection models using DCNNs—Deep convolutional neural networks. J. Adv. Res. 2021, 35, 33–48. [Google Scholar] [CrossRef]

- Jiao, L.; Zhang, F.; Liu, F.; Yang, S.; Li, L.; Feng, Z.; Qu, R. A survey of deep learning-based object detection. IEEE Access 2019, 7, 128837–128868. [Google Scholar] [CrossRef]

- Lateef, F.; Ruichek, Y. Survey on semantic segmentation using deep learning techniques. Neurocomputing 2019, 338, 321–348. [Google Scholar] [CrossRef]

- Hao, S.; Zhou, Y.; Guo, Y. A Brief Survey on Semantic Segmentation with Deep Learning. Neurocomputing 2020, 406, 302–321. [Google Scholar] [CrossRef]

- Hafiz, A.M.; Bhat, G.M. A survey on instance segmentation: State of the art. Int. J. Multimed. Inf. Retr. 2020, 9, 171–189. [Google Scholar] [CrossRef]

- Liang, H.; Fu, W.; Yi, F. A Survey of Recent Advances in Transfer Learning. In Proceedings of the 2019 IEEE 19th International Conference on Communication Technology (ICCT), Xi’an, China, 16–19 October 2019; pp. 1516–1523. [Google Scholar] [CrossRef]

- Mastouri, R.; Khlifa, N.; Neji, H.; Hantous-Zannad, S. Transfer Learning vs. Fine-Tuning in Bilinear CNN for Lung Nodules Classification on CT Scans. In Proceedings of the 2020 3rd International Conference on Artificial Intelligence and Pattern Recognition, Xiamen, China, 26–28 June 2020; pp. 99–103. [Google Scholar] [CrossRef]

- Karungaru, S. Kitchen Utensils Recognition Using Fine Tuning and Transfer Learning. In Proceedings of the 3rd International Conference on Video and Image Processing, Shanghai, China, 20–23 December 2019; pp. 19–22. [Google Scholar] [CrossRef]

- Shorten, C.; Khoshgoftaar, T.M. A survey on Image Data Augmentation for Deep Learning. J. Big Data 2019, 6, 60. [Google Scholar] [CrossRef]

- DAGM 2007. Available online: https://conferences.mpi-inf.mpg.de/dagm/2007/prizes.html (accessed on 1 December 2022).

- COCO-Common Objects in Context. Available online: https://cocodataset.org/#home (accessed on 1 December 2022).

- Kaggle: Your Machine Learning and Data Science Community. Available online: https://www.kaggle.com/ (accessed on 1 December 2022).

- Song, K.C.; Shaopeng, H.; Song, K.; Hu, S.; Yan, Y. Automatic recognition of surface defects on hot-rolled steel strip using scattering convolution network Automatic Recognition of Surface Defects on Hot-rolled Steel Strip using Scattering Convolution Network. Artic. J. Comput. Inf. Syst. 2014, 10, 3049–3055. [Google Scholar]

- Jiang, Q.; Tan, D.; Li, Y.; Ji, S.; Cai, C.; Zheng, Q. Object Detection and Classification of Metal Polishing Shaft Surface Defects Based on Convolutional Neural Network Deep Learning. Appl. Sci. 2019, 10, 87. [Google Scholar] [CrossRef]

- Cao, X.; Yao, B.; Chen, B.; Wang, Y. Multi-defect detection for magnetic tile based on SE-U-Net. In Proceedings of the ISPCE-CN 2020—IEEE International Symposium on Product Compliance Engineering—Asia 2020, Chongqing, China, 6–8 November 2020. [Google Scholar] [CrossRef]

- Aslam, Y.; Santhi, N.; Ramasamy, N.; Ramar, K. Localization and segmentation of metal cracks using deep learning. J. Ambient. Intell. Humaniz. Comput. 2021, 12, 4205–4213. [Google Scholar] [CrossRef]

- Min, B.; Tin, H.; Nasridinov, A.; Yoo, K.H. Abnormal detection and classification in i-ceramic images. In Proceedings of the 2020 IEEE International Conference on Big Data and Smart Computing, BigComp 2020, Pusan, Republic of Korea, 19–22 February 2020; pp. 17–18. [Google Scholar] [CrossRef]

- Lin, H.I.; Wibowo, F.S. Image Data Assessment Approach for Deep Learning-Based Metal Surface Defect-Detection Systems. IEEE Access 2021, 9, 47621–47638. [Google Scholar] [CrossRef]

- Le, X.; Mei, J.; Zhang, H.; Zhou, B.; Xi, J. A learning-based approach for surface defect detection using small image datasets. Neurocomputing 2020, 408, 112–120. [Google Scholar] [CrossRef]

- Block, S.B.; Silva, R.D.D.; Dorini, L.B.; Minetto, R. Inspection of Imprint Defects in Stamped Metal Surfaces Using Deep Learning and Tracking. IEEE Trans. Ind. Electron. 2021, 68, 4498–4507. [Google Scholar] [CrossRef]

- Tabernik, D.; Šela, S.; Skvarč, J.; Skočaj, D. Segmentation-Based Deep-Learning Approach for Surface-Defect Detection. J. Intell. Manuf. 2019, 31, 759–776. [Google Scholar] [CrossRef]

- Xu, Y.; Li, D.; Xie, Q.; Wu, Q.; Wang, J. Automatic defect detection and segmentation of tunnel surface using modified Mask R-CNN. Measurement 2021, 178, 109316. [Google Scholar] [CrossRef]

- Lian, J.; Jia, W.; Zareapoor, M.; Zheng, Y.; Luo, R.; Jain, D.K.; Kumar, N. Deep-Learning-Based Small Surface Defect Detection via an Exaggerated Local Variation-Based Generative Adversarial Network. IEEE Trans. Ind. Inform. 2020, 16, 1343–1351. [Google Scholar] [CrossRef]

- Shu, Y.F.; Li, B.; Li, X.; Xiong, C.; Cao, S.; Wen, X.Y. Deep learning-based fast recognition of commutator surface defects. Measurement 2021, 178, 109324. [Google Scholar] [CrossRef]

- Karangwa, J.; Kong, L.; You, T.; Zheng, J. Automated Surface Defects Detection on Mirrorlike Materials by using Faster R-CNN. In Proceedings of the 2020 7th International Conference on Information Science and Control Engineering, ICISCE 2020, Changsha, China, 18–20 December 2020; pp. 2288–2294. [Google Scholar] [CrossRef]

- Luo, Q.; Jiang, W.; Su, J.; Ai, J.; Yang, C. Smoothing Complete Feature Pyramid Networks for Roll Mark Detection of Steel Strips. Sensors 2021, 21, 7264. [Google Scholar] [CrossRef] [PubMed]

- Zheng, M.; Lei, Z.; Zhang, K. Intelligent detection of building cracks based on deep learning. Image Vis. Comput. 2020, 103, 103987. [Google Scholar] [CrossRef]

- Zou, Z.; Zhao, P.; Zhao, X. Virtual restoration of the colored paintings on weathered beams in the Forbidden City using multiple deep learning algorithms. Adv. Eng. Inform. 2021, 50, 101421. [Google Scholar] [CrossRef]

- Ding, F.; Zhuang, Z.; Liu, Y.; Jiang, D.; Yan, X.; Wang, Z. Detecting Defects on Solid Wood Panels Based on an Improved SSD Algorithm. Sensors 2020, 20, 5315. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, K.; Wang, L. Metal Surface Defect Detection Using Modified YOLO. Algorithms 2021, 14, 257. [Google Scholar] [CrossRef]

- Lv, X.; Duan, F.; Jiang, J.J.; Fu, X.; Gan, L. Deep Metallic Surface Defect Detection: The New Benchmark and Detection Network. Sensors 2020, 20, 1562. [Google Scholar] [CrossRef]

- Kim, B.; Yuvaraj, N.; Preethaa, K.R.S.; Pandian, R.A. Surface crack detection using deep learning with shallow CNN architecture for enhanced computation. Neural Comput. Appl. 2021, 33, 9289–9305. [Google Scholar] [CrossRef]

- Li, K.; Wang, X.; Ji, L. Application of Multi-Scale Feature Fusion and Deep Learning in Detection of Steel Strip Surface Defect. In Proceedings of the 2019 International Conference on Artificial Intelligence and Advanced Manufacturing, AIAM 2019, Dublin, Ireland, 17–19 October 2019; pp. 656–661. [Google Scholar] [CrossRef]

- Sauter, D.; Atik, C.; Schenk, C.; Buettner, R.; Baumgartl, H. Visual defect detection of metal screws using a geep convolutional neural network. In Proceedings of the 2021 IEEE 45th Annual Computers, Software, and Applications Conference, COMPSAC 2021, Madrid, Spain, 12–16 July 2021; pp. 303–311. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, W.; Yang, Z. Batch-normalized Convolutional Neural Networks for Defect Detection of the Steel Strip. In Proceedings of the 2019 2nd International Conference on Robot Systems and Applications, Moscow, Russia, 4–7 August 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Xu, F.; Liu, Y.; Zi, B.; Zheng, L. Application of Deep Learning for Defect Detection of Paint Film. In Proceedings of the 2021 IEEE 6th International Conference on Intelligent Computing and Signal Processing, ICSP 2021, Xi’an, China, 9–11 April 2021; pp. 1118–1121. [Google Scholar] [CrossRef]

- Ahmed, S.; Ishtiak, T.; Suhan, A.U.R.C.; Anila, M.H.; Farah, T. Road State Classification of Bangladesh with Convolutional Neural Network Approach. Syst. Cybern. Inform. 2019, 17, 50–58. [Google Scholar]

- Liu, R.; Huang, M.; Cao, P. An End-to-End Steel Strip Surface Defects Detection Framework: Considering Complex Background Interference. In Proceedings of the 33rd Chinese Control and Decision Conference, CCDC 2021, Kunming, China, 22–24 May 2021; pp. 317–322. [Google Scholar] [CrossRef]

- Ren, Q.; Geng, J.; Li, J. Slighter Faster R-CNN for real-time detection of steel strip surface defects. In Proceedings of the 2018 Chinese Automation Congress, CAC 2018, Xi’an, China, 30 November–2 December 2018; pp. 2173–2178. [Google Scholar] [CrossRef]

- Feng, X.; Gao, X.; Luo, L. A Method for Surface Detect Classification of Hot Rolled Strip Steel based on Xception. In Proceedings of the 33rd Chinese Control and Decision Conference, CCDC 2021, Kunming, China, 22–24 May 2021; pp. 1485–1489. [Google Scholar] [CrossRef]

- Mittel, D.; Kerber, F. Vision-Based Crack Detection using Transfer Learning in Metal Forming Processes. In Proceedings of the 2019 24th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Zaragoza, Spain, 10–13 September 2019; pp. 544–551. [Google Scholar] [CrossRef]

- Baskaran, R.; Fernando, P. Steel Frame Structure Defect Detection Using Image Processing and Artificial Intelligence. In Proceedings of the 2021 International Conference on Smart Generation Computing, Communication and Networking, SMART GENCON 2021, Pune, India, 29–30 October 2021. [Google Scholar] [CrossRef]

- Ooi, J.; Tay, L.C.; Lai, W.K. Bottom-hat filtering for Defect Detection with CNN Classification on Car Wiper Arm. In Proceedings of the 2019 IEEE 15th International Colloquium on Signal Processing and its Applications, CSPA 2019, Penang, Malaysia, 8–9 March 2019; pp. 90–95. [Google Scholar] [CrossRef]

- Mouzinho, F.A.L.N.; Fukai, H. Hierarchical Semantic Segmentation Based Approach for Road Surface Damages and Markings Detection on Paved Road. In Proceedings of the 2021 8th International Conference on Advanced Informatics: Concepts, Theory, and Application, ICAICTA 2021, Online, 29–30 September 2021. [Google Scholar] [CrossRef]

- Sun, J.; Wang, P.; Luo, Y.K.; Li, W. Surface Defects Detection Based on Adaptive Multiscale Image Collection and Convolutional Neural Networks. IEEE Trans. Instrum. Meas. 2019, 68, 4787–4797. [Google Scholar] [CrossRef]

- Kumar, P.; Sharma, A.; Kota, S.R. Automatic Multiclass Instance Segmentation of Concrete Damage Using Deep Learning Model. IEEE Access 2021, 9, 90330–90345. [Google Scholar] [CrossRef]

- Han, F.; Zou, J.; Ai, Y.; Xu, C.; Liu, S. Image classification and analysis during the additive manufacturing process based on deep convolutional neural networks. In Proceedings of the 2019 20th International Conference on Electronic Packaging Technology, ICEPT 2019, Hong Kong, China, 12–15 August 2019. [Google Scholar] [CrossRef]

- Kumar, P.; Batchu, S.; S., N.S.; Kota, S.R. Real-time concrete damage detection using deep learning for high rise structures. IEEE Access 2021, 9, 112312–112331. [Google Scholar] [CrossRef]

- Santolini, G.; Rota, P.; Gandolfi, D.; Bosetti, P. Cut quality estimation in industrial laser cutting machines: A machine learning approach. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition Workshops, Long Beach, CA, USA, 15–20 June 2019; pp. 389–397. [Google Scholar] [CrossRef]

- Saeed, M.S. Unmanned Aerial Vehicle for Automatic Detection of Concrete Crack using Deep Learning. In Proceedings of the 2021 2nd International Conference on Robotics, Electrical and Signal Processing Techniques (ICREST), Khaka, Bangladesh, 5–7 January 2021; pp. 624–628. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Dong, C.Y.; Zhou, P.; Zhu, M.J.; Ren, J.W.; Chen, X.Y. Detecting Surface Defects of Wind Tubine Blades Using an Alexnet Deep Learning Algorithm. IEICE Trans. Fundam. Electron. Commun. Comput. Sci. 2019, 102, 1817–1824. [Google Scholar] [CrossRef]

- Kamiyama, M.; Shimizu, K.; Akiniwa, Y. Estimation of low-cycle fatigue damage of sputtered Cu thin films at the micro scale using deep learning. Mechatronics 2021, 78, 102606. [Google Scholar] [CrossRef]

- Guo, F.; Hao, K.; Xia, M.; Zhao, L.; Wang, L.; Liu, Q. Detection of Insulator Defects Based on YOLO V3. In Lecture Notes of the Institute for Computer Sciences, Social-Informatics and Telecommunications Engineering, LNICST; Springer: Cham, Switzerland, 2019; Volume 287, pp. 291–299. [Google Scholar] [CrossRef]

- Mao, S.; Rajan, D.; Chia, L.T. Deep residual pooling network for texture recognition. Pattern Recognit. 2021, 112, 107817. [Google Scholar] [CrossRef]

- Wang, N.; Zhao, Q.; Li, S.; Zhao, X.; Zhao, P. Damage Classification for Masonry Historic Structures Using Convolutional Neural Networks Based on Still Images. Comput.-Aided Civ. Infrastruct. Eng. 2018, 33, 1073–1089. [Google Scholar] [CrossRef]

- Phua, C.; Theng, L.B. Semiconductor wafer surface: Automatic defect classification with deep CNN. In Proceedings of the 2020 IEEE Region 10 Annual International Conference, Proceedings/TENCON, Osaka, Japan, 16–19 November 2020; pp. 714–719. [Google Scholar] [CrossRef]

- Ferguson, M.; Ak, R.; Lee, Y.T.T.; Law, K.H. Detection and Segmentation of Manufacturing Defects with Convolutional Neural Networks and Transfer Learning. Smart Sustain. Manuf. Syst. 2018, 2, 137–164. [Google Scholar] [CrossRef]

- Ali, S.B.; Wate, R.; Kujur, S.; Singh, A.; Kumar, S. Wall Crack Detection Using Transfer Learning-based CNN Models. In Proceedings of the 2020 IEEE 17th India Council International Conference, INDICON, New Delhi, India, 10–13 December 2020. [Google Scholar] [CrossRef]

- Sun, W.; Yao, B.; Chen, B.; He, Y.; Cao, X.; Zhou, T.; Liu, H. Noncontact Surface Roughness Estimation Using 2D Complex Wavelet Enhanced ResNet for Intelligent Evaluation of Milled Metal Surface Quality. Appl. Sci. 2018, 8, 381. [Google Scholar] [CrossRef]

- Zhou, X.; Nie, Y.; Wang, Y.; Cao, P.; Ye, M.; Tang, Y.; Wang, Z. A Real-time and High-efficiency Surface Defect Detection Method for Metal Sheets Based on Compact CNN. In Proceedings of the 2020 13th International Symposium on Computational Intelligence and Design, ISCID 2020, Hangzhou, China, 12–13 December 2020; pp. 259–264. [Google Scholar] [CrossRef]

- Shang, L.; Yang, Q.; Wang, J.; Li, S.; Lei, W. Detection of rail surface defects based on CNN image recognition and classification. In Proceedings of the 2018 20th International Conference on Advanced Communication Technology, ICACT, Chuncheon, Republic of Korea, 1–14 February 2018; pp. 45–51. [Google Scholar] [CrossRef]

- Bahrami, Z.; Zhang, R.; Rayhana, R.; Wang, T.; Liu, Z. Optimized Deep Neural Network Architectures with Anchor Box optimization for Shipping Container Corrosion Inspection. In Proceedings of the 2020 IEEE Symposium Series on Computational Intelligence, SSCI 2020, Canberra, Australia, 1–4 December 2020; pp. 1328–1333. [Google Scholar] [CrossRef]

- Jung, S.Y.; Tsai, Y.H.; Chiu, W.Y.; Hu, J.S.; Sun, C.T. Defect detection on randomly textured surfaces by convolutional neural networks. In Proceedings of the 2018 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, AIM 2018, Auckland, New Zealand, 9–12 July 2018; pp. 1456–1461. [Google Scholar] [CrossRef]

- Maningo, J.M.Z.; Bandala, A.A.; Bedruz, R.A.R.; Dadios, E.P.; Lacuna, R.J.N.; Manalo, A.B.O.; Perez, P.L.E.; Sia, N.P.C. Crack detection with 2D wall mapping for building safety inspection. In Proceedings of the IEEE Region 10 Annual International Conference, Proceedings/TENCON, Osaka, Japan, 16–19 November 2020; pp. 702–707. [Google Scholar] [CrossRef]

- Li, Y.; Huang, H.; Xie, Q.; Yao, L.; Chen, Q. Research on a Surface Defect Detection Algorithm Based on MobileNet-SSD. Appl. Sci. 2018, 8, 1678. [Google Scholar] [CrossRef]

- Gai, X.; Ye, P.; Wang, J.; Wang, B. Research on Defect Detection Method for Steel Metal Surface based on Deep Learning. In Proceedings of the 2020 IEEE 5th Information Technology and Mechatronics Engineering Conference, ITOEC 2020, Chongqing, China, 12–14 June 2020; pp. 637–641. [Google Scholar] [CrossRef]

- Birlutiu, A.; Burlacu, A.; Kadar, M.; Onita, D. Defect detection in porcelain industry based on deep learning techniques. In Proceedings of the 2017 19th International Symposium on Symbolic and Numeric Algorithms for Scientific Computing, SYNASC 2017, Timisoara, Romania, 21–24 September 2017; pp. 263–270. [Google Scholar] [CrossRef]

- Jiang, J.; Cao, P.; Lu, Z.; Lou, W.; Yang, Y. Surface Defect Detection for Mobile Phone Back Glass Based on Symmetric Convolutional Neural Network Deep Learning. Appl. Sci. 2020, 10, 3621. [Google Scholar] [CrossRef]

- Natarajan, V.; Hung, T.Y.; Vaikundam, S.; Chia, L.T. Convolutional networks for voting-based anomaly classification in metal surface inspection. In Proceedings of the 2017 IEEE International Conference on Industrial Technology, Toronto, ON, Canada, 22–25 March 2017; pp. 986–991. [Google Scholar] [CrossRef]

- Yun, J.P.; Shin, W.C.; Koo, G.; Kim, M.S.; Lee, C.; Lee, S.J. Automated defect inspection system for metal surfaces based on deep learning and data augmentation. J. Manuf. Syst. 2020, 55, 317–324. [Google Scholar] [CrossRef]

- Ramesh, G.; Siddhartha, T.; Sivaraman, K.; Subramani, V. Identification of Timber Defects Using Convolution Neural Network. In Proceedings of the 6th International Conference on Communication and Electronics Systems, ICCES 2021, Coimbatore, India, 8–10 July 2021; pp. 1641–1647. [Google Scholar] [CrossRef]

- Jiang, B.; Chen, S.; Wang, B.; Luo, B. MGLNN: Semi-supervised learning via Multiple Graph Cooperative Learning Neural Networks. Neural Netw. 2022, 153, 204–214. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Nie, F.; Huang, H.; Huang, J. Large-scale multi-view spectral clustering via bipartite graph. In Proceedings of the Twenty-Ninth AAAI Conference on Artificial Intelligence, Austin, TX, USA, 25–30 January 2015; Volume 29. [Google Scholar]

- Roy, A.M.; Bhaduri, J. DenseSPH-YOLOv5: An automated damage detection model based on DenseNet and Swin-Transformer prediction head-enabled YOLOv5 with attention mechanism. Adv. Eng. Inform. 2023, 56, 102007. [Google Scholar] [CrossRef]

- Soto-Orozco, O.A.; Corral-Sáenz, A.D.; Rojo-González, C.E.; Ramírez-Quintana, J.A. Análisis del desempeño de redes neuronales profundas para segmentación semántica en hardware limitado. ReCIBE Rev. Electrón. Comput. Inform. Bioméd. Electrón. 2019, 8, 1–21. [Google Scholar]

- Sharma, R.; Saqib, M.; Lin, C.; Blumenstein, M. A Survey on Object Instance Segmentation. SN Comput. Sci. 2022, 3, 499. [Google Scholar] [CrossRef]

- Cai, H.; Li, J.; Hu, M.; Gan, C.; Han, S. EfficientViT: Lightweight Multi-Scale Attention for On-Device Semantic Segmentation. arXiv 2023, arXiv:2205.14756. [Google Scholar]

- Bousselham, W.; Thibault, G.; Pagano, L.; Machireddy, A.; Gray, J.; Chang, Y.H.; Song, X. Efficient Self-Ensemble for Semantic Segmentation. arXiv 2022, arXiv:cs.CV/2111.13280. [Google Scholar]

- Ke, L.; Danelljan, M.; Li, X.; Tai, Y.W.; Tang, C.K.; Yu, F. Mask transfiner for high-quality instance segmentation. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, New Orleans, LA, USA, 18–24 June 2022; pp. 4412–4421. [Google Scholar]

- Duy, T.V.T.; Natori, N. Efficient Defect Detection from Consecutive Monocular Images by Deep Learning. In Proceedings of the 19th IEEE International Conference on Machine Learning and Applications, ICMLA 2020, Miami, FL, USA, 14–17 December 2020; pp. 473–478. [Google Scholar] [CrossRef]

- Yin, T.; Yang, J. Detection of Steel Surface Defect Based on Faster R-CNN and FPN. In Proceedings of the 2021 7th International Conference on Computing and Artificial Intelligence, Tianjin, China, 23–26 April 2021; pp. 15–20. [Google Scholar] [CrossRef]

- Havryliv, D.; Ivakhiv, O.; Semenchenko, M. Defect detection on the surface of the technical ceramics using image processing and deep learning algorithms. In Proceedings of the 2020 21st International Conference on Research and Education in Mechatronics, REM 2020, Cracow, Poland, 9–11 December 2020. [Google Scholar] [CrossRef]

| #Q | Quality Questions | Yes | Partially | No |

|---|---|---|---|---|

| QA1 | Are the objectives of the study clearly identified? | |||

| QA2 | Are the limitations of the study specified? | |||

| QA3 | Is the type of surface specified and characterized? | |||

| QA4 | Does the study have a description and characterization of the used technology? | |||

| QA5 | Is it clear how the data collection was performed for the datasets? | |||

| QA6 | Is the dataset size appropriate? | |||

| QA7 | Are the findings and results correctly declared and discussed? | |||

| QA8 | Is the research methodology repeatable? | |||

| QA9 | Was a comparative analysis conducted (algorithm types)? |

| # | Rank | Category | Studies |

|---|---|---|---|

| 1 | Very high | 6 | |

| 2 | High | 35 | |

| 3 | Medium | 18 | |

| 4 | Low | 2 | |

| 5 | Very low | 1 |

| Reference | Author | Reference | Author |

|---|---|---|---|

| [6] | Kou et al. | [29] | Q. Jiang et al. |

| [9] | He et al. | [30] | Cao et al. |

| [31] | Aslam et al. | [32] | Min et al. |

| [33] | Lin and Wibowo | [34] | Le et al. |

| [35] | Block et al. | [36] | Tabernik et al. |

| [37] | Y. Xu, Li, et al. | [38] | Lian et al. |

| [39] | Shu et al. | [40] | Karangwa et al. |

| [41] | Luo et al. | [42] | Zheng et al. |

| [43] | Zou et al. | [44] | Ding et al. |

| [45] | Y. Xu, Zhang, et al. | [46] | Lv et al. |

| [47] | Kim et al. | [48] | K. Li et al. |

| [49] | Sauter et al. | [50] | J. Liu et al. |

| [51] | F. Xu et al. | [52] | Ahmed et al. |

| [53] | R. Liu et al. | [54] | Ren et al. |

| [55] | Feng et al. | [56] | Mittel and Kerber |

| [57] | Baskaran and Fernando | [58] | Ooi et al. |

| [59] | Mouzinho and Fukai | [60] | J. Sun et al. |

| [61] | Kumar, Sharma, et al. | [62] | Han et al. |

| [63] | Kumar, Batchu, et al. | [64] | Santolini et al. |

| [65] | Saeed | [66] | Zhao et al. |

| [67] | Kamiyama et al. | [68] | Guo et al. |

| [69] | Mao et al. | [70] | Wang et al. |

| [71] | Phua and Theng | [72] | Ferguson et al. |

| [73] | Ali et al. | [74] | W. Sun et al. |

| [75] | Zhou et al. | [76] | Shang et al. |

| [77] | Bahrami et al. | [78] | Jung et al. |

| [79] | Maningo et al. | [80] | Y. Li et al. |

| [81] | Gai et al. | [82] | Birlutiu et al. |

| [83] | J. Jiang et al. | [84] | Natarajan et al. |

| [85] | Yun et al. |

| Reference | Surface | Details |

|---|---|---|

| [43] | Special | Colored paintings on the surfaces of ancient Chinese buildings |

| [51] | Special | Paint film to protect and decorate metallic workpieces |

| [83] | Special | Mobile phone back glass defects |

| [34] | Special | Decorative sheets and welding defects |

| [36] | Special | Plastic embedding defects in electrical commutators |

| [80] | Special | Sealing surface defect of a container in the filling line |

| Reference | Problem | Dataset | Camera | Technique | Year | Network Architecture |

|---|---|---|---|---|---|---|

| [6] | P2 | D1 | C4 | T1-T2 | 2021 | Custom R-CNN |

| [9] | P1 | D1 | C1 | T2 | 2021 | ResNet, DenseNet |

| [31] | P3 | D1 | C4 | T1 | 2021 | Custom U-Net |

| [33] | P2 | D1 | C1 | T1-T2 | 2021 | YOLO, SDD, Faster R-CNN |

| [35] | P2 | D1 | C1 | T1 | 2021 | RetinaNet |

| [39] | P2 | D1 | C4 | T1-T2 | 2021 | Custom YOLOv3 |

| [41] | P2 | D1 | C1 | T1 | 2021 | Custom FPN |

| [45] | P2 | D2 | C1 | T1-T2 | 2021 | Custom YOLOv3 |

| [49] | P1 | D2 | C1 | T1-T2 | 2021 | Custom VGG16 |

| [53] | P2 | D2 | C3 | T1 | 2021 | Custom Faster R-CNN |

| [55] | P1 | D1 | C4 | T2 | 2021 | Custom Xception |

| [57] | P1 | D2 | C3 | T1-T2 | 2021 | Custom MobileNet |

| [67] | P1 | D1 | C2 | T1-T2 | 2021 | Custom VGG19 |

| [69] | P1 | D2 | C3 | T1 | 2021 | Custom ResNet |

| [71] | P1 | D1 | C2 | T1-T2 | 2020 | ResNet, SSD-VGG16 |

| [75] | P1 | D1 | C1 | T1 | 2020 | Compact CNN |

| [77] | P2 | D1 | C2 | T1 | 2020 | Faster R-CNN, SSD, Inception v2 |

| [81] | P1 | D1 | C1 | T1-T2 | 2020 | Custom VGG |

| [85] | P1 | D1 | C1 | T2 | 2020 | Custom CNN |

| [29] | P2 | D1 | C1 | T1 | 2020 | Custom CNN |

| [30] | P3 | D2 | C3 | T1-T2 | 2020 | Custom SE-U-Net |

| [38] | P1 | D1 | C1 | T2 | 2020 | Custom CNN |

| [46] | P2 | D1 | C1 | T1 | 2020 | EDDN |

| [48] | P2 | D2 | C3 | T1-T2 | 2019 | Custom Faster R-CNN and FPN |

| [50] | P1 | D2 | C3 | T3 | 2019 | Custom with BN |

| [54] | P2 | D1 | C1 | T1-T2 | 2019 | Custom Slighter Faster R-CNN |

| [56] | P1 | D1 | C2 | T1-T2 | 2019 | GoogLeNet, AlexNet |

| [58] | P1 | D1 | C4 | T2 | 2019 | Custom CNN |

| [60] | P1 | D1 | C1 | T1-T2 | 2019 | Custom VGG16 |

| [62] | P1 | D1 | C2 | T1-T2 | 2019 | Custom Inception v4 |

| [64] | P1 | D2 | C3 | T1 | 2019 | Custom CNN |

| [66] | P1 | D1 | C1 | T2 | 2019 | AlexNet, BP neural network |

| [68] | P2 | D1 | C4 | T1 | 2019 | YOLOv3 |

| [72] | P4 | D2 | C1 | T1-T2 | 2018 | Custom CNN |

| [74] | P1 | D1 | C1 | T1-T2 | 2018 | Custom CNN |

| [76] | P2 | D1 | C1 | T1 | 2018 | Inception v3 |

| [84] | P1 | D2 | C2 | T1 | 2017 | Custom VGG |

| Reference | Problem | Dataset | Camera | Technique | Year | Network Architecture |

|---|---|---|---|---|---|---|

| [37] | P4 | D1 | C1 | T1-T2 | 2021 | Custom Mask R-CNN |

| [47] | P1 | D2 | C3 | T1 | 2021 | Custom LeNet-5 |

| [59] | P3 | D1 | C2 | T1-T2 | 2021 | U-Net |

| [61] | P4 | D1 | C2 | T1 | 2021 | Mask R-CNN |

| [63] | P2 | D1 | C2 | T1 | 2021 | YOLOv3 |

| [65] | P1 | D1 | C2 | T3 | 2021 | Custom CNN |

| [73] | P1 | D2 | C2 | T1-T2 | 2020 | Custom CNN |

| [79] | P2 | D2 | C3 | T1 | 2020 | Faster R-CNN |

| [42] | P3 | D1 | C2 | T1 | 2020 | FCN, R-CNN, and RFCN |

| [52] | P1 | D1 | C2 | T3 | 2019 | Custom CNN, Inception-ResNet-v2, Inception-v3, and Xception |

| [70] | P2 | D1 | C2 | T1-T2 | 2018 | AlexNet for MHSD, GoogLeNet for MHSD |

| Reference | Problem | Dataset | Camera | Technique | Year | Network Architecture |

|---|---|---|---|---|---|---|

| [32] | P1 | D1 | C4 | T1-T2 | 2020 | ResNet |

| [40] | P2 | D1 | C1 | T1-T2 | 2020 | Faster R-CNN with VGG16 |

| [82] | P1 | D1 | C4 | T3 | 2017 | Custom CNN |

| Reference | Problem | Dataset | Camera | Technique | Year | Network Architecture |

|---|---|---|---|---|---|---|

| [44] | P2 | D1 | C1 | T1-T2 | 2020 | Custom SSD |

| [78] | P1 | D1 | C1 | T1-T2 | 2018 | LeNet, VGG19, DenseNet121 |

| Reference | Problem | Dataset | Camera | Technique | Year | Network Architecture |

|---|---|---|---|---|---|---|

| [43] | P3 | D1 | C2 | T1-T2 | 2021 | Custom U-Net |

| [51] | P2 | D1 | C1 | T1-T2 | 2021 | SSD and Faster R-CNN |

| [83] | P3 | D1 | C1 | T1 | 2020 | Custom U-Net |

| [34] | P1 | D1 | C1 | T1-T2 | 2020 | MobileNet, Inception |

| [36] | P3 | D1 | C4 | T1-T2 | 2019 | Custom CNN |

| [80] | P2 | D1 | C1 | T1-T2 | 2018 | Custom MobileNet-SSD |

| Surface | Total | Percentage |

|---|---|---|

| Metal | 37 | 62.71% |

| Building | 11 | 18.64% |

| Special | 6 | 10.17% |

| Ceramic | 3 | 5.08% |

| Wood | 2 | 3.39% |

| Problem Type | Total | Percentage | Details |

|---|---|---|---|

| P1 | 29 | 49.15% | Studies using image classification |

| P2 | 20 | 33.90% | Studies using object detection |

| P3 | 7 | 11.86% | Studies using semantic segmentation |

| P4 | 3 | 5.08% | Studies using instance segmentation |

| Network | Total | Percentage | Details |

|---|---|---|---|

| CNN | 19 | 32.20% | Studies that used unmodified networks to perform the experiments |

| Custom CNN | 40 | 67.80% | Studies that created a CNN based on other networks |

| Technique | Total | Percentage | Details |

|---|---|---|---|

| DA | 6 | 10.17% | Studies that use only data augmentation |

| TL | 19 | 32.20% | Studies that use only transfer learning |

| DA and TL | 30 | 50.85% | Studies that use a combination of data augmentation and transfer learning |

| No technique | 4 | 6.78% | Studies that do not use these techniques |

| Technique | Total | Percentage | Details |

|---|---|---|---|

| TL | 49 | 83.05% | Studies that use data augmentation |

| DA | 36 | 59.32% | Studies that use transfer learning |

| Origin | Total | Percentage |

|---|---|---|

| Created | 46 | 77.97% |

| Already exists | 13 | 22.03% |

| Origin | Total | Percentage |

|---|---|---|

| Private | 39 | 66.10% |

| Public | 20 | 33.90% |

| Availability | Total | Percentage |

|---|---|---|

| Private | 39 | 86.67% |

| Public | 7 | 13.33% |

| Camera | Studies | Percentage |

|---|---|---|

| Industrial | 26 | 44.07% |

| Nonindustrial | 15 | 25.42% |

| Camera dataset | 9 | 15.25% |

| No information | 9 | 15.25% |

| Year | Total | Percentage |

|---|---|---|

| 2017 | 2 | 3.39% |

| 2018 | 6 | 10.17% |

| 2019 | 11 | 18.64% |

| 2020 | 18 | 30.51% |

| 2021 | 22 | 37.29% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cumbajin, E.; Rodrigues, N.; Costa, P.; Miragaia, R.; Frazão, L.; Costa, N.; Fernández-Caballero, A.; Carneiro, J.; Buruberri, L.H.; Pereira, A. A Systematic Review on Deep Learning with CNNs Applied to Surface Defect Detection. J. Imaging 2023, 9, 193. https://doi.org/10.3390/jimaging9100193

Cumbajin E, Rodrigues N, Costa P, Miragaia R, Frazão L, Costa N, Fernández-Caballero A, Carneiro J, Buruberri LH, Pereira A. A Systematic Review on Deep Learning with CNNs Applied to Surface Defect Detection. Journal of Imaging. 2023; 9(10):193. https://doi.org/10.3390/jimaging9100193

Chicago/Turabian StyleCumbajin, Esteban, Nuno Rodrigues, Paulo Costa, Rolando Miragaia, Luís Frazão, Nuno Costa, Antonio Fernández-Caballero, Jorge Carneiro, Leire H. Buruberri, and António Pereira. 2023. "A Systematic Review on Deep Learning with CNNs Applied to Surface Defect Detection" Journal of Imaging 9, no. 10: 193. https://doi.org/10.3390/jimaging9100193

APA StyleCumbajin, E., Rodrigues, N., Costa, P., Miragaia, R., Frazão, L., Costa, N., Fernández-Caballero, A., Carneiro, J., Buruberri, L. H., & Pereira, A. (2023). A Systematic Review on Deep Learning with CNNs Applied to Surface Defect Detection. Journal of Imaging, 9(10), 193. https://doi.org/10.3390/jimaging9100193