Automatic Method for Vickers Hardness Estimation by Image Processing

Abstract

1. Introduction

2. Materials and Methods

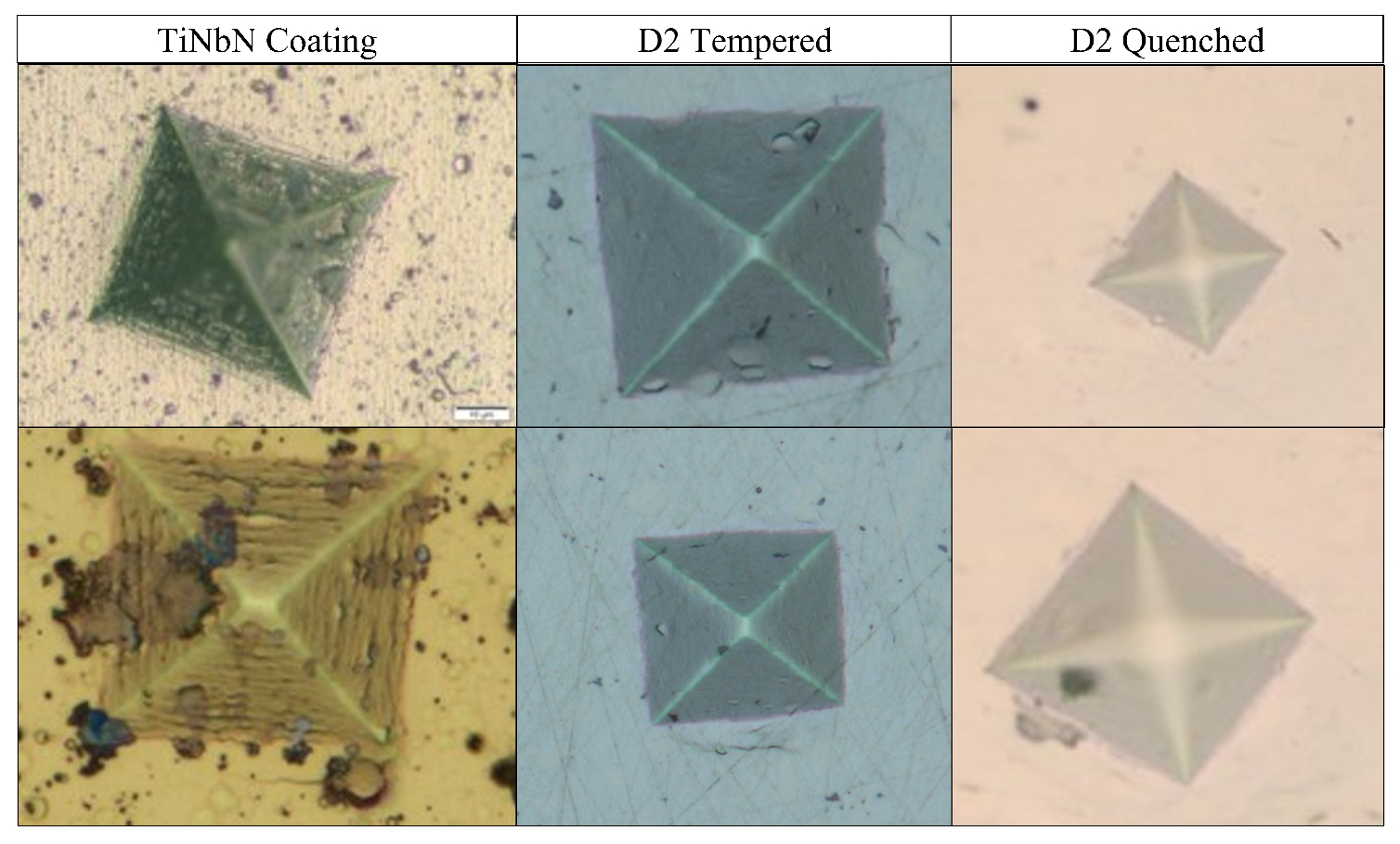

2.1. Materials

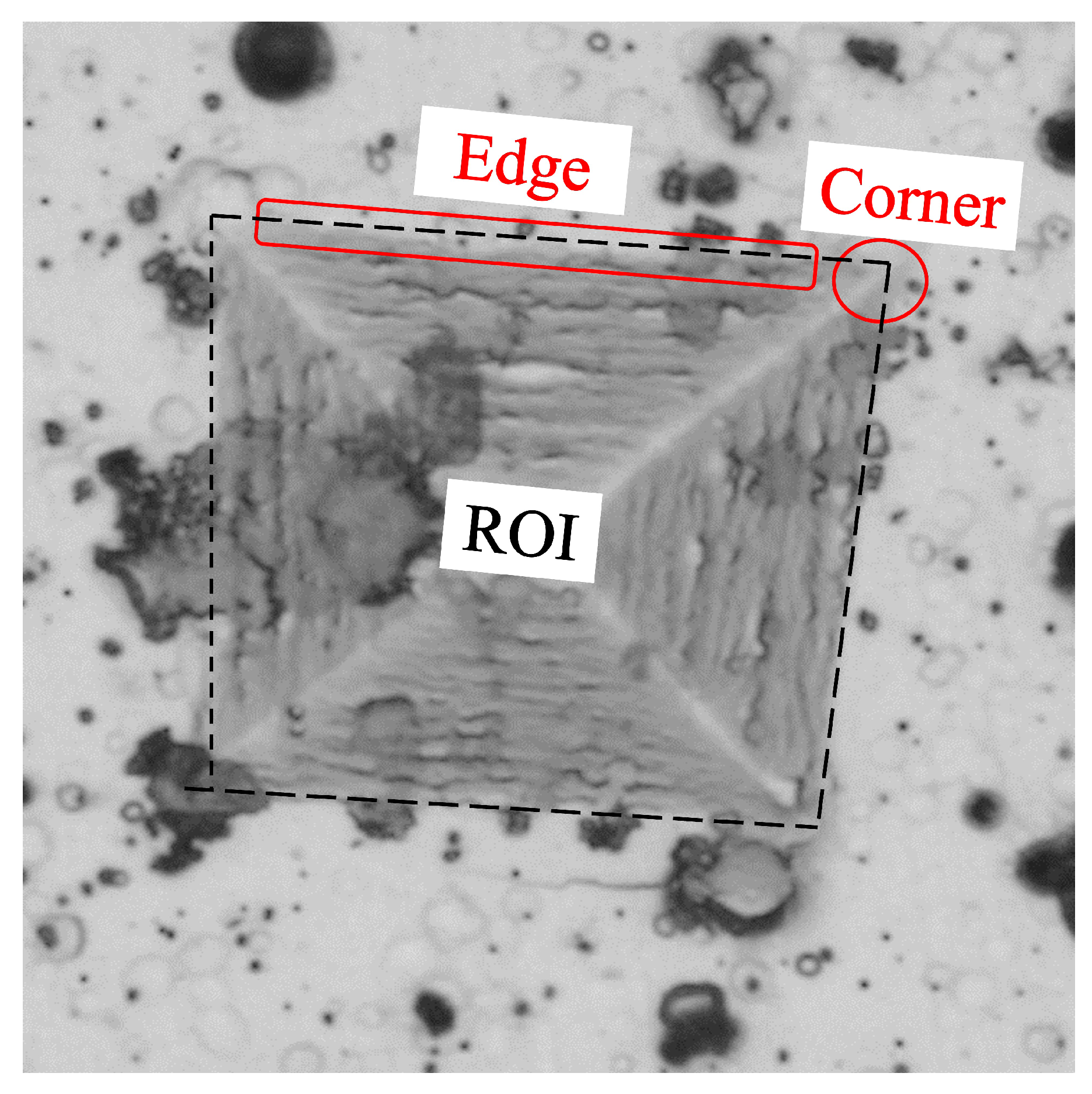

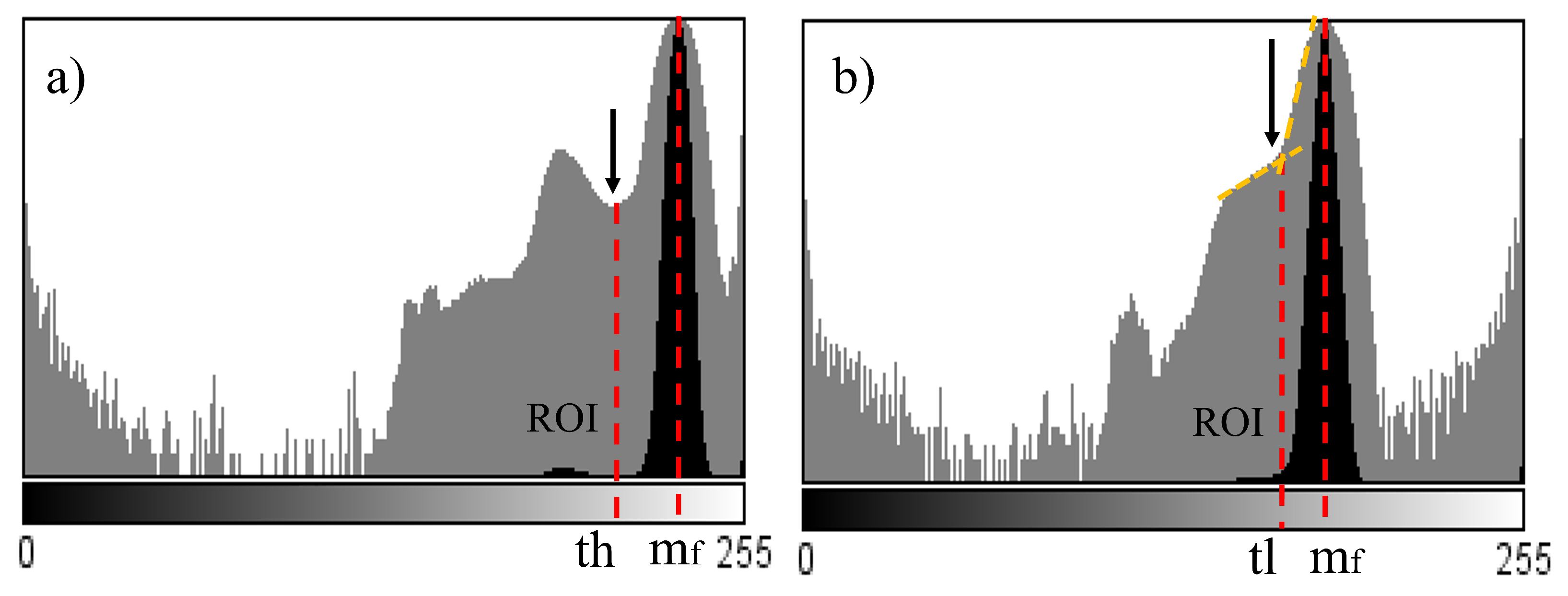

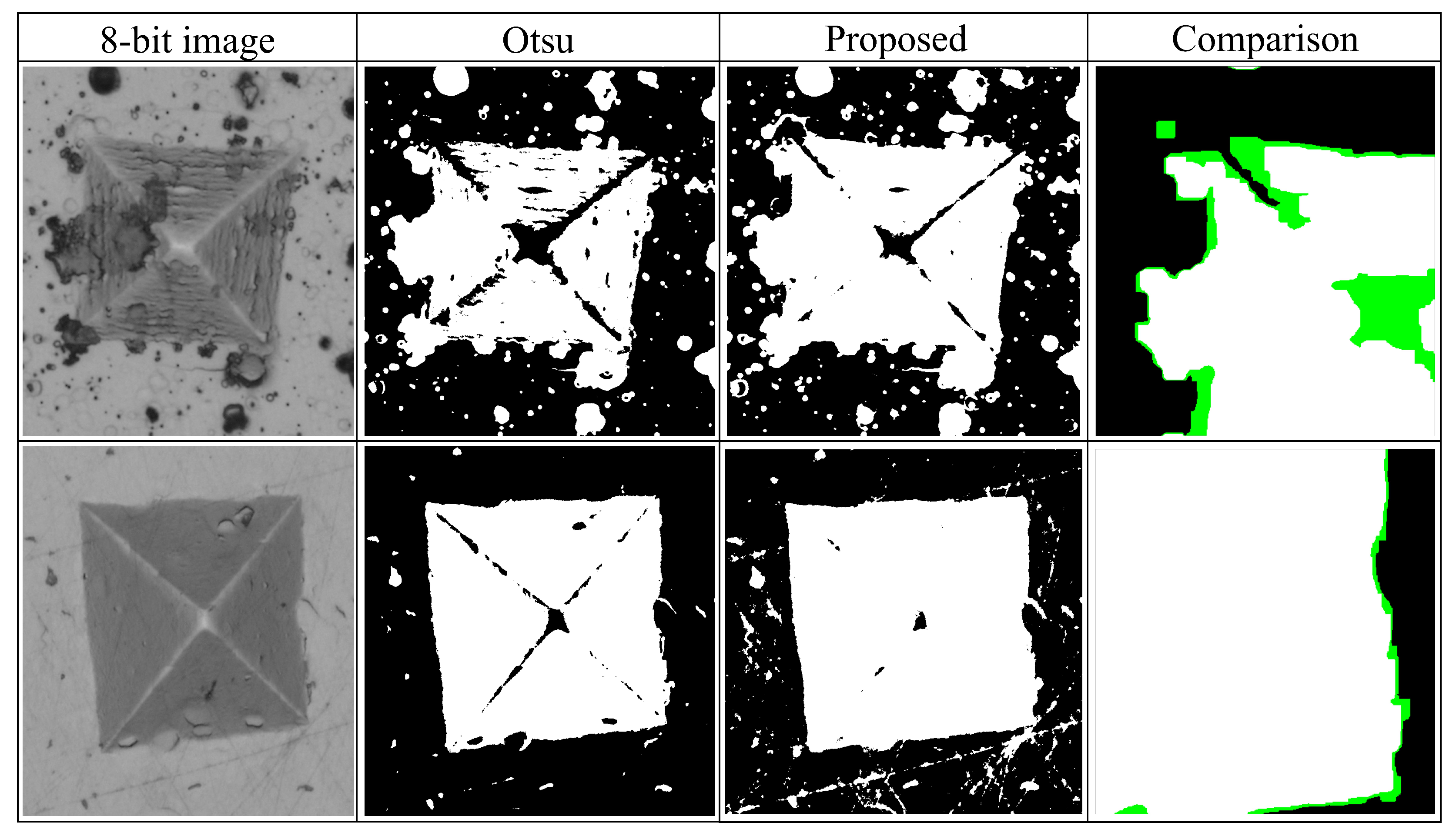

2.2. Methods

| Pseudocode |

| Input: |

| Color image Q |

| 1. Find indentation mark |

| Get color channels R, G, B from Q |

| Find channel A with Maximun entropy |

| Binarize A, using the proposed method |

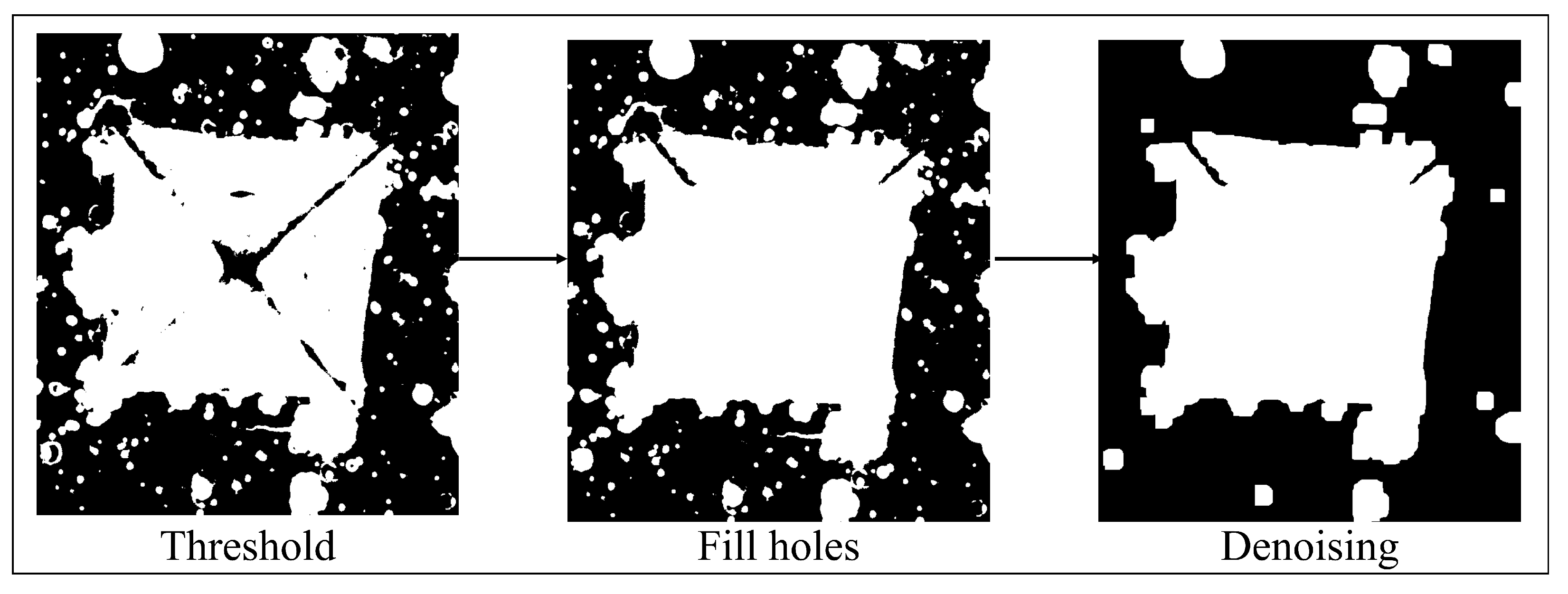

| Fill holes and remove noise using mathematical morphology |

| Label objects |

| Select larger object |

| 2. Indentation corner detection: |

| Using local maximum radius: |

| Find corners |

| Get Quadrature index |

| Using indentation perimeter: |

| Find corners |

| Get Quadrature index |

| Using Hough transform: |

| Find corners |

| Get Quadrature index |

| 3. Find best indentation result: |

| if ( > && > ) { |

| Select local maximum radius solution } |

| else if ( > && > ) { |

| Select Perimeter solution } |

| else{ |

| Select Hough solution } |

| 4. Calculate hardness estimation HV. |

| Output: HV |

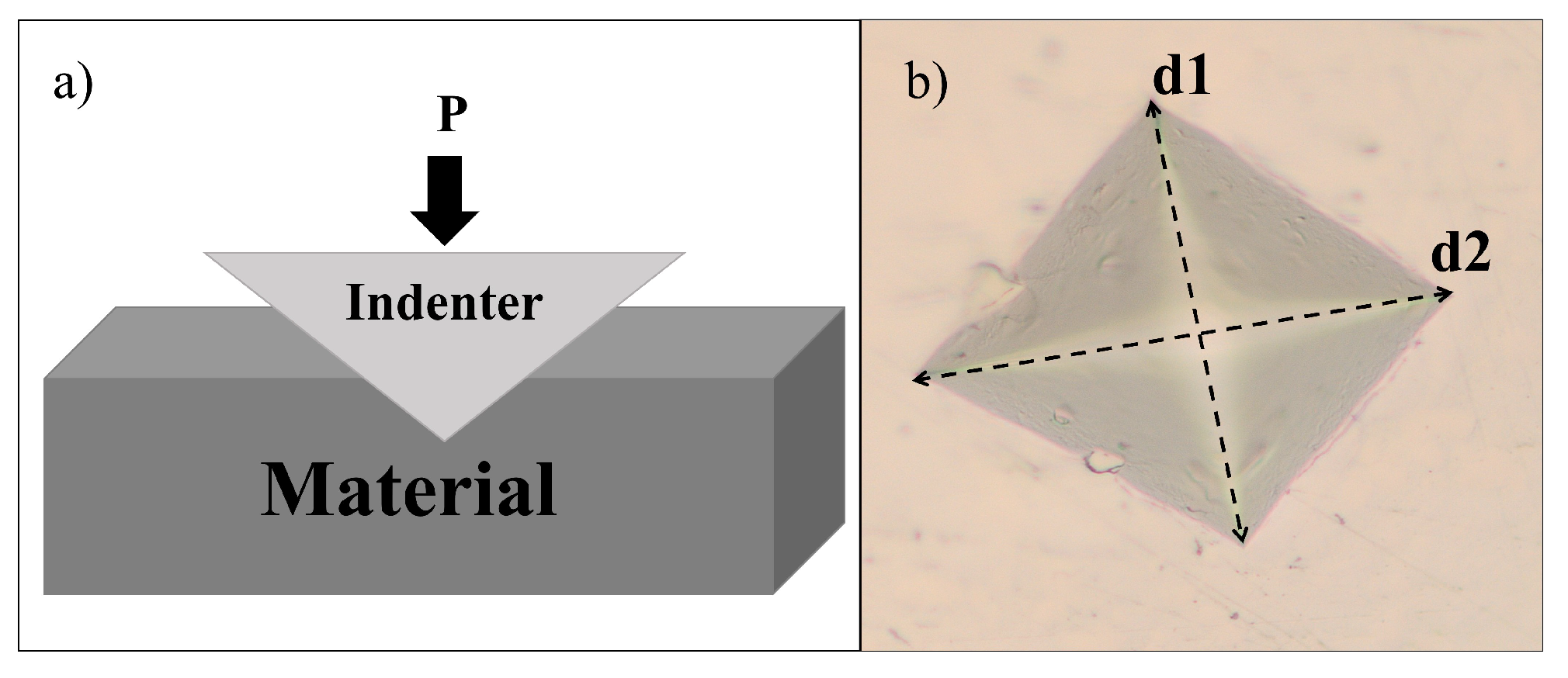

- (a)

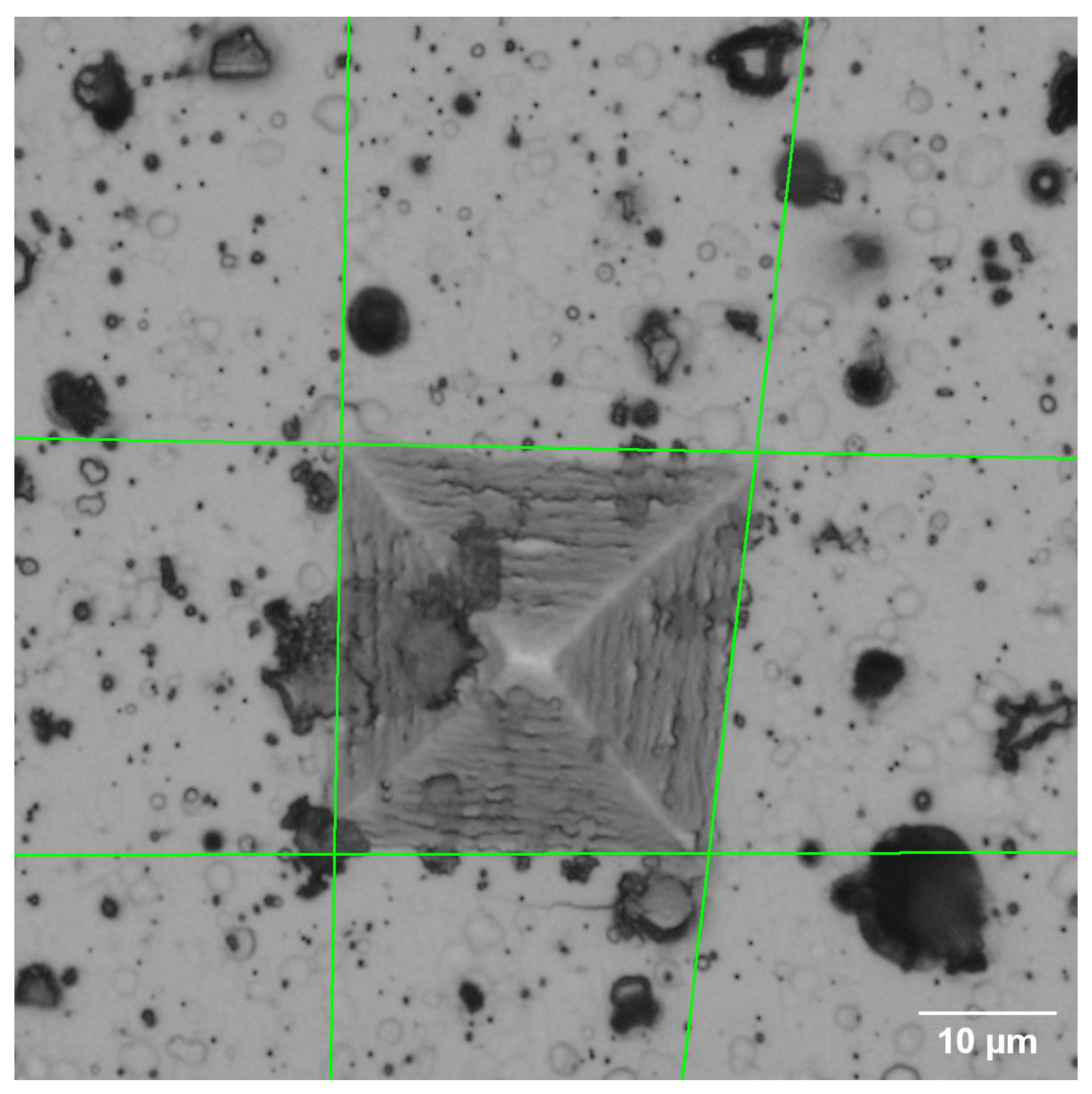

- Solution by local maximum radius: This solution works in the case where the shape of the indentation trace can be approximated to a square. If this is the case, the centroid of the figure is calculated and the four major diagonals are found, which would correspond to the four corners. In this solution, the distances of the pixels of the perimeter to the centroid of the figure are found, in such a way that, to find the corners, it is taken into account that their distance is a local maximum in the function of distances with respect to the centroid. This strategy is a rather simplified version of the method used to recognize figures from the distances relative to the centroid [25].

- (b)

- Perimeter solution: In the case that the region of interest is affected by “noise” that may be due to the heat treatment applied or the type of material, this solution would be useful. For this solution, we calculate the perimeter of the figure, and perform a linear regression using least squares for each side. The intersections of these regressions would correspond to the four corners of the indentation mark. If the edge of the figure is “broken” or open, there would be the disadvantage of an infinite diagonal, which makes it impossible to calculate the perimeter of the figure.

- (c)

- Solution by Hough transform: this solution has the advantage that the pixels do not need to be contiguous to determine a line; therefore, it favors the detection under a certain level of noise. It also does not limit us to obtain a single solution as in the case of a linear regression; with this transform, multiple lines can be drawn by adjusting to the irregularity of the object of interest [26].

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Corner Detection Results on 24 Images

References

- Callister, W.D. Introducción a la Ciencia E ingeniería de los Materiales: Tomo 1; Reverté: Barcelona, Spain, 1997. [Google Scholar]

- Askeland, D.R.; Fulay, P.P. The Science and Engineering of Materials; Cengage: Boston, MA, USA, 2016. [Google Scholar]

- Sydor, M.; Pinkowski, G.; Jasińska, A. The Brinell method for determining hardness of wood flooring materials. Forests 2020, 11, 878. [Google Scholar] [CrossRef]

- Zeng, X.; Xiao, Y.; Ji, X.; Wang, G. Mineral identification based on deep learning that combines image and Mohs hardness. Minerals 2021, 11, 506. [Google Scholar] [CrossRef]

- Rodríguez-Prieto, A.; Primera, E.; Frigione, M.; Camacho, A.M. Reliability prediction of acrylonitrile O-ring for nuclear power applications based on shore hardness measurements. Polymers 2021, 13, 943. [Google Scholar] [CrossRef] [PubMed]

- Schiavi, A.; Origlia, C.; Germak, A.; Prato, A.; Genta, G. Indentation modulus, indentation work and creep of metals and alloys at the macro-scale level: Experimental insights into the use of a primary Vickers hardness standard machine. Materials 2021, 14, 2912. [Google Scholar] [CrossRef] [PubMed]

- Hościło, B.; Molski, K.L. Determination of Surface Stresses in X20Cr13 Steel by the Use of a Modified Hardness Measurement Procedure with Vickers Indenter. Materials 2020, 13, 4844. [Google Scholar] [CrossRef] [PubMed]

- Albella, J.M. Láminas Delgadas y Recubrimientos. Preparación, Propiedades y Aplicaciones; Consejo Superior de Investigaciones Científicas: Madrid, Spain, 2003; p. 704. [Google Scholar]

- Jairo Florez Olaya, J.; Chipatecua, Y.L.G.; Rodil, S.E.P. Resistencia a la corrosión de recubrimientos de nitruros metálicos depositados sobre acero AISI M2 Corrosion resistance of transition metal nitride films deposited on AISI M2 steel. Ing. Y Desarro. 2012, 30, 1–22. [Google Scholar]

- Baptista, A.; Silva, F.; Porteiro, J.; Míguez, J.; Pinto, G. Sputtering Physical Vapour Deposition (PVD) Coatings: A Critical Review on Process Improvement and Market Trend Demands. Coatings 2018, 8, 402. [Google Scholar] [CrossRef]

- Soffritti, C.; Fortini, A.; Sola, R.; Fabbri, E.; Merlin, M.; Garagnani, G.L. Influence of Vacuum Heat Treatments on Microstructure and Mechanical Properties of M35 High Speed Steel. Metals 2020, 10, 643. [Google Scholar] [CrossRef]

- Barrena-Rodríguez, M.d.J.; Acosta-González, F.A.; Téllez-Rosas, M.M. A Review of the Boiling Curve with Reference to Steel Quenching. Metals 2021, 11, 974. [Google Scholar] [CrossRef]

- Cicek, H.; Baran, O.; Keles, A.; Totik, Y.; Efeoglu, I. A comparative study of fatigue properties of TiVN and TiNbN thin films deposited on different substrates. Surf. Coatings Technol. 2017, 332, 296–303. [Google Scholar] [CrossRef]

- Sheppard, L.R.; Zhang, H.; Liu, R.; Macartney, S.; Murphy, T.; Wuhrer, R. Reactive sputtered Ti X Nb Y N Z thin films. I. Basic processing relationships. Mater. Chem. Phys. 2019, 224, 308–313. [Google Scholar] [CrossRef]

- Sheppard, L.R.; Zhang, H.; Liu, R.; Macartney, S.; Murphy, T.; Wainer, P.; Wuhrer, R. Reactive sputtered Ti x Nb y N coatings. II. Effect of common deposition parameters. Mater. Chem. Phys. 2019, 224, 320–327. [Google Scholar] [CrossRef]

- ASTM International Standards. Standard Test Method for Microindentation Hardness of Materials; ASTM International: West Conshohocken, PA, USA, 2017; Volume E384, pp. 1–40. [Google Scholar] [CrossRef]

- Sugimoto, T.; Kawaguchi, T. Development of an automatic Vickers hardness testing system using image processing technology. IEEE Trans. Ind. Electron. 1997, 44, 696–702. [Google Scholar] [CrossRef]

- Dominguez-Nicolas, S.M.; Wiederhold, P. Indentation Image Analysis for Vickers Hardness Testing. In Proceedings of the 2018 15th International Conference on Electrical Engineering, Computing Science and Automatic Control (CCE), Mexico City, Mexico, 5–7 September 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Fedotkin, A.; Laktionov, I.; Kravchuk, K.; Maslenikov, I.; Useinov, A. Automatic Processing of Microhardness Images Using Computer Vision Methods. Instruments Exp. Tech. 2021, 64, 357–362. [Google Scholar] [CrossRef]

- Privezentsev, D.; Zhiznyakov, A.; Kulkov, Y. Automation of Measuring Microhardness of Materials using Metal-Graphic Images. In Proceedings of the 2019 International Russian Automation Conference (RusAutoCon), Sochi, Russia, 8–14 September 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Tanaka, Y.; Seino, Y.; Hattori, K. Automated Vickers hardness measurement using convolutional neural networks. Int. J. Adv. Manuf. Technol. 2020, 109, 1345–1355. [Google Scholar] [CrossRef]

- Jalilian, E.; Uhl, A. Deep Learning Based Automated Vickers Hardness Measurement. In Computer Analysis of Images and Patterns; Tsapatsoulis, N., Panayides, A., Theocharides, T., Lanitis, A., Pattichis, C., Vento, M., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 3–13. [Google Scholar] [CrossRef]

- Li, Z.; Yin, F. Automated measurement of Vickers hardness using image segmentation with neural networks. Measurement 2021, 186, 110200. [Google Scholar] [CrossRef]

- Cheng, W.S.; Chen, G.Y.; Shih, X.Y.; Elsisi, M.; Tsai, M.H.; Dai, H.J. Vickers Hardness Value Test via Multi-Task Learning Convolutional Neural Networks and Image Augmentation. Appl. Sci. 2022, 12, 10820. [Google Scholar] [CrossRef]

- Chang, C.; Hwang, S.; Buehrer, D. A shape recognition scheme based on relative distances of feature points from the centroid. Pattern Recognit. 1991, 24, 1053–1063. [Google Scholar] [CrossRef]

- Mukhopadhyay, P.; Chaudhuri, B.B. A survey of Hough Transform. Pattern Recognit. 2015, 48, 993–1010. [Google Scholar] [CrossRef]

| Material | Algorithm (HV) | Manual (HV) | Error Rate | Runtime (s) | Selected Solution | |||

|---|---|---|---|---|---|---|---|---|

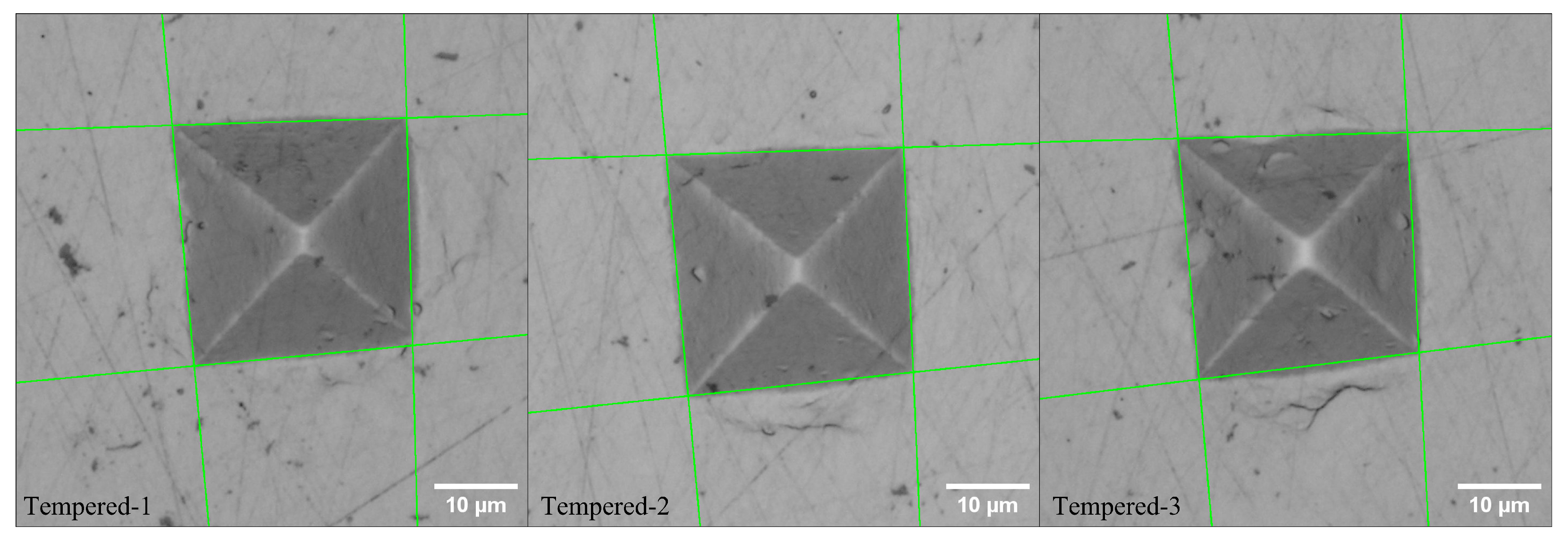

| Tempered-1 | 620.46 | 625.49 | 0.80 | 1.39 | 0.971 | 0.979 | 0.975 | Max radius |

| Tempered-2 | 609.32 | 610.61 | 0.21 | 1.42 | 0.981 | 0.981 | 0.980 | Max radius |

| Tempered-3 | 632.88 | 626.54 | 1.01 | 1.40 | 0.968 | 0.178 | 0.970 | Max radius |

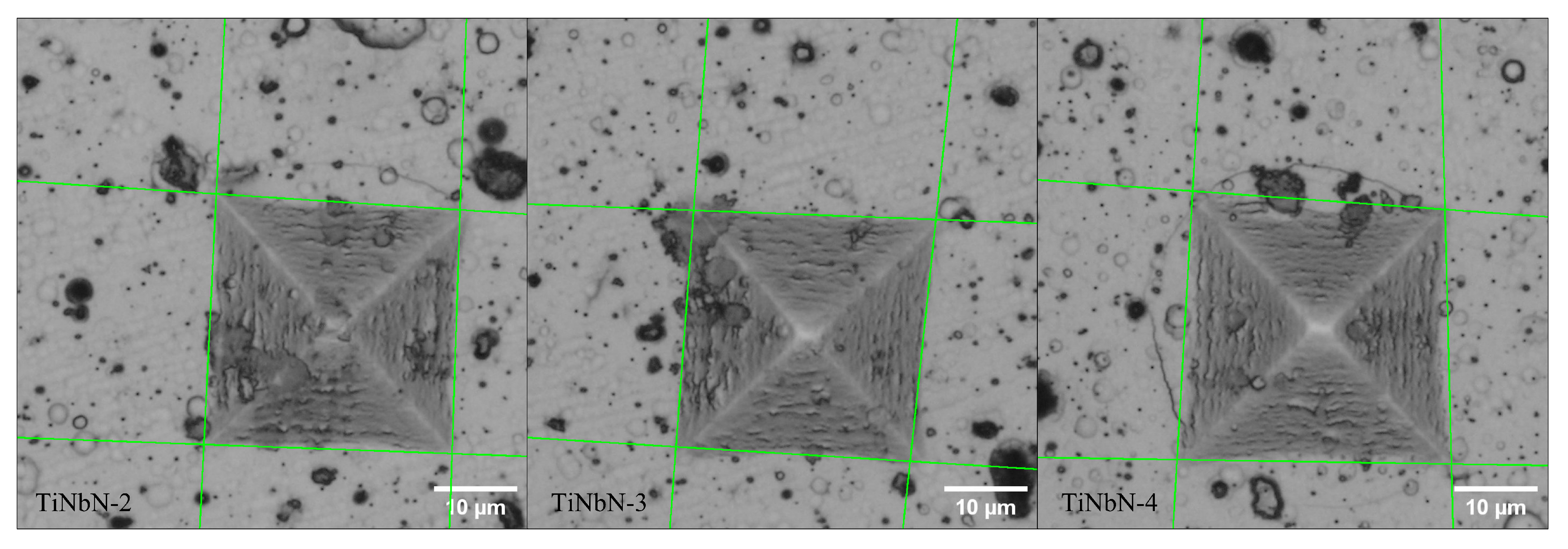

| TiNbN-1 | 1105.00 | 1104.74 | 0.02 | 1.34 | 0.978 | 0.423 | 0.926 | Hough |

| TiNbN-2 | 1125.77 | 1172.74 | 4.00 | 1.36 | 0.989 | 0.934 | 0.939 | Hough |

| TiNbN-3 | 1127.42 | 1157.46 | 2.60 | 0.83 | 0.984 | 0.413 | 0.928 | Hough |

| TiNbN-4 | 1122.60 | 1150.30 | 2.41 | 0.97 | 0.983 | 0.087 | 0.497 | Hough |

| Steel-1 | 174.54 | 168.70 | 3.46 | 4.74 | 0.922 | 0.949 | 0.955 | Max radius |

| Steel-2 | 169.71 | 164.59 | 3.11 | 4.72 | 0.947 | 0.954 | 0.959 | Max radius |

| Steel-3 | 177.11 | 172.65 | 2.58 | 4.76 | 0.963 | 0.961 | 0.965 | Max radius |

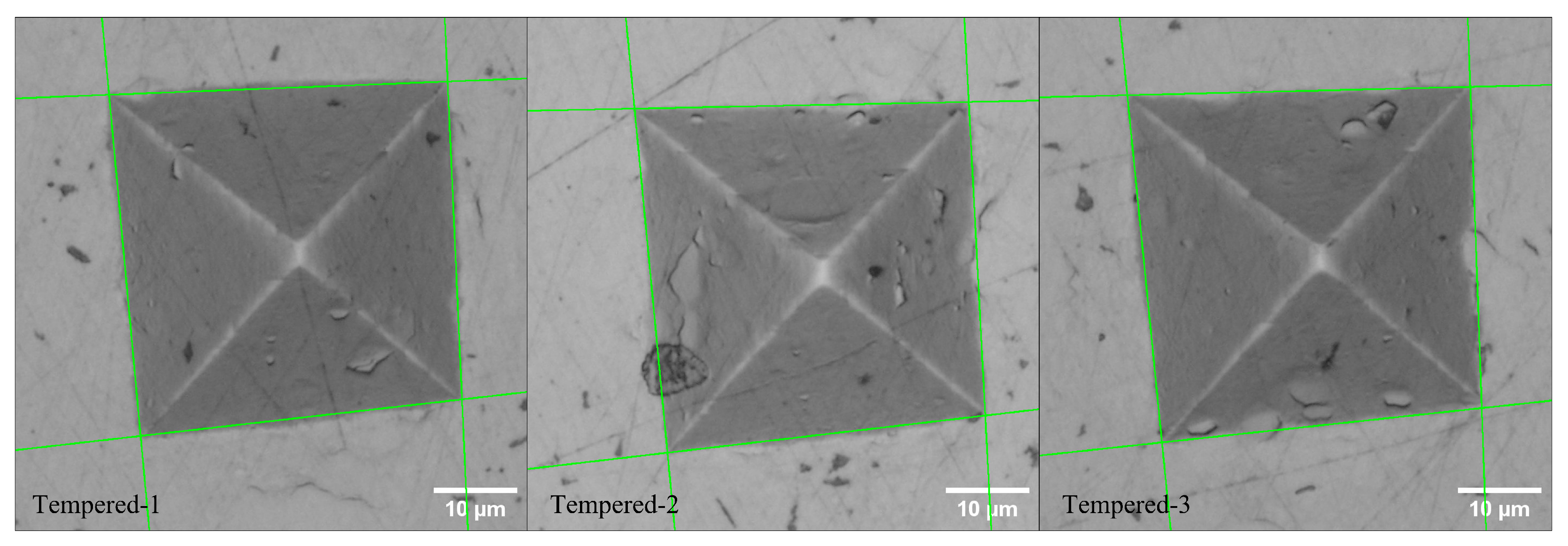

| Quenched-1 | 742.65 | 711.03 | 4.45 | 1.99 | 0.954 | 0.972 | 0.970 | Max radius |

| Quenched-2 | 659.97 | 640.88 | 2.98 | 1.14 | 0.959 | 0.966 | 0.969 | Max radius |

| Quenched-3 | 628.92 | 620.36 | 1.38 | 1.61 | 0.598 | 0.961 | 0.822 | Perimeter |

| Material | Algorithm (HV) | Manual (HV) | Error Rate | Runtime (s) | Selected Solution | |||

|---|---|---|---|---|---|---|---|---|

| Tempered-1 | 604.27 | 599.50 | 0.80 | 0.93 | 0.971 | 0.979 | 0.980 | Max radius |

| Tempered-2 | 612.89 | 609.86 | 0.50 | 0.92 | 0.981 | 0.973 | 0.974 | Max radius |

| Tempered-3 | 593.55 | 595.47 | 0.32 | 0.89 | 0.974 | 0.975 | 0.977 | Max radius |

| TiNbN-1 | 1060.26 | 1075.99 | 1.46 | 0.74 | 0.973 | 0.970 | 0.969 | Max radius |

| TiNbN-2 | 1074.71 | 1069.96 | 0.44 | 0.86 | 0.991 | 0.678 | 0.551 | Hough |

| TiNbN-3 | 1145.3 | 1113.35 | 2.87 | 0.89 | 0.982 | 0.990 | 0.914 | Perimeter |

| TiNbN-4 | 950.06 | 931.23 | 2.02 | 0.96 | 0.933 | 0.895 | 0.977 | Max radius |

| TiNbN-5 | 899.22 | 910.07 | 1.19 | 0.97 | 0.984 | 0.879 | 0.930 | Hough |

| TiNbN-6 | 917.31 | 908.14 | 1.01 | 0.90 | 0.983 | 0.518 | 0.874 | Hough |

| Steel-1 | 267.16 | 261.84 | 2.03 | 4.74 | 0.970 | 0.971 | 0.969 | Max radius |

| Steel-2 | 269.78 | 264.61 | 1.95 | 4.73 | 0.969 | 0.958 | 0.962 | Max radius |

| Steel-3 | 273.06 | 271.75 | 0.48 | 4.86 | 0.945 | 0.958 | 0.960 | Max radius |

| Quenched-1 | 1020.45 | 1029.43 | 0.87 | 3.55 | 0.968 | 0.982 | 0.962 | Max radius |

| Quenched-2 | 980.49 | 967.21 | 1.37 | 1.70 | 0.953 | 0.968 | 0.969 | Max radius |

| Quenched-3 | 967.41 | 943.70 | 2.51 | 2.26 | 0.954 | 0.964 | 0.966 | Max radius |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Polanco, J.D.; Jacanamejoy-Jamioy, C.; Mambuscay, C.L.; Piamba, J.F.; Forero, M.G. Automatic Method for Vickers Hardness Estimation by Image Processing. J. Imaging 2023, 9, 8. https://doi.org/10.3390/jimaging9010008

Polanco JD, Jacanamejoy-Jamioy C, Mambuscay CL, Piamba JF, Forero MG. Automatic Method for Vickers Hardness Estimation by Image Processing. Journal of Imaging. 2023; 9(1):8. https://doi.org/10.3390/jimaging9010008

Chicago/Turabian StylePolanco, Jonatan D., Carlos Jacanamejoy-Jamioy, Claudia L. Mambuscay, Jeferson F. Piamba, and Manuel G. Forero. 2023. "Automatic Method for Vickers Hardness Estimation by Image Processing" Journal of Imaging 9, no. 1: 8. https://doi.org/10.3390/jimaging9010008

APA StylePolanco, J. D., Jacanamejoy-Jamioy, C., Mambuscay, C. L., Piamba, J. F., & Forero, M. G. (2023). Automatic Method for Vickers Hardness Estimation by Image Processing. Journal of Imaging, 9(1), 8. https://doi.org/10.3390/jimaging9010008