A Fast and Low-Cost Human Body 3D Scanner Using 100 Cameras

Abstract

1. Introduction

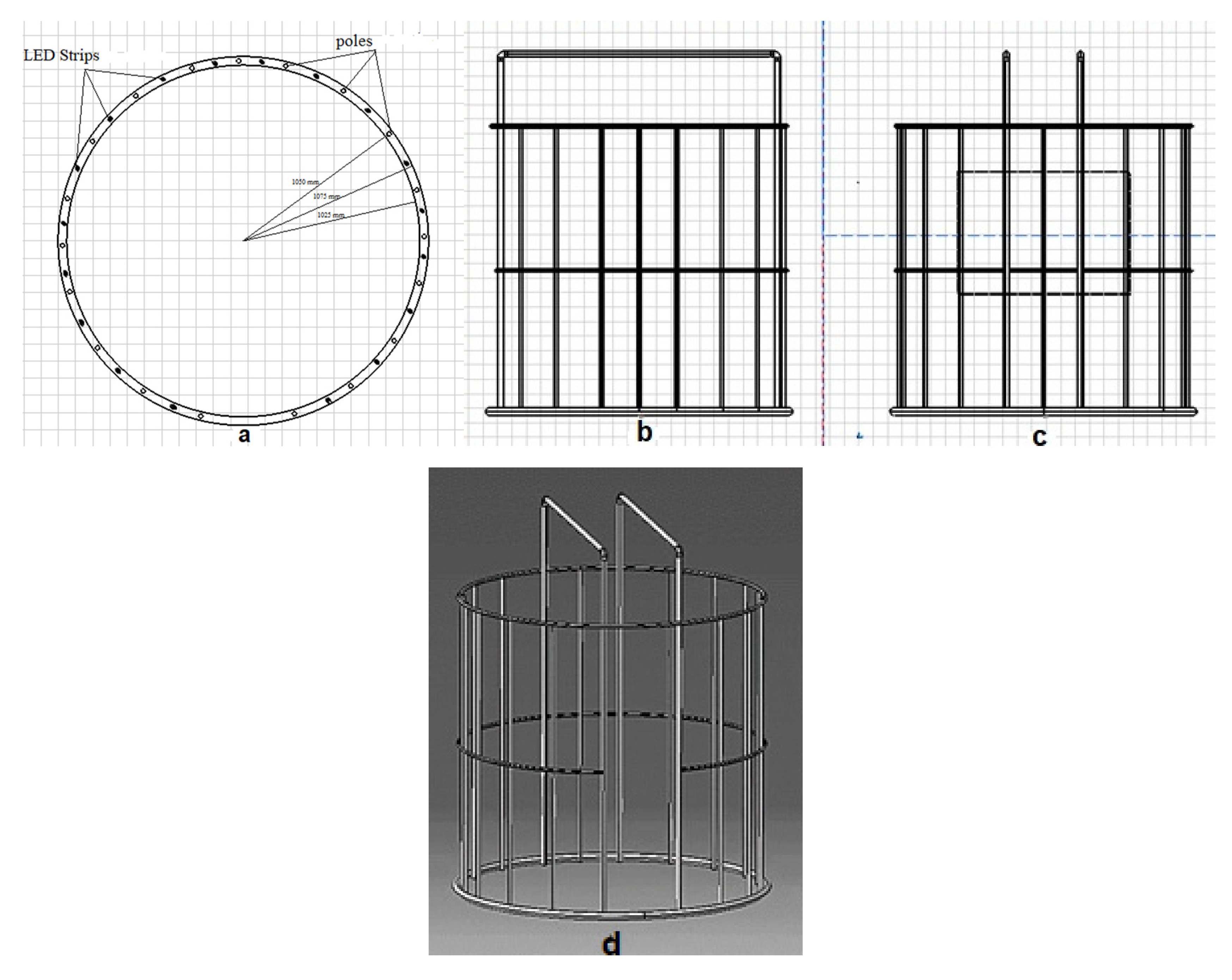

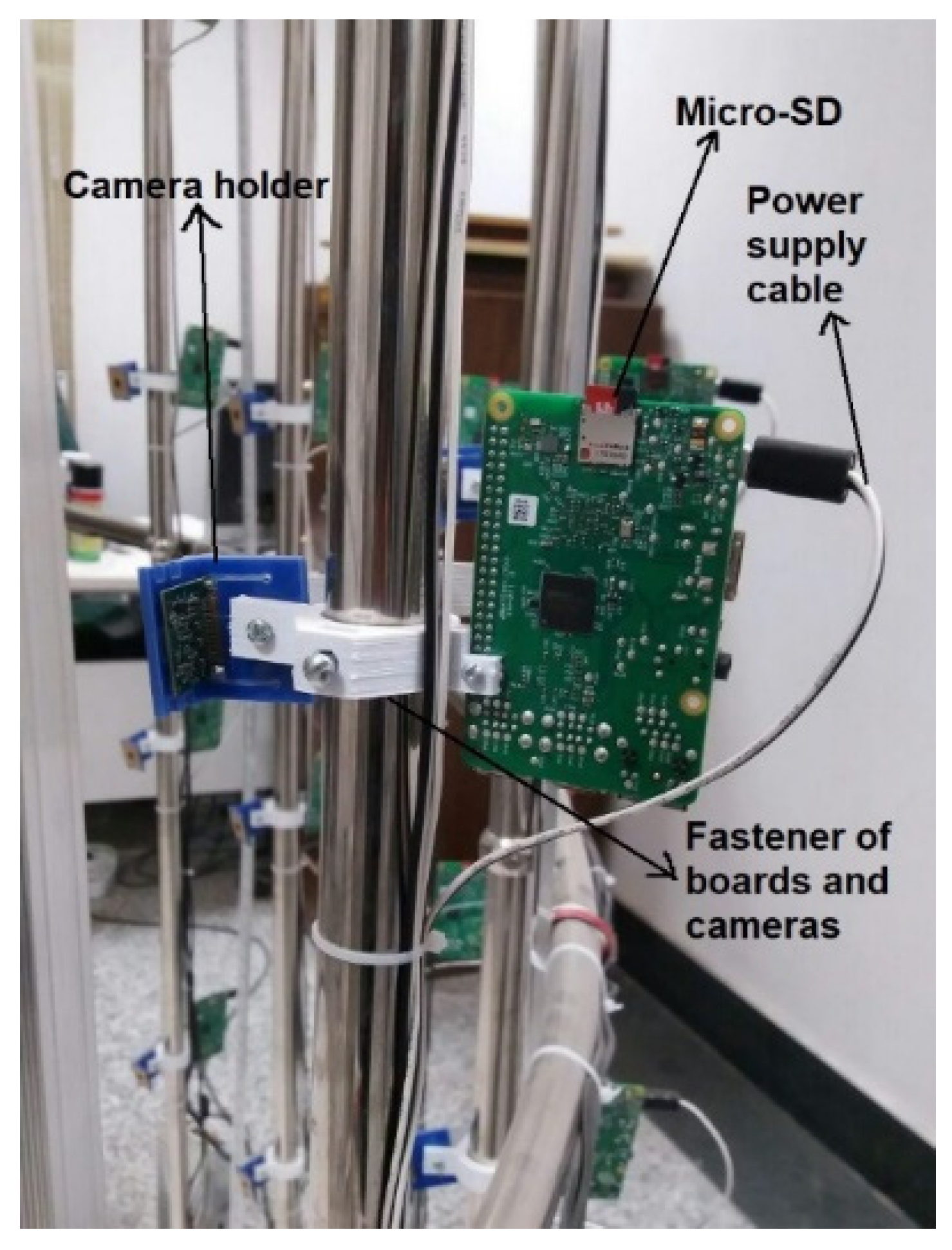

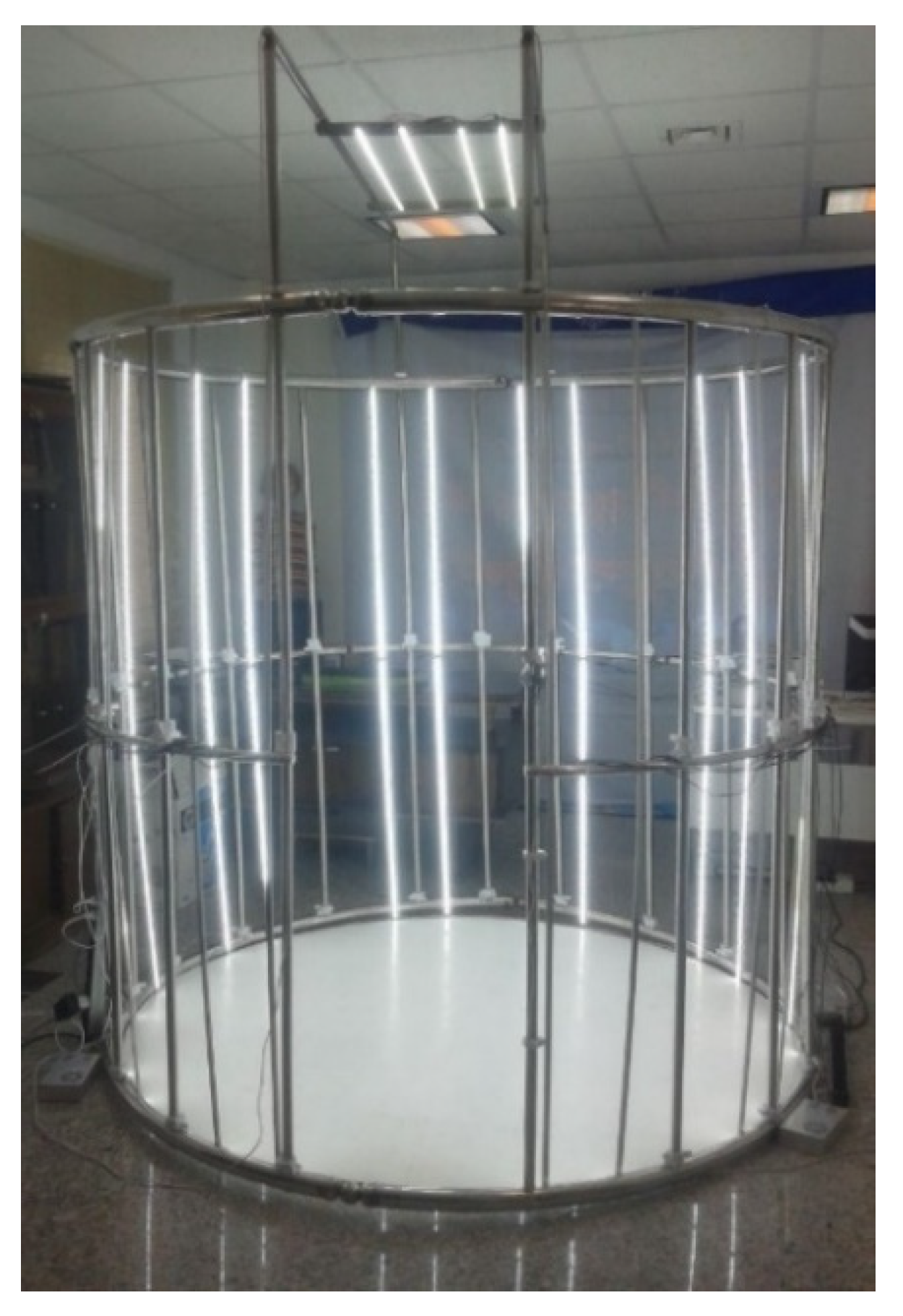

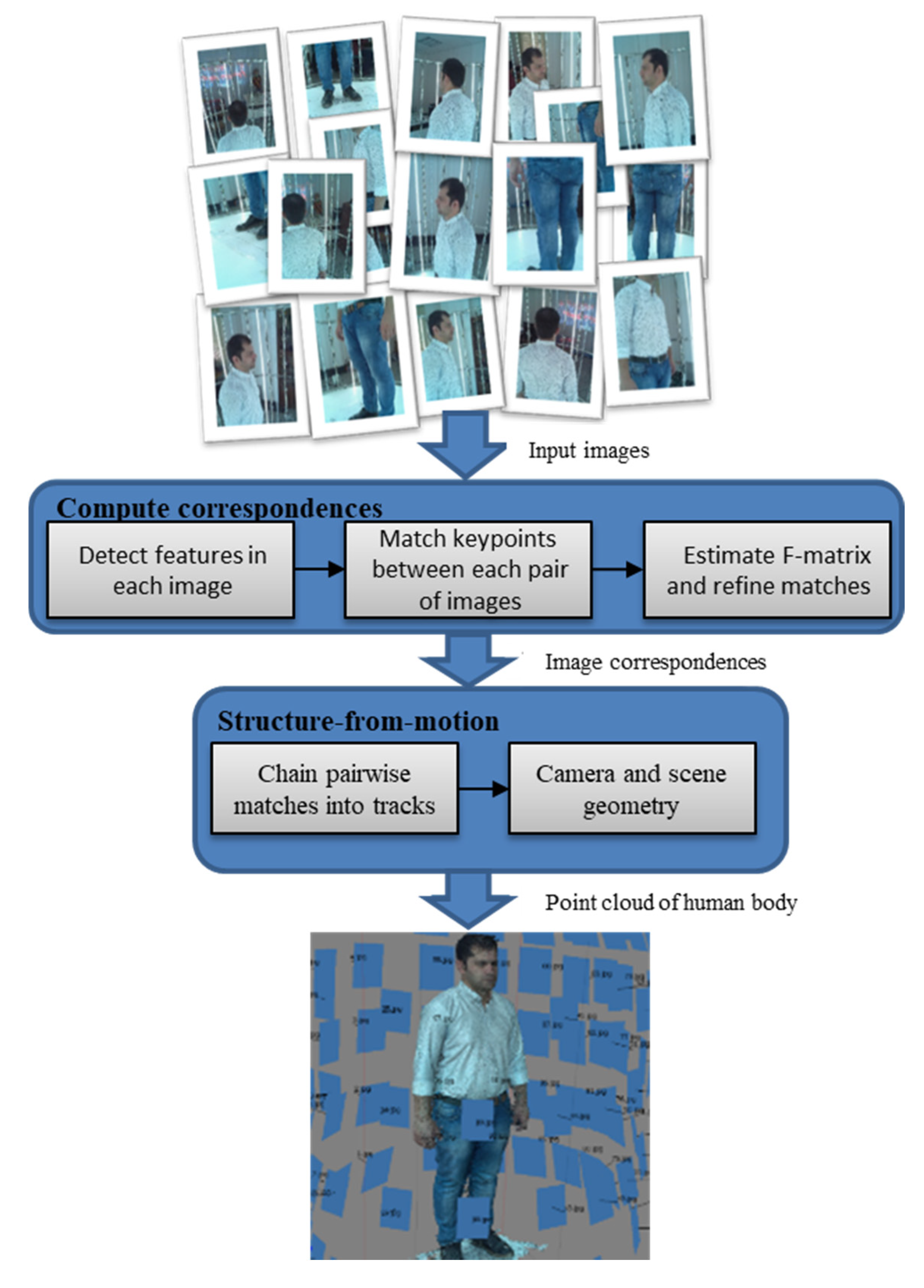

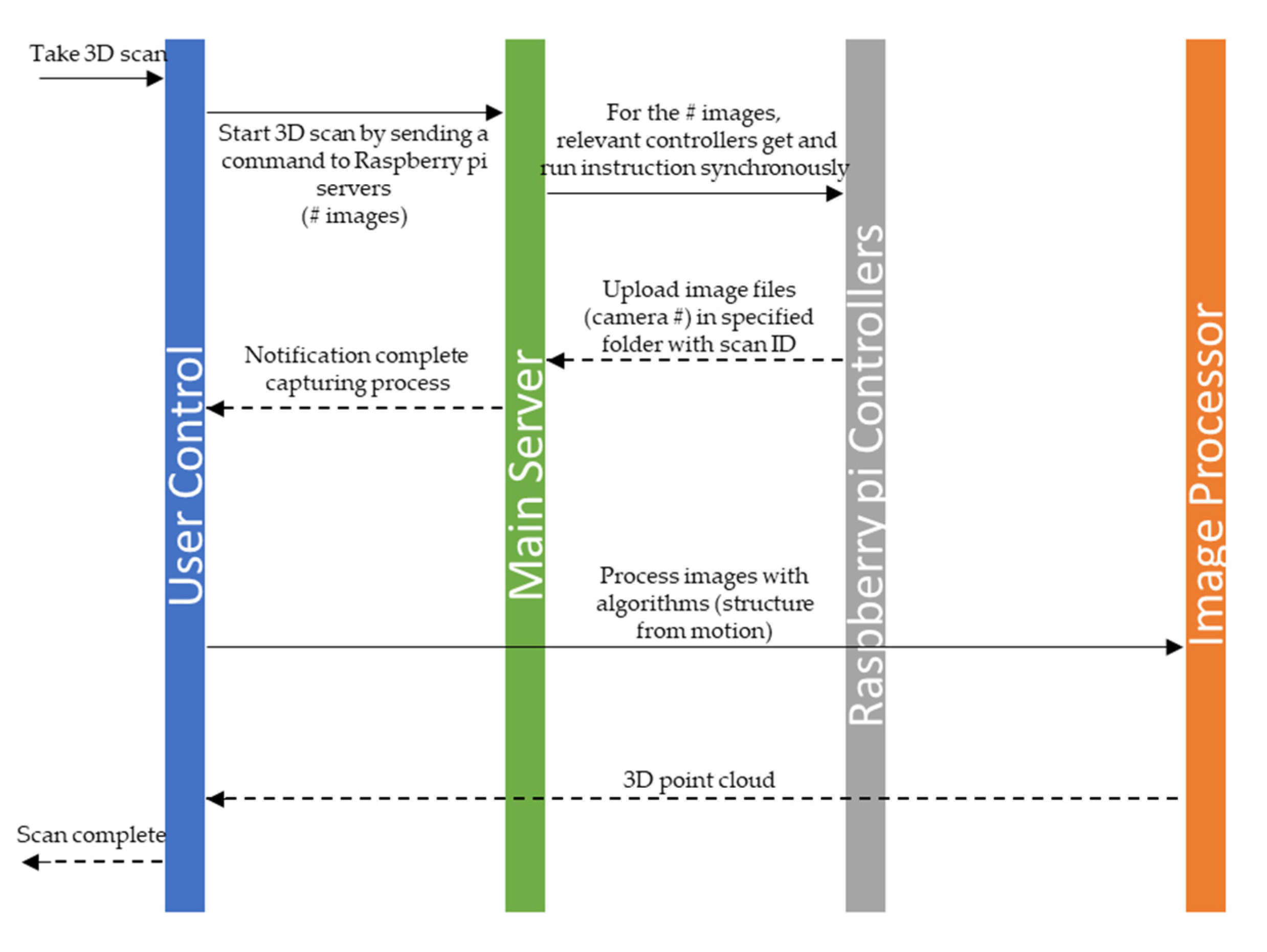

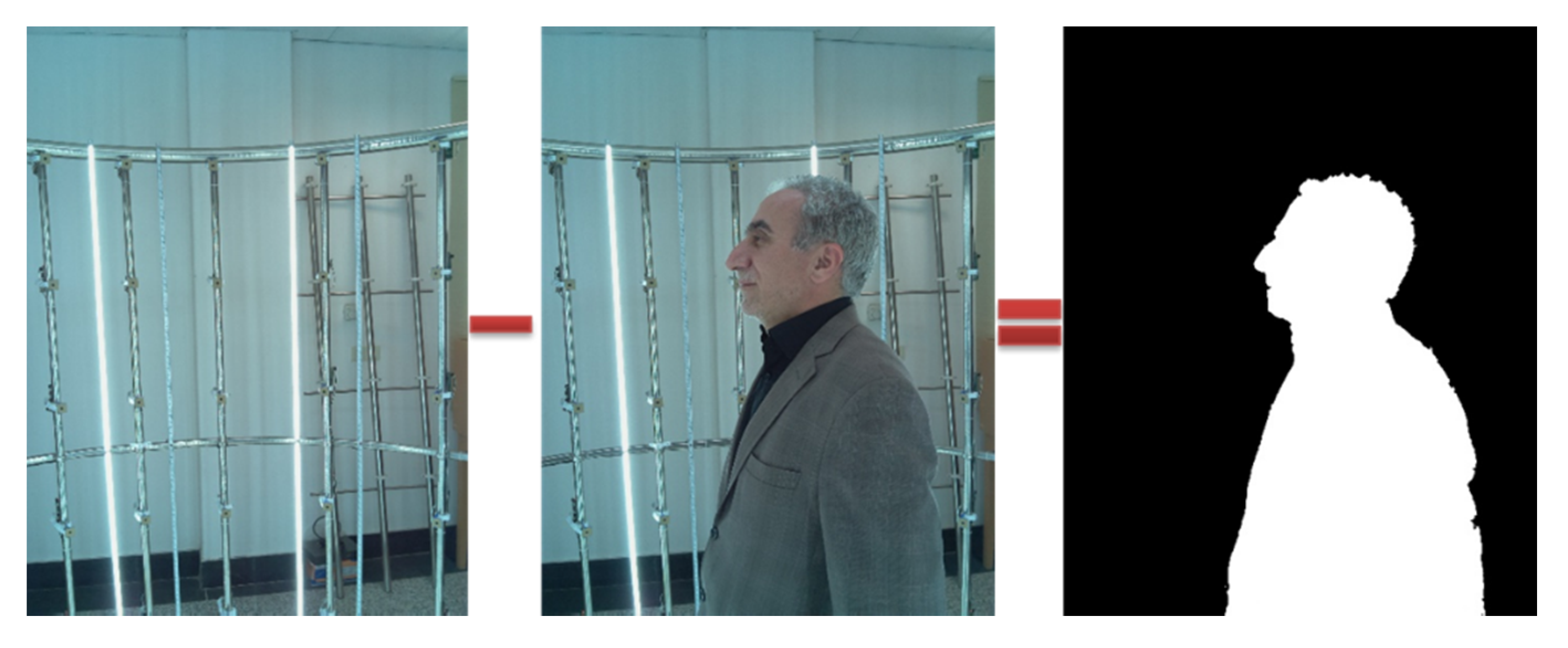

2. Materials and Methods

- The main server (Quad-core Intel Core i7, 16 GB RAM, 2 GB GPU, ASUS, Taipei, Taiwan)

- 100 Raspberry pi controllers (Raspberry Pi Foundation, Cambridge, UK)

- 100 Raspberry pi cameras (Raspberry Pi Foundation, Cambridge, UK)

- 100 8 GB external storage cards (SanDisk, Milpitas, CA, USA)

- A wireless router (Linksys EA6300, Linksys, Irvine, CA, USA)

- A lighting system

- Adjustable power supplies

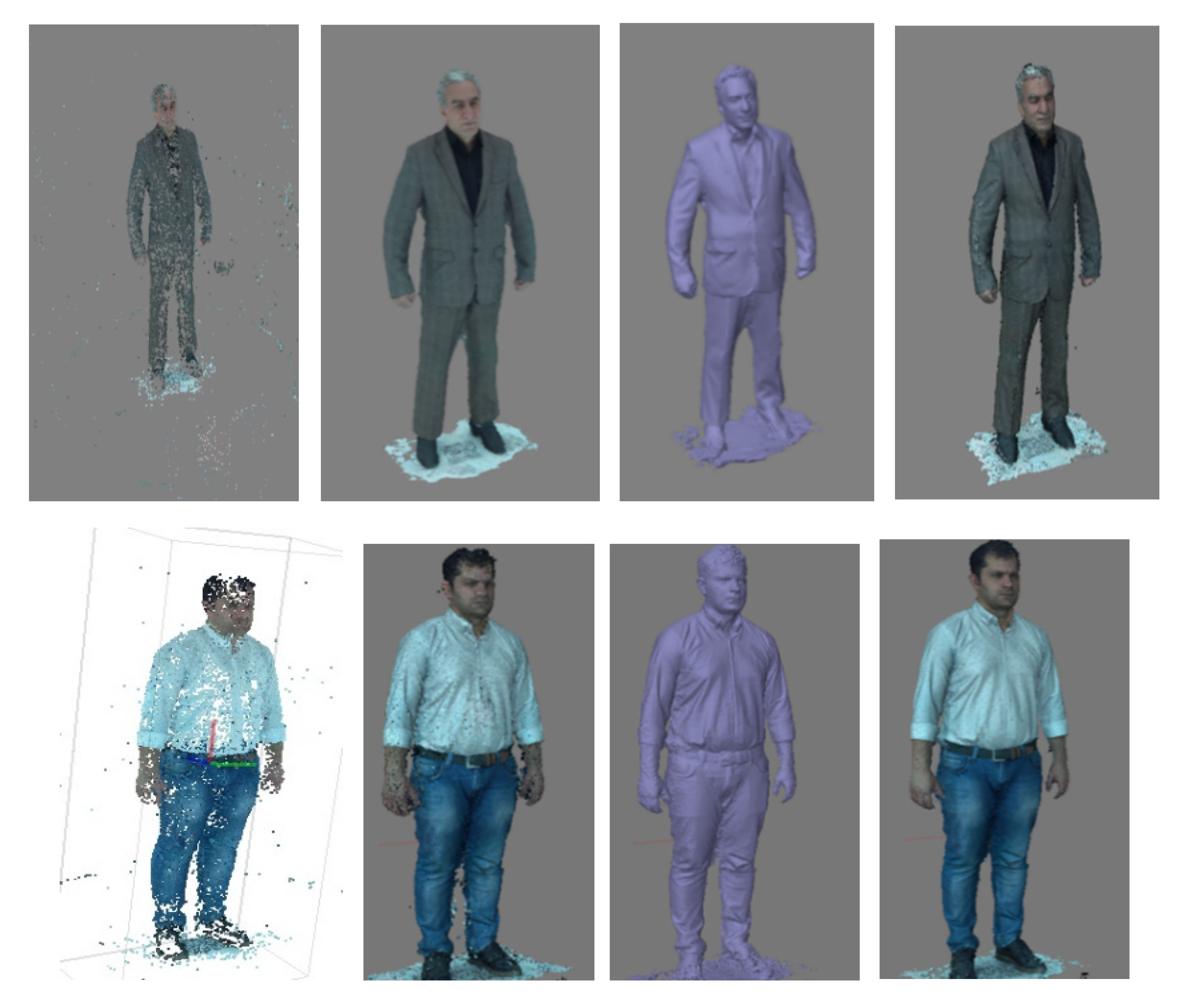

3. Results and Discussion

4. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Percoco, G.; Salmerón, A.J.S. Photogrammetric measurement of 3D freeform millimetre-sized objects with micro features: An experimental validation of the close-range camera calibration model for narrow angles of view. Meas. Sci. Technol. 2015, 26, 095203. [Google Scholar] [CrossRef]

- Zeraatkar, M.; Khalili, K.; Foorginejad, A. High-precision laser scanning system for three-dimensional modeling of saffron flower. J. Food Process Eng. 2016, 39, 553–563. [Google Scholar] [CrossRef]

- Burens-Carozza, A.; Grussenmeyer, P.; Guillemin, S.; Carozza, L.; Leveque, F.; Mathé, V. Methodological developments in 3D scanning and modelling of archaeological French heritage site: The Bronze Age painted cave of” Les Fraux”. Dordogne 2013, XL-5/W2, 131–135. [Google Scholar]

- Hu, J.; You, S.; Neumann, U. Approaches to large-scale urban modeling. IEEE Comput. Graph. Appl. 2003, 23, 62–69. [Google Scholar]

- Daanen, H.A.; Ter Haar, F.B. 3D whole body scanners revisited. Displays 2013, 34, 270–275. [Google Scholar] [CrossRef]

- Khalili, K.; Zeraatkar, M. Design and Development of a Rotary 3D Scanner for Human Body Scanning. In Proceedings of the 8th International Conference and Exhibition on 3D Body Scanning and Processing Technologies, Montreal, QC, Canada, 11–12 October 2017; pp. 312–318. [Google Scholar]

- Haleem, A.; Javaid, M. 3D scanning applications in medical field: A literature-based review. Clin. Epidemiol. Glob. Health 2019, 7, 199–210. [Google Scholar] [CrossRef]

- Jones, P.R.M.; Rioux, M. Three-dimensional surface anthropometry: Applications to the human body. Opt. Lasers Eng. 1997, 28, 89–117. [Google Scholar] [CrossRef]

- Volonghi, P.; Baronio, G.; Signoroni, A. 3D scanning and geometry processing techniques for customised hand orthotics: An experimental assessment. Virtual Phys. Prototyp. 2018, 13, 105–116. [Google Scholar] [CrossRef]

- Grazioso, S.; Selvaggio, M.; Di Gironimo, G. Design and development of a novel body scanning system for healthcare applications. Int. J. Interact. Des. Manuf. 2018, 12, 611–620. [Google Scholar] [CrossRef]

- Treleaven, P.; Wells, J. 3D body scanning and healthcare applications. Computer 2007, 40, 28–34. [Google Scholar] [CrossRef]

- Berryman, F.; Pynsent, P.; Fairbank, J.; Disney, S. A new system for measuring three-dimensional back shape in scoliosis. Eur. Spine J. 2008, 17, 663–672. [Google Scholar] [CrossRef] [PubMed]

- Ares, M.; Royo, S.; Vidal, J.; Campderrós, L.; Panyella, D.; Pérez, F.; Vera, S.; Ballester, M.A.G. 3D scanning system for in-vivo imaging of human body. In Fringe 2013; Springer: Berlin, Germany, 2014; pp. 899–902. [Google Scholar]

- Stephan, C.N.; Guyomarc’h, P. Quantification of Perspective-Induced shape change of clavicles at radiography and 3D scanning to assist human identification. J. Forensic Sci. 2014, 59, 447–453. [Google Scholar] [CrossRef] [PubMed]

- Ciobanu, O.; Xu, W.; Ciobanu, G. The use of 3D scanning and rapid prototyping in medical engineering. Fiability Durab. 2013, 1, 241–247. [Google Scholar]

- Stuyck, T.; Vandermeulen, D.; Smeets, D.; Claes, P. HR-kinect-high-resolution dynamic 3D scanning for facial expression analysis. Available online: http://www.student.kuleuven.be/~s0200995/paper.pdf (accessed on 10 August 2014).

- Galantucci, L.; Ferrandes, R.; Percoco, G. Digital photogrammetry for facial recognition. J. Comput. Inf. Sci. Eng. 2006, 6, 390–396. [Google Scholar] [CrossRef]

- Galantucci, L.M.; Di Gioia, E.; Lavecchia, F.; Percoco, G. Is principal component analysis an effective tool to predict face attractiveness? A contribution based on real 3D faces of highly selected attractive women, scanned with stereophotogrammetry. Med. Biol. Eng. Comput. 2014, 52, 475–489. [Google Scholar] [CrossRef] [PubMed]

- Crease, R.P. Invasion of the Full-Body Scanners. Wall Street Journal, 21 May 2010. [Google Scholar]

- D’Apuzzo, N. 3D body scanning technology for fashion and apparel industry. In Proceedings of the SPIE—The International Society for Optical Engineering, San Jose, CA, USA, 29 January 2007; p. 64910O. [Google Scholar]

- Percoco, G. Digital close range photogrammetry for 3D body scanning for custom-made garments. Photogramm. Rec. 2011, 26, 73–90. [Google Scholar] [CrossRef]

- Straub, J.; Kerlin, S. A very low-cost 3D scanning system for whole-body imaging. In Proceedings of the Smart Biomedical and Physiological Sensor Technology XII, Baltimore, MD, USA, 13 May 2015; p. 94870X. [Google Scholar]

- Daanen, H.A.; Psikuta, A. 3D body scanning. In Automation in Garment Manufacturing; Elsevier Woodhead Publishing: Cambridge, UK, 2018; pp. 237–252. [Google Scholar]

- Kaneko, H. Estimating breathing movements of the chest and abdominal wall using a simple, newly developed breathing movement-measuring device. Respir. Care 2014, 59, 1133–1139. [Google Scholar] [CrossRef]

- Kaneko, H.; Horie, J. Breathing movements of the chest and abdominal wall in healthy subjects. Respir. Care 2012, 57, 1442–1451. [Google Scholar] [CrossRef]

- Daanen, H.M.; van de Water, G.J. Whole body scanners. Displays 1998, 19, 111–120. [Google Scholar] [CrossRef]

- Emam, S.M.; Khatibi, S.; Khalili, K. Improving the accuracy of laser scanning for 3D model reconstruction using dithering technique. Procedia Technol. 2014, 12, 353–358. [Google Scholar] [CrossRef]

- Mendricky, R.; Maly, V. Draft design solution for automated 3D scanning of persons. Mod. Mach. Sci. J. 2019, 3418–3425. [Google Scholar] [CrossRef]

- Wang, R.; Choi, J.; Medioni, G. Accurate full body scanning from a single fixed 3d camera. In Proceedings of the 2012 Second International Conference on 3D Imaging, Modeling, Processing, Visualization & Transmission, Zurich, Switzerland, 13–15 October 2012; pp. 432–439. [Google Scholar]

- Deli, R.; Galantucci, L.M.; Laino, A.; D’Alessio, R.; Di Gioia, E.; Savastano, C.; Lavecchia, F.; Percoco, G. Three-dimensional methodology for photogrammetric acquisition of the soft tissues of the face: A new clinical-instrumental protocol. Prog. Orthod. 2013, 14, 32. [Google Scholar] [CrossRef] [PubMed]

- Galantucci, L.M.; Lavecchia, F.; Percoco, G.; Raspatelli, S. New method to calibrate and validate a high-resolution 3D scanner, based on photogrammetry. Precis. Eng. 2014, 38, 279–291. [Google Scholar] [CrossRef]

- Snavely, N.; Seitz, S.M.; Szeliski, R. Modeling the world from internet photo collections. Int. J. Comput. Vis. 2008, 80, 189–210. [Google Scholar] [CrossRef]

- Agarwal, S.; Furukawa, Y.; Snavely, N.; Simon, I.; Curless, B.; Seitz, S.M.; Szeliski, R. Building rome in a day. Commun. ACM 2011, 54, 105–112. [Google Scholar] [CrossRef]

- Snavely, N.; Seitz, S.M.; Szeliski, R. Photo tourism: Exploring photo collections in 3D. ACM Trans. Graph. (Tog) 2006, 25, 835–846. [Google Scholar] [CrossRef]

- El Hazzat, S.; Saaidi, A.; Satori, K. Structure from motion for 3D object reconstruction based on local and global bundle adjustment. In Proceedings of the 2015 Third World Conference on Complex Systems (WCCS), Marrakech, Morocco, 23–25 Novemebr 2015; pp. 1–6. [Google Scholar]

- Grazioso, S.; Caporaso, T.; Selvaggio, M.; Panariello, D.; Ruggiero, R.; Di Gironimo, G. Using photogrammetric 3D body reconstruction for the design of patient–tailored assistive devices. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0 & IoT), Naples, Italy, 4–6 June 2019; pp. 240–242. [Google Scholar]

- Fraser, C.S.; Woods, A.; Brizzi, D. Hyper redundancy for accuracy enhancement in automated close range photogrammetry. Photogramm. Rec. 2005, 20, 205–217. [Google Scholar] [CrossRef]

- Kraus, K. Photogrammetry: Geometry from Images and Laser Scans; Walter de Gruyter: Berlin, Germany, 2011. [Google Scholar]

- Khalili, K.; Webb, P. The development and application of a multiple wavelength illumination technique for the vision-based process monitoring of aero-structure riveting. Mach. Vis. Appl. 2007, 18, 73–83. [Google Scholar] [CrossRef]

- Moons, T.; Van Gool, L.; Vergauwen, M. 3D reconstruction from multiple images part 1: Principles. Found. Trends® Comput. Graph. Vis. 2010, 4, 287–404. [Google Scholar] [CrossRef]

- Lowe, D.G. Distinctive image features from scale-invariant keypoints. Int. J. Comput. Vis. 2004, 60, 91–110. [Google Scholar] [CrossRef]

- Arya, S.; Mount, D.M.; Netanyahu, N.S.; Silverman, R.; Wu, A.Y. An optimal algorithm for approximate nearest neighbor searching fixed dimensions. J. ACM 1998, 45, 891–923. [Google Scholar] [CrossRef]

- Fischler, M.A.; Bolles, R.C. Random sample consensus: A paradigm for model fitting with applications to image analysis and automated cartography. Commun. ACM 1981, 24, 381–395. [Google Scholar] [CrossRef]

- Hartley, R.I. In defense of the eight-point algorithm. IEEE Trans. Pattern Anal. Mach. Intell. 1997, 19, 580–593. [Google Scholar] [CrossRef]

- Wu, C. VisualSFM: A visual structure from motion system. Available online: http://ccwu.me/vsfm/doc.html (accessed on 26 December 2019).

- Snavely, N.; Simon, I.; Goesele, M.; Szeliski, R.; Seitz, S.M. Scene reconstruction and visualization from community photo collections. Proc. IEEE 2010, 98, 1370–1390. [Google Scholar] [CrossRef]

- AL-Khalidi, F.Q.; Saatchi, R.; Burke, D.; Elphick, H.; Tan, S. Respiration rate monitoring methods: A review. Pediatric Pulmonol. 2011, 46, 523–529. [Google Scholar] [CrossRef]

- Subbe, C.; Davies, R.; Williams, E.; Rutherford, P.; Gemmell, L. Effect of introducing the Modified Early Warning score on clinical outcomes, cardio-pulmonary arrests and intensive care utilisation in acute medical admissions. Anaesthesia 2003, 58, 797–802. [Google Scholar] [CrossRef]

- Hagman, C.; Janson, C.; Malinovschi, A.; Hedenström, H.; Emtner, M. Measuring breathing patterns and respiratory movements with the respiratory movement measuring instrument. Clin. Physiol. Funct. Imaging 2016, 36, 414–420. [Google Scholar] [CrossRef]

- Malaguti, C.; Rondelli, R.R.; de Souza, L.M.; Domingues, M.; Dal Corso, S. Reliability of chest wall mobility and its correlation with pulmonary function in patients with chronic obstructive pulmonary disease. Respir. Care 2009, 54, 1703–1711. [Google Scholar]

| Scanner | Type | Cost | Time of Scanning |

|---|---|---|---|

| 3D Systems Sense 1 | Optical subject or scanner must move | $419 | Depends on subject/operator |

| Artec EVA 2 | Optical subject or scanner must move | $19,800 | Depends on subject/operator |

| Geomagic Capture 3 | Optical with LED point emitter Subject or scanner must move | $14,900 | Depends on subject/operator |

| Gotcha 3D Scanner 4 | Optical subject or scanner must move | $10,000 | Depends on subject/operator |

| Head & Face Color 3D Scanner (Model 3030/RGB/PS)—(CyEdit+) 5 | Laser Fixed scanner/fixed subject | $63,200 | Not specified |

| Head & Face Color 3D Scanner (Model 3030/sRGB/PS)-Hires Color—(CyEdit+) 6 | Laser Fixed scanner/fixed subject | $73,200 | Not specified |

| Head & Face Color 3D Scanner (Model PX)—Single View—(PlyEdit) 7 | Laser Fixed scanner/fixed subject | $67,000 | Not specified |

| Head & Face Color 3D Scanner (Model PX/2)—Dual View—(PlyEdit) 8 | Laser Fixed scanner/fixed subject | $77,000 | Not specified |

| Vitronic-Vitus Smart XXL 9 | Laser-fixed subject | $65,000 | 12 s |

| KX-16 3D Body Scanner 10 | Infrared subject or scanner must move | $10,000 | 7 s |

| IIIDBody 11 | Optical fixed subject and scanner | $20,000–50,000 | Not specified |

| SizeStream-3D Body Scanner 12 | Infrared | $15,000–20,000 | 6 s |

| SpaceVision-Cartesia 13 | Laser structured light-fixed subject and scanner | $20,000 | 2 s |

| INBODY | Photogrammetric full-body scanner | Not specified | 0.05 s |

| 3dMDbody-Flex8 14 | Stereophotogrammetry | $190,000 | 0.002 s |

| Whole-Body 3D Scanner (Model WBX)—(DigiSize Pro) 15 | Laser line-fixed subject | $200,000 | 17 s |

| Whole-Body Color 3D Scanner (Model WBX/RGB)—(DigiSize Pro) 16 | Laser line-fixed subject | $240,000 | 17 s |

| Component | Quantity | Unit Price | Total * | Possible Suppliers |

|---|---|---|---|---|

| Raspberry Pi 3 Model B with external storage | 100 | $34.5 | $3450 | https://www.newark.com/buy-raspberry-pi?ost=raspberri+pi+3+model+b&rd=raspberri+pi+3+model+b |

| Pi Camera | 100 | $14 | $1400 | https://www.amazon.com/Camera-Module-Raspberry-Atomic-Market/dp/B075DKDGPF |

| Frame construction | 1 | $300 | $300 | |

| Main server | 1 | $800 | $800 | |

| LED strips full spectrum 18 × 2 m + 4 × 1 m | 18 + 4 | $9.5 | $380 | https://www.alibaba.com/product-detail/Full-spectrum-LED-grow-strip-warm_60666295850.html?spm=a2700.7724857.normalList.118.1c39449dZvYvbn |

| Power-supply 5V, 30A | 4 | $23 | $92 | https://www.amazon.com/LETOUR-Converter-200Watts-Adapter-Lighting/dp/B07FX8HL79 |

| Led Power-supply 12V, 30A | 4 | $18.95 | $75.8 | https://www.amazon.com/eTopxizu-Universal-Regulated-Switching-Computer/dp/B00D7CWSCG |

| Ethernet Switches | 1 | $50 | $50 | https://www.linksys.com/ae/p/P-EA6300/#product-features |

| Scanner | Time Required (s) |

|---|---|

| Sense | High: depends on subject/operator, scanner or subject should be rotated |

| Artec EVA | High: depends on subject/operator, scanner or subject should be rotated |

| Cyberware Whole-Body Color 3D Scanner | 17 |

| SizeStream-3D Body Scanner | 6 |

| Vitronic-Vitus Smart XXL | 12 |

| SpaceVision-Cartesia | 2 |

| INBODY | 0.05 |

| 3dMDbody-Flex8 | 0.002 |

| Designed scanner | 0.001 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeraatkar, M.; Khalili, K. A Fast and Low-Cost Human Body 3D Scanner Using 100 Cameras. J. Imaging 2020, 6, 21. https://doi.org/10.3390/jimaging6040021

Zeraatkar M, Khalili K. A Fast and Low-Cost Human Body 3D Scanner Using 100 Cameras. Journal of Imaging. 2020; 6(4):21. https://doi.org/10.3390/jimaging6040021

Chicago/Turabian StyleZeraatkar, Mojtaba, and Khalil Khalili. 2020. "A Fast and Low-Cost Human Body 3D Scanner Using 100 Cameras" Journal of Imaging 6, no. 4: 21. https://doi.org/10.3390/jimaging6040021

APA StyleZeraatkar, M., & Khalili, K. (2020). A Fast and Low-Cost Human Body 3D Scanner Using 100 Cameras. Journal of Imaging, 6(4), 21. https://doi.org/10.3390/jimaging6040021