Abstract

Durable building materials are essential for sustainability in construction projects, aiming to reduce environmental damage from the start to the end of a building’s life. Reducing the use of Portland cement in concrete production is essential because of the significant CO2 emissions generated globally during its production process. This study investigates the workability, compressive strength, and water absorption of concrete when Portland cement is partially substituted with waste glass powder (WGP) and recycled concrete powder (RCP). These two waste powders can be used to partially substitute Portland cement in order to produce environmentally friendly concrete. The activity of the particles in concrete made from these two waste powders is mostly determined by the type and rate of the powders, as well as the curing methods. Therefore, the current research examines how different curing conditions impact the workability, compressive strength, and water absorption characteristics of this innovative eco-friendly concrete that includes the abovementioned waste powders. According to the experimental results obtained, adequate strength can be achieved using an appropriate replacement level of the powders and curing methods. Therefore, the application of these two recycled mineral admixtures in concrete can save Portland cement and has certain environmental and economic benefits.

1. Introduction

Sustainable building materials are essential for advancing the sustainability of construction and infrastructure projects by reducing the environmental impact at every stage. These resources are designed to lower energy usage, decrease waste, reduce greenhouse gas emissions including CO2, and promote eco-friendly construction methods. As the amount of waste produced worldwide grows, it becomes more important to have effective waste management plans, as improper disposal can damage the environment. Sustainable development focuses on incorporating recycled materials into construction, especially in concrete production, to meet current needs without destroying future generations’ abilities [1,2]. Incorporating materials such as recycled aggregates, silica fume, fly ash, waste glass, waste plastic, and other industrial byproducts can greatly decrease the construction industry’s carbon footprint. Using a combination of different waste materials in concrete production improves waste management sustainability, while also preserving natural resources and cutting down on expenses [1,2,3].

Concrete sustainability is receiving more attention in engineering projects, resulting in efforts to reduce the environmental impact of the construction industry. The rapid expansion of this industry is driven by the strong demand for cement in the construction of infrastructure and buildings, particularly in less developed, developing, and developed countries [3,4].

The global construction sector, essential for economic progress and societal advancement, is largely dependent on concrete as a key construction material. Concrete is essential for building a range of civil engineering structures, including homes, roads, bridges, and dams. Yet, the conventional linear process of producing concrete, which includes its extraction, processing, use, and disposal, has notable environmental and sustainability disadvantages [5,6]. The extraction of natural resources, especially sand, gravel, and cement, leads to the destruction of habitats, erosion, and changes in waterways. Furthermore, the manufacturing of cement, an essential ingredient in concrete, requires a significant amount of energy and contributes significantly to the worldwide release of carbon dioxide [7,8]. Moreover, the concrete waste produced during construction, renovation, and demolition activities creates a notable problem by taking up space in landfills and hindering opportunities for resource recycling. Therefore, it is worth mentioning here that, in the quest for sustainable development, it is crucial that we prioritize durability alongside the mechanical properties of construction materials to extend the service life, to avoid depleting natural resources and causing damage to the environment in construction practices.

First and foremost, it is crucial that we reduce the extraction of raw materials. This includes examining different sources of aggregates and cement, like recycled concrete powder (RCP) or industrial by-products, to decrease the dependence on new resources. Moreover, maximizing the mixture composition guarantees that the concrete attains the necessary characteristics using a reduced quantity of raw ingredients. Another crucial element is optimizing the reutilization and recycling of concrete waste. Concrete waste from the construction, renovation, and demolition stages can be transformed into recycled aggregates or recycled powders, diverting materials from landfills and decreasing the demand for new extraction [9].

In construction materials engineering, affordable concrete is crucial, providing cost-effective choices for building projects. The focus of sustainable concrete production is to minimize environmental damage by utilizing recycled materials and decreasing global CO2 emissions, particularly in the production of Portland cement [10]. According to the literature, the mass production of Portland cement (PC) is subject to significant energy pressure due to its synthesis temperature of up to 1450–1500 °C. In contrast, there are some other types of cements with a lower energy consumption such as calcium sulfoaluminate (CSA) cement. It has a lower calcination temperature (1250 °C) during production; therefore, CSA cement can reduce energy pressure and CO2 emissions through research and promotion [11,12]. In the production process of this type of cement, raw materials can be replaced by other industrial wastes, such as calcium carbide slag, red mud, and desulfurization gypsum. Because of its quick setting time, high strength and durability properties, and excellent early strength characteristics, CSA cement is typically utilized in grouting materials. Recently, the impacts of sodium aluminate and quicklime, and potassium and sodium sulfates on the characteristics and hydration process of a double-liquid grouting material based on calcium sulfoaluminate (CSA) cement were investigated [11,12]. They concluded that the sodium sulfate and potassium sulfate accelerate the hydration of CSA cement and the formation of ettringite from the very beginning. Furthermore, sodium aluminate accelerated the early formation of ettringite but did not increase the overall amount of hydration products. The initially accelerated hydration by sodium aluminate and quicklime facilitated the later strength development of CSA cement.

The concrete sector currently requires focused initiatives to investigate substitute materials, especially waste materials, that do not consume natural resources and tackle environmental issues. Waste glass powder (WGP), obtained from different sources such as bottles and containers, offers a potential option for the cement and concrete sectors as supplementary cementitious materials (SCMs) because of its chemical makeup and pozzolanic characteristics. By grinding waste glass to a fine powder, it can be used in place of certain elements in normal concrete, providing a sustainable option that helps preserve natural resources and lower CO2 emissions. Incorporating WGP into concrete mixes helps reduce the increasing amount of waste glass and supports sustainability objectives in the construction industry [13,14,15,16]. Many studies have been conducted on the use of WGP as SCMs in the production of geopolymer concrete due to its high concentration of amorphous silica, which is required for pozzolanic reactivity. This innovative method lowers the quantity of glass trash produced, the price of producing concrete, and the quantity of CO2 emissions that have a negative impact on the environment when cement is produced. Contradictory findings about the benefits or disadvantages of utilizing WGP in concrete have been documented due to the variety of glass varieties and their varying compositions and particle sizes. While some studies have found improvements in concrete’s workability and compressive strength, others have found decreases in the material’s compressive strength [17,18,19]. Research from the past [20,21,22,23] has demonstrated that adding WGP, fibers, and micro-silica to concrete can improve its behavior. Some researchers have even gone so far as to propose the practical application of waste glass in the subbase and base of roads as well as asphalt concrete [24]. Although the use of WGP in concrete has been shown to increase the tensile strength in numerous research projects, it has also been reported by some researchers to decrease the mechanical properties [24].

In civil engineering, emphasis is being placed on substituting natural aggregates with recycled resources, such as recycled concrete aggregates (RCAs) from the construction, renovation, and demolition stages [25,26,27,28,29,30,31,32]. One issue with employing RCAs is that it causes the concrete sample to absorb water at a higher rate and have significant porosity. This is because the cement paste bonded to the RCA hydrates, which reduces the mechanical and durability properties of recycled aggregate concrete (RAC) [33]. Reducing the amount of old cement paste adhered to RCA has, regrettably, limited their use on a broad scale and increased energy consumption [34,35]. However, eliminating the cement paste that is connected on its own accelerates the rate at which waste is produced and accumulates at landfill locations. Thankfully, there have been encouraging developments lately regarding the use of recycled concrete powder (RCP) as a cementitious material in concrete mixtures [35].

A recently published study [35] investigated the characteristics of RCP and analyzed the engineering properties of concrete mixes with different percentages of RCP replacement. Their investigation found that changing the replacement rate of recycled concrete powder (RCP) had an effect on the slump of the newly made RAC. The findings also showed a reduction in compressive strength as the replacement rate of RCP increased at all ages. In another study [36], fully recycled concrete with 100% recycled cement + 100% recycled aggregates were investigated. According to their results, the water absorption (WA) behavior of fully recycled concrete can be divided into three stages, with the initial stage being three times faster than ordinary concrete. In another work of research [37], the effect of different factors, including the burn temperature for preparing recycled cement, the carbonation degree of the precursor, the particle size of the recycled cement, and the water-cement (w/c) ratio on the compressive strength, was studied. The results showed that the burn temperature is the most important parameter for recycled cement, and a temperature of 650 °C performed best and resulted in the highest compressive strength of the paste.

The objective of this study is to develop a concrete solution that is both financially viable and environmentally friendly, tailored for various civil engineering applications including low strength uses like pedestrian walkways, in order to contribute to sustainable development. The current research examines how various curing conditions impact the fresh and hardened characteristics of this innovative eco-efficient concrete that includes WGP and RCP mineral admixtures. Although there is similar research in the literature, due to the lack of the available data on the performance of concrete, and contradictions and variations of the available test results of concrete modified with WGP and RCP, this work presents an experimental program to study in detail the effect of these two recycled powders on concrete properties. Specifically, the influence of using WGP and RCP on the workability, compressive strength, and water absorption under various curing conditions have been explored in the present study. The outcome of the present investigation would be communicated to engineers, construction companies, and concrete production plants in order to obtain concrete with an adequate performance utilizing recycled powders while saving large quantities of natural resources.

2. Materials and Methods

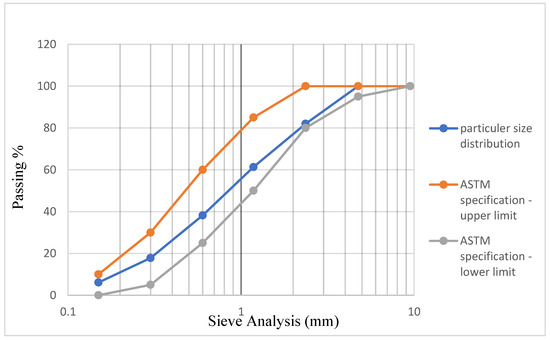

2.1. Fine Aggregates

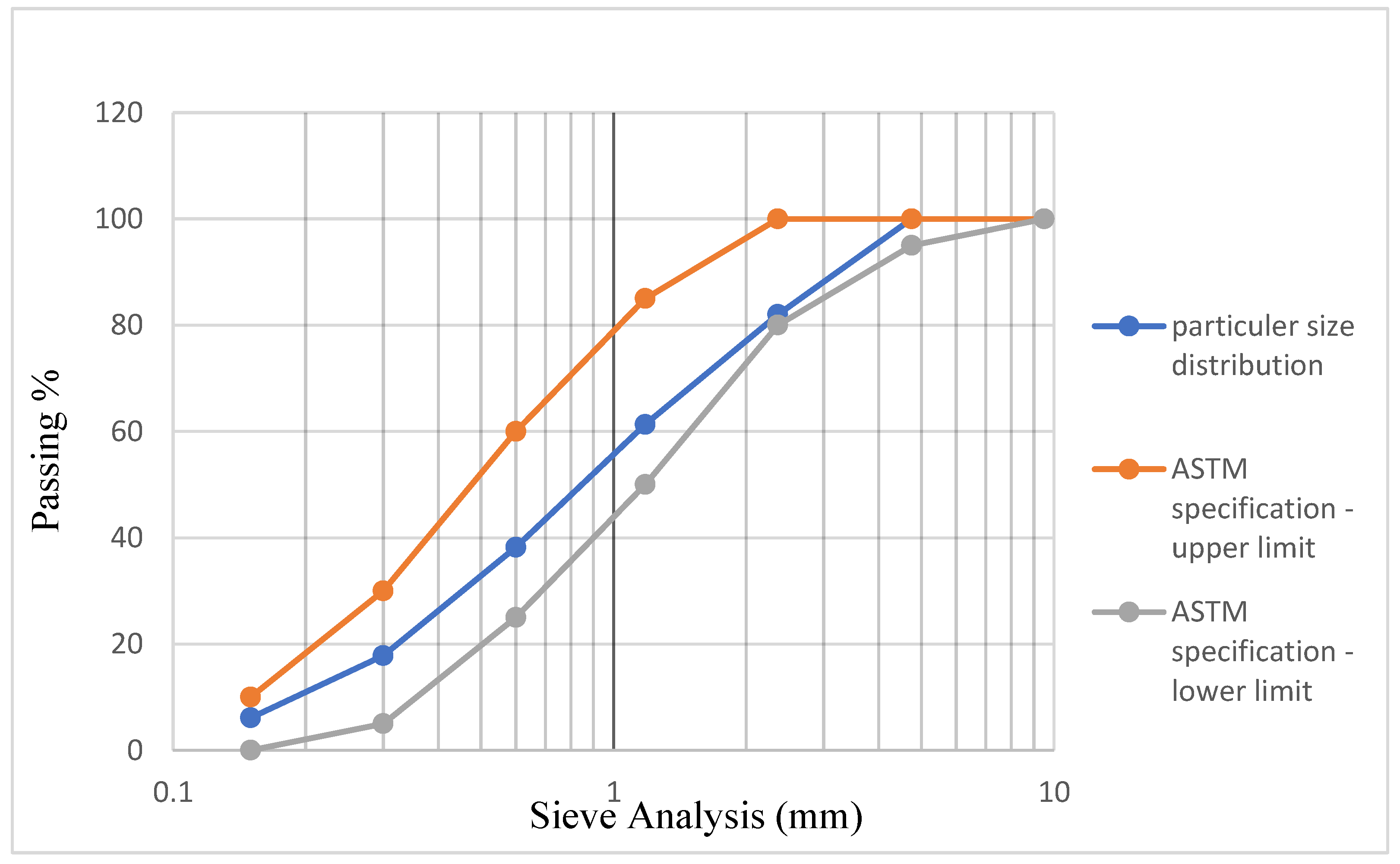

Table 1 provides a detailed description of the physical properties of river sand originating from Soran, Kurdistan region, Iraq. Additionally, the ASTM C136-06 [38] standard is followed to show the particle size distribution of fine aggregate (FA), which is illustrated in Figure 1.

Table 1.

Physical properties of FA.

Figure 1.

Particle size distribution of FA.

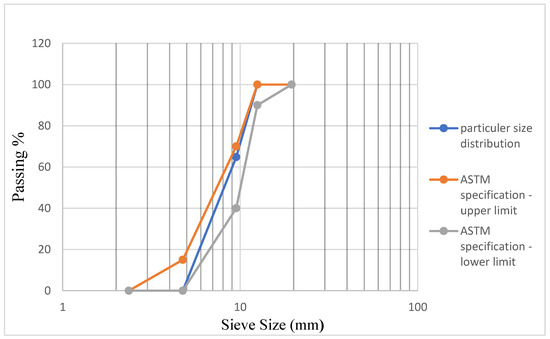

2.2. Coarse Aggregates

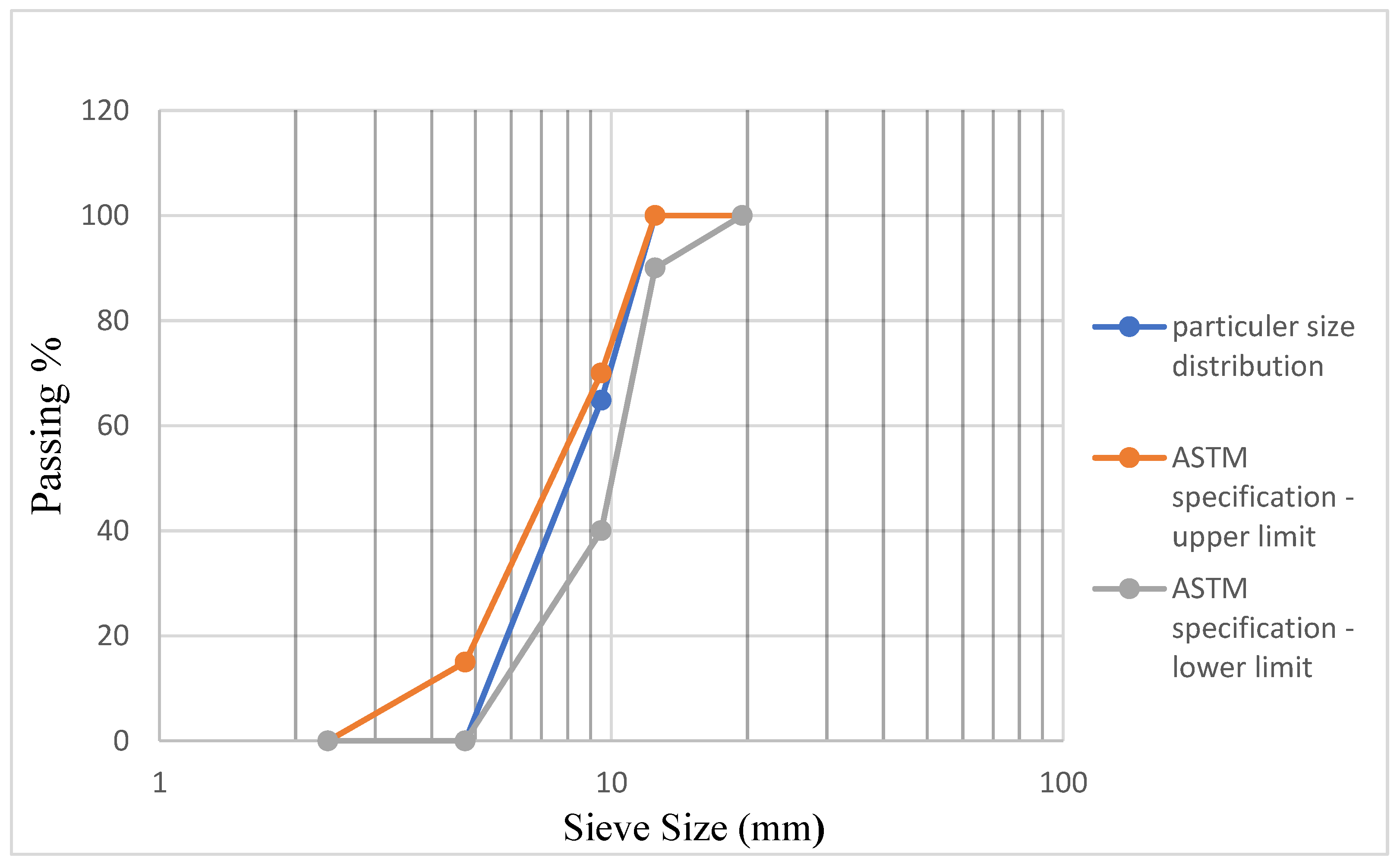

This experiment utilized natural crushed stone from Soran, Kurdistan, Iraq. The crushed stones were able to pass through a sieve with a diameter of 12.5 mm. Table 2 displays the physical characteristics, while Figure 2 illustrates the particle size distribution of coarse aggregate (CA) based on ASTM C136-06 [38].

Table 2.

Physical properties of CA.

Figure 2.

Particle size distribution of CA.

2.3. Portland Cement

The Tasluja cement plant [39] in Kurdistan, Iraq is renowned for its consistent quality, following the Iraqi standard IQS 5:1984 [40], ensuring trustworthiness in building projects. Table 3 details the physical characteristics, verifying its suitability for the planned evaluation. The precise production method guarantees the reliability of the cement as a stable foundation for demanding assessments in various construction scenarios.

Table 3.

Physical properties of cement.

2.4. Waste Glass Powder

During the study, various colored waste from glassware was used and put through a grinding process using an abrasion machine. The powder (Figure 3) from sieve No. 200 was used as an alternative to cement in various ratios. The density of WGP was measured to be 2.6.

Figure 3.

(A) WGP and (B) RCP.

2.5. Recycled Concrete Powder

Mixed-aged concrete was used in this study. As with the WGP, it was subjected to grinding using a special machine, then sieved. Afterwards, the powder (Figure 3) passing through sieve No. 200 was used as a substitute for cement in various proportions. The powder’s specific gravity was determined to be 2.69. Information on the chemical properties of WGP, RCP, and cement is presented in Table 4.

Table 4.

Chemical composition of WGP, RCP and Portland cement.

2.6. Mix Proportion

In this experiment, all mixtures were made using a 1:2:4 ratio of cement, fine aggregate, and coarse aggregate. Additionally, the water-to-binder ratio (W/B) of 0.5 remained consistent across all mixtures. The mixture calculation was carried out using the absolute volume method (Equation (1)), with 10% of each material added as a reserve for any dilution during mixing, as detailed in Table 5.

Table 5.

Concrete mix proportions.

This study involved conducting fifteen different mixtures. Mix 1 was used as a control concrete mix without recycled concrete powder (RCP) and waste glass powder (WGP), cured under water condition, to assess its characteristics in comparison to other mixes with RCP or WGP under the same curing conditions. Mix 2 was used as a second control concrete mix without RCP and WGP, undergoing wrapping curing (covered with wet gunny bags) for comparison with mixes containing RCP or WGP under the same curing conditions. The third control concrete mix, named Mix 3, was prepared without adding RCP and WGP, and instead used 1% PEG-400 for self-curing, with samples kept at room temperature. The self-curing agent used was poly-ethylene glycol PEG-400 [41]. Its properties were compared to other mixes containing RCP or WGP under similar curing conditions. The ratios of 10% and 20% of RCP and WGP by weight of ordinary Portland cement (OPC) were used, and they were mixed in an electric concrete mixer. Two slump measurements were conducted for every mixture, and then the average was calculated based on the results. For every test/curing age in the study, three samples were prepared. The cubes were carefully stacked in three layers with manual compaction. The samples remained at room temperature in the laboratory for 24 h. Following this period, the cubes were prepared to be taken out of the mold and stored in various curing environments such as water, wrapping, and self-curing. The curing durations were 7 and 28 days.

2.7. Testing Methods

The slump test, conducted following ASTM C143 [42] guidelines, evaluates the maneuverability of recently blended concrete by gauging its deformation right after mixing. For each mix in the study, two tests were carried out using a metal mold called a slump cone, and the average of the results was calculated.

To ascertain the compressive strength, three cubes from each concrete mix were tested and the results were averaged. Testing took place at 7 and 28 days under different curing times and conditions. A compression machine with a 2000 KN capacity and 1 KN accuracy is considered standard.

The current research conducted the water absorption (WA) test following ASTM C1585 [43], using three cubes for each concrete mix to determine WA rates, and then averaging the results from all three cubes.

The cubes were tested every 7 and 28 days to observe changes as time passed. In the experimental process, the saturated cubes were initially weighed and recorded as W1. After that, the cubes were dried in an oven at 110 °C for 24 h until they reached a uniform dry weight. After this drying period, the cubes were weighed again, and the final weight was recorded as W2. By using Equation (1), it was possible to assess WA traits in the concrete samples in a controlled environment, providing a better understanding of the material’s behavior and performance across different time periods.

Assessing the density of concrete, especially in terms of saturated surface dry (SSD) conditions, is essential in comprehending the material’s physical properties and its performance in structural uses.

This research focuses on finding the density of concrete by testing three cubic samples, then calculating the average weight and dividing it by their volume.

3. Results and Discussion

3.1. Workability

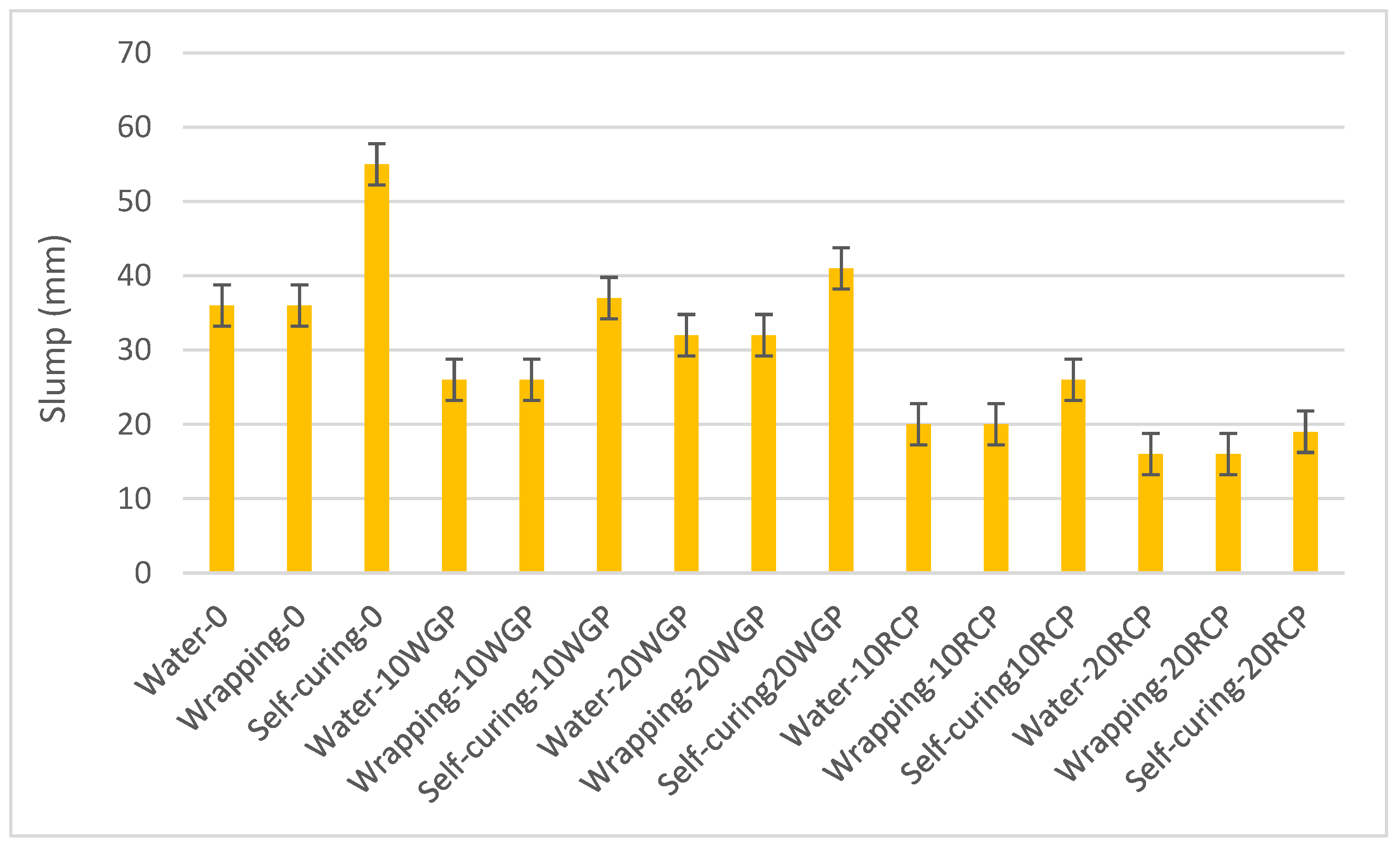

3.1.1. Effect of WGP

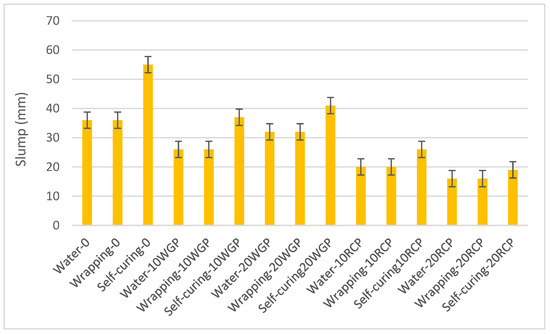

Figure 4 shows how the workability of fresh concrete is affected by the WGP content when exposed to various curing conditions. The findings show a decline in workability at 10% WGP, followed by a steady increase in workability as the percentage of WGP rises to 20%. This betterment is credited to the higher amount of water in the combination, as shown by the increasing actual water-to-cement ratio with the greater incorporation of WGP particles. This pattern is consistent with the results of [27], indicating a slow improvement in the ease of working with increased levels of WGP. As an example, the workability is 36 mm without any substitution, but decreases to 26 mm with the 10% replacement and then increases to 32 mm with the 20% WGP replacement. The slump values for concrete containing RCP are different. The workability decreases from 36 mm to 20 mm with 10% RCP and decreases more to 16 mm with 20% RCP.

Figure 4.

Slump values of concretes containing different levels of WGP and RCP.

3.1.2. Effect of RCP

Figure 4 also demonstrates how incorporating RCP affects the workability of fresh concrete in various curing conditions. Concrete workability involves how smoothly it flows, pumps, and undergoes finishing processes, all of which are essential for construction. It is crucial in achieving proper compaction and ensuring the overall quality of the final structure. The findings showed a small decrease in workability with higher proportions of RCP. A study [44] also found similar results, as they observed that the workability of different RCP mixtures did not show significant changes when monitoring the slump. For instance, the decrease in the workability of standard concrete mixes (M1 and M2) is over two times greater than that seen in the concrete with 20% RCP.

3.1.3. Effect of Curing Regimes

Figure 4 also demonstrates how the workability of fresh concrete, which includes various amounts of waste powders, is affected by the inclusion of 1% PEG as a self-curing agent. The slump in concrete increased with a higher WGP content and decreased with a higher RCP content. Based on the findings, the impact of PEG-400 on the consistency of traditional concrete mixes is greater compared to mixes with varying amounts of WGP and RCP. For instance, the drop in the slump for the control concrete (M3) is double the amount seen in the concrete with 10% and 20% RCP.

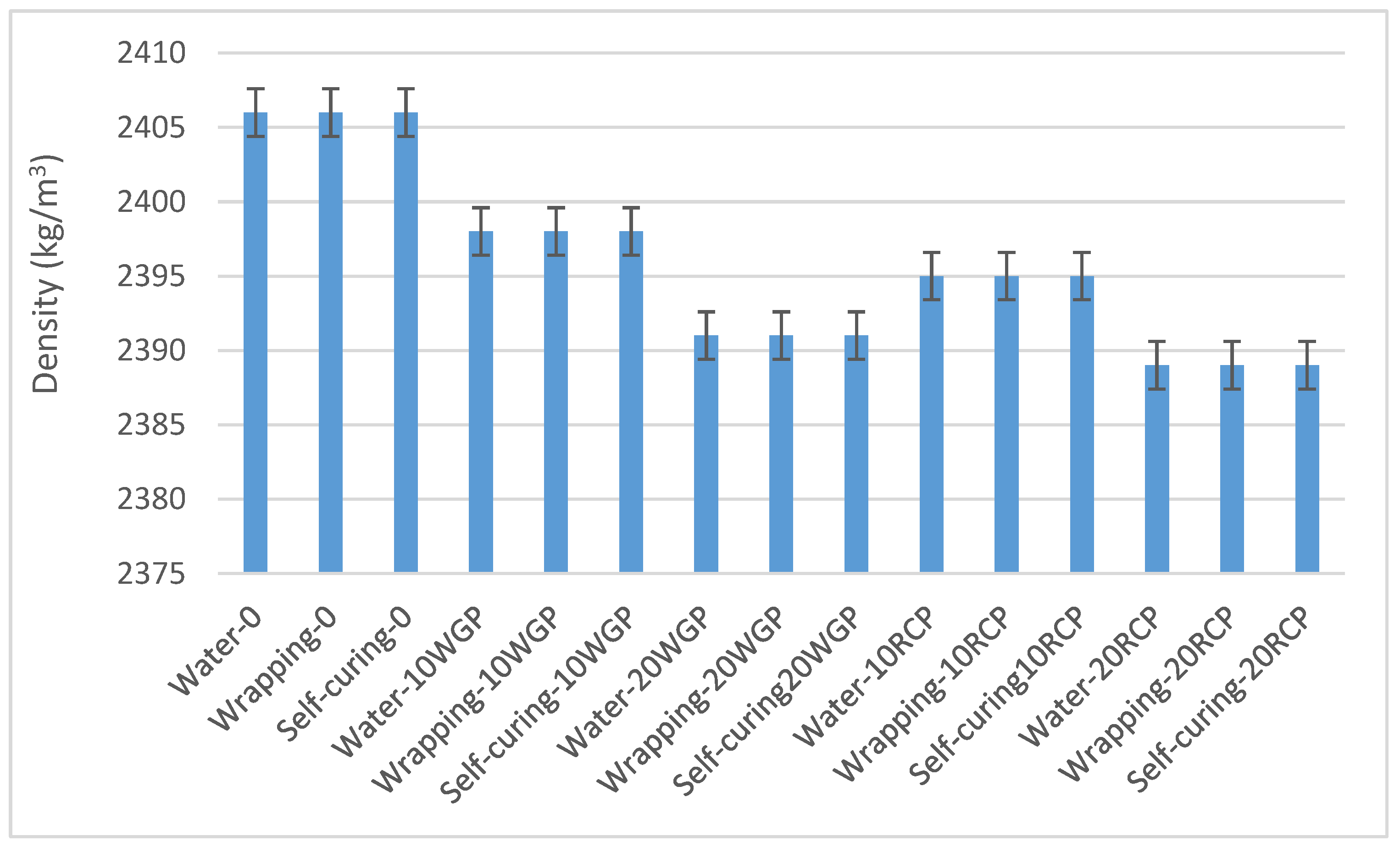

3.2. Density

3.2.1. Effect of WGP

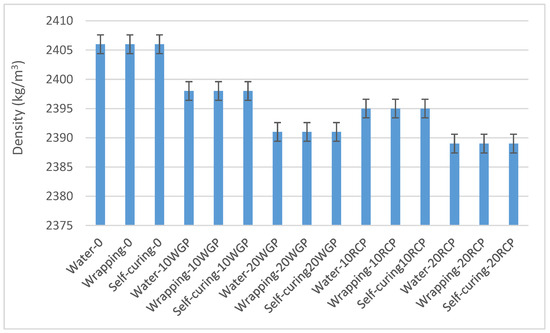

During this trial, the impact of WGP on the density of concrete in the SSD condition was examined by varying the amounts by 10% and 20%. As with conventional concrete, various WGP ratios were tested in different curing periods, as illustrated in Figure 5. An increase in the percentage of WGP used instead of cement in a concrete mix typically results in a reduction in density. Nevertheless, the decrease is not substantial. This is due to the lower density of WGP compared to cement, which leads to a decrease in the overall density of the mixture when it is used as a substitute. Nonetheless, there are situations where increasing the WGP replacement may result in an increase in density. The higher overall density may be attributed to factors like the type, particle size, and shape of the WGP, which enhance the packing density in the concrete mix. Furthermore, there is a possibility of specific chemical reactions occurring between the WGP and other elements in the concrete mixture, resulting in a more compact product. A higher WGP content can also impact the compaction process, leading to a tighter and denser concrete mix. A recently published investigation [9] has documented comparable findings.

Figure 5.

Density of concretes incorporating different contents of WGP and RCP.

3.2.2. Effect of RCP

The present study was carried out to assess how RCP impacts the density of concrete, as illustrated in Figure 5. The impact on the concrete mix density from replacing RCP is comparable to the replacement of WGP. Nevertheless, the drop in the density of concrete with RCP is greater than that of concrete with WGP when compared to control mixes. For instance, the reduction in percentage for the 10% WGP concrete is 0.3%, while, for the 10% RCP concrete, it is 0.5% when compared to the control mixes.

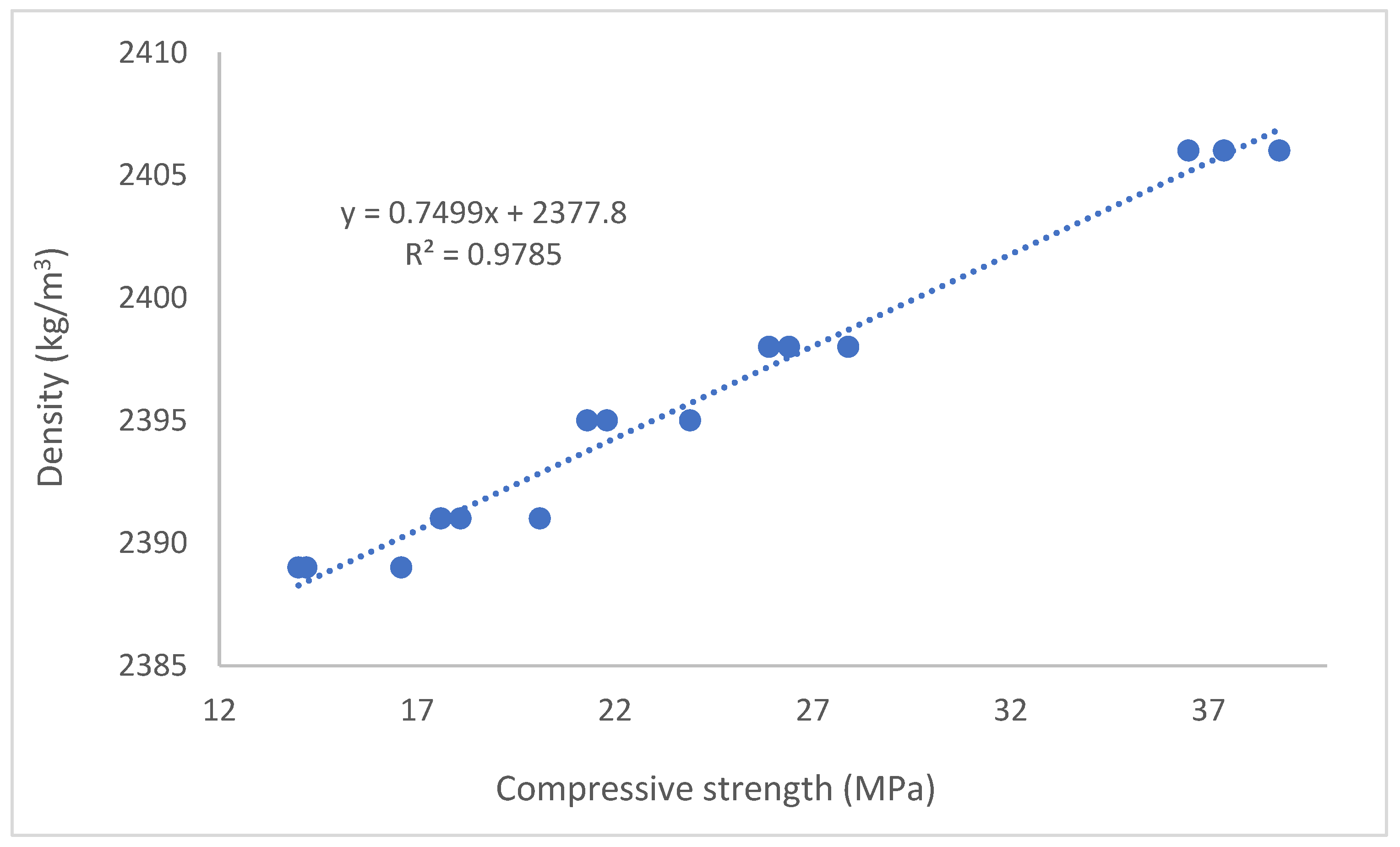

3.2.3. Correlation between Strength and Density

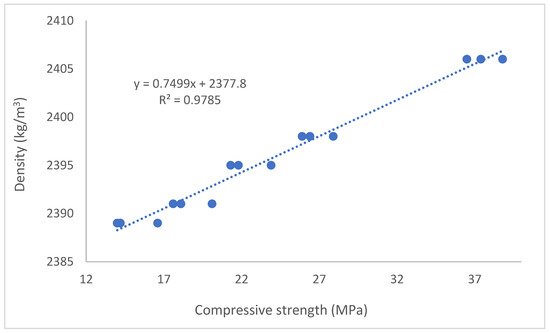

Typically, there is a direct correlation between the concrete density and compressive strength, indicating that denser concrete usually exhibits a greater compressive strength. This happens because denser concrete generally contains fewer empty spaces, leading to enhanced strength. Yet, the connection may not always be straightforward, as variables like the water–cement ratio, aggregate type, and curing conditions can impact the compressive strength regardless of density. Figure 6 displays a significant correlation (R2 = 0.98) between these two characteristics.

Figure 6.

Correlation between strength and density of concretes.

3.3. Compressive Strength

3.3.1. Effect of WGP

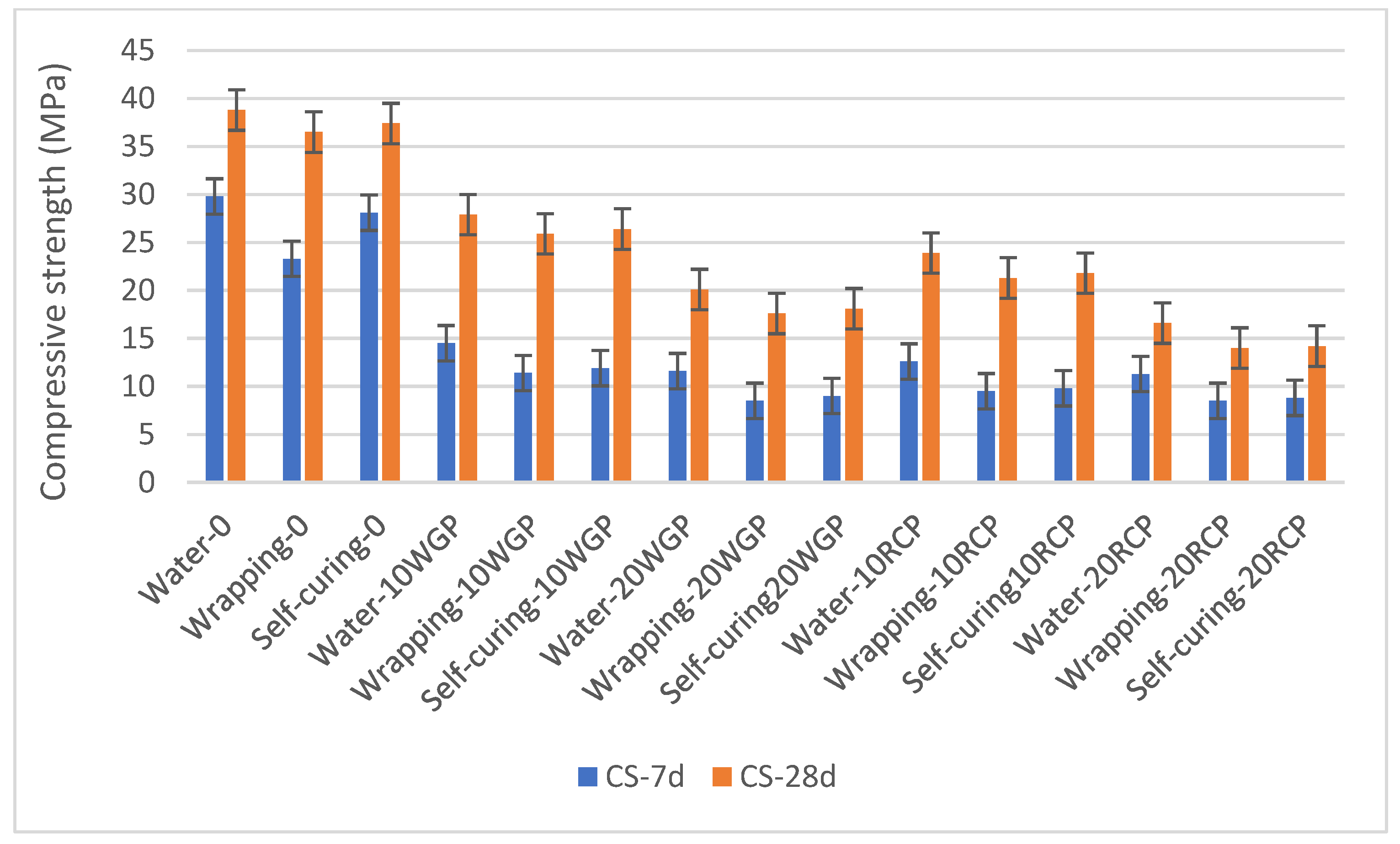

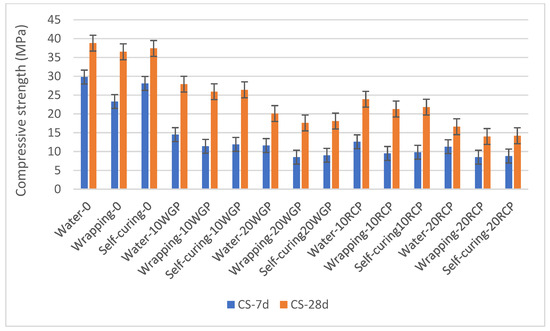

Figure 7 shows a graphical display of the compressive strength of concrete mixtures with various levels of WGP and RCP replacements, at 7-day and 28-day intervals, using different curing methods. The results indicate that adding WGP results in a lower compressive strength when compared to regular concrete. The compressive strength of concrete was found to change depending on the different mixtures of WGP used, specifically 10% and 20% as replacements. An illustration of this is seen in the compressive strength values of concretes with 10% WGP at 7 and 28 days of curing, which varied from 11.4 to 14.5 MPa and 25.9 to 27.9 MPa, respectively. This indicates the ongoing hydration process leading to a higher compressive strength as the curing time increases. In other studies [29,30], similar findings have also been documented. Usually, concrete containing WGP is suitable for non-structural applications like pavements, precast elements, decorative concrete, etc. Continuing research is necessary in order to fully understand the long-term performance and potential applications of concrete incorporating WGP.

Figure 7.

Compressive strength of concrete containing different contents of WGP and RCP under different curing conditions at different curing times.

3.3.2. Effect of RCP

The results indicate that adding RCP to concrete causes a decrease in compressive strength when compared to traditional concrete, as demonstrated in Figure 7. Before labeling RCP as eco-friendly, it is important to evaluate its impact on structural integrity, despite the potential benefits in waste reduction. It might be more suitable for non-structural purposes or projects where a high compressive strength is not crucial. Different levels of compressive strength were observed in concrete with varying replacement percentages of RCP at 10% and 20%. For instance, with 10% RCP, concrete strengths ranged from 9.5 to 12.6 MPa at 7 days and from 21.3 to 23.9 MPa at 28 days, showing ongoing hydration and strength gain with longer curing periods. RCP might show irregular properties compared to traditional cement, leading to differences in strength. The decreased compressive strength of concrete when using RCP could be caused by different factors related to hydration and the pozzolanic process. The composition and reactivity of RCP may vary compared to Portland cement, which can affect the hydration process and lead to less strong connections. Furthermore, impurities or contaminants found in recycled materials might hinder the pozzolanic reaction, reducing the creation of strength-enhancing substances like calcium silicate hydrates (C-S-Hs). This primary factor probably plays a role in the documented decrease in compressive strength in comparison to the control concrete.

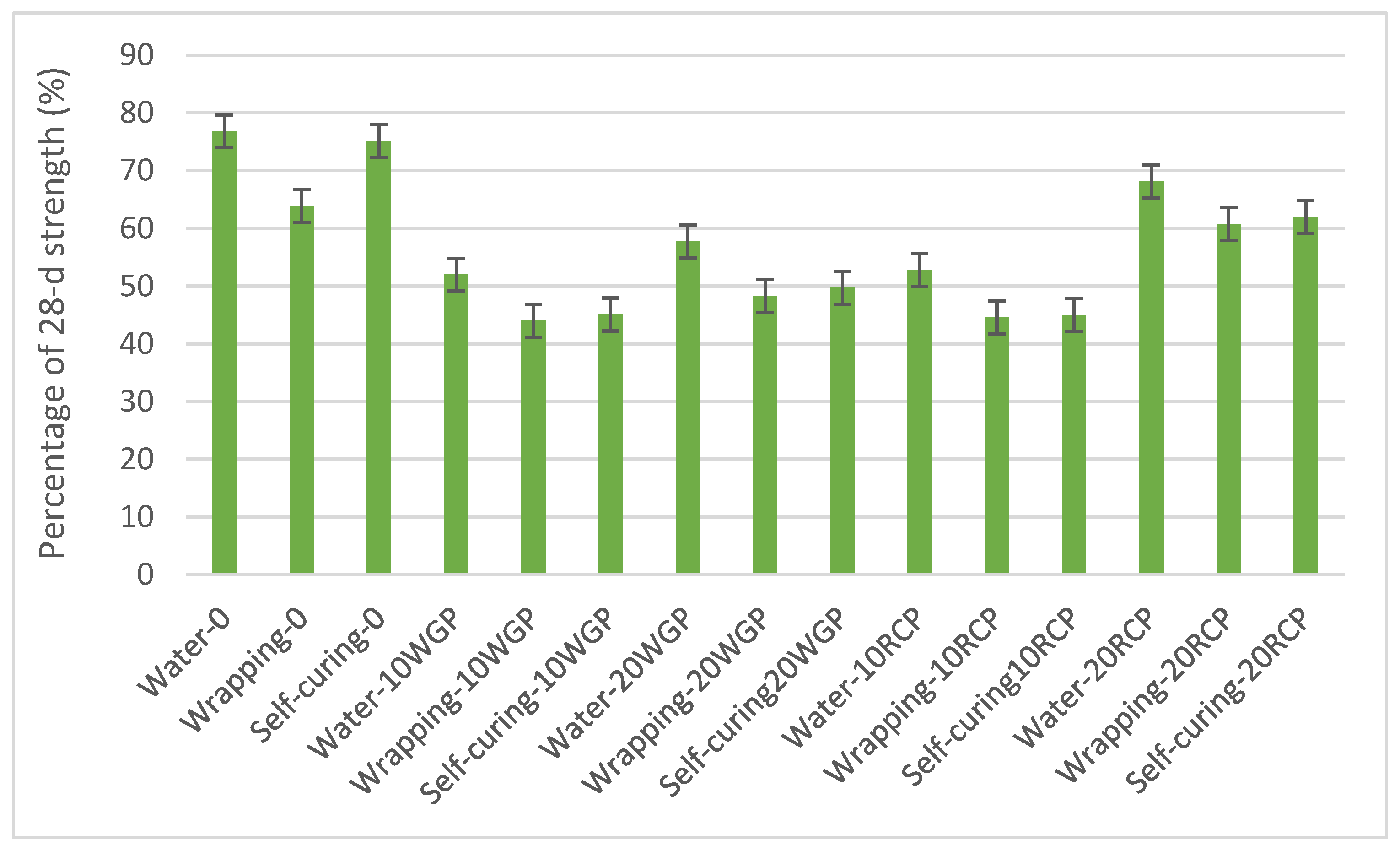

3.3.3. Effect of Curing Regimes

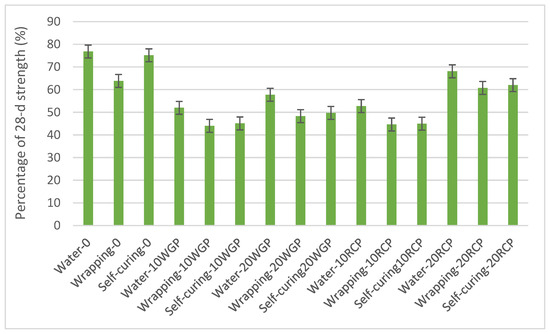

Based on the findings shown in Figure 8, the WGP achieved 44%, 45.1%, and 52% of their 28-day strength after 7 days with a 10% ratio for wrapping, self-curing, and water curing, respectively. In 7 days, the strength of control concrete has achieved 63.8%, 75.1%, and 76.8% of its 28-day strength for wrapping, self-curing, and water curing, respectively. The strength improvements of concrete with 20% WGP are 48.3%, 49.7%, and 57.7% for different curing methods: wrapping, self-curing, and water curing. These low values in concretes with WGP may be due to the slower hydration at the start of the strength development compared to control concretes. Wrapping curing resulted in the lowest compressive strength due to incomplete hydration caused by the lack of water availability. Notable is the demonstration of the PEG-400 admixture efficacy at a 1% dosage in the current research to retain water within the concrete for ongoing hydration, resulting in a strength enhancement greater than wrapping but less than water curing. Self-curing agents like PEG-400 contain a polymer that forms hydrogen bonds with water molecules, decreasing the evaporation rate from the concrete surface [7,37,41,44]. Hence, the higher compressive strength seen in mixes with PEG-400, as opposed to those without, is attributed to the presence of water that facilitates ongoing hydration.

Figure 8.

Relative strength gain of concrete mixtures by 28-day curing.

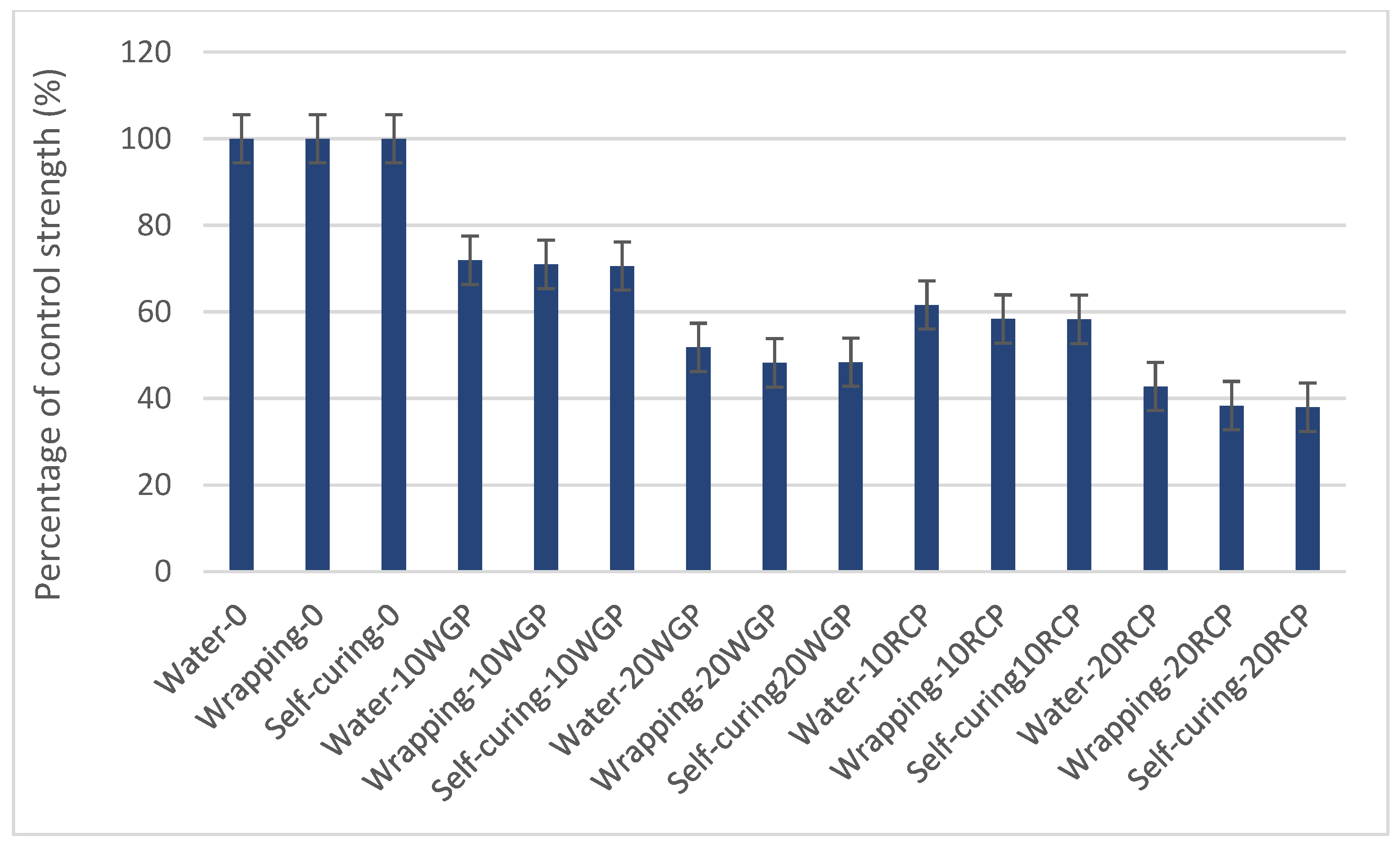

3.3.4. Strength Development

Figure 8 reveals that concrete with 10% RCP achieved 44.6%, 45.0%, and 52.7% of its strength gain within 7 days for wrapping, self-curing, and water curing, respectively, by 28 days. The concrete strength increases by 60.7%, 62.0%, and 68.1% when 20% RCP is used in wrapped, self-cured, and water-cured conditions. Figure 5 reveals that the increase in strength is greater for high percentages (20%) of both WGP and RCP compared to lower replacement levels (10%). Water curing is considered the most effective curing condition as it has resulted in the highest compressive strength for all types of concretes—control, WGP, and RCP. The clear distinction between the curing methods occurs since, in water curing, hydration reaches its final stages with little to no remaining cement to be hydrated.

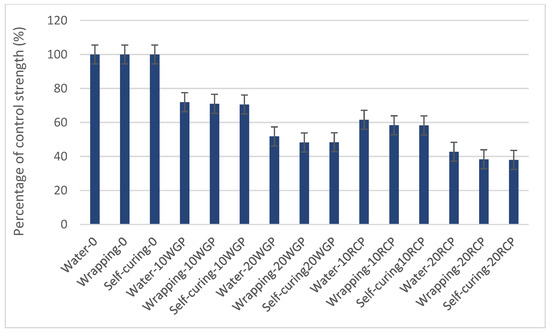

Figure 9 displays the comparative compressive strength of concrete mixes with water, self-curing, and wrapping curing at 28 days, in relation to control mixes. The concrete with 10% WGP displayed the highest relative strength of 71.9% under the water condition, while 71.0% under wrapping and 70.6% under self-curing regimes were also achieved compared to control concretes. The values fell to 51.8%, 48.4%, and 48.2% for 20% WGP concretes in water, with self-curing, and with wrapping curing. Concrete with RCP has exhibited a reduced strength gain compared to concrete with WGP under all curing conditions.

Figure 9.

Relative strength gain of concretes compared to control mixtures.

3.4. Water Absorption

3.4.1. Effect of WGP

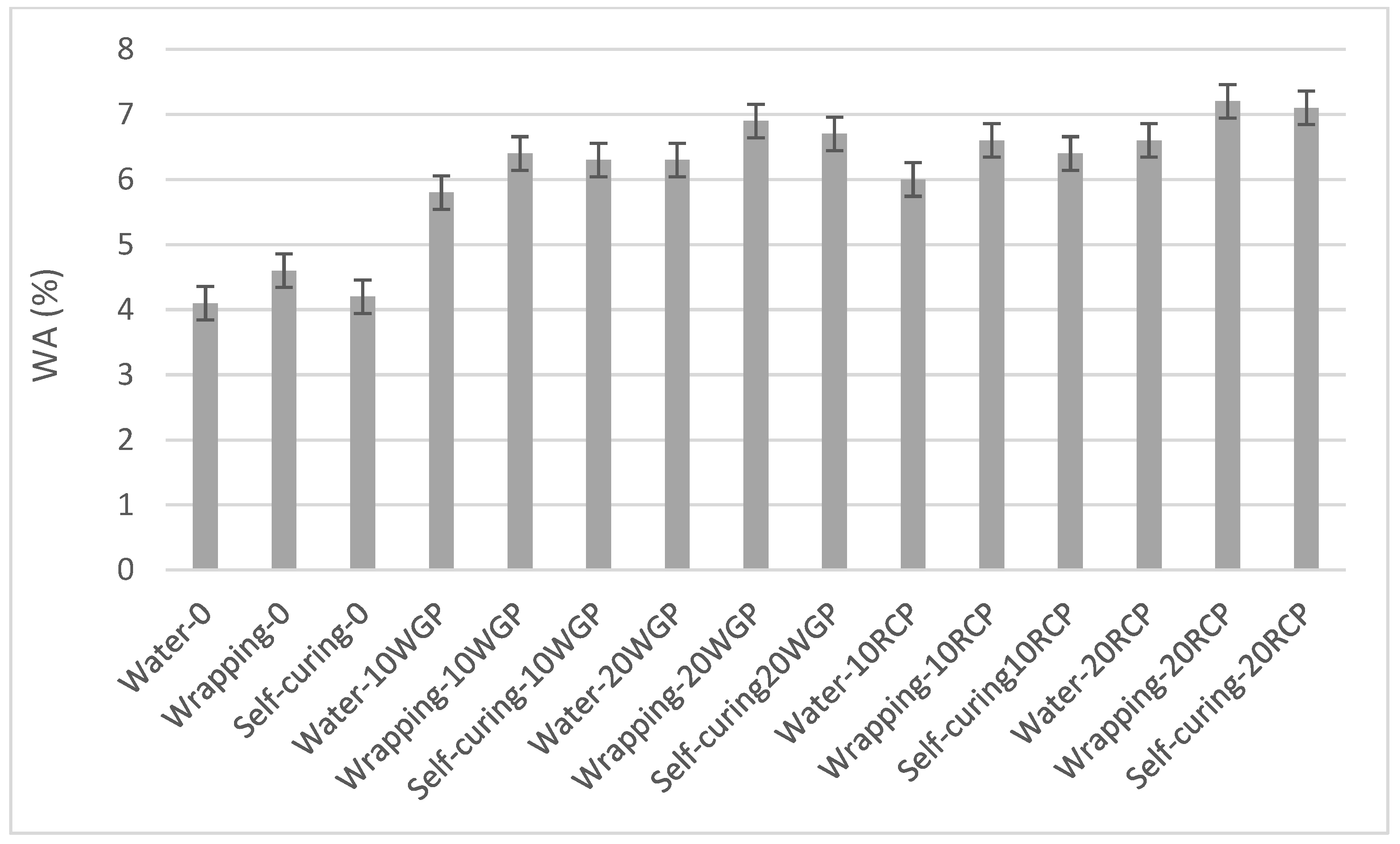

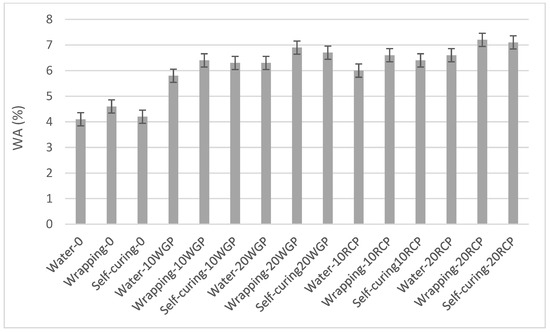

The findings illustrated in Figure 10 display the water absorption (WA) of concrete with various WGP and RCP levels in various curing conditions at 28 days. One of the key properties of concrete is its absorption characteristic, which can be used, particularly in engineering, as a representative descriptor to reflect and forecast the material’s durability [45,46]. In order to ensure sufficient strength, it is crucial for concrete’s water absorption (WA) to be between 4–6% under normal pressure [46]. The concrete with 10% WGP consistently shows WA values within the range of 4–6%. Some blends exceed this boundary. Substituting larger quantities of WGP for Portland cement in concrete causes a rise in WA as a result of the uneven form and porous composition, resulting in additional empty spaces within the concrete. The silica in WGP reacts with water and alkalis in the cement mixture, increasing the water absorption of concrete. Moreover, the surface properties of WGP enhance the WA, while its poor adhesion to cement paste allows for water infiltration. Based on the findings, the WA values for concrete with 10% WGP are 5.8% when cured in water, 6.3% when self-cured, and 6.4% when wrapped for curing. An investigation [36] has reported similar results. The percentages of 6.3%, 6.7%, and 6.9% are observed for water curing, self-curing, and wrapping curing with the 20% WGP replacement.

Figure 10.

WA of concrete mixtures.

3.4.2. Effect of RCP

The water absorption values for concrete with varying levels of RCP replacement are greater than those of the control and WGP concrete, as demonstrated in Figure 10. The water-cured concrete with 10% RCP content consistently maintains a WA range of 4–6% [7,46]. Nevertheless, WA can exceed this range in certain mixtures containing 20% RCP under various curing conditions. The higher the quantity of RCP in concrete is, the higher the WA rates increase because of RCP’s physical irregularities and porous structure, which make WA easier. Moreover, the leftover cement in RCP stimulates hydration processes, resulting in a higher number of pores in the concrete and elevated water absorption. These observations have implications for enhancing concrete mixtures to address water penetration issues in construction.

The WA results show that adding PEG-400 in concrete reduced the WA compared to traditional wrapping curing. According to sources [41,47,48], the decline in the water absorption of concrete during self-curing suggests a lower porosity level. Using 1% PEG-400 in concrete with waste powders reduced the water absorption compared to the control concrete due to the self-curing method application. Similar findings have been reported in recently published studies [41,49].

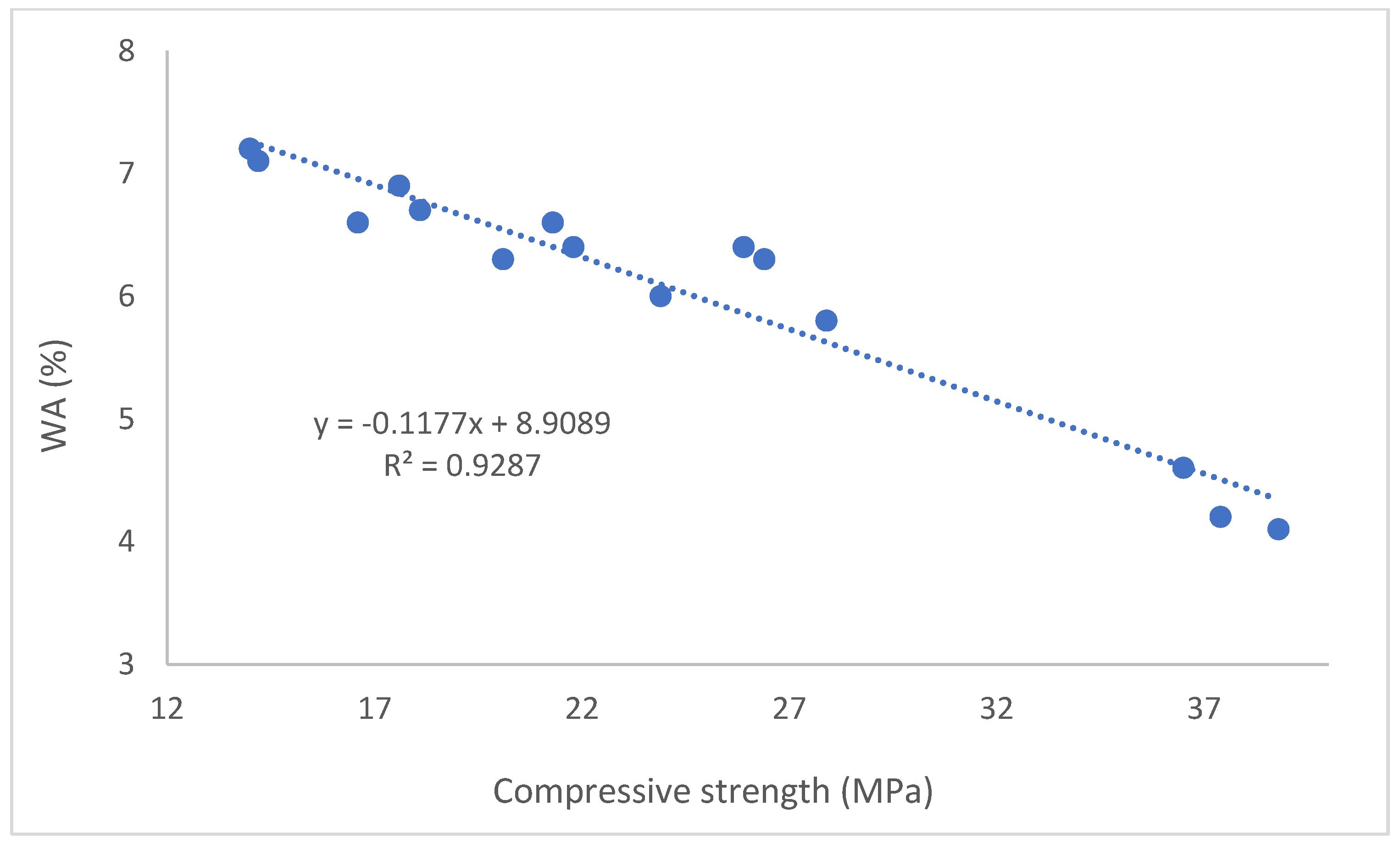

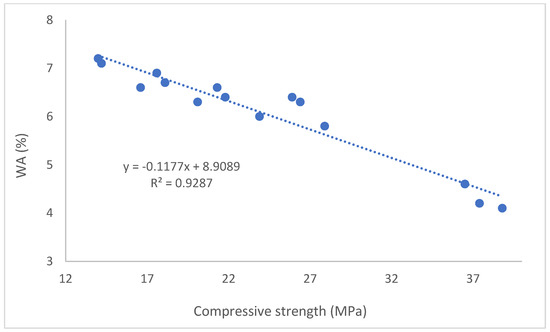

3.4.3. Correlation between Strength and WA

The relationship between the concrete compressive strength and water absorption is shown in Figure 11. Nevertheless, there is typically a negative correlation between the compressive strength and water absorption. Concrete with an increased compressive strength usually has a decreased water absorption, showing a more compact, less permeable composition and high durability. On the other hand, concrete that has a lower compressive strength might show a higher WA, indicating it is a more porous and less long-lasting material. The relationship between these two characteristics is highly evident in Figure 11 which indicates a very strong correlation (R2 = 0.93).

Figure 11.

Correlation between strength and WA.

4. Conclusions

Waste materials allow for cost savings and support environmental sustainability by reducing landfill waste and the need for natural resources. This study explores the potential of waste glass and recycled concrete powders as substitutes for some of the Portland cement in construction materials. Both waste powders have a detrimental impact on the engineering properties of concrete. Under identical curing conditions and with the same percentage of replacement, RCP has a greater impact compared to WGP. Although the engineering properties decreased by replacing ordinary Portland cement with these two recycled powders, the findings validate the possibility of effectively utilizing small amounts of these two waste powders by implementing an appropriate curing method for structural purposes. The practicality of incorporating greater amounts of these two waste powders is still feasible and appropriate for low-strength uses like pedestrian walkways with a focus on cost-efficiency. As a result, each application will determine the best replacement level and curing technique. While it is true that recycling concrete and waste glass can lead to some degradation in material properties over multiple cycles, there are ways to mitigate these issues including quality control, a passport for products, blending materials, ongoing research, etc. Overall, despite the difficulties, cautious management and creative solutions can contribute to the continued viability and sustainability of recycled concrete and waste glass as building materials.

- The findings show a decline in workability at 10% WGP, followed by a steady increase in workability as the percentage of WGP rises to 20%; however, the slump values for concrete containing RCP are different. The workability decreases with 10% RCP and decreases more with 20% RCP.

- An increase in the percentage of WGP results in a reduction in density. Nevertheless, the decrease is not substantial. The impact on the concrete mix density from replacing RCP is comparable to the replacement of WGP. Nevertheless, the drop in density of concrete with RCP is greater than that of concrete with WGP. For instance, the reduction in percentage for the 10% WGP concrete is 0.3%, while, for the 10% RCP concrete, it is 0.5% when compared to the control mixes.

- The compressive strength of concrete containing WGP decreased with increasing percentages of WGP. The compressive strength of concretes with 10% WGP at 28 days of curing varied from 25.9 to 27.9 MPa under different curing conditions. The compressive strength for concrete with 10% RCP ranged from 9.5 to 12.6 MPa at 7 days and from 21.3 to 23.9 MPa at 28 days, showing ongoing hydration and strength gain with longer curing periods.

- The concrete containing 10% WGP achieved 44%, 45.1%, and 52% of their 28-day strength after 7 days under wrapping, self-curing, and water curing, respectively. This strength gain for concrete with 10% RCP is 44.6%, 45.0%, and 52.7%. Wrapping curing resulted in the lowest compressive strength due to incomplete hydration caused by the lack of water availability. Water curing is considered the most effective curing condition as it has resulted in the highest compressive strength for all types of concretes—control, WGP, and RCP.

- Higher proportions of WGP and RCP resulted in increased water absorption due to their porous nature; however, the acceptable level of 4–6% can be achieved with a 10% WGP and RCP replacement.

Future research work could involve examining the microstructural properties, additional mechanical properties, and durability properties by different replacement percentages of these recycled powders with Portland cement and examining different curing conditions.

Funding

This research received no external funding.

Data Availability Statement

The necessary data can be available up on request.

Acknowledgments

The author would like to acknowledge the technical support of the University of Wolverhampton (UK) and the Faculty of Engineering, Soran University (Kurdistan, Iraq).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jahami, A.; Issa, C.A. Exploring the use of mixed waste materials (MWM) in concrete for sustainable Construction: A review. Constr. Build. Mater. 2023, 398, 132476. [Google Scholar] [CrossRef]

- Yang, D.; Liu, M.; Zhang, Z.; Yao, P.; Ma, Z. Properties and modification of sustainable foam concrete including eco-friendly recycled powder from concrete waste. Case Stud. Constr. Mater. 2022, 16, e00826. [Google Scholar] [CrossRef]

- Ahmad, Z.; Paleologou, M.; Xu, C.C. Oxidative depolymerization of lignin using nitric acid under ambient conditions. Ind. Crops Prod. 2021, 170, 113757. [Google Scholar] [CrossRef]

- Hamid, S.; Naji, K.; Younis, A.; Ebead, U. Material performance and cost effectiveness of seawater-mixed rubberized concrete. Case Stud. Constr. Mater. 2021, 15, e00735. [Google Scholar] [CrossRef]

- Gencel, O.; Nodehi, M.; Hekimoğlu, G.; Ustaoğlu, A.; Sarı, A.; Kaplan, G.; Bayraktar, O.Y.; Sutcu, M.; Ozbakkaloglu, T. Foam Concrete Produced with Recycled Concrete Powder and Phase Change Materials. Sustainability 2022, 14, 7458. [Google Scholar] [CrossRef]

- Kim, Y.-J. Quality properties of self-consolidating concrete mixed with waste concrete powder. Constr. Build. Mater. 2017, 135, 177–185. [Google Scholar] [CrossRef]

- Xiao, J.; Ma, Z.; Sui, T.; Akbarnezhad, A.; Duan, Z. Mechanical properties of concrete mixed with recycled powder produced from construction and demolish waste. J. Clean. Prod. 2018, 188, 720–731. [Google Scholar] [CrossRef]

- Jain, K.L.; Sancheti, G.; Gupta, L.K. Durability performance of waste granite and glass powder added concrete. Constr. Build. Mater. 2020, 252, 119075. [Google Scholar] [CrossRef]

- Balasubramanian, B.; Gopala Krishna GV, T.; Saraswathy, V.; Srinivasan, K. Experimental investigation on concrete partially replaced with waste glass powder and waste E-plastic. Constr. Build. Mater. 2021, 278, 122400. [Google Scholar] [CrossRef]

- Limbachiya, M.; Meddah, M.S.; Ouchagour, Y. Use of recycled concrete aggregate in fly-ash concrete. Constr. Build. Mater. 2012, 27, 439–449. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Yu, J.; Xu, L.; Li, M.; Cheng, J.; Li, Z. Effects of sodium sulfate and potassium sulfate on the properties of calcium sulfoaluminate (CSA) cement based grouting materials. Constr. Build. Mater. 2022, 353, 129045. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, J.; Wang, J.; Xiang, D.; Gu, H.; Cheng, J. Effects of sodium aluminate and quicklime on the properties of CSA grouting materials. J. Build. Eng. 2022, 58, 105060. [Google Scholar] [CrossRef]

- Baikerikar, A.; Mudalgi, S.; Ram, V.V. Utilization of waste glass powder and waste glass sand in the production of Eco-Friendly concrete. Constr. Build. Mater. 2023, 377, 131078. [Google Scholar] [CrossRef]

- Tang, Q.; Ma, Z.; Wu, H.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cem. Concr. Compos. 2020, 114, 103807. [Google Scholar] [CrossRef]

- Mendoza, J.-M.F.; Oliver-Solà, J.; Gabarrell, X.; Rieradevall, J.; Josa, A. Planning strategies for promoting environmentally suitable pedestrian pavements in cities. Transp. Res. Part D Transp. Environ. 2012, 17, 442–450. [Google Scholar] [CrossRef]

- Bahraq, A.A.; Jose, J.; Shameem, M.; Maslehuddin, M. A review on treatment techniques to improve the durability of recycled aggregate concrete: Enhancement mechanisms, performance and cost analysis. J. Build. Eng. 2022, 55, 104713. [Google Scholar] [CrossRef]

- Borhan, T.M. Properties of glass concrete reinforced with short basalt fibre. Mater. Design. 2012, 42, 265–271. [Google Scholar] [CrossRef]

- Allan, P. Assessment of Australian Recycling Infrastructure-Glass Packaging Update; Department of Environment and Energy: Canberra, Australia, 2019. [Google Scholar]

- Al-Sibahy, A.; Edwards, R. Mechanical and thermal properties of novel lightweight concrete mixtures containing recycled glass and metakaolin. Constr. Build. Mater. 2012, 31, 157–167. [Google Scholar] [CrossRef]

- Orouji, M.; Mehdi Zahrai, S.; Najaf, E. Effect of glass powder & polypropylene fibers on compressive and flexural strengths, toughness and ductility of concrete, An environmental approach. Structures 2021, 33, 4616–4628. [Google Scholar]

- Zahrai, S.M.; Mortezagholi, M.H.; Najaf, E. Using AP2RC & P1RB micro-silica gels to improve concrete strength and study of resulting contamination. Adv. Concr. Constr. 2016, 4, 195–206. [Google Scholar]

- Najaf, E.; Orouji, M.; Zahrai, S.M. Improving nonlinear behavior and tensile and compressive strengths of sustainable lightweight concrete using waste glass powder, nanosilica, and recycled polypropylene fiber. Nonlinear Eng. 2022, 11, 58–70. [Google Scholar] [CrossRef]

- Najaf, E.; Abbasi, H.; Zahrai, S.M. Effect of waste glass powder, microsilica and polypropylene fibers on ductility, flexural and impact strengths of lightweight concrete. Int. J. Struct. Integr. 2022, 13, 511–533. [Google Scholar] [CrossRef]

- Mohajerani, A.; Vajna, J.; Cheung, T.H.H.; Kurmus, H.; Arulrajah, A.; Horpibulsuk, S. Practical recycling applications of crushed waste glass in construction materials: A review. Constr. Build. Mater. 2017, 156, 443–467. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty AE, M.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Islam GM, S.; Rahman, M.H.; Kazi, N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef]

- Elaqra, H.A.; Haloub MA, A.; Rustom, R.N. Effect of new mixing method of glass powder as cement replacement on mechanical behavior of concrete. Constr. Build. Mater. 2019, 203, 75–82. [Google Scholar] [CrossRef]

- Rajendran, R.; Sathishkumar, A.; Perumal, K.; Pannirselvam, N.; Lingeshwaran, N.; Babu Madavarapu, S. An experiment on concrete replacing binding material as waste glass powder. Mater. Today Proc. 2021, 47, 5447–5450. [Google Scholar] [CrossRef]

- Amran, M.; Onaizi, A.M.; Qader, D.N.; Murali, G. Innovative use of fly ash-finely powdered glass cullet as a nano additives for a sustainable concrete: Strength and microstructure and cost analysis. Case Stud. Constr. Mater. 2022, 17, e01688. [Google Scholar] [CrossRef]

- Oikonomou, N.D. Recycled concrete aggregates. Cement Concr. Compos. 2005, 27, 315–318. [Google Scholar] [CrossRef]

- Sakai, Y.; Tarekegne, B.T.; Kishi, T. Recycling of hardened cementitious material by pressure and control of volumetric change. J. Adv. Concr. Technol. 2016, 14, 47–54. [Google Scholar] [CrossRef]

- Gebremariam, A.T.; Di Maio, F.; Vahidi, A.; Rem, P. Innovative technologies for recycling End-of-Life concrete waste in the built environment. Resour. Conserv. Recycl. 2020, 163, 104911. [Google Scholar] [CrossRef]

- Saravanakumar, P.; Abhiram, K.; Manoj, B. Properties of treated recycled aggregates and its influence on concrete strength characteristics. Constr. Build. Mater. 2016, 111, 611–617. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, M.; Duan, Z.; Liang, C.; Wu, H. Effects of active waste powder obtained from C&D waste on the microproperties and water permeability of concrete. J. Clean. Prod. 2020, 257, 120518. [Google Scholar]

- Chen, X.; Li, Y.; Kang, X.; Fan, Y. Study on Recycled Concrete Powders as Mineral Admixture in Recycled Concrete. IOP Conf. Ser. Earth Environ. Sci. 2019, 330, 022113. [Google Scholar] [CrossRef]

- Xu, L.; Wang, J.; Hu, X.; Ran, B.; Wu, T.; Zhou, X.; Xiong, Y. Physical performance, durability, and carbon emissions of recycled cement concrete and fully recycled concrete. Constr. Build. Mater. 2024, 447, 138128. [Google Scholar] [CrossRef]

- Wang, J.; Xu, L.; Li, M.; Wang, Y.; He, H.; Xiang, D.; Li, K.; Hao, T. Investigations on factors influencing physical properties of recycled cement and the related carbon emissions and energy consumptions. J. Clean. Prod. 2023, 414, 137715. [Google Scholar] [CrossRef]

- ASTM C136-06; Standard Test Method for Sieve Analysis of Fine and Course Aggregates. Annual Book of ASTM Standards: West Conshohocken, PA, USA, 2008; Volume 4.02.

- Tasluja Cement Company. Available online: https://www.lafarge-iraq.com/en/tasluja (accessed on 2 August 2024).

- Iraqi Standards Cement Specifications (IQS 5:1984). Available online: https://www.samancement.iq/products.aspx?jimare=84 (accessed on 2 August 2024).

- Herki, B.M.A.; Khatib, J.M.; Hamadamin, M.N.; Kareem, F.A. Sustainable Concrete in the Construction Industry of Kurdistan-Iraq through Self-Curing. Buildings 2022, 12, 1318. [Google Scholar] [CrossRef]

- Standard C143-00; Standard Test Method for Slump of Hydraulic Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C1585-04; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic Cement Concrete. ASTM: West Conshohocken, PA, USA, 2004.

- Mohnika, S.; Vinodkumar, K.; Mallikharjunarao, K. Effect of Different Dosages of Self Curing Compound (Using Peg-400) On M-25 Mix Concrete. Int. J. Adv. Arts Sci. Eng. 2016, 4, 103–112. [Google Scholar]

- Golewski, G.L. Assessing of water absorption on concrete composites containing fly ash up to 30% in regards to structures completely immersed in water. Case Stud. Constr. Mater. 2023, 19, e02337. [Google Scholar] [CrossRef]

- Zhuang, S.; Wang, Q.; Zhang, M. Water absorption behaviour of concrete: Novel experimental findings and model characterization. J. Build. Eng. 2022, 53, 104602. [Google Scholar] [CrossRef]

- Santhiyaraj, I.; Robin, A.; Suganthi, S.L.; Santhi, T.S. Experimental Investigation of Self Curing Concrete using Polyethylene Glycol. Int. J. Recent Technol. Eng. (IJERT) 2020, 9, 777–779. [Google Scholar]

- Herki, B.M.A. Concrete Capillarity under Different Curing Conditions Produced in Kurdistan-Iraq. Adv. Sci. Technol. Res. J. 2020, 14, 131–139. [Google Scholar] [CrossRef] [PubMed]

- Herki, B.M.A. Absorption Characteristics of Lightweight Concrete Containing Densified Polystyrene. Civ. Eng. J. 2017, 3, 594–609. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).