Abstract

This review article gathers the most recent recycling technologies for thermoset and thermoplastic polymers. Results about existing experimental procedures and their effectiveness are presented. For thermoset polymers, the review focuses mainly on fibre-reinforced polymer composites, with an emphasis on epoxy-based systems and carbon/glass fibres as reinforcement, due to the environmental concerns of their end-of-life management. Thermal processes (fluidised bed, pyrolysis) and chemical processes (different types of solvolysis) are discussed. The most recent combined processes (microwave, steam, and ultrasonic assisted techniques) and extraordinary recycling attempts (electrochemical, biological, and with ionic liquids) are analysed. Mechanical recycling that leads to the downgrading of materials is excluded. Insights are also given for the upcycling methodologies that have been implemented until now for the reuse of fibres. As for thermoplastic polymers, the most state-of-the-art recycling approach for the most common polymer matrices is presented, together with the appropriate additivation for matrix upcycling. Mechanical, chemical, and enzymatic recycling processes are described, among others. The use of fibre-reinforced thermoplastic composites is quite new, and thus, the most recent achievements are presented. With all of the above information, this extensive review can serve as a guide for educational purposes, targeting students and technicians in polymers recycling.

1. Introduction

The transition from a fossil- to renewable-based society and recycling are vital for the next generations, as the fundamental steps toward a circular economy regenerative system able to minimize resource input and waste, emission, and energy consumption [1]. According to Plastics Europe, worldwide plastic production in 2022 was 400.3 Mt, with a CAGR of 5–6% [2], with thermosets counting for around 11% of plastic production volume (42 Mt) [3]. Recent trends indicate significantly increased circular plastics production, reaching nearly 10% of global production (35.5 Mt) and showing a 16-fold increase compared to fossil-based plastics, with circular plastics production increasing by 29.2% since 2018 in Europe, reaching a share of 19.7% of overall European plastics production by 2022.

Thermoset polymers are one of the most produced and used material worldwide, due to their numerous advanced characteristics such as toughness and resistance in harsh environmental conditions. They are used mainly as matrices in composite materials, along with several other engineering applications, such as adhesives, coatings, insulating foams, etc., that find applications in naval, aerospace, aviation, building, and wind energy. Among the most common thermoset polymers are acrylic resins, polyesters and vinyl esters, epoxies, polyurethanes, phenolic, amino, and furan resins, as well as polybenzoxazines.

Thermoset polymers are mainly used for the manufacturing of fibre-reinforced polymers (FRPs) that offer significant advantages over conventional isotropic materials such as their steel and aluminium counterparts. According to the R-strategies [4], the recycling of FRP has a great advantage in that it can be applied to all structural parts made of composite materials. Furthermore, this approach can be an advantageous combination for repetitive applications, such as the production of non-structural components from end-of-life composite parts [5], as the waste stream of residual composites generated during the production process can be reduced.

Due to the high Young’s modulus of carbon fibres, carbon fibre-reinforced polymers (CFRPs) are used in a wide number of sectors in which high strength-to-weight ratio and stiffness are required, including the transport sector (i.e., automotive, aeronautic, shipbuilding) and energy sector (i.e., wind energy). CFRPs are expected to reach a global demand of 290 kt by the end of 2024 [6,7], and from renewable energy sectors alone, it has been estimated that by 2030, composite waste will reach 500 kt [8].

Glass fibre-reinforced plastics (GFRPs) composites remain the dominant material in the composites market, with a market share of over 95% [9] thanks to significant industrial interest (e.g., lightweight for automotive, unlimited design possibilities coupled with high performance for home appliances, and much lower cost for a railway).

Thermoplastic polymers are one of the most widely used materials in packaging, home appliances, and the automotive industry, among others. Specifically, the rapidly increasing amount of electronic waste (WEEE) reached ~52.2 Mt in 2021 [10], with estimations to exceed 74 Mt in 2030 [11], while formal documented collection and recycling only accounted for 9.3 Mt, a mere 17.4%, in 2019, illustrating that recycling activities are not at all keeping pace with the global growth of WEEE. Likewise, toys made from polymeric materials are identified to be the most plastic-intensive industry in the world, with 40 t of plastic used for every $1 M in revenue [12]. Considering that children grow quickly, and their abilities and interests shift even faster, toys are often thrown away after a short lifespan, with 80% [13] of them ending up in landfills or being incinerated. Textiles are another consumer sector of plastic products with high global revenue annually, having only 13% of the fibre input for clothing recycled [14] and less than 1% of closed-loop recycling, i.e., fibres recycled back into clothing rather than into lower value uses, such as cleaning cloths and insulation. The circular fibre concludes the crisis caused by the global COVID-19 pandemic and its economic consequences further highlight and exacerbate the vulnerabilities along the textile value chain, intensifying pressure on this already out-of-control problem and creating a significant increase in waste production across textile types, highlighting the urgency of transitioning from the industry’s current model to a more sustainable, socially inclusive, and circular model [15]. More than 8 Mt of pandemic-associated plastic waste have been generated globally [16], with more than 25 t entering the global ocean [17].

The European Green Deal and Circular Economy Action Plan 2.0, following the European Plastics Strategy [18], aim to increase the recycling of plastics, boost the recycled content in everyday products, and reduce the use of virgin materials. EU rules on single-use plastic products [19] aim to prevent and reduce the impact of certain plastic products on the environment and on human health, focusing on promoting the transition to a circular economy with innovative and sustainable business models, products, and materials, therefore also contributing to the efficient functioning of the internal market. Specific targets include a 77% separate collection target for plastic bottles by 2025, increasing to 90% by 2029, and incorporating 25% of recycled plastic in PET beverage bottles from 2025, and 30% in all plastic beverage bottles from 2030. The targets set by the environmental legislation for the recycling of EoL components and structures will mean that 33,000 tons of CFRP will be recycled every year in Europe by 2025 [20].

To reach all these goals, the recycling of thermoplastic waste industry must overcome a number of challenges. One of the most demanding tasks to be addressed is the rise in microplastic burden from recycling processes. The degradation of plastic and the subsequent release of microplastics into the environment have attracted significant public attention. Microplastic generation during plastic recycling, particularly during the size reduction phase, is a concerning unintended consequence. Despite being detected in recycling facility wastewater and sludge, pathways, factors, and minimization strategies for microplastic generation remain understudied. Material type and environmental weathering significantly influence microplastic generation rates, with material hardness strongly correlated to microplastic generation [21]. This suggests that plastic recycling facilities may inadvertently contribute to microplastic pollution. Mitigating microplastic release from recycling processes has become a key focus in the literature recently, highlighting the need for research into capturing methods and understanding the proportion of generated microplastics released into the environment [22]. With mechanical recycling expected to increase, urgent efforts are needed to comprehend the scale of microplastic generation and release, especially considering their presence in ecosystems worldwide [23].

Furthermore, thermoplastic manufacturing is highly dependent on the utilisation of fillers during the industrial production, for the improvement in properties as well as the reduction in costs. Most thermoplastics in their original form are impact resistant, often brittle, hard, combustible, etc.; fillers are incorporated during the processing to improve these properties, such as strength, stiffness, thermal conductivity, etc. Some common filler materials used are glass fibres, talc, calcium carbonate, silica, carbon black, flame retardants, etc. [24]. Although filler incorporation is vital for the industry and production, it causes several issues afterwards, during the recycling of those waste materials. Waste streams from the electrical and electronic equipment, and automotive and construction sector suffer from contamination, which in many cases is with substances of high concern. As a result, highly contaminated waste streams pose environmental issues and have lower market value, sometimes decreased properties, and increased complexity of processing [25]. Specifically, the mechanical recycling of polymers from WEEE and automotive waste suffer from the presence of brominated flame retardants, which have been used in products for years and have recently been evaluated as substances of very high concern (SVHC) or even persistent organic pollutants (POP). The presence of those substances poses threats to humans, animals, and the environment, and therefore, their removal from streams has to be dealt with. The detection of those substances is possible through spectroscopic techniques and their quantification using chromatographic techniques [26]. Regarding their purification, extraction in supercritical conditions has been proven to be effective [27,28], as well as their purification through solvent-based recycling processes, such as the CreaSolv® Process [29].

Nowadays, due to their strategic properties, the integration of thermoplastics and thermosets as matrices in composite materials is rising, with their market penetration growing in established sectors and their adoption in new sectors, although their deployment is currently limited due to a lack of recyclability and re-usability, which is hindered by their complexity [30]. Inevitably, this results in more waste from manufacturing, and an increasing challenge to develop economically sustainable recycling routes for end-of-life (EoL), taking also into account that, according to their chemical composition, from a technological point of view, thermoplastics are easily recycled and reprocessed by conventional methods, while thermosets have long been considered thermally unprocessable as a result of the presence of covalent intermolecular cross-links. However, each recycling technology has its challenges and limitations for either polymer recycling, reinforcement reclamation, upcycling, and re-use.

Thus, based on the needs resulting from the use of polymer materials, all recent trends, challenges, and outcomes in polymer and polymer composites recycling are analysed in this review.

2. Recycling Technologies of Thermoset Polymers and Their Composites

Thermosets are polymers with high molecular weight, offering alternative properties and applications compared to thermoplastics. This is due to their cross-linked molecular structure, which provides mechanical strength, thermal stability, endurance, and chemical resistance [31]. However, their crosslinked nature is what makes their recycling challenging. Thermosets can be found in coatings and insulation systems, but mostly as matrices in composite materials, reinforced by various fibres such as glass and carbon fibres [32]. Τhe recycling of thermoset materials mainly addresses their composites, as the reinforcement is the one to be reclaimed, mostly due to its high value [33]. The methods analysed below can also be applied to the neat thermoset resins.

2.1. Thermal Processes

Thermal processes are usually applied to the recycling of thermoset FRPs, as these materials lack processability aspects and the capabilities to separate fillers and reinforcement. After thermal recycling, the reinforcing fibres can be reclaimed and can be upcycled or re-used in composite applications. Recycling thermal processes are using heat as an energy source in order to break the polymer chain and crosslinks of the polymeric matrix, resulting in various by-products, such as gas, liquid molecules, and solids.

Thermal processes for the recycling of polymers are being used at an industrial level, targeting energy recovery (with suitable apparatus) compared to the incineration process, where the energy is lost during combustion and the collection of liquid by-products to be further used as fuels [34]. In the case of thermoset FRPs, thermal processes are being used to also recover the reinforcement. Two main processes are considered: (i) fluidised bed and (ii) pyrolysis. In the following paragraphs, the thermal processes and their recycling capabilities are summarised.

2.1.1. Fluidised Bed

Main Principle and Process Description: Fluidised bed is a thermal recycling method used for reclaiming size-down reinforcement and/or fillers from composite scraps. Fluidised bed has industrial applications, as it is very efficient in heat transfer and its parameters are easy to control. Usually, the composites are previously grinded to smaller granules (approx. 25 mm) to be fed into the fluidised bed reactor, consisting of a sand bed. Within reactor preheated air is circulated [35]. After the material insertion to the reactor, a hot gas stream (450–550 °C), e.g., oxygen, breaks down the polymer and separates the fibres and inorganic fillers. After this step and through a cyclone, separation is achieved depending on the weight of the produced products. In this method, high fibre fraction collection is feasible; however, the polymer matrix cannot be recycled since it totally decomposes to solid and gas by-products. Thus, fluidised bed is a suitable recycling method to reclaim fillers and clean short fibres for further valorisation in other applications.

Reclamation of GFs from polyesters: Kennerley et al. [36] studied the reclamation of glass fibres (GFs) from polyester moulding compound (SMC) scraps, with a total formulation (by weight) of 25% polyester resin, 22% chopped GFs, 35% hydroxide carbonate filler, 15% aluminium hydroxide filler, and 3% additives and processing aids. Recycling conditions were set to 450–550 °C with cyclone velocities of 1.3 m/s to 1.7 m/s. After a purification step (washing), the reclaimed fibres turned out to be up to 40% of the total fillers collected in the bin. It was identified that at 450 °C, the fibres had half of the virgin GF’s mechanical strength. To evaluate the reusability, the fibres were functionalised with polyester-compatible silane solution and used to manufacture a dough moulding compound in various concentrations. From tensile and flexural testing, it was concluded that in a material manufactured by Dough Moulding Compounding (DMC), the addition of up to 50% of reclaimed GFs can be performed without affecting the physical properties. Another study performed by Pickering et al. [37] evaluated the reclamation of GFs from three different post-industrial scraps; SMC, a filament wound pipe and an E-glass/polyester sandwich panel. The characteristics and properties of the obtained GFs were characterised by measuring the length distribution, as well as mechanical testing, and through comparison to virgin fibre properties. By image analysis, the average length was measured to be 5.6 mm. From mechanical testing, the results showed a 50% reduction at a 450 °C processing temperature, while at 650 °C, the reduction was more than 80%. A general conclusion obtained from the parametric study is that the degradation of properties depends on both temperature and time conditions. The authors highlighted that due to the high operating temperatures of the bed, composites need to be grinded in granules of 10 mm or smaller for the polymer to be combusted completely. For larger fragments, the residence times had to increase to receive clean fibres, and this will probably lead to a reduction in mechanical properties.

Reclamation of CFs from epoxies: Jiang et al. [38] studied the reclamation of carbon fibres (CFs) from epoxy-based thermoset composite using fluidised bed, and the effect of this thermal treatment was assessed. The temperature was set at 550 °C and the hot air was inserted with a velocity of 1.0 m s−1. The results showed that after 10 min, the epoxy was fully removed. To ensure that fibres were clean from any debris after the process, they dispersed them in acetone and cleaned in an ultrasonic bath for 30 min.

2.1.2. Pyrolysis

Main principle: For the reclamation of larger quantities and lengths of reinforcement from GFRPs/CFRPs, pyrolysis has been studied as a thermal treatment. Pyrolysis operates with the same principles as fluidised bed, as high temperatures that are applied; however, in pyrolysis, inert atmosphere is used in the process [39]. On principle, when polymers are being pyrolysed, depending on the process parameters, the polymeric main chains degrade or rapture, resulting in the creation of side groups. For the second case, typically, volatile products and char residues are formed. In the case of thermoset polymers, less volatiles and a higher amount of char by-products are formed, due to the crosslinked nature [40]. Resulting volatile compounds can be divided into gases (non-condensable gases) and liquids (condensable gases) [41]. The composition of those by-products, as well as the temperatures applied to the process, are highly dependent on the chemical nature of the thermoset matrix. To identify those compounds, usually the pyrolysis is coupled with gas chromatography/mass spectroscopy (Py-GC/MS) [42]. Evans et al. [43] have studied the thermal degradation of 23 types of polyesters, at 600 °C, and evaluated the decomposition by-products through GC. It was identified that styrene was the predominant degradation product from the degraded polyester and phthalic anhydride was the main product from the styrene-free polyesters.

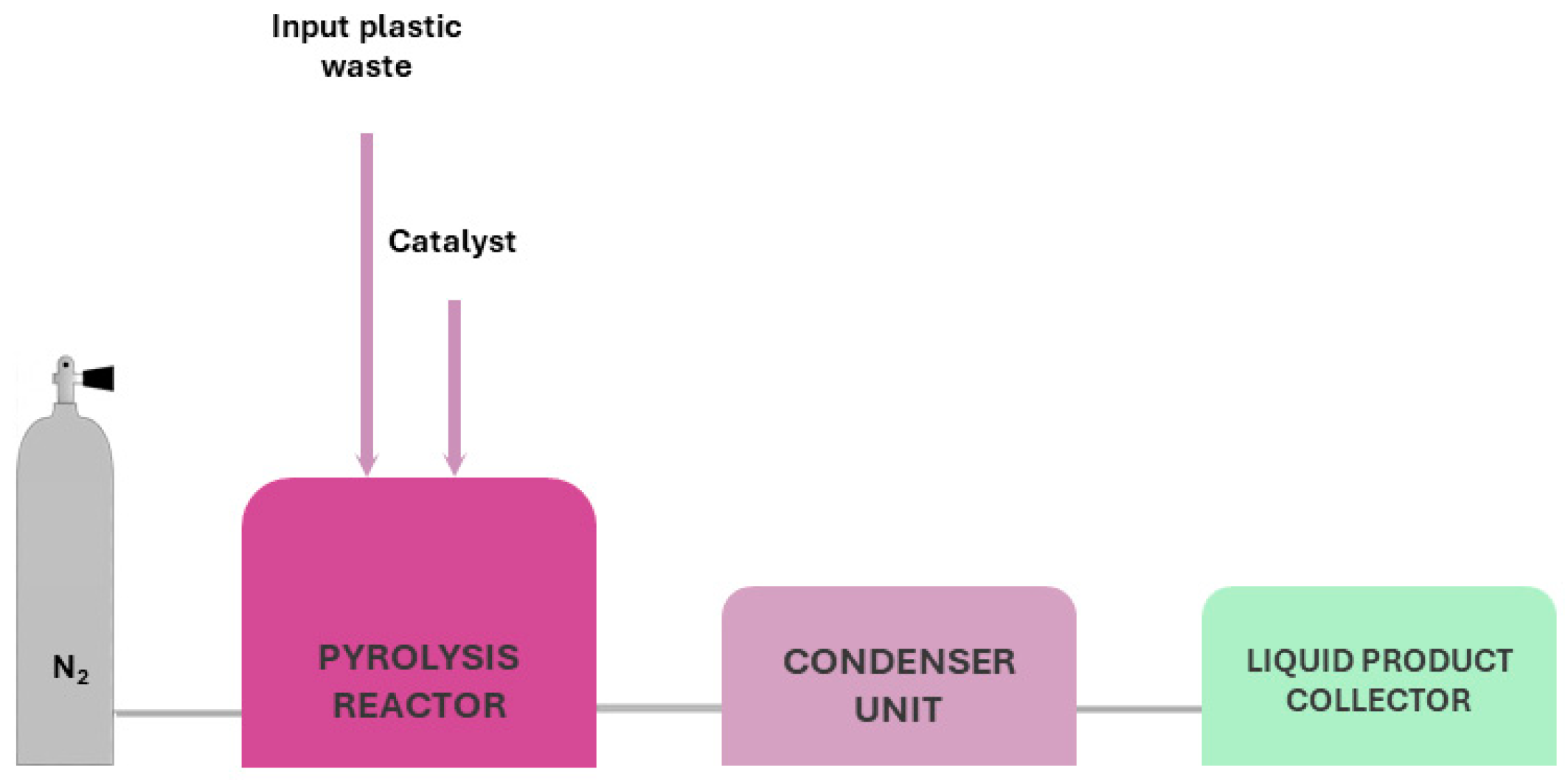

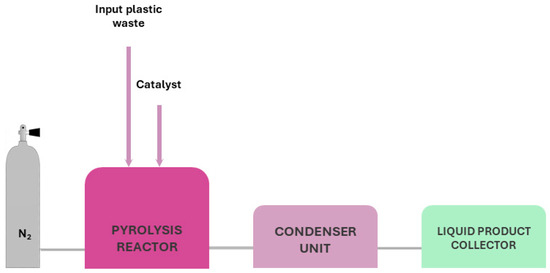

Process Description and Equipment: A typical pyrolysis system is the fixed bed reactor. The apparatus is horizontally or vertically mounted and in cylindrical shape. For a horizontal pyrolysis furnace, the main parts, as depicted in Figure 1, are:

Figure 1.

Typical set up for pyrolysis of thermoset and thermoplastic waste.

- Pyrolysis chamber; the material is inserted to be pyrolysed;

- Gas inlet, located at beginning of the chamber; it is connected with the inert gas to ensure proper conditions;

- Gas outlet located at the end of the chamber to ensure the proper removal of gas and liquid by-products;

- Condenser chamber for condensable gases;

- Scrubber unit;

- Gas filtration system.

The process usually carried out is the following: The material is inserted in the centre of the chamber, where isothermal conditions are met, before the initiation of the process. Afterwards, the inert gas is inserted to remove oxygen and reach inert conditions (purging). Once purging is complete, the furnace is heated to the desired pyrolysis temperature with steady heating rate. During pyrolysis, the gas and liquid by-products are driven by gas flow, out of the chamber and into the condensers, to collect liquids and oils. Then, the rest of the gases are passed through scrubbers to entrap any solids. Afterwards, the rest of the gases are filtered before being exhausted. When pyrolysis is completed, the heating is stopped and the system is left to cool at room temperature, under inert conditions, before retrieving the solids [44].

Mechanism: The pyrolysis process needs to be adapted based on the composite material’s chemical nature, making it a challenge when it comes to composite reinforcement reclamation. A study from Cunliffe et al. [45] was performed to evaluate the correlation between applied temperature and polymeric matrix. Composites with polyester, polyester-styrene, polybenzoxazine, and epoxy resins as matrices were evaluated. The solid, liquid, and gas by-products were characterised depending on the pyrolysis temperature profiles for each type of matrices. Furthermore, the definition of the pyrolysis parameters was supported by thermogravimetric analysis. They concluded on several aspects, such as that the chemical nature of the polymeric matrix strongly influenced the produced solid and gas compositions. At higher temperatures, fillers such as calcium carbonate, influenced the yields of the process, and for phenolic and epoxy resin matrices, it was observed that the mass loss was continuous compared to the other resins, which could be attributed to carbonisation phenomena.

Epoxies Case: An example of a pyrolysis mechanism for thermosets is given for epoxy resin composed of DGEBA. It has been identified that the thermal degradation follows two main mechanisms: (1) the the cleavage of cross-linked and ether bonds, and (2) polycondensation stages. The thermal decomposition takes place between 330 °C and 390 °C, and a residue of 10% of the total mass is left behind. However, for bisphenol A compounds, higher temperatures that can reach up to 420 °C are needed [46].

The cleavage stage consists of the removal of side groups from the main polymer chain, producing a high number of free radicals and low molecular weight groups (gas by-products). From these groups, OH, C-C, and CH3 are the intermediate for the formation of H2O, CO, and CH4. From the main chain breakage, liquid by-products are being produced, such as BPA, phenol, benzene, etc. Dehydroxylation reaction can take place for phenol, forming aromatic hydrocarbons. Ring-opening reactions can also occur, resulting in chain-like hydrocarbons. After the complete cleaving stage, H/C mass ratio gaseous products, as well as low H/C mass ratio liquids and solids, are generated.

In the polycondensation stage, the produced liquid and solids are dehydrogenated to form pyrolysis char, while the gases generate H2, H2O, and CO. By increasing the pyrolysis temperature, the rates of the by-products are affected [47].

The presence of the reinforcing fibres in the pyrolysis process in thermoset composites and their influence on the pyrolysis process was evaluated by Ge et al. TGA characterisation was performed on pure epoxy and epoxy CFRPs, and the degradation rate of the two was studied [48]. Different ratios of carbon fibre/epoxy were characterised, and they identified that for ratios 2:7, 3:6, and 4:5 epoxy/carbon fibre, the final weight loss was smaller, when applying high heating rates. Compared to pure epoxy resin, they identified that the maximum weight loss was much larger than the weight loss of the composites at the higher heating rate. This phenomenon was attributed to the presence of carbon fibre, which made pyrolysis rate of epoxy resin lower. Finally, after TG-FTIR analysis and pyrolysis produced gas detection, they proposed a possible mechanism for the pyrolysis reaction in a CFRP system. The model indicates that in the first stage of pyrolysis, the long polymeric chains break down to monomers, e.g., bisphenol A and 2-methyloxirane. With the increase in temperature, the C-C bond dissociated to form phenol, methanol, and alkanes.

Another study performed by Adler et al. evaluated the degradation characteristics of epoxy CFRP composites and epoxy CFRPs composites manufactured with pyrolysed CFs, through TGA analysis [49]. The results showed that the curves between the two materials were not identical, and this deference was attributed to the influence of the fibres sizing on the epoxy resin’s network during curing. The phenomenon was explained based on the compatibility of the sizing on the fibres with epoxy matrix, compared to fibres with no sizing. The fibres with no sizing resulted to different cross-linked epoxy network, compared to the sized ones, presenting different degradation behaviour, with greater mass loss in the pyrolysed fibre-CFRP.

Table 1 summarises the literature results on pyrolysis studies conducted on reinforcing composites (FRPs).

Table 1.

Literature review on the pyrolysis of FRPs.

As can be observed from Table 1, for the separation and reclamation of fibre reinforcement, the applied pyrolysis temperature and residence time are important factors, especially when considering the yield of the by-products. The pyrolysis products, i.e., solids (reinforcing fibres, char) oils, and gases, produced under suitable conditions, can allow the valorisation of these products for enhancing the material circularity [53]. The gases can be valorised for energy recovery, the liquids when post-processed can be used as fuels, and solids, in case of fibres, can be used as reinforcement for composite applications.

When pyrolysis is applied as a recycling approach, apart from the thermal degradation of the polymer matrix, the structural and mechanical integrity of the reinforcing fibres should also be considered. Nahil et al. [50] have investigated the pyrolysis of woven CF/Polybenzoxazine resin composites as well as their produced by-products. The produced gases were analysed by GC and the produced liquids by coupled GC/MS. The investigation was performed at 350, 400, 450, 500, and 550 °C for 1 h in nitrogen atmosphere. They identified that by increasing the temperature from 350 °C to 700 °C, the solids residue yield was decreased while the liquids yield was increased. For the produced gases, the yield was similar to those of the liquids. With regard to the fibre reinforcement, solid residue was left on the fibres in the form of char from the resin carbonisation. Oxidation was performed, under different temperatures, to remove the formed char and then the fibres were evaluated for their mechanical performance through tensile testing. They concluded that the best conditions for CF reclamation with 93% retained tensile properties were pyrolysis and oxidation at 500 °C.

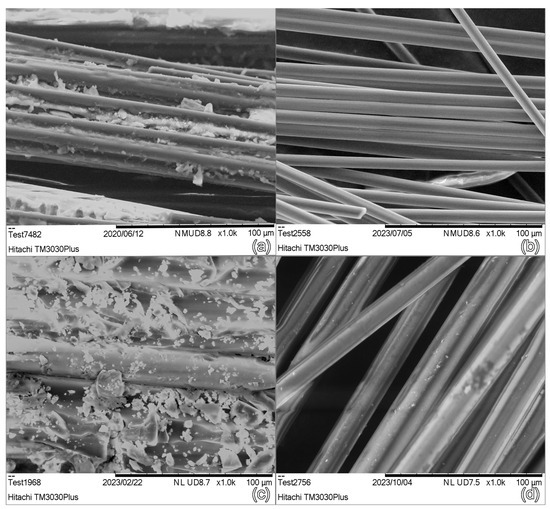

Post-pyrolysis treatment: As evident from Nahil et al.’s [50] study, in FRPs, the solid residue product from pyrolysis consists of the remaining fibres and char residue (pyrolytic carbon). In order for fibres to be re-used, further steps are needed to remove the char from the surface, as already mentioned. Post-pyrolysis or post-treatment in oxidative medium at a high temperature burns the char and results in clean fibres. Giorgini et al. [52] have investigated the correlation between residue char amount (thickness) formed on the fibre’s surface and the applied pyrolysis temperature. They identified that with the increase in the pyrolysis temperature from 500 °C to 600 °C, the amount formed on the fibre’s surface was reduced. Termine et al. [44] investigated the correlation between the removal of the formed char of the CFs with temperature and residence time. CF woven fabrics were post-pyrolysed for 10, 20, 30, 40, and 50 min of residence time at 400 °C and 500 °C in air. They concluded, through SEM analysis, that at 500 °C for 50 min, the char was removed from the fibres and the fibre structure was intact, as evaluated by Raman spectroscopy. The structure integrity is an important factor for the capability of CFs to be reused, as after the pyrolysis process, the fibres should result in their mechanical properties being close to those of a virgin CF. Termine et al. reclaimed CF fabrics from epoxy-based CFRPs and reused the fabrics with the most promising results as reinforcement to manufacture epoxy-based CFRPs. The composites were evaluated under tensile and flexural testing; however, the results showed a decrease of 30% and 12% in tensile and flexural strength, respectively. Thus, for the use of recycled CFs from pyrolysis, non-structural CFRP applications were proposed.

Last but not least, pyrolysis is also applied for the reclamation of GFs. However, in their case, the parameters should be further tailored, as the mechanical properties of reclaimed GFs can be greatly degraded [37].

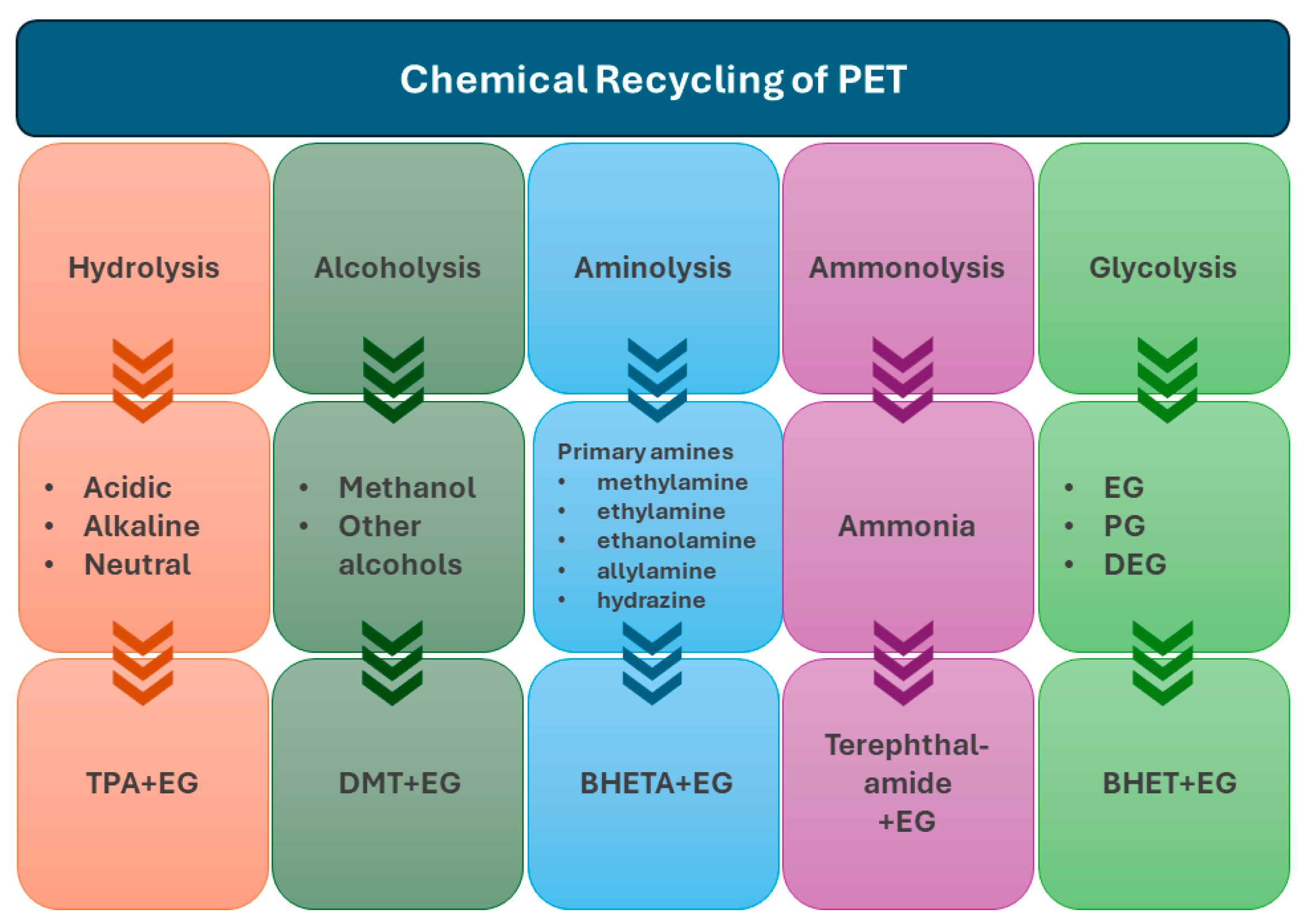

2.2. Chemical Processes—Solvolysis

Chemical recycling refers to the chemical decomposition of polymers into mono-oligomers and the recovery of fibres in the case of composite materials. However, the recovery of the mono-oligomers, due to the solvents and catalysts used, is a hazardous process; therefore, they are typically discarded as waste and only the reinforcement is recovered [33].

The main processes are solvolysis at low temperatures and ambient pressure, and solvolysis at near- or super-critical conditions. Solvolysis uses solvents such as water, alcohols, acetone, glycol, or acids in order to break down the chemical bond of the polymer matrix (either epoxy, polyester, or phenolic). The interest is that fibres can be recovered and can be reused. Solvolysis offers a large number of possibilities due to its wide range of solvents, catalysts, temperature, and pressure used, and can be applied successfully for both CFRPs and GFRPs, as shown in Figure 2.

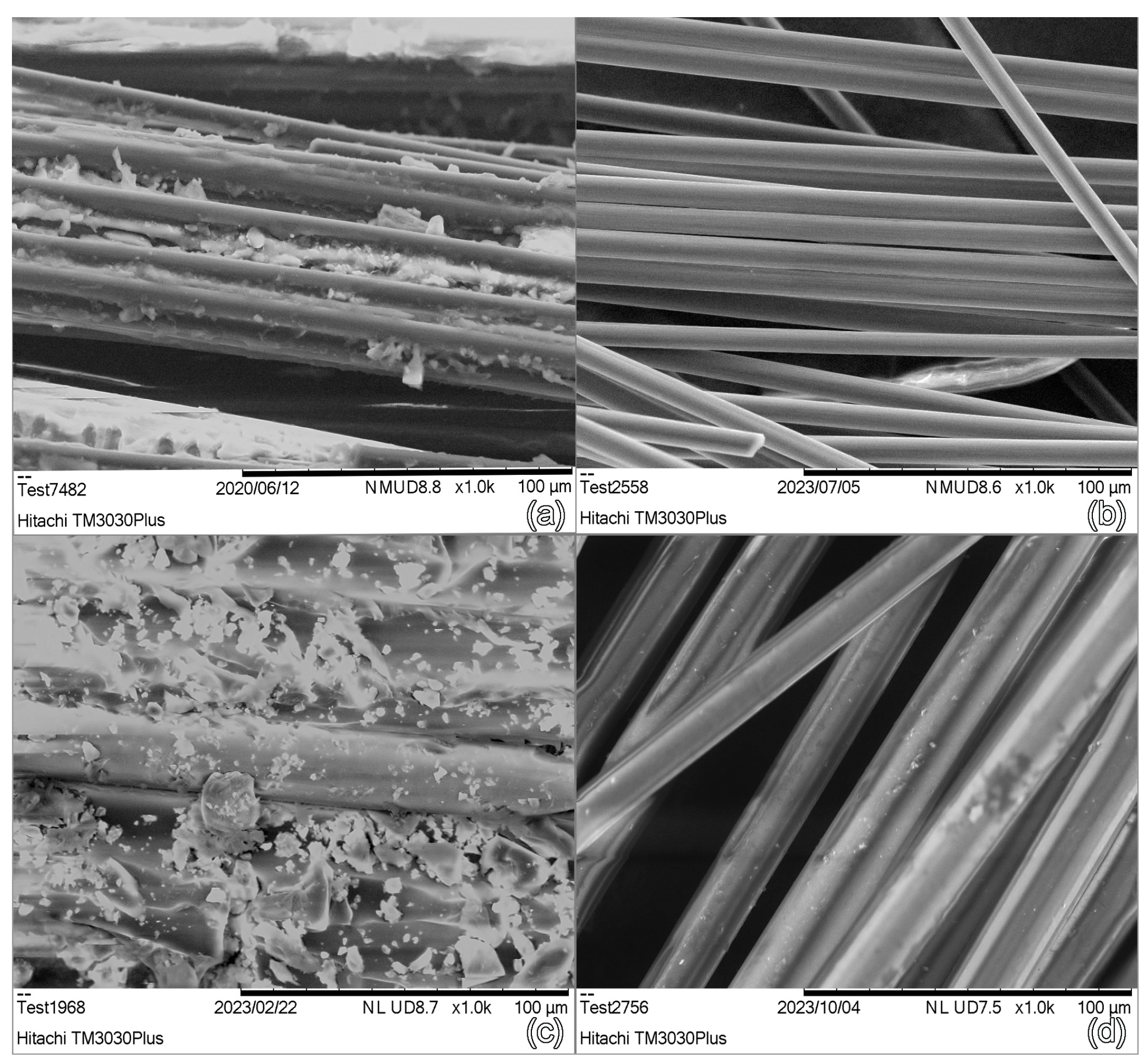

Figure 2.

SEM images of (a) CFRP, (b) chemical recycled CFs, (c) GFRPs, (d) chemical recycled GFs.

2.2.1. Low Temperature and Pressure Solvolysis

Solvolysis at low temperatures and pressure is generally carried out below 200 °C and at atmospheric pressure. For that reason, in order to degrade the resin in mild conditions, the use of acids or bases and catalysts is necessary. Extensive research has been carried out for epoxy-based composites through this process. Epoxy-based CFRPs treated with bases: Regarding the treatment with bases, Peng et al. [54] conducted recycling of fibre/epoxy resin composite with a poly(ethylene glycol)/NaOH system at a temperature of 200 °C for 4 h. The experiment occurred with 200 g PEG200, 1 g NaOH, and 10 g of FRC with a high decomposition efficiency of 84.1–93.0%.

Epoxy-based CFRPs treated with acids: As for the use of acids, Feraboli et al. [55] developed a solvolysis process for FRCs using sulfuric acid with hydrogen peroxide to accelerate the reaction and oxidize the matrix. The experiment relies on 110 °C in ordinary pressure with mechanical stirring throughout the 30 min duration of the entire process. According to SEM images of recycled CFs, they appear to have a clean and smooth surface, with very limited traces of resin or coating residue. Mechanical properties were also tested through tension, compression, flexure, and short beam shear tests, which showed traits similar to those of virgin fibres. For the nitric acid solution, Liu et al. recycled carbon fibre with epoxy matrix. At a temperature of 90 °C in a glass vessel, the experiment took place with a nitric acid solution at a concentration of 8 M with a ratio of 40 g/L of the composite being the best. Under these parameters, the resin liquefied with a conversion of more than 99 wt.% and the undamaged CFs were recovered with tension strength loss of 1.1% [56]. A novel recycling method, using formic acid as a solvent, was proposed by Ballout et al. [57]. The recycling process transpires with CFs reinforced with epoxy resin at room temperature and ambient pressure. SEM and TGA results showed 10 wt.% of residual epoxy resin, indicating that the applied condition does not lead to the full dissolution of the cured epoxy resin.

Epoxy-based GFRPs treated with acids: Dang et al. [58] also investigated recycling using a nitric acid solution for GFRPs. They recycled GFs (E-glass and T-glass fibre type) by decomposing epoxy resin with a solution of nitric acid of 4 M at a temperature of 80 °C. Tensile strength and stiffness tests were not performed on the fibres; however, it was observed that T-glass fibre possessed more excellent corrosion resistance to the acid solution.

2.2.2. Solvolysis at Near- or Super-Critical Condition

Solvolysis at near- or super-critical conditions is a relatively new process that is more environmentally friendly and sustainable. Using high pressure as a processing tool can exempt the use of catalysts and toxic solvents. Sub- and super-critical fluids such as water, acetone, and alcohol are excellent reaction media for the depolymerization or decomposition of thermoplastics and thermosets. Composite materials are decomposed into smaller molecular components and fibres rapidly. The process is considered a green process, since there are no toxic products released into the environment, and the solvents can be recovered and reused. Epoxy-based CFRPs treated with supercritical acetone: Okajima et al. [59] studied the decomposition epoxy resin in CFRPs using super-critical acetone testing of different parameters of the experiment. The decomposition was at a maximum of 95.6% efficiency at 350 °C at 140 bar pressure for 60 min with a ratio of 4.35 mol of acetone per litre of the reactor volume. The reactor was a stainless-steel tube with an inner volume of 8.9 cm3, while the CFRP plate was a rectangular piece 1 mm thick, 50 mm × 5 mm. The supercritical mixture of acetone/water was also investigated by Keith et al. [60], with regard to decomposing carbon fibre-reinforced epoxy resin. The recycling process transpires in a volume ratio of 8:2 of the acetone/water mixture with temperatures and pressures at a range of 300–380 °C and 16–30 MPa, respectively, at a reaction time of up to 150 min. For this process, a stainless steel 100 mL reactor without stirring was used with 50 mL of solvent mixture. The CFRP contained a 35 wt.% of resin; therefore, the ratios of 30 g, 60 g, and 90 g of resin per litre of solvent were investigated. After processing 20 MPa and 30 g/L of resin for 120 min at 320 °C, the minimum conditions necessary for effective fibre recovery, up to 95 wt.% of the resin was decomposed and the original weave architecture of the fibre was retained.

Epoxy-based CFRPs treated with supercritical water: The use of solvent mixtures was also researched by Henry et al. [61] to separate the CFs from epoxy resin matrices. The experiment relies on super critical water (SCW) and (50/50 vol%) water/ethanol mixtures in supercritical conditions at a temperature of approximately 375 °C and 25 MPa pressure for a range of 15 to 120 min. SEM images coupled with TGA analysis of the reclaimed fibres showed that up to 98 wt.% of the resin was decomposed. The CFs that were treated by SCW proved to have a higher tensile strength; on the other hand, for the ones that were treated with the water/ethanol mixtures, their surface underwent a gentle in situ oxidation. Knight et al. [62] recycled epoxy CFRPs using only supercritical water but with 0.5 M KOH as catalyst. The process occurred at approximately 28.5 MPa, 410 °C and a reaction time of 15 to 120 min. The higher resin elimination was 99.2 wt.% at a reaction time of 120 min. Phenolic-based CFRPs treated with ethylene glycol: In a different approach to solvent mixtures, Yildirir et al. [63] recycled CFRPs with a phenolic matrix. The solvents used were ethylene glycol (EG) and an EG/water mixture, and they were placed in a 500 mL stainless steel reactor in a volume of 60 mL, along with a 2.5 g CFRP, under a N2 purge. Ethylene glycol alone decomposed 92.1% at 400 °C and 4.2 MPa; however, the addition of water in a volume ratio of EG/water 5:1 and 3:1 decomposed 97.6% and 95.2% at 400 °C in zero residence, respectively. The mechanical properties between virgin fibres and recovered fibres had minimal differences. Polyester-based GFRPs treated with supercritical water: With supercritical water, Oliveux et al. [64] performed chemical recycling on GFRPs. The composites contained 37.5 wt.% unsaturated polyester resin. The experiment took place in a 587 mL batch system testing different temperatures, reaction times, water-to-resin ratio, pressure, and NaOH catalyst concentration. Out of 19 experiments, the best conditions were carried out at 300 °C, 85 MPa, without NaOH catalyst for 30 min with a ratio mass of resin per distilled water volume at 0.01 g/mL. A second hydrolysis at 250 °C for 10 min with a ratio mass of contaminated fibres per distilled water volume of 0.05 g/mL, was performed on the GFs after the first hydrolysis. Then, the fibres were washed with dichloromethane (DCM), in order to clear the coated formation of an organic gluing substance of the fibres. Particularly, after two washes with DCM, the yield of eliminated resin reached 100%. An investigation of the mechanical properties of the fibres showed that a 35% to 65% reduction in strength was observed in a range of different temperatures and reaction times.

2.3. Extraordinary and Combined Recycling Processes

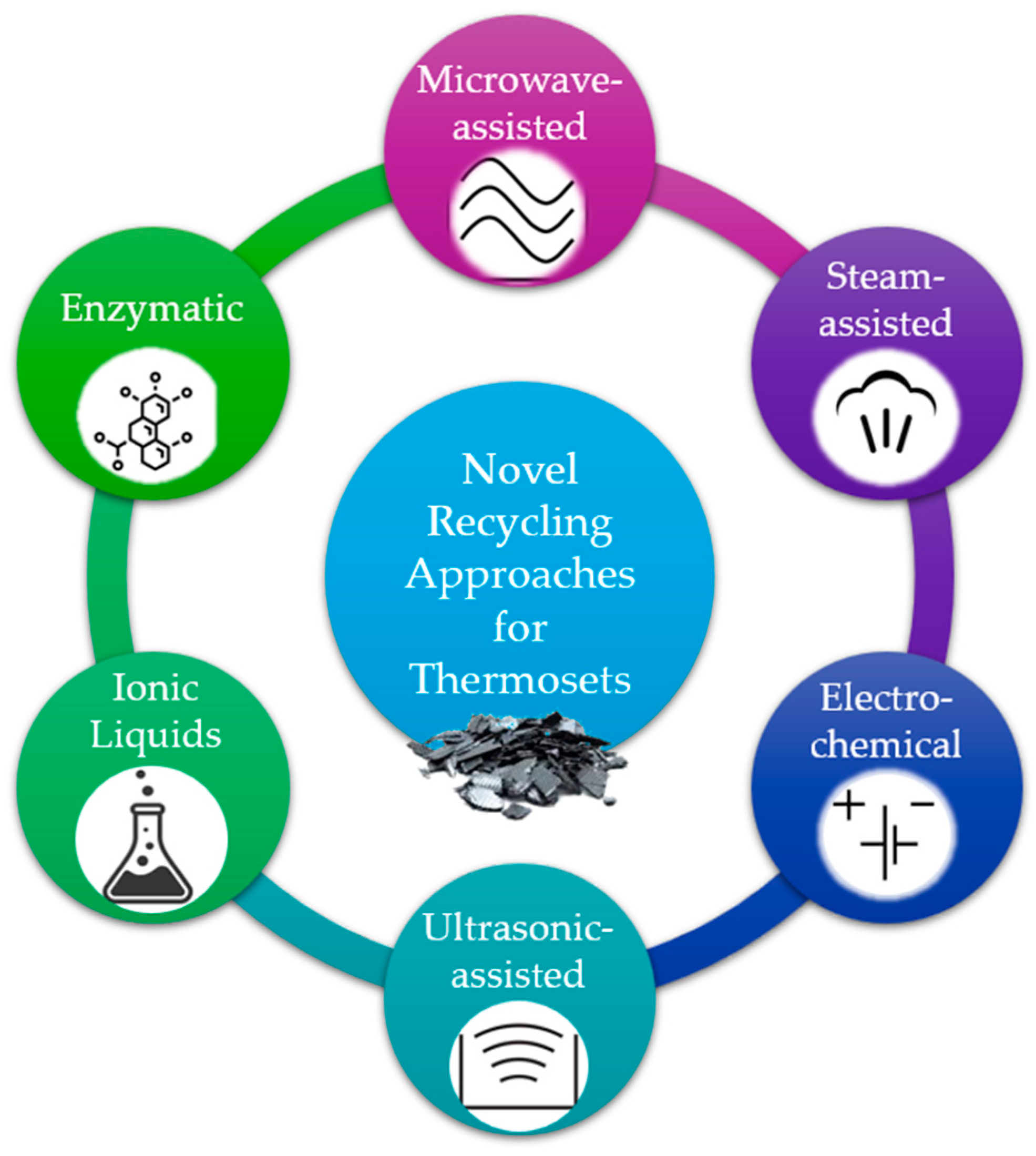

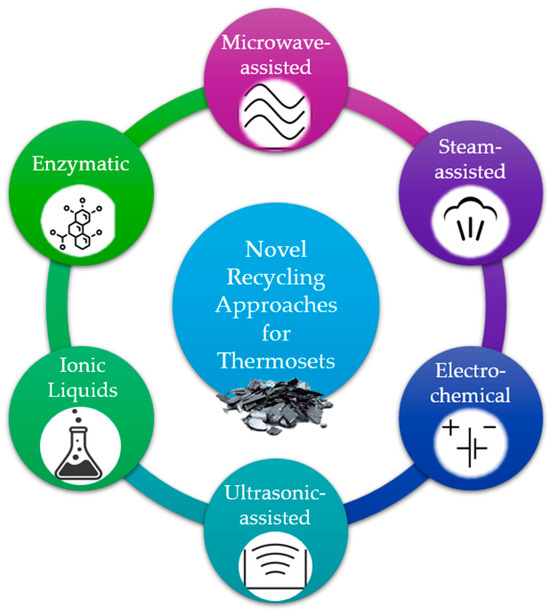

Several extraordinary techniques have been developed for the recycling of thermoset composite materials, either by combining steps of the aforementioned procedures or by exploiting other means of energy for the breakage of the chemical bonds of the polymers. Combining multiple recycling techniques, such as chemical and mechanical methods, in a hybrid approach can synergistically improve the overall efficiency and effectiveness of thermoset composite recycling processes. The most unique techniques are presented in Figure 3, and they are analysed in the following paragraphs.

Figure 3.

Energy sources, triggers, and media of new recycling approaches.

2.3.1. Microwave-Assisted Recycling

Microwave-assisted recycling utilizes microwave energy to selectively heat and break down thermoset composites. This process can be more energy-efficient and selective compared to traditional thermal methods, allowing for the targeted decomposition of the polymer matrix while preserving the reinforcing fibres.

Epoxy-based CFRPs: One of the first successful trials of extracting CFs from waste CFRPs by microwave irradiation was that of Obunai et al. in 2015 [65]. In this study, two types of epoxy-based CFRPs were used as wastes, and a simplified microwave irradiation apparatus with three different atmospheres (Ar, N2, air) was utilized. For all experiments carried out, the power and frequency of microwaves was set to 700 W and 2.45 GHz. It was proven that the most effective extraction of CFs was that under an Ar atmosphere, since spark glow plasma was generated, which decomposed the gasified resin. On the other hand, the study of Jiang et al. [66] during the same year investigated the effect of the temperature during a similar procedure, in N2 atmosphere for epoxy-based CFRPs, for 30 min exposure in a microwave oven. From the chosen temperatures, the 500 °C was selected as the optimum one since it offered an acceptable level of fibres cleanliness and without severe defects. The most recent study on the recycling of CFRRs, with a low cost and green microwave-assisted chemical method, is that of Zabihi et al. (2020) [67]. This one-step process is fast (only 1 min exposure in microwaves), catalyst-free, and uses a mixture of hydrogen peroxide and tartaric acid. Different mixing ratios of the hydrogen peroxide and the acid were tested, while the microwave power was constant at 800 W, for different time durations. Compared to other chemical approaches, is seems that is the fastest until now in terms of process duration (25 min in total, including the cooling down), the lowest in temperature from those executed in elevated temperatures, and the most promising regarding tensile strength retention. Also, compared to the electrochemical techniques that will be presented in the next section, the microwave-assisted chemical method of Zabihi et al. excels in time but not in temperature.

Epoxy-based GFRPs: A recent study (Rani et al., 2022) [68] describes the recovery of GFs from epoxy-based waste composites through a microwave-based approach. In this procedure, a combination of solvolysis and microwave treatment was tried out. A chemical solution with acetic acid and hydrogen peroxide with different mixing ratios was prepared with an increment of volume ratio of hydrogen peroxide from 20% to 50% in the acetic acid. As a process parameter, the exposure time was investigated, while the power was constant at 700 W. Both the decomposition rate of the resin and the mechanical properties of the reclaimed GFs were studied. An exposure of 180 s in microwaves, in a stepwise process, was proven to be the most effective since the reclaimed GFs had similar strain-to-failure responses as the virgin ones. GFs were also reclaimed from scraps through microwave pyrolysis and reused in new composites, in combination with virgin GFs, according to the study of Akesson and Skrifvars [69]. The power was set at 1 kW and the samples were pyrolysed at 450 °C for 1 h, but the reclaimed GFs were covered with char that had not been degraded after the pyrolysis process.

2.3.2. Superheated Steam Recycling

Superheated steam treatment involves subjecting thermoset composites to high-pressure steam at elevated temperatures. This process can cause the polymer matrix to degrade, facilitating the separation of fibres from the resin. The resulting materials can then be reused in new composite applications.

Epoxy-based CFRPs: Extensive research of the superheated stream recycling of CFRPs has been executed by Cai et al. [70,71,72] for thermoplastic PA6 composites with CFs. They used an induction heating superheated stream generating system (5 kg/h steam flow rate) with a temperature range from 500 °C to 700 °C. The procedure included the following steps: (a) 1 h treatment at 400 °C with pure superheated stream, and (b) 1 h superheated steam treatment at 500 °C in the presence of 4 vol% O2. A similar apparatus and procedure were employed by Wada et al. [72] to study the effect of the superheated stream to the interfacial adhesion of CFs on epoxy resin and as a surface treatment method of CFs that can be used after their reclamation from composite wastes. The fastest and most promising route using steam for CFs recovery from CFRPs is described in the work of Joeng et al. (2019) [73]. In this work, steam was used as an oxidant to remove the resin from the CFRP, at a medium temperature range (600–800 °C) in a pyrolysis furnace. The heating rate and holding time at the target oxidation temperature were determined to be 10 °C/min and 60 min, respectively. Surface-clean CFs can be collected from waste CFRPs at 700–800 °C in 140 min of total process time, excluding cooling time with this methodology, which can also be transferred to a continuous process. Polyesters: Superheated steam recycling has also been implemented on terephthalic and ortho phthalic acid-based co-polyesters crosslinked with styrene to recover oligomers [74]. Since the process was promising, it can be reproduced for co-polyester thermoset composites, to valorise both the reinforcement and the matrix material.

2.3.3. Electrochemical Recycling

Electrochemical methods involve applying an electric current to thermoset composites immersed in an electrolyte solution. This process can induce chemical reactions at the polymer-electrolyte interface, leading to the breakdown of the polymer chains. Electrochemical recycling holds promise for selectively degrading thermoset materials while preserving valuable components like reinforcing fibres.

Epoxy-based CFRPs: In 2015, a study on the recycling of CFs from CFRPs through an electrochemical method was published by Sun et al. [75]. The electrochemical recycling system consisted of a direct current (4, 10, 20, and 25 mA) power supply, a stainless-steel cathode connected to the negative terminal of the power supply, and, as the anode, the CFRP specimen, connected to the positive terminal of the power source. As the electrolyte, a NaCl solution was used, with concentrations of 3%, 10%, and 20%. The recycling procedure lasted for 21 days and samples were taken on regular intervals to quantify the recycling depth (surface degradation). The cleanest fibres were obtained at applied current of 4 mA and NaCl solution concentration of 3%; the measured tensile strength of the reclaimed fibres on these conditions was 80% of the virgin ones. After 5 years, the study of Oshima et al. [76] presented a rapid removal of epoxy resin from a UD CFRP by high-voltage electrical treatment, causing water electrolysis, by using a similar setup of the electrochemical cell of Sun et al. This treatment was performed under a constant voltage of 2.5–15.0 V and different electrolytes were tested (aqueous solutions of NaCl, KCl, NaOH, KOH, and Na2CO3), with concentrations between 0.01 and 1.0 mol L−1. It was proven that the weight loss in neutral electrolytes such as the NaCl or KCl solution was higher than that in basic electrolytes. The weight loss and current density increased with an increase in the electrolyte concentration. This suggests that high electrolyte concentrations improve the effectiveness of the electrical treatment. In this process, the maximum electrical treatment time was 20 h. Weight loss was measured as an indicator of the process effectiveness and a removal rate of approximately 200 μm/day was achieved. However, the high voltage application in the long-time induced damage of the CFs made it difficult to operate as a main recycling method, but it worked more as a supporting one, in combination with other techniques.

Polyester-based GFRPs: GFRPs have been successfully recycled through high-voltage fragmentation, a technique developed by Mativenga et al. [77], which was first reported in 2016. The high-voltage fragmentation process uses repetitive pulse electrical discharges between two electrodes within a dielectric liquid environment (water in this case), to disintegrate the composite material. The discharge creates a spark channel that travels between material internal boundaries and the latter generates an intense shockwave with pressure up to 1010 Pa and temperature greater than 104 K. For the current study, the tests were conducted at 160 kV applied voltage, 10 mm electrode gap, and 1 Hz pulse frequency. The number of pulses (500, 1000, 1500, 2000) was selected as the process parameter and it was proven that residual resin content depends on the number of electrical pulses applied inversely. The process offers cleaner fibres, longer fibre length distribution of the reclaimed fibres, higher percentage of fibres at mean fibre length, and lower retained resin content than composites recycled mechanically. However, it is highly energy consuming.

Reclamation of continuous CFs from CFRPs: Recently, the recycling of continuous CFs from CFRPs was achieved by Sarmah et al. [78] by exploiting the Joule heating effect, using a simple electrical connection DC setup. The target was the composite specimen to reach 400 °C through Joule heating (recorded through an IR camera), which was proven to be an effective decomposition temperature for the resin, according to the TGA results. The reclaimed fibres showed a 10–15% decrease in tensile strength. The methodology can also be applied to continuous composite rolls, with a potential upscaling to industrial level. It is worth noting that current research through the European Project “EuReComp” of Horizon Europe investigates the use of plasma during solvolysis for the reclamation of continuous CFs from thermoset composites. In this case, the use of nitrogen plasma inside concentrated nitric acid solution is proposed, since a plethora of reactive species are produced (NO2+, H3O+, OH•, H+, H•, NO2•, H2O2, O•+, HO•−, H2, O2, NO3−, OH−, NO2−) that can enhance the resin degradation. It has been proven that the time needed for the matrix dissolution and complete detachment of the fibres is significantly shorter than the time reported for conventional HNO3 solvolysis [79].

2.3.4. Ultrasonic Recycling

Ultrasonic waves can be utilized to mechanically disrupt the molecular structure of thermoset composites. By subjecting the material to high-frequency vibrations, ultrasonic recycling aims to break down the polymer matrix and facilitate the separation of fibres. This technique offers potential advantages in terms of energy efficiency and scalability.

A sonochemical approach for the enhanced recovery of CFs from CFRP waste using a mild acid (diluted nitric acid) and peroxide mixture was presented by Das and Varughese in 2016 [80]. A two-stage process comprising a pretreatment stage followed by a sonochemical stage was carried out. In the first stage, composite samples were immersed for pretreatment in an aqueous mixture of 2 M HNO3 and 9 M H2O2 of various concentrations. In the second stage, sonication was carried out in an ultrasonication tank where solid-to-fluid ratio was maintained at 1:60 for optimum cavitation efficiency. The required pretreatment time was determined by measuring the mass uptake of the solution by the sample with immersion time. When the composite samples were fully swollen, the samples were placed in a 470 kHz ultrasonication tank maintained at 65 °C. It was proven that the sonochemical reaction increased the resin decomposition ratio to almost 3 times that of the process without ultrasound, and the recovered fibres had comparable tensile strength to that of virgin fibres. Increasing the H2O2 amount reduced the resin decomposition ratio and oxidized the fibre surface (as the H2O2 content increased in the solutions, the brittleness of the fibres increased and the resin remaining on the fibre surface appeared charred); thus, the optimum ratio of dilute HNO3 and H2O2 was 98–2% vol, since it gave better resin decomposition in the presence of ultrasound without damaging the fibre’s surface.

It is worth noting that recently [81], power ultrasonics have been used for the interlaminar pre-cracking of thermoplastic CF composites, in order to separate the layers and enable their reuse. The ultrasonic assisted pre-cracking proved to be a fast and robust method to initiate controlled artificial pre-cracks in thermoplastic composite materials, avoiding any fibre damage that could affect the mechanical properties.

2.3.5. Recycling with Ionic Liquids

Epoxy-based resins and CFRPs: The decomposition behaviour of epoxy-based CFRPs in a molten KOH was investigated by Nie et al. in 2015 [82]. The reaction was conducted in a stainless-steel reactor which heated in a salt bath. The KOH was put into the reactor in solid form and heated to a molten state and the CFRPs were fed into the molten KOH. CFRPs were decomposed under atmospheric pressure at temperatures from 285 to 330 °C, under N2 flow. Time and temperature are inversely proportional in this process, and it was proved that thermolysis plays an important role in breaking the chemical bond of epoxy resin in molten KOH. The results showed that more than 95% tensile strength compared to virgin CFs was retained. Also, the decomposition product was extracted selectively with water, dichloromethane, ethanol, and acetone. With this process, most of the contaminants in waste composites (thermoplastics, paints, sealants, and GFs) can be decomposed, which is promising for treatment of CFRP waste with many contaminates.

An ecologically friendly recycling method for both epoxy resins and epoxy-based CFRPs (with milled CFs) in the presence of ionic liquids and alcohols under mild working conditions (150 °C and atmospheric pressure) was reported by Perez et al. in 2021 [83]. From a variety of ionic liquids that have been studied, it was proven that the most effective mixture was that of 1-butyl-3-methyl imidazolium acetate with ethylene glycol, which worked in 150 min. The recovered monomer from the depolymerised resin was obtained through precipitation and was employed for the preparation of a recycled epoxy. Additionally, CFs were recovered and reused to manufacture new CFPRs. The mechanical properties of the recycled materials (both epoxy and CFRPs) were similar to the virgin ones.

Recently, a combination of solvolysis with degradation of the polymeric matrix through ionic liquids was presented by Perli et al. [84]. In this work, a cleavable building block for tailoring the degradation of thermoset networks was introduced, based on ionic liquids affording the programable deconstruction of composites. Specifically, a solvent-assisted transesterification reaction was carried out, using ethylene glycol and an acid ionic liquid. The introduction of 10% tetra-epoxidised ionic liquid comonomer in the network with 10% of acid ionic liquid lead to a degradation in activity of 83.7%. When the concentration reached 50% into the networks, it resulted in 95% degradation of the resin, while maintaining excellent thermal and mechanical properties. A significant disassembly of the composites was observed at 190 °C for 4.5 h by using 10% of acid ionic liquid.

Epoxy-based GFRPs: It is worth noting that in 2023, polyionic liquids were produced in situ during the recycling of GFs thermoset epoxy composites during their treatment with sulfuric acid in ambient conditions, which enabled the cleaning of the GFs and the maintenance of their mechanical and surface properties. H2SO4 liquefied the polymer matrix via the formation of oxonium poly ionic liquid and benzenesulfonic acid. This process may last up to two weeks; however, the by-product of this process (the dissolved epoxy) can be used in cement mixtures, increasing their compressive strength, since it can be transformed to a superplasticizer [85].

2.3.6. Biological Recycling

Recent research is exploring the potential for biological methods, such as enzymatic degradation or microbial treatment, to break down thermoset composites; however, the relevant studies are scarce. Enzymes or microorganisms capable of breaking down specific polymers within the composite matrix could offer a sustainable and environmentally friendly recycling solution. Biotechnology can provide solutions for the biodegradation of complex plastics and composites, by using oxidative enzymes. With a model compound simulating the epoxy resin RTM6, a colorimetric high-throughput screening assay was developed by Dolz et al. [86], used to screen unspecific peroxygenases mutant libraries of S. cerevisiae. It was proven that organic solvents help to solubilize the recalcitrant and enhance availability for enzymatic attack. Moreover, the use of chemical and mechanical pretreatment of resins is necessary to enhance the enzymatic recycling of composites and managing their disposal.

From the conventional thermoset composites, trials of enzymatic recycling have been carried out in polyurethane matrix, which contains ester and amide bonds that must be cleaved for efficient recycling. Enzymes target the ester bonds, and many high-value products can be obtained, including alcohols, acids, and aromatic precursors, that can be used as recycled raw materials in chemical industry [87].

The most recent research on thermoset recycling through engineering of oxidoreductases and hydrolytic enzymes is currently carried out by the EU project Bizente, funded by the European Commission. Through protein engineering, enzymes are molecularly modified (pre-engineered through directed evolution to adapt them to the degradation process) to enable the thermoset resin recovery from composites and give them a second life. The project develops a biodegradation technology using enzymes that will enable the recyclability of thermoset composites and recover resins and other products at their end of life, with the aim of making them reusable [88]. This research is still ongoing; thus, there are not yet available results.

2.4. Upcycling of Thermoset Composites to Vitrimers

In recent years, intrinsically recyclable epoxy resins based on covalent adaptable networks (CANs) have been employed for obtaining unconventional polymer networks with exchangeable bonds, rearrangeable under heat, pH, and UV light [89] or another stimulus, while keeping the network integrity, giving the potential to be recycled, reused, and reprocessed [90]. Based on the mechanism of bond exchange, CANs are classified as (1) dissociative CANs, in which the cross-linking bonds break upon heating and reform at lower temperature resulting in a decrease in network connectivity and modification of the cross-linking degree during network rearrangement and (2) associative CANs, which do not depolymerize and exhibit constant cross-link density when changing temperature. In both cases, the bond breaks only when a new bond is formed conducting to a permanent degree of connectivity [91]. Vitrimers are a class of associative dynamic covalent networks, a versatile class of materials that could potentially overcome some of the above-mentioned limitations of thermoset polymers and composites [90,92], as they do not lose their network integrity due to their stable cross-linking density of associative bonds during the plastic rearrangement, allowing for in situ reshaping and repairing by applying heat and pressure [93]. Different approaches have been reported [94,95], patented (e.g., 3R technology based on epoxy type matrix with reversible aromatic disulfide linkages [96], and explored in national and EU projects research projects (e.g., AIRPOXY, Carbo4Power, Ecoxy etc.), but EoL opportunities vs. traditional thermoset materials have not been proven at pilot level yet nor commercialized (e.g., available various reversible building-blocks of various thermoset materials e.g., acrylate, or vinylester) [91]. Current results show that materials present thermoplastic-like behaviour due to the reshuffling capacity of dynamic crosslinks and the polymer network can be regenerated by applying heat and pressure for repair of matrix microcracks and CFRP delamination’s; thermo-conformability; mechanical recyclability via grinding/compression-moulding and chemical recyclability has been proven at a lab scale showing easier fibre separation under mild conditions without causing surface damage on the fibres, but further research is required for upscale and valorisation [97].

Versatile dynamic covalent chemistries were reported, such as transesterification [98,99,100], imine amine exchange [101], vinylogous transamination [102], disulfide exchange [103], acetal bonds [104], and DA/retro-DA chemistry [105]. In contrast to some of the traditional exchange reactions, these associative mechanisms do not require high temperature treatments, petrol-based additional monomer, special processing (e.g., sonication), and/or metal catalysts to allow for the recycling process. Moreover, recent attention has been paid to exploring new recycling strategies, e.g., to convert the rigid networks into viscoelastic liquids; e.g., imine dynamic exchanges can combine both associative (transimination) and dissociative mechanisms (imine hydrolysis and reformation), where resulting vitrimers can be recycled through acidic hydrolysis [104,106].

More specifically, Liang Yue et al. introduced a new approach for the inversion of existing thermoset waste to vitrimers, allowing unrecyclable thermoset materials to be reprocessed and valorised in several applications. The methodology introduced relies on swelling–drying methods, milling, and hot pressing. More specifically, a solution of a catalyst, in this case, (tin(II) 2hexanoate (Sn(Oct)2)), is used for the swelling of the thermoset network (PU or epoxy), which causes transesterification reactions that enable the forming of dynamic bonds between ester and hydroxyl groups. Afterwards, the material can be milled using a ball milling set up and then formed using hot pressing technologies [107]. In the same frame, EVA thermoset waste was treated to be converted to vitrimer with the use of a zinc acetate catalyst and similar methodology, as described above, for the formation of dynamic covalent bonds between ester and hydroxyl groups via transesterification. The resulting material was able to be processed with extrusion and compression moulding methods [108]. The ability of vitrimer materials to undergo shape reconfigurability as the transesterification reaction is the underlying mechanism providing another superior possibility, which is the self-healing capabilities, as demonstrated by Hubbard et al.; furthermore, the ability of self-healing and processability are dependent on the catalyst and its sufficient concentration to enable, while the vitrimer’s shape memory capabilities are catalyst-independent [98].

Electroactive vitrimers—epoxy resins nanocomposites with carbon nanotubes (CNT)—have been mechanically recycled by milling and hot-pressing, conserving partial CNT integrity and dispersion, maintaining the mechanical strength of the pristine nanocomposites, and having the ability to be electrically welded through heating by the Joule effect [109]. Moreover, chemical recycling of polycyanurate thermosets has been demonstrated by activating ‘dormant’ covalent bonds, and they can be recycled into the original monomers, which can be circularly reused for their original purpose [110]. Moreover, vinylogous urethane vitrimers synthesized from bis-polyethylene glycol acetoacetates (aPEG) and tris(2-aminoethyl)amine can be degraded by water at a moderate temperature with almost quantitative recovery (>98%) of aPEG [102].

Epoxy vitrimers with outstanding mechanical properties and water insensitivity have been synthesized by crosslinking diglycidyl ether of bisphenol F (DGEBF) with a novel curing agent bearing imine backbones and amino terminals [111]. The dynamic imine bonds of the curing agent enable malleability, shape reconfiguration, and programming of the epoxy vitrimer; the aromatic structure of the curing agent imparts the epoxy vitrimer with high tensile strength, Young’s modulus, and thermal stability, while high water resistance was obtained due to the hydrophobicity and high crosslinking density of the network.

2.5. Upcycling of Thermoset Composites

Many recovery strategies for fibres have been discussed in the previous sections. In the case of the thermoset composite, upcycling refers mainly to the upgrade of the reclaimed fibres and specifically for CFs, which have a high cost and added value. An upcycling method of CFRPs was proposed by Zhang et al. in 2023 [112], where a combination of plasma under microwave irradiation in a nitrogen atmosphere pyrolysed the thermoset polymer matrix of a CFRP and in parallel improved the graphitization degree of the valorised CFs, in comparison to the virgin ones. In our recent research studies [113,114], nano-enabled solutions were investigated to evaluate the impact of nanomaterials on the surface morphology and mechanical properties of CFs. In the first one, recycled CFs were decorated with magnetic nanoparticles during a supercritical CO2-acetone process. The direct synthesis of magnetic nanoparticles in hydrothermal conditions and the deposition of already synthesized particles was investigated. In this process, no CF surface activation was needed thanks to the presence of functional groups due to the remaining matrix after the treatment in supercritical conditions. The resulting nano-enabled CFs showed a strong magnetic behaviour and no degradation. In the second one, a novel sizing approach was developed that can be applied as an upcycling route for reclaimed CFs, since it resulted in enhanced affinity between fibres and the polymeric epoxy matrix. The incorporation of nanomaterials, specifically N2-plasma-functionalized CNTs and few-layer graphene, demonstrated notable improvements in the interfacial shear properties (90% increase), verified by mechanical and push-out tests.

Also, the valorisation of the polymer matrix is of high importance, and the current research is seeking new ways of exploiting and upcycling the decomposed thermoset polymers. The study of Liu et al. [115] reported the direct conversion of waste epoxy resins into multiple-responsive (temperature, water, and pH) supramolecular materials via acid-catalysed oxidation. A strategy of upcycling an anhydride cured epoxy the reutilization of decomposed dual monomers into several applications was suggested by Shao et al. [116] recently. An aminolysis reaction took place in aminoethanol without using any catalysts. The epoxy resin was fully decomposed at 160 °C in 4 h, resulting in two distinct high purity monomers (HHPA-OH and BPA-OH). The latter was used to synthesize a polyurethane coating with superior properties (Tg of 88.9 °C, scratch hardness of 8 H, gouge hardness of 6 H, adhesive strength of 5B, and strong solvent resistance). The HHPA-OH reacted with methacrylic anhydride to form a dimethacrylate monomer, which was then used as a viable crosslinker for photo-curable 3D printing thermosetting polymer. This work demonstrates a feasible pathway to convert anhydride-cured epoxy waste to new monomeric recyclates.

3. Recycling Technologies of Thermoplastic Polymers

3.1. Overview

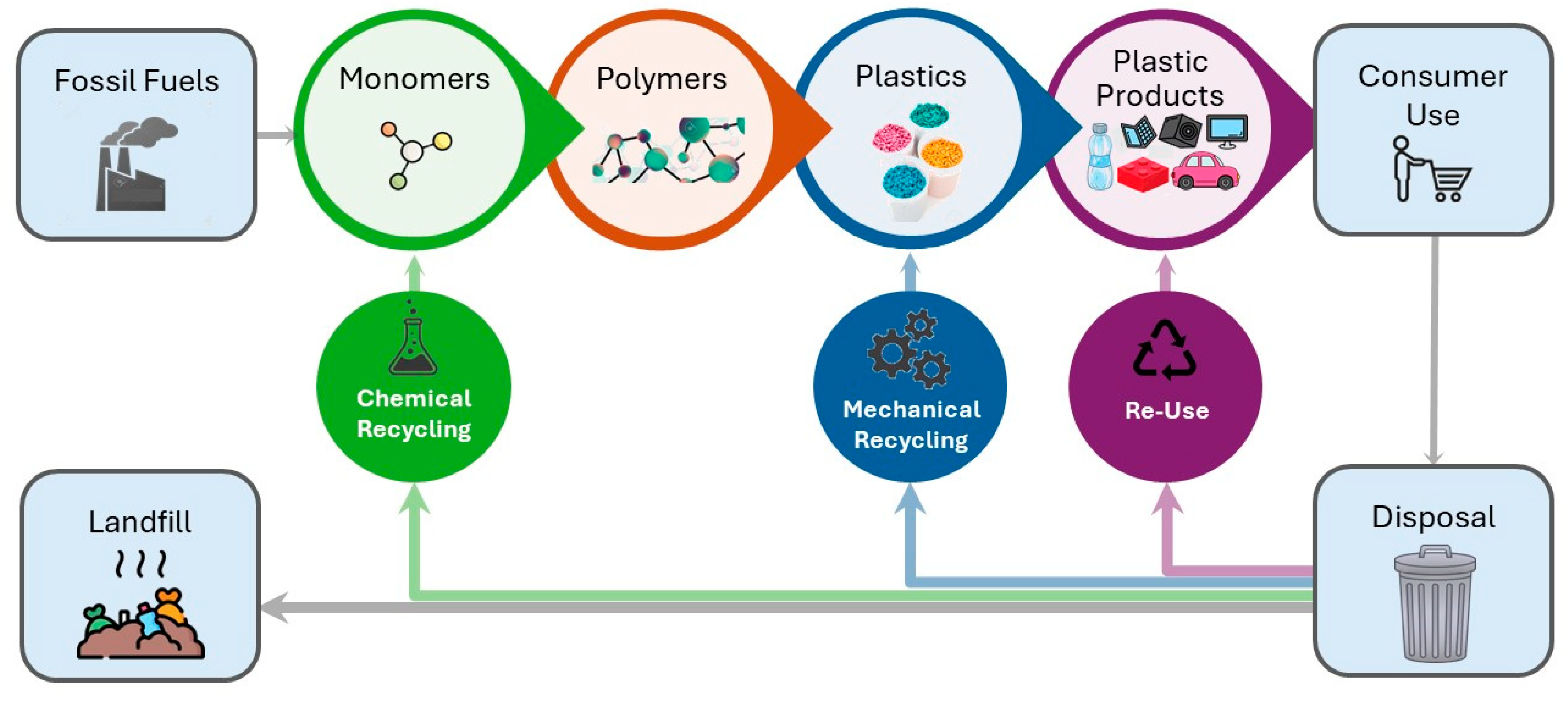

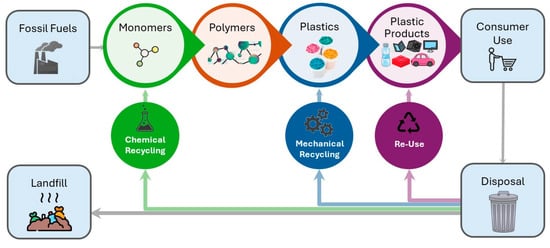

Thermoplastics have made significant contributions to both our daily lives and industrial growth. They have become ubiquitous and irreplaceable due to their adaptability and superior material qualities such as strength and durability, as well as their low-cost and automated manufacturing. Also, thermoplastics can be used for the manufacturing of high-performance composites in high-demanding applications, such as in the energy and marine sectors [117]. However, thermoplastics production relies on petroleum resources that are depleting, imposing limitations on their production. Also, plastics constitute an environmental threat when they are improperly discarded in the environment. Thermoplastics’ superior characteristic is their ability to remelt and dissolve, allowing reprocessing and reshaping, as well as chemical modifications, and chemical depolymerisation for monomer and feedstock reclamation. There are four approaches for polymer recycling, termed primary, secondary, tertiary, and quaternary recycling, which are presented in Table 2 and Figure 4.

Table 2.

Approaches for recycling of thermoplastics.

Figure 4.

Conventional process flow of plastics life cycle.

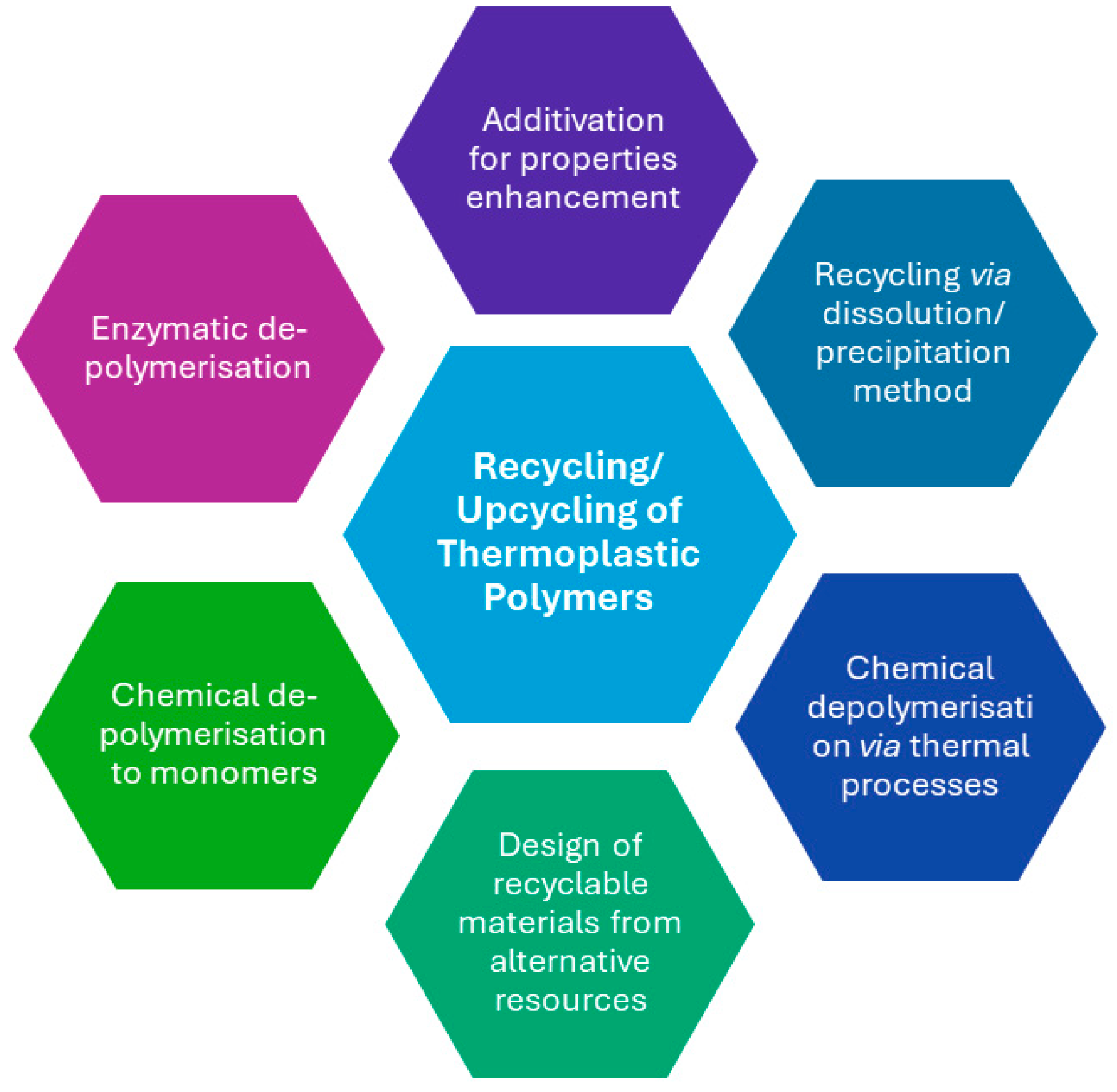

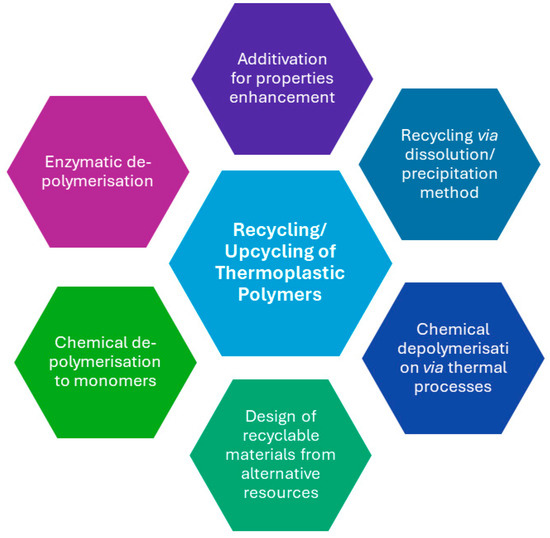

In general, the traditional recycling processes end up producing downgraded materials. The most promising technologies for the future are those attempting to end the materials life cycle by producing value-added materials. Upcycling refers to a process that converts by-products, undesirable, unwanted, or waste materials into new, higher-value materials. The concept of upcycling procedures can be defined as the use of post-industrial or post-consumer plastic waste as a feedstock for the synthesis of value-added products such as polymers, molecules, or materials, and is considered complementary to chemical and mechanical recycling [122,123,124]. Approaches for the upcycling of thermoplastic polymers that are discussed in this review are presented in Figure 5.

Figure 5.

Different approaches for upcycling of thermoplastic polymers.

3.2. Mechanical Recycling and Upcycling

The heterogeneity and low purity of post-consumer polymer waste streams, along with thermal degradation during the remelting and reshaping processes, lead to lower value products (downgrading). More specifically, the polymers degrade on a first level during their lifetime and afterwards during the thermal reprocessing, either due to chain scission reactions that happen due to presence of water molecules or acidic impurities [119,125]. This thermomechanical degradation results in decreased molecular weight and hence, the material does not retain its properties and the products that can be manufactured are downgraded [123]. To overcome this obstacle and achieve a higher number of polymer life cycles, recycling industries use several additives, such as stabilizers, chain extenders, flow enhancers, etc. [120].

The first step to recover polymers from various post-consumer waste streams before the recycling process is the identification and separation of plastic waste streams. There are several methods for automated sorting of polymers in one polymer rich stream, as shown in Table 3, based on the physical properties of the targeted polymer, such as electrostatic and density separation, as well as sensing-based methods, such as separation with near-infrared (NIR) spectroscopy. Sorting is insufficiently discussed so far, despite its potential to significantly increase the efficiency and yield of the mechanical recycling.

The reduction in the mechanical properties of reprocessed acrylonitrile butadiene styrene (ABS) has been extensively studied as one of the main industrial and most consumed polymers in the world. The assessment conducted by Scaffaro et al. [126] involved examining the impact of post-consumer ABS content in blends containing both virgin and post-consumer ABS, as well as analysing the influence of reprocessing cycles on the physical characteristics of these blends. The mechanical and thermo-mechanical properties of the blends deteriorated with an increase in the proportion of post-consumer ABS and with each subsequent reprocessing operation. In another study, Rahimi et al. [127] concluded that reprocessing leads to ABS degradation, primarily due to the breakage of polybutadiene bonds. They determined that the optimal blend of virgin and recycled material to minimize shrinkage was 50% w/w, while the most favourable mechanical properties were attained with blends containing up to 20% w/w recycled material. Polycarbonate (PC)/ABS blends were subjected to examination for up to 20 reprocessing cycles [128]. Despite PC/ABS demonstrating considerable thermal stability during reprocessing, its mechanical properties deteriorated with an escalation in reprocessing cycles. This decline was attributed to increased stiffness resulting from polymer chain scission. Recovery of the 20-time reprocessed blend was achieved by adding virgin material in combination with chain extender and styrene maleic anhydride at 30%, 1.5%, and 2% w/w, respectively.

Table 3.

Sorting methods for thermoplastics.

Table 3.

Sorting methods for thermoplastics.

| Sorting Method | Main Principle | Ref. |

|---|---|---|

| Magnetic density separation | A magnetic mixture is used to separate plastics by their differences in densities. | [129] |

| Electrostatic separation | Electrostatic field is used to separate different plastics according due to their differences in electrical properties. Usually, friction is used to electrostatically charge the different plastics and then the fractions are separated due to their negative or positive charges. | [129] |

| Froth flotation separation | In this method, different plastics are separated by hydrophobic and hydrophilic properties. | [130] |

| NIR separation | Separation based in the different spectrums of different polymers. | [131] |

| LIBS separation | Based on the different atomic emission spectrums of different polymers. | [132] |

Secondary or mechanical recycling has been used broadly and it has been a very successful recycling method, especially in the case of polyethylene terephthalate (PET) bottles [120,123,133]. It is a valuable method as it decreases the overall energy demand for processing, considering that the production of virgin materials require significantly more energy than materials derived from recycling process. Hence, it lacks two crucial objectives of circular economy planning, which are the elimination of waste and the development of value-added products in a circular way [125].

Mechanical processing of polyolefins induces degradation at the molecular level and the formation of aldehydes, ketones, and short-chain hydrocarbons [134]. Post-consumer high-density polyethylene (HDPE) was blended with virgin polymer at ratios of 0, 20, 40, 60, 80, and 100% by weight via extrusion by Curtzwiler et al. [135] in 2018 and the properties of the different blends were measured. A significant increase was observed in UVA absorption, in carbonyl and terminal vinyl functional groups, and in the degradation temperature. The fluorescence properties and the polymer crystal quality were deteriorated. In another study by Curtzwiler et al. [136] performed in 2019, the optical, thermal, mechanical, morphological, and gas barrier properties of post-consumer recycled polyolefin materials (87.5% post-consumer recycled polypropylene and 12.5% post-consumer recycled polyethylene) melt blended with virgin polypropylene at different blend ratios have been investigated. The presence of phase separated domains and increased compatibility from oxygenated functional groups resulted in increase in the yield stress by 74%, the strain at yield by 49% and the UV blocking by 160%, whereas the gas transmission was reduced by 30–40%. The effect of accelerated thermal and photo-aging and subsequent reprocessing on homopolymers of low-density polyethylene (LDPE), HDPE, polypropylene (PP) and high-impact polystyrene (HIPS) was monitored by Luzuriaga et al. [137]. LDPE and HIPS were more sensitive to thermo-oxidation than HDPE and PP, whereas HDPE and PP were affected more by UV exposure. It was concluded that the application of stabilizers prior to reprocessing is mandatory to prevent the accelerating effect of thermal and photo-aging caused by the structural inhomogeneities built up in the materials. The use of natural materials such as ground rice hull (RH) of 17 μm diameter as a modifier to a PE/PP recycled resin from waste fishing ropes, resulting in the improvement in the mechanical properties, has been reported by Sato and Shishido [138].

To deal with the challenges of mechanical recycling such as polymer incompatibility, phase separation, and polymer degradation, and to overcome the downgraded of thermoplastics during reprocessing and achieve a higher number of polymer life cycles, the recycling industries use a number of additives, such as compatibilizers, coupling agents, impact modifiers, stabilizers, chain extenders, flow enhancers, and many others [120,139]. Recycling of multi-layer barrier packaging [140] lays in this category and additives such as compatibilizers and impact modifiers are needed in these cases to recycle or upcycle waste polymers into new materials with desired properties.

To avoid low-quality recycled materials with inferior mechanical properties and to deal with constraints of mechanical recycling arising from the heterogeneous nature of polymers and the contaminants present in the plastic waste streams [141], the use of specialty additives [142] and techniques that improve the melt processability and mechanical performance of final products is necessary [143].

3.2.1. Compatibilizers

When multiple thermoplastics are blended without being chemically compatible, it is important to apply certain performance modifiers during their reprocessing to prevent phase separation and inferior-quality materials with poor mechanical characteristics. Differences in chemical structures, melting points, and degradation profile during high shear melt-extrusion need to be considered. Compatibilizers are used in order to reduce the interphase tension that can create phase dispersion and to stabilize the morphology in order to withstand high stress and strain application. Furthermore, compatibilizers can enhance the adhesion between the phases in the solid-state, improving the mechanical properties of the products. Compatibilization in polymer blends is achieved using additives such as low-molecular-weight coupling agents, traditional polymeric compatibilizers, impact modifiers, and reactive nano fillers. There are two different approaches for the compatibilization of polymer blends. The first one is the addition of compatibilising agents, usually block or core-shell copolymers, or components miscible with all phases that reduce the interfacial tension of the blend. The second approach is the in situ reactive compatibilization where trans-reactions such as transesterification, graft, or block copolymers’ in situ formation, ionically bonded structures formation and mechanochemical blending that generates copolymers by breaking and recombining polymer chains can be used [144]. The use of compatibilizers such as reactive low-molecular-weight coupling agents or crosslinkers [145], dialkyl peroxides [146], coupling agents based on silane, phosphite, isocyanate, bis-caprolactam, and bisoxazoline [144,147,148] and epoxy-based coupling agents [149] has been reported in the literature.

Polylactic acid (PLA) blends with three different thermoplastic elastomers were compatibilized by a low amount (2 wt.%) of 4,4-methylene diphenyl diisocyanate. Mechanical, thermomechanical, and impact strength measurements proved the favoured interfacial adhesion of PLA and thermoplastic elastomer (TPE). Compatibilized blends of high toughness were demonstrated by Vuillaume et al. [148]. Incompatible and immiscible blends of polyamide-6 (PA6) and polybutylene terephthalate (PBT) were effectively compatibilized by a multifunctional epoxy resin. The in situ-formed copolymer enhanced the mechanical properties of the PA6/PBT blends, as reported by Chiou at al. [149]. The in situ compatibilization of recycled PA6 with PP blends has been also reported by grafting maleic anhydride onto PP using benzoyl peroxide catalyst. Improved mechanical properties were achieved in comparison to the uncompatibilised blends [146].

Furthermore, polymeric compatibilizers such as functionalized polyolefins [150], styrenic block polymers [151], epoxy resins [152], anhydride based compatibilizers [153], and isocyanate polymers [154] have been widely used. Ha et al. [155] reported the use of chlorinated polyethylene (CPE), ethylene-propylene rubber (EPR), and their 1/1 mixture as compatibilizers for HDPE/PP/polyvinyl chloride (PVC) blends, while the CPE, styrene-ethylene-propylene block copolymer (SEP), or their 1/1 mixture were used as compatibilizers of the HDPE/PS/PVC blends. EPR and SEP exhibited the best behaviour as impact modifiers on the HDPE/PP/PVC and HDPE/PS/PVC blends, respectively. In another study, styrene ethylene butylene styrene (SEBS) elastomer functionalized by maleic anhydride (SEBS-g-MA) compatibilized recycled PP/PET blends improving blend homogeneity and properties [156]. A positive effect on the mechanical properties and thermal stability was observed through the addition of 5% PP-g-MA and epoxy resin as a compatibilizer to recycled ABS and recycled PC-rich blends [157].

3.2.2. Impact Modifiers