Abstract

Plastic product consumption and disposal are widespread. Given that these products are derived from crude oil, it is critical to reduce their consumption and effectively recycle plastic waste as recycled resources to achieve a low-carbon society. Japan enacted the “Containers and Packaging Recycling Law” in 2000, encouraging the recycling of plastic packaging and containers. However, material recycling of plastic waste has stalled due to recycling costs and technical challenges. This paper examines and evaluates the transition process and operational status of Japan’s recycling policy for plastic containers and packaging, as well as clarifies the limits of resources recycling. The limits and issues of current identification technology are discussed by analyzing the characteristics of plastic marks and detecting the material compositions of waste samples. The paper also discusses a new sorting technology that uses terahertz waves to improve plastic recycling. This analysis revealed that plastic containers are typically made of two or more plastic materials, which makes resources recycling more difficult. Terahertz waves are safer than other high-accuracy sorting technologies currently in use. Thus, material recycling can be expanded by accurately analyzing the composition of plastic waste and introducing sorting devices appropriate for achieving the circular economy with sustainable resource recycling.

1. Introduction

Due to climate change caused by global warming, it has become evident that large-scale earthquakes, super typhoons, and wildfires occur frequently each year in various countries around the world, and to resolve these problems, countries around the world must immediately reduce their emissions of greenhouse gases. The Paris Agreement, which took effect in November 2016, requires all countries to submit and renew their greenhouse gas emission reduction targets every five years. Japan announced in 2021 that it would aim to achieve carbon neutrality by 2050, reduce its greenhouse gas emissions by 46% in the fiscal year 2030 from its fiscal year 2013 levels, and continue strenuous efforts in its challenge to meet the lofty goal of cutting its emissions by 50% [1].

In the meantime, Japan adopted the Ocean Plastics Charter at the G7 conference held in Canada in June 2018 and called on countries around the world to tackle the plastic problem in earnest with the goal of “Working with industry towards 100% reusable, recyclable, or, where viable alternatives do not exist, recoverable, plastics by 2030” [2].

In addition, according to the Ministry of the Environment (MOE), the rising demands for resources and energy, as well as the amount of waste generated, are becoming increasingly problematic on a global scale. The transition to a “circular economy” that aims for the sustainable circulation of resources becomes a global trend. Under the various recycling systems established for the formation of a recycling-oriented society, Japan aims to promote reduce, reuse, recycle (the 3Rs) and the circular economy through cooperation among different stakeholders. In particular, Japan’s Annual Report on the Environment emphasizes “materialization of the plastic resource recycling strategy” and “international cooperation for solving the marine plastic waste problem”, demonstrating a high level of concern for the waste plastic problem [3].

Inexpensive, easy-to-mold, and highly convenient plastic products are being consumed and disposed of in large quantities, mainly in developing countries. Given that these products are derived from crude oil, it is crucial to reduce the consumption of plastic products and effectively recycle waste plastics as recycled resources to achieve a low-carbon society and the circular economy. However, the COVID-19 pandemic has led to an increase in the use of single-use plastic containers, home delivery packaging, plastic shopping bags, etc. In 2021, when Sapporo City declared a state of emergency, changes in environmental consciousness began to be seen, such as an increase of approximately 12% in plastic containers and packaging and other plastic waste [4].

Japan’s plastic containers and packaging recycling policy is based on EU policy (European Parliament and Council Directive 94/62/EC of 20 December 1994 on packaging and packaging waste), and Asian countries often refer to Japan’s recycling policy. However, it is a unique and complex recycling system, and to achieve the goal of sustainable resources recycling, many issues must be resolved, including improvements and developments in policy, recycling technology, resources recycling efficiency, and the enhancement of environmental awareness. Japan then finally signed the agreement at the G20 meeting in Osaka. Furthermore, looking ahead beyond those initiatives and existing actions by each member, it shares and calls on other members of the international community to also share, as a common global vision, the “Osaka Blue Ocean Vision” that we aim to reduce additional pollution by marine plastic litter to zero by 2050 through a comprehensive life-cycle approach that includes reducing the discharge of mismanaged plastic litter by improved waste management and innovative solutions while recognizing the important role of plastics for society. They also endorsed the “G20 Implementation Framework for Actions on Marine Plastic Litter” [5].

In this way, the problem of plastic waste is an important issue for solving the carbon-neutral and circular economies that are attracting global attention. Japan has established recycling policies since the mid-1990s to create a recycling-based society. In 2000, Japan enacted the “Law for Promotion of Sorted Collection and Recycling of Containers and Packaging”, which encouraged the recycling of plastic containers and packaging. However, material recycling of waste plastics has stalled due to recycling costs and technical obstacles.

There are numerous studies on the proper treatment and recycling of waste plastics, most of them are comparative analyses of plastic types and treatment methods with the specific case. It is noteworthy that Maga, D., Hiebel, M., and Aryan, V. (2019) conducted an environmental impact assessment based on differences in tray materials and waste management policies in EU countries [6]. Changes in recycling policies influence the selection of materials for containers and packaging by businesses, and as a result, the environmental impact of material changes will also shift. Alhazmi, H., Almansour, F., and Aldhafeeri, Z. (2021) conducted a comprehensive review of LCA studies on plastics and highlighted the need for environmental impact assessment from a long-term perspective as an issue with existing LCA studies on plastics [7]. The study by Jang, Y.C., Lee, G., Kwon, Y., Lim, J.-h., and Jeong, J.-h. (2020) and other LCA studies of plastic recycling (MFA: material flow analysis case studies) that have been conducted on waste treatment methods and carbon dioxide emissions of recycling technologies are frequently compared and analyzed, or scenarios are analyzed under various conditions of materials and waste management [8]. However, it is difficult for the results of environmental impact assessments based on limited conditions to provide clear evidence for policy recommendations or the development of new technologies.

A study by Meert, J., Izzo, A., and Atkinson, J.D. (2021) analyzed the effects of municipal recycling policies on the impact of plastic bag bans on retail return polyethylene in New York City. This paper examines the effects of plastic bag recycling before and after the implementation of plastic bag bans. It is commendable that the policy effects were analyzed by collecting, sorting, and classifying plastic waste. However, it is difficult to assert that this analysis and evaluation of plastic materials are accurate [9].

On the other hand, there are many research results on comparative analysis of recycling technologies for waste plastics; however, no revolutionary recycling technologies have been developed in the last few decades, and the majority of these studies compare material sorting technologies and material recycling versus chemical recycling. Ragaert, K., Delva, L., and Van Geem, K. (2017) presented a structured analysis of the characteristics of chemical recycling and mechanical recycling. Particularly, for mechanical recycling, they discussed the limitations and significance of sorting technology, whereas for chemical recycling, they presented the most recent technology and outlined future possibilities [10]. Similar to this paper, Beghetto, V., Sole, R., Buranello, C., Al-Abkal, M., and Facchin, M. (2021) examined the current status and recycling technologies for plastic containers and packaging waste. They provide an overview of the latest trends in polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and polystyrene (PS) [11]. Furthermore, Khalid, M.Y., Arif, Z.U., Ahmed, W., and Arshad, H. (2022) present specific recycling technologies and case studies based on a vast amount of the most recent data. Not only does the paper provide a comparative analysis of recycling technologies, but it also presents various applications of recycled plastics and considers recycling as well as reuse perspectives [12]. Thus, sorting technology for waste plastics is crucial not only for material recycling, but also for chemical recycling, and is effective in energy recovery for controlling air pollutants.

According to previous research, the majority of studies addressing the issue of waste plastic focused on recycling policies and technologies, analyzing the relationship between policies and technologies and environmental impacts. However, no studies have proposed a comprehensive waste recycling policy based on the analysis of changes in recycling policies and actual conditions, the examination of the characteristics of plastic containers and packaging waste, the discussion of recycling issues, and the proposal of new sorting technologies.

This paper examines and analyzes the transition process and operational status of Japan’s plastic container and packaging recycling policy, and clarifies the limits of sustainable resource recycling. By analyzing the characteristics of plastic marks of 1439 household plastic containers and packaging samples, and detecting material compositions of 3.22 kg sorted container and packaging waste, it identifies obstacles to waste plastic recycling and corrective measures in recent recycling economy trends. In addition, by verifying and comparing technologies for sorting plastic wastes, this study introduces and discusses a new sorting technology using terahertz waves to improve plastic resource recycling, and presents the possibility of sustainable resource recycling by proposing a new plastic sorting technology. Through discussions and research on recycling policies, waste characteristics, and sorting technologies, new possibilities for building the circular economy with sustainable resource recycling are presented. The originality of this study lies in the use of plastic waste samples from households and recycling spots to evaluate local characteristics and the current status of plastic waste disposal and recycling, as well as to validate the application of the terahertz technology in plastic waste recycling.

2. Plastic Recycling Policy and Its Actual Performance

2.1. Characteristics of Plastic Container and Packaging Waste Recycling System in Japan

2.1.1. Circular Economic Trends in the EU

The idea of the circular economy appeared in the 6th Environment Action Programme (6EAP) in 2002. Resource-Efficient Europe in 2011, which embodies this plan, introduced the concept of “waste to resources”. Strategies for 2020 include expanding demand for recycled resources and revitalizing the market by giving economic incentives, clarifying the criteria for “final disposal as waste”, transitioning from landfill to reuse and recycling, considering standards for recycled resources contained in products, establishing standards for durability and reusability, and expanding producer responsibility [13,14].

Closing the loop—An EU action plan for the Circular Economy, in 2015, emphasized the “life cycle approach” and cited plastics as one of its top priorities. Plastics-related life cycle approaches include eco-design (durability, recyclability, etc.), extended producer responsibility (EPR) in product design, acceleration of the recycled materials market, and establishment of quality standards [15]. Following the Circular Economy Plan in 2015, A European Strategy for Plastics in a Circular Economy was announced in 2018 [16]. The objectives are to reduce disposable plastics through regulatory measures and to recycle more than half of plastic containers and packaging. The numerical target is to commercialize 10 million tons of recycled plastic (nearly 40% of EU plastic waste) annually in the EU market by 2025. As one of the methods to realize this strategy, the idea of environmental regulation (eco-modulation) in EPR charges is drawing attention. It allows producers to pay different amounts depending on how easily the product can be reused or recycled [17].

Furthermore, the new Circular Economy Action Plan, revised in 2020, outlines action plans for creating value from key product value chains and waste. It is encouraged that plastics-related key products, such as plastic containers and packaging, construction and buildings, and automobiles, should be designed to be recyclable and manufactured with recycled materials [17,18].

2.1.2. Individual Recycling Laws and Container and Packaging Recycling in Japan

The Containers and Packaging Recycling Law in Japan was promulgated in 1995, partially enforced for cans, bottles, and PET bottles in 1997, and fully implemented in 2000, including plastic containers and packaging waste. In particular, plastics accounted for 39.4% by volume (8.2% by weight) of the containers and packaging waste at the beginning of revision (2006) [19]. Furthermore, in 2021 after the COVID-19 pandemic, the proportion increased to 50.4% (12.8% by weight) [20].

In 1971, during the period of high economic growth, and since the “Waste Management and Public Cleansing Act” was enacted to reduce the volume of waste generated in large quantities aiming for hygiene and non-pollution, the general waste administration has maintained this policy for more than 20 years. However, since the above-mentioned container and packaging recycling policies were fully enforced in 2000, individual recycling laws have been introduced one after another to form a recycling-based society. Starting with the “Basic Act on Establishing a Sound Material-Cycle Society” in 2001, the “Law for the Promotion of Effective Utilization of Resources”, “Home Appliance Recycling Law”, “Food Recycling Law”, and the “Act on Promoting Green Procurement” were enacted. To build a recycling-based society where the consumption of natural resources is suppressed and environmental load is vigorously reduced, the 3R Initiative has been comprehensively promoted based on the individual recycling systems that incorporate the concept of the 3Rs. The “Construction Material Recycling Law” was enforced in 2002, the “Automobile Recycling Law” in 2005, and the “Small Home Appliance Recycling Law” in 2013 [21].

It can be said that the Containers and Packaging Recycling Law was a catalyst for promoting 3R policies, but the relationship between consumers, local governments, and producers is complicated, and a reexamination is necessary to achieve a circular economy. Although it was revised once in 2006, the same recycling policies and methods have been maintained for many years despite the rapid increase in and diversification of plastic waste. To study the revisions of the container and packaging recycling system, Yu (2006) suggests that by thoroughly analyzing the characteristics, environmental impact, and recycling costs of each container, and accumulating and disclosing the information, clearer policy decisions and fairer responsibility-sharing can be made [22]. With the enactment of the “Act on the Promotion of Resource Circulation Related to Plastics” in April 2022, sustainable resource circulation has ushered in a major turnaround. However, to improve recycling efficiency and determine the priority of recycling technologies, a lot of data collection and data analyses are needed, and the issues to be discussed based on the analysis results (evidence) have piled up.

2.1.3. Transition of Container and Packaging Waste Recycling System

Like Germany’s “Packaging Waste Decree (1991)” and France’s “Packaging Waste Decree (1992)”, after EU countries started to recycle containers and packaging waste, the EU adopted the “EU Containers and Packaging Recycling Directive” in 1994. After that, Japan and South Korea developed their container and packaging recycling systems by referring to the systems of Germany and France, with the former formulating a “French-type” system that emphasizes partnerships between industry and local governments, and the latter formulating a “German-type” system that clarifies the responsibilities and roles of industry [21]. That is, in Japan, producers bear part of the recycling costs based on the extended producer responsibility, while the actual collection, transportation, and intermediate treatment (sorting, compressing, packaging, and storage) of containers and packaging waste are performed by local governments. In 1997, there was a rapid increase in the amount of PET bottles, which were not only light and easy to form, but also convenient to keep and carry. On the other hand, however, the generation of containers and packaging waste and the increase in disposal costs became a social problem. Later, in 2000, with the implementation of “Basic Act on Establishing a Sound Material-Cycle Society”, the scope of containers and packaging recycling was expanded to include plastic containers and packaging. According to a survey by the Ministry of Economy, Trade, and Industry, about 76.3% of municipalities in Japan are implementing the classification of plastic containers and packaging [23].

In the case of Sendai City, in response to the full enforcement of the Containers and Packaging Recycling Law in 2000, a model project for sorted collection of plastic containers and packaging other than PET bottles was implemented, and comprehensive sorted collection has been carried out throughout the city since 2002. Most of the large cities in Japan have built cleansing plants (waste incineration plants), aiming for reducing the volume of a large amount of general waste and for sanitary treatment. Of course, instead of simply incinerating, energy recovery is implemented by using the waste heat as a heat source in the factory, generating electricity, or operating a heated swimming pool. Further, to improve the energy recovery efficiency, the higher the energy potential of general waste as the heat source of waste incineration, the better. In other words, lots of waste plastic having a high calorific value should be contained. However, it is estimated that the start of the sorted collection of plastic containers and packaging waste will reduce the calorific value of waste by about 12% and the income from electric power selling by about 10% in the case of Sendai City [24]. On the other hand, if the amount of recycling (materials and chemical recycling) of plastic containers and packaging increases, it can be expected to reduce air pollutants such as carbon dioxide and hydrochloric gas. Thus, if the relationship between existing waste treatment facilities and recycling is not fully studied in terms of environmental impact and economic evaluation, inefficiencies would be likely to occur in waste management administration.

In 2006, the “Revised Containers and Packaging Recycling Law” was enacted. In this amendment, the Containers and Packaging Recycling Law was revised from the aspects of promotion of reduce, reuse, recycle (the 3Rs) for containers and packaging waste, improvement of the efficiency of recycling costs for the whole society, and cooperation among the state, local governments, producers, consumers, and other stakeholders. Due to the soaring crude oil prices at that time, it was believed that the PET bottles would flow overseas. To recycle containers and packaging waste in Japan, content so that the containers and packaging waste can be smoothly delivered from municipalities to the designated corporations has been added to the law. In addition, the fine for “free riders” was raised. In April 2007, efforts to curb emissions were promoted and fuel conversion was recognized as a recycling method of plastic containers and packaging. The following year, a mechanism was created to contribute funds to businesses or municipalities, to improve the efficiency of recycling costs of containers and packaging waste, support the sorted collection in municipalities, and ensure high-quality renewable resources [25].

In the “Resource Circulation Strategy for Plastics” formulated in May 2019, to promote plastic resource recycling, thorough implementation of reduction was positioned as one of the key strategies. In the strategy, the necessity of mandatory charging for plastic shopping bags (prohibition of free distribution, etc.) was presented. To achieve it, the “Method of Charging for Plastic Shopping Bags (Draft)” was summarized. In addition, based on this, the “Ministerial Orders related to the Act on the Promotion of Sorted Collection and Recycling of Containers and Packaging” was revised [26].

In June 2021, to promote the resource recovery of plastics, stakeholders in the whole process from the design of plastic-based products to the disposal of plastic-based product waste established the “Act on the Promotion of Resource Circulation Related to Plastics (commonly known as the New Plastic Law)”, and put it into effect on 1 April 2022. The law aims to accelerate the transition to a circular economy through “3Rs + Renewable” throughout the life cycle of plastics. Therefore, at the design and manufacturing stages, the design of plastic products would be converted to eco-friendly types, and the government would certify and support related products. Then, it would promote the reduction in disposable products at the sales and provision stages, and admit the collection routes not only by local governments but also by manufacturers and dischargers at the discharge/collection and recycling stages. On this basis, including existing plastic containers and packaging, the efficient collection and recycling of all types of plastic have been promoted [27]. The transitions of the Containers and Packaging Recycling Law are shown in Table 1.

Table 1.

The transition of Containers and Packaging Recycling Law [28].

2.2. Analysis of Current Status and Issues of Plastic Containers and Packaging Recycling

2.2.1. Impediments to Sustainable Resource Circulation

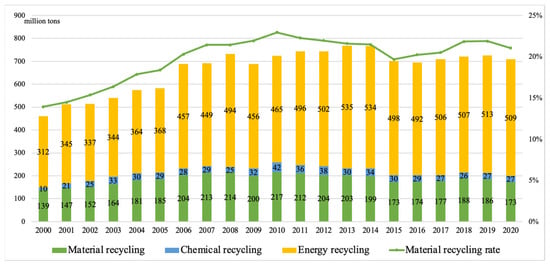

With the implementation and revision of the Containers and Packaging Recycling Law in 2000, municipalities increased their public relations and education efforts, and citizens’ environmental awareness improved, so the containers and packaging recycling system contributed to the reduction in waste to a certain extent. In Japan, mostly material recycling, energy recovery, and chemical recycling are used for the treatment of plastic waste. Collected plastic wastes are washed, sorted, pelletized, and utilized as a raw material for material recycling. Considering the priority of the 3Rs, material recycling should have been prioritized originally. However, as shown in Figure 1, energy recycling shows the highest recycling rate, whereas material recycling is on a declining trend and has remained flat at about 21% in recent years (2015–2020) [29].

Figure 1.

Data of effective utilization of plastic containers and packaging waste in Japan.

Easy-to-sort plastic containers and packaging, such as PET bottles and trays, are relatively advanced in terms of material recycling. In the case of other plastics, numerous dirty or composite materials are difficult to sort out, making them challenging to recycle. Since composite materials are a feature of containers and packaging waste in Japan, it is difficult to recycle them as single materials.

On the other hand, under the Containers and Packaging Recycling Law, the recycling system is composed of consumers (sorted disposal), municipalities (sorted collection), and business entities (recycling) [30]. Municipalities bear the collection cost, and business entities should pay for recycling. Currently, over 70% of municipalities in Japan are collecting and separating plastic containers and packaging waste [31].

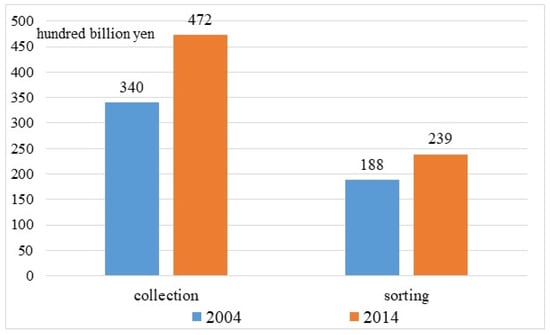

However, the results of the 2014 MOE survey show that the municipalities bear a significant financial burden of approximately JPY 80 billion for the processing of plastic containers and packaging waste. Additionally, compared to 2004, the cost of collection and sorting of plastic containers and packaging waste has considerably increased (Figure 2) [32]. Although the EPR system has been implemented, the increase in municipal costs to comply with the Containers and Packaging Recycling Law is unavoidable, therefore, sorted collection by each local government is the most important process for recycling waste resources. In other words, since the burden on municipalities has reached its limit, it is desirable to construct a new recycling system to alleviate the pressure of waste management.

Figure 2.

Estimated costs of plastic containers and packaging collection and sorting in Japan.

Japan aims to reduce single-use plastics emissions by 25% by 2030, achieve a rate of recycling/reusing containers and packaging of 60% by 2030, and realize 100% effective utilization of used plastics by 2035 [33]. At present, however, plastic container and packaging recycling in Japan relies primarily on combustion or energy recovery. This recycling method emits a substantial amount of carbon dioxide and, as a result, does not meet the recycling requirements of many countries, including the EU. In other words, the treatment of plastic containers and packaging waste in Japan is accompanied by significant environmental impact. On the other hand, it is difficult to improve the collection efficiency of the recycling system because of the current cost burden on the municipalities. These factors are considered the impediments to sustainable resource recycling of plastic packaging and containers.

2.2.2. Significance and Limits of the Plastic Resource Circulation Act

The impact of marine litter on the ecosystem is becoming more serious, so it is essential to restrict the use of plastic products and promote their collection and recycling on a global scale. To address climate change issues and realize a genuinely zero-carbon society, the conversion of fossil resource-derived materials to alternative materials is necessary. Furthermore, restrictions on importing plastic waste have been tightened in China and other countries, so the domestic circulation of plastic resources is necessary. Based on this background, Japan enacted the New Plastic Law to promote the resource recycling of plastics further.

This new law imposes an eco-friendly design in the manufacturing process that contributes to reducing the generation of plastic waste and promoting recycling of materials. That is, developing guidelines for designing plastic products and promoting the use of single materials and easy recycling design will allow for the material recycling of plastic containers and packaging waste [34].

Collected household waste currently varies according to the population, the age range, and the environmental efforts of municipalities. Therefore, obtaining a nationwide unified standard (such as type of resources and collection methods) for implementing sorted collection is challenging. The new law allows municipalities to take advantage of their autonomy and permits them to utilize different collection routes for plastic containers and packaging. Furthermore, it allows multiple municipalities to collaborate and encourage recycling. This kind of mechanism aims to increase the number of household plastic resources recovered.

On the other hand, this law has established a certification system for manufacturers, distributors, and service providers to voluntarily collect used plastic products. By increasing collection routes, more plastic products and single materials can be collected while shopping, and the recycling rate can be improved. It is anticipated that promoting the voluntary collection will diversify collection routes and encourage the collection and recycling of plastic products. The processing costs for plastic containers and packaging have increased as a result of import regulations, and the utilization of voluntary collection routes may reduce the cost burden on municipalities.

Although this new recycling law encouraged individual stakeholders to take part in the recycling system, such as the Small Home Appliance Recycling Law, it is not mandatory. At the same time, it can be supposed that municipalities will expand the number of waste items to increase the amount of collected plastic waste. However, as plastic products become more complex and diverse, how to sort the recyclable materials that can be recycled is considered an important issue.

3. Local Characteristics of Plastic Containers and Packaging Waste

3.1. Collection Area and Sample Size of Plastic Containers and Packaging Waste

Under the support of a major recycling company in the Tohoku region of Japan, plastic containers and packaging waste samples (1439 items) were randomly collected from household plastic waste in five areas based on the population: Aomori City, Goshogawara City, Hiranai Town in Aomori Prefecture, Koriyama City, Aizu Wakamatsu City in Fukushima Prefecture.

Regarding the characteristics of the five areas, Aomori City is the prefectural capital with a population of about 270,000 and has developed into an important transportation and logistics hub connecting Hokkaido. Goshogawara City is located in the northwestern portion of Aomori Prefecture with a population of 50,000, and its agriculture and fishing industries are thriving. Hiranai Town is town with a scallop aquaculture industry. Koriyama City is located in the center of Fukushima Prefecture and is the third-largest city with a population of 320,000. Aizu Wakamatsu City is situated in the western portion of Fukushima Prefecture and is home to numerous well-known tourist destinations. Populations and the number of samples in the five areas are shown in Table 2.

Table 2.

Population and sample size in studied areas.

3.2. Types and Regional Differences of Plastic Containers and Packaging Waste in Five Areas

To analyze the material compositions of the samples, Fourier transform infrared spectroscopy (FTIR), which can read and analyze the absorption spectrum of infrared rays specific to the material being measured, was used to separate single materials and composite material. Samples of single materials were separated into PP, PE, PS, polyvinyl chloride (PVC), and PET.

The results are shown in Table 3. It can be seen that PP, usually used for packaging of bread and sweets, shares about 30% of the total, indicating that it is widely used as a material for plastic containers and packaging. There are regional differences in PP emissions, with Hiranai Town emitting the most emissions compared to other cities. Assumably, this is because sashimi and sushi trays are frequently discarded in Hiranai Town, which has a thriving fishing industry. PVC material was not detected in all regions, which means that PVC is not commonly used in household containers and packaging. Even though the lids and containers of lunch boxes are usually made of PET material, the proportion of PET does not exceed 10%. Composite materials often have different materials on the front and back of the packaging, such as PP on the front side and PE on the back side. The ratio of composite material containers and packaging waste is about 25% of the total. This indicates that composite materials are commonly used. The arterial industry, which is the producer of plastic containers and packaging, uses composite materials to ensure the quality and designs of products to increase consumers’ purchasing motivation, and recycling of the venous industry has not been considered.

Table 3.

The proportion of sample size by different material compositions in studied areas.

3.3. Plastic Marks and Material Labels of Plastic Containers and Packaging Waste

In Japan, the law (“Act on the Promotion of Effective Utilization of Resources”) requires that containers and packaging be labeled with an identification mark. However, some of the samples did not have any plastic marks. This was usually the case with plastic bags and packaging materials used for international online shopping. In addition, it was not possible to analyze all the plastic marks on all of the samples because some of them were broken when they were collected. As shown in Table 4, 688 samples (about 48% of total samples) were able to confirm the plastic marks. Material labels on samples were checked as well. Material labels are a way to inform consumers about the material composition of the product and to encourage recycling. Of the 688 samples, 298 (43%) had material labels. In other words, less than 50% of the remaining samples have only the plastic mark, indicating that the material labeling is left to the discretion of each manufacturer. This highlights the ambiguity of this Law for Promotion of Effective Utilization of Resources Recycling.

Table 4.

Sample size and proportion of plastic marks and material labels.

3.4. Evaluation of Plastic Containers and Packaging Waste and Near Infrared Sorting Technology

On the technical side, existing near-infrared devices are utilized to sort plastic containers and packaging waste. These near-infrared devices are widely used by all of the recyclers in Japan to separate waste plastics. Measuring the waste plastic’s absorption spectrum by reflection can test the material. The identified materials are sorted and recycled as pellets or ingots based on their composition. The recycled material is reportedly traded at a lower price than virgin material due to its high impurity. Therefore, it is a problem that impurities are mistakenly mixed in with the sorted materials using near-infrared devices. In this study, a group of sorted PP material (1.36 kg) and a group of sorted PE material (1.86 kg) were randomly picked out from the recycling process to estimate the near-infrared technology. To detect the composition of plastic materials, all sample materials are identified using the FTIR device.

The results (Table 5) showed that the sample identified as PP contained approximately 40% impurities, with a near-infrared device accuracy of approximately 60%. The PE group was found to consist of approximately 70% PE and 5% PP. These results indicate that the near-infrared device can sort plastic containers and packaging waste with an accuracy of 60–70%. On the other hand, 30–40% of different materials are mixed in, and this is one of the reasons why recycled pellets are less expensive. It is considered that this near-infrared method can be used to produce high-quality recycled pellets by enhancing the accuracy.

Table 5.

The weight and its proportion of materials sorted by near-infrared device [40].

3.5. Proposal for Advanced Sorting of Plastic Containers and Packaging Waste

3.5.1. Evaluation of Identification of Terahertz Waves

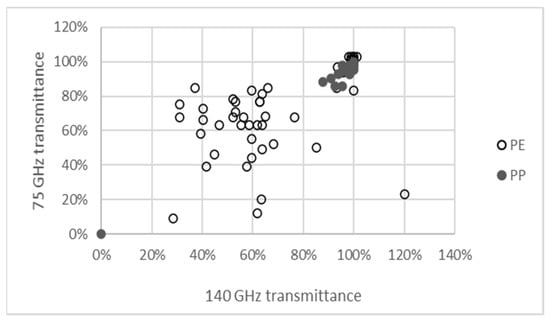

It has been confirmed that 0.12 kg (78 items) of PE and 0.1 kg (28 items) of PP are misclassified by near-infrared devices. The inclusion of these misclassified different materials diminishes the quality of recycled products made from plastic wastes. In addition to near-infrared sorting equipment, the authors propose terahertz sorting. Misclassified PE and PP were exposed to two terahertz waves and their transmittance was measured.

The results are shown in Figure 3. Since 95% of PP items are plastic films, the transmittance rate approaches 90% for both terahertz waves. Even for PP trays, the transmittance exceeds 80%. For PE items, the transmittance rate of PE films is over 90%. However, unlike PP items, PE bottle caps and trays are detected with transmission rates below 80%. If the discriminating threshold between PP and PE by terahertz waves is set below 80%, approximately 37% of PE samples (29 items) misclassified as PP by the near-infrared device can be recovered.

Figure 3.

Identification results of misclassified PP and PE samples using terahertz waves.

3.5.2. Possibility of Advanced Identification

These results have shown that plastic containers and packaging waste are composed of different materials. It was also confirmed that the existing near-infrared device was incapable of identifying some waste containers so those wastes are burned as energy. On the other hand, the limitations of the existing near-infrared sorting device can be compensated for with terahertz waves. To perform more advanced identification and classification, the authors are developing an identification technology using terahertz waves.

Terahertz waves are both linear and transmissive, and the transmittance differs depending on the material by irradiating the plastic. Terahertz waves are suitable for the identification of colored plastic containers and packaging waste because they are not affected by the color of the waste, which has been a problem in the past. In this study, previously collected information on plastic containers and packaging waste has been converted into big data, and machine learning has also been developed. It is considered that new technologies will aid in the identification and separation of plastic containers and packaging waste.

4. Potential of New Sorting Technology

4.1. What Is a Terahertz Wave?

Terahertz waves have been difficult to generate and detect, but devices and equipment in this frequency range have recently been developed for practical use, including 5G communications and automatic car driving (0.076 THz). A terahertz wave is an electromagnetic wave in the frequency range of 0.1 to 10 THz and wavelength range of 30 to 3000 μm. Since this region is located between radio waves and light waves, terahertz waves have both the transparency of a radio wave and the straightness of a light wave. Straightness enables optical designs that would be impossible for radio waves. Its energy is equivalent to room temperature, so it does not ionize materials and is safe for the human body. In a pioneering study of terahertz identification, Koch carried out a study on wood and food products in 1998 [41]. For black plastics, which are difficult to discriminate by NIR, sub-terahertz discrimination in the 300–350 GHz frequency band has been demonstrated [42]. In 2019, the industrial application of terahertz non-destructive testing, covering measurement principles, evaluation of internal structures, material identification, and coating film evaluation, was widely explained, including not only actual examples but also diagrams of the equipment [43].

The terahertz region corresponds to the energy of vibrations between molecular chains in plastics, rather than local vibrational modes with small effective masses, which are detected by conventional infrared spectroscopy. Therefore, based on the dielectric constant at the terahertz frequency, it is possible to identify plastics by material based on the unique spectrum revealed by the plastic. The transmission and reflectance of terahertz waves are based on plastic material and additives, which enables sorting based on the discrimination of materials. Terahertz waves can be used to identify colored and flame retardant-containing plastics, which are currently difficult to sort. Furthermore, this dielectric constant is sensitive to strain and degradation of plastic materials.

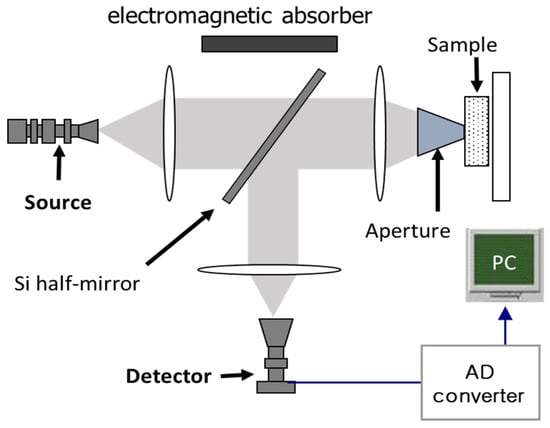

As an example, Figure 4 shows a single-frequency measurement system in which reflectance can be monitored at the same time. THz light sources are GUNN, IMPATT, and TUNNETT diodes, and the detector is a Schottky barrier diode. These solid-state devices are compact and portable, and are expected to be used as portable instruments.

Figure 4.

Terahertz measurement system with reflection configuration.

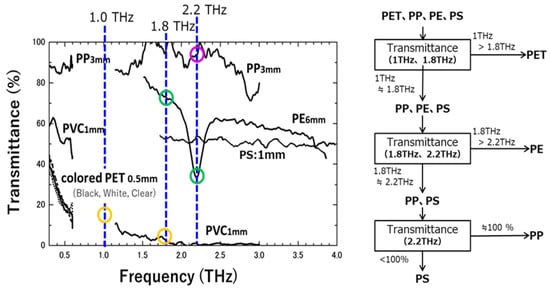

The identification algorithms for four typical container and packaging plastics (PP, PE, PS, and PET) are shown in Figure 5. The circled symbols in the figure indicate the transmittance corresponding to the plastic sample at each frequency. Olefin-based PP and PE have high terahertz transparency and low reflectance over a wide terahertz frequency range, whereas PS has low transparency and high reflectance. In contrast, PS has low transparency and high reflectance, while PET has no transmittance in the frequency range above 1 THz and its reflectance is even higher than PP, PE, and PS. PE has a characteristic absorption at 2.2 THz, which causes an increase in reflectance in that frequency range. The unique transmittance/reflectance of terahertz waves for each plastic allows for discrimination, and measurements at 1.0 THz, 1.8 THz, and 2.2 THz are effective for sorting PP, PE, PS, and PET.

Figure 5.

Identification algorithms for PP, PE, PS, and PET.

4.2. Comparison of Sorting Technologies for Plastic Wastes

Table 6 shows the material sorting technologies for waste plastics, including specific gravity sorting, near-infrared sorting, and X-ray fluorescence (XRF) identification in addition to terahertz technology. “+” means yes and good. “○” means neutral. “-” means no and bad. The specific gravity of plastics increases due to the presence of additives, so the accuracy of specific gravity sorting is poor. Near-infrared is absorbed by colors and printing inks on plastics, and reflectance is reduced, so the identification accuracy is not high. X-ray fluorescence analysis has a low intensity of irradiating X-rays for safe use on site, which reduces the accuracy of sorting, especially if metal powder adheres to the surface. In addition, electromagnetic sorting used in conventional recycling can detect magnetic materials such as iron, but it cannot sort non-magnetic materials such as aluminum vapor-deposited film used for plastic interior film and lithium-ion batteries.

Table 6.

Comparison of plastic identification methods.

Terahertz waves can identify even colored plastics, which dominate the general waste stream, and can also detect additives that are included in the material. Furthermore, they can also detect aluminum film in multi-layered plastic (laminated film), which is used to avoid freeze-drying, including for frozen foods. Thus, the feature of terahertz identification is the ability to identify multi-layered plastics that contain coloring and additives, which are a large portion of general wastes. Industrial waste plastics are often single-layered plastics that do not contain additives or contain only plastic materials and information on additives can be obtained.

5. Conclusions and Challenges for the Future

Even though Japan has been recycling plastic containers and packaging waste for more than two decades, single-use plastics emissions remain high. Although the charging for plastic bags and restrictions on single-use containers have been enacted, the consumption of plastic products has increased due to the COVID-19 pandemic. In addition, the material recycling of plastic waste, which should be emphasized, has stalled due to the high dependence on energy recovery, the diversification of plastic products, recycling costs, and technical obstacles for waste sorting. Instead of focusing solely on the convenience and functionality of consumers and designing products that are easy to recycle, avoiding the use of plastic products and packaging with composite materials or that are difficult to recycle is considered a fundamental solution, however, it is also true that altering the existing arterial and venous industrial systems simultaneously is difficult.

In other words, there is a limit to the development of recycling policies based on the EPR, and it is necessary to provide incentives to motivate producers, consumers, and recyclers to actively promote material recycling. The characteristics analysis of plastic waste from households reveals that they are usually composed of two or more plastic materials, or with aluminum-embedded materials, flame retardants, or additives. Actually, approximately 70% of the recycled materials produced at recycling facilities are single materials, and 30% of them are other complex materials. Possessing sophisticated plastic waste sorting and quality control becomes an essential issue. To produce recycled plastic materials of higher quality, it is necessary to increase the precision of identification and sorting.

This study examines and evaluates local characteristics of plastic containers and packaging waste and clarifies the limits and issues of current identification technology, and then introduces and discusses a new sorting technology using terahertz waves. Plastic sorting utilizing terahertz waves can differentiate the material of black plastic, as well as plastic with aluminum deposition, compared to the weak points of near-infrared. Additionally, terahertz waves are safer than specific gravity sorting and XRP sorting with accuracy. Plastic containers and packaging waste are diverse and intricate, and their composition varies by area. Existing near-infrared devices are insufficient to precisely and rapidly identify their materials. Thus, the development of an identification and sorting device that combines near-infrared and terahertz waves is proposed. Material recycling can be expanded by accurately analyzing the composition of plastic containers, as well as by introducing sorting equipment suitable for each local recycling facility. It is also essential to categorize and sort those materials that are unsuitable for material recycling into chemical recycling and energy recovery. Ultimately, if such a recycling process can be completed, it will be possible to build a sustainable resource circulation network that promotes a low-carbon society and a circular economy.

The results of this study are based on literature reviews, data analysis, and demonstration experiments, and it is necessary to collect and analyze huge amounts of big data and improve the accuracy of sorting in the future. Although it has been confirmed that the use of higher terahertz waves can improve the discrimination accuracy for each material, diverse shapes, stains, the presence or absence of additives, and the degree of deterioration have not been adequately tested. It will be necessary to collect, analyze, and compile big data from various recycling facilities and areas.

Author Contributions

Conceptualization, J.Y. and X.L.; methodology, J.Y. and X.L.; validation, J.Y., X.L., G.M. and T.T.; formal analysis, J.Y., X.L., G.M., T.T. and K.O.; investigation, J.Y., X.L., G.M., T.T., S.O. and K.O.; resources, J.Y. and X.L.; data curation, J.Y.; writing—original draft preparation, J.Y., X.L., G.M. and T.T.; writing—review and editing, J.Y., X.L. and S.O.; visualization, J.Y. and X.L.; supervision, J.Y.; project administration, J.Y.; funding acquisition, J.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the program for Creating Start-ups from Advanced Research and Technology (2021) by the Japan Science and Technology Agency (JST).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Ministry of Foreign Affairs of Japan Intended Nationally Determined Contributions (INDC). Greenhouse Gas Emission Reduction Target in FY2030. Tokyo, Japan. Available online: https://www.mofa.go.jp/ic/ch/page1we_000104.html (accessed on 26 July 2022).

- Government of Canada. Ocean Plastics Charter; Government of Canada, 2018. Available online: https://www.canada.ca/en/environment-climate-change/services/managing-reducing-waste/international-commitments/ocean-plastics-charter.html (accessed on 29 July 2022).

- Ministry of the Environment of Japan. Annual Report on the Environment in Japan 2021; Ministry of the Environment of Japan: Tokyo, Japan, 2021. [Google Scholar]

- Jeongsoo, Y. Challenges and Prospects for Waste Treatment after the COVID-19 Pandemic; Institute of Scientific Approaches for Fire&Disaster: Tokyo, Japan, 2021. [Google Scholar]

- Ministry of Foreign Affairs of Japan G20 Osaka Leaders’ Declaration|Documents and Materials|G20 Osaka Summit. 2019. Available online: https://www.mofa.go.jp/policy/economy/g20_summit/osaka19/en/documents/final_g20_osaka_leaders_declaration.html (accessed on 31 July 2022).

- Maga, D.; Hiebel, M.; Aryan, V. A Comparative Life Cycle Assessment of Meat Trays Made of Various Packaging Materials. Sustainability 2019, 11, 5324. [Google Scholar] [CrossRef]

- Alhazmi, H.; Almansour, F.H.; Aldhafeeri, Z. Plastic Waste Management: A Review of Existing Life Cycle Assessment Studies. Sustainability 2021, 13, 5340. [Google Scholar] [CrossRef]

- Jang, Y.C.; Lee, G.; Kwon, Y.; Lim, J.-h.; Jeong, J.-h. Recycling and management practices of plastic packaging waste towards a circular economy in South Korea. Resour. Conserv. Recycl. 2020, 158, 104798. [Google Scholar] [CrossRef]

- Meert, J.; Izzo, A.; Atkinson, J.D. Impact of plastic bag bans on retail return polyethylene film recycling contamination rates and speciation. Waste Manag. 2021, 135, 234–242. [Google Scholar] [CrossRef] [PubMed]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Beghetto, V.; Sole, R.; Buranello, C.; Al-Abkal, M.; Facchin, M. Recent Advancements in Plastic Packaging Recycling: A Mini-Review. Materials 2021, 14, 4782. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Ahmed, W.; Arshad, H. Recent trends in recycling and reusing techniques of different plastic polymers and their composite materials. Sustain. Mater. Technol. 2022, 31, e00382. [Google Scholar] [CrossRef]

- European Commission Communication from The Commission to The European Parliament, The Council, The European Economic and Social Committee and The Committee of the Regions Roadmap to a Resource Efficient Europe. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52011DC0571 (accessed on 29 July 2022).

- European Commission Communication from The Commission to The European Parliament, The Council, The European Economic and Social Committee and The Committee of The Regions Tackling The Challenges in Commodity Markets and on Raw Materials. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52011DC0025 (accessed on 29 July 2022).

- European Commission Communication from The Commission to The European Parliament, The Council, The European Economic and Social Committee and The Committee of The Regions Closing the Loop—An EU Action Plan for the Circular Economy. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52015DC0614 (accessed on 29 July 2022).

- European Commission Communication from The Commission to The European Parliament, The Council, The European Economic and Social Committee and The Committee of The Regions A European Strategy for Plastics in a Circular Economy. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1516265440535&uri=COM:2018:28:FIN (accessed on 29 July 2022).

- Aoki-Suzuki, C.; Morita, Y. The EU Plastic Strategy and Relevant Policy Trends and Initiatives for a Circular Economy EU; Material Cycles and Waste Management Research, 2018; Volume 29, No.4; pp. 286–293. Available online: https://www.jstage.jst.go.jp/article/mcwmr/29/4/29_286/_article/-char/ja/ (accessed on 29 July 2022).

- European Commission Communication from The Commission to The European Parliament, The Council, The European Economic and Social Committee and The Committee of The Regions a new Circular Economy Action Plan for a Cleaner and More Competitive Europe. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2020%3A98%3AFIN (accessed on 29 July 2022).

- Ministry of the Environment of Japan Outline of Survey on the Consumption and Disposal of Containers and Packaging Waste in 2006. Available online: https://www.env.go.jp/recycle/yoki/c_2_research/research_H18.html (accessed on 29 July 2022).

- Ministry of the Environment of Japan Outline of Survey on the Consumption and Disposal of Containers and Packaging Waste in 2021. Available online: https://www.env.go.jp/recycle/yoki/c_2_research/research_R03.html (accessed on 29 July 2022).

- Ministry of Economy, Trade and Industry. Resources Circulation Handbook 2018; Ministry of Economy, Trade and Industry: Tokyo, Japan, 2018. [Google Scholar]

- Jeongsoo, Y. Roles of Consumers, Municipalities, and Manufacturers in Revising the Containers and Packaging Recycling Law—Issues for Japan from an International Trends Perspective; Research Institute for Regional Planning and Development: Nagoya, Japan, 2006. [Google Scholar]

- Ministry of Economy, Trade and Industry. Recent Developments in the Containers and Packaging Recycling System. Available online: https://www.meti.go.jp/shingikai/sankoshin/sangyo_gijutsu/haikibutsu_recycle/yoki_wg/pdf/023_03_00.pdf (accessed on 31 July 2022).

- Yu, J.; Ohmura, M.; Shigeno, Y.; Iwasaki, R. Effects of Plastic Containers and Packaging Segregated Collection in Sendai-City: Case Study of Pilot Project; Graduate School of International Cultural Studies, Tohoku University: Sendai, Japan, 2002. [Google Scholar]

- Hirao, Y. Amendment to the Containers and Packaging Recycling Act and Actions to Prevent the Use of Plastic Bags. 2008, Volume 19. Available online: https://www.jstage.jst.go.jp/article/wmr1990/19/5/19_5_194/_article/-char/ja/ (accessed on 29 July 2022).

- Ministry of Economy, Trade and Industry. Introduction of Fee-Incurring Plastic Checkout Bags Starts in July 2020 in All Stores across Japan. Available online: https://www.meti.go.jp/english/press/2019/1227_007.html (accessed on 31 July 2022).

- Ministry of the Environment of Japan. Cabinet Decision on the Bill for the Act on Promotion of Resource Circulation for Plastics. Available online: https://www.meti.go.jp/english/press/2021/0309_001.html (accessed on 31 July 2022).

- Ministry of the Environment of Japan. What Is Containers and Packaging Recycling Law. Available online: https://www.env.go.jp/recycle/yoki/a_1_recycle/index.html#recycle_06 (accessed on 31 July 2022).

- Plastic Waste Management Institute of Japan. Statistics of Plastic Products, Plastic Waste and Resouce Recovery; Plastic Waste Management Institute of Japan: Tokyo, Japan, 2020. [Google Scholar]

- The Japan Containers and Packaging Recycling Association (JCPRA). The Containers and Packaging Recycling System in Japan. Available online: https://www.jcpra.or.jp/english/tabid/603/index.php (accessed on 30 July 2022).

- Ministry of the Environment of Japan Statistics of Collected Containers and Packaging by Municipalities in 2019. Available online: https://www.env.go.jp/press/109333.html (accessed on 30 July 2022).

- Ministry of the Environment of Japan. Results of a Survey on Costs for Separated Collection and Sorting of Containers and Packaging Waste. Available online: https://www.meti.go.jp/shingikai/sankoshin/sangyo_gijutsu/haikibutsu_recycle/yoki_wg/pdf/018_s03_00.pdf (accessed on 30 July 2022).

- Ministry of the Environment of Japan. Japan Environment Quarterly; Ministry of the Environment of Japan: Tokyo, Japan, 2019; p. 3. [Google Scholar]

- Ministry of the Environment of Japan. The Plastic Resource Circulation Act. Available online: https://www.env.go.jp/content/000050290.pdf (accessed on 30 July 2022).

- Aomori City. Population of Aomori City. Available online: http://honyaku.j-server.com/LUCAOMORIC/ns/tl.cgi/http%3A//www.city.aomori.aomori.jp/shimin/shiseijouhou/aomorishi-konnamati/toukei/jinkou-seitaisuu.html?SLANG=ja&TLANG=en&XMODE=0&XPARAM=q,&XCHARSET=utf-8&XPORG=,&XJSID=0 (accessed on 30 July 2022).

- Goshogawara City. Goshogawara City Website. Available online: https://www-city-goshogawara-lg-jp.translate.goog/index.html?_x_tr_sl=ja&_x_tr_tl=en&_x_tr_hl=ja (accessed on 30 July 2022).

- Hiranai Town Population Information. Available online: https://www-town-hiranai-aomori-jp.translate.goog/index.cfm/1,0,47,357,html?_x_tr_sl=ja&_x_tr_tl=en&_x_tr_hl=ja (accessed on 30 July 2022).

- Koriyama City. Infromation about Koriyama City. Available online: https://www.city.koriyama.lg.jp/site/foreignlanguageportal/list204-502.html (accessed on 30 July 2022).

- Aizuwakamatsu City. Overview of Aizuwakamatsu City. Available online: https://www.city.aizuwakamatsu.fukushima.jp.e.amh.hp.transer.com/docs/2007080901584/ (accessed on 30 July 2022).

- Gaku, M.; Jeongsoo, Y.; Tadao, T. Study on the Technology of Sorting the Plastic Container and Packaging Recycling. Available online: https://www.iumrs-icyram2022.org/en/prg/programList_oral.php?id=B (accessed on 22 August 2022).

- Koch, M.; Hunsche, S.; Schuacher, P.; Nuss, M.C.; Feldmann, J.; Fromm, J. THz-imaging: A new method for density mapping of wood. Wood Sci. Technol. 1998, 32, 421–427. [Google Scholar] [CrossRef]

- Küter, A.; Reible, S.; Geibig, T.; Nüßler, D.; Pohl, N. THz imaging for recycling of black plastics. Tech. Mess. 2018, 85, 191–201. [Google Scholar] [CrossRef]

- Naftaly, M.; Vieweg, N.; Deninger, A. Industrial Applications of Terahertz Sensing: State of Play. Sensors 2019, 19, 4203. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).