Biofuel Generation from Potato Peel Waste: Current State and Prospects

Abstract

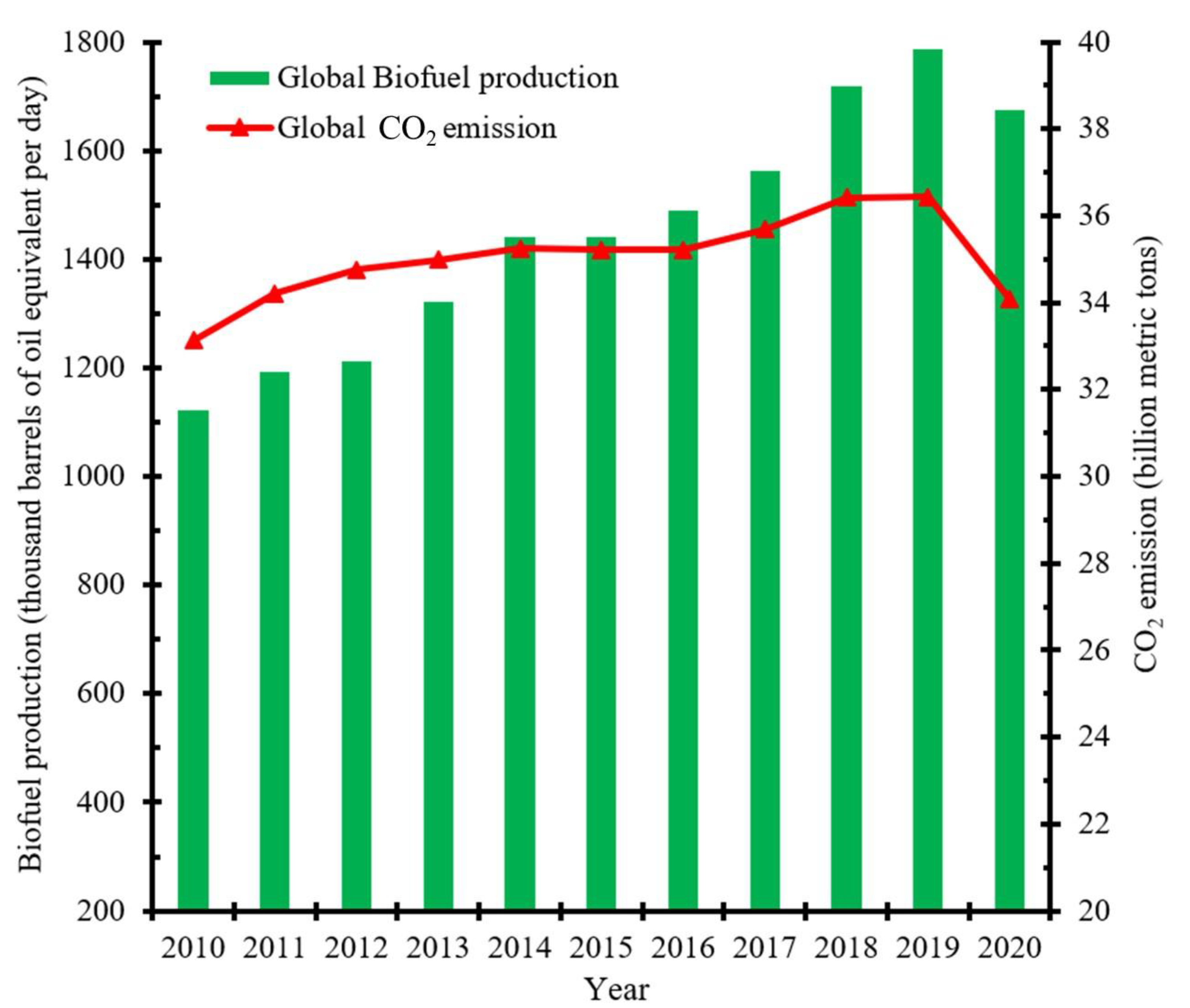

:1. Introduction

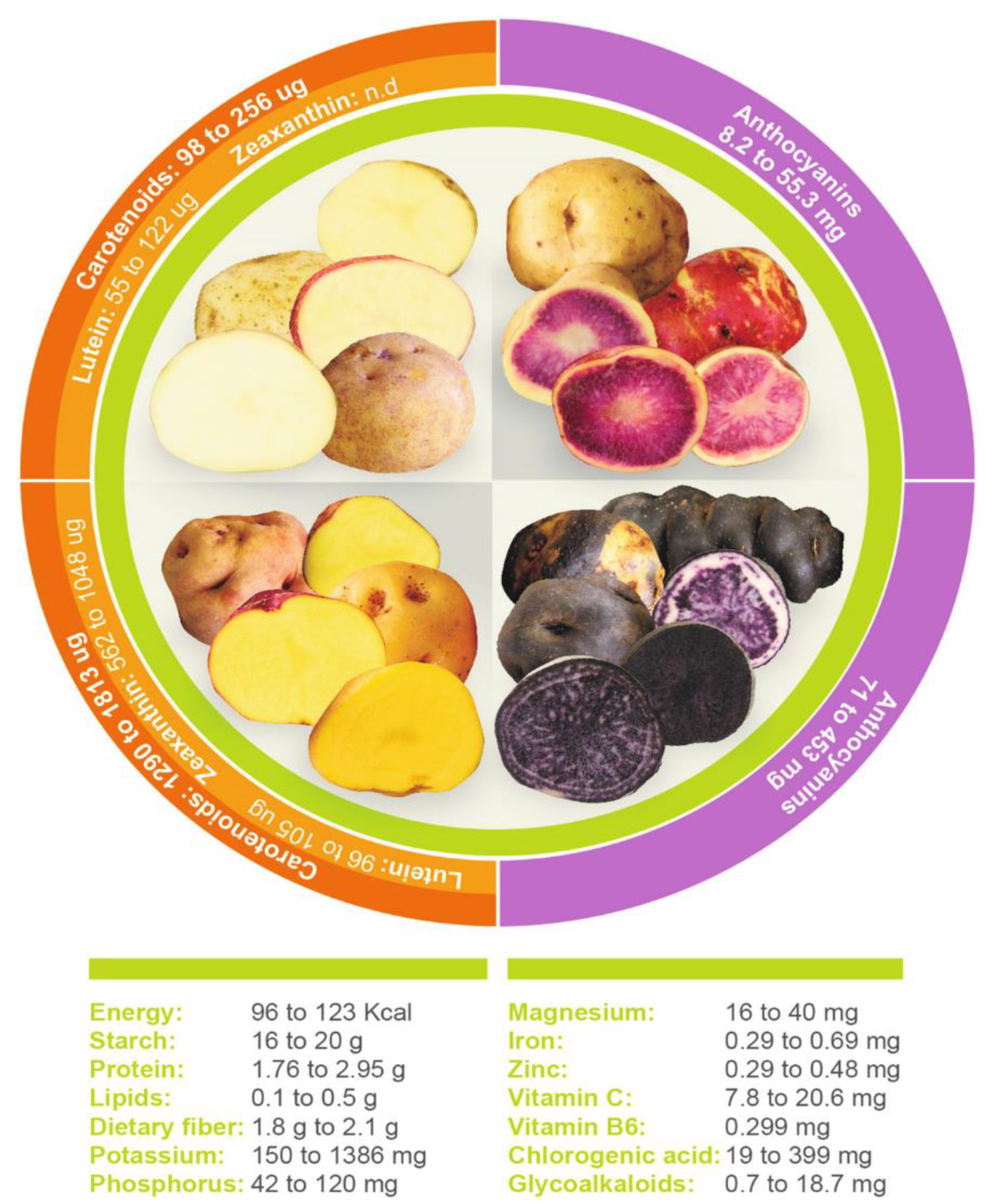

2. Potato and Potato Peel

3. Application of PPW for Biogas Production

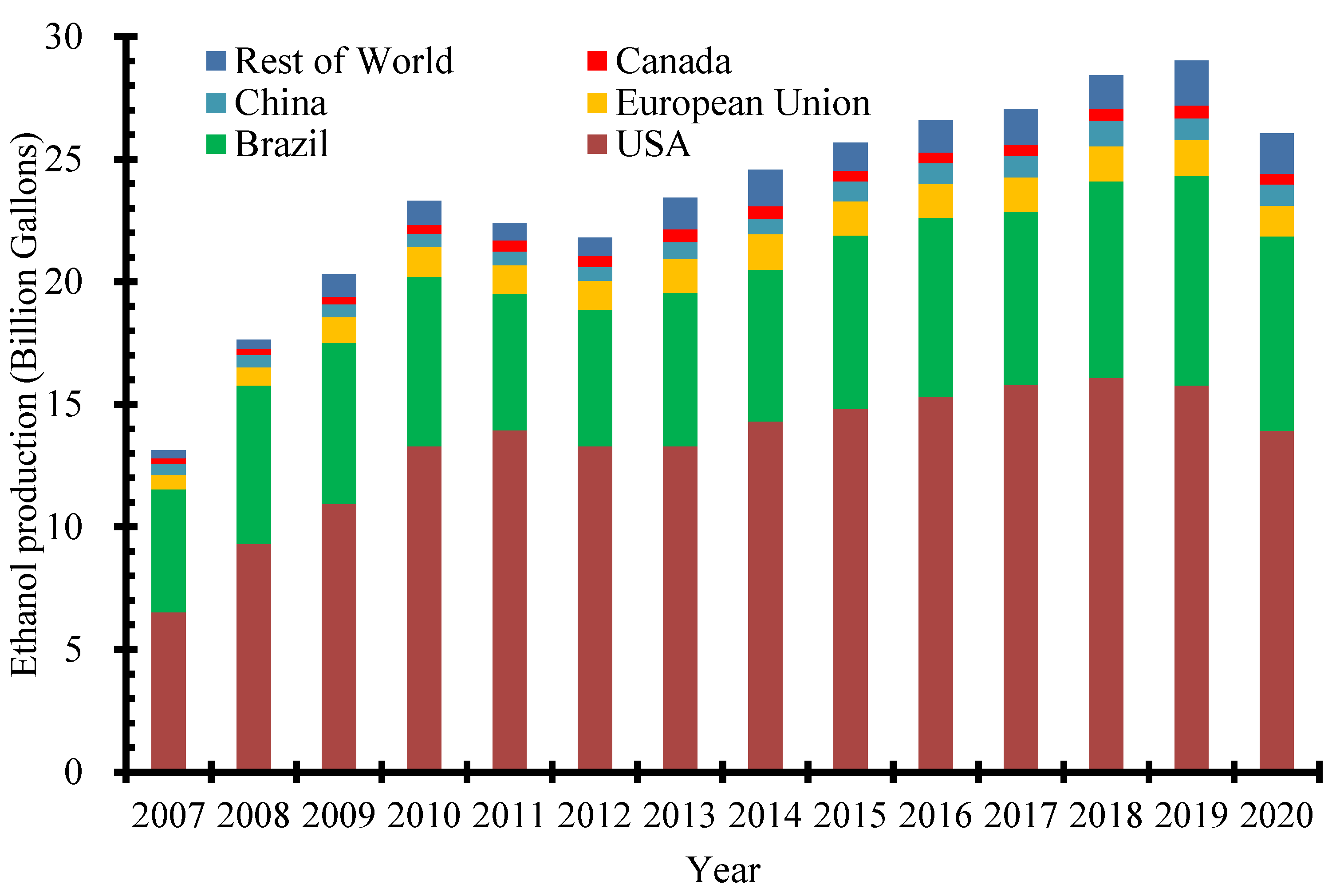

4. Application of PPW for Bioethanol Production

5. Prospect of PPW in the Biofuel Sector

5.1. Potential of PPW as Feedstock for Biohydrogen Production

5.2. Potential of PPW as Biocatalyst for Biofuel Production

5.3. Other Applications of PPW

6. Implications

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- World Population. Available online: https://www.worldometers.info/world-population/ (accessed on 29 August 2021).

- Santos, N.D.S.A.; Roso, V.R.; Malaquias, A.C.T.; Baêta, J.G.C. Internal combustion engines and biofuels: Examining why this robust combination should not be ignored for future sustainable transportation. Renew. Sustain. Energy Rev. 2021, 148, 111292. [Google Scholar] [CrossRef]

- Global Biofuels—An Overview. Available online: https://www.etipbioenergy.eu/national-profiles/global-r-d-d/global-overview (accessed on 31 August 2021).

- Datta, A.; Hossain, A.; Roy, S. An overview on biofuels and their advantages and disadvantages. Asian J. Chem. 2019, 31, 1851–1858. [Google Scholar] [CrossRef]

- Biofuel Production Worldwide from 2000 to 2020. Available online: https://www.statista.com/statistics/274163/global-biofuel-production-in-oil-equivalent/ (accessed on 31 August 2021).

- Annual Global CO2 Emissions from 2000 to 2020. Available online: https://www.statista.com/statistics/276629/global-co2-emissions/ (accessed on 31 August 2021).

- Pelemo, J.; Awogbemi, O.; Inambao, F.; Onuh, E.I. In-situ Hybridization of Waste Palm Oil: A Physicochemical, Thermal, and Spectroscopic analysis. Jordan J. Mech. Ind. 2020, 14, 393–400. [Google Scholar]

- Zhang, Z.; O’Hara, I.M.; Mundree, S.; Gao, B.; Ball, A.S.; Zhu, N.; Bai, Z.; Jin, B. Biofuels from food processing wastes. Curr. Opin. Biotechnol. 2016, 38, 97–105. [Google Scholar] [CrossRef] [PubMed]

- Awogbemi, O.; Von Kallon, D.V.; Aigbodion, V.S. Trends in the development and utilization of agricultural wastes as heterogeneous catalyst for biodiesel production. J. Energy Inst. 2021, 98, 244–258. [Google Scholar] [CrossRef]

- Awogbemi, O.; Von Kallon, D.V.; Onuh, E.I.; Aigbodion, V.S. An overview of the classification, production and utilization of biofuels for internal combustion engine applications. Energies 2021, 14, 5687. [Google Scholar] [CrossRef]

- Awogbemi, O.; Von Kallon, D.V.; Aigbodion, V.S.; Panda, S. Advances in biotechnological applications of waste cooking oil. Case Stud. Chem. Environ. Eng. 2021, 4, 100158. [Google Scholar] [CrossRef]

- Atikpo, E.; Aigbodion, V.S.; Von Kallon, D.V. CaCO3-derived from eggshell waste for improving the corrosion resistance of zinc composite coating on mild steel for biodiesel storage tank. Chem. Data Collect. 2022, 37, 100794. [Google Scholar] [CrossRef]

- Subedi, S.; Ghimire, Y.N.; Gautam, S.; Poudel, H.K.; Shrestha, J. Economics of potato (Solanum tuberosum L.) production in terai region of Nepal. Arch. Agric. Environ. Sci. 2019, 4, 57–62. [Google Scholar] [CrossRef]

- Potato Production Worldwide from 2002 to 2019 (In Million Metric Tons). Available online: https://www.statista.com/statistics/382174/global-potato-production/ (accessed on 29 August 2021).

- Top Countries in Potatoes Production. Available online: https://www.nationmaster.com/nmx/ranking/potatoes-production-fao (accessed on 29 August 2021).

- Gustavsen, G.W. Sustainability and Potato Consumption. Potato Res. 2021, 64, 571–586. [Google Scholar] [CrossRef]

- Burgos, G.; Zum Felde, T.; Andre, C.; Kubow, S. The potato and its contribution to the human diet and health. In The Potato Crop: Its Agricultural, Nutritional and Social Contribution to Humankind; Campos, H., Ortiz, O., Eds.; Springer: Cham, Switzerland, 2020; pp. 37–74. [Google Scholar] [CrossRef]

- Shepelev, I.; Galoburda, R.; Rakcejeva, T. Changes in the total phenol content in the industrial potato peel wastes during the storage. Agron Res. 2016, 14, 1442–1450. [Google Scholar]

- Fouda, T.; Darwesh, M.; Elkhodarey, M. Wearing behaviours for abrasive peeling machine under using fresh and stored potatoes. Sci. Pap. Ser.-Manag. Econ. Eng. Agric. Rural. Dev. 2020, 20, 215–219. [Google Scholar]

- Li, X. Methods of Peeling Fruits and Vegetables. In Handbook of Food Preservation, 3rd ed.; Rahman, M.S., Ed.; CRC Press: Boca Raton, FL, USA, 2020; pp. 19–24. [Google Scholar]

- Martin, A.; Osen, R.; Karbstein, H.P.; Emin, M.A. Linking Expansion Behaviour of Extruded Potato Starch/Rapeseed Press Cake Blends to Rheological and Technofunctional Properties. Polymers 2021, 13, 215. [Google Scholar] [CrossRef] [PubMed]

- Olawale, K.M.; Ojokoh, A.O. Effects of Fermentation and Extrusion on the Proximate Compositions and Organoleptic Properties of Sweet Potato (Ipomoea batatas) and Beniseed (Sesamum indicum) Blends. South Asian J. Res. Microbiol. 2019, 5, 1–12. [Google Scholar] [CrossRef]

- Joshi, A.; Sethi, S.; Arora, B.; Azizi, A.F.; Thippeswamy, B. Potato Peel Composition and Utilization. In Potato; Raigond, P., Singh, B., Dutt, S., Chakrabarti, S., Eds.; Springer: Singapore, 2020; pp. 229–245. [Google Scholar] [CrossRef]

- Singh, B.; Raigond, P.; Barwal, S.; Mehta, A.; Chopra, S.; Joshi, A.; Dutt, S. Glycoalkaloids in peels of Indian potatoes. Potato J. 2016, 43, 86–92. [Google Scholar]

- Javed, A.; Ahmad, A.; Tahir, A.; Shabbir, U.; Nouman, M.; Hameed, A. Potato peel waste-its nutraceutical, industrial and biotechnological applacations. AIMS Agric. Food 2019, 4, 807–823. [Google Scholar] [CrossRef]

- Arapoglou, D.; Varzakas, T.; Vlyssides, A.; Israilides, C. Ethanol production from potato peel waste (PPW). Waste Manag. 2010, 30, 1898–1902. [Google Scholar] [CrossRef]

- Liang, S.; McDonald, A.G.; Coats, E.R. Lactic acid production with undefined mixed culture fermentation of potato peel waste. Waste Manag. 2014, 34, 2022–2027. [Google Scholar] [CrossRef]

- Hijosa-Valsero, M.; Paniagua-García, A.I.; Díez-Antolínez, R. Industrial potato peel as a feedstock for biobutanol production. New Biotechnol. 2018, 46, 54–60. [Google Scholar] [CrossRef]

- Hossain, T.; Miah, A.B.; Mahmud, S.A.; Mahin, A.A. Enhanced bioethanol production from potato peel waste via consolidated bioprocessing with statistically optimized medium. Appl. Biochem. Biotechnol. 2018, 186, 425–442. [Google Scholar] [CrossRef]

- Wu, D. Recycle technology for potato peel waste processing: A review. Procedia Environ. Sci. 2016, 31, 103–107. [Google Scholar] [CrossRef] [Green Version]

- Sepelev, I.; Galoburda, R. Industrial potato peel waste application in food production: A review. In Proceedings of the annual 21st International Scientific Conference on Research for Rural Development, Jelgava, Latvia, 13–15 May 2015; pp. 130–136. [Google Scholar]

- Gebrechristos, H.Y.; Chen, W. Utilization of potato peel as eco-friendly products: A review. Food Sci. Nutr. 2018, 6, 1352–1356. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Arikan, E.B.; Bilgen, E.D. Production of bioplastic from potato peel waste and investigation of its biodegradability. Int. Adv. Res. Eng. J. 2019, 3, 93–97. [Google Scholar] [CrossRef]

- Chen, D.; Lawton, D.; Thompson, M.; Liu, Q. Biocomposites reinforced with cellulose nanocrystals derived from potato peel waste. Carbohydr. Polym. 2012, 90, 709–716. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Raigond, P.; Raigond, B.; Kochhar, T.; Sood, A.; Singh, B. Conversion of potato starch and peel waste to high value nanocrystals. Potato Res. 2018, 61, 341–351. [Google Scholar] [CrossRef]

- Ben Atitallah, I.; Antonopoulou, G.; Ntaikou, I.; Alexandropoulou, M.; Nasri, M.; Mechichi, T.; Lyberatos, G. On the evaluation of different saccharification schemes for enhanced bioethanol production from potato peels waste via a newly isolated yeast strain of Wickerhamomyces anomalus. Bioresour. Technol 2019, 289, 121614. [Google Scholar] [CrossRef]

- Dos Santos, R.G.; Ventura, P.; Bordado, J.C.; Mateus, M.M. Direct and efficient liquefaction of potato peel into bio-oil. Environ. Chem. Lett. 2017, 15, 453–458. [Google Scholar] [CrossRef]

- Kreidenweis, U.; Breier, J.; Herrmann, C.; Libra, J.; Prochnow, A. Greenhouse gas emissions from broiler manure treatment options are lowest in well-managed biogas production. J. Clean. Prod. 2021, 280, 124969. [Google Scholar] [CrossRef]

- Global Potential of Biogas. Available online: https://www.worldbiogasassociation.org/ (accessed on 31 August 2021).

- Production of Biogas Worldwide (Exajoules). Available online: https://www.statista.com/statistics/481791/biogas-production-worldwide/ (accessed on 31 August 2021).

- Market Analysis Report. Available online: https://www.grandviewresearch.com/industry-analysis/biogas-market/toc (accessed on 31 August 2021).

- Suntikunaporn, M.; Echaroj, S.; Rimpikul, W.; Kaewprapha, P.; Puttarak, N.; Geethalakshmi, B.; Yiarayong, P. Evaluation of agricultural wastes for biogas production. Thammasat. Int. J. Sci. Tech. 2014, 19, 1–8. [Google Scholar]

- Sheikh, A.; Sandeep, N.M. Sustainable Low-Thermal Pretreatment Enhances Substrate Solubilization and Biogas Production: A Case Study with Potato Peel Waste. Int. J. Innov. Eng. Technol. 2019, 12, 31–38. [Google Scholar]

- Liang, S.; McDonald, A.G. Anaerobic digestion of pre-fermented potato peel wastes for methane production. Waste Manag. 2015, 46, 197–200. [Google Scholar] [CrossRef] [PubMed]

- Achinas, S.; Li, Y.; Achinas, V.; Euverink, G.J.W. Biogas potential from the anaerobic digestion of potato peels: Process performance and kinetics evaluation. Energies 2019, 12, 2311. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.; Zhang, Q.; Wang, X.; Zhou, X.; Zhu, J. Effect of pH on volatile fatty acid production from anaerobic digestion of potato peel waste. Bioresour. Technol. 2020, 316, 123851. [Google Scholar] [CrossRef] [PubMed]

- Lahbab, A.; Djaafri, M.; Kalloum, S.; Benatiallah, A.; Atelge, M.R.; Atabani, A.E. Co-digestion of vegetable peel with cow dung without external inoculum for biogas production: Experimental and a new modelling test in a batch mode. Fuel 2021, 306, 121627. [Google Scholar] [CrossRef]

- Awosusi, A.; Sethunya, V.; Matambo, T. Synergistic effect of anaerobic co-digestion of South African food waste with cow manure: Role of low density-polyethylene in process modulation. Mater. Today Proc. 2021, 38, 793–803. [Google Scholar] [CrossRef]

- Sanaei-Moghadam, A.; Abbaspour-Fard, M.H.; Aghel, H.; Aghkhani, M.H.; Abedini-Torghabeh, J. Enhancement of biogas production by co-digestion of potato pulp with cow manure in a CSTR system. Appl. Biochem. Biotechnol. 2014, 173, 1858–1869. [Google Scholar] [CrossRef]

- Bożym, M.; Florczak, I.; Zdanowska, P.; Wojdalski, J.; Klimkiewicz, M. An analysis of metal concentrations in food wastes for biogas production. Renew. Energy 2015, 77, 467–472. [Google Scholar] [CrossRef]

- Global Ethanol Production by Country or Region. Available online: https://afdc.energy.gov/data/?q=ethanol (accessed on 9 September 2021).

- Ethanol Market Size. Available online: https://www.globenewswire.com/news-release/2021/01/18/2160198/0/en/Ethanol-Market-Size-Worth-Around-USD-155-6-Billion-by-2030.htm (accessed on 9 September 2021).

- Meenakshi, A.; Kumaresan, R. Ethanol production from corn, potato peel waste and its process development. Int. J. Chem. Tech. Res. 2014, 6, 2843–2853. [Google Scholar]

- Soltaninejad, A.; Jazini, M.; Karimi, K. Sustainable bioconversion of potato peel wastes into ethanol and biogas using organosolv pretreatment. Chemosphere 2022, 291, 133003. [Google Scholar] [CrossRef]

- Chintagunta, A.D.; Jacob, S.; Banerjee, R. Integrated bioethanol and biomanure production from potato waste. Waste Manage 2016, 49, 320–325. [Google Scholar] [CrossRef]

- Chohan, N.A.; Aruwajoye, G.S.; Sewsynker-Sukai, Y.; Kana, E.G. Valorisation of potato peel wastes for bioethanol production using simultaneous saccharification and fermentation: Process optimization and kinetic assessment. Renew. Energy 2020, 146, 1031–1040. [Google Scholar] [CrossRef]

- Ben Taher, I.; Fickers, P.; Chniti, S.; Hassouna, M. Optimization of enzymatic hydrolysis and fermentation conditions for improved bioethanol production from potato peel residues. Biotechnol. Prog. 2017, 33, 397–406. [Google Scholar] [CrossRef]

- Sujeeta, K.M.; Mehta, S.; Sihag, K. Optimization of conditions for bioethanol production from potato peel waste. Int. J. Chem. Stud. 2018, 6, 2021–2024. [Google Scholar]

- Chavez, A.Y.; Morales, R.; González, C.; Moya, F.V.; Yépez, A.; Viteri, F. Production of Ethanol from Two Varieties of Potato Peel Waste Through Cellulolytic and Amylolytic Enzymes. Int. J. Energy Clean Environ. 2020, 21, 41–58. [Google Scholar] [CrossRef]

- Khawla, B.J.; Sameh, M.; Imen, G.; Donyes, F.; Dhouha, G.; Raoudha, E.G.; Oumèma, N.-E. Potato peel as feedstock for bioethanol production: A comparison of acidic and enzymatic hydrolysis. Ind. Crop. Prod. 2014, 52, 144–149. [Google Scholar] [CrossRef]

- Kamboj, R.; Ms, D. Orange peel extract enhanced sugar recovery and butanol production from potato peel by Clostridium acetobutylicum. Int. J. Green Energy 2021, 18, 987–997. [Google Scholar] [CrossRef]

- Abedini, A.; Amiri, H.; Karimi, K. Efficient biobutanol production from potato peel wastes by separate and simultaneous inhibitors removal and pretreatment. Renew. Energy 2020, 160, 269–277. [Google Scholar] [CrossRef]

- Önal, E.P.; Uzun, B.B.; Pütün, A.E. Steam Pyrolysis of an industrial waste for bio-oil production. Fuel Process. Technol. 2011, 92, 879–885. [Google Scholar] [CrossRef]

- Da Silva Batista, M.; Guimarães, C.O.; Marra, L.C.; Maloncy, M.L. Bio-oil production from waste potato peel and rice hush. Rev. Eletrônica Gestão Educ. Tecnol. Ambient. 2015, 19, 220–227. [Google Scholar] [CrossRef]

- Daimary, N.; Eldiehy, K.S.H.; Boruah, P.; Deka, D.; Bora, U.; Kakati, B.K. Potato peels as a sustainable source for biochar, bio-oil and a green heterogeneous catalyst for biodiesel production. J. Environ. Chem. Eng. 2022, 10, 107108. [Google Scholar] [CrossRef]

- Liang, S.; Han, Y.; Wei, L.; McDonald, A.G. Production and characterization of bio-oil and bio-char from Pyrolysis of potato peel wastes. Biomass Convers. Biorefinery 2015, 5, 237–246. [Google Scholar] [CrossRef]

- Kim, D.; Kim, S.; Oh, S.; No, S.Y. Engine performance and emission characteristics of hydrotreated vegetable oil in light duty diesel engines. Fuel 2014, 125, 36–43. [Google Scholar] [CrossRef]

- Frantzi, D.; Zabaniotou, A. Waste-Based Intermediate Bioenergy Carriers: Syngas Production via Coupling Slow Pyrolysis with Gasification under a Circular Economy Model. Energies 2021, 14, 7366. [Google Scholar] [CrossRef]

- Global Hydrogen Demand by Sector in the Sustainable Development Scenario, 2019–2070. Available online: https://www.iea.org/data-and-statistics/charts/global-hydrogen-demand-by-sector-in-the-sustainable-development-scenario-2019-2070 (accessed on 27 October 2021).

- Hydrogen Generation Market. Available online: https://www.marketsandmarkets.com/Market-Reports/hydrogen-generation-market-494.html (accessed on 27 October 2021).

- The Future of Hydrogen. Available online: https://www.iea.org/reports/the-future-of-hydrogen (accessed on 27 October 2021).

- Cagalitan, D.F.-D.; Abundo, M. A review of biohydrogen production technology for application towards hydrogen fuel cells. Renew. Sustain. Energy Rev. 2021, 151, 111413. [Google Scholar] [CrossRef]

- Atilhan, S.; Park, S.; El-Halwagi, M.M.; Atilhan, M.; Moore, M.; Nielsen, R.B. Green hydrogen as an alternative fuel for the shipping industry. Curr. Opin. Chem. Eng. 2021, 31, 100668. [Google Scholar] [CrossRef]

- Islam, A.; Dunlop, P.S.; Hewitt, N.J.; Lenihan, R.; Brandoni, C. Bio-hydrogen production from wastewater: A comparative study of low energy intensive production processes. Clean. Technol. 2021, 3, 156–182. [Google Scholar] [CrossRef]

- Midilli, A.; Kucuk, H.; Topal, M.E.; Akbulut, U.; Dincer, I. A comprehensive review on hydrogen production from coal gasification: Challenges and Opportunities. Int. J. Hydrogen Energy 2021, 46, 25385–25412. [Google Scholar] [CrossRef]

- Navas-Anguita, Z.; García-Gusano, D.; Dufour, J.; Iribarren, D. Revisiting the role of steam methane reforming with CO2 capture and storage for long-term hydrogen production. Sci. Total Environ. 2021, 771, 145432. [Google Scholar] [CrossRef]

- Mehrpooya, M.; Raeesi, M.; Pourfayaz, F.; Delpisheh, M. Investigation of a hybrid solar thermochemical water-splitting hydrogen production cycle and coal-fueled molten carbonate fuel cell power plant. Sustain. Energy Technol. Assess. 2021, 47, 101458. [Google Scholar] [CrossRef]

- Burton, N.; Padilla, R.; Rose, A.; Habibullah, H. Increasing the efficiency of hydrogen production from solar powered water electrolysis. Renew. Sustain. Energy Rev. 2021, 135, 110255. [Google Scholar] [CrossRef]

- Sánchez-Bastardo, N.; Schlögl, R.; Ruland, H. Methane Pyrolysis for zero-emission hydrogen production: A potential bridge technology from fossil fuels to a renewable and sustainable hydrogen economy. Ind. Eng. Chem. Res. 2021, 60, 11855–11881. [Google Scholar] [CrossRef]

- Sinha, P.; Pandey, A. Biohydrogen production from various feedstocks by Bacillus firmus NMBL-03. Int. J. Hydrogen Energy 2014, 39, 7518–7525. [Google Scholar] [CrossRef]

- Zhang, T.; Jiang, D.; Zhang, H.; Jing, Y.; Tahir, N.; Zhang, Y.; Zhang, Q. Comparative study on bio-hydrogen production from corn stover: Photo-fermentation, dark-fermentation and dark-photo co-fermentation. Int. J. Hydrogen Energy 2020, 45, 3807–3814. [Google Scholar] [CrossRef]

- Rezaeitavabe, F.; Saadat, S.; Talebbeydokhti, N.; Sartaj, M.; Tabatabaei, M. Enhancing bio-hydrogen production from food waste in single-stage hybrid dark-photo fermentation by addition of two waste materials (exhausted resin and biochar). Biomass Bioenergy 2020, 143, 105846. [Google Scholar] [CrossRef]

- Srivastava, N.; Alhazmi, A.; Mohammad, A.; Haque, S.; Srivastava, M.; Pal, D.B.; Singh, R.; Mishra, P.; Vo, D.V.N.; Yoon, T.; et al. Biohydrogen production via integrated sequential fermentation using magnetite nanoparticles treated crude enzyme to hydrolyze sugarcane bagasse. Int. J. Hydrogen Energy 2021, in press. [Google Scholar] [CrossRef]

- Sivaramakrishnan, R.; Ramprakash, B.; Ramadoss, G.; Suresh, S.; Pugazhendhi, A.; Incharoensakdi, A. High potential of Rhizopus treated rice bran waste for the nutrient-free anaerobic fermentative biohydrogen production. Bioresour. Technol. 2021, 319, 124193. [Google Scholar] [CrossRef]

- Reaño, R.L. Assessment of environmental impact and energy performance of rice husk utilization in various biohydrogen production pathways. Bioresour. Technol. 2020, 299, 122590. [Google Scholar] [CrossRef]

- Marone, A.; Izzo, G.; Mentuccia, L.; Massini, G.; Paganin, P.; Rosa, S.; Varrone, C.; Signorini, A. Vegetable waste as substrate and source of suitable microflora for bio-hydrogen production. Renew. Energy 2014, 68, 6–13. [Google Scholar] [CrossRef]

- Mars, A.E.; Veuskens, T.; Budde, M.A.W.; van Doeveren, P.F.N.M.; Lips, S.J.; Bakker, R.R.; de Vrije, T.; Claassen, P.A.M. Biohydrogen production from untreated and hydrolyzed potato steam peels by the extreme thermophiles Caldicellulosiruptor saccharolyticus and Thermotoga neapolitana. Int. J. Hydrogen Energy 2010, 35, 7730–7737. [Google Scholar] [CrossRef]

- Ferreira, A.F.; Ribau, J.P.; Silva, C.M. Energy consumption and CO2 emissions of potato peel and sugarcane biohydrogen production pathways, applied to Portuguese road transportation. Int. J. Hydrogen Energy 2011, 36, 13547–13558. [Google Scholar] [CrossRef]

- Athar, M.; Zaidi, S. A review of the feedstocks, catalysts, and intensification techniques for sustainable biodiesel production. J. Environ. Chem. Eng. 2020, 8, 104523. [Google Scholar] [CrossRef]

- Alagumalai, A.; Mahian, O.; Hollmann, F.; Zhang, W. Environmentally benign solid catalysts for sustainable biodiesel production: A critical review. Sci. Total Environ. 2021, 768, 144856. [Google Scholar] [CrossRef] [PubMed]

- Okolie, J.A.; Escobar, J.I.; Umenweke, G.; Khanday, W.; Okoye, P.U. Continuous biodiesel production: A review of advances in catalysis, microfluidic and cavitation reactors. Fuel 2022, 307, 121821. [Google Scholar] [CrossRef]

- Kumar, V.; Mohapatra, T.; Dharmadhikari, S.; Ghosh, P. A review paper on heterogeneous Fenton catalyst: Types of preparation, modification techniques, factors affecting the synthesis, characterization, and application in the wastewater treatment. Bull. Chem. React Eng. Catal 2020, 15, 1–34. [Google Scholar] [CrossRef] [Green Version]

- Balajii, M.; Niju, S. Biochar-derived heterogeneous catalysts for biodiesel production. Environ. Chem. Lett. 2019, 17, 1447–1469. [Google Scholar] [CrossRef]

- Sree, J.V.; Chowdary, B.A.; Kumar, K.S.; Anbazhagan, M.P.; Subramanian, S. Optimization of the biodiesel production from waste cooking oil using homogeneous catalyst and heterogeneous catalysts. Mater. Today Proc. 2020, 46, 4900–4908. [Google Scholar] [CrossRef]

- Rajkumari, K.; Rokhum, L. A sustainable protocol for production of biodiesel by transesterification of soybean oil using banana trunk ash as a heterogeneous catalyst. Biomass Convers. Biorefinery 2020, 10, 839–848. [Google Scholar] [CrossRef]

- Hussein, M.F.; Abo El Naga, A.O.; El Saied, M.; AbuBaker, M.M.; Shaban, S.A.; El Kady, F.Y. Potato peel waste-derived carbon-based solid acid for the esterification of oleic acid to biodiesel. Environ. Technol. Innov. 2021, 21, 101355. [Google Scholar] [CrossRef]

- Kyzas, G.Z.; Deliyanni, E.A.; Matis, K.A. Activated carbons produced by Pyrolysis of waste potato peels: Cobalt ions removal by adsorption. Colloids Surf. A Physicochem. Eng. Asp. 2016, 490, 74–83. [Google Scholar] [CrossRef]

- Moreno-Piraján, J.C.; Giraldo, L. Activated carbon obtained by Pyrolysis of potato peel for the removal of heavy metal copper (II) from aqueous solutions. J. Anal. Appl. Pyrolysis 2011, 90, 42–47. [Google Scholar] [CrossRef]

- El-Azazy, M.; El-Shafie, A.S.; Issa, A.A.; Al-Sulaiti, M.; Al-Yafie, J.; Shomar, B.; Al-Saad, K. Potato peels as an adsorbent for heavy metals from aqueous solutions: Eco-structuring of a green adsorbent operating Plackett–Burman design. J. Chem. 2019, 2019, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Quisperima, A.; Pérez, S.; Flórez, E.; Acelas, N. Valorization of potato peels and eggshells wastes: Ca-biocomposite to remove and recover phosphorus from domestic wastewater. Bioresour. Technol. 2022, 343, 126106. [Google Scholar] [CrossRef] [PubMed]

- El-Nahas, S.; Salman, H.M.; Seleeme, W.A. Aluminum building scrap wire, take-out food container, potato peels and bagasse as valueless waste materials for nitrate removal from water supplies. Chem. Afr. 2019, 2, 143–162. [Google Scholar] [CrossRef] [Green Version]

- Maleki, A.; Daraei, H.; Khodaei, F.; Aghdam, K.B.; Faez, E. Direct blue 71 dye removal probing by potato peel-based sorbent: Applications of artificial intelligent systems. Desalin. Water Treat. 2016, 57, 12281–12286. [Google Scholar] [CrossRef]

- Kyzas, G.Z.; Deliyanni, E.A. Modified activated carbons from potato peels as green environmental-friendly adsorbents for the treatment of pharmaceutical effluents. Chem. Eng. Res. Des. 2015, 97, 135–144. [Google Scholar] [CrossRef]

- Wesley, R.J.; Durairaj, A.; Ramanathan, S.; Obadiah, A.; Justinabraham, R.; Lv, X.; Vasanthkumar, S. Potato peels biochar composite with copper phthalocyanine for energy storage application. Diam. Relat. Mater. 2020, 115, 108360. [Google Scholar] [CrossRef]

- Durairaj, A.; Liu, J.; Lv, X.; Vasanthkumar, S.; Sakthivel, T. Facile synthesis of waste-derived carbon/MoS2 composite for energy storage and water purification applications. Biomass Convers. Biorefin. 2021, 1–12. [Google Scholar] [CrossRef]

- Khalafallah, D.; Quan, X.; Ouyang, C.; Zhi, M.; Hong, Z. Heteroatoms doped porous carbon derived from waste potato peel for supercapacitors. Renew. Energy 2021, 170, 60–71. [Google Scholar] [CrossRef]

- Andreas Arie, A.; Lenora, S.; Kristianto, H.; Frida Susanti, R.; Kee Lee, J. Potato Peel Based Carbon–Sulfur Composite as Cathode Materials for Lithium Sulfur Battery. J. Nanosci. Nanotechnol. 2021, 21, 6243–6247. [Google Scholar] [CrossRef] [PubMed]

- Calcio Gaudino, E.; Colletti, A.; Grillo, G.; Tabasso, S.; Cravotto, G. Emerging processing technologies for the recovery of valuable bioactive compounds from potato peels. Foods 2020, 9, 1598. [Google Scholar] [CrossRef]

- Elkhalifa, S.; Al-Ansari, T.; Mackey, H.R.; McKay, G. Food waste to biochars through pyrolysis: A review. Resour. Conserv. Recycl. 2019, 144, 310–320. [Google Scholar] [CrossRef]

- Panahi, H.K.S.; Dehhaghi, M.; Guillemin, G.J.; Gupta, V.K.; Lam, S.S.; Aghbashlo, M.; Tabatabaei, M. Bioethanol production from food wastes rich in carbohydrates. Curr. Opin. Food Sci. 2022, 43, 71–81. [Google Scholar] [CrossRef]

- Karmee, S.K. Liquid biofuels from food waste: Current trends, prospect and limitation. Renew. Sustain. Energy Rev. 2016, 53, 945–953. [Google Scholar] [CrossRef]

- Neto, J.G.; Ozorio, L.V.; de Abreu, T.C.; Dos Santos, B.F.; Pradelle, F. Modeling of biogas production from food, fruits and vegetables wastes using artificial neural network (ANN). Fuel 2021, 285, 119081. [Google Scholar] [CrossRef]

| Parameter | Composition | ||||

|---|---|---|---|---|---|

| Dry Weight (g per 100 g) [25] | Dry Weight (%) [26] | Dry Weight (%) [27] | Dry Weight (%) [28] | Dry Weight (%) [29] | |

| Water | 83.3–85.1 | 85.06 | ns | 5.26 | 77.3 |

| 1.2–2.3 | 8 | 17.1 ± 0.3 | 10.73 | 13.125 | |

| Total lipids | 0.1–0.4 | ns | 1.2 ± 0.0 | ns | ns |

| Total carbohydrate | 8.7–12.4 | 68.7 | 63.2 ± 4.2 | 43.2 | 70.3 |

| Starch | 7.8 | 52.14 | 34.3.2 ± 2.7 | 23.01 | ns |

| Total dietary fiber | 2.5 | ns | ns | ns | ns |

| Total soluble sugar | ns | 1 | ns | ns | ns |

| Ash | 0.9–1.6 | 6.34 | 9.6 ± 0.1 | 7.45 | 5.9 |

| Total phenolic content | 1.02–2.92 | ns | ns | 2.5 mg/g | ns |

| Total flavonoids | 0.51–0.96 | ns | ns | ns | ns |

| Fat | ns | 2.6 | ns | 2.45 | ns |

| Nitrogen | ns | 1.3 | ns | ns | 2.1 |

| Lignin | ns | ns | ns | 32.88 | ns |

| Reducing sugar | ns | 0.16 | ns | ns | 0.78 |

| Acid soluble | ns | ns | 6.2 ± 0.2 | ns | ns |

| Acid insoluble | ns | ns | 4.1 ± 0.0 | ns | ns |

| Type of Digester | CH4 Content | Yield | Remark | Ref. |

|---|---|---|---|---|

| 20 L plastic floating drum tank | 40–50% | 3500 mL/d | PPW is a viable feedstock for AD | [42] |

| ns | 65% | High methane yield | Addition of PPW led to a 112% increase in biomethane yield | [43] |

| 1 L glass batch reactor | 60–70% | 273 L/kg VS | PPW exhibited good performance and biogas yield | [44] |

| 500 mL glass bottles | 56% | 383.7 mL/g VSadded | Good biogas yield | [45] |

| 500 mL glass bottles | 57.5% | 453.2 mL/g VSadded | Grinding of PPW feedstock led to improved biogas yield and CH4 concentration | [45] |

| 500 mL glass bottles | 58.3% | 485.4 mL/g VSadded | Acid hydrolysis pretreatment of PPW led to improved biogas yield and CH4 concentration | [45] |

| 5 L reactor | ns | 41.9 g COD/L and 632.2 mg COD/g VSfed | PPW substrate maintained at pH of 7.0 achieved highest VFA | [46] |

| 1 L glass bottle | ns | 170 mL (CH4)/g VS | Improved biogas production | [47] |

| 600 L polyethylene | 66% | 1.6 m3 | Co-digestion improved the biogas yield and CH4 concentration | [48] |

| 5 L double-wall glass cylinder | ns | 375 LN (kg VS)−1 | Addition of cow dung substrate improve the efficiency of biogas production | [49] |

| Production Techniques | Enzymes | Production Rate (g/L) | Yield (%) | Remark | Ref. |

|---|---|---|---|---|---|

| Fermentation | Saccharomyces cerevisae var. bayanus | 7.6 | 91.6 | Efficient conversion of PPW to ethanol | [26] |

| Autohydrolysis and enzymatic hydrolysis | Clostridium | 40 | ns | Production of biobutanol at industrial scale | [28] |

| Fermentation | Saccharomyces cerevisae | 48.76 | 80.62 | Low-cost ethanol production | [55] |

| Saccharification and fermentation | Saccharomyces cerevisiae BY4743 | 22.54 | ns | Effective bioethanol production | [56] |

| Enzymatic hydrolysis and fermentation | Saccharomyces cerevisiae | 30 | ns | Improved yield of bioethanol | [57] |

| Enzymatic hydrolysis, saccharification and fermentation | Saccharomyces cerevisiae | ns | 5.8 | Low-cost bioethanolProduction at moderate conditions | [58] |

| Enzymatic hydrolysis and fermentation | Alpha amylase and cellulase | 11.9 | ns | Bioethanol production from varieties of PPW | [59] |

| Fermentation | Termamyl and amyloglucosidase | 21 | ns | Effective production of bioethanol from PPW | [60] |

| Fermentation | Clostridium acetobutylicum MTCC 11274 | ns | 96 | Improved yield of biobutanol | [61] |

| Fermentation | Clostridium acetobutylicum | 24.8 | 75 | Low-cost and eco-friendly production of biobutanol | [62] |

| Pyrolysis | ns | ns | 47.5 | Effective biooil production | [63] |

| Pyrolysis | ns | ns | 29.18 | Novel conversion of PPW to biofuel | [64] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Awogbemi, O.; Kallon, D.V.V.; Owoputi, A.O. Biofuel Generation from Potato Peel Waste: Current State and Prospects. Recycling 2022, 7, 23. https://doi.org/10.3390/recycling7020023

Awogbemi O, Kallon DVV, Owoputi AO. Biofuel Generation from Potato Peel Waste: Current State and Prospects. Recycling. 2022; 7(2):23. https://doi.org/10.3390/recycling7020023

Chicago/Turabian StyleAwogbemi, Omojola, Daramy Vandi Von Kallon, and Adefemi O. Owoputi. 2022. "Biofuel Generation from Potato Peel Waste: Current State and Prospects" Recycling 7, no. 2: 23. https://doi.org/10.3390/recycling7020023

APA StyleAwogbemi, O., Kallon, D. V. V., & Owoputi, A. O. (2022). Biofuel Generation from Potato Peel Waste: Current State and Prospects. Recycling, 7(2), 23. https://doi.org/10.3390/recycling7020023