Abstract

Transforming the plastic industry toward producing more sustainable alternatives than conventional plastics, as an essential enabler of the bio-based circular economy (CE), requires reinforcing initiatives to drive solutions from the lab to the market. In this regard, startups and ideation and innovation events can potentially play significant roles in consolidating efforts and investments by academia and industry to foster bio-based and biodegradable plastic-related developments. This study aimed to present the current trends and challenges of bioplastics and bio-based materials as sustainable alternatives for plastics. On this basis, having conducted a systematic literature review, the seminal research themes of the bio-based materials and bioplastics literature were unfolded and discussed. Then, the most recent developments of bio-based sustainable products in Ukraine, as alternatives to petroleum-based plastics, that have gained publicity through local startup programs and hackathons were presented. The findings shed light on the potential of the bio-based sector to facilitate the CE transition through (i) rendering innovative solutions most of which have been less noticed in academia before; (ii) enhancing academic debate and bridging the gap between developers, scholars, and practitioners within the plastic industry toward creating circularity across the supply chain; (iii) identifying the main challenges and future perspectives for further investigations in the future.

1. Introduction

The worldwide plastics production in 2020 has increased by 36% since 2010 [1], leading to the generation of a massive amount of plastic waste. The global environmental pollution of micro- and macroplastic [2] demonstrates extensive usage of fossil-based plastics [3] and the inability of even the most advanced waste management systems to deal with a wide range of plastic products at their End of Life (EoL) [2]. The increasing concerns about global pollution and its negative consequences on the planet’s ecosystem are initiating the active development of bio-based plastics [4] and bio-based materials and products, as alternatives to fossil-based plastics. In the same vein, the production of biodegradable plastics obtained from renewable resources [5], including the waste of other production chains, such as the food industry, agriculture, and forestry [6], have gained momentum. Bio-based plastics (or bio-plastics) have been recognized by the European Union (EU) as a promising alternative to conventional plastics with regard to finite fossil resources, a healthy environment, and climate change [7]. The European plastic strategy aims to bring the plastic-related legislation in line with the circular economy (CE) action plan [8] and hence to launch principal legal initiatives across EU countries. Driven by a low-carbon CE [9], bioplastics production is estimated to archive a 40% plastics market share by 2030 [4].

In recent years, biodegradable and bio-based plastics production and applications have been increasingly investigated by research communities in the material science, chemical engineering, and environmental science domains. On this basis, the main focus of research has been on technological aspects [10], environmental effects [11], and sustainability issues [12,13]. Nevertheless, the research in this area toward enabling a CE model is still in its infancy stage.

Hence, it is crucial to understand how bio-based products and bioplastics initiatives, as potential alternatives to conventional plastics, perform in terms of implementation from the lab to the market and contribution to the bio-based CE (or circular bioeconomy). Furthermore, those solutions that have not received discussion in academia but gained publicity through local startup programs and hackathons can be shown worldwide to enhance research and development (R&D) through collaboration between developers and scientists across countries. While the issues of biodegradable and bio-based plastics and products are vigorously discussed in academia, there is a need for presenting the overview of the state-of-the-art of bio-based products and bioplastic solutions as potential alternatives to conventional plastics originating in startups. Moreover, the contribution of these solutions to the bio-based CE and their improvement stage in terms of moving from lab to the market should be analyzed. In this regard, the present study aims to (i) provide a comprehensive overview of the bio-based materials and bioplastic research themes at a global level in academia and (ii) present the most recent and progressive solutions in the field of bio-based products and bioplastics at a country level, focusing on Ukraine in Eastern Europe, as the second-largest country by area in Europe.

The remainder of this paper is organized as follows: The search protocol adopted to collect data and conduct the systematic review analysis is explained in Section 2. Section 3 presents the results in two subsections. Section 3.1 provides the current developments and challenges of bio-based plastics in a CE. Bioplastics and bio-based products initiatives and advancements to replace traditional plastics with a special focus on Ukraine are provided and discussed in Section 3.2. Challenges and future perspectives of bio-based products and bioplastics production and utilization are rendered in Section 4. Finally, Section 5 concludes the main remarks of the research.

2. Data Source and Methodology

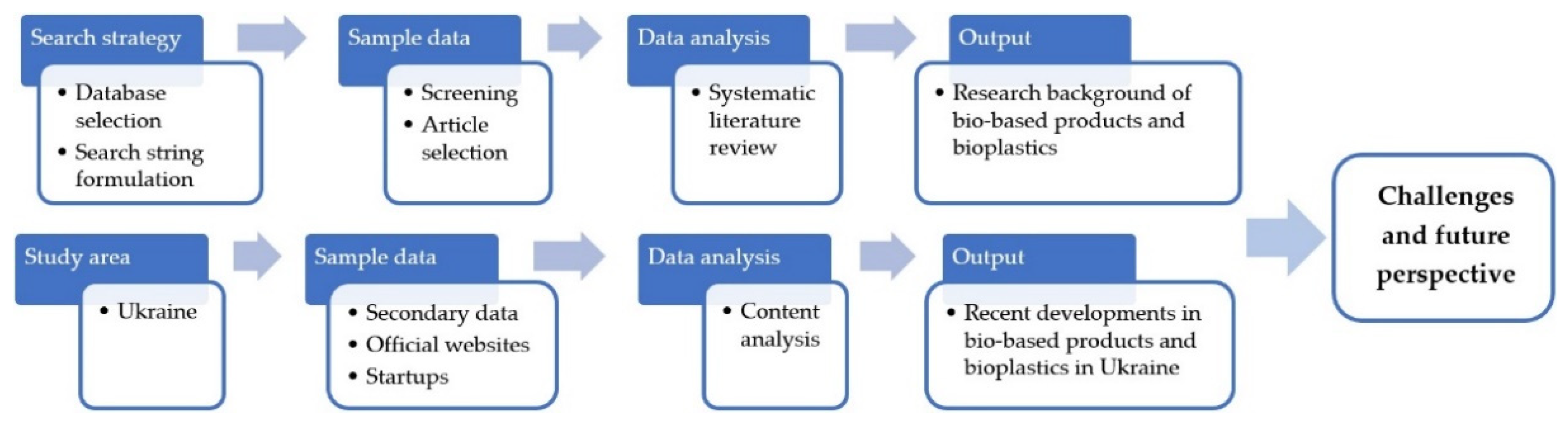

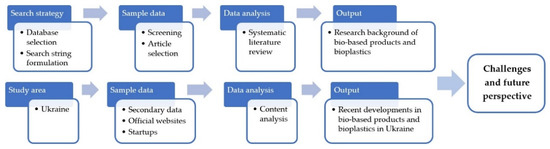

An analytical method, combining a systematic literature review and content analysis, was employed in this study. First, a systematic literature review based on the PRISMA statement [14] was carried out to provide a state-of-the-art of bioplastics and bio-based materials applications, production, and utilization worldwide. Then, content analysis was conducted on the recent advancements in the field of bio-based products and materials and relevant initiatives in Ukraine. The overall research framework is illustrated in Figure 1.

Figure 1.

Research framework.

To ensure the reliability of the review process, a well-structured search protocol to sufficiently collect relevant data from the target literature [15,16] was adopted. In this regard, the Scopus database was selected as the main database for conducting the analysis. In the next step, different combinations of the keywords—namely, “bioplastics”, “bio-based product”, “bio-based material”, “circular economy”, and “innovation”—were investigated within the literature, to build an effective search string for searching articles in Scopus. As a result, the following two search strings using OR/AND Boolean operators were designed to catch data:

(i) Searching “bioplastic*” OR “bio-plastic*” OR “bio plastic*” OR “bio-based plastic*” OR “bio-based material” OR “biomaterial” OR “bio-based product” (search within article title), AND “circular economy ‘OR’ circularity” (in the title, abstract, and keywords);

(ii) Searching “bioplastic*” OR “bio-plastic*” OR “bio plastic*” OR “bio-based plastic*” OR “bio-based material” OR “biomaterial” OR “bio-based product” (search in the title) AND “R&D” OR “innovat*” OR “startup*” OR “accelerator*” (in the title, abstract, keywords).

The results were limited to only peer-reviewed journal articles, and other types of documents were excluded from the sample. The initial run of the two designed search strings returned 67 and 244 results without a time limit, respectively. Having removed the duplicates, a careful screening of the remaining articles was performed to exclude irrelevant documents to the main focus of the study from the sample, leading to selecting 55 articles as the final sample for further analysis in the present study.

3. Results and Discussion

The findings are presented and discussed in the following three subsections. Section 3.1 provides an inclusive review of the main research background within the bioplastics and bio-based materials domain in a CE. Section 3.2 presents main bio-based products developments toward a CE in Ukraine.

3.1. Research Background in Bioplastics and Bio-Based Products toward a CE

3.1.1. Biodegradation of Bioplastics through Aerobic and Anaerobic Methods

Underutilized or low-value biomass, water-soluble biopolymers, biocolloids, polymerizable monomers, and nutrients are used as feasible building blocks for biotechnological conversion into bioplastics [17]. The biodegradable properties of bioplastics, as a potential solution to address the global concern regarding plastic pollution, can enable the capture of food waste through anaerobic digestion as an energy-positive waste treatment strategy toward an integrated food–energy–water–waste nexus in a CE [18]. Bioplastics can be biodegraded through three main biodegradation mechanisms, including microbial, aerobic, and anaerobic degradation [19]. Cisneros-López et al. [6] provided insight on biodegradation of bioplastics under different environmental conditions as a principal determinant of biodegradability of biopolymers in addition to their physical and chemical structures. The biodegradability of poly(3-hydroxybutyrate) (PHB) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV), as the common members of polyhydroxyalkanoates (PHAs), and also poly(butylene succinate) (PBS), poly(butylene adipate-co-terephthalate) (PBAT), poly(ε-caprolactone) (PCL), polylactic acid (PLA), and PLA–PCL has been compared by García-Depraect et al. [20] under aerobic and anaerobic aqueous conditions based on the assessment of biodegradation kinetics, extent, carbon fate, and particle size influence. The study of Ruggero et al. [21] outlined different methodologies to assess the biodegradation of bioplastics during aerobic composting and anaerobic digestion. They highlighted that the process conditions of the experimental setup, such as test duration, waste composition, and temperature, often vary in different studies and in accordance with the international standard followed for the test, including, but not limited, to ISO 20200, ISO 14853, EN 13432, ASTM D5338, and ASTM D5526-94D.

3.1.2. Biowaste as a Raw Material for the Production of Bioplastics

In recent years, a significant part of the contribution to the growth of global bioplastic production belongs to innovative biopolymers, such as PLA and PHAs [3]. However, industrial expenses to produce PHA are estimated to be 5–10 times more than petroleum-derived polymers [3]. Regarding raw materials for bioplastics production, a major part comes from agricultural crops [22]. At the same time, the food and agriculture industries generate significant amounts of organic waste, which could be used for bioplastics production. According to Scarpi et al. [23], bio-based plastics derived from waste, as a recent innovation in the field, could contribute to managing this organic waste more sustainably and more in line with CE strategies. In a similar line, Morone et al. [24] highlighted that biowaste has emerged as a resource with a significant potential to be employed as a raw material for the production of chemicals, materials, and fuels given its abundant volumes generated globally. As a step toward more sustainable packaging solutions, Liu et al. [25] proposed a waste-free, green, and sustainable method of synthesizing hydrophobic bioplastic films from tea waste, which uses only spent tea leaves, water, and citric acid. In a study on the potential development of the bioplastics technological niche that uses biowaste, Morone et al. [24] explored possible factors that may hinder the full development of this niche. Based on an extensive literature review, Jogi and Bhat [3] provided an overview of bioplastics, including production methods and possibilities of industrial food waste valorization for bioplastic production.

The microalgae cultivation methods, microalgal bio-based plastics production technologies, and possible applications were summarized and discussed in the studies conducted by Park and Lee [26], Chong et al. [19], and Cinar et al. [27]. According to Park and Lee [26], microalgae have a very distinctive growth yield, compared with typical lignocellulosic biomass; hence, they can be considered as an attractive raw material source for bioplastics production. Chong et al. [19] argued that microalgae are an effective dual strategy for bio-valorization of food processing wastewater and food waste hydrolysate, which contribute to microalgae cultivation as value-added by-products, mainly carbohydrates, lipids, and proteins to the advantageous of bio-based plastics production. In addition, incorporating microalgae in food processing wastewater significantly reduces wastewater treatment costs, compared with the traditional approach and provides additional profitable by-products such as low-cost fertilizer and bioplastics, since protein, starch, lipids, and PHAs, which are the main ingredients of bioplastic, can be obtained from various microalgae [19].

3.1.3. Bioplastics from the CE Perspective

Developing new value chains and innovative bio-based products through valorizing biomass components supports transitioning from traditional production technologies to the concept of biorefineries [28] and the bio-based CE or circular bioeconomy [29,30]. The emerging circular bioeconomy with a special focus on bio-based waste valorization to close the loops of product lifecycle has gained momentum [29]. In this regard, the circular bioeconomy leads to considerable changes in various industries, and the plastics production sector is no exception. As a part of a CE, bioplastics, which are typically made of bio-based polymers, stand to contribute to more sustainable commercial plastic life cycles by using renewable or recycled raw materials [31]. Biodegradable and bio-based plastics, with their properties, offer alternative waste management solutions to make the modern economy more circular. From a CE perspective, the increasing concerns regarding waste disposal and high cost of pure substrates in PHA and bioplastics production have led to the high need for (i) upgrading the waste streams from different industries to produce appropriate feedstock for PHA production and (ii) recycling and efficient upstream and downstream processes of various waste streams to maintain the circularity in the entire process [32]. Bioplastics provide the benefit of diverting biodegradable waste from landfilling or incineration to “greener” streams, such as anaerobic digestion and composting, contributing to the transition toward CE [33]. Briassoulis et al. [34] argued that optimal alternative end-of-use (EoU) and EoL routes are defined for the bio-based products in such a way that they are turned into valuable resources in line with the CE. They provided an insight into bio-based plastics in the context of the CE and gave an overview of its status and potential future development. The assessment of the potential environmental impacts of different EoL options and resource circulation of bio-based plastics with the use of lifecycle assessment (LCA) was substantially studied by Spierling et al. [35]. However, although the production of such bioplastics has advanced on the scale, the EoL technologies to promote circularity are lagging behind. While composting and biogas plants are the only managed EoL options today, advanced biotechnological recycling technologies for biodegradable bioplastics are still in embryonic stages [2]. The bio-based products market is currently limited resulting in relatively small quantities of waste streams, viewed as contaminants of conventional waste streams. García-Depraect et al. [2] provided a critical evaluation of terminology and international standards to quantify polymer biodegradability together with the latest biotechnological recycling strategies, including the use of different pretreatments for bioplastic waste. Additionally, Prieto [36] noted that there is a clear need for standardized labeling and instructions, which should be regulated in a coordinated way by policymakers and material producers. In this context, waste management of bio-based plastic will be one of the most important issues in the near future in terms of CE.

3.1.4. Consumer Behavior and Bioplastics Product Acceptance

As of today, little is known in academia about how citizens perceive the shift toward a bio-based economy, even though they are among the most important actors in this transition. As a result, further investigations are needed to address bioplastics product acceptance by potential consumers. For instance, Scarpi et al. [23] noted that a greater understanding of consumers’ intention to switch to bioplastic products provides opportunities for firms to develop profitable and sustainable food systems. They concluded that consumer switching to sustainable products is a tenuous topic, as consumers often value other product attributes, such as cost, quality, and associated prestige more than their sustainability attributes among which fewer natural resources are expended, such as lower carbon footprints and EoL recoverability [23]. Confente et al. [37] developed a conceptual model to address psychological drivers that encourage consumers’ intentions to switch to and purchase products made from organic waste, the results of which showed that green self-identity positively influences consumer perceived value, leading to higher behavioral intention. According to the study of Zwicker et al. [38], consumers hold very favorable views and are willing to pay more for bio-based products. However, they also harbor misconceptions, especially overestimating bio-based plastics’ biodegradability, and they find it less important to recycle bio-based than fossil-based plastic [38].

3.1.5. Metrics for Quantifying Bioplastics in Light of Sustainability and Circularity

Bio-based products differ from conventional plastics by raw materials used, technological processes applied, and recycling technologies involving the biological cycle rather than technical cycles. The biological cycle is based on resources that can decompose and build nutrients to transform into new renewable resources [39]. Briassoulis et al. [40] through defining techno-economic sustainability analysis criteria to evaluate the feasibility of mechanical recycling of post-consumer bioplastics showed that organic recycling could be a suitable EoL option only when post-consumer biodegradable bio-based plastics are nonrecyclable by the proposed criteria for mechanical recycling. Their techno-economic sustainability criteria for mechanical recycling include economic viability, mechanical recyclability, recirculation of the recovered materials, and environmental factors. D’Adamo et al. [41] by proposing a new socio-economic indicator for EoL strategies for bio-based products indicated that (i) while resource efficiency, waste disposal cost, and EoL responsibility play key roles in EoL management, value chain actors are the most influential category of stakeholders in this management; (ii) mechanical recycling is the highest value EoL strategy for PLA-based film for food packaging, followed by chemical recycling. Moreover, they highlighted the importance of incentives and responsibility for recycled materials and green processes and circularity assessment criteria for policymakers and decision support systems. To measure circularity performance and environmental impacts of various types of bioplastics, appropriate metrics and indicators are crucial. However, few studies on specific indicators for bio-based plastics are available. Concerning circularity measurement, Razza et al. [42] developed a methodological approach for the circularity metric of bio-based and biodegradable mulch films. Their method is an adaptation of the material circularity indicator in which (i) the mass of the biocomponent corresponds to the recycled material in input, and (ii) the mass of the biocomponent leaving the system due to composting or biodegradation in the soil is considered as recycled. LCA methods have been used as the principal tool to evaluate environmental impacts for both conventional and bio-based plastics. LCA tools and methods allow determining the overall impact on the environment by measuring all the input and output at different stages, including production, using, and recycling of products. It is crucial to assess the environmental performance of EoL bioplastics and bio-based products options at the early stages [43]. Bishop et al. [44] noted the lack of a holistic picture of the environmental impacts of bioplastic products and called for further efforts to effectively apply LCA tools in practice. In a study by Tamburini et al. [45], the LCA of bottles was undertaken for outdoor drinking water for three options: conventional plastic polyethylene terephthalate (PET) bottles, innovative biodegradable PLA bottles, and reusable and almost infinitely refilling aluminum bottles. As a result of their LCA study, various impact categories were identified, such as global warming potential, eutrophication potential, human and ecotoxicity. Accordingly, they showed that PET bottles production and use assure the lower environmental impacts, compared with PLA bottles, burdened by the agricultural phase for corn cultivation, and aluminum bottles [45]. In a similar LCA study on the impact of PLA and petroleum-based plastic packaging of fresh fruit and vegetables, Bishop et al. [44] revealed that PLA production has a higher impact in contrast to petroleum-based plastic production across many impact categories. At the same time, redirection of PLA-packaged food waste to organic recycling can compensate for this, improving the overall environmental performance of bioplastic packaging options [44].

The calculation for the global sustainability performance of bio-based plastics was conducted by Spierling et al. [46] for the environmental impact category global warming potential. Their results showed that bioplastics could potentially save 241 to 316 Mio. t of CO2-eq. per year. However, although bioplastics have potential environmental benefits for global warming and nonrenewable energy use, the agricultural inputs required for bioplastics’ raw material production are often negated [33]. In other words, according to Rosenboom et al. [31], compared with fossil-based plastics, although bio-based plastics can potentially bring some benefits, such as lower carbon footprint, they can have negative agricultural impacts, unclear EOL management, food production competition, and higher costs. Hence, appropriate and effective strategies are required to better manage (i) LCA guidelines and existing bioplastic identification standards and (ii) the development of financial incentives and clear regulations [31]. Moreover, a coordinated approach within the whole value chain is crucial to achieving an integrated and innovated business model that incorporates efficient resource management activities—namely, mechanical recycling, chemical recycling, and energy/thermal recovery [47].

3.2. Recent Progressive Bio-Based Products Solutions in Ukraine

In order to provide financial support to Ukrainian startups in the form of grants, two main programs in Ukraine should be noted: (i) the Grant program of the Ukrainian Startup Fund (USF), which aims to promote the creation and growth of early-stage technology startups in Ukraine to increase their global competitiveness [48] and (ii) Startup Kyiv or National Startup Competition Ukraine, which aims to promote innovative startups’ advances and to reward them with tools that will add to their entrepreneurial learning curve [49].

Recently supported startups by Startup Kyiv are working toward making an impact in the world and have incorporated Sustainable Development Goals (SDGs), CE, or regenerative approaches to their idea. Startup Kyiv provides a set of benefits to startups, including access to a Digital Bootcamp, receiving feedback from business professionals, gaining national and international exposure, becoming part of a network of like-minded entrepreneurs, and competing for a chance to represent Ukraine at University Startup World Cup (USWC). For the last five years, Startup Kyiv accelerated several startups in the “Environmental” category with a focus on traditional plastics alternatives [49].

Furthermore, to impulse ideation toward finding solutions in bioplastics development and bio-based polymers recycling, a few hackathons on the topic were held in Ukraine. For instance, the first hackathon, entitled “Plastics challenge Hackathon 2021” (PlasticCH2021), was held at Sumy National Agrarian University on 27–28 May 2021 [50]. PlasticCH2021 was the partner event for EU Green Week 2021. The event aimed to consolidate academic and business efforts to find innovative solutions and support the initiatives of innovators in the development of bio-based products as replacements for traditional plastics, bioplastics, and polymers recycling in compliance with the “EU Plastics Strategy” and the “EU Circular Economy Action Plan”. PlasticCH2021 was the first Ukrainian forum in which the latest studies and practices in plastics circularity and sustainability areas were shared, discussed, and promoted.

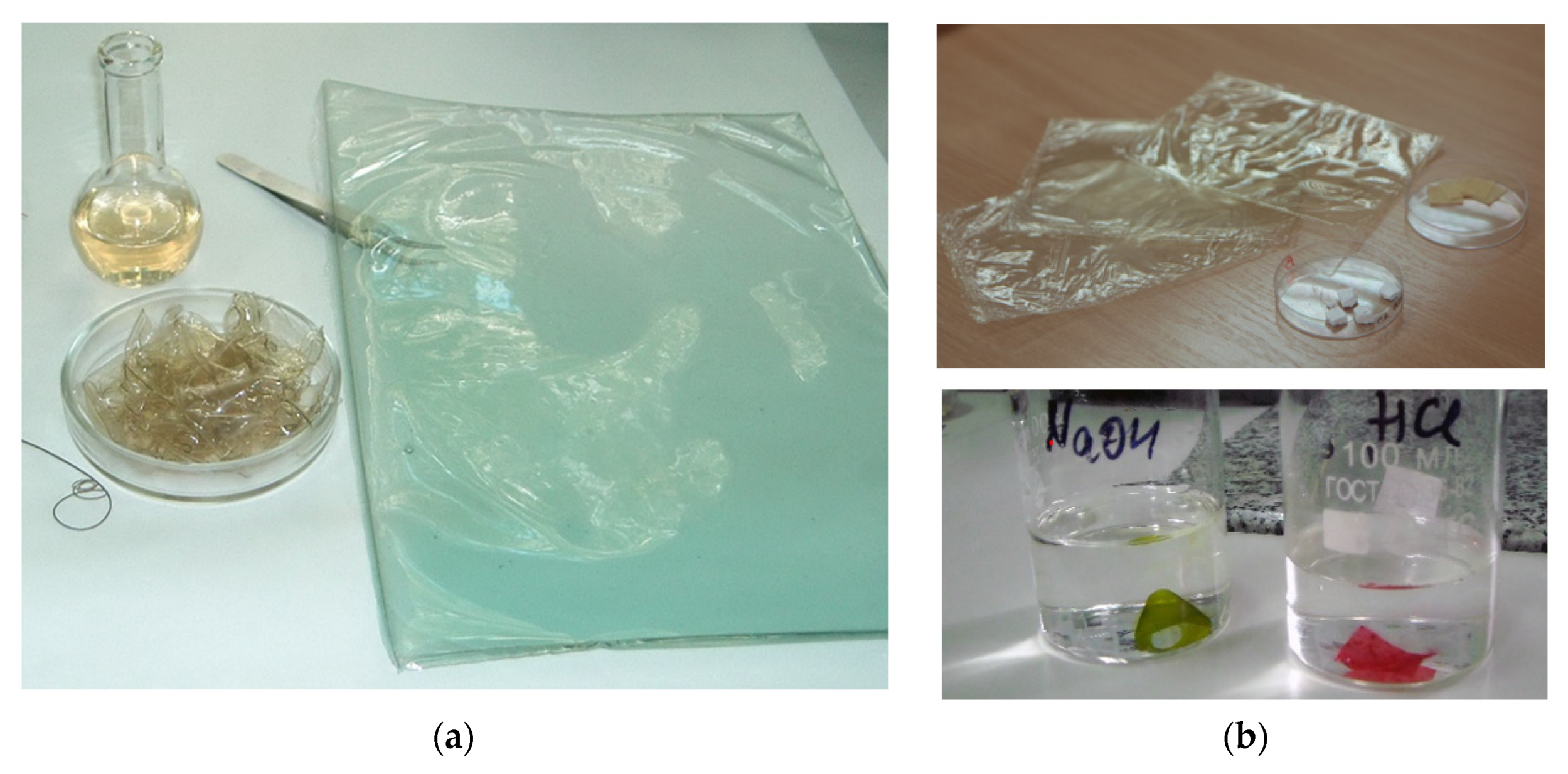

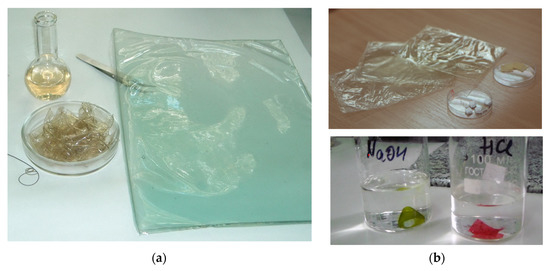

A method for obtaining films based on chitosan was presented by a team from the Institute of Applied Physics of the National Academy of Sciences of Ukraine Oksana Kalinkevich in PlasticCH2021 [51]. These films (illustrated in Figure 2) can be used as packaging materials, especially for food products. Packaging made of this polymer is completely biodegradable. The polymer base of such films, chitosan, is a derivative of chitin, the second most common biopolymer in nature. Crustacean processing wastes (ocean krill, shrimp, and crabs) are mainly used as a source of chitin, but other sources, such as fungal biomass and insect exoskeletons, have recently received increasing attention in this regard [52]. In addition to packaging materials, it is possible to produce a lot of other materials based on chitin and chitosan that have a number of valuable consumer properties [53].

Figure 2.

Films based on chitosan: (a) experimental sample of the film made from chitosan; (b) smart film (Open source photos) [51].

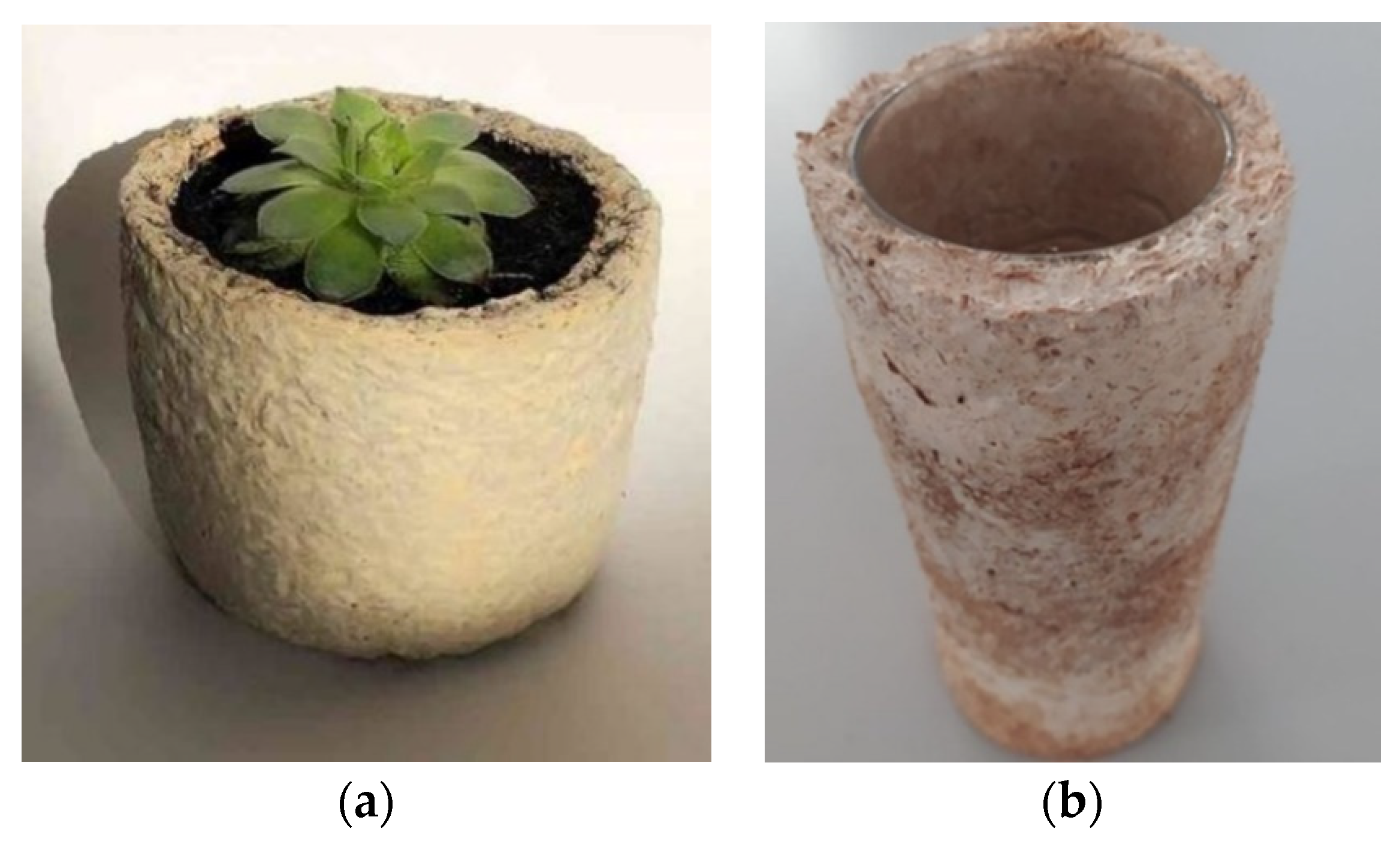

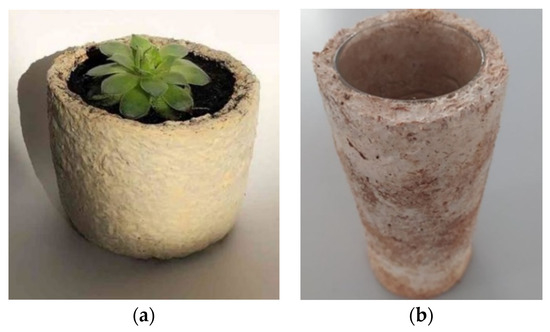

Among the many bio-based products and bioplastic initiatives, the production technology based on the use of mycelia deserves special attention. The Ukrainian workshop S.Lab makes dishes, decor, building materials, and furniture from mycelia and hemp (Figure 3a). Mycelium is a complex network of interlaced microscopic fibers, comprising the vegetative part of Saprophytic fungi [54], and is a key component for the binding of various residual substrates, turning them into functional, high-value materials. For mycelium-based products, raw materials or substrates such as small grain crop waste, straw, sunflower husks waste, woodworking industry residuals, agricultural wastes can be applied, which are inoculated with mycelia. The cultivation of a mycelium requires favorable conditions, which can be provided in the laboratory, as the biological process is stopped by drying. The process of growing the product takes 5–7 days in the Ukrainian Workshop S.Lab. The resulting products are environmentally friendly and decompose within 30–45 days [55]. Similar technology for growing mycological biomaterial, but with the use of other substrates, was proposed by scholars from Kherson State Agrarian and Economic University (Figure 3b). The biopolymers presented by these scholars are light, flexible, durable, and 100% compostable. This innovative technology has the potential to radically change the existing standards of consumption of a wide range of chemical products, for instance, in interior design, architecture, construction, horticulture, and packaging [56].

Figure 3.

Mycelium-based biodegradable polymers: (a) flowerpot made from mycelium (Open source photo) [55]; (b) experimental sample of mycelium biopolymer (Open source photo) [56].

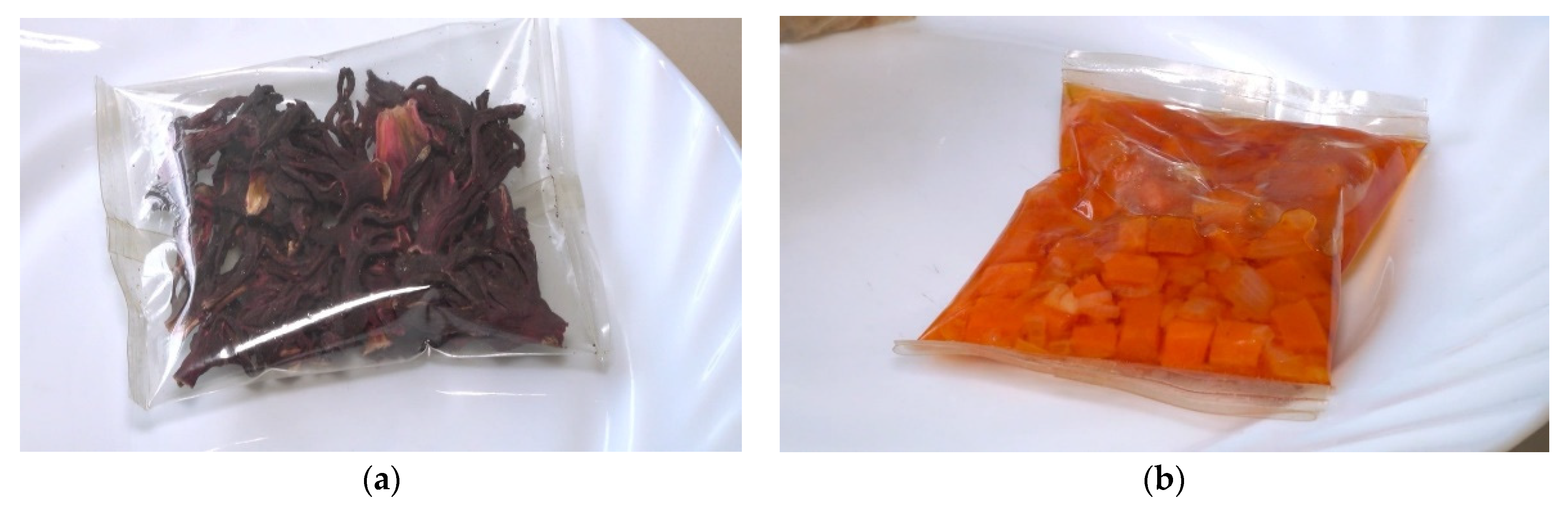

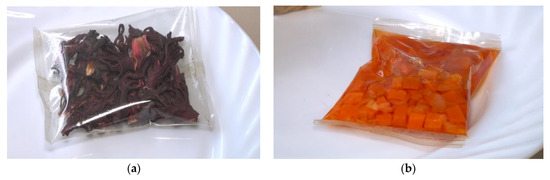

As part of the PlasticCP2021, edible packaging for semifinished products and sticks (Figure 4a) was presented by Sumy National Agrarian University. The developed packaging consists of 50% food waste, including fillers (e.g., leftover vegetables and fruits), and 50% binders—namely, biopolymers obtained from animal bones and fish [57]. This packaging is 100% compostable, and the technology and materials used make the disposable packaging edible. Since this packaging is water-soluble, it is advised to be used for sugar, tea, and coffee sticks instead of traditional packaging. In the same vein, storing oil-stewed vegetables for soups in this package is also experimented with (Figure 4b). The developers of this packaging also tested packaging made of nuts shells and eggshells, which decompose in natural conditions, i.e., do not require additional conditions for disposal and, therefore, are completely safe for the environment [57]. Figure 5a,b show experimental laboratory prototypes of biodegradable packaging and labels made from eggshells, respectively, which can be disposed of using the composting method. These two promising solutions were presented within a special case from Galicia and received financial support for moving toward marketization. For the inscriptions on the label, dyeing from natural dyes obtained from vegetable residues was used. Moreover, since the presented packaging and label are made exclusively of organic food materials, they can be used as a food additive for poultry, in particular hens. For this packaging production, confectionery enterprises could become potential “suppliers” of eggshells as raw materials, and poultry farms could be potential “consumers” of this packaging at its EoL [57].

Figure 4.

(a) Edible packaging for dry foods; (b) edible packaging for semifinished products (Open source photos) [57].

Figure 5.

(a) Biodegradable eggshell packaging for food; (b) biodegradable eggshell labels for bottles (Open source photo) [57].

Several solutions for disposable tableware production have been proposed by Ukrainian developers over the last four years. As raw materials, the developers use natural materials and waste, including beet pulp, flax, hemp, soybean and cornmeal, leaves and stems of corn, and spent coffee grounds. The production technology of disposable tableware that utilizes spent coffee grounds has been proposed by Dmytro Bidyuk from the startup “Rekava” (Figure 6a). The advantage of this type of tableware is its easy disposal after use as fertilizer, animal feed additive, or biofuel. The project is currently being developed with the prospect of launching a production line [50]. Moreover, the production technology of disposable tableware using beet pulp, flax, hemp, soybean, and cornmeal as a raw material (Figure 6b) was proposed by the “Bionus” startup. This tableware is manufactured by compression molding in high temperatures [50]. Similar production technology for disposable tableware from corn waste was proposed by researchers from Uzhorod National University. As raw materials, the developers used corn leaves and stems, as well as edible and/or inedible starch (chestnuts and acorns) [58]. The technological properties of this disposable tableware include thermal stability, strength, ease of production, and low price, and it can be disposed of as fertilizer, animal feed, and biogas after use.

Figure 6.

Biodegradable disposable tableware: (a) a laboratory prototype of disposable tableware based on biomaterial from spent coffee grounds (Open source photo) [50]; (b) biodegradable disposable tableware based on the meal (Open source photo) [58].

Leaf processing technology with a subsequent paper production was proposed by the startup “Re-leaf” as an innovative solution in the fight against traditional plastic. Figure 7 shows a craft paper made by using this technology with a density of 80 and 90 g/m2 that has appropriate physical and mechanical characteristics, making it suitable for packaging [8]. In the proposed technology, fallen leaves are separated from garbage, dried, and granulated. Then, granules are combined with waste paper in appropriate proportions, and rolls of paper are made. In the production of paper, cellulose fibers from fallen leaves can be used as the main or additional components. The peculiarity of products from fallen leaves is that sulfur and chlorine compounds are absent in the technological process, in contrast with traditional production. To obtain one ton of paper, 2.3 tons of fallen leaves are required, which saves an average of 17 trees. In addition, the environmental benefits would be a reduction of 15 times water consumption, and a reduction in CO2 emissions by 78.3%. Disposal of containers and packaging from fallen leaves involves the use of traditional recycling technologies [8].

Figure 7.

Biodegradable bags made of leaves (Open source photos) [8].

The production of environmentally friendly glass frames from spent coffee grounds (Figure 8) is another original solution, which was proposed by the startup “Ochis”. These coffee glasses are made of recycled coffee grounds, natural oils, and a biopolymer based on vegetable oils that are used as a binder. The glasses are waterproof due to a special type of hydrophobic coating. The technological process includes 39 stages of processing, most of which are performed manually. The biomaterial of the frames decomposes in about 10 years, under natural conditions [50].

Figure 8.

Coffee glasses “Ochis” from spent coffee grounds (Open source photo) [50].

4. Challenges and Future Perspectives

Despite the significant potential of bio-based sustainable products and bioplastics to replace petroleum-based plastics across industries, emerging challenges and barriers arise when new alternatives enter the market.

In this regard, bioplastics recycling has increased the risk of contaminating the current recycling system due to the lack of adequate waste management legislation and appropriate recycling practices. Since bio-based plastics are different from fossil-based ones, they require appropriate and sustainable recycling practices. Today, bioplastics often enter technical recycling chains after use because of inadequate collection infrastructure and recycling capacity [59]. This leads to disturbing the current recycling of plastics, thereby making it more complicated to close the loop of conventional plastics [59]. Along the same line, Alaerts et al. [60] highlighted that bio-based plastics potentially separate sources of contamination in current recycling systems. For instance, for PLA, a severe incompatibility with PET recycling is known, and future recycling risks are assessed by measuring amounts of PLA ending up in the PET waste stream [60]. For this particular case, with the growth of the market share of PLA, the risks associated with closing the loop of PET will increase if the first stream remains uncontrollable.

Lima et al. [59] showed that, in many cases, biodegradable bioplastics-related laws and regulations have not been well clarified to enable proper and effective waste management. As a result, due to the lack of an inclusive policy toolkit to sufficiently encourage using bioplastics in a sustainable manner, the risk of emerging pseudo-solutions can occur in the market, leading to intensifying the rebound effects of bioplastics production and utilization for communities. In the same vein, legislative norms and standards across countries need to be more in line with promoting sustainable alternatives to contribute to the bio-based CE.

Despite an expected increase in the production of bio-based products, the bioplastic market is still limited due to the low availability and lack of information in public, high prices, and insufficient marketing strategies [61]. Moreover, many consumers are not necessarily ready to adopt bioplastic-based products [23]. Nevertheless, research on consumer preferences, attitudes, choices, and perceptions in the context of bioplastics is still in its infancy stage [23]. As a result, in addition to the technological infrastructure and production facilities aspects, motivating consumer intention to switch from conventional plastic products to bio-based plastic products is a significant challenge that needs more research and effort.

5. Conclusions

The development and production of bioplastics have gained much attention in academia due to their biodegradability. Bioplastics and bio-based products and materials seem to be a sustainable alternative to petroleum-based plastics, due to their potential in decreasing pollution and greenhouse gas emissions. Hence, investments in the bio-based sector for bioplastic production and utilization have gained momentum among policymakers, municipal authorities, practitioners, and research communities. In this regard, many countries worldwide are installing new production capabilities [5] in response to the growing demand of a wide range of industries from packaging to electronics, pharmaceuticals, agriculture, and textiles toward implementing CE platforms.

This research aimed at providing the current state-of-the-art of bioplastics and bio-based products developments, trends, and challenges to replace petroleum-based plastics. To this end, a systematic literature review, supported by content analysis, was carried out in two stages. First, the major research themes of the literature related to bioplastics and bio-based products were identified and discussed. Then, the most recent advancements were provided in the context of bioplastics and bio-based products initiatives in Ukraine, as the second-largest country by area in Europe, which have gained publicity through local startup programs and hackathons. The provided review supports using the bio-based sector potentials to foster the CE transition by (i) presenting recent bioplastic and bio-based products solutions that mainly come from the industry and startups rather than academia, (ii) providing insights to encourage academic debate and bridging industry practitioners and research communities, and (iii) identifying the main challenges and future perspectives for further investigations, including recycling challenges, lack of an inclusive legislation and policy framework, and the need to motivate consumers for using bio-based products.

Author Contributions

Conceptualization, T.S. and M.R.; methodology, M.R. and Z.S.E.; formal analysis, T.S., M.R., Z.S.E., Y.D. and K.B.-D.; investigation, T.S., Y.D. and K.B.-D.; writing—original draft preparation, T.S.; writing—review and editing, T.S., M.R., Z.S.E., Y.D. and K.B.-D.; All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the European Union within the project “Towards circular economy thinking & ideation in Ukraine according to the EU action plan” [Grant number 620966-EPP-1-2020].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study.

Acknowledgments

This study was conducted within the project “Towards circular economy thinking and ideation in Ukraine according to the EU action plan” supported by the European Union. Moreover, we would like to thank the Ukrainian developers and experts, including Dmytro Bidyuk, Oleksiy Kalinkevich, Igor Chernishov, Tetiana Jarmosh for their support in terms of providing photos and insights for conducting this research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nanda, S.; Patra, B.R.; Patel, R.; Bakos, J.; Dalai, A.K. Innovations in applications and prospects of bioplastics and biopolymers: A review. Environ. Chem. Lett. 2022, 20, 379–395. [Google Scholar] [CrossRef] [PubMed]

- García-Depraect, O.; Bordel, S.; Lebrero, R.; Santos-Beneit, F.; Börner, R.A.; Börner, T.; Muñoz, R. Inspired by nature: Microbial production, degradation and valorization of biodegradable bioplastics for life-cycle-engineered products. Biotechnol. Adv. 2021, 53, 107772. [Google Scholar] [CrossRef] [PubMed]

- Jõgi, K.; Bhat, R. Valorization of food processing wastes and by-products for bioplastic production. Sustain. Chem. Pharm. 2020, 18, 100326. [Google Scholar] [CrossRef]

- Samantaray, P.K.; Little, A.; Haddleton, D.M.; McNally, T.; Tan, B.; Sun, Z.; Huang, W.; Ji, Y.; Wan, C. Poly(glycolic acid) (PGA): A versatile building block expanding high performance and sustainable bioplastic applications. Green Chem. 2020, 22, 4055–4081. [Google Scholar] [CrossRef]

- Moshood, T.; Nawanir, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.; Abdul Ghani, A. Expanding Policy for Biodegradable Plastic Products and Market Dynamics of Bio-Based Plastics: Challenges and Opportunities. Sustainability 2021, 13, 6170. [Google Scholar] [CrossRef]

- Cisneros-López, E.O.; Pal, A.K.; Rodriguez, A.U.; Wu, F.; Misra, M.; Mielewski, D.F.; Kiziltas, A.; Mohanty, A.K. Recycled poly(lactic acid)–based 3D printed sustainable biocomposites: A comparative study with injection molding. Mater. Today Sustain. 2020, 7–8, 100027. [Google Scholar] [CrossRef]

- EU. EU Plastics Strategy. Available online: https://ec.europa.eu/environment/strategy/plastics-strategy_en (accessed on 14 February 2022).

- EU Circular Economy Action Plan. Available online: https://ec.europa.eu/environment/strategy/circular-economy-action-plan_en (accessed on 14 February 2022).

- Di Bartolo, A.; Infurna, G.; Dintcheva, N.T. A Review of Bioplastics and Their Adoption in the Circular Economy. Polymers 2021, 13, 1229. [Google Scholar] [CrossRef]

- Lazarev, S.I.; Kovaleva, O.A.; Bogomolov, V.Y.; Shestakov, K.V.; Kuznetsov, M.A. Determination of Technological and Construction Parameters of an Electroultrafiltration Apparatus with Flat Chambers for Demineralization and Concentration of Solutions from Biodegradable Plastics Production. Chem. Pet. Eng. 2017, 53, 364–368. [Google Scholar] [CrossRef]

- Qin, M.; Chen, C.; Song, B.; Shen, M.; Cao, W.; Yang, H.; Zeng, G.; Gong, J. A review of biodegradable plastics to biodegradable microplastics: Another ecological threat to soil environments? J. Clean. Prod. 2021, 312, 127816. [Google Scholar] [CrossRef]

- Moshood, T.D.; Nawanir, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.H.; AbdulGhani, A. Biodegradable plastic applications towards sustainability: A recent innovations in the green product. Clean. Eng. Technol. 2022, 6, 100404. [Google Scholar] [CrossRef]

- Moshood, T.D.; Nawanir, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.H.; AbdulGhani, A. Sustainability of biodegradable plastics: New problem or solution to solve the global plastic pollution? Curr. Res. Green Sustain. Chem. 2022, 5, 100273. [Google Scholar] [CrossRef]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.A.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate health care interventions: Explanation and elaboration. J. Clin. Epidemiol. 2009, 62, e1–e34. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ranjbari, M.; Shams Esfandabadi, Z.; Shevchenko, T.; Chassagnon-Haned, N.; Peng, W.; Tabatabaei, M.; Aghbashlo, M. Mapping healthcare waste management research: Past evolution, current challenges, and future perspectives towards a circular economy transition. J. Hazard. Mater. 2022, 422, 126724. [Google Scholar] [CrossRef]

- Ranjbari, M.; Shams Esfandabadi, Z.; Zanetti, M.C.; Scagnelli, S.D.; Siebers, P.-O.; Aghbashlo, M.; Peng, W.; Quatraro, F.; Tabatabaei, M. Three pillars of sustainability in the wake of COVID-19: A systematic review and future research agenda for sustainable development. J. Clean. Prod. 2021, 297, 126660. [Google Scholar] [CrossRef] [PubMed]

- Otoni, C.G.; Azeredo, H.M.C.; Mattos, B.D.; Beaumont, M.; Correa, D.S.; Rojas, O.J. The Food–Materials Nexus: Next Generation Bioplastics and Advanced Materials from Agri-Food Residues. Adv. Mater. 2021, 33, 2102520. [Google Scholar] [CrossRef] [PubMed]

- Kakadellis, S.; Lee, P.-H.; Harris, Z.M. Two Birds with One Stone: Bioplastics and Food Waste Anaerobic Co-Digestion. Environments 2022, 9, 9. [Google Scholar] [CrossRef]

- Chong, J.W.R.; Khoo, K.S.; Yew, G.Y.; Leong, W.H.; Lim, J.W.; Lam, M.K.; Ho, Y.-C.; Ng, H.S.; Munawaroh, H.S.H.; Show, P.L. Advances in production of bioplastics by microalgae using food waste hydrolysate and wastewater: A review. Bioresour. Technol. 2021, 342, 125947. [Google Scholar] [CrossRef]

- García-Depraect, O.; Lebrero, R.; Rodriguez-Vega, S.; Bordel, S.; Santos-Beneit, F.; Martínez-Mendoza, L.J.; Aragão Börner, R.; Börner, T.; Muñoz, R. Biodegradation of bioplastics under aerobic and anaerobic aqueous conditions: Kinetics, carbon fate and particle size effect. Bioresour. Technol. 2022, 344, 126265. [Google Scholar] [CrossRef]

- Ruggero, F.; Gori, R.; Lubello, C. Methodologies to assess biodegradation of bioplastics during aerobic composting and anaerobic digestion: A review. Waste Manag. Res. 2019, 37, 959–975. [Google Scholar] [CrossRef] [Green Version]

- George, N.; Debroy, A.; Bhat, S.; Singh, S.; Bindal, S. Biowaste to bioplastics: An ecofriendly approach for a sustainable future. J. Appl. Biotechnol. Rep. 2021, 8, 221–233. [Google Scholar] [CrossRef]

- Scarpi, D.; Russo, I.; Confente, I.; Hazen, B. Individual antecedents to consumer intention to switch to food waste bioplastic products: A configuration analysis. Ind. Mark. Manag. 2021, 93, 578–590. [Google Scholar] [CrossRef]

- Morone, P.; Tartiu, V.E.; Falcone, P. Assessing the potential of biowaste for bioplastics production through social network analysis. J. Clean. Prod. 2015, 90, 43–54. [Google Scholar] [CrossRef]

- Liu, M.; Arshadi, M.; Javi, F.; Lawrence, P.; Davachi, S.M.; Abbaspourrad, A. Green and facile preparation of hydrophobic bioplastics from tea waste. J. Clean. Prod. 2020, 276, 123353. [Google Scholar] [CrossRef]

- Park, Y.-K.; Lee, J. Achievements in the production of bioplastics from microalgae. Phytochem. Rev. 2022, 8, 1–19. [Google Scholar] [CrossRef]

- Onen Cinar, S.; Chong, Z.K.; Kucuker, M.A.; Wieczorek, N.; Cengiz, U.; Kuchta, K. Bioplastic Production from Microalgae: A Review. Int. J. Environ. Res. Public Health 2020, 17, 3842. [Google Scholar] [CrossRef]

- Degli Esposti, M.; Morselli, D.; Fava, F.; Bertin, L.; Cavani, F.; Viaggi, D.; Fabbri, P. The role of biotechnology in the transition from plastics to bioplastics: An opportunity to reconnect global growth with sustainability. FEBS Open Bio 2021, 11, 967–983. [Google Scholar] [CrossRef]

- Ranjbari, M.; Shams Esfandabadi, Z.; Quatraro, F.; Vatanparast, H.; Lam, S.S.; Aghbashlo, M.; Tabatabaei, M. Biomass and organic waste potentials towards implementing circular bioeconomy platforms: A systematic bibliometric analysis. Fuel 2022, 318, 123585. [Google Scholar] [CrossRef]

- Ranjbari, M.; Shams Esfandabadi, Z.; Ferraris, A.; Quatraro, F.; Rehan, M.; Nizami, A.-S.; Gupta, V.K.; Lam, S.S.; Aghbashlo, M.; Tabatabaei, M. Biofuel supply chain management in the circular economy transition: An inclusive knowledge map of the field. Chemosphere 2022, 296, 133968. [Google Scholar] [CrossRef]

- Rosenboom, J.-G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef]

- Yadav, B.; Pandey, A.; Kumar, L.R.; Tyagi, R.D. Bioconversion of waste (water)/residues to bioplastics—A circular bioeconomy approach. Bioresour. Technol. 2020, 298, 122584. [Google Scholar] [CrossRef]

- Kakadellis, S.; Harris, Z.M. Don’t scrap the waste: The need for broader system boundaries in bioplastic food packaging life-cycle assessment—A critical review. J. Clean. Prod. 2020, 274, 122831. [Google Scholar] [CrossRef]

- Briassoulis, D.; Pikasi, A.; Hiskakis, M. End-of-waste life: Inventory of alternative end-of-use recirculation routes of bio-based plastics in the European Union context. Crit. Rev. Environ. Sci. Technol. 2019, 49, 1835–1892. [Google Scholar] [CrossRef]

- Spierling, S.; Röttger, C.; Venkatachalam, V.; Mudersbach, M.; Herrmann, C.; Endres, H.-J. Bio-based Plastics—A Building Block for the Circular Economy? Procedia CIRP 2018, 69, 573–578. [Google Scholar] [CrossRef]

- Prieto, A. To be, or not to be biodegradable… that is the question for the bio-based plastics. Microb. Biotechnol. 2016, 9, 652–657. [Google Scholar] [CrossRef] [Green Version]

- Confente, I.; Scarpi, D.; Russo, I. Marketing a new generation of bio-plastics products for a circular economy: The role of green self-identity, self-congruity, and perceived value. J. Bus. Res. 2020, 112, 431–439. [Google Scholar] [CrossRef]

- Zwicker, M.V.; Brick, C.; Gruter, G.-J.M.; van Harreveld, F. (Not) Doing the Right Things for the Wrong Reasons: An Investigation of Consumer Attitudes, Perceptions, and Willingness to Pay for Bio-Based Plastics. Sustainability 2021, 13, 6819. [Google Scholar] [CrossRef]

- Ribul, M.; Lanot, A.; Tommencioni Pisapia, C.; Purnell, P.; McQueen-Mason, S.J.; Baurley, S. Mechanical, chemical, biological: Moving towards closed-loop bio-based recycling in a circular economy of sustainable textiles. J. Clean. Prod. 2021, 326, 129325. [Google Scholar] [CrossRef]

- Briassoulis, D.; Pikasi, A.; Hiskakis, M. Recirculation potential of post-consumer/industrial bio-based plastics through mechanical recycling—Techno-economic sustainability criteria and indicators. Polym. Degrad. Stab. 2021, 183, 109217. [Google Scholar] [CrossRef]

- D’Adamo, I.; Falcone, P.M.; Imbert, E.; Morone, P. A Socio-economic Indicator for EoL Strategies for Bio-based Products. Ecol. Econ. 2020, 178, 106794. [Google Scholar] [CrossRef]

- Razza, F.; Briani, C.; Breton, T.; Marazza, D. Metrics for quantifying the circularity of bioplastics: The case of bio-based and biodegradable mulch films. Resour. Conserv. Recycl. 2020, 159, 104753. [Google Scholar] [CrossRef]

- Spierling, S.; Venkatachalam, V.; Mudersbach, M.; Becker, N.; Herrmann, C.; Endres, H.-J. End-of-Life Options for Bio-Based Plastics in a Circular Economy—Status Quo and Potential from a Life Cycle Assessment Perspective. Resources 2020, 9, 90. [Google Scholar] [CrossRef]

- Bishop, G.; Styles, D.; Lens, P.N.L. Environmental performance of bioplastic packaging on fresh food produce: A consequential life cycle assessment. J. Clean. Prod. 2021, 317, 128377. [Google Scholar] [CrossRef]

- Tamburini, E.; Costa, S.; Summa, D.; Battistella, L.; Fano, E.A.; Castaldelli, G. Plastic (PET) vs bioplastic (PLA) or refillable aluminium bottles—What is the most sustainable choice for drinking water? A life-cycle (LCA) analysis. Environ. Res. 2021, 196, 110974. [Google Scholar] [CrossRef] [PubMed]

- Spierling, S.; Knüpffer, E.; Behnsen, H.; Mudersbach, M.; Krieg, H.; Springer, S.; Albrecht, S.; Herrmann, C.; Endres, H.-J. Bio-based plastics—A review of environmental, social and economic impact assessments. J. Clean. Prod. 2018, 185, 476–491. [Google Scholar] [CrossRef]

- Kawashima, N.; Yagi, T.; Kojima, K. How Do Bioplastics and Fossil-Based Plastics Play in a Circular Economy? Macromol. Mater. Eng. 2019, 304, 1900383. [Google Scholar] [CrossRef]

- USF Home—Ukrainian Startup Fund. Available online: https://usf.com.ua/#usf-sc-5 (accessed on 14 February 2022).

- NSCU National Startup Competition Ukraine. Available online: https://sites.google.com/view/startup-competition-ukraine/national-startup-competition-ukraine?authuser=0 (accessed on 14 February 2022).

- Bionus Bionus—Biodegradable Tableware Made of Flax, Hemp, Sugar Beet, Soybeans and Corn. Available online: https://bionus.com.ua/home_en/ (accessed on 14 February 2022).

- Kalinkevich, O. Obtaining Films Based on Chitosan (FlyChit), Plastic Challenge Hackathon 2021. Available online: https://jm.snau.edu.ua/wp-content/uploads/2021/06/proiekt_oleksii_kalinkevich_ta_inshi.pdf (accessed on 15 February 2022).

- Kalinkevich, O.; Sklyar, A.; Gudakov, A.; Zinchenko, Y.; Kalinkevich, A.; Danilchenko, S.; Sofronov, D.; Chivanov, V.; Starikov, V.; Markina, T.; et al. Insect Chitin Nanofibers for Medical Application: Obtaining and Characterization. In Proceedings of the 2021 IEEE 11th International Conference Nanomaterials: Applications & Properties (NAP), Odessa, Ukraine, 5–11 September 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Kalinkevich, O.; Sklyar, A.; Kalinkevich, A.; Chivanov, V.; Zinchenko, Y.; Trofimenko, Y.; Starikov, V.; Sofronov, D.; Holubnycha, V. Preparation and characterisation of new biomaterials based on chitosan iodide with biologically active dyes. Prog. Chem. Appl. Chitin Its Deriv. 2021, 26, 121–134. [Google Scholar] [CrossRef]

- Attias, N.; Danai, O.; Tarazi, E.; Pereman, I.; Grobman, Y.J. Implementing bio-design tools to develop mycelium-based products. Des. J. 2019, 22, 1647–1657. [Google Scholar] [CrossRef] [Green Version]

- S.LAB. S.LAB—Innovative Laboratory of Sustainability—Construction&Building Materials, Furniture&Accessories, Packaging Products. Available online: https://ilab-s.com/ (accessed on 15 February 2022).

- Chernishov, I. Production Technology Based on the Use of Mycelia, Plastic Challenge Hackathon 2021. Available online: https://jm.snau.edu.ua/wp-content/uploads/2021/06/proiekt_igor_chernishov_ta_inshi.pdf (accessed on 15 February 2022).

- Jarmosh, T. Biodegradable Packaging for Food (FoodWastePack), Plastic Challenge Hackathon 2021. Available online: https://jm.snau.edu.ua/wp-content/uploads/2021/06/proiekt_tetjana_jarmosh_ta_inshi.pdf (accessed on 15 February 2022).

- Grjadil, T. Production of Disposable Utensils from Corn (EcoGreenPlates), Plastic Challenge Hackathon 2021. Available online: https://jm.snau.edu.ua/wp-content/uploads/2021/06/proiekt_taras_grjadil_ta_inshi.pdf (accessed on 15 February 2022).

- Lima, L.R.; Gutierrez, R.F.; Cruz, S.A. Challenges in the context of single-use plastics and bioplastics in Brazil: A legislative review. Waste Manag. Res. J. Sustain. Circ. Econ. 2021; online first. [Google Scholar] [CrossRef]

- Alaerts, L.; Augustinus, M.; Van Acker, K. Impact of Bio-Based Plastics on Current Recycling of Plastics. Sustainability 2018, 10, 1487. [Google Scholar] [CrossRef] [Green Version]

- Notaro, S.; Lovera, E.; Paletto, A. Consumers’ preferences for bioplastic products: A discrete choice experiment with a focus on purchase drivers. J. Clean. Prod. 2022, 330, 129870. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).