Abstract

Recycling plastic is an important step towards a circular economy. Attaining high-quality recycled plastics requires the separation of plastic waste by type, color, and size prior to reprocessing. Automated technology is key for sorting plastic objects in medium- to high-volume plants. The current state of the art of commercial equipment for sorting plastic as well as challenges faced by Material Recovery Facilities (MRFs) to sort post-consumer plastics are analyzed here. Equipment for sorting plastic recyclables were identified using publicly available information obtained from manufacturers’ websites, press releases, and journal articles. Currently available automated sorting equipment and artificial intelligence (AI)-based sorters are evaluated regarding their functionality, efficiency, types of plastics they can sort, throughput, and accuracy. The information compiled captures the progress made during the ten years since similar reports were published. A survey of MRFs, reclaimers, and brokers in the United States identified methods of sorting used for plastic, sorting efficiency, and current practices and challenges encountered at MRFs in sorting plastic recyclables. The commercial sorting equipment can address some of the challenges that MRFs face. However, sorting of film, multilayered, blended, or mixed-material plastics is problematic, as the equipment is typically designed to sort single-component materials. Accordingly, improvements and/or new solutions are considered necessary.

1. Introduction

Post-consumer plastics are difficult to manage with the current recycling infrastructure, mainly due to the large volume of waste generated, combined with the complexity of effectively sorting different types, shapes, and sizes of plastics for recycling. In 2017, the United States produced 35.4 million tons of plastics [1], of which only 2.96 million tons (~8.4%) were recycled. Higher recycling rates of post-consumer plastics can be achieved by improving sorting efficiency. Poorly sorted plastics result in higher reprocessing costs and a lower value for reprocessed plastics [2]. In order to achieve circularity and improve the utilization of resources, it is necessary to reduce the amount of post-consumer plastics that ends up in landfills or released into the environment.

Plastics can be recycled via mechanical or chemical means [3,4]. Mechanical recycling of plastic involves a sequence of steps, namely, sourcing, sorting, washing, shredding, identification, and separation of different plastic types, and extrusion and compounding of desired types of plastic (typically HDPE). For mechanical recycling, plastics need to be separated by type and color before reprocessing. For municipal solid waste, separation by type is performed at the Materials Recovery Facility (MRF) level, while industrial single-type plastics are typically handled by brokers. However, a few MRFs sort plastics from both municipal and industrial waste. Reclaimers obtain plastics sorted by MRFs and brokers for reprocessing into new plastic materials [5,6].

Plastics can be sourced from households and industry (e.g., manufacturing companies, retail stores, offices) through (1) single-stream, (2) mixed municipal waste, (3) dual-stream, (4) pre-sorted recyclables, or (5) container deposits [7]. Single-stream recycling is a system in which all recyclables (e.g., paper, fibers, plastics, metals, glass, and other containers) are sourced together using a single bin, a method commonly used in the US [8,9]. Single-stream recycling reportedly helped increase participation in recycling from 22% in 2005 to 73% in 2014 [9]. However, this method is often associated with cross-contamination levels in recovered plastics [9]. The mixed municipal waste consists of a mixture of waste from all places, including household waste, retail stores and other businesses, office wastes, miscellaneous waste, and non-hazardous waste. Dual-stream is sourced into separate bins by the depositor (i.e., mixed paper and cardboard in one bin, and commingled materials, such as glass, plastics, cans, and jars in another) [9]. Pre-sorted recyclables are materials (i.e., plastic waste) sorted by MRFs that are sent to a secondary MRF (for further sorting) or to reclaimers. Container deposits (i.e., “Bottle Bills”) work by adding a fee on top of a beverage product that is later refunded to the customer when the empty container is returned to an authorized redemption center for recycling.

The types of plastics sorted at MRFs are (1) poly(ethylene terephthalate) (PET), (2) high-density polyethylene (HDPE), (3) poly(vinyl chloride) (PVC), (4) low-density poly-ethylene (LDPE), (5) polypropylene (PP), (6) polystyrene (PS), and (7) other, where the numbers 1, 2, …, 7 refer to the Plastic Identification Codes [10]. Even though all these types of plastics have the potential to be sorted, most have little to no market value, except for PET and HDPE. The “residual” plastic left after the selection of valuable plastic (such as PET and HDPE) is typically landfilled. A report by Vedantam et al. [11] documented the drastic difference between the amount of HDPE recovered in New York State compared to the amount of PVC, LDPE, PS, and other plastics. The amount of PVC processed in New York State in 2019 was about 240,015 tons, 177,260 tons for LDPE and PS, and 7250 tons for others. The recovered amount of PVC, LDPE, PS, and other plastics are much lower than the amount of HDPE (colored HDPE 502,845 tons, natural HDPE 20,138) processed in the same year in New York State by brokers and reclaimers [11].

At the MRF level, post-consumer plastics can be sorted manually by operators or mechanically by exploiting differences in the optical, chemical, or electrostatic properties of materials [12]. The wide variety of plastic types makes it hard for MRF operators to efficiently distinguish plastics visually; thus, automated sorters are favored for medium- to high-volume MRFs. Automated sorting involves methods such as air classification, eddy current device, disc screen, magnetic separator, traveling chain curtains, trommel screens, optical sorters, and robotics [13]. The traditional sorters, such as magnetic and eddy currents, process waste mixtures to remove ferrous and non-ferrous materials. Separation of plastics by type, color, shape, and/or texture requires specialized equipment such as optical sorters and/or artificial intelligence (AI)-equipped sorters [14,15,16]. Sorting method varies based on the product(s) of interest, thus driving the choice of the best applicable method or technology. Optical sorters and/or AI-equipped sorters can sometimes be combined to improve product yield or sorting efficiency [16]. However, many MRFs rely on manual sorting to achieve high purity levels. This can be expensive and time-consuming for high volumes of waste, and it endangers operators’ health due to toxic additives [17,18]. In contrast, automated sorting is more efficient and can be cost-effective [17]. More versatile sorting technologies are needed to efficiently separate plastics based on resin type and grade.

The current state-of-the-art of plastic sorting equipment together with challenges faced by MRFs operating in the United States to sort post-consumer plastics are analyzed here. The previous reports published on plastic sorting equipment (by 4R Sustainability [19] and by Delavelle [20]) date from over ten years ago. Recent advances in technology and increasing pressure to recycle higher amounts of plastics motivate this effort to compile an updated inventory of established and emerging sorting equipment, and to ascertain whether this equipment can meet challenges reported at the MRF level. To this end, we evaluated both conventional systems (i.e., optical sorters) and emerging sorting equipment (i.e., AI sorting robots) using metrics on their efficiency, types of plastic sorted, size of plastic sorted, and ability to sort by color.

The following section describes the methodology used to obtain data on sorting equipment and provides an overview of our survey of MRFs. Physical principles enabling plastic materials to be sorted by type are outlined in the next section. Challenges encountered by MRFs to sort plastics and factors affecting sorting efficiency are then discussed, based on results from the survey we have conducted. Next, the inventory of sorting equipment is organized as sorters for whole plastic objects, sorters for films, flake sorters, and AI-based sorters. Equipment efficiency, type and size of plastic sorted, and throughput are reported. Finally, conclusions are presented on whether limitations at MRFs can be addressed with currently available technologies.

2. Methodology

This study synthesized and analyzed two streams of information: (1) availability and capabilities of automated sorting equipment used for plastic waste, obtained from suppliers of said equipment, and (2) utilization of sorting equipment at MRFs, sorting efficiency, and challenges faced, obtained from a survey of companies active in the field.

Equipment for sorting plastic recyclables were identified using publicly available information obtained from manufacturers’ websites, press releases, and journal articles. A search for sorting equipment and companies was conducted using Google, Google Scholar, Web of Science, Science Direct, and Engineering Village databases; with keywords such as “sorting equipment manufacturers or companies”, “optical sorters”, “plastic sorters”, “plastic sorting machines”, “sorting equipment’, and “plastic recycling”. Contact information of sorting equipment suppliers is reported in Appendix A. The companies listed come from North America and Europe. Our search was conducted in the English language; hence, it may not have captured companies in, e.g., China. The information collected here reveals the progress made during the 10 years since similar reports were published. This information is further used to assess whether challenges reported by MRFs in our survey (see next paragraph) can be addressed by currently available technologies or emerging technologies. The gap between the sorting efficiency reported by manufacturers and sorting efficiency obtained at MRFs is also obtained and reported here.

Limitations and challenges encountered at MRFs in sorting plastic recyclables were identified in a survey conducted by our team and through interviews with industry professionals. The survey was developed using Qualtrics XM software and was distributed to over 100 recycling entities (MRFs, reclaimers, and brokers) in the United States during the period August 2020 to March 2021. The list of companies surveyed was developed through Google search and magazines: Waste Today (https://www.wastetodaymagazine.com/article/largest-north-american-material-recovery-facilities last accessed on 12 February 2022), Recycling Today (https://www.recyclingtoday.com/ last accessed on 12 February 2022), and Waste 360 (https://www.waste360.com/ last accessed on 12 February 2022). The companies were contacted prior to sending the survey, and the survey was sent out to companies that showed interest in participating. Survey takers were guided through a series of quantitative and qualitative questions linked to their position in the broader plastics supply chain. Note that businesses self-identified their role in the plastics supply chain and responded to presented questions accordingly. A total of 22 responses were obtained (from 12 reclaimers, 7 MRFs, and 3 brokers), which is a satisfactory response rate for such a survey that required significant effort to collect valuable responses.

Survey questions were designed to understand the sources of plastic recyclables, amounts of plastics processed and recovered by type, methods used to sort plastic, size and types of plastics sorted, types of sorting technology in use, sorting efficiency, the technological developments that MRFs hope to see, top contaminants, average percentage contamination in the bales, the quantity of residual/landfilled material, and the types of plastic objects produced by reclaimers from recycled plastic. Specifically, survey questions were organized into 6 sections. Section 1 involved data on the type of facility (i.e., MRF, broker, or recycler) and the location of the facility. Facility locations would help estimate the amount of plastic processed from different regions. In Section 2, the waste sourcing method was designed to understand the impact of sourcing methods of plastic (i.e., municipal waste (single stream), dual stream, industrial source) on the quality of sorted plastic. Section 3 was based on the separation process used at MRFs, whether manual, automated separation, or both manual and automated sorting. If automated sorting or a combination of automated and manual sorting was selected, it was asked to provide details on the type of sorting equipment employed (magnetic separator, eddy current device, disc screen, trommel, screen, vibrating screen, traveling chain curtains, air classification system, and optical sorting equipment and the brand of the optical sorting equipment). Optical sorting equipment details would allow the comparison of sorting efficiency at the MRF level to the sorting efficiency reported by the equipment manufacturer. Section 4 was based on the challenges and limitations associated with sorting plastic waste at MRFs and how these challenges affect MRFs operations. Moreover, MRFs were asked to provide improvement recommendations in current or emerging sorting technologies that would benefit them and improve sorting efficiency. In Section 5, MRFs were asked to provide data on the type (e.g., PET), form (rigid or film), and amount of plastic sorted. MFRs were also asked to provide details and the fate of produced residuals. Section 6 was based on contamination on sorted plastic or efficiency of sorting technologies and their impact at the MRF level. Examples of survey questions are included in Appendix B. Note that only the parts of the survey that pertain to automated sorting are discussed here.

3. Plastic Type Identification Principles

In order to achieve the US national recycling rate target of 50% by 2030, with specific goals of reducing contamination in recycled content and improving the quality of recycled materials [21], a technology improvement is expected in order to keep pace with today’s diverse and changing waste system. Eriksen et al. [22] reported that 17% to 100% of post-consumer plastic could be recovered with an improved source separation system and improved separation efficiency at the MRF level. The same study concluded that <42% of plastic could be sorted with current technology [22].

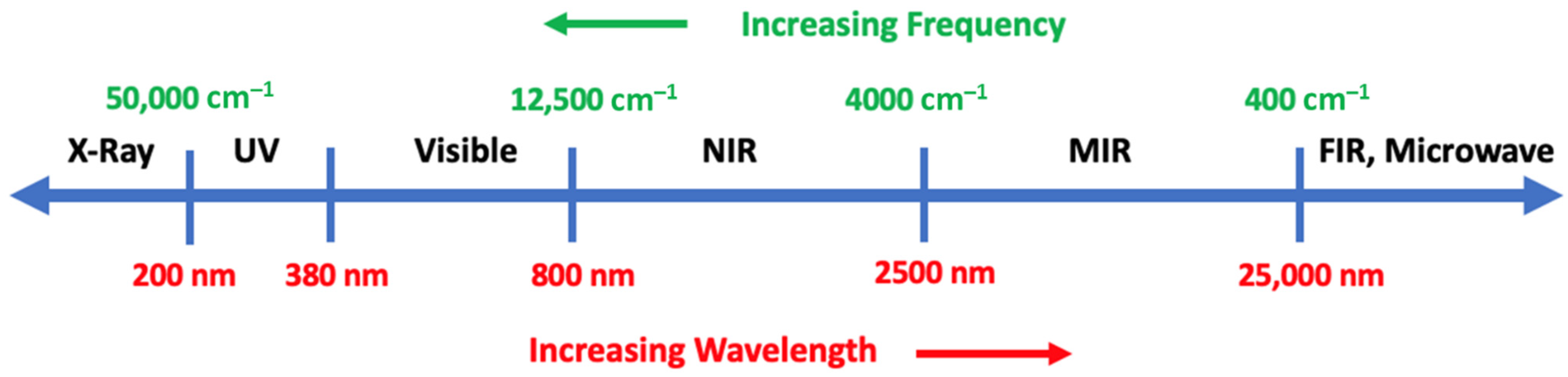

Current technologies used to sort plastic waste are based on Near Infrared (NIR), X-ray Fluorescence (XRF), and VIS (color analysis by camera or spectro-colorimeter) [23,24,25]. Some other technologies, such as mid-infrared (MIR), shape recognition, hyperspectral imaging, electrostatic separators, and barcode scanners, show potential for sorting plastic recyclables but are yet to be used in large scale plastic sorting [26,27,28,29]. The wavelength ranges for each optical technology vary, from lower (X-ray) to higher wavelengths for NIR and Microwave (Figure 1). The three key methods (i.e., NIR, XRF, VIS) have different advantages in sorting different types of plastic, as outlined below. In general, optical sorting works because, when light reaches an object, some light is reflected, and some is absorbed. Different materials reflect and absorb light at different wavelengths. The reflected light minus the absorbed light produces a signature or fingerprint, which is unique to the chemical makeup of the object, allowing plastic objects to be sorted based on their chemical composition [30,31].

Figure 1.

Wavelength range for different optical technologies (adapted from [20,32]).

Near InfraRed (NIR) based sorters employ rapid, non-destructive analysis to sort post-consumer PET, HDPE, PP, and PS [28,30]. NIR sensors detect variation in absorption, transmittance, and scattering of light in infrared wavelengths produced by different materials, which enables it to sort by plastic type [18,33]. The sorting of plastics waste can be influenced by the plastic color, surface texture, and shape, as these properties can influence the intensity of the obtained spectra [27,34]. NIR spectroscopy (wavelengths between 0.8 and 2.5 µm, Figure 1) has many advantages, such as remote high-speed measurements, the high penetration depth of the NIR radiation, and a high signal-to-noise ratio [28]. However, NIR optical sorters are not effective in sorting black plastics because the carbon black pigment interferes with the reflected light, making identification impossible because most light is absorbed. Similarly, NIR optical sorters perform poorly in sorting plastics containing brominated flame retardants (BFRs) [26].

X-ray Fluorescence (XRF) based sorters: X-rays penetrate materials and are absorbed or scattered depending on the material [18,35]. XRF works by projecting primary X-rays onto the plastic under analysis, and measures the fluorescent X-ray emitted at another wavelength by the elements present in the plastic. Each element is characterized by a unique fingerprint (spectrum), making identification of heavy elements such as chlorine and bromine possible [19]. XRF sorters are widely used to sort PVC and plastics containing BFRs [18]. However, the implementation of XRF-based sorters at an industrial level is often limited to the separation of PVC from PET [36].

Vision Technology (VIS): Optical sorting or color analysis by camera sort plastics by color. Camera-based sensors are used for identification based on the surface appearance of materials [13,37]. Commonly used technologies are the prism-coupled color camera system and visible spectrometry [20]. The prism-coupled color camera system works by measuring colors (red, green, and blue) based on intensity. Visible spectrometry works by analyzing the total range of the visible spectrum, thus accurately characterizing all colors [20]. In order to assess whether current sorting equipment can address the challenges reported by MRF operators, we evaluated both current systems (i.e., optical sorters) and emerging sorting equipment (i.e., AI sorting robots) using metrics on their efficiency, types of plastic sorted, size of plastic sorted, and ability to sort by color [13,37].

4. Challenges in Sorting Plastics

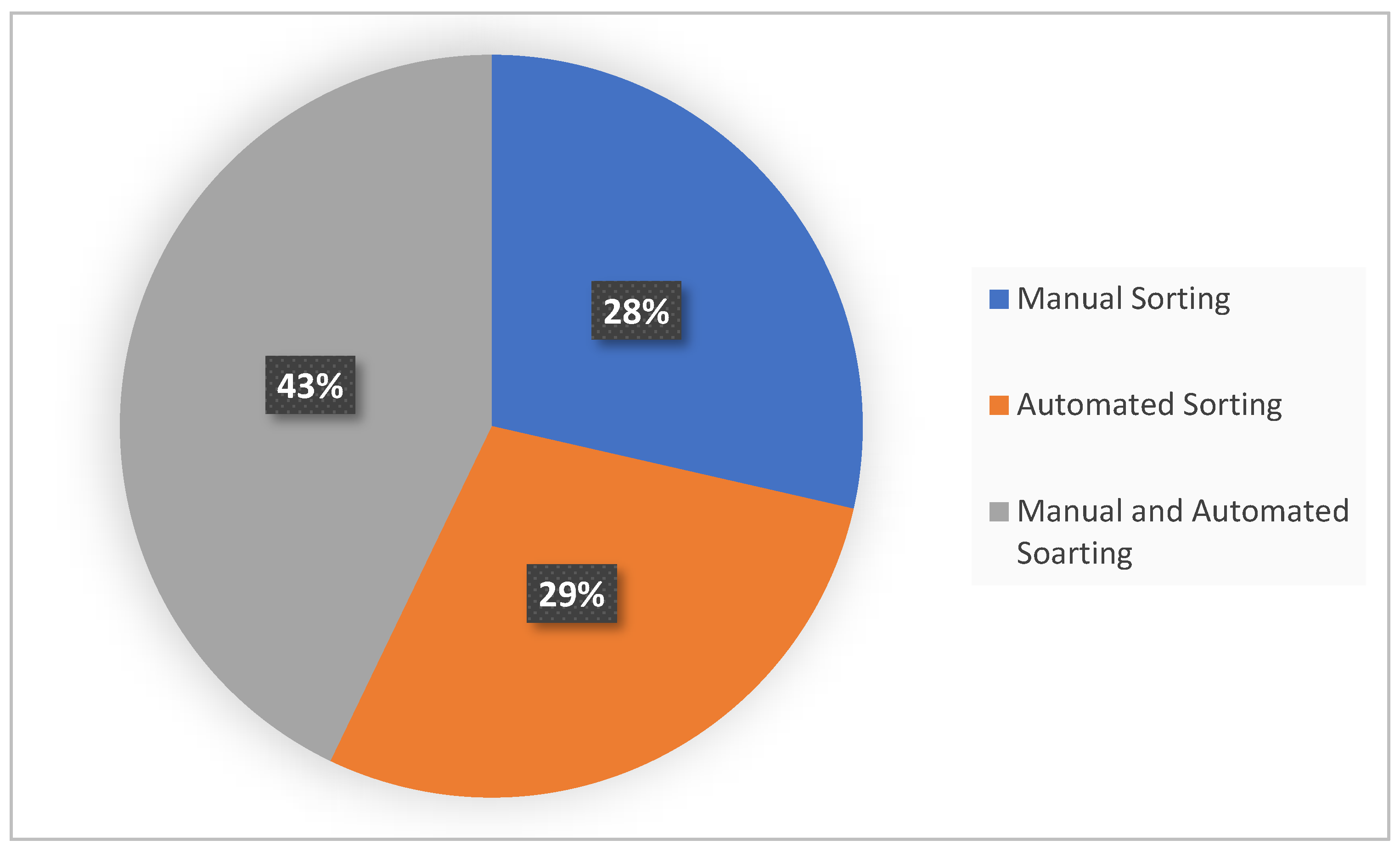

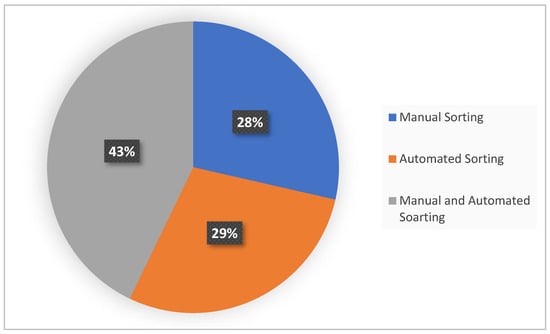

This section describes the main challenges of sorting post-consumer plastic waste, as reported by surveyed MRFs that are based in the United States. Regarding sorting technology, 29% of the seven MRFs responding to our survey use fully automated sorting facilities with little human input, 28% rely heavily on manual sorting, and 43% use both manual and automated sorting, as illustrated in Figure 2.

Figure 2.

Breakdown of sorting methodologies currently used at MRFs in the U.S.

MRFs reported difficulties in sorting a variety of plastics. Survey results indicate that 5 out of 12 plastic reclaimers (i.e., the entities to which the MRFs send their sorted plastics) reported concerns about the quality of bales provided by MRFs, and indicated that up to 5% of bales from MRFs are rejected due to poor sorting. Low bale quality is often associated with the presence of labels on plastic materials, multilayered films, mixed polymers, wires, and incorrectly sorted individual types of polymers. One reclaimer indicated that up to 35% of colored plastic is sorted incorrectly and therefore wasted.

Limitations reported by MRFs in their survey responses are summarized in Table 1. MRFs that rely on manual sorting of plastic recyclables reported a low throughput of materials. Automated sorting could help resolve throughput limitations faced by such facilities. Another challenge for MRFs relying on manual sorting of plastic recyclables was the growing number and types of plastic reducing sorting efficiency (see Table 1). MRFs using automated sorting (or a combination of automated and manual sorting) reported that tanglers wrapping around sorting equipment presented a challenge. Tanglers are materials such as ropes, cords, plastic films, or chains that become wrapped around sorting equipment at MRFs, affecting the functionality of equipment and/or causing the shutdown of operations [38,39]. Films (e.g., plastic bags, wrapping films) are flexible plastic materials (mostly made of LDPE or HDPE), often used for packaging (e.g., bags, pouches) or wrappers [38,40]. Bale de-wiring technology is reported to be needed by MRFs using automated sorters due to shutdowns caused by wires and tanglers, which can occur up to five times a day and last up to 30 min. MRFs and reclaimers have reported that films are difficult to sort and are generally dirty, with high contamination rates. Film sorting challenges can occur due to technology limitations at MRFs, coupled with an insufficient supply of films. Reclaimers indicated that films are costly to reprocess due to intensive washing requirements.

Table 1.

Common limitations in sorting plastic wastes reported by MRFs.

Another concern identified in the survey was the inability to sort black plastics. Black plastics are reportedly a challenge to correctly sort at MRFs [41,42]. Industry professionals (Scott Farling, personal communication, 4 June 2020) mentioned that black plastics are often considered residuals at MRFs; they are difficult to sort and have low market value. A few technologies are reported to sort black plastics [42]; however, no indication of black plastic sorting efficiency was reported by sorting equipment manufacturers.

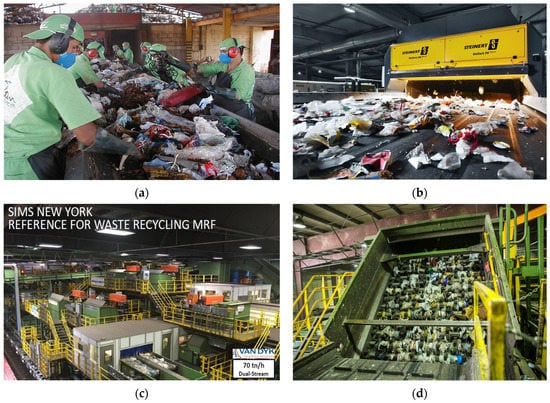

Figure 3 shows photographs from manual sorting at MRFs, automated sorting MRFs, and some of the limitations faced by MRFs.

Figure 3.

(a) Manual sorting process at MRFs, (b) automated sorting using optical sorter, (c) overview of an MRF sorting facility using multiple automated sorters, and (d) tanglers as a key problem encountered by MRFs. Extracted from cleantechloops, steinertglobal, simsmunicipal, mydisposal.

5. Factors Affecting Sorting Efficiency at the MRF Level

Sorting efficiency is affected by the composition of the incoming stream, the method of sourcing, sorting technology, and operational procedures at the MRF, as described below.

The composition of the incoming stream can directly relate to the method of sourcing, as materials can be sourced from household and industry (e.g., manufacturing companies, retail stores, offices) through (1) single-stream, (2) mixed municipal waste, (3) dual-stream, (4) pre-sorted recyclables, or (5) containers deposits [7].

Survey responses indicate that sourcing materials from container deposits (1% contamination) and industrial sources (0% contamination) resulted in higher sorting efficiency, compared to materials sourced using single stream (up to 12% contamination) or dual stream (up to 5% contamination) (see Table 2). However, anecdotal evidence from MRFs that switched from single-stream to dual-stream recycling indicates that the purity level did not differ much from bales recovered from single and double-stream recycling. Additional data are required to confirm this.

Table 2.

Sorting efficiency based on collection method, stream type, and materials sources.

Regarding sorting technology, manual and automated sorting have different efficiencies, according to survey respondents. MRFs using manual sorting reported less downtime and higher sorting efficiency compared to MRFs employing automated sorting or a combination of automated and manual sorting. The higher sorting efficiency (>98%) of manual sorting MRFs is related to the fact that one MRF uses manual sorting and receives pre-sorted plastics with a reduced presence of foreign materials (i.e., paper, glass, aluminum cans), while the second MRF using manual sorting sourced plastic from dual-stream waste.

Operational procedures at MRFs affect sorting efficiency. Running operations beyond designed capacity were reported as a problem by one respondent, as it reduced sorting efficiency. Running operations at greater than design capacity can indicate that processing more materials might be more important than sorting efficiency for this MRF.

In order to ensure quality plastics for reprocessing, it is important to limit contamination in sorted materials (1.5% commonly used limit, 0.5% for China since the National Sword program was adopted) [43]. For example, as little as 50 ppm of PVC can render an entire load of PET unmarketable [9,17].

MRFs report that film separation from municipal solid waste is challenging [44]. Over 60% of survey respondents indicated this problem, and that the recovery rate is low and contamination in the sorted plastics is high (>2%). Up to 5% of film bales received by reclaimers from MRFs are discarded or returned. Moreover, the demand for films is low, attributed to low quality associated with sorting challenges. One MRF that processes plastic films indicated that <10% of sorted films are sold for reprocessing.

In Section 6, commercially available sorting equipment is evaluated as a potential remedy to the problems reported by MRFs in sorting plastic.

6. Advances in Sorting Plastics

6.1. Sorting Equipment for Post-Consumer Plastics

This section describes commercial sorting equipment for sorting mixed plastics. The optical sorters considered here utilize NIR, VIS (light- or camera-based), and XRF. Reported technologies are classified here based on criteria such as plastic identification method (e.g., NIR or XRF), primary application, throughput, whether they sort plastics by color, and/or by size, accuracy, and additional features (Table 3).

Table 3.

Inventory of commercially available sorters for whole (i.e., bottle) plastic.

A total of 46 optical sorters manufactured by 17 companies have been identified. Of these, 22 can sort plastic by color, with 21 of them capable of sorting black plastics from other colors using a combination of NIR and VIS technologies. The number of optical sorters available has increased by 70% since 4R Sustainability released their report in 2011 [19]. The reported recovery efficiency that the sorters can attain is 99.99%, depending on the input materials, with a wide range (up to 10 tons/h) of throughput capacities.

As discussed in the previous section, film separation from municipal solid waste is challenging for MRFs [44]. While traditional sorters designed to sort whole plastic items are not efficient in sorting plastic films and other 2D or lightweight materials, the technology exists to sort plastic films. In Table 4, nine specialist film sorters manufactured by eight companies are listed. None of these sorters was identified in the previous reports by 4R Sustainability [19] and by Delavelle [20]. These film sorters can reportedly attain an efficiency of 98%, dependent on material inputs. Three of them have the ability to sort films by color, and most of them (67% of sorters) use a combination of NIR and VIS. The film sorter Machina Cattura Sacchetti Film grabber Machine Unit by Amut Ecotech is not an optical sorter as it uses a blower to separate films or plastic bags, but is reported to be efficient in sorting films or plastic bags at the MRF level.

Table 4.

Inventory of commercially available film sorters.

Flake sorting is an important step prior to reprocessing plastic, as it reduces contamination from foreign materials or unwanted plastics that passed through previous sorting steps. In Section 5, we mentioned that as little as 50 ppm of PVC could contaminate an entire load of PET plastics; thus, further sorting can be necessary after whole plastic items are flaked. Flake sorters separate plastics down to 1 mm in size, depending on equipment types. Table 5 reports the currently available plastic flake sorters. Thirty-five flake sorters, manufactured by 16 companies, have been identified. This compares to 25 sorters identified in the 2011 4R Sustainability report. The reported accuracy that flake sorters can attain is 99%, depending on material inputs. Identification of plastic type is achieved using NIR, XRF, or VIS. Seventeen flake sorters have the ability to sort flakes by color.

Table 5.

Inventory of commercially available flake sorters.

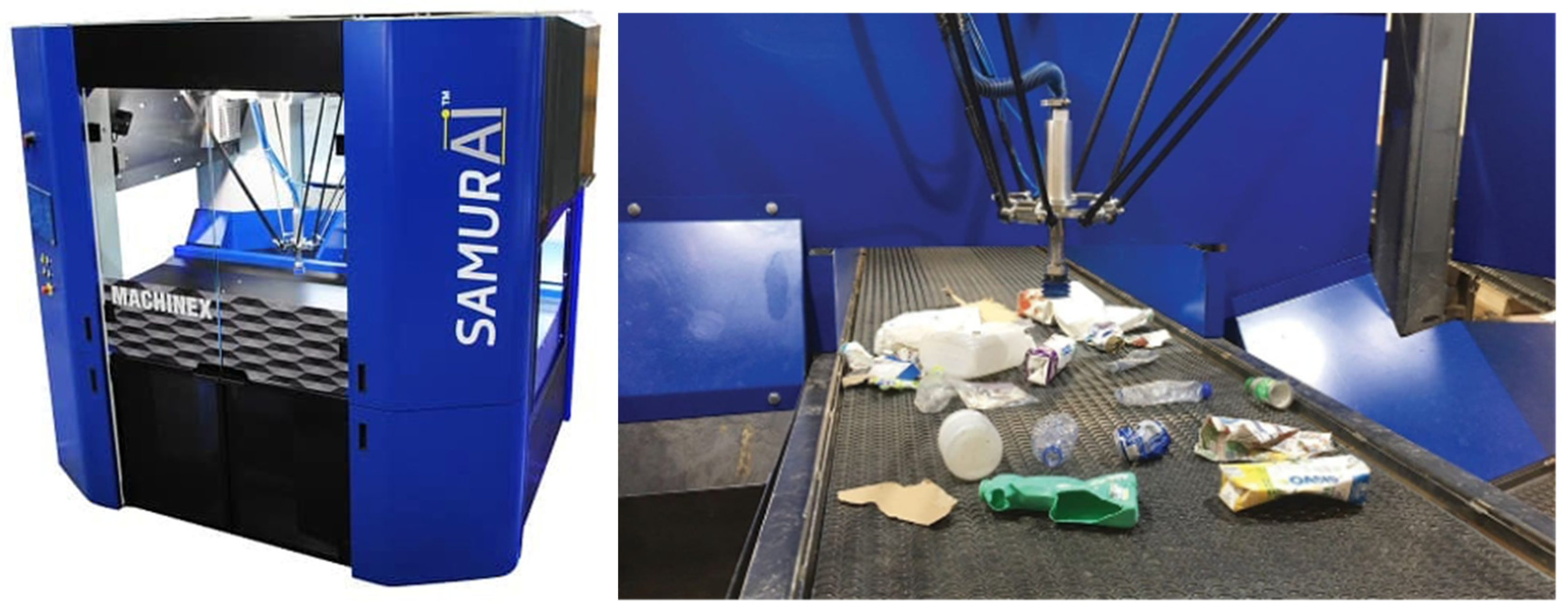

6.2. AI-based Sorting Robots

In order to tackle challenges encountered in the field of waste management, new approaches are being developed based on the use of computers and robotic technologies (Figure 4) [16,45]. Sorting robots, guided by AI, can either operate as an alternative to traditional optical sorters or can supplement optical sorters by purging incorrectly sorted plastics at the end of the sorting process [16]. Moreover, AI sorters have the ability to improve sorting efficiency over time by using available data to mimic a human brain’s learning and decision-making processes [46,47,48].

Figure 4.

AI-based sorting robots, extracted from: https://www.machinexrecycling.com/products/samurai-sorting-robot/ (last accessed on 12 February 2022).

A total of seven AI-based sorters are reported here from seven different companies, all with the ability to sort plastic by type and color (Table 6). Some MRFs have already integrated AI-based sorters in their processing line, according to manufacturers of AI-based sorters that report in their publicity materials lists of MRFs that have adopted their technologies. The plastic identification method or sorting method involves Deep Learning and VIS, and in some cases, combine Deep Learning, VIS, and NIR. Past reports (4R Sustainability [19] and Delavelle [20]) did not report any AI-based sorters.

Table 6.

Inventory of emerging AI-based sorters.

7. Conclusions

Large volumes of plastic are generated and landfilled every year, increasing pressure to recycle them. For efficient recycling, sorting is important, as it increases the quantity and improves the quality and value of post-consumer plastics for reprocessing. As most MRFs receive large volumes of mixed plastics, automated sorting has proven efficient in separating large plastics while maintaining a high throughput of sorted materials.

This study identifies current limitations or challenges encountered by US-based MRFs when sorting plastic recyclables, reports on the types and capabilities of plastic-sorting equipment that is commercially available in North America and Europe, and assesses how the available equipment can address the sorting challenges that MRFs face. This study does not address the financial aspects of automated sorting deployment.

Findings from a survey identifying MRF needs and interviews with industry professionals indicate that MRFs struggle to sort tanglers, films, black plastics, and plastic objects made of a combination of polymers or polymer blends. Other reported challenges are that MRFs that rely heavily on manual sorting have throughput constraints. The commercial sorting equipment presented here can address some of the challenges that MRFs encounter. Black plastics can be sorted with currently available sorters (Table 3, Table 4, Table 5 and Table 6). Tanglers can be partially addressed using AI-based sorters, as they have the ability to sort materials by shape and can sort wires. However, the efficiency of AI sorters in high-volume MRFs is yet to be reported. Moreover, AI-based sorters are typically placed at the end of a sorting line to remove residual or recover materials missed by optical sorters. Thus, they may not address shutdowns caused by tanglers. Throughput constraints experienced by MRFs currently utilizing manual sorting can be solved by implementing automated sorting. However, the effective sorting of multilayered, blended, or mixed-material plastics remains a challenge as sorting equipment is designed to sort single-component materials. Accordingly, new solutions or improvements are needed to improve current optical sorters to sort these complex plastics.

The inventory of commercially available sorting equipment includes 46 optical sorters for whole plastic objects, 35 flake sorters (from 16 companies), 9 film sorters (from 9 companies), and 7 AI-based sorters for mixed plastic recyclables. The previous reports were published on plastic sorting equipment date from over ten years ago [19,20]. The recovery efficiency of sorting equipment reported herein can be as high as 99.99%, depending on input materials, with a wide range of throughput capacities (up to 10 ton/h). Growth in available sorting technology was observed (70% increase in whole plastic sorters, 26% increase in flake sorters) compared to the 2011 report by 4R Sustainability [19]. Continued growth in plastic usage and waste generation creates demand for more plastic sorters. This inventory of commercially available sorting equipment includes nine film sorters and seven AI-based sorters; past studies did not report any of these technologies, reflecting the recent advances in AI. The efficiency of film sorting at the MRF level remains low, evidenced by high contamination rates (10 wt%) reported in most outgoing bales. Thus, further progress in film sorting equipment is necessary.

The sorting efficiency (91% to 99%) reported by MRFs in the survey is lower than that reported by equipment manufacturers (up to 99.99%). However, a direct comparison of sorting equipment efficiency between manufacturers and MRFs was not possible, as MRFs provided little detail on the specific types of sorters in use. In practice, factors such as the composition of the incoming stream, method of sourcing, and operations at MRFs can affect the achieved sorting efficiency of optical sorters. In order to improve sorting efficiency at the MRF level, operating conditions that favor higher sorting efficiency could be required, e.g., a reduced capacity that tends to yield cleaner bales but can be financially unfavorable, or reduced heterogeneity of incoming waste, or use of sorting technologies with higher sorting efficiency.

This report reveals an improvement in the availability of sorting equipment for plastic over the past ten years, evidenced by film sorters and AI-based sorters that were not previously available. The potential efficiency of sorting equipment from past reports and currently available sorting equipment remains similar. This study can serve as a guide for MRFs interested in evaluating the current state of sorting equipment and identifying equipment that best matches their needs.

Perspective and Outlook: Technology for automated sorting of plastics is widely available and deployed at MRFs. Sorting technology advances will continue, with AI-driven identification and robotic manipulation being currently at the forefront. Some of the challenges in mechanical recycling that are associated with tanglers and black plastic remain to be addressed. A series of sorters specializing in different shapes or sizes of plastic would improve the sorting efficiency. Deployment of advanced technology, however, comes at a cost, and the recovery of investment depends on the market value of sorted plastic, incentives for sorting plastic and/or disincentives associated with not sorting plastic waste. Chemical recycling, if/when widely deployed, can handle plastic that currently poses challenges in mechanical recycling involving sorting. MRFs with different levels of scale and specialization, and corresponding sorting equipment, can coordinate their inputs and outputs and connect to chemical recycling plants, working toward a concerted goal to decrease the plastic that ends up in landfills and the environment, and increase the plastic that is being reused in products for the benefit of a circular economy.

Author Contributions

C.L.: Methodology, Investigation, Data Curation, Writing—Original Draft. P.A.: Conceptualization, Methodology, Resources, Writing—Review and Editing, Supervision, Project Administration, Funding Acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

The authors thank New York’s Environmental Protection Fund, the New York State Department of Environmental Conservation (NYSDEC), for financial support. The work was supported by a grant from NYSDEC to the University at Buffalo (UB), under Memorandum of Understanding AMI 1642. Research on plastic recycling in P.A.’s laboratory is supported by the US National Science Foundation (NSF) award 2029375 “EFRI E3P: Valorization of Plastic Waste via Advanced Separation and Processing.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The survey data are not publicly available due to privacy reasons.

Acknowledgments

The authors acknowledge useful discussions with Amit Goyal, Project Director of this grant, and with John D. Atkinson (UB Civil, Structural and Environmental Engineering), Michael Shelly (UB RENEW Institute), Aditya Vedantam (UB School of Management), as well as Amy Bloomfield, Terry Laibach, Jaime Lang, Gerard Wagner, and David Vitale at NYSDEC. John D. Atkinson and Michael Shelly provided valuable feedback on this document. We thank project team-members Jenna Mert, Austin Izzio, and Khadija Amal for their contribution in developing and administering the survey results that are reported here. We also thank all the industry professionals who participated in our survey or provided information through interviews.

Conflicts of Interest

The authors have no conflict of interest in regard to this work or any commercial association with the results of this work at this present time.

Appendix A

Optical sorter supplier contact information.

| Amut Ecotech Via San Marco 11/a 31052 Candelù-Maserada sul Piave (TV)-Italy Phone: +39 0422 877 688/689 Fax +39 0422 877 690 E-mail: info@amutecotech.it Website: www.amutecotech.it (last accessed 15 February 2022) | Best Contact details unavailble Website: http://best-sea.primary-engineering.co.th/recycling.html www.amutecotech.it (last accessed 16 February 2022) |

| Binder + Co Grazer Straße 19-25 A-8200 Gleisdorf, Austria Phone: +43-3112-800-0 Email: office@binder-co.at www.binder-co.com (last accessed 12 February 2022) | BT-Wolfgang Binder GmbH (Redwave) Wolfgang Binder Str. 4 8200 Eggersdorf bei Graz, Austria Phone: +43-3117-25152-2100 E-mail: office@btw-plantsolutions.com http://www.btw-binder.com/en/ (last accessed 12 February 2022) www.redwave.com (last accessed 12 February 2022) |

| Buhler Gupfenstrasse 5 Uzwil 9240 Switzerland Phone: +41 71 955 19 00 Website: https://www.buhlergroup.com (last accessed 16 February 2022) | Cimbria Faartoftvej 22 7700, Thisted, Denmark Phone: +45-96-17-90-00 E-mail: cimbria.holding@agcocorp.com https://www.cimbria.com (last accessed 12 February 2022) |

| CP Group (MSS) Sorting Equipment 795 Calle de Linea San Diego, CA 92154, USA Phone: 19-477-3175 Fax: 619-477-3426 https://www.cpgrp.com (last accessed 12 February 2022) | Eagle Vizion 425 Boul. Industriel Sherbrooke, QC Canada Email: nlortie@eaglevizion Phone: 912-563-7374 Fax: 819-340-1034 www.eaglevizion.com (last accessed 12 February 2022) |

| Green Machine LLC 8300 State Route 79 Whitney Point, NY 13862-2504, U.S.A. Phone: (800)-639-6306 Email: ap@greenmachine.com Website: www.greenmachine.com (last accessed 12 February 2022) | IMRO Landwehrstrasse 2, Uffenheim, D-97215, Germany Phone: +49 (0) 9848-9797-0 Email: luis@imro.us Website: https://www.imro-maschinenbau.de/en/ (last accessed 12 February 2022) |

| Mogensen GmbH/Allgaier Process Technology GmbH Kronskamp 126 22880 Wedel, Germany Phone: +49-4103-8042-0 E-mail: info@mogensen.de https://www.allgaier-process-technology.com/de (last accessed 12 February 2022) | MSS, Inc. [A division of CP Group] 300 Oceanside Drive Nashville, TN 37204, U.S.A. Phone: 615-781-2669 Email: info@mssoptical.com https://www.mssoptical.com (last accessed 12 February 2022) |

| NRT 1508 Elm Hill Pike Nashville, TN 37210, U.S.A. Phone: +1-615-734-6400 Email: service@nrtsorters.com www.nrtsorters.com (last accessed 12 February 2022) | Pellenc ST 84-124 Pertuis Cedex 4 France Phone: +33-4-90-09-47-90 www.pellencst.com (last accessed 12 February 2022) |

| PicVisa Isaac Newton, 2 Barcelona, Spain Phone: +34-93-868-08-45 www.picvisa.com (last accessed 12 February 2022) | Rhewum GmbH Rosentalstrasse 24 42899 Remscheid, Germany Phone: +49 2191 5767-0 Email: info@rhewum.de Website: https://www.rhewum.com/en Website: https://steinertglobal.com (last accessed 16 February 2022) |

| Rofin Australia 6/42-44 Garden Boulevard Dingley Victoria 3172 Australia Phone: 61 3 9558 0344 Fax 61 3 9558 0252 E-mail: info@rofin.com.au Website: http://www.rofin.com.au/index.htm (last accessed 16 February 2022) | Rofin USA 696 San Ramon Valley Blvd. #334 Danville, CA 94526 Phone: 925-552-5922 Fax: 925-886-8833 E-mail: keith@rofinusa.com Website: http://www.rofin.com.au/index.htm (last accessed 16 February 2022) |

| RTT Steinert GmbH Widdersdorfer Str. 329-331 50933 Köln, Germany Phone: +49-221-49840 Email: sales(at)steinert.de Website: https://steinertglobal.com (last accessed 12 February 2022) | Satake 10900 Cash Road Stafford, Texas 77477 USA Phone: +1 (281) 972-3581 Website: https://satake-usa.com (last accessed 16 February 2022) |

| Sesotec GmbH (S+S Separation and Sorting Technology GmbH) Regener Strabe 130 D-94513 Schonberg, Germany Phone: +49-8554-308-0 www.sesotec.com (last accessed 12 February 2022) | Steiner US 285 Shorland Drive Jeremy Hundley Phone: +1 (859) 462-4878 Website: https://steinertglobal.com/us/ (last accessed 12 February 2022) |

| TiTech GmbH Otto- Hahn-Straβe 6 56218 Mülheim-Kälich, Germany Email: wolf@titech.com Phone: +1-203-524-3555 Fax: +1-203-967-1199 Website: www.titech.com (last accessed 12 February 2022) | TOMRA Systems ASA Drengsrudhagen 2 Asker 1385 Norway Phone: +47-66-79-91-00 https://www.tomra.com/en (last accessed 12 February 2022) |

| Unisensor Sensorsysteme GmbH Am Sandfeld 11 76149 Karlsruhe, Germany Phone: +49-(721)-97884-0 Email: info(at)unisensor.de Website: www.unisensor.de/en/ (last accessed 12 February 2022) | Visys Birlik Sanayi Sitesi 2. Cadde No:97 34520 Beylikdüzü—İstanbul—Turkey Phone: +90-212-876-90-36 Fax: +90-212-876-90-37 E-mail: info@visystr.com Website: www.visys.com.tr (last accessed 12 February 2022) |

Artificial intelligence-based sorter supplier contact information.

| AMP Robotics 1500 Cherry Street, Suite A Louisville, CO 80027, U.S.A Phone: (888) 402-1686 Website: www.amprobotics.com (last accessed 12 February 2022) | Back Handling Systems (BHS) 3592 West 5th Avenue Eugene, OR 97402, U.S.A. Phone: 541.485.0999 Website: https://www.bulkhandlingsystems.com (last accessed 12 February 2022) |

| Bollegraaf Recycling Solutions Tweede Industrieweg 1, 9902 AM Appingedam, Netherlands Phone: +31-596-654-333 Website: https://www.bollegraaf.com (last accessed 12 February 2022) | BT-Wolfgang Binder GmbH (Redwave) Wolfgang Binder Str. 4 8200 Eggersdorf bei Graz, Austria Phone: +43-3117-25152-2100 E-mail: office@btw-plantsolutions.com http://www.btw-binder.com/en/ (last accessed 12 February 2022) |

| Machinex 2121, Olivier Street Plessisville QC, G6L 3G9 Canada Phone: +1-(819) 362-3281 Website: www.machinexrecycling.com (last accessed 12 February 2022) | OP teknik Truck path 2 298 32 Tollarp, Sweden Phone: 010-456-82-87 Website: https://www.opteknik.se/?lang=en (last accessed 12 February 2022) |

| TOMRA Systems ASA Drengsrudhagen 2 Asker 1385, Norway Phone: +47-66-79-91-00 Website: https://www.tomra.com/en (last accessed 12 February 2022) |

Appendix B

Survey questions used to obtain information from MRFs and reclaimers.

| Please indicate how you would classify your facility? (MFR, Broker, or Reclaimer) |

| Please select which region(s) your company currently is operating in |

| What types of material streams does your facility process? (Single stream, dual stream, both) |

| In total, what percentage of your facility’s incoming stream(s) are from post-industrial sources? |

| What techniques are used at your facility to sort plastic? (Please select all that apply, Manual Separation, Automated Separation, or both) |

| If automated sorting is used, please indicate which of the following mechanical sorting equipment is used in your facility and in what quantity—Optical (Sensor-based) Sorting Equipment—Quantity (# of equipment) |

| What is the basis(es) of operation of the sorting technology? |

| Does your sorting technology sort whole plastic items and/or flakes? |

| What is the brand manufacturer of your sorting equipment? |

| Please comment on the limitations of the sorting methods currently in use at your facility |

| What type of technological development(s) would benefit your facility? |

| Overall, please identify the top 3 reasons for a facility shut down |

| Please comment on what you expect to see as future trends regarding technology (e.g. more automation relative to manual, certain type of technology vs other types of technologies) |

| At present, what type (i.e., PET) and form (rigid, films) of plastic does your facility process for recycling? (i.e., it is sorted and sold to a downstream buyer?). select all that apply (Rigid PET, HDPE, PVC, LDPE, PP, PS, other, films, industrial scrap) |

| Approximately, how many pounds of plastic bales were processed at your facility in 2019?—PET (#1), HDPE (#2), PVC (#3), LDPE (#4), PP (#4), films, Industrial scrap, and other (7)—Quantity (tons per year) |

| Overall, what percentage of plastic bags (films) received do you on-sell for processing? |

| What are some of the reasons why your facility does not process plastic films and bags for recycling? Please select all that apply: (insufficient supply of materials, insufficient demand, difficult to sort and process) |

| What percent of the incoming stream at your facility is residual/non-recyclable material? |

| Does your facility produce plastic only residual (mixed plastic not sold for recycling)? |

| If plastic residual is produced, how is it managed? (Incineration, landfill, other) |

| What are the top three contaminants of concern at your MRF? |

| What is the average percent contamination in the bales of each product produced by your facility? |

| What is the average percent contamination in the bales of each product produced by your facility? (Please input "0" if no contamination or leave blank if unsure)-PET (Plastic #1)-% Weight |

| What is the average percent contamination in the bales of each product produced by your facility? (Please input "0" if no contamination or leave blank if unsure)-Colored HDPE (Plastic #2)-% Weight |

| What is the average percent contamination in the bales of each product produced by your facility? (Please input "0" if no contamination or leave blank if unsure)-PVC (#3)-% Weight |

| What is the average percent contamination in the bales of each product produced by your facility? (Please input "0" if no contamination or leave blank if unsure)-Polypropylene (#5)-% Weight |

| What is the average percent contamination in the bales of each product produced by your facility? (Please input "0" if no contamination or leave blank if unsure)-LDPE, Polystyrene, Other Plastics (#4, #6, & #7)-% Weight |

| What is the average percent contamination in the bales of each product produced by your facility? (Please input "0" if no contamination or leave blank if unsure)-Mixed Rigid Plastic (MRP)-% Weight |

| What is the average percent contamination in the bales of each product produced by your facility? (Please input "0" if no contamination or leave blank if unsure)-Plastic Films & Bags-% Weight |

References

- US Environmental Protection Agency. Facts and Figures about Materials, Waste and Recycling. Available online: https://www.epa.gov/sites/default/files/2021-01/documents/2018_ff_fact_sheet_dec_2020_fnl_508.pdf (accessed on 19 June 2021).

- Northfield, R. Despite Our Best Efforts, Plastic Is Still a Blight in our World. What Are We Doing Wrong? Available online: https://eandt.theiet.org/content/articles/2019/03/the-problem-with-plastic/ (accessed on 12 February 2022).

- Vollmer, I.; Jenks, M.J.F.; Roelands, M.C.P.; White, R.J.; van Harmelen, T.; de Wild, P.; van der Laan, G.P.; Meirer, F.; Keurentjes, J.T.F.; Weckhuysen, B.M. Beyond mechanical recycling: Giving new life to plastic waste. Angew. Chem. (Int. Ed. Engl.) 2020, 59, 15402–15423. [Google Scholar] [CrossRef] [Green Version]

- da Silva, D.J.; Wiebeck, H. Current options for characterizing, sorting, and recycling polymeric waste. Prog. Rubber Plast. Recycl. Technol. 2020, 36, 284–303. [Google Scholar] [CrossRef]

- Lawrence, M.J. 10—Disposal of Plastics. In A Guide to the Manufacture, Performance, and Potential of Plastics in Agriculture; Orzolek, M.D., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 187–195. [Google Scholar]

- Brunner, S.; Fomin, P.; Kargel, C. Automated sorting of polymer flakes: Fluorescence labeling and development of a measurement system prototype. Waste Manag. 2015, 38, 49–60. [Google Scholar] [CrossRef]

- Cimpan, C.; Maul, A.; Wenzel, H.; Pretz, T. Techno-economic assessment of central sorting at material recovery facilities—The case of lightweight packaging waste. J. Clean. Prod. 2016, 112, 4387–4397. [Google Scholar] [CrossRef] [Green Version]

- Hundertmark, T.; Pietro, M.; Ryba, A.; Simons, T.J.; Wallach, J. Accelerating Plastic Recovery in the United States; McKinsey & Company, U.S.A, 2019; Available online: https://www.mckinsey.com/industries/chemicals/our-insights/accelerating-plastic-recovery-in-the-united-states (accessed on 12 February 2022).

- Damgacioglu, H.; Hornilla, M.; Bafail, O.; Celik, N. Recovering value from single stream material recovery facilities—An outbound contamination analysis in Florida. Waste Manag. 2020, 102, 804–814. [Google Scholar] [CrossRef]

- American Chemistry Council. 2018 United States National Postconsumer Plastic Bottle Recycling Report. 2018. Available online: https://plasticsrecycling.org/images/library/2018-postconsumer-bottle-recycling-report.pdf (accessed on 12 February 2022).

- Vedantam, A.; Shelly, M.; Ajmal, K. Evaluating Secondary Market Conditions for Plastic Recyclables, Assessment of Processing Capacity in NYS and the U.S.; University at Buffalo, The State University of New York: Buffalo, NY, USA, 2021. [Google Scholar]

- Bledzki, A.K.; Goracy, K. Installations to sort packaging plastics wastes. Polimery 1998, 43, 1–10. [Google Scholar] [CrossRef]

- Gundupalli, S.P.; Hait, S.; Thakur, A. A review on automated sorting of source-separated municipal solid waste for recycling. Waste Manag. 2017, 60, 56–74. [Google Scholar] [CrossRef]

- Maulidati, N.; Cahyo, A.D.N.; Djamari, D.W.; Fikri, M.R.; Triawan, F. Development of sorting system for plastic bottle waste management. IOP Conf. Series. Mater. Sci. Eng. 2021, 1098, 062103. [Google Scholar] [CrossRef]

- Kim, J.; Nocentini, O.; Scafuro, M.; Limosani, R.; Manzi, A.; Dario, P.; Cavallo, F. An innovative automated robotic system based on deep learning approach for recycling objects. In Proceedings of the 16th International Conference on Informatics in Control, Automation and Robotics (ICINCO), Prague, Czech Republic, 29–31 July 2019; pp. 613–622. [Google Scholar]

- Wilts, H.; Garcia, B.R.; Garlito, R.G.; Gomez, L.S.; Prieto, E.G. Artificial intelligence in the sorting of municipal waste as an enabler of the circular economy. Resources 2021, 10, 28. [Google Scholar] [CrossRef]

- Alexander, D. Design of a Materiasl Recovery Facility (MRF) For Processing The Recyclable Materials of New York City Municipal Solid Waste; Columbia University: New York, NY, USA, 2000. [Google Scholar]

- Vrancken, C.; Longhurst, P.J.; Wagland, S.T. Critical review of real-time methods for solid waste characterisation: Informing material recovery and fuel production. Waste Manag. 2017, 61, 40–57. [Google Scholar] [CrossRef] [Green Version]

- 4R Sustainability Inc. Demingling the Mix: An Assessment of Commercially Available Automated Sorting Technology. 2011. Available online: https://www.polyester-technology.com/download/demingling-the-mix-an-assessment-of-commercially-available-automated-sorting-technology-4/?wpdmdl=604&refresh=612e6f490214d1630433097 (accessed on 12 October 2020).

- Delavelle, C. State of the Art of Waste Identification and Sorting Technology. 2012. Available online: https://www.ademe.fr/sites/default/files/assets/documents/87753_rapport-ajeurope-technologies-de-tri.pdf (accessed on 12 February 2022).

- US Environmental Protection Agency. The National Recycling Goal; US Environmental Protection Agency: Washington, DC, USA, 2020. Available online: https://www.epa.gov/sites/default/files/2020-12/documents/final_one_pager_to_print_508.pdf (accessed on 12 February 2022).

- Eriksen, M.K.; Damgaard, A.; Boldrin, A.; Astrup, T.F. Quality assessment and circularity potential of recovery systems for household plastic waste. J. Ind. Ecol. 2019, 23, 156–168. [Google Scholar] [CrossRef] [Green Version]

- Vogt, B.D.; Stokes, K.K.; Kumar, S.K. Why is recycling of postconsumer plastics so challenging? ACS Appl. Polym. Mater. 2021, 3, 4325–4346. [Google Scholar] [CrossRef]

- Cimpan, C.; Maul, A.; Jansen, M.; Pretz, T.; Wenzel, H. Central sorting and recovery of MSW recyclable materials: A review of technological state-of-the-art, cases, practice and implications for materials recycling. J. Environ. Manag. 2015, 156, 181–199. [Google Scholar] [CrossRef]

- Araujo-Andrade, C.; Bugnicourt, E.; Philippet, L.; Rodriguez-Turienzo, L.; Nettleton, D.; Hoffmann, L.; Schlummer, M. Review on the photonic techniques suitable for automatic monitoring of the composition of multi-materials wastes in view of their posterior recycling. Waste Manag. Res. 2021, 39, 631–651. [Google Scholar] [CrossRef]

- Siddappaji, K.; Sujatha, K.; Radha, R.C. Technologies for segregation and management of solid waste: A review. In Proceedings of the 2016 International Conference on Emerging Trends in Engineering, Technology and Science (ICETETS), Pudukkottai, India, 24–26 February 2016; pp. 1–4. [Google Scholar]

- Henriksen, M.L.; Karlsen, C.B.; Klarskov, P.; Hinge, M. Plastic classification via in-line hyperspectral camera analysis and unsupervised machine learning. Vib. Spectrosc. 2022, 118, 103329. [Google Scholar] [CrossRef]

- Zheng, Y.; Bai, J.R.; Xu, J.N.; Li, X.Y.; Zhang, Y.M. A discrimination model in waste plastics sorting using NIR hyperspectral imaging system. Waste Manag. 2018, 72, 87–98. [Google Scholar] [CrossRef]

- Cucuzza, P.; Serranti, S.; Bonifazi, G.; Capobianco, G. Effective recycling solutions for the production of high-quality PET flakes based on hyperspectral imaging and variable selection. J. Imaging 2021, 7, 181. [Google Scholar] [CrossRef]

- Wu, X.; Li, J.; Yao, L.; Xu, Z. Auto-sorting commonly recovered plastics from waste household appliances and electronics using near-infrared spectroscopy. J. Clean. Prod. 2020, 246, 118732. [Google Scholar] [CrossRef]

- Weiss, M. XRF-New Applications in Sensor-Based-Sorting Using X-ray Fluorescence. 2012. Available online: https://www.vivis.de/wp-content/uploads/WM3/2012_WM_139_148_Weiss.pdf (accessed on 12 February 2022).

- Shimadzu. UV-Vis Frequently Asked Questions-Light and Theory. Available online: https://www.ssi.shimadzu.com/products/uv-vis-spectrophotometers/faqs/light-and-theory.html (accessed on 24 May 2021).

- Bonifazi, G.; Serranti, S. Quality control by HyperSpectral Imaging (HSI) in solid waste recycling: Logics, algorithms and procedures. Proc. SPIE 2014, 9024, 90240T. [Google Scholar]

- Kuppers, B.; Schloegl, S.; Oreski, G.; Pomberger, R.; Vollprecht, D. Influence of surface roughness and surface moisture of plastics on sensor-based sorting in the near infrared range. Waste Manag. Res. 2019, 37, 843–850. [Google Scholar] [CrossRef]

- Ramasubramanian, M.K.; Venditti, R.A.; Ammineni, C.; Mallapragada, V. Optical sensor for noncontact measurement of lignin content in high-speed moving paper surfaces. IEEE Sens. J. 2005, 5, 1132–1139. [Google Scholar] [CrossRef]

- Bezati, F.; Froelich, D.; Massardier, V.; Maris, E. Addition of X-ray fluorescent tracers into polymers, new technology for automatic sorting of plastics: Proposal for selecting some relevant tracers. Resour. Conserv. Recycl. 2011, 55, 1214–1221. [Google Scholar] [CrossRef] [Green Version]

- Torres-García, A.; Rodea-Aragón, O.; Longoria-Gandara, O.; Sánchez-García, F.; González-Jiménez, L.E. Intelligent waste separator. Comput. Sist. 2015, 19, 487–500. [Google Scholar] [CrossRef]

- Meert, J.; Izzo, A.; Atkinson, J.D. Impact of plastic bag bans on retail return polyethylene film recycling contamination rates and speciation. Waste Manag. 2021, 135, 234–242. [Google Scholar] [CrossRef]

- Debrecht, S. Recycle Right: Designing Tools for Resource Responsible Consumers. Ph.D. Thesis, University of Cincinnati, Cincinnati, OH, USA, 2021. [Google Scholar]

- Soto, J.M.; Blazquez, G.; Calero, M.; Quesada, L.; Godoy, V.; Martin-Lara, M.A. A real case study of mechanical recycling as an alternative for managing of polyethylene plastic film presented in mixed municipal solid waste. J. Clean. Prod. 2018, 203, 777–787. [Google Scholar] [CrossRef]

- Turner, A. Black plastics: Linear and circular economies, hazardous additives and marine pollution. Environ. Int. 2018, 117, 308–318. [Google Scholar] [CrossRef]

- Becker, W.; Sachsenheimer, K.; Klemenz, M. Detection of black plastics in the middle infrared spectrum (MIR) using photon up-conversion technique for polymer recycling purposes. Polymers 2017, 9, 435. [Google Scholar] [CrossRef] [Green Version]

- Vedantam, A.; Ajmal, K.; Shelly, M. Impact of China’s National Sword Policy on the Plastics Recycling Industry in the U.S.; University at Buffalo, The State University of New York: Buffalo, NY, USA, 2021. [Google Scholar]

- Feil, A.; Pretz, T.; Jansen, M.; Thoden van Velzen, E.U. Separate collection of plastic waste, better than technical sorting from municipal solid waste? Waste Manag. Res. 2016, 35, 172–180. [Google Scholar] [CrossRef]

- Chin, L.; Lipton, J.; Yuen, M.C.; Kramer-Bottiglio, R.; Rus, D. Automated recycling separation enabled by soft robotic material classification. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Korea, 14–18 April 2019; pp. 102–107. [Google Scholar]

- Sarc, R.; Curtis, A.; Kandlbauer, L.; Khodier, K.; Lorber, K.E.; Pomberger, R. Digitalisation and intelligent robotics in value chain of circular economy oriented waste management—A review. Waste Manag. 2019, 95, 476–492. [Google Scholar] [CrossRef]

- Bobulski, J.; Kubanek, M. Deep learning for plastic waste classification system. Appl. Comput. Intell. Soft Comput. 2021, 2021, 6626948. [Google Scholar] [CrossRef]

- Sirawattananon, C.; Muangnak, N.; Pukdee, W. Designing of IoT-based smart waste sorting system with image-based deep learning applications. In Proceedings of the 2021 18th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Chiang Mai, Thailand, 19–22 May 2021; pp. 383–387. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).