Abstract

The article compares the energetic qualities of fuels from waste with hard coal. A cogeneration system has been modeled based on the organic Rankine cycle (ORC) powered by the investigated fuels in order to identify possibilities as well as problems in use of fuels from waste in an exemplary cogeneration unit in distributed generation. The emission of thermal transition of the investigated fuels has been calculated on the basis of their energetic use in order to determine the aggregate impact on the environment, people’s health and the ecosystem. In order to conduct the research, Ebsilon Professional and SIMAPro software were used. The article demonstrated the energetic and ecological validity of the use of fuels form waste in small-scale combined heat and power (CHP). The energetic potential and influence on the environment, people’s health and the ecosystem depends on the quality of fuel, but the strict regulations for generating fuels from waste and the flexibility in forming them, allow for a product which is more beneficial economically and ecologically than hard coal.

1. Introduction

The major part of European energy technology is based on hard and brown coal. It involves high emission of carbon dioxide which is in contradiction to European Union Policy and its aims. It strives for complete elimination of coal power plants in an energetic mix among member states. These actions force EU members to search for optimal solutions and in concordance with EU expectations. Additionally, growing prices for the emission of carbon dioxide are going to contribute to the growth of prices for electrical and heat energy. State members obliged themselves to develop renewable sources of energy so that their part in the production of electrical and heat energy would be at least 15% until 2020 which is imposed by the climate and energy package [1,2,3,4,5,6]. Moreover, available technologies, economics and the need for energetic security, including industrial plants, encourage prosumer solutions which can guarantee a stable generation of electrical and heat energy [7]. Regarding energetic plans among the members of the EU, the majority of generated electrical and heat energy is going to be distributed generation which will allow the improvement of energetic security, including a constant supply of high quality energy which is going to influence the development of the economy in EU countries and limit climate destruction [1,2,3,4]. Generating energy in distributed generation might be based on renewable sources of energy, such as solar energy, wind energy, but also high-performance cogeneration powered by biomass or fuels from waste. It seems that another interesting solution is a hybrid system which has at least two sources of generation supporting each other when there is not enough production from a source of a changeable kind of production, such as photovoltaic panels. To produce electrical and heat energy in distributed generation, local sources should be used, e.g., in farming areas where there is an economic and ecological potential of establishing farm biogas plants. Biogas produced as a result of anaerobic digestion can empower a cogeneration system with the power of that particular area’s needs, or it can empower a production plant which needs heat throughout the year [8]. There are raw materials which are globally available and they could lower the cost of transportation and eliminate issues related to it when used locally and they are waste. There are a number of ideas on how to limit the production of waste and how to deal with it, and a consumer lifestyle and the need to develop lead to its growth [9,10,11]. Waste has energetic potential which can be used locally all over the world together with limiting the use of conventional sources of energy and limiting the storage of waste. This is supported by the Directive of the European Parliament and of the Council 2018/850 from 30 May, 2018 [12] which changed Directive 1999/31/WE regarding the storage of waste. It premised the lack of waste storage which might be reused until 2030. Small power-plants might be a solution for the energetic use of waste, as fuels formed from waste in distributed generation can be the ecological source of production of high-efficiency cogeneration. High-efficiency cogeneration was promoted by the European Union in Directive of the European Parliament and the Council 2012/22/EU from 25 October, 2012 [13]. Regarding energetic effectiveness, the change of Directives 2009/125 in case of small-scale units which are units of installed energetic power no bigger than 1 MW is classified as unit which provides primary energy savings. The aim of the article is to compare different fuels from waste from the perspective of using them as a substitute for coal in the generation of electrical energy and thermal energy in combined heat and power (CHP).

2. Fuel from Waste

Fuels produced from waste according to PN-EN 15359: 2012 are classified as:

- (1)

- Refuse derived fuel (RDF)—selected combustible fraction of municipal waste, meeting defined energetic properties.

- (2)

- Solid recovered fuel (SRF)—selected combustible fraction of municipal waste with the admission of industrial waste presence, excluding dangerous waste, meeting defined energetic properties.

Fuels formed of waste, just like biomass, belong to a group of so called difficult fuels due to its specific physicochemical properties and frequent differences in element composition which cause a number of issues during thermal treatment. Fuels formed from waste are used in many developed European Union countries and energy produced is partly taken as a renewable source of energy (RES) and its biodegradable part contributes to that [8,9,14,15].

The quality of waste fuels is determined on the basis of three parameters and classes 1–5 are assigned to them where class 1 is the highest quality:

- (1)

- The first parameter is a factor describing economic potential of particular waste fuel, classified by its calorific value.

- (2)

- Parameter 2 is a factor describing a threat to technology due to the use of particular waste fuel, classified by the content of chlorine.

- (3)

- Parameter 3 is a factor describing safety for the environment during thermal treatment of particular fuel formed from waste, classified by the content of mercury.

The quality requirements for fuels formed from waste are very restrictive. Meeting the requirements of class 1 for each parameter, fuel formed from waste is often better than hard coal whose calorific value is most often 20 MJ∙kg−1 and for class 1 of waste value, it has to be minimum 25 MJ∙kg−1. The content of chlorine for fuels formed of waste in class 1 is low and does not go beyond 0.2%. For waste fuels, unlike conventional fuels, there is the requirement for determining the content of mercury, and for waste fuels in class 1, it does not go beyond 0.04% (Table 1) [16].

Table 1.

Quality requirements for particular classes of fuels formed from waste [16].

Fuels formed of waste are in accordance with the ideology of the circular economy which is a worldwide trend and direction of world economic development. The purpose of the ideology is for the raw materials and products to be in circulation as long as possible. Meeting the requirements is essential on every stage of the life of the product, beginning with the plan of forming it in a way that fits the circular economy. The aim of the circular economy is to become independent from new raw materials, including conventional fuels, because their recourses are limited. Further, it also aims to limit the emission of greenhouse gasses and harmful substances into the atmosphere, and in addition, to limit the waste stored in landfills which is a huge burden for the environment. The circular economy will be, in most cases, economically beneficial, which is the main reason to motivate corporations and businesses to implement it. Waste fuel might be used in distributed energy facilities as a source of energy for cogeneration, e.g., working on the basis of ORC [9,11,17].

Poland might be an example of unused potential of fuels formed from waste. In 2016—2,608,958 Mg waste fuels were formed, but only 1,250,000 Mg of them were used [15].

3. Research Materials

To research energetic properties, emission and its impact on the environment, people’s health and the ecosystem, these materials were chosen:

- (1)

- Coal–hard coal which is extracted in ‘Sośnica’ coal mine, and used in the power industry.

- (2)

- Fuel 1–selected fraction of collected waste in Silesia (region of Poland), characterized by high calorific value. According to Table 1 (Quality requirements for particular classes of fuels formed from waste), it is class 21X (X lack of data).

- (3)

- Fuel 2–selected fraction of collected waste in Zagłebie Dąbrowskie (region of Poland), characterized by high calorific value. According to Table 1 (Quality requirements for particular classes of fuels formed from waste), it is class 321.

- (4)

- Fuel 3–Municipal polyolefins mixed with dried and granulated sludge. According to Table 1 (Quality requirements for particular classes of fuels formed from waste), it is class 411.

- (5)

- Fuel 4–Industrial waste. According to Table 1 (Quality requirements for particular classes of fuels formed from waste), the fuel was classified as 515.

Silesia and Zagłebie Dąbrowskie were selected due to the highly differentiated waste streams and the specification of regions, which affects fuel parameters.

4. Methods of Research

The analysis of technological systems was conducted by Ebsilon Professional version 14.01 computing environment which is used for analysis of thermodynamic processes and cycles. It allows the mapping of already existing circulation of conventional plants, as well as atomic power plants, the solar ones and hybrid systems, the use of fuel cells and to create their own conception systems. The software also has installed library of turbines, thermodynamic factors and fuel cards. The simple graphic interface allows to intuitively model complex circuit, and to solve problems, there is a tool for error analysis and identification of possible causes operating on the basis of the laws of thermodynamics, balance equations and enthalpy. Ebsilon also allows the user to conduct e.g., an analysis of a partial boiler load and also present the results of research on a status plot. The software also allows using the user templates in Microsoft Excel. The research on emission of particular substances in the ORC system from Figure 1 and its impact on the environment, people’s health and the ecosystem were completed by SIMA Pro programme. The methodology of the research was described in publications [9,16,18].

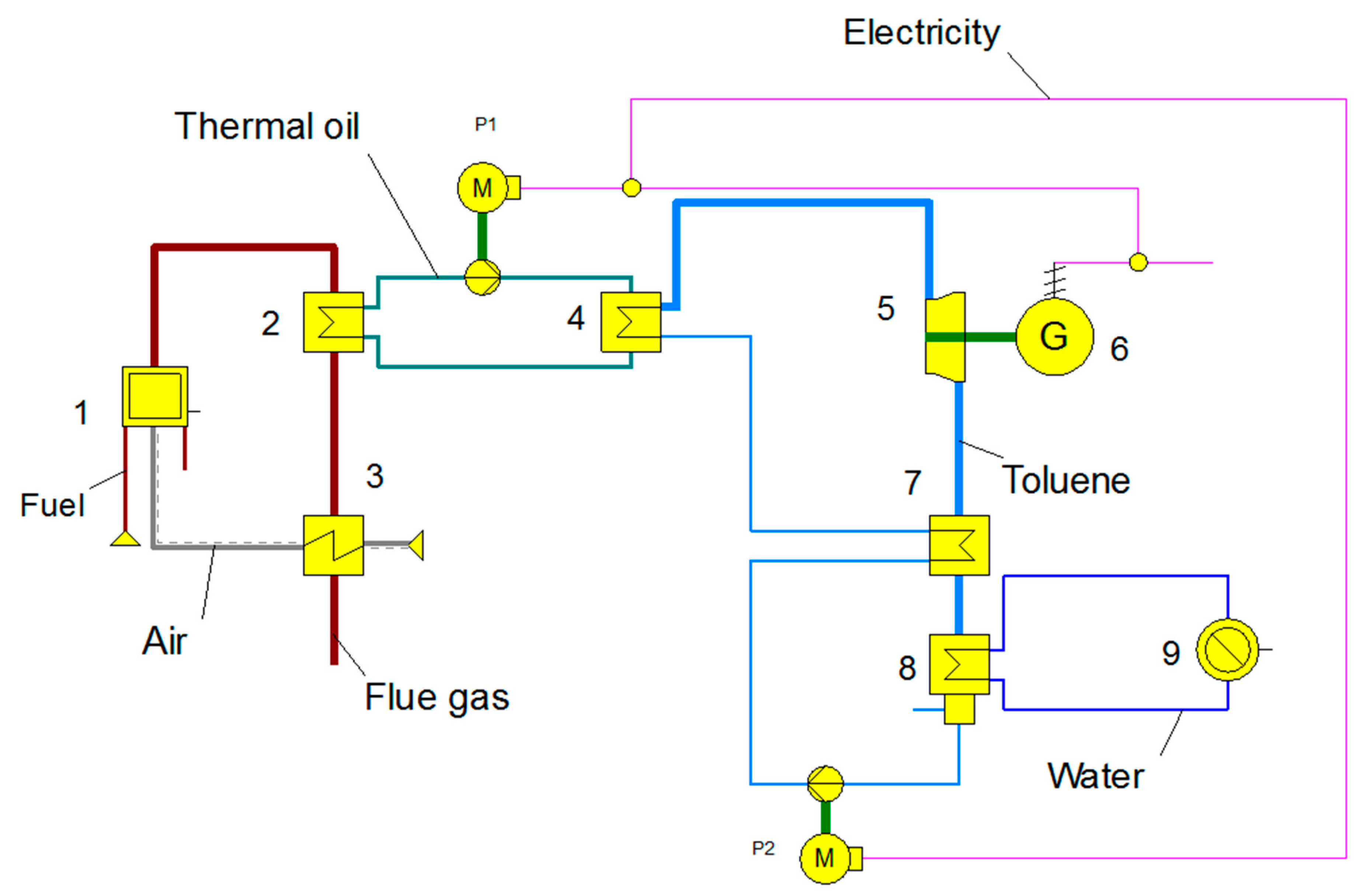

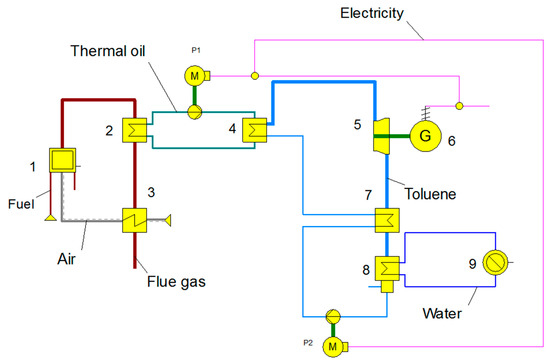

Figure 1.

The authorial idea of the technological system, organic Rankine cycle, (ORC) with regeneration (1—combustion chamber, 2—heat exchanger from fumes to thermal oil, 3—regenerative air preheater, 4—the organic liquid evaporator, 5—turbine, 6—generator, 7—regenerative heat exchanger ORC, 8—condenser organic liquid, 9—node heating, P1—thermal oil pump, P2—organic liquid pump, M—pump drive motors).

5. Model of Organic Rankine Cycle Dedicated for Fuel Form Waste

The Rankine cycle, due to high flexibility of action, is widely applied in cooperation with gas turbines, biomass power-plants, solar farms as well as geothermal network. The organic Rankine cycle (ORC) blocks might be used as the main source of power in industrial facilities, factories, swimming pools, hotels or hospitals as well as being used in the peak of demand or be an additional source of energy. Due to its compact build, the ORC might be a solution for places which are not easily available, and where there is not a developed heating network. These solutions can be installed in places where the demand for electricity and heating lasts throughout the year or in places where there is periodical demand for heating, and where they can generate cold in air-conditioning and ventilation systems out of season [19,20,21,22].

The operating principle of the ORC system is not much different from the classical Rankine cycle [21,22]. The essential difference is working fluid. Water is replaced by organic liquids, such as cooling liquids or other mixtures of hydrocarbons, which must meet important requirements, such as high density and heat of evaporation. Fluids that are characterized by high density and heat of evaporation are able to absorb more energy from the source. The ORC turbine uses a thermal oil of average temperature for initial heating and proper evaporation of organic liquid (Toluene) in the evaporator. The ORC is a turbine based on a turbine generator. The ORC system evaporates the organic liquid, characterized by slower turbine rotation, lower pressure and the erosion of metal parts and blades. The air fuel mixture is led to combustion chamber (1) where it is oxidized and then the hot fumes are directed to the heat exchanger; (2) where the heat is transferred to the intermedium that is the thermal oil. Fumes of high enthalpy are directed to the air heater (3) where the initial air heating takes place and increases the efficiency of the whole system and at the same time, the properly cooled fumes are directed to the environment. The oil cycle mediated in the heat exchange between the fumes and the organic factor. In the evaporator (4), the heat passed from the thermal oil and provide the evaporation of organic liquid whose fumes are directed to the turbines (5) rotating the blades of the disc, turning kinetic energy into mechanical energy and then in the electrical generator, mechanical energy is turned into the final product which is electrical energy on the generator (6). The expanded fluid vapour are passed to the generator (7) and cooled to the evaporator where the heat is collected, which for instance, can be used for central heating, the heat centre (9), which allows the distribution of heat to many recipients. The liquefied condensate is pumped back to the generator where it is initially heated before it is re-evaporated closing the ORC (Figure 1).

6. Results

The physicochemical properties of the investigated fuels were analyzed. Fuel 4 had the highest percentage of total moisture (29.45%), bulk density (300 kg∙m−3) and mercury (0.29 mg∙MJ−1). Fuel 3 had the highest content of ash, 21.71%. Fuel 2 had the highest percentage of combustible substances, 71.67%. In fuel 1, the highest content of volatiles was noticed (79.47%). The higher calorific value was 22.03 MJ∙kg−1 and the lower calorific value was 20.57 MJ∙kg−1. Fuel 4 had the lowest higher calorific value of 9.78 MJ∙kg−1 and the lower calorific value was 6.46 MJ∙kg−1. The content of ash was 5.86% which was the lowest in fuel 2. The lowest quantity of mercury was measured in fuel 3 (0.02 mg∙MJ−1). After the analysis of the table, it has been noticed that none of the parameters in case of hard coal was the highest, while it was characterized by the lowest content of total moisture (19.26%) (Table 2).

Table 2.

Physicochemical properties of investigated fuels from waste and hard coal (wet basis).

Among the investigated fuels, the biggest content of carbon has been noticed in hard coal and in fuel 1 (50–52%), while the least percentage of coal was fuel 4 (25.77%). The content of hydrogen, regardless the kind of fuel, was between 2–5%. The content of sulphur for the investigated waste fuels was between 0.3% (fuel 4) and 0.61% (fuel 3). The biggest content of nitrogen has been noticed in fuel 3 (3.76%), the least for fuel 1 (0.46%). The content of chlorine in analyzed fuels was between 0.08% (fuel 1) and 0.41% (fuel 2). The content of oxygen and other substances was between 1.8% (fuel 3) and 33.64% (fuel 4) (Table 3).

Table 3.

The elemental composition of chosen waste fuels and hard coal.

The cogeneration system was analysed (Figure 1) by powering it with investigated fuels. The highest parameters of the system were obtained while powering the cogeneration system fuel 1 where the electrical power was 1.10 MW, thermal power was 3.35 MW, and the total efficiency of the system was 92.84%. The system powered by fuel 1 was characterized by the lowest use of the fuel being 0.232 kg∙s−1. The worst parameters were obtained for fuel 4 where electrical power was 0.83 MW, thermal power was 2.54 MW, and the total efficiency of the system was 77.04%. While powering the system with fuel 4, the system used most fuel 0.675 kg∙s−1. The total efficiency of the system for each fuel qualifies the ORC system as high efficiency cogeneration (efficiency above 75%) (Table 4).

Table 4.

The energetic parameters obtained with the use of the authorial system ORC with regeneration.

The investigated fuels were examined for emissions generated when generating 1MJ of energy through their thermal transformation. Hard coal was characterized by the highest emission of SO2 (1.29 × 10−3 kg∙MJ−1) in relation to 1 MJ of generated energy. Fuel 1 emitted most Hg (9.14 × 10−10 kg∙MJ−1) in relation to 1 MJ of generated energy. Fuel 2 was characterized by the highest emission of HCI (1.24 × 10−4 kg∙MJ−1) in relation to 1 MJ of generated energy. Fuel 3 emitted N2 most (5.64 × 10−1 kg∙MJ−1), O2 (5.68 × 10−2 kg∙MJ−1), CO (1.15 × 10−3 kg∙MJ−1), NO (1.85 × 10−4 kg∙MJ−1) and TSP (3.86 × 10−3 kg∙MJ−1) in relation to 1 MJ of generated energy. Fuel 4 was characterized by the highest emission of CO2 (1.46 × 10−1 kg∙MJ−1) and H2O (8.29 × 10−2 kg∙MJ−1) in relation to 1 MJ of generated energy (Table 5).

Table 5.

The value of exhaust emissions for 1 MJ of energy obtained.

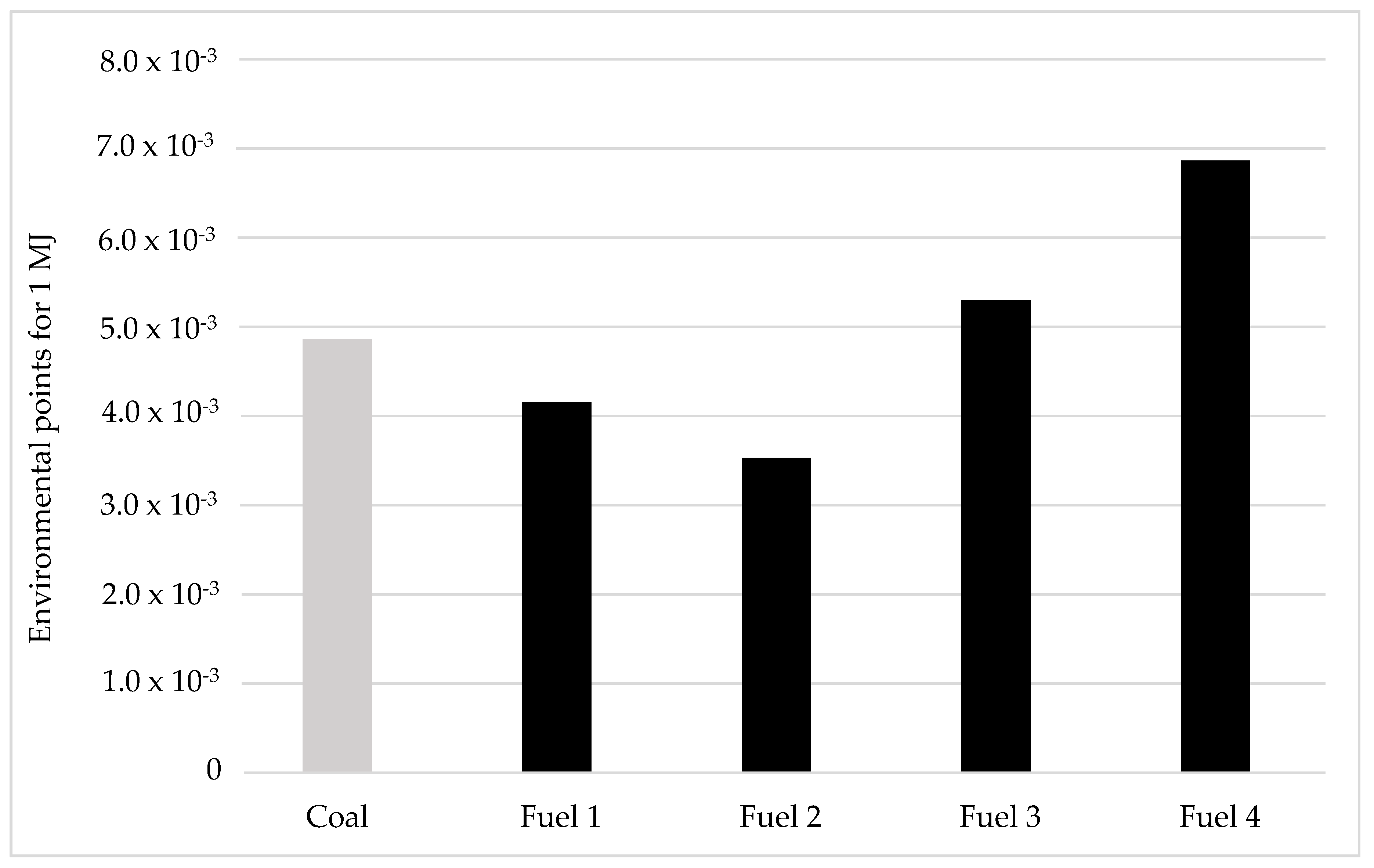

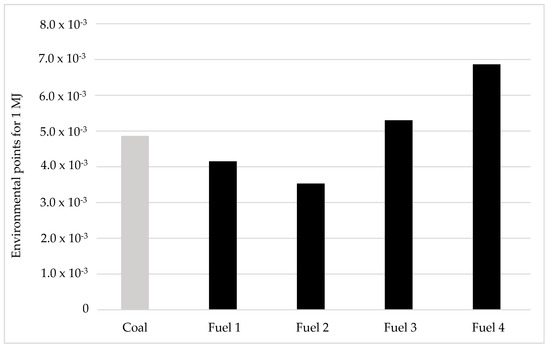

The total burden for the environment of the investigated fuels was analyzed with reference to 1 MJ of energy obtained. Fuel 4 was of the biggest burden for the environment in relation to 1 MJ of generated energy. The least burdensome for the environment was fuel 2 in relation to 1 MJ of generated energy (Figure 2).

Figure 2.

The total burden for the environment expressed in environmental points for 1 MJ of obtained energy.

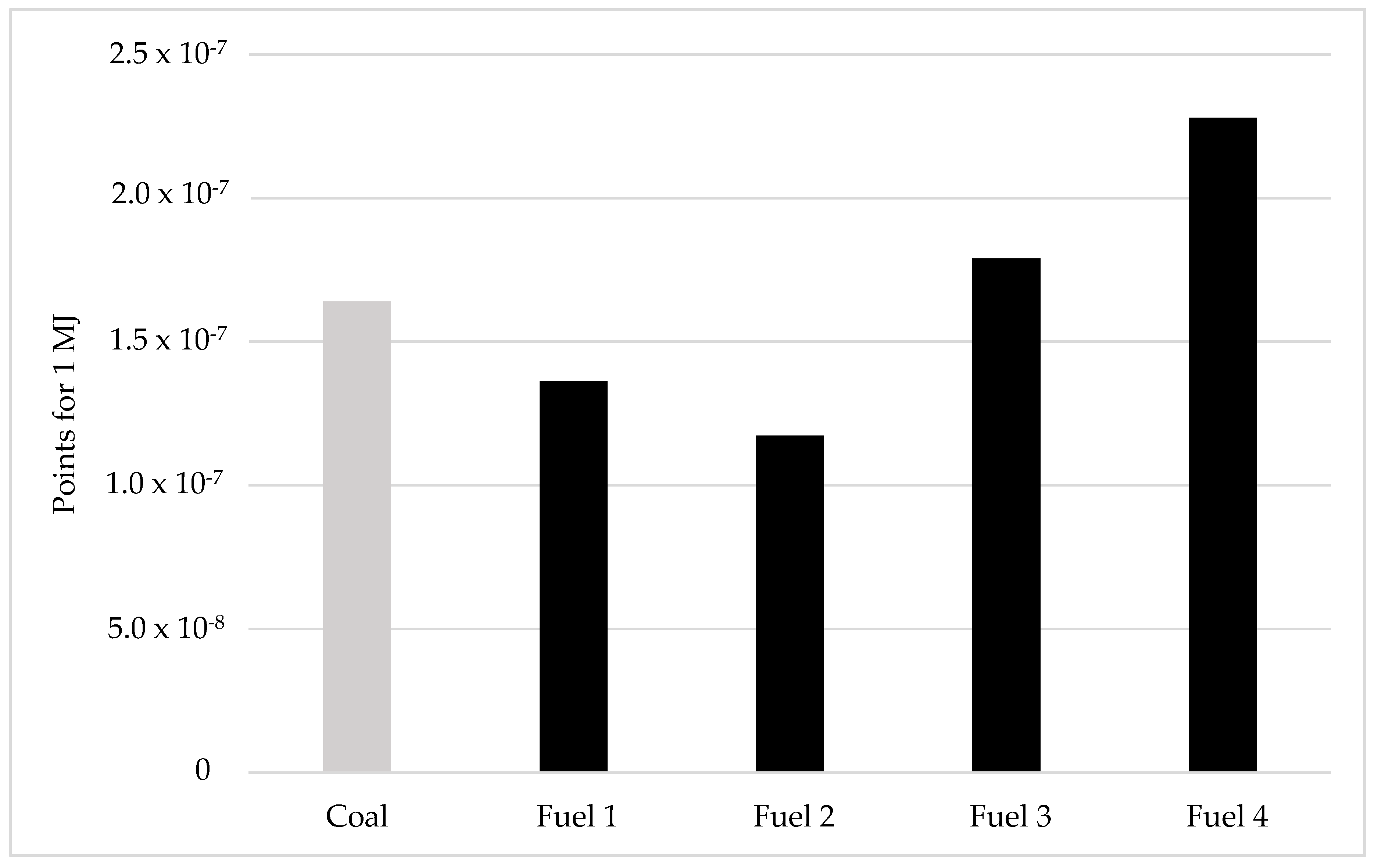

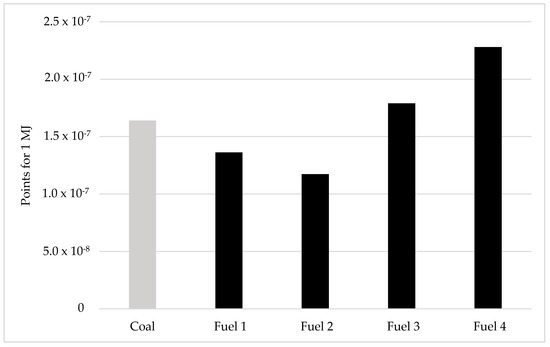

The total burden for the person’s health of the investigated fuels was analyzed with reference to 1 MJ of energy obtained. Fuel 4 was most of a burden for people’s health in relation to 1 MJ of generated energy. The least burdensome for people’s health was fuel 2 in relation to 1 MJ of obtained energy (Figure 3).

Figure 3.

The total burden for people’s health expressed in points for 1 MJ of obtained energy.

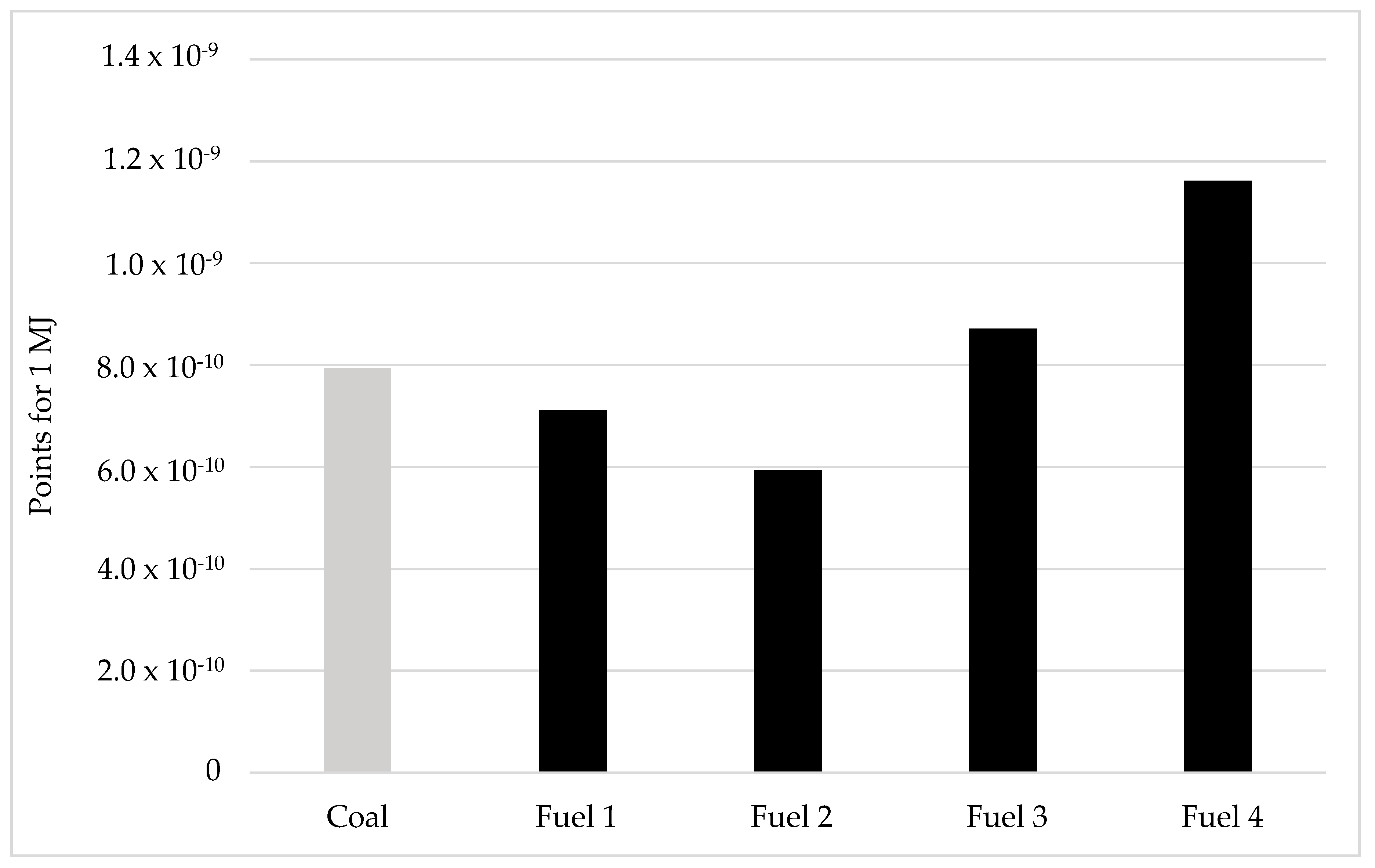

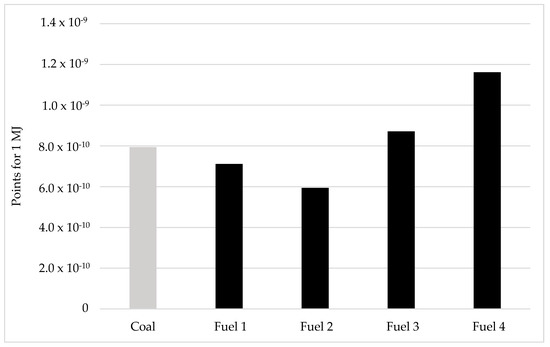

The total burden for the ecosystem of the investigated fuels was analyzed with reference to 1 MJ of energy obtained. Fuel 4 was most of a burden for the ecosystem in relation to 1 MJ of generated power. The least burdensome for the ecosystem was fuel 2 in relation to 1 MJ of generated energy (Figure 4).

Figure 4.

The total burden for the ecosystem expressed in points for 1 MJ of obtained energy.

7. Conclusions

Technological development, the need for energetic security and awareness of climate destruction, forces society to create waste fuels, but it should be of the highest quality. One of the diversification of forming energy is waste fuel, but it should be of the highest quality because only then its thermal processing can be connected with the lowest emission of carbon dioxide and harmful substances into the atmosphere, compared to hard coal. Fuels from waste have beneficial energetic properties but also quite high flexibility while forming them. Fuels formed from waste show a lesser burden on the environment than hard coal, and their direct impact on people’s health and the ecosystem is lower than usage of conventional fuel. Using waste as energetic raw materials minimizes their storage in landfills [8,14,15]. Fuels formed of waste are a good solution to replenishing the energy fuel market. Analysing the direction of the development in Poland as a EU member, as one of the countries with the biggest energetic issues, it needs energetic transformation and its policy premises the development of high-efficiency cogeneration whose empowering should be renewable sources, including fuels formed from waste [5,9,11]. The authorial system, the ORC, with regeneration presented in this article might be a real solution for the instability of energy prices for businesses and it might influence the development of the economy making industrial plants less dependent on central generating units. The system is in accordance with thermodynamic laws. The precise energetic parameters, as well as exploration problems, should be tested in a real pilot unit which is supported by the beneficial calculation results in the Ebsilon Professional environment used for modelling any energetic systems [7].

Author Contributions

conceptualization, M.C., N.P., A.C. and Ł.W.; methodology, M.C., N.P., A.C. and Ł.W.; software, M.C., N.P., A.C. and Ł.W.; formal analysis, M.C., N.P., A.C. and Ł.W.; investigation, M.C., N.P., A.C. and Ł.W.; resources, M.C., N.P., A.C. and Ł.W.; data curation, M.C., N.P., A.C. and Ł.W.; writing—original draft preparation, N.P., A.C. and Ł.W.; writing—review and editing, M.C., N.P., A.C. and Ł.W.; visualization, N.P., A.C. and Ł.W.; supervision, M.C.; project administration, M.C.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- The European Parliament and the Council of the European Union. Directive 2009/29/EC of the European Parliament and of the Council from 23 April 2009. Off. J. Eur. Union 2009, 30, 3–27. [Google Scholar]

- The European Parliament and the Council of the European Union. Directive 2009/406/EC of the European Parliament and of the Council from 23 April 2009. Off. J. Eur. Union 2009, 17, 126–138. [Google Scholar]

- The European Parliament and the Council of the European Union. Directive 2009/31/EC of the European Parliament and of the Council from 23 April 2009. Off. J. Eur. Union 2009, 26, 158–179. [Google Scholar]

- The European Parliament and the Council of the European Union. Directive 2009/28/EC of the European Parliament and of the Council from 23 April 2009. Off. J. Eur. Union 2009, 11, 39–85. [Google Scholar]

- Ministry of Energy. Polish Energy Policy until 2040; Ministry of Energy: Warsaw, Poland, 2018.

- 2020 Climate & Energy Package. Available online: https://ec.europa.eu/clima/policies/strategies/2020_en#tab-0-0 (accessed on 22 May 2019).

- EMEP/EEA Emission Inventory Guidebook (2013), Open Burning of Waste. Available online: https://www.eea.europa.eu/ds_resolveuid/UGS13MO6A5 (accessed on 7 May 2019).

- Uwarunkowania dla Wykorzystania Paliw z Odpadów w Energetyce i Ciepłownictwie. Available online: https://ekocykl.org/wp-content/uploads/2018/03/5_Ryszard_Wasielewski.pdf (accessed on 21 May 2019).

- Czop, M.; Poranek, N.; Czajkowski, A. Energetic usability and nuisance to the environment of selected fuels made of waste. Przemysł Chem. 2018, 97, 1460–1462. [Google Scholar]

- Energy Production & Changing Energy Sources. Available online: https://ourworldindata.org/energy-production-and-changing-energy-sources (accessed on 19 May 2018).

- Circular Economy. Available online: https://ec.europa.eu/growth/industry/sustainability/circular-economy_en (accessed on 20 May 2019).

- The European Parliament and the Council of the European Union. Directive 2018/850 of the European Parliament and of the Council 2018/850 from 30 May 2018. Off. J. Eur. Union 2018, L 150, 109–140. [Google Scholar]

- The European Parliament and the Council of the European Union. Directive 2012/22/EU of the European Parliament and of the Council from 25 August 2012. Off. J. Eur. Union 2012, L 227, 7–10. [Google Scholar]

- Polish Government. The act of 14 december 2012 on waste Poland. J. Laws 2018 2018, 2018, item 992. [Google Scholar]

- Internetowa Baza Danych o Odpadach, Rynek Paliw Alternatywnych 2016/2017. Available online: https://ibdo.pl/?page_id=771 (accessed on 31 April 2019).

- PN-EN 15359:2012. Fixed Secondary Fuel—Technical Requirements and Classes from 10.02.2012; Polish Committee for Standardization: Warszawa, Poland, 2012. [Google Scholar]

- Krajowy Ośrodek Bilansowania i Zarządzania Emisjami, Wskaźniki Emisji Zanieczyszczeń ze Spalania Paliw. Available online: https://krajowabaza.kobize.pl/docs/male_kotly.pdf (accessed on 3 May 2019).

- ReCiPe. Available online: https://www.rivm.nl/en/life-cycle-assessment-lca/recipe (accessed on 4 May 2019).

- Andreasen, J.G.; Kærn, M.R.; Haglind, F. Assessment of methods for performance comparison of pure and zeotropic working fluids for organic rankine cycle power systems. Energies 2019, 12, 1783. [Google Scholar] [CrossRef]

- Collings, P.; Mckeown, A.; Wang, E.; Yu, Z. Experimental investigation of a small-scale ORC power plant using a positive displacement expander with and without a regenerator. Energies 2019, 12, 1452. [Google Scholar] [CrossRef]

- Aracil, C.; Haro, P.; Fuentes-Cano, D.; Gómez-Barea, A. Implementation of waste-to-energy options in landfill-dominated countries: Economic evaluation and GHG impact. Waste Manag. 2018, 76, 443–456. [Google Scholar] [CrossRef] [PubMed]

- SedphoSate, S.; Chaiyat, N.; Gheewala, S.H.; Sampattagu, S. Conventional and exergetic life cycle assessment of organic rankine cycle implementation to municipal waste management: The case study of Mae Hong Son (Thailand). Int. J. Life Cycle Assess. 2017, 22, 1773–1784. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).