An Assessment of Material Waste Disposal Methods in the Nigerian Construction Industry

Abstract

1. Background of the Study

- identifying material wastes disposal methods;

- determining whether a relationship exists between company characteristics and disposal methods; and,

- recommending sustainable alternatives.

2. Study Area and Research Methodology

2.1. Research Design

2.2. Research Materials

2.3. Research Participants

2.4. Research Procedure

3. Findings and Discussion

3.1. Response Rate

3.2. Respondents and Organisations’ Characteristics

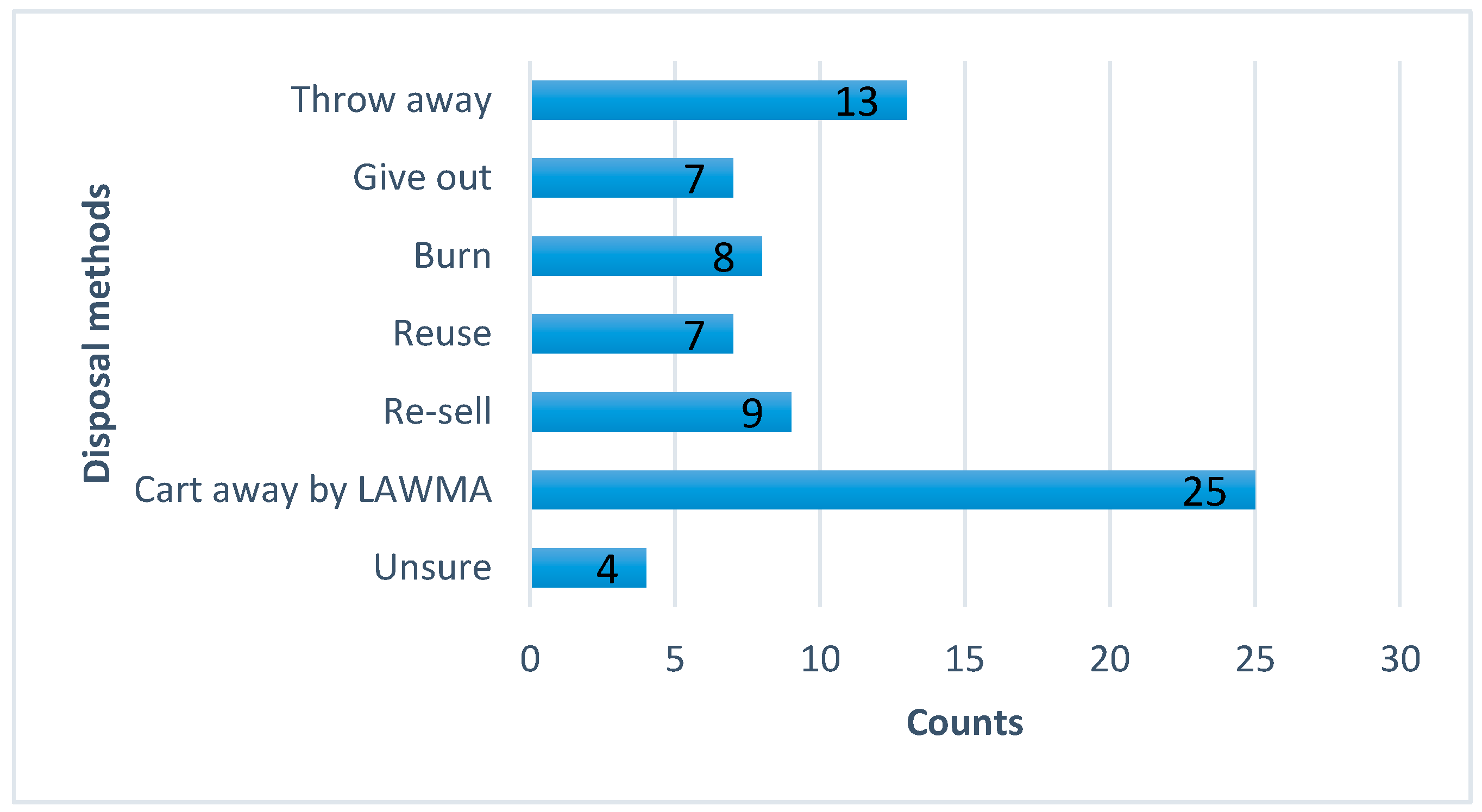

3.3. Disposal Methods

3.4. Disposal Methods and Company Characteristics

4. Conclusions and Recommendations

- The main waste disposal method in the NCI is landfilling.

- When compared to other firm’s characteristics (ownership status, age, project specialisation), there is a significant relationship between a firm’s size and the disposal methods that they adopt.

- Large firms adopt incineration, burying, and burning, while small firms adopt reuse as backfill, landfilling, open dumping, and recycling.

- Burning is still practiced in the NCI despite environmental legislation against it.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Asase, M.; Yanful, E.K.; Mensah, M.; Stanford, J.; Amponsah, S. Comparison of municipal solid waste management systems in Canada and Ghana: A case study of the cities of London, Ontario, and Kumasi, Ghana. Waste Manag. 2009, 29, 2779–2786. [Google Scholar] [CrossRef] [PubMed]

- Esin, T.; Cosgun, N. A study conducted to reduce construction waste generation in Turkey. Build. Environ. 2007, 42, 1667–1674. [Google Scholar] [CrossRef]

- Kofoworola, O.F.; Gheewala, S.H. Estimation of construction waste generation and management in Thailand. Waste Manag. 2009, 29, 731–738. [Google Scholar] [CrossRef] [PubMed]

- Saraiva, T.S.; Borges, M.M.; Filho, A.C. The Importance of Recycling of Construction and Demolition Waste. In Proceedings of the PLEA2012—28th Conference, Opportunities, Limits & Needs towards an Environmentally Responsible Architecture, Lima, Perú, 7–9 November 2012. [Google Scholar]

- Al-Hajj, A.; Hamani, K. Material Waste in the UAE Construction Industry: Main Causes and Minimisation Practices. Archit. Eng. Des. Manag. 2011, 7, 221–235. [Google Scholar] [CrossRef]

- Arponen, J.; Granskog, A.; Pantsar, M. The Opportunities of a Circular Economy for Finland; Sitra: Helsinki, Finland, 2015. [Google Scholar]

- Viljoen, A. Quality Factors Contributing to the Generation of Construction Waste. Master’s Thesis, Cape Peninsula University of Technology, Cape Town, South Africa, 2010. [Google Scholar]

- Ekanayake, L.L.; Ofori, G. Construction material waste source evaluation. In Proceedings of the Second Southern African Conference on Sustainable Development in the Built Environment: Strategies for a Sustainable Built Environment, Pretoria, South Africa, 23–25 August 2000. [Google Scholar]

- Osmani, M.; Glass, J.; Price, A.D.F. Architects’ perspectives on construction waste reduction by design. Waste Manag. 2008, 28, 1147–1158. [Google Scholar] [CrossRef]

- Garba, A.; Olaleye, Y.O.; Jibrin, N.S. Material Resources Optimization for Sustainable Construction in Nigeria. J. Eng. Archit. 2016, 4, 33–47. [Google Scholar] [CrossRef]

- Watuka, J.; Aligula, E.M. Sustainable Construction Practices in the Kenyan Construction Industry: The Need for a Facilitative Regulatory Environment. In Proceedings of the CIB W107 1st International Conference: Creating a Sustainable Construction Industry in Developing Countries, Stellenbosch, South Africa, 11–13 November 2002. [Google Scholar]

- Nwokoro, I.; Onukwube, H. Sustainable or Green Construction in Lagos, Nigeria: Principles, Attributes and Framework. J. Sustain. Dev. 2011, 4, 166. [Google Scholar] [CrossRef]

- Zuo, J.; Zhao, Z.Y. Green building research–current status and future agenda: A review. Renew. Sustain. Energy Rev. 2014, 30, 271–281. [Google Scholar] [CrossRef]

- Enshassi, A.; Mohamed, S.; Abushaban, S. Factors Affecting the Performance of Construction Projects in the Gaza Strip. J. Civ. Eng. Manag. 2009, 15, 269–280. [Google Scholar] [CrossRef]

- Adewuyi, T.O. Construction Material Waste Planning and Control Techniques on Building Sites in South-South of Nigeria. Ph.D. Thesis, Department of Building, Faculty of Environmental Studies, University of Uyo, Uyo, Nigeria, 2012. [Google Scholar]

- Dajadian, S.A.; Koch, D.C. Waste Management Models and Their Applications on Construction Sites. Int. J. Constr. Eng. Manag. 2014, 3, 91–98. [Google Scholar]

- Garas, G.L.; Anis, A.R.; Gammal, A.E. Materials waste in the Egyptian construction Industry. In Proceedings of the IGLC-9, Rent Ridge Crescent, Singapore, 6–8 August 2001. [Google Scholar]

- Polat, G.; Ballard, G. Waste in Turkish Construction- Need for Lean Construction Techniques. In Proceedings of the 12th Annual Conference of the International Group for Lean Construction IGLC-12, Helsingør, Denmark, 3–6 August 2004; pp. 488–501. [Google Scholar]

- Poon, C.S.; Yu, A.T.W.; Ng, L.H. A Guide for Managing and Minimizing Building and Demolition Waste; The Hong Kong Polytechnic University: Hong Kong, 2001. [Google Scholar]

- Al-Moghany, S.S. Managing and Minimizing Construction Waste in Gaza Strip. Master’s Thesis, The Islamic University of Gaza, Gaza City, Palestine, 2006. [Google Scholar]

- Odusami, K.T.; Oladiran, O.J.; Ibrahim, S.A. Evaluation of Materials Wastage and Control in some selected Building sites in Nigeria. Emir. J. Eng. Res. 2012, 17, 53–65. [Google Scholar]

- Ajayi, S. Design, Procurement and Construction Strategies for Minimizing Waste in Construction Projects. Ph.D. Thesis, University of the West of England, Bristol, UK, 2017. [Google Scholar]

- Mata, T.M.; Mendes, A.M.; Caetano, N.S.; Martins, A.A. Sustainability and economic evaluation of microalgae grown in brewery wastewater. Bioresour. Technol. 2014, 168, 151–158. [Google Scholar] [CrossRef] [PubMed]

- Nagapan, S.; Rahman, I.A.; Asmi, A. Factors contributing to physical and non-physical waste generation in construction industry. Int. J. Adv. Appl. Sci. 2012, 1, 1–10. [Google Scholar] [CrossRef]

- Shen, L.Y.; Tam, W.Y.V.; Tam, C.M.; Drew, D. Mapping approach for examining waste management on construction sites. J. Constr. Eng. Manag. 2004, 130, 472–481. [Google Scholar] [CrossRef]

- Rodgers, M. Fundamentals of Development Administration; S.K. Publishers: London, UK, 2011. [Google Scholar]

- Ekanayake, L.L.; Ofori, G. Building Waste Assessments Score: Design based tool. Build. Environ. 2004, 39, 851–861. [Google Scholar] [CrossRef]

- Greenwood, R. Construction Waste Minimisation: Good Practice Guide; Centre for Research in the Built Environment, Cardiff University: Cardiff, Wales, 2003. [Google Scholar]

- Geng, Y.; Fu, J.; Sarkis, J.; Xue, B. Towards a national circular economy indicator system in China: An evaluation and critical analysis. J. Clean. Prod. 2012, 23, 216–224. [Google Scholar] [CrossRef]

- Preston, F. A Global Redesign: Shaping the Circular Economy; Chatham House: London, UK, 2012. [Google Scholar]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (EPA); Municipal and Industrial Waste Division. Decision-Makers’ Guide to Solid Waste Management, Volume II. 1995. Available online: http://www.epa.gov/epaoswer/non-hw/muncpl/dmg2/chapter8.pdf (accessed on 12 December 2018).

- Seo, S.; Aramaki, T.; Hwang, Y.; Hanaki, K. Environmental impact of solid waste treatment methods in Korea. J. Environ. Eng. 2004, 130, 81–89. [Google Scholar] [CrossRef]

- Kamalan, H.; Sabour, M.; Shariatmadari, N. A Review on Available Landfill Gas Models. J. Environ. Sci. Technol. 2011, 4, 79–92. [Google Scholar] [CrossRef]

- Den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product design in a circular economy: Development of a typology of key concepts and terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- Ajie, U.E.; Dienye, A. Spatial Data Analysis of Solid Waste Management System in Port Harcourt Metropolis after 100 years of its Existence. In Proceedings of the FIG Congress 2014: Engaging the Challenges–Enhancing the Relevance, Kuala Lumpur, Malaysia, 16–21 June 2014. [Google Scholar]

- Van den Berg, M.R.; Bakker, C.A. A product design framework for a circular economy. In Proceedings of the PLATE Conference, Nottingham, UK, 17–19 June 2015. [Google Scholar]

- Shi, L.; Xing, L.; Bi, J.; Zhang, B. Circular economy: A new development strategy for sustainable development in China. In Proceedings of the 3rd World Congress of Environmental and Resource Economists, Kyoto, Japan, 3–7 July 2006. [Google Scholar]

- Su, B.; Heshmati, A.; Geng, Y.; Yu, X. A review of the circular economy in China: Moving from rhetoric to implementation. J. Clean. Prod. 2013, 42, 215–227. [Google Scholar] [CrossRef]

- Jun, H.; Xiang, H. Development of circular economy is a fundamental way to achieve agriculture sustainable development in China. Energy Procedia 2011, 5, 1530–1534. [Google Scholar] [CrossRef]

- Bartl, A. Withdrawal of the circular economy package: A wasted opportunity or a new challenge? Waste Manag. 2015, 44. [Google Scholar] [CrossRef] [PubMed]

- Moreno, M.; Braithwaite, N.; Cooper, T. Moving beyond the circular economy. In Proceedings of the Going Green-CARE Innovation, Vienna, Austria, 17–20 November 2014. [Google Scholar]

- European Commission. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives. Off. J. Eur. Union 2008, 312, 3–10. [Google Scholar]

- Ezeigwe, C. Appropriate solid waste disposal methods for developing countries. Nse Tech. Trans. 1995, 32, 33–34. [Google Scholar]

- Charnpetheep, K.; Zhou, Q.; Garner, B. Preliminary landfill site screening using fuzzy Geographical Information System. Waste Manag. Res. 1997, 15, 197–215. [Google Scholar] [CrossRef]

- Ajani, O.I.Y. Determinants of an effective solid waste management in Ibadan Metropolis Oyo State, Nigeria. J. Food Agric. Environ. 2007, 6, 152–157. [Google Scholar]

- Igoni, A.H.; Ayotamuno, M.; Ogaji, S.O.T.; Probert, S.D. Municipal solid waste in Port Harcourt, Nigeria. Appl. Energy 2007, 84, 664–670. [Google Scholar] [CrossRef]

- Akanni, P.O. An Empirical Survey of the Effect of Materials Wastage on Contractors’ Profit Level in Construction Projects. Prof. Build. J. Niger. Inst. Build. 2007, 1, 35–46. [Google Scholar]

- Adewuyi, T.O.; Idoro, G.I.; Ikpo, I.J. Empirical Evaluation of Construction Material Waste Generated on Sites in Nigeria. Civ. Eng. Dimens. 2014, 16, 96–103. [Google Scholar]

- Wahab, A.B.; Lawal, A.F. An evaluation of waste control measure in construction industry in Nigeria. Afr. J. Environ. Sci. Technol. 2011, 3, 246–254. [Google Scholar]

- Kareem, W.A.; Asa, O.A.; Lawal, M.O. Resources conservation and waste management practices in construction industry. Arab. J. Bus. Manag. Rev. (Oman Chapter) 2015, 4, 20. [Google Scholar] [CrossRef]

- Dania, A.A.; Kehinde, J.O.; Bala, K. A Study of Construction Material Waste Management Practices by Construction Firms in Nigeria. In Proceedings of the 3rd Scottish Conference for Postgraduate Researchers of the Built and Natural Environment, Glasgow, UK, 20–22 November 2007; pp. 121–129. [Google Scholar]

- Ogwueleka, T.C. Municipal Solid Waste Characteristics and Management in Nigeria Iran. J. Env. Health Sci. 2009, 6, 173–180. [Google Scholar]

- Ganiyu, S.A.; Ogunmakinde, O.E.; Oladokun, S.D. Managing Waste in Construction Site, in Akure, Ondo State. In Proceedings of the Joint International Conference (JIC) on 21st Century Human Habitat: Issues, Sustainability and Development, Akure, Nigeria, 21–24 March 2016; pp. 215–223. [Google Scholar]

- LAWMA. Landfill—Monthly Dump Reports 2014. Available online: http://www.lawma.gov.ng/inside-lawma/departments/landfill/ (accessed on 20 January 2019).

- Igbinomwanhia, D.I. Status of waste management. In Integrated Waste Management-Volume II; InTech: London, UK, 2011. [Google Scholar]

- Obadina, A. Solid Waste Management Livelihood on Lagos Dumpsite: Analysis of Gender and Social Difference. Ph.D. Thesis, Loughborough University, Loughborough, UK, 2016. [Google Scholar]

- Odewumi, S.G. Appraisal of storage and collection strategies of municipal solid waste in Lagos State. J. Humanit. Soc. Sci. 2013, 10, 61–67. [Google Scholar] [CrossRef]

- Kofoworola, O.F. Comparative assessment of the environmental implication of management options for municipal solid waste in Nigeria. Int. J. Waste Resour. 2016, 7, 1–5. [Google Scholar] [CrossRef]

- Ajanlekoko, A.S. Sustainable housing development in Nigeria: The financial infrastructural implication. In Proceedings of the International Conference on Spatial Information for Sustainable Development, Nairobi, Kenya, 2–5 October 2001; pp. 1–13. [Google Scholar]

- NIOB. Facilities Management for Sustainable Building Performance. In Proceedings of the 2-days National Seminar Organized by the Nigerian Institute of Building (NIOB), Lafia, Nigeria, 27–28 April 2005. [Google Scholar]

- Creswell, J.W.; Plano Clark, V.L.; Gutmann, M.L.; Hanson, W.E. Advanced mixed methods research designs. In Handbook of Mixed Methods in Social and Behavioural Research; Sage Publications: Thousand Oaks, CA, USA, 2003; pp. 209–240. [Google Scholar]

- Oladiran, O.J. Causes and Minimization Techniques of Materials Waste in Nigerian Construction Process. In Proceedings of the Fifth International Conference on Construction in the 21st Century (CITC-V), Istanbul, Turkey, 20–22 May 2009; pp. 20–22. [Google Scholar]

- Saidu, I.; Winston, S. The contributions of construction material waste to project cost overruns in Abuja, Nigeria. Acta Structilia 2016, 23, 99–113. [Google Scholar] [CrossRef]

- Cochran, W.G. Experimental Designs; Wiley Publications in Applied Statistics: New York, NY, USA, 1983. [Google Scholar]

- Oladapo, A.A. A quantitative assessment of the cost and time impact of variation orders on construction projects. J. Eng. Des. Technol. 2007, 5, 35–48. [Google Scholar] [CrossRef]

- Olaleye, F.; Abdullah, M. Influence of Information Technology on the Performance of Small and Medium sized Construction Firms in Nigeria. Res. J. Bus. Manag. Account. 2014, 3, 21–27. [Google Scholar]

- Odediran, S.J.; Adeyinka, B.F.; Opatunji, O.A.; Morakinyo, K.O. Business Structure of Indigenous Firms in the Nigerian Construction Industry. Int. J. Bus. Res. Manag. 2012, 3, 255–264. [Google Scholar]

- Bhattacherjee, A. Social Science Research: Principles, Methods, and Practices; Global Text Project: Athens, Georgia, 2012. [Google Scholar]

- Chinyio, E.A.; Olomolaiye, P.O. A needs based methodology for classifying construction clients and selecting contractors-a rejoinder. Constr. Manag. Econ. 1999, 17, 413–417. [Google Scholar] [CrossRef]

- Akintoye, A. Analysis of factors influencing project cost estimating practice. Constr. Manag. Econ. 2000, 18, 77–89. [Google Scholar] [CrossRef]

- Dulaimi, M.F.; Ling, F.Y.; Bajracharya, A. Organizational motivation and inter-organizational interaction in construction innovation in Singapore. Constr. Manag. Econ. 2003, 21, 307–318. [Google Scholar] [CrossRef]

- Takim, R.; Akintoye, A.; Kelly, J. Analysis of performance measurement in the Malaysian construction industry. In Proceedings of the Globalization and Construction, AIT Conference Centre, Bangkok, Thailand, 17–19 November 2004. [Google Scholar]

- Tam, V.W. The effectiveness of the green building evaluation and labelling system. Archit. Sci. Rev. 2007, 50, 323–330. [Google Scholar] [CrossRef]

- Chinowsky, P.S.; Meredith, J.E. Strategic management in construction. J. Constr. Eng. Manag. 2000, 126, 1–9. [Google Scholar] [CrossRef]

- Fahmy, A.; Hassan, T.M.; Bassioni, H. Improving RCPSP solutions quality with Stacking Justification–Application with particle swarm optimization. Expert Syst. Appl. 2004, 41, 5870–5881. [Google Scholar] [CrossRef]

- Olorunfemi, F.B. Landfill development and current practices in Lagos metropolis, Nigeria. J. Geogr. Reg. Plan. 2011, 4, 656. [Google Scholar]

- The National Environmental Standards and Regulations Enforcement Agency (NESREA). Available online: http://www.nesrea.gov.ng/about/index.php (accessed on 12 December 2018).

- Dania, A.A. Sustainable Construction at the Firm Level: Case Studies from Nigeria. Ph.D. Thesis, University of Reading, Reading, UK, 2017. [Google Scholar]

- Brown, Z.S.; Johnstone, N. Better the devil you throw: Experience and support for pay-as-you-throw waste charges. Environ. Sci. Policy 2014, 38, 132–142. [Google Scholar] [CrossRef]

- Dahlén, L.; Anders, L. Pay as you throw: Strengths and weaknesses of weight-based billing in household waste collection systems in Sweden. Waste Manag. 2010, 30, 23–31. [Google Scholar] [CrossRef] [PubMed]

- Scharff, H. Landfill reduction experience in The Netherlands. Waste Manag. 2014, 34, 2218–2224. [Google Scholar] [CrossRef]

- Akadiri, O.P. Development of a Multi-Criteria Approach for the Selection of Sustainable Materials for Building Projects. Ph.D. Thesis, University of Wolverhampton, Wolverhampton, UK, 2011. [Google Scholar]

- Ola-Adisa, E.; Sati, Y.C.; Ojonugwa, I.I. An Architectural Approach to Solid Waste Management on Selected Building Construction Sites in Bauchi Metropolis. Int. J. Merging Eng. Res. Technol. 2015, 3, 67–77. [Google Scholar]

- Ajayi, O.M.; Koleoso, H.A.; Soyingbe, A.A.; Oladiran, O.J. The practice of waste management in construction sites in Lagos state; Nigeria. In Proceedings of the Construction and Building Research Conference of the Royal Institution of Chartered Surveyors, Kaduna, Nigeria, 4 September 2008. [Google Scholar]

- Abidin, N.Z. Investigating the awareness and application of sustainable construction concept by Malaysian developers. Habitat Int. 2010, 34, 421–426. [Google Scholar] [CrossRef]

- Chang, R.D.; Zuo, J.; Zhao, Z.Y.; Soebarto, V.; Lu, Y.; Zillante, G.; Gan, X.L. Sustainability attitude and performance of construction enterprises: A China study. J. Clean. Prod. 2018, 172, 1440–1451. [Google Scholar] [CrossRef]

| PC | Project Type and Location | A | E | F | MC | PM | QS | SC | Total |

|---|---|---|---|---|---|---|---|---|---|

| S1 | Religious, Ikoyi | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 7 |

| S2 | Residential, Ajah | X | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 6 |

| S3 | Commercial, Victoria Island | ✓ | ✓ | ✓ | ✓ | X | ✓ | ✓ | 6 |

| S4 | Residential, Ikoyi | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 7 |

| S5 | Commercial, Lekki | ✓ | ✓ | ✓ | ✓ | ✓ | X | ✓ | 6 |

| S6 | Religious, Yaba | ✓ | ✓ | X | ✓ | ✓ | ✓ | ✓ | 6 |

| S7 | Residential, Ipaja | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 7 |

| S8 | Recreation/Entertainment, Ikeja | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 7 |

| S9 | Mixed (Commercial & Residential), Ikeja | ✓ | ✓ | ✓ | ✓ | ✓ | X | ✓ | 6 |

| S10 | Commercial, Ikoyi | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 7 |

| Total | 9 | 10 | 9 | 10 | 9 | 8 | 10 | 65 | |

| Respondents’ Job Description | ||

| Frequency | Percentage | |

| Urban planner | 1 | 0.4 |

| CEO | 14 | 5.8 |

| Manager | 7 | 2.9 |

| Project Manager | 40 | 16.5 |

| Architect | 88 | 36.2 |

| Engineer | 25 | 10.3 |

| Contract/Quality Manager | 2 | 0.8 |

| Quantity Surveyor | 53 | 21.8 |

| Builder | 11 | 4.5 |

| Technician | 2 | 0.8 |

| Level of Educational | ||

| Ordinary National Diploma | 2 | 0.8 |

| Higher National Diploma | 30 | 12.3 |

| Post Graduate Diploma | 10 | 4.1 |

| Bachelor Degree | 78 | 32.1 |

| Master Degree | 120 | 49.4 |

| PhD | 3 | 1.2 |

| Ownership Status | ||

| Frequency | Percentage | |

| Privately owned | 161 | 66.3 |

| Partnership | 38 | 15.6 |

| Government owned | 18 | 7.4 |

| Public Limited Company | 26 | 10.7 |

| Age of Organisation | ||

| 1–5 years | 48 | 19.8 |

| 6–10 years | 58 | 23.9 |

| 11–15 years | 39 | 16.0 |

| 16–20 years | 34 | 14.0 |

| Above 21 years | 64 | 26.3 |

| Size of Organisation | ||

| Up to ₦50million (Small) | 114 | 46.9 |

| ₦51–₦500million (Medium) | 60 | 24.7 |

| Above ₦501million (Large) | 69 | 28.4 |

| Area of Project Specialisation | ||

| New build | 208 | 85.6 |

| Maintenance/repair | 17 | 7.0 |

| Renovation | 14 | 5.8 |

| Demolition/deconstruction | 4 | 1.6 |

| Experience | |

| Years of experience | No of Interviewees |

| 3–5 years | 16 |

| 6–10 years | 18 |

| 11–15 years | 11 |

| 16–20 years | 6 |

| 21–25 years | 6 |

| 26–30 years | 4 |

| Above 31 years | 4 |

| Average years | 13.1 years |

| Educational Level | |

| Maximum | Masters (MSc.) |

| Minimum | Ordinary National Diploma (OND) |

| Disposal methods | Frequency | Percentage |

|---|---|---|

| Open dumping | 43 | 17.7 |

| Recycling | 53 | 21.8 |

| Landfilling | 57 | 23.5 |

| Incineration | 18 | 7.4 |

| Reuse as backfill | 54 | 22.2 |

| Onsite dig and bury | 11 | 4.5 |

| Burning | 7 | 2.9 |

| Total | 243 | 100.0 |

| Cross Tabulation | Chi-Square Tests | ||

|---|---|---|---|

| Value | df | p-Value | |

| Disposal method and company ownership status | 19.080 a | 18 | 0.387 |

| Disposal method and Company age | 26.605 b | 24 | 0.323 |

| Disposal method and Company size | 25.121 c | 12 | 0.014 |

| Disposal method and Company’s main construction activity | 21.428 d | 18 | 0.258 |

| Small | Medium | Large | Total | |||

|---|---|---|---|---|---|---|

| Disposal method | Open dumping | Count | 25 | 14 | 4 | 43 |

| % within disposal method | 58.1% | 32.6% | 9.3% | 100.0% | ||

| % within company size | 21.9% | 23.3% | 5.8% | 17.7% | ||

| % of Total | 10.3% | 5.8% | 1.6% | 17.7% | ||

| Recycling | Count | 22 | 14 | 17 | 53 | |

| % within disposal method | 41.5% | 26.4% | 32.1% | 100.0% | ||

| % within company size | 19.3% | 23.3% | 24.6% | 21.8% | ||

| % of Total | 9.1% | 5.8% | 7.0% | 21.8% | ||

| Landfilling | Count | 28 | 15 | 14 | 57 | |

| % within disposal method | 49.1% | 26.3% | 24.6% | 100.0% | ||

| % within company size | 24.6% | 25.0% | 20.3% | 23.5% | ||

| % of Total | 11.5% | 6.2% | 5.8% | 23.5% | ||

| Incineration | Count | 6 | 2 | 10 | 18 | |

| % within disposal method | 33.3% | 11.1% | 55.6% | 100.0% | ||

| % within company size | 5.3% | 3.3% | 14.5% | 7.4% | ||

| % of Total | 2.5% | 0.8% | 4.1% | 7.4% | ||

| Reuse as backfill | Count | 29 | 11 | 14 | 54 | |

| % within disposal method | 53.7% | 20.4% | 25.9% | 100.0% | ||

| % within company size | 25.4% | 18.3% | 20.3% | 22.2% | ||

| % of Total | 11.9% | 4.5% | 5.8% | 22.2% | ||

| Onsite dig and bury | Count | 3 | 3 | 5 | 11 | |

| % within disposal method | 27.3% | 27.3% | 45.5% | 100.0% | ||

| % within company size | 2.6% | 5.0% | 7.2% | 4.5% | ||

| % of Total | 1.2% | 1.2% | 2.1% | 4.5% | ||

| Burning | Count | 1 | 1 | 5 | 7 | |

| % within disposal method | 14.3% | 14.3% | 71.4% | 100.0% | ||

| % within company size | 0.9% | 1.7% | 7.2% | 2.9% | ||

| % of Total | 0.4% | 0.4% | 2.1% | 2.9% | ||

| Total | Count | 114 | 60 | 69 | 243 | |

| % within disposal method | 46.9% | 24.7% | 28.4% | 100.0% | ||

| % within company size | 100.0% | 100.0% | 100.0% | 100.0% | ||

| % of Total | 46.9% | 24.7% | 28.4% | 100.0% | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ogunmakinde, O.E.; Sher, W.; Maund, K. An Assessment of Material Waste Disposal Methods in the Nigerian Construction Industry. Recycling 2019, 4, 13. https://doi.org/10.3390/recycling4010013

Ogunmakinde OE, Sher W, Maund K. An Assessment of Material Waste Disposal Methods in the Nigerian Construction Industry. Recycling. 2019; 4(1):13. https://doi.org/10.3390/recycling4010013

Chicago/Turabian StyleOgunmakinde, Olabode Emmanuel, William Sher, and Kim Maund. 2019. "An Assessment of Material Waste Disposal Methods in the Nigerian Construction Industry" Recycling 4, no. 1: 13. https://doi.org/10.3390/recycling4010013

APA StyleOgunmakinde, O. E., Sher, W., & Maund, K. (2019). An Assessment of Material Waste Disposal Methods in the Nigerian Construction Industry. Recycling, 4(1), 13. https://doi.org/10.3390/recycling4010013