Characterization of Polystyrene Wastes as Potential Extruded Feedstock Filament for 3D Printing

Abstract

1. Introduction

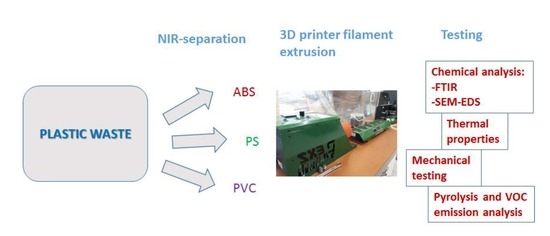

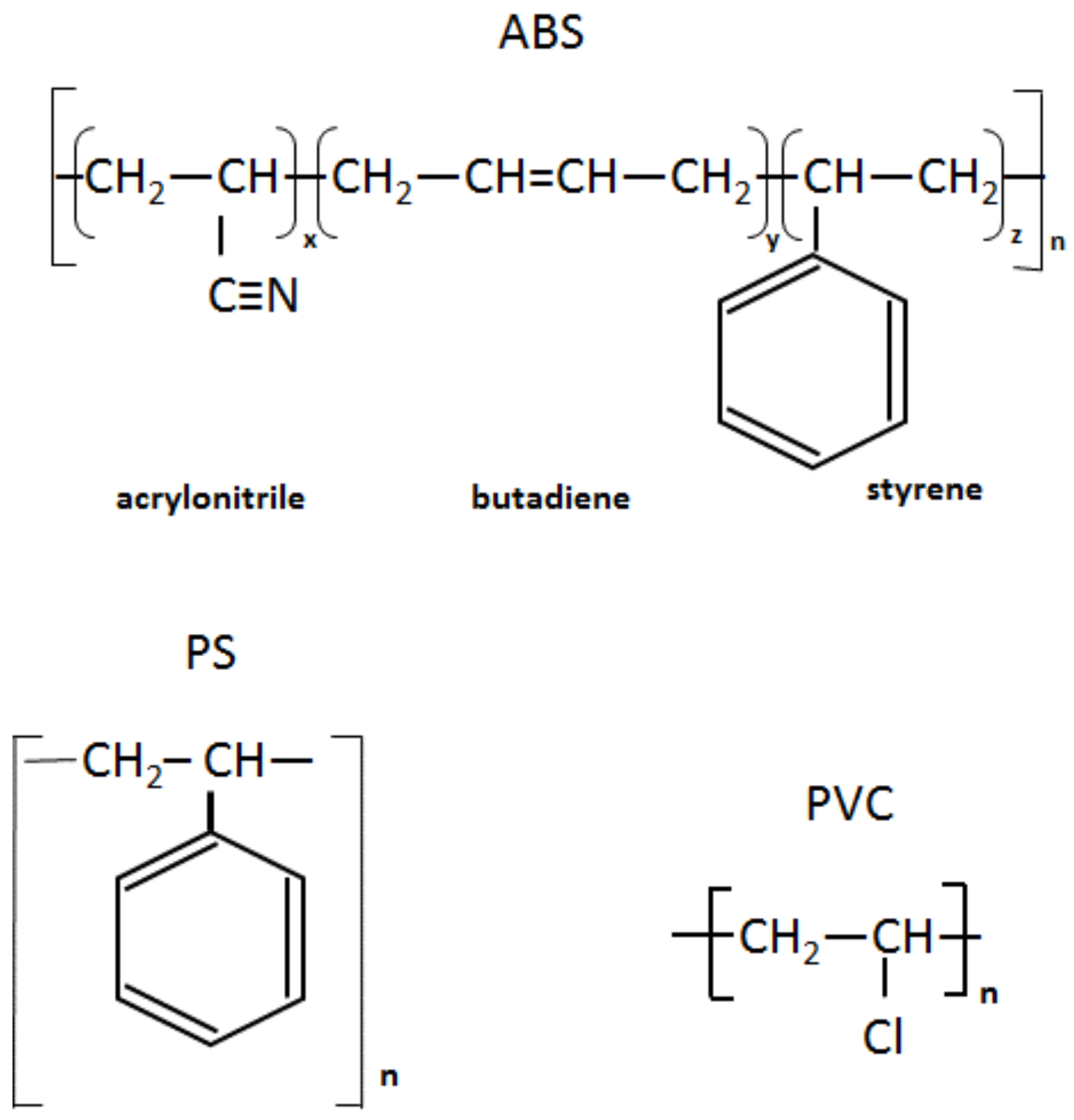

2. Materials and Methods

2.1. Plastic Sources and Filament Manufacturing

2.2. Melt Flow Index

2.3. Fourier-Transform Infrared Analysis (FTIR)

2.4. Tensile Property Testing

2.5. Differential Scanning Calorimeter (DSC) and Thermogravimetric Analysis (TGA)

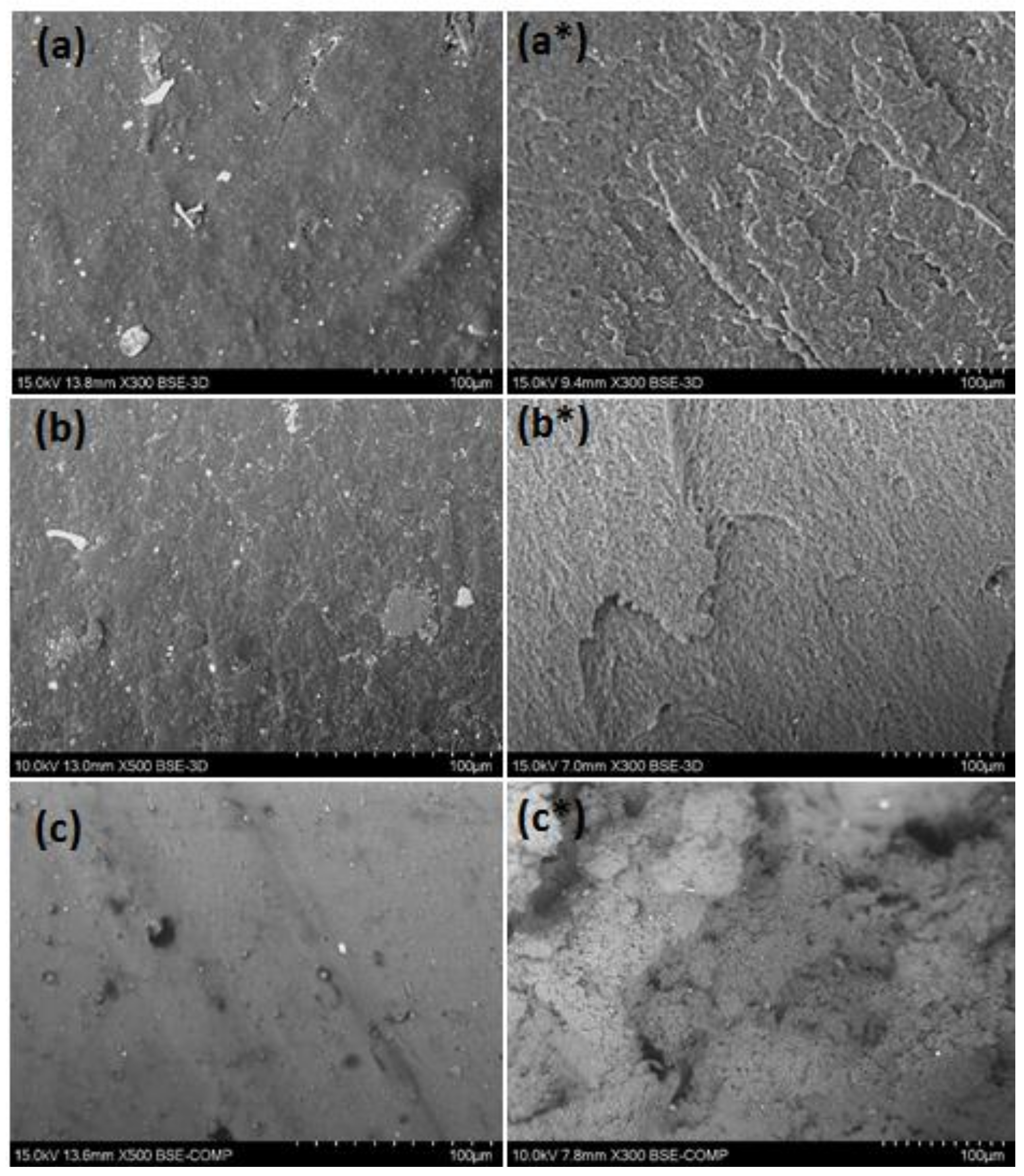

2.6. Scanning Electron Microscope (SEM) Analysis and Energy-Dispersive Spectroscopy (EDS)

3. Results and Discussion

3.1. Melt Flow Index (MFI)

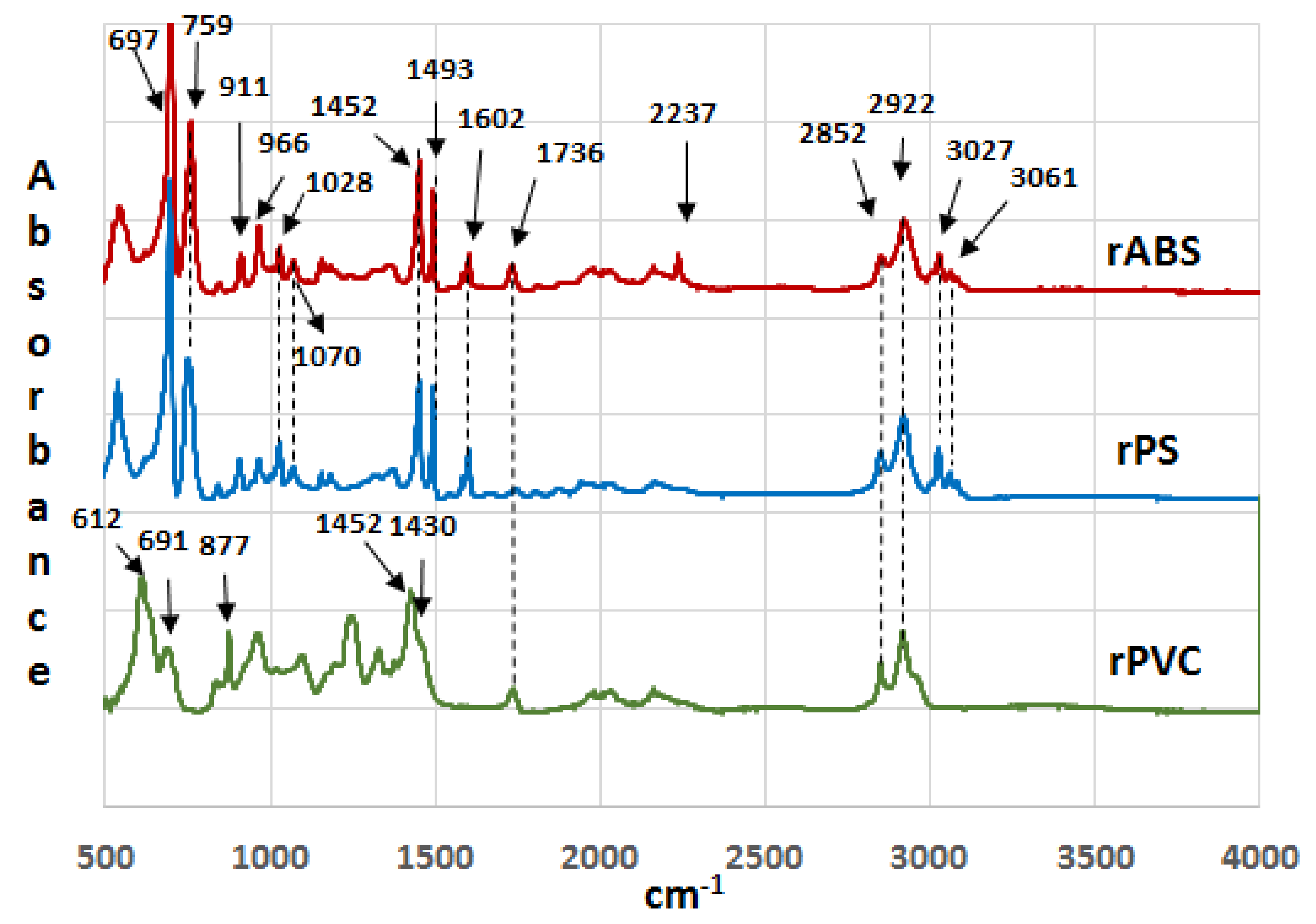

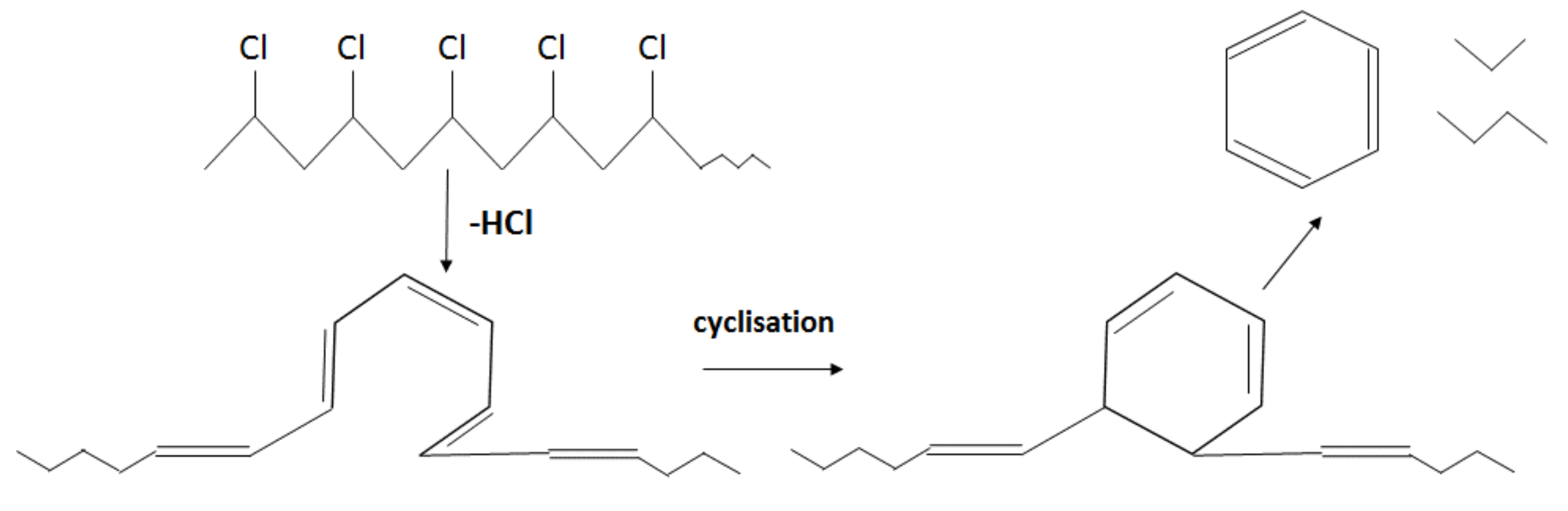

3.2. Fourier-Transform Infrared Analysis

3.3. Differential Scanning Calorimeter (DSC) Analysis

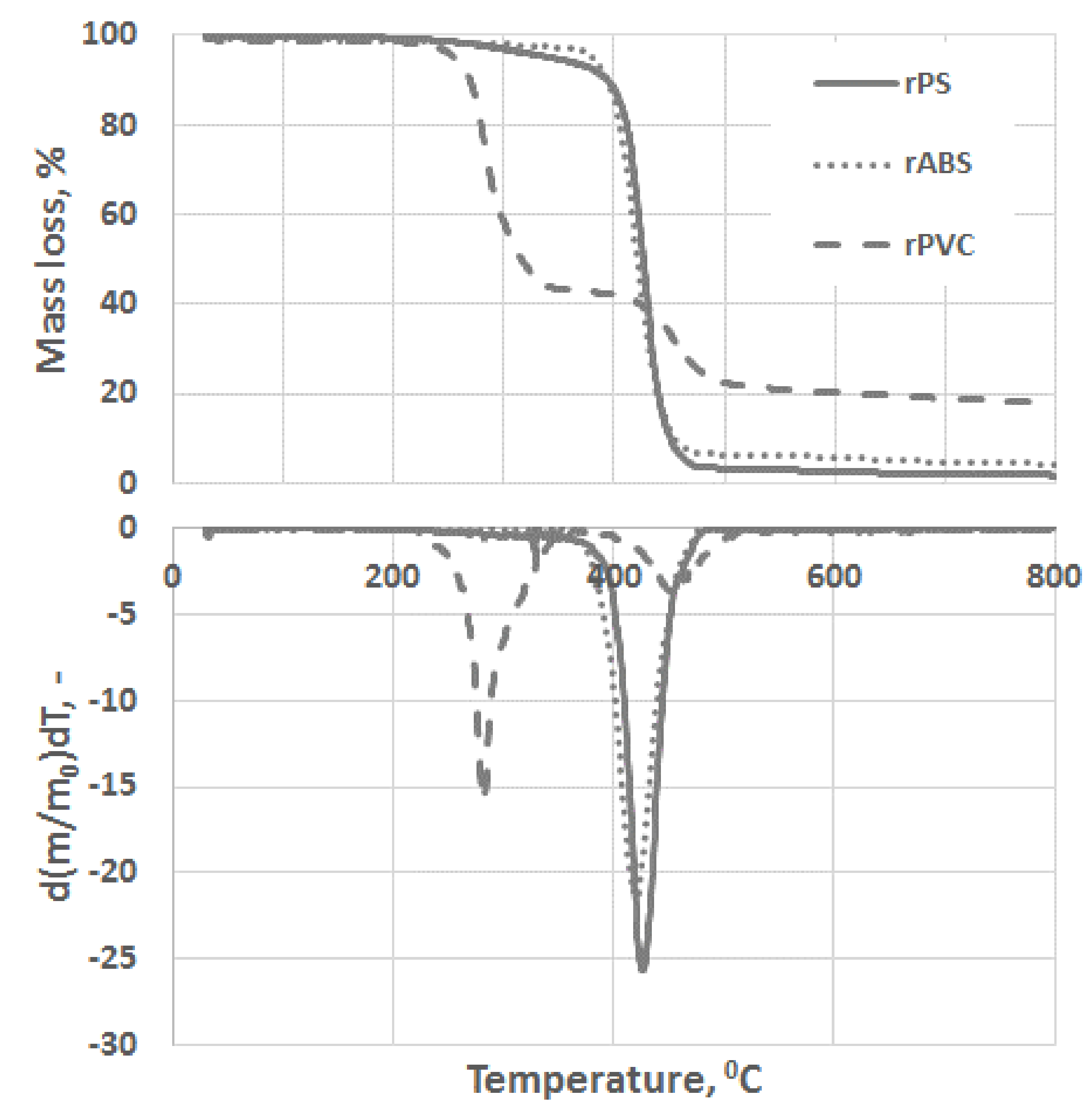

3.4. Heat Resistance and Thermal Stability

3.5. SEM-EDS Analysis

3.6. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- PlasticsEurope. An analysis of European plastics production, demand and waste data. Available online: https://www.plasticseurope.org/application/files/5715/1717/4180/Plasti2cs_the_facts_2017_FINAL_for_website_one_page.pdf (accessed on 26 November 2018).

- A European Strategy for plastics in a circular economy. Available online: http://ec.europa.eu/environment/circular-economy/pdf/plastics-strategy.pdf (accessed on 26 November 2018).

- Huysman, S.; Sala, S.; Mancini, L.; Ardente, F.; Alvarenga, R.A.F.; Meester, S.; Mathieux, F.; Dewulf, J. Toward a systematized framework for resource efficiency indicators. Resour. Conserv. Recycl. 2015, 95, 68–76. [Google Scholar] [CrossRef]

- REACH Restricted Substances Finder. Available online: https://www.chemsafetypro.com/Topics/EU/REACH_Restricted_Substances_List_RRS_Finder.html (accessed on 26 November 2018).

- Quaghebeur, M.; Laenen, B.; Geysen, D.; Nielsen, P.; Pontikes, Y.; Van Gerven, T.; Spooren, J. Characterization of landfilled materials: Screening of the enhanced landfill mining potential. J. Clean. Prod. 2013, 55, 72–83. [Google Scholar] [CrossRef]

- Rayna, T.; Striukova, L. From rapid prototyping to home fabrication: How 3D printing is changing business model innovation. Technol. Forecast. Soc. Chang. 2016, 102, 214–224. [Google Scholar] [CrossRef]

- Baechler, C.; DeVuono, M.; Pearce, J.M. Distributed recycling of waste polymer into RepRap feedstock. Rapid Prototyp. J. 2013, 19, 118–125. [Google Scholar] [CrossRef]

- Available online: www.3d-printer-filaments.com (accessed on 23 November 2018).

- Available online: www.bigrep.com (accessed on 23 November 2018).

- Available online: www.bpetfilament.com (accessed on 23 November 2018).

- Mirón., V.; Ferrándiz, S.; Juárez, D.; Mengual, A. Manufacturing and characterization of 3D printer filament using tailoring materials. Procedia Manuf. 2017, 13, 888–894. [Google Scholar] [CrossRef]

- Anderson, I. Mechanical properties of specimens 3D printed with virgin and recycled polylactic acid. 3D Print. Addit. Manuf. 2017, 4, 110–115. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Lambeth, R.H. Recycled polyethylene terephthalate as a new FFF feedstock material. Addit. Manuf. 2018, 21, 174–182. [Google Scholar] [CrossRef]

- Available online: https://webbook.nist.gov/chemistry/ (accessed on 23 November 2018).

- Available online: https://cdn.shopify.com/s/files/1/0762/2839/files/TDS_ABS_Filament.pdf (accessed on 23 November 2018).

- Available online: https://www.innofil3d.com/wp-content/uploads/2016/05/TDS-Innofil3D-ABS-160609.pdf (accessed on 23 November 2018).

- Available online: www.merck.com.

- Jin, H.; Gonzales-Gutierrez, J.; Oblak, P.; Zupancic, B.; Emri, I. Effect of extensive recycling on flow properties of LDPE. In Proceedings of the ANTEC, Cincinnati, OH, USA, 22–24 April 2013; pp. 98–101. [Google Scholar]

- Available online: https://plastics.ulprospector.com/generics/46/c/t/polyvinyl-chloride-pvc-properties-processing/sp/7 (accessed on 23 November 2018).

- Wang, J.; Li, Y.; Song, J.; He, M.; Song, J.; Xia, K. Recycling of acrylonitrile-butadiene-styrene (ABS) copolymers from waste electrical and electronic equipment (WEEE), through using an epoxy-based chain extender. Polym. Dégrad. Stab. 2015, 112, 167–174. [Google Scholar] [CrossRef]

- Olmos, D.; Martén, E.V.; González-Benito, J. New molecular-scale information on polystyrene dynamics in PS and PS-BaTiO3 composites from FTIR spectroscopy. Phys. Chem. Chem. Phys. 2014, 16, 24339–24349. [Google Scholar] [CrossRef] [PubMed]

- Tiganis, B.E.; Burn, L.S.; Davis, P.; Hill, A.J. Thermal degradation of acrylonitrile-butadiene-styrene (ABS) blends. Polym. Dégrad. Stab. 2002, 76, 425–434. [Google Scholar] [CrossRef]

- Mallakpour, S.; Sadaty, M.A. Thiamine hydrochloride (vitamin B1) as modifier agent for TiO2 nanoparticles and the optical, mechanical and thermal properties of poly(vinyl chloride) composite film. RSC Adv. 2016, 6, 92596–92604. [Google Scholar] [CrossRef]

- Available online: www.asminternational.org/documents/10192/1883419/amp (accessed on 23 November 2018).

- Available online: www.shimadzu.com/an/industry/petrochemicalchemical/chem0201010.htm (accessed on 23 November 2018).

- Scheirs, J.; Priddy, D. Modern Styrenic Polymers: Polystyrene and Styrenic Copolymers; John Willey & Sons, Ltd: West Sussex, UK, 2003; p. 323. [Google Scholar]

- Available online: www.misumi-techcentral.com/tt/en/mold/2011/12/106-glass-transition-temperature-tg-of-plastics.html (accessed on 23 November 2018).

- Castro, A.; Soares, D.; Vilarinho, C.; Castro, F. Kinetics of thermal de-chlorination of PVC under pyrolytic conditions. Waste Manag. 2012, 32, 847–851. [Google Scholar] [CrossRef] [PubMed]

- Starnes, W.H. Structural and mechanical aspects of the thermal degradation of poly(vinyl chloride). Prog. Polym. Sci. 2002, 27, 2133–2170. [Google Scholar] [CrossRef]

- Carty, P.; White, S. Char formation in polymer blends. Polymer 1994, 35, 343–347. [Google Scholar] [CrossRef]

- Slapak, M.J.P.; Kasteren, J.M.N.; Drinkengburg, A.A.H. Determination of the pyrolytic degradation kinetics of virgin-PVC and PVC-waste by analytical and computational methods. Comput. Theor. Polym. Sci. 2000, 10, 481–489. [Google Scholar] [CrossRef]

- Miranda, R.; Yang, J.; Roy, C.; Vasile, C. Vacuum pyrolysis of PVC I. Kinetic study. Polym. Dégrad. Stab. 1999, 64, 127–144. [Google Scholar] [CrossRef]

- Matsuzawa, Y.; Ayabe, M.; Nishino, J.; Kubota, N.; Motegi, M. Evaluation of char fuel ratio in municipal pyrolysis waste. Fuel 2004, 83, 1675–1687. [Google Scholar] [CrossRef]

- Schartel, B.; Kunze, R.; Neubert, D.; Tidjani, A. ZnS fire retardant in plasticized PVC. Polym. Int. 2002, 51, 213–222. [Google Scholar] [CrossRef]

- Xu, J.; Liu, C.; Qu, H.; Ma, H.; Jiao, Y.; Xie, J. Investigation on the thermal degradation of flexible poly(vinyl chloride) filled with ferrites as flame retardant and smoke suppressant using TGA-FTIR and TGA-MS. Polym. Dégrad. Stab. 2013, 1506–1514. [Google Scholar] [CrossRef]

- McNeill, I.C.; Memetea, L.; Cole, W.J. A study of the products of PVC thermal degradation. Polym. Dégrad. Stab. 1995, 49, 181–191. [Google Scholar] [CrossRef]

- Suzuki, M.; Wilkie, C.A. The thermal degradation of acrylonitrile-butadiene-styrene terpolymer as studied by TGA/FTIR. Polym. Dégrad. Stab. 1995, 47, 217–221. [Google Scholar] [CrossRef]

- Available online: www.perkinelmer.com/labsolutions/resources/docs/APP_009908_01_Characterization_of_Polymers_using_TGA.pdf (accessed on 23 November 2018).

- Available online: http://www.thermal-instruments.co.uk/ABR_PVCbyTG-GCMS.pdf (accessed on 23 November 2018).

- Chigwada, G.; Kandare, E.; Wang, D.; Majoni, S.; Mlambo, D.; Wilkie, C.A.; Hossenlopp, J.M. Thermal stability and degradation kinetics of polystyrene/organically-modified montmorillonite nanocomposites. J. Nanosci. Nanotechnol. 2008, 8, 1927–1936. [Google Scholar] [CrossRef] [PubMed]

- Özsin, G.; Pütün, A.E. Insights into pyrolysis and co-pyrolysis of biomass and polystyrene: Thermochemical behaviors, kinetics and evolved gas analysis. Energy Convers. Manag. 2017, 149, 675–685. [Google Scholar] [CrossRef]

- Seleem, S.; Hopkins, M.; Olivio, J.; Schiraldi, D.A. Comparison of thermal decomposition of polystyrene products vs. bio-based polymer aerogels. Ohio J. Sci. 2017, 117, 50–60. [Google Scholar] [CrossRef]

- Saraji-Bozorgzad, M.; Geissler, R.; Streibel, T.; Mühlberger, F.; Sklorz, M.; Kaisersberger, E.; Denner, T.; Zimmermann, R. Thermogravimetry coupled to single photon ionization quadrupole mass spectrometry: A tool to investigate the chemical signature of thermal decomposition of polymeric materials. Analyt. Chem. 2008, 80, 3393–3403. [Google Scholar] [CrossRef] [PubMed]

- Available online: www.hitachi-hightech.com/file/global/pdf/products/science/appli/ana/thermal/application_TA_066e.pdf (accessed on 23 November 2018).

- Vouvoudi, E.C.; Rousi, A.T.; Achilias, D.S. Thermal degradation characteristics and products obtained after pyrolysis of specific polymers found in waste electrical and electronic equipment. Front. Environ. Sci. Eng. 2017, 11, 1–10. [Google Scholar] [CrossRef]

- Matuana, L.M.; Kamdem, D.P.; Zhang, J. Photoaging and stabilization of rigid PVC/wood-fiber composites. J. Appl. Polym. Sci. 2001, 180, 943–960. [Google Scholar] [CrossRef]

- Available online: https://www.multistation.com/voy_content/uploads/2017/11/161219_tds_ps_owa.pdf (accessed on 23 November 2018).

| Material/Parameter | Textr (°C) | d (cm) | MFI (g/10 min) | MFI, Virgin (g/10min) |

|---|---|---|---|---|

| ABS | 180 | 3.81(0.12) | 8.9(0.8) | 15 [15], 43.1 [16] |

| PS | 200 | 2.98(0.08) | 11.5(0.9) | 12–16 [17] |

| PVC | 196 | 3.57(0.14) | N/A | 1.4–54 [19] |

| Material/ Element | C | O | Cl | Mg | Al | Ca | Na | Ti | Si | S | K | Fe, Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ABS | 86(8) | 3(2) | 0.3(0.1) | 0.02(0.03) | 1.1(0.4) | 0.2(0.1) | 0.2(0.1) | 0.7(0.3) | 0.1(0.06) | 0.04(0.04) | 0.3(0.1) | <0.02 |

| PS | 98(0.4) | 0.14(0.02) | 0.7(0.4) | 0.1(0.03) | 0.1(0.1) | 0.6(0.1) | <0.1 | |||||

| PVC | 57(6) | 4(0.6) | 37(9) | <0.01 | 0.6(0.1) | 1.3(0.1) | 0.1(0.01) | 0.02(0.01) |

| Material/ Property | Tg (°C) | Tg Virgin (°C) | |

|---|---|---|---|

| II cyc | III cyc | ||

| rABS | 106.4 | 106.5 | 105 [26] |

| rPS | 87.5 | 85.6 | 100 [26,27] |

| rPVC | 81 | 80.9 | 87 [27] |

| Material/ Property | Tensile, Measured | Tensile, Virgin | ||||

|---|---|---|---|---|---|---|

| Strength, MPa | Modulus, GPa | Elongation at Break, % | Strength, MPa | Modulus, GPa | Elongation at Break, % | |

| rABS | 14.5(1) | 2.7(2.8) | 2(2) | 45 [15] | 2.3 [15] | - |

| rPS | 4.3(0.35) | 1.85(0.4) | 1(1) | 15 [47] | - | 5.2 [47] |

| rPVC | 17(1) | 2.9(0.1) | 8(8) | 28–51 * [17] | 2.5–3.2 * [17] | 10–180 [17] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turku, I.; Kasala, S.; Kärki, T. Characterization of Polystyrene Wastes as Potential Extruded Feedstock Filament for 3D Printing. Recycling 2018, 3, 57. https://doi.org/10.3390/recycling3040057

Turku I, Kasala S, Kärki T. Characterization of Polystyrene Wastes as Potential Extruded Feedstock Filament for 3D Printing. Recycling. 2018; 3(4):57. https://doi.org/10.3390/recycling3040057

Chicago/Turabian StyleTurku, Irina, Sushil Kasala, and Timo Kärki. 2018. "Characterization of Polystyrene Wastes as Potential Extruded Feedstock Filament for 3D Printing" Recycling 3, no. 4: 57. https://doi.org/10.3390/recycling3040057

APA StyleTurku, I., Kasala, S., & Kärki, T. (2018). Characterization of Polystyrene Wastes as Potential Extruded Feedstock Filament for 3D Printing. Recycling, 3(4), 57. https://doi.org/10.3390/recycling3040057