Recycling of Post-Consumer HDPE Bottle Caps into New Caps for Food Contact

Abstract

1. Introduction

2. Results

2.1. Input Control

2.2. Contamination Levels

2.3. Proposed Criteria for the Evaluation of Recycled Bottle Caps

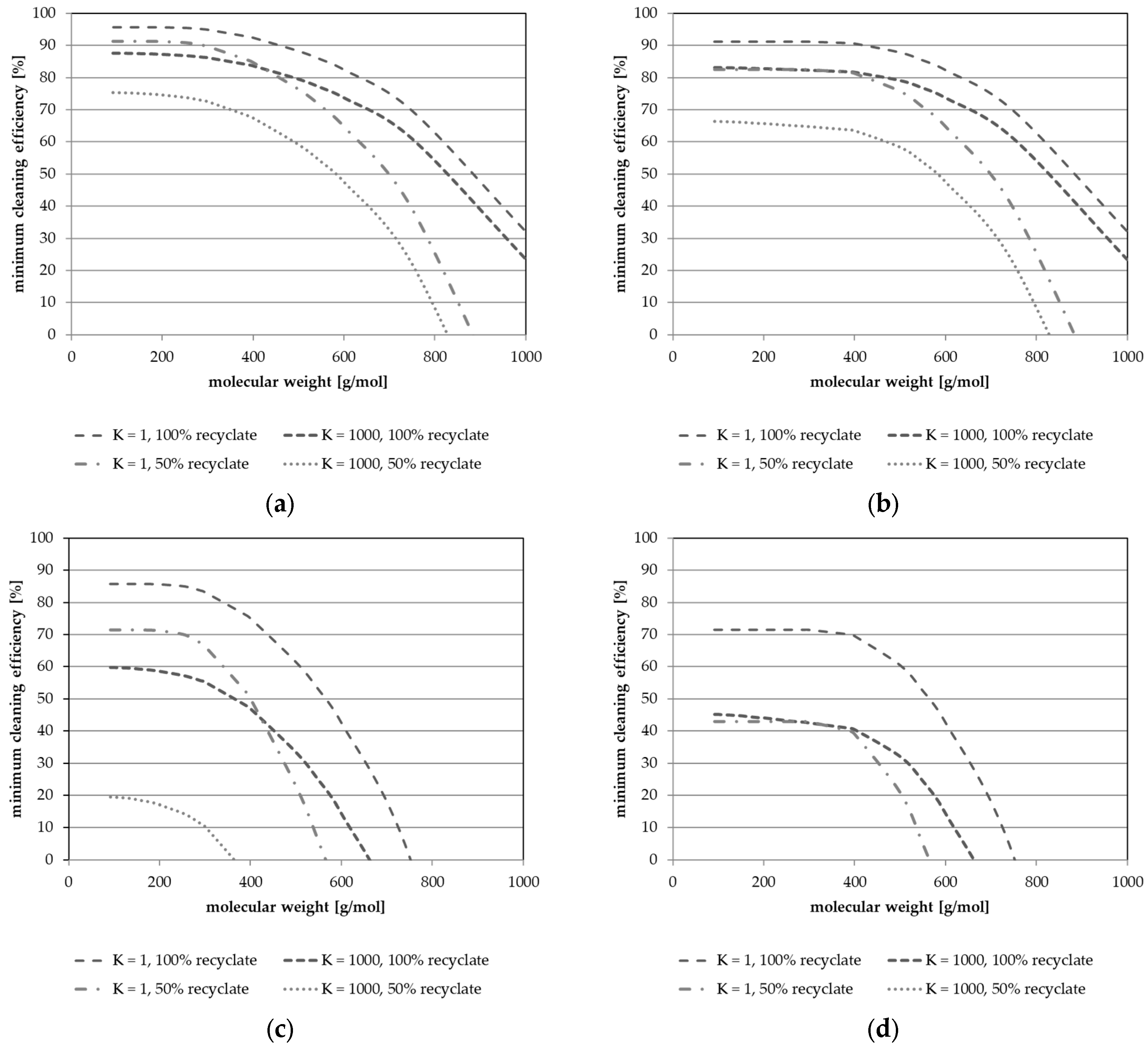

2.4. Minimum Cleaning Efficiencies

3. Discussion

4. Materials and Methods

5. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Regulation (EU) 2025/40 of the European Parliament and of the Council of 19 December 2024 on packaging and packaging waste, amending Regulation (EU) 2019/1020 and Directive (EU) 2019/904, and repealing Directive 94/62/EC. Off. J. Eur. Union 2025, 40. Available online: http://data.europa.eu/eli/reg/2025/40/oj (accessed on 20 October 2025).

- Welle, F. Twenty years of PET bottle to bottle recycling—An overview. Resour. Conserv. Recycl. 2011, 55, 865–875. [Google Scholar] [CrossRef]

- Thoden van Velzen, E.U.; Brouwer, M.T.; Stärker, C.; Welle, F. The effect of recycled content and rPET quality on the properties of PET bottles, Part II: Migration. Packag. Technol. Sci. 2020, 33, 359–371. [Google Scholar] [CrossRef]

- Pinter, E.; Welle, F.; Mayrhofer, E.; Pechhacker, A.; Motloch, L.; Lahme, V.; Grant, A.; Tacker, M. Circularity study on PET bottle-to-bottle recycling. Sustainability 2021, 13, 7370. [Google Scholar] [CrossRef]

- Cecon, V.S.; Da Silva, P.F.; Curtzwiler, G.W.; Vorst, K.L. The challenges in recycling post-consumer polyolefins for food contact applications: A review. Resour. Conserv. Recycl. 2021, 167, 105422. [Google Scholar] [CrossRef]

- Su, Q.-Z.; Vera, P.; Salafranca, J.; Nerin, C. Decontamination efficiencies of post-consumer high-density polyethylene milk bottles and prioritization of high concern volatile migrants. Resour. Conserv. Recycl. 2021, 171, 105640. [Google Scholar] [CrossRef]

- Vera, P.; Canellas, E.; Su, Q.-Z.; Mercado, D.; Nerin, C. Migration of volatile substances from recycled high density polyethylene to milk products. Food Packag. Shelf Life 2023, 35, 101020. [Google Scholar] [CrossRef]

- Palkopoulou, S.; Joly, C.; Feigenbaum, A.; Papaspyrides, C.D.; Dole, P. Critical review on challenge tests to demonstrate decontamination of polyolefins intended for food contact applications. Trends Food Sci. Technol. 2016, 49, 110–120. [Google Scholar] [CrossRef]

- Boldizar, A.; Jansson, A.; Gevert, T.; Möller, K. Simulated recycling of post-consumer high density polyethylene material. Polym. Degrad. Stab. 2000, 68, 317–319. [Google Scholar] [CrossRef]

- Thoden van Velzen, E.U.; Workala, Y.; Teunissen, W.; Smeding, I. Volatile organic contaminants in HDPE milk bottles along the mechanical recycling value chain, revealing origins and contamination pathways. J. Clean. Prod. 2024, 459, 142571. [Google Scholar] [CrossRef]

- Brouwer, M.T.; Thoden van Velzen, E.U.; Ragaert, K.; ten Klooster, R. Technical limits in circularity for plastic packages. Sustainability 2020, 12, 10021. [Google Scholar] [CrossRef]

- Regulation No 2022/1616 of 15 September 2022 on recycled plastic materials and articles intended to come into contact with foods, and repealing Regulation (EC) No 282/2008. Off. J. Eur. Union 2022, 243, 3–46.

- Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the reduction of the impact of certain plastic products on the environment. Off. J. Eur. Union 2019, L 155, 1–19. Available online: http://data.europa.eu/eli/dir/2019/904/oj (accessed on 20 October 2025).

- Commission Regulation (EU) No 10/2011 of 14 January 2011 on plastic materials and articles intended to come into contact with food. Off. J. Eur. Union 2011, L 12, 1–89. Available online: http://data.europa.eu/eli/reg/2011/10/oj (accessed on 20 October 2025).

- Regulation No 282/2008 of 27 March 2008 on recycled plastic materials and articles intended to come into contact with foods and amending Regulation (EC) No 2023/2006. Off. J. Eur. Union 2008, L 86, 9–18. Available online: http://data.europa.eu/eli/reg/2008/282/oj (accessed on 20 October 2025).

- EFSA CEP Panel (EFSA Panel on Food Contact Materials, Enzymes and Processing Aids); Lambré, C.; Baviera, J.M.B.; Bolognesi, C.; Chesson, A.; Cocconcelli, P.S.; Crebelli, R.; Gott, D.M.; Grob, K.; Mengelers, M.; et al. Scientific Opinion on the safety assessment of the process Starlinger recoSTAR HDPE FC 1—PET2PET used to recycle post-consumer HDPE closures into food contact closures. EFSA J. 2022, 20, 7001. [Google Scholar] [CrossRef]

- EFSA Panel on food contact materials; Enzymes, Flavourings and Processing aids (CEF). Scientific Opinion on the criteria to be used for safety evaluation of a mechanical recycling process to produce recycled PET intended to be used for manufacture of materials and articles in contact with food. EFSA J. 2011, 9, 2184. [Google Scholar] [CrossRef]

- EFSA Panel on food contact materials, enzymes, flavourings and processing aids (CEF). Scientific Guidance on the criteria for the evaluation and on the preparation of applications for the safety assessment of post-consumer mechanical PET recycling processes intended to be used for manufacture of materials and articles in contact with food. EFSA J. 2024, 22, 8879. [Google Scholar] [CrossRef]

- EFSA CEF Panel (EFSA Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids). Scientific Opinion on the safety assessment of the processes ‘Biffa Polymers’ and ‘CLRrHDPE’ used to recycle high-density polyethylene bottles for use as food contact material. EFSA J. 2015, 13, 4016. [Google Scholar] [CrossRef]

- Welle, F. Post-consumer contamination in high-density polyethylene (HDPE) milk bottles and the design of a bottle-to-bottle recycling process. Food Addit. Contam. 2005, 22, 999–1011. [Google Scholar] [CrossRef]

- Franz, R.; Mauer, A.; Welle, F. European survey on post-consumer poly(ethylene terephthalate) materials to determine contamination levels and maximum consumer exposure from food packages made from recycled PET. Food Addit. Contam. 2004, 21, 265–286. [Google Scholar] [CrossRef]

- Agence Francaise de Securite Sanitaire des Aliments (AFSSA). Evaluation Sanitaire des «Matériaux en Poly(Éthylène Téréphtalate) Recyclés Utilisés en Tant que Matériaux au Contact des Denrées Alimentaires et de L’eau de Boisson». 2006. Available online: https://www.anses.fr/fr/system/files/MCDA2001sa0315Ra.pdf (accessed on 2 September 2025).

- Mayrhofer, E.; Prielinger, L.; Sharp, V.; Rainer, B.; Kirchnawy, C.; Rung, C.; Gruner, A.; Juric, M.; Springer, A. Safety assessment of recycled plastics from post-consumer waste with a combination of a miniaturized Ames Test and chromatographic analysis. Recycling 2023, 8, 87. [Google Scholar] [CrossRef]

- Prielinger, L.; Ortner, E.; Novak, M.; Markart, L.; Rainer, B. Preliminary analysis of printed polypropylene foils and pigments after thermal treatment using DSC and Ames tests. Materials 2025, 18, 3325. [Google Scholar] [CrossRef] [PubMed]

- Su, Q.-Z.; Vera, P.; Nerin, C.; Lin, Q.-B.; Zhong, H.-N. Safety concerns of recycling postconsumer polyolefins for food contact uses: Regarding (semi-)volatile migrants untargetedly screened. Resour. Conserv. Recycl. 2021, 167, 105365. [Google Scholar] [CrossRef]

- Su, Q.-Z.; Vera, P.; Nerin, C. Combination of structure databases, in silico fragmentation, and MS/MS libraries for untargeted screening of non-volatile migrants from recycled high-density polyethylene milk bottles. Anal. Chem. 2023, 95, 8780–8788. [Google Scholar] [CrossRef]

- Horodytska, O.; Cabanes, A.; Fullana, A. Non-intentionally added substances (NIAS) in recycled plastics. Chemosphere 2020, 251, 126373. [Google Scholar] [CrossRef]

- Tumu, K.; Vorst, K.; Curtzwiler, G. Understanding intentionally and non-intentionally added substances and associated threshold of toxicological concern in post-consumer polyolefin for use as food packaging materials. Heliyon 2024, 10, e23620. [Google Scholar] [CrossRef]

- Zeng, S.-F.; Zeng, Y.; Guo, P.; Hu, C.-Y.; Wang, Z.-W. Characterization of odors and volatile organic compounds changes to recycled high-density polyethylene through mechanical recycling. Polym. Degrad. Stab. 2023, 208, 110263. [Google Scholar] [CrossRef]

- Perez-Bondia, E.; Domeno, C.; Nerin, C.; Aznar, M. Evaluation of new safety decontamination approaches at lab scale for recycled highdensity polyethylene (rHDPE) intended for food contact. J. Chromatogr. A 2024, 1736, 465348. [Google Scholar] [CrossRef]

- Zhang, M.-Y.; Su, Q.-Z.; Lin, Q.-B.; Zhong, H.-N.; Chen, S.; Li, D.; Dong, B.; Xu, M.-Q.; Li, W.-L. Identification and quantification of volatile organic compounds in Chinese recycled HDPE: Consequences for its applicability. Food Packag. Shelf Life 2025, 47, 101424. [Google Scholar] [CrossRef]

- EFSA Scientific Committee. Guidance on the use of the Threshold of Toxicological Concern approach in food safety assessment. EFSA J. 2019, 17, 5708. [Google Scholar] [CrossRef]

- Kroes, R.; Kleiner, J.; Renwick, A. The threshold of toxicological concern concept in risk assessment. Toxicol. Sci. 2005, 86, 226–230. [Google Scholar] [CrossRef]

- Practical Guidelines on the Application of Migration Modelling for the Estimation of Specific Migration; EU Report 27529 EN; European Commission: Brussels, Belgium, 2015; ISBN 978-92-79-52790-6. Available online: https://op.europa.eu/de/publication-detail/-/publication/1b79bc61-97f6-11e5-983e-01aa75ed71a1 (accessed on 2 September 2025).

- Roduit, B.; Borgeat, C.H.; Cavin, S.; Fragniere, C.; Dudler, V. Application of finite element analysis (FEA) for the simulation of release of additives from multilayer polymeric packaging structures. Food Addit. Contam. Part A 2005, 22, 945–955. [Google Scholar] [CrossRef]

| Surrogate | Molecular Weight [g/mol] | Minimum Cleaning Efficiency [%] | |||

|---|---|---|---|---|---|

| Migration Only Inside K = 1 | Migration Only Inside K = 1000 | Migration Inside and Outside K = 1 | Migration Inside and Outside K = 1000 | ||

| toluene | 92 | 95.6 | 87.7 | 91.3 | 83.2 |

| 100 | 95.6 | 87.7 | 91.3 | 83.2 | |

| chlorobenzene | 113 | 95.6 | 87.6 | 91.3 | 83.1 |

| chloroform | 119 | 95.6 | 87.6 | 91.3 | 83.1 |

| limonene | 136 | 95.6 | 87.6 | 91.3 | 83.1 |

| methyl salicylate | 152 | 95.6 | 87.5 | 91.3 | 83.1 |

| phenyl cyclohexane | 160 | 95.6 | 87.5 | 91.3 | 83.0 |

| benzophenone | 182 | 95.6 | 87.4 | 91.3 | 82.9 |

| butyl salicylate | 194 | 95.6 | 87.3 | 91.3 | 82.9 |

| 200 | 95.6 | 87.3 | 91.3 | 82.9 | |

| 250 | 95.4 | 86.9 | 91.3 | 82.6 | |

| methyl palmitate | 271 | 95.3 | 86.7 | 91.3 | 82.5 |

| lindane | 291 | 95.0 | 86.4 | 91.3 | 82.4 |

| methyl stearate | 298 | 94.9 | 86.3 | 91.3 | 82.4 |

| DEHP | 391 | 92.7 | 84.0 | 90.8 | 81.9 |

| 400 | 92.4 | 83.7 | 90.7 | 81.7 | |

| 500 | 88.2 | 79.6 | 87.9 | 79.2 | |

| TEHTM | 548 | 85.7 | 77.0 | 85.5 | 76.9 |

| 600 | 82.4 | 73.8 | 82.4 | 73.8 | |

| 750 | 69.6 | 61.0 | 69.6 | 61.1 | |

| 1000 | 32.1 | 23.5 | 32.1 | 23.5 | |

| Surrogate | Molecular Weight [g/mol] | Minimum Cleaning Efficiency [%] | |||

|---|---|---|---|---|---|

| Migration Only Inside K = 1 | Migration Only Inside K = 1000 | Migration Inside and Outside K = 1 | Migration Inside and Outside K = 1000 | ||

| toluene | 92 | 85.8 | 59.8 | 71.5 | 45.2 |

| 100 | 85.8 | 59.8 | 71.5 | 45.2 | |

| chlorobenzene | 113 | 85.8 | 59.7 | 71.5 | 45.0 |

| chloroform | 119 | 85.8 | 59.7 | 71.5 | 45.0 |

| limonene | 136 | 85.8 | 59.6 | 71.5 | 44.9 |

| methyl salicylate | 152 | 85.8 | 59.4 | 71.5 | 44.7 |

| phenyl cyclohexane | 160 | 85.8 | 59.2 | 71.5 | 44.6 |

| benzophenone | 182 | 85.7 | 59.0 | 71.5 | 44.3 |

| butyl salicylate | 194 | 85.7 | 58.7 | 71.5 | 44.1 |

| 200 | 85.6 | 58.6 | 71.5 | 44.1 | |

| 250 | 85.1 | 57.4 | 71.5 | 43.3 | |

| methyl palmitate | 271 | 84.5 | 56.6 | 71.5 | 42.9 |

| lindane | 291 | 83.7 | 55.7 | 71.5 | 42.7 |

| methyl stearate | 298 | 83.4 | 55.4 | 71.5 | 42.6 |

| DEHP | 391 | 76.0 | 47.9 | 70.0 | 40.8 |

| 400 | 75.1 | 47.0 | 69.5 | 40.5 | |

| 500 | 61.5 | 33.5 | 60.5 | 32.1 | |

| TEHTM | 548 | 53.2 | 25.1 | 52.8 | 24.8 |

| 600 | 42.6 | 14.5 | 42.6 | 14.5 | |

| 750 | 0.9 | 0 | 0.9 | 0 | |

| 1000 | 0 | 0 | 0 | 0 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Welle, F. Recycling of Post-Consumer HDPE Bottle Caps into New Caps for Food Contact. Recycling 2025, 10, 197. https://doi.org/10.3390/recycling10060197

Welle F. Recycling of Post-Consumer HDPE Bottle Caps into New Caps for Food Contact. Recycling. 2025; 10(6):197. https://doi.org/10.3390/recycling10060197

Chicago/Turabian StyleWelle, Frank. 2025. "Recycling of Post-Consumer HDPE Bottle Caps into New Caps for Food Contact" Recycling 10, no. 6: 197. https://doi.org/10.3390/recycling10060197

APA StyleWelle, F. (2025). Recycling of Post-Consumer HDPE Bottle Caps into New Caps for Food Contact. Recycling, 10(6), 197. https://doi.org/10.3390/recycling10060197