Second-Generation Recycled Concrete Aggregates: Comprehensive Characterization of Physical, Mechanical, and Microstructural Properties

Abstract

1. Introduction

2. Results and Discussion

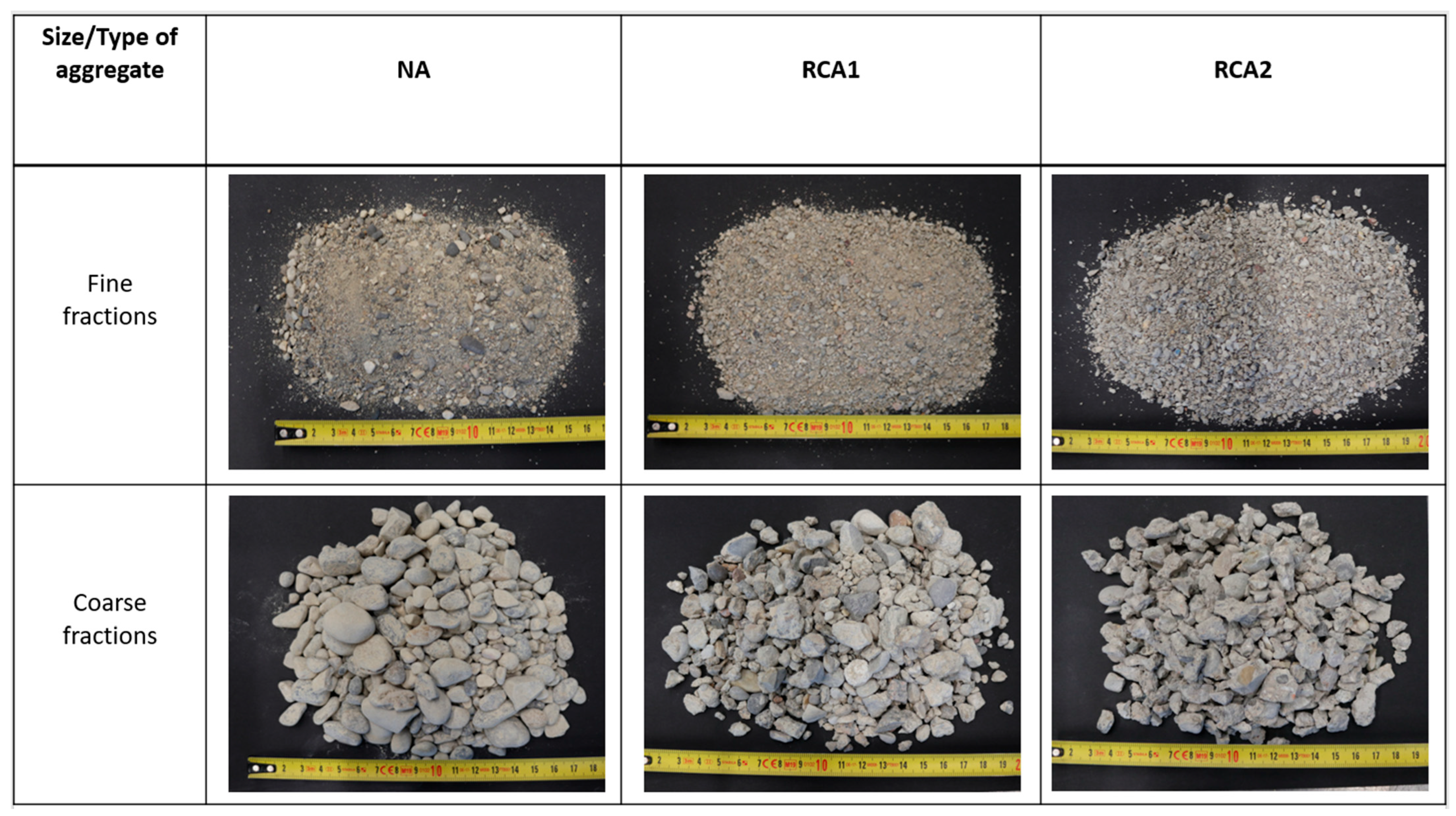

2.1. Gradation and Shape Analysis

2.1.1. Particle Size Distribution

2.1.2. Morphology Analysis

| Shape Parameter a | NA | RCA1 | RCA2 |

|---|---|---|---|

| x [mm] at Q3 = 10.0% | 6.04 | 5.61 | 5.01 |

| x [mm] at Q3 = 50.0% | 9.98 | 9.60 | 7.61 |

| x [mm] at Q3 = 90.0% | 14.49 | 14.28 | 11.73 |

| Q3 (SPHT = 0.9) [%] | 53.66 | 93.15 | 98.62 |

| Q3 (Symm = 0.9) [%] | 27.45 | 63.33 | 79.94 |

| Q3 (b/l = 0.9) [%] | 100.00 | 99.83 | 100.00 |

| Mean value SPHT3 | 0.88 | 0.81 | 0.76 |

| Mean value Symm3 | 0.92 | 0.89 | 0.87 |

| Mean value b/l3 | 0.69 | 0.67 | 0.65 |

| SPAN3 | 0.85 | 0.90 | 0.88 |

| U3 | 1.87 | 1.87 | 1.68 |

| Shape Parameter | NA | RCA1 | RCA2 |

|---|---|---|---|

| x [mm] at Q3 = 10.0% | 0.303 | 0.392 | 0.537 |

| x [mm] at Q3 = 50.0% | 0.954 | 1.438 | 1.697 |

| x [mm] at Q3 = 90.0% | 2.511 | 3.172 | 3.407 |

| a Q3 [%] at x = 1.000 mm | 51.62 | 34.75 | 27.69 |

| a Q3 [%] at x = 2.000 mm | 81.33 | 66.46 | 58.87 |

| a Q3 [%] at x = 4.000 mm | 100.00 | 100.00 | 100.00 |

| SPAN3 | 2.314 | 1.934 | 1.691 |

| U3 | 4.045 | 4.570 | 3.804 |

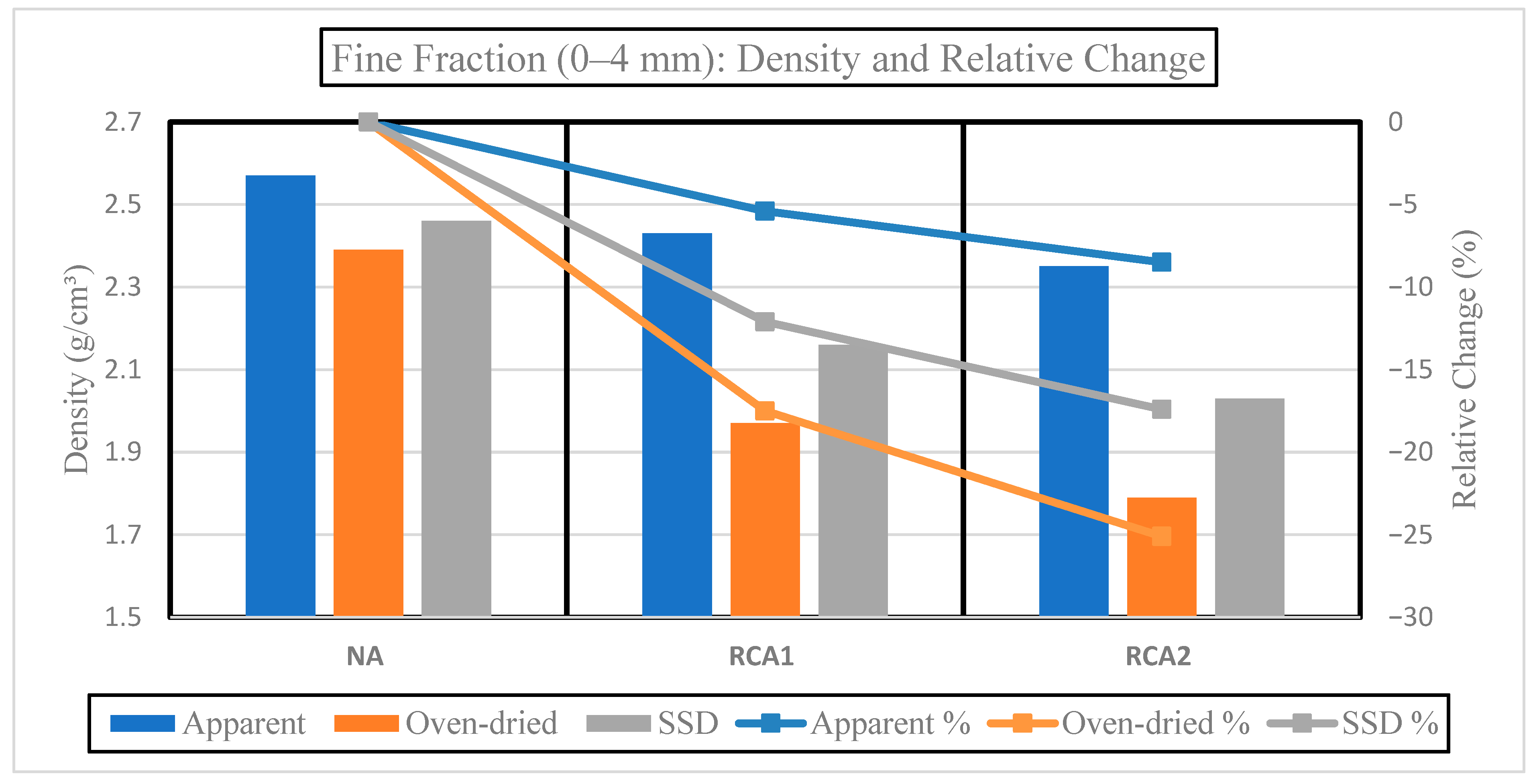

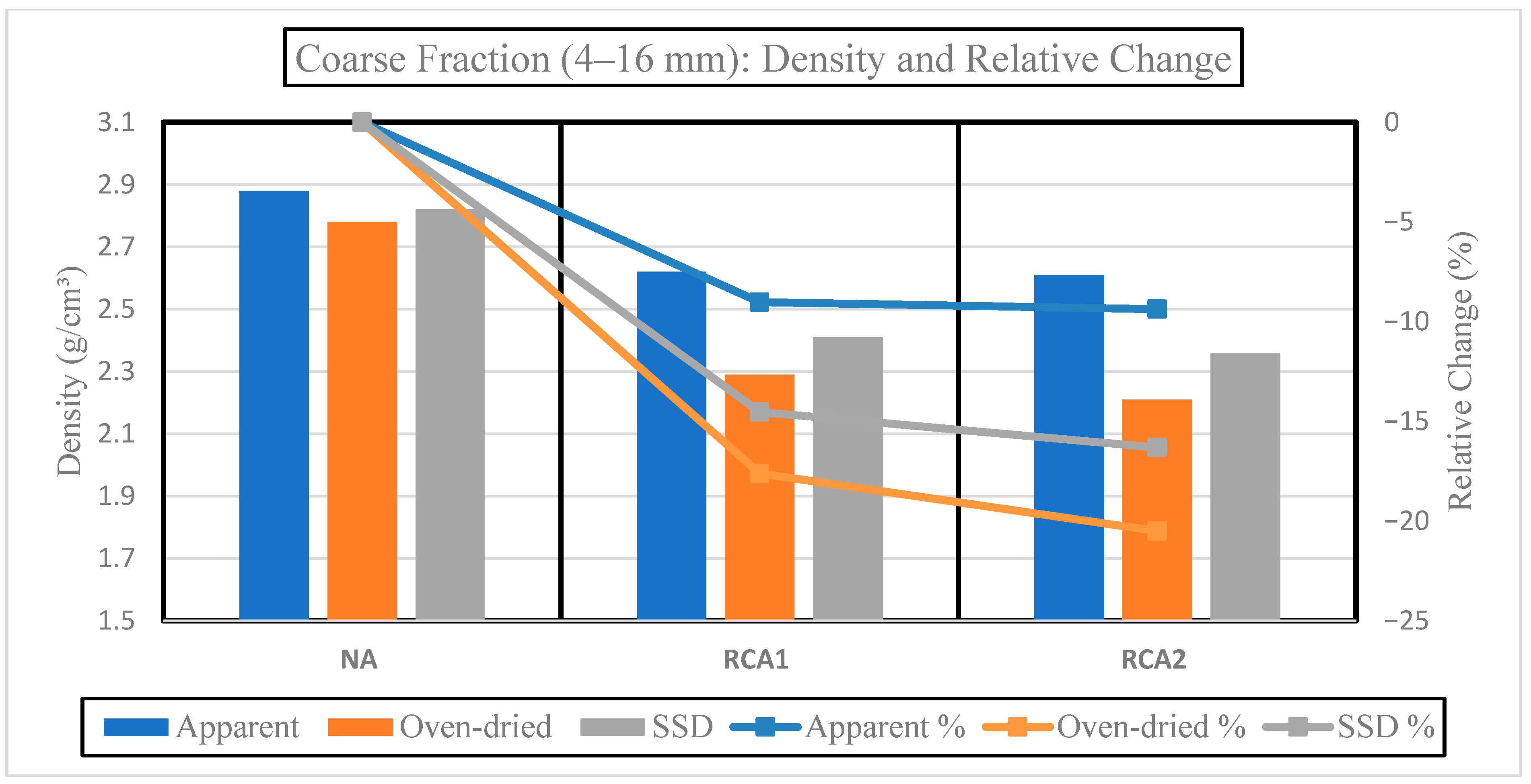

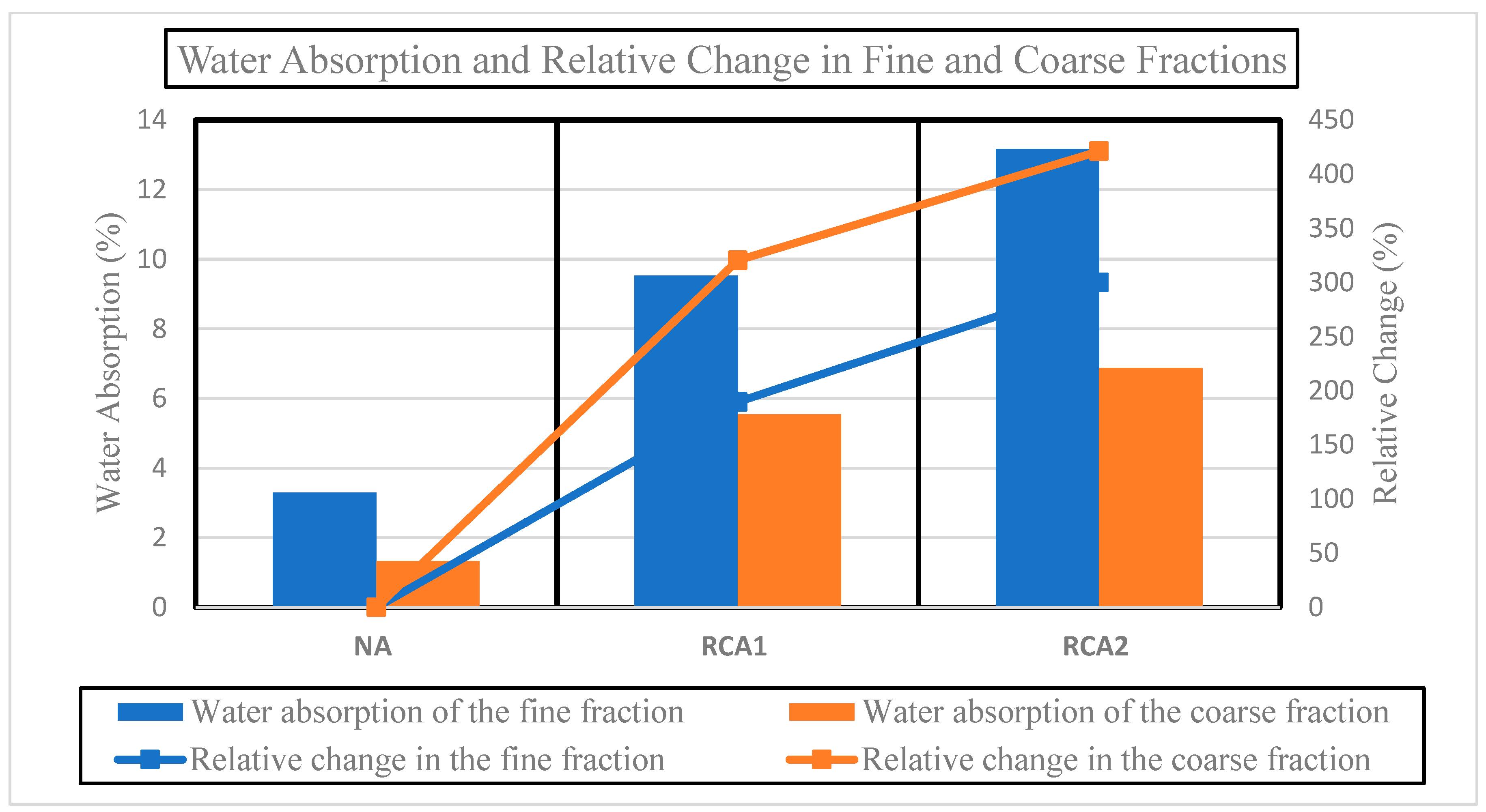

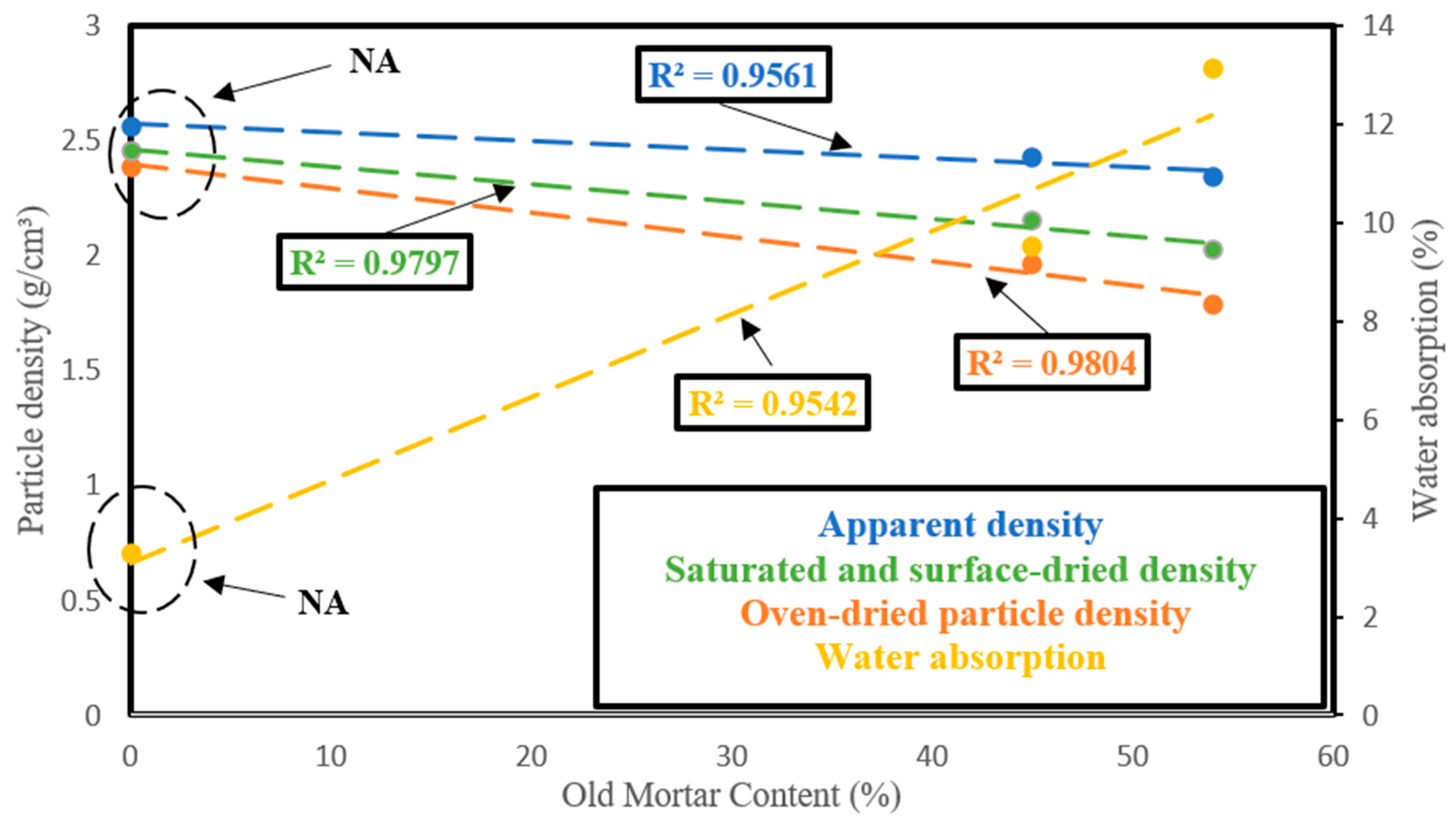

2.2. Density and Water Absorption

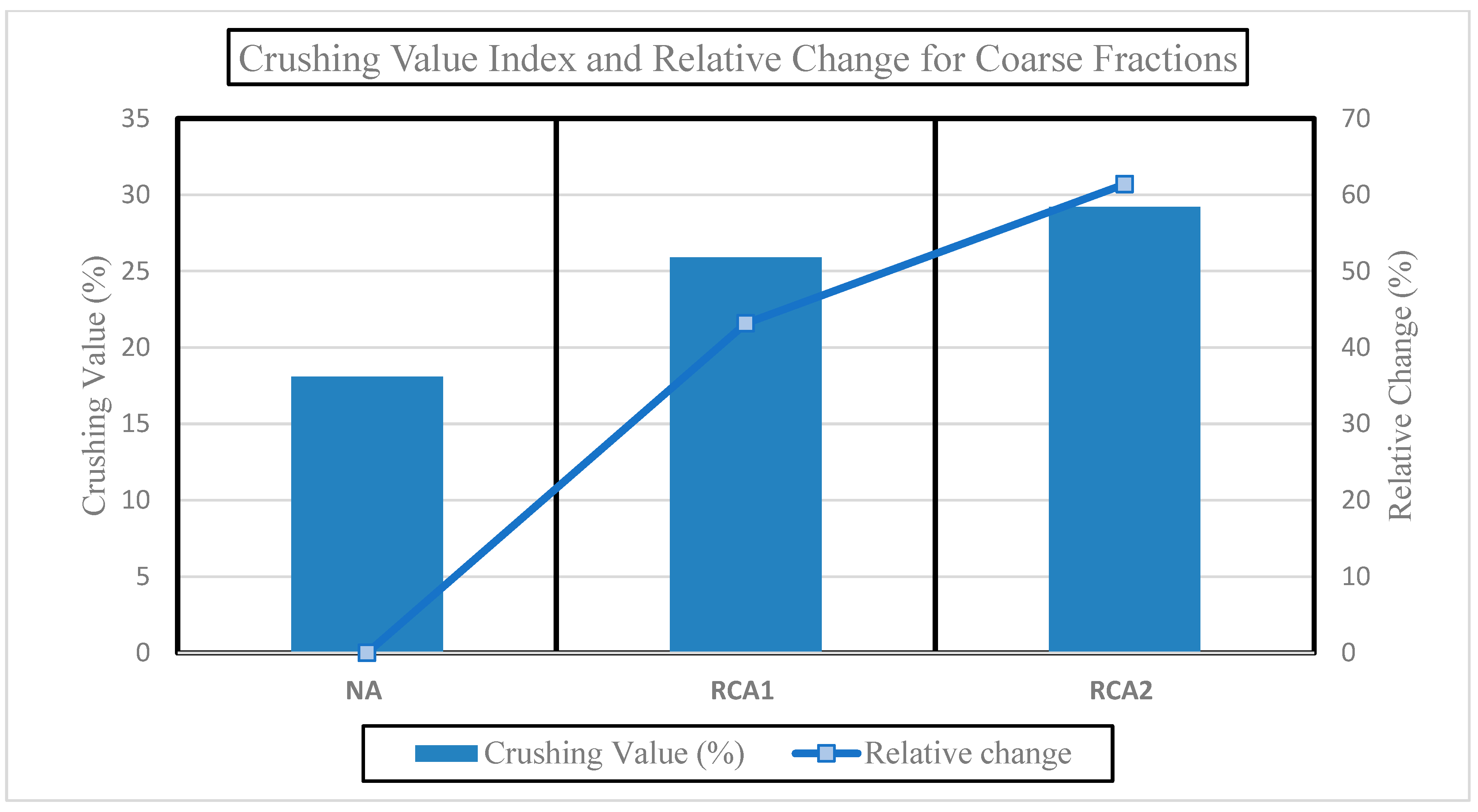

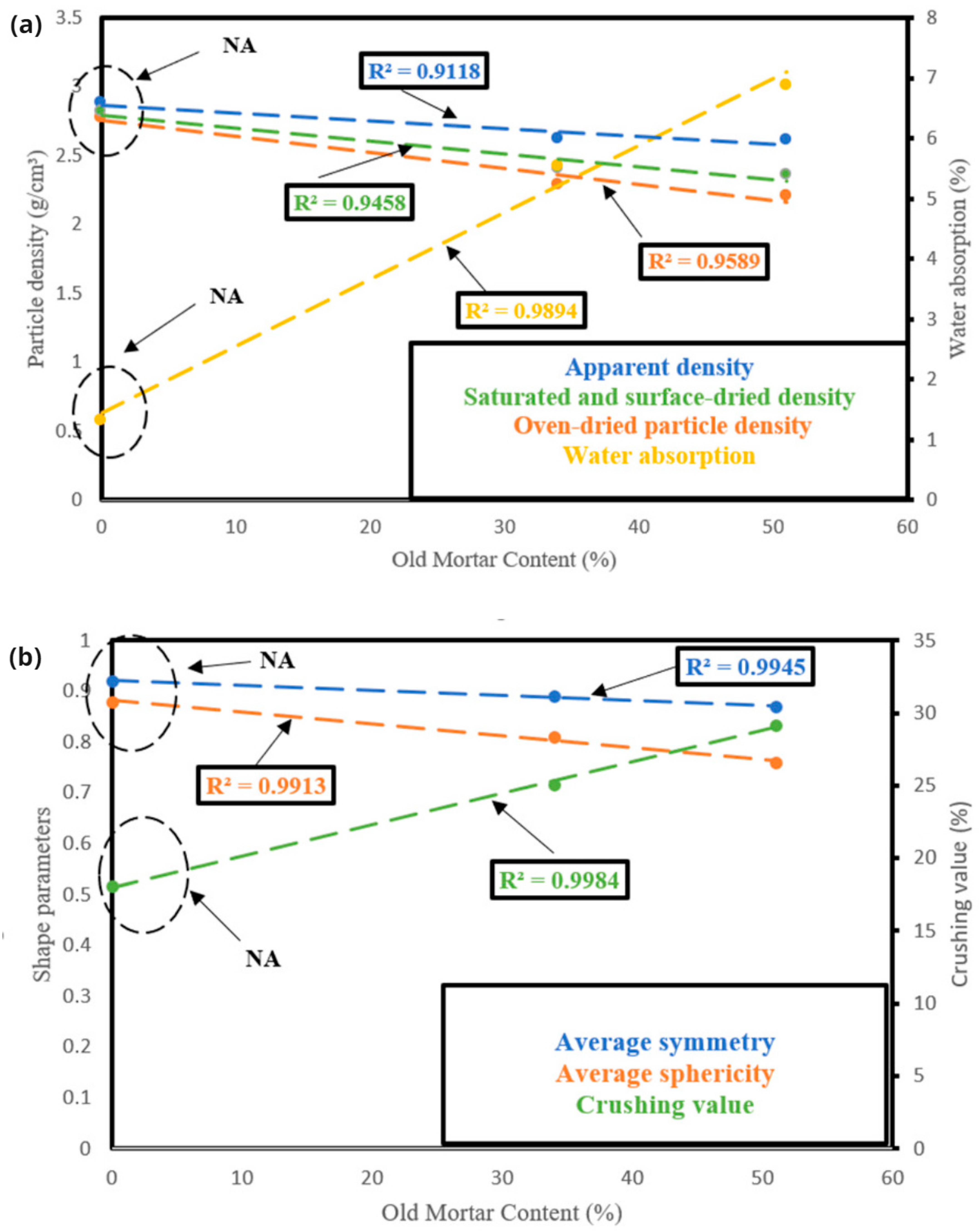

2.3. Crushing Value

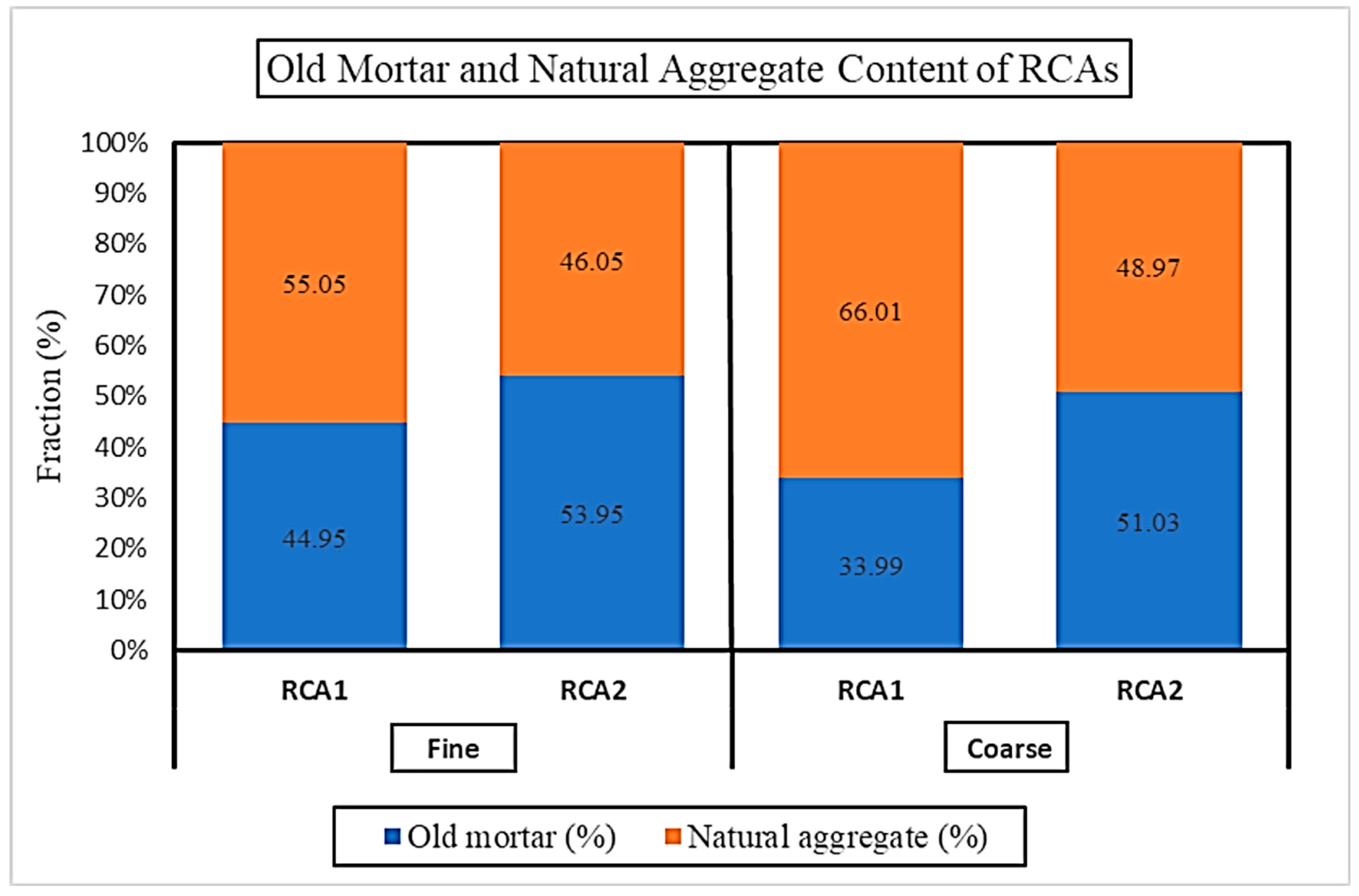

2.4. Residual Mortar Content

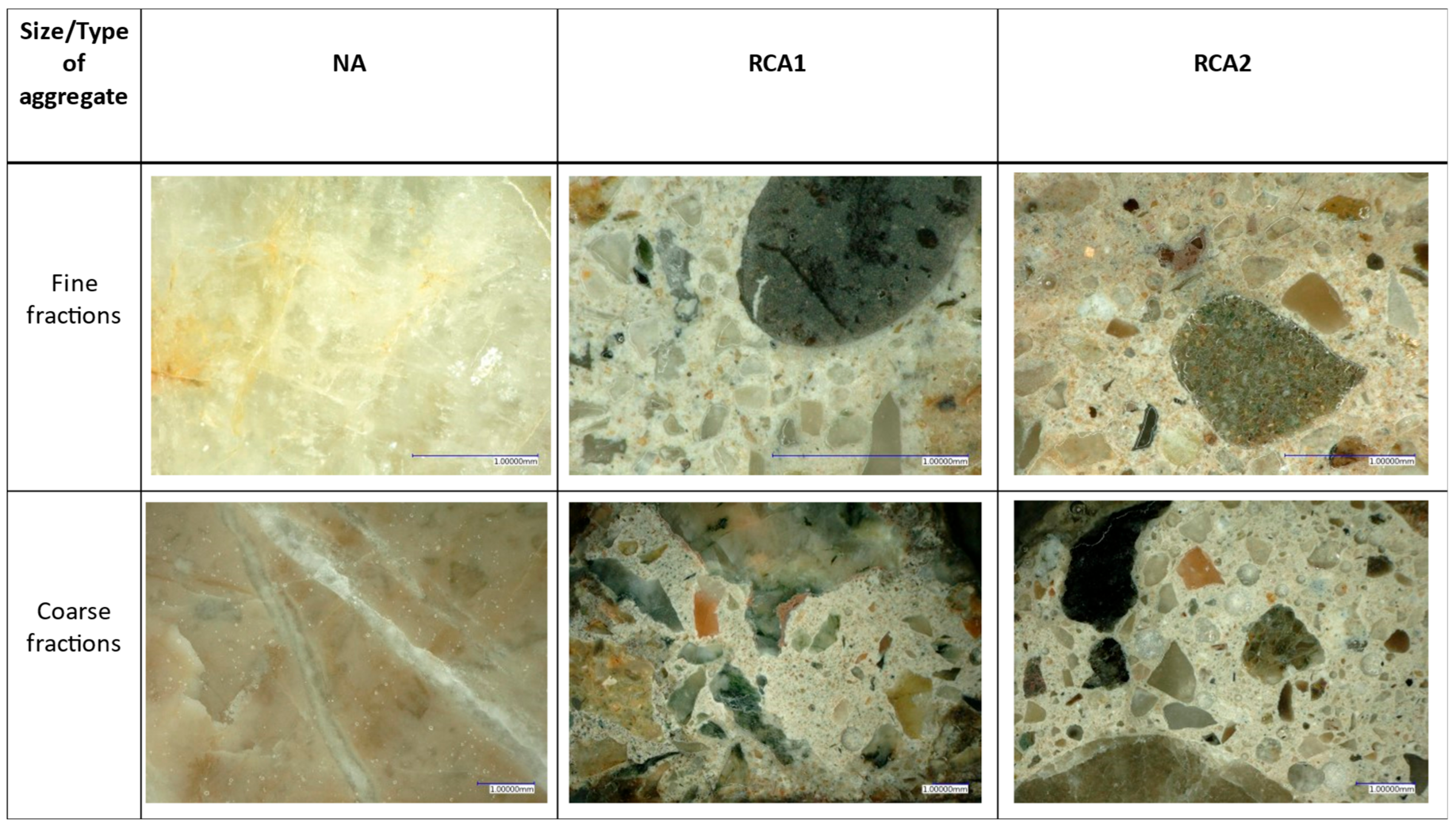

2.5. Microstructural Analysis

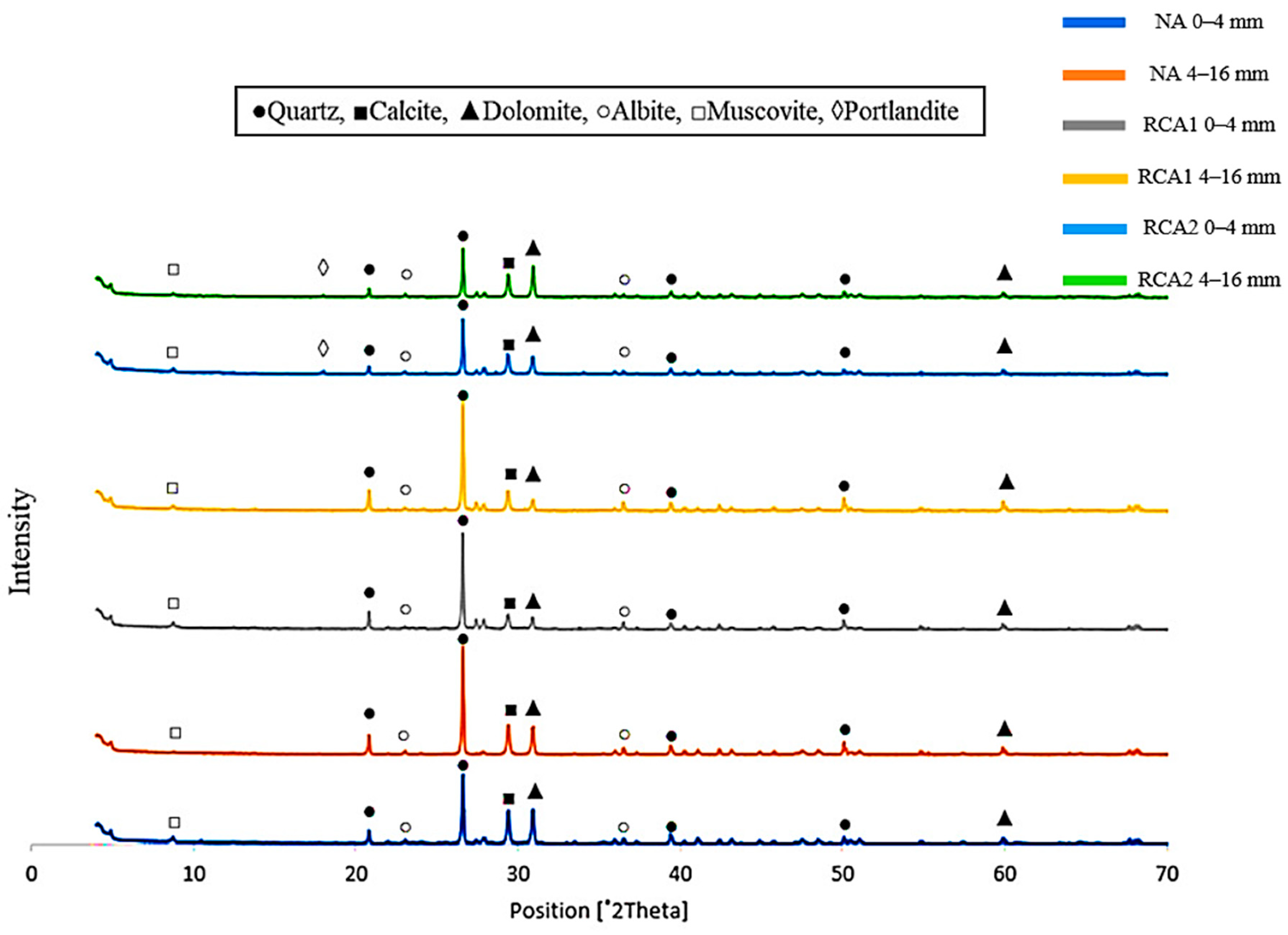

2.5.1. Mineralogical Characterization

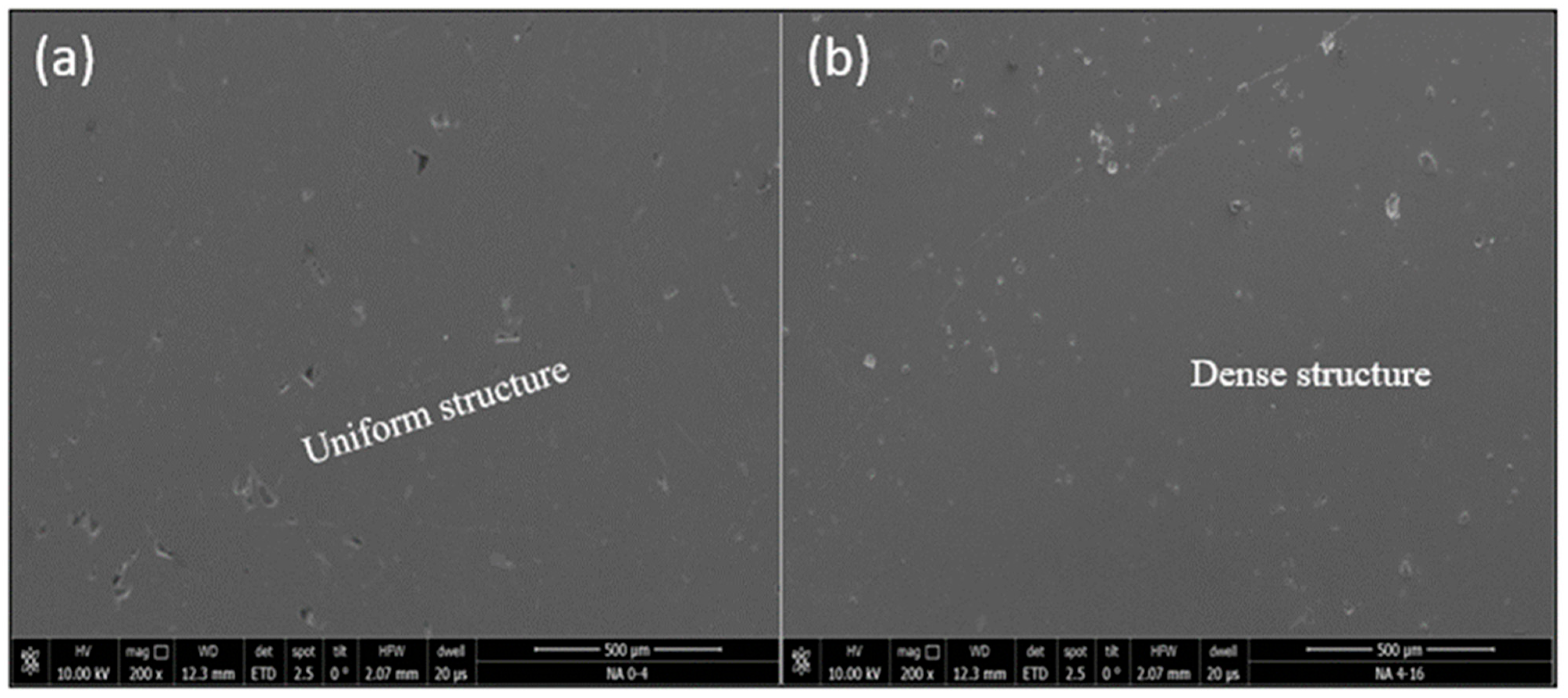

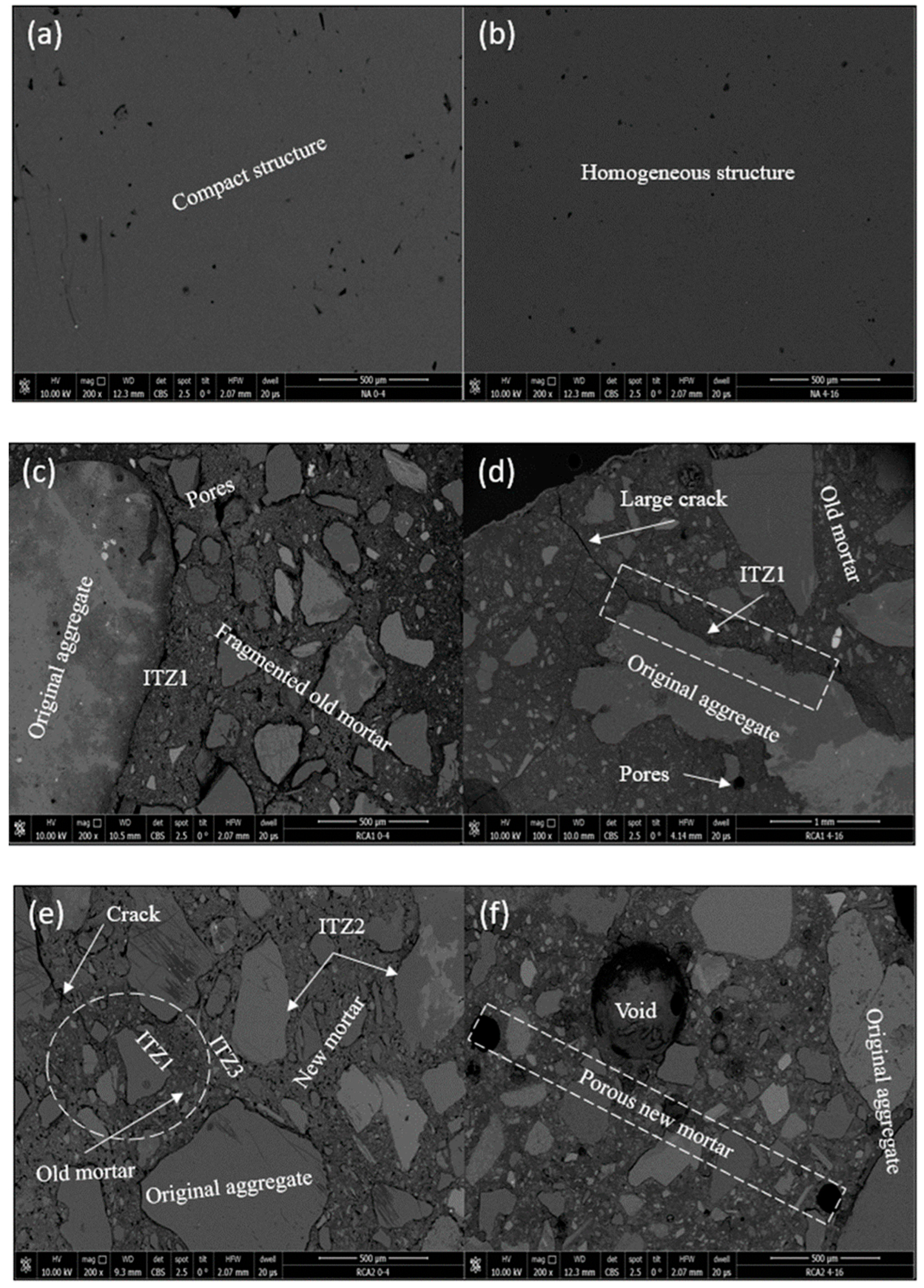

2.5.2. Scanning Electron Microscopy (SEM)

2.5.3. Backscattered Electron (BSE)

2.6. Correlation Analysis of Old Mortar Content with Aggregate Properties

3. Experimental Program

3.1. Materials

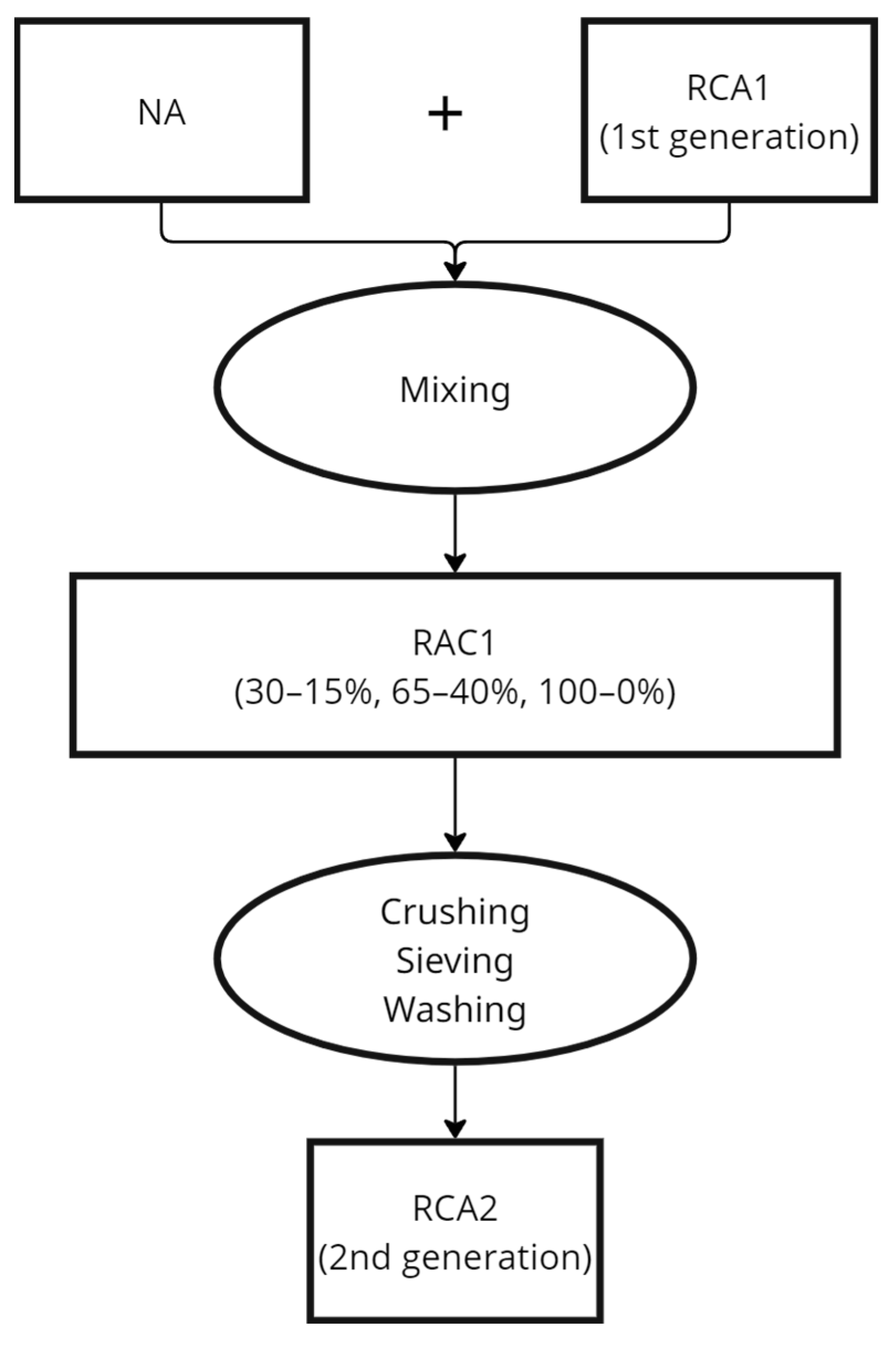

3.2. Preparation of RCA2

3.3. Test Methods

3.3.1. Sieve Analysis

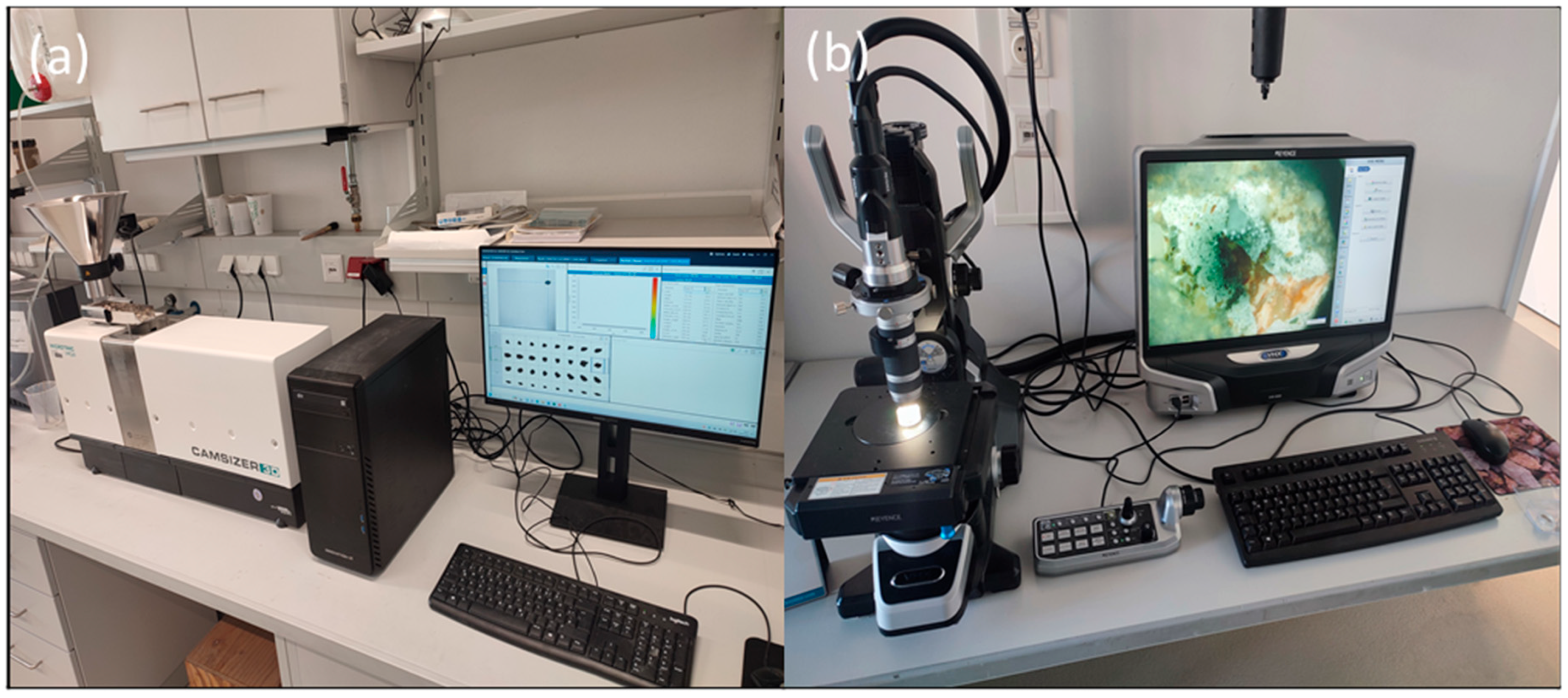

3.3.2. Particle Morphology

3.3.3. Density & Water Absorption

3.3.4. Crushing Value

3.3.5. Adhered Mortar Content

3.3.6. Microstructural Analysis

4. Conclusions and Recommendations

- Particle morphology and size distribution: Recycling progressively altered aggregate geometry. As cycles increased from NA to RCA1 and RCA2, average particle size decreased and irregular fragments became more frequent, especially in RCA2. Fine RCA2 exhibited coarser grading trends compared to RCA1.

- Density: Both RCA1 and RCA2 showed lower densities than NA, but the difference between RCA1 and RCA2 was small, suggesting near-stabilization after the first cycle.

- Water absorption: RCA2 exhibited the most severe degradation, with water absorption about four times higher than NA for fines and nearly five times for coarse fractions, due to increased adhered mortar and microcracking.

- Mechanical strength: RCA2 reached a crushing value of 29.2%, placing it in the medium-quality category (25–35%). While this indicates higher crushing susceptibility than RCA1, RCA2 remains within the range suitable for structural concrete.

- Adhered mortar content: RCA2 contained 53.95% adhered mortar in the fine fraction and 51.03% in the coarse fraction, confirming adhered mortar as a key parameter controlling quality.

- Mineralogical composition: XRD confirmed quartz, calcite, and dolomite as dominant phases, with portlandite present in RCA2 due to relatively young parent concrete, indicating incomplete carbonation.

- Microstructural analysis: SEM and BSE revealed highly porous mortar zones, multiple weak ITZs, and extensive microcracking, highlighting structural weaknesses induced by repeated recycling.

- Correlation analysis: Strong correlations between adhered mortar content and aggregate properties underline its predictive value for assessing RCA quality.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, L.; Wu, H.; Zhang, H.; Duan, H.; Wang, J.; Jiang, W.; Dong, B.; Liu, G.; Zuo, J.; Song, Q. Characterizing the generation and flows of construction and demolition waste in China. Constr. Build. Mater. 2017, 136, 405–413. [Google Scholar] [CrossRef]

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete—A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Berredjem, L.; Arabi, N.; Molez, L. Mechanical and durability properties of concrete based on recycled coarse and fine aggregates produced from demolished concrete. Constr. Build. Mater. 2020, 246, 118421. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Butera, A.; Le, K.N.; Li, W. Utilising CO2 technologies for recycled aggregate concrete: A critical review. Constr. Build. Mater. 2020, 250, 118903. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Y.; Yan, C.; Liu, Y. Influence of crushing index on properties of recycled aggregates pervious concrete. Constr. Build. Mater. 2017, 135, 112–118. [Google Scholar] [CrossRef]

- Li, Y.; Fu, T.; Wang, R.; Li, Y. An assessment of microcracks in the interfacial transition zone of recycled concrete aggregates cured by CO2. Constr. Build. Mater. 2020, 236, 117543. [Google Scholar] [CrossRef]

- Abid, S.R.; Nahhab, A.H.; Al-aayedi, H.K.H.; Nuhair, A.M. Expansion and strength properties of concrete containing contaminated recycled concrete aggregate. Case Stud. Constr. Mater. 2018, 9, e00201. [Google Scholar] [CrossRef]

- Rangel, C.S.; Filho, R.D.T.; Amario, M.; Pepe, M.; de Castro Polisseni, G.; Puente de Andrade, G. Generalized quality control parameter for heterogenous recycled concrete aggregates: A pilot scale case study. J. Clean. Prod. 2019, 208, 589–601. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Agrela, F.; De Juan, M.S.; Ayuso, J.; Geraldes, V.L.; Jiménez, J.R. Limiting properties in the characterisation of mixed recycled aggregates for use in the manufacture of concrete. Constr. Build. Mater. 2011, 25, 3950–3955. [Google Scholar] [CrossRef]

- Nováková, I.; Mikulica, K. Properties of Concrete with Partial Replacement of Natural Aggregate by Recycled Concrete Aggregates from Precast Production. Procedia Eng. 2016, 151, 360–367. [Google Scholar] [CrossRef]

- Prokopski, G.; Halbiniak, J. Interfacial transition zone in cementitious materials. Cem. Concr. Res. 2000, 30, 579–583. [Google Scholar] [CrossRef]

- Zhang, H.; Ji, T.; Liu, H. Performance evolution of the interfacial transition zone (ITZ) in recycled aggregate concrete under external sulfate attacks and dry-wet cycling. Constr. Build. Mater. 2019, 229, 116938. [Google Scholar] [CrossRef]

- Bai, G.; Zhu, C.; Liu, C.; Liu, B. An evaluation of the recycled aggregate characteristics and the recycled aggregate concrete mechanical properties. Constr. Build. Mater. 2020, 240, 117978. [Google Scholar] [CrossRef]

- Kim, J.; Jang, H. Closed-loop recycling of C&D waste: Mechanical properties of concrete with the repeatedly recycled C&D powder as partial cement replacement. J. Clean. Prod. 2022, 343, 130977. [Google Scholar] [CrossRef]

- Abreu, V.; Evangelista, L.; de Brito, J. The effect of multi-recycling on the mechanical performance of coarse recycled aggregates concrete. Constr. Build. Mater. 2018, 188, 480–489. [Google Scholar] [CrossRef]

- Thomas, C.; de Brito, J.; Cimentada, A.; Sainz-Aja, J.A. Macro- and micro-properties of multi-recycled aggregate concrete. J. Clean. Prod. 2020, 24, 118843. [Google Scholar] [CrossRef]

- Kasulanati, M.L.; Pancharathi, R.K. Multi-recycled aggregate concrete towards a sustainable solution—A review. Cem. Wapno Beton 2021, 26, 35–45. [Google Scholar] [CrossRef]

- Abed, M.; Nemes, R. Los Angeles index and water absorption capacity of crushed aggregates. Pollack Period. 2020, 15, 65–78. [Google Scholar] [CrossRef]

- Lei, B.; Yu, H.; Guo, Y.; Zhao, H.; Wang, K.; Li, W. Mechanical properties of multi-recycled aggregate concrete under combined compression-shear loading. Eng. Fail. Anal. 2022, 143, 106910. [Google Scholar] [CrossRef]

- Huda, S.B.; Alam, M.S. Mechanical behavior of three generations of 100% repeated recycled coarse aggregate concrete. Constr. Build. Mater. 2014, 65, 574–582. [Google Scholar] [CrossRef]

- Silva, S.; Evangelista, L.; de Brito, J. Durability and shrinkage performance of concrete made with coarse multi-recycled concrete aggregates. Constr. Build. Mater. 2021, 272, 121645. [Google Scholar] [CrossRef]

- Thomas, C.; de Brito, J.; Gil, V.; Sainz-Aja, J.A.; Cimentada, A. Multiple recycled aggregate properties analysed by X-ray microtomography. Constr. Build. Mater. 2018, 166, 171–180. [Google Scholar] [CrossRef]

- Zhu, P.; Zhang, X.; Wu, J.; Wang, X. Performance degradation of the repeated recycled aggregate concrete with 70% replacement of three-generation recycled coarse aggregate. J. Wuhan Univ. Technol. Sci. Ed. 2016, 31, 989–995. [Google Scholar] [CrossRef]

- Kim, J.; Grabiec, A.M.; Ubysz, A.; Yang, S.; Kim, N. Influence of Mix Design on Physical, Mechanical and Durability Properties of Multi-Recycled Aggregate Concrete. Materials 2023, 16, 2744. [Google Scholar] [CrossRef]

- Zhu, P.; Chen, K.; Hu, K. Carbonation Behavior of Repeated Recycled Fine Aggregate Concrete under Bending Load. KSCE J. Civ. Eng. 2019, 23, 729–736. [Google Scholar] [CrossRef]

- Visintin, P.; Dadd, L.; Alam, M.U.; Xie, T.; Bennett, B. Flexural performance and life-cycle assessment of multi-generation recycled aggregate concrete beams. J. Clean. Prod. 2022, 360, 132214. [Google Scholar] [CrossRef]

- Kim, J. Sustainable Construction Exploration: A Review of Multi-Recycling of Concrete Waste. Int. J. Environ. Res. 2024, 18, 103. [Google Scholar] [CrossRef]

- Salesa, Á.; Pérez-Benedicto, J.A.; Colorado-Aranguren, D.; López-Julián, P.L.; Esteban, L.M.; Sanz-Baldúz, L.J.; Sáez-Hostaled, J.L.; Ramis, J.; Olivares, D. Physico—Mechanical properties of multi—Recycled concrete from precast concrete industry. J. Clean. Prod. 2017, 141, 248–255. [Google Scholar] [CrossRef]

- Florea, M.V.A.; Brouwers, H.J.H. Properties of various size fractions of crushed concrete related to process conditions and re-use. Cem. Concr. Res. 2013, 52, 11–21. [Google Scholar] [CrossRef]

- Han, S.; Zhao, S.; Lu, D.; Wang, D. Performance Improvement of Recycled Concrete Aggregates and Their Potential Applications in Infrastructure: A Review. Buildings 2023, 13, 1411. [Google Scholar] [CrossRef]

- Pacheco, J.; de Brito, J. Recycled aggregates produced from construction and demolition waste for structural concrete: Constituents, properties and production. Materials 2021, 14, 5748. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Zhang, J.; Cao, D.; Dang, H.; Ding, B. Comparison of recycled aggregate treatment methods on the performance for recycled concrete. Constr. Build. Mater. 2020, 234, 117366. [Google Scholar] [CrossRef]

- Dawson, M.R. Evaluation of the Retsch Technology Camsizer P4 to Assess the Shape of Crushed Particles Proposed to Be Added to Natural Sand Fine Aggregate Used in Portland Cement Concrete. 2021. Available online: https://trid.trb.org/View/2350696?utm_source=chatgpt.com (accessed on 5 October 2025).

- Jung, H.; Kim, J.; Yang, H.; Kim, N. Evaluation of residual properties and recovery of fire-damaged concrete with repeatedly recycled fine aggregates. In Construction Materials and Their Properties for Fire Resistance and Insulation; Elsevier: Amsterdam, The Netherlands, 2025; pp. 165–178. [Google Scholar]

- Zhu, P.; Liu, W.; Niu, Z.; Wei, D.; Hu, K. Strength and Chloride Diffusion Behaviour of Three Generations of Repeated Recycled Fine Aggregate Concrete. J. Wuhan Univ. Technol. Sci. Ed. 2018, 33, 1113–1120. [Google Scholar] [CrossRef]

- Yang, F.; Yao, Y.; Wang, X.; Wei, J.; Feng, Z. Preparation of Recycled and Multi-Recycled Coarse Aggregates Concrete with the Vibration Mixing Process. Buildings 2022, 12, 1369. [Google Scholar] [CrossRef]

- de Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, X.; Liu, W.; Zhao, B.; Wang, Q. Influence of the moisture states of aggregate recycled from waste concrete on the performance of the prepared recycled aggregate concrete (RAC)—A review. Constr. Build. Mater. 2022, 326, 126891. [Google Scholar] [CrossRef]

- Chen, C.; Liu, R.; Zhu, P.; Liu, H.; Wang, X. Carbonization durability of two generations of recycled coarse aggregate concrete with effect of chloride ion corrosion. Sustainability 2020, 12, 10544. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. Quality improvement of recycled concrete aggregate by removal of residual mortar: A comprehensive review of approaches adopted. Constr. Build. Mater. 2021, 288, 123066. [Google Scholar] [CrossRef]

- Li, Z.; Liu, J.; Xiao, J.; Zhong, P. A method to determine water absorption of recycled fine aggregate in paste for design and quality control of fresh mortar. Constr. Build. Mater. 2019, 197, 30–41. [Google Scholar] [CrossRef]

- Zhu, P.; Hao, Y.; Liu, H.; Wei, D.; Liu, S.; Gu, L. Durability evaluation of three generations of 100% repeatedly recycled coarse aggregate concrete. Constr. Build. Mater. 2019, 210, 442–450. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.C.G.; Zhang, M.H.; Tam, C.T.; Foo, T.W.J. Microwave-assisted beneficiation of recycled concrete aggregates. Constr. Build. Mater. 2011, 25, 3469–3479. [Google Scholar] [CrossRef]

- Spaeth, V.; Tegguer, A.D. Improvement of recycled concrete aggregate properties by polymer treatments. Int. J. Sustain. Built Environ. 2013, 2, 143–152. [Google Scholar] [CrossRef]

- Moreno-Pérez, E.; Hernández-Ávila, J.; Rangel-Martínez, Y.; Cerecedo-Sáenz, E.; Arenas-Flores, A.; Reyes-Valderrama, M.I.; Salinas-Rodríguez, E. Chemical and mineralogical characterization of recycled aggregates from construction and demolition waste from Mexico city. Minerals 2018, 8, 237. [Google Scholar] [CrossRef]

- Shah, M.M.; Khalid, U.; Mujtaba, H.; Naqvi, S.A.Z.; Masood, S. Environmental impacts and performance assessment of recycled fine aggregate concrete. Environ. Sci. Pollut. Res. 2024, 31, 36938–36957. [Google Scholar] [CrossRef]

- Ruviaro, A.S.; Silvestro, L.; Pelisser, F.; de Azevedo, A.R.G.; de Matos, P.R.; Gastaldini, A.L.G. Long-term effect of recycled aggregate on microstructure, mechanical properties, and CO2 sequestration of rendering mortars. Constr. Build. Mater. 2022, 321, 126357. [Google Scholar] [CrossRef]

- Limbachiya, M.C.; Marrocchino, E.; Koulouris, A. Chemical-mineralogical characterisation of coarse recycled concrete aggregate. Waste Manag. 2007, 27, 201–208. [Google Scholar] [CrossRef]

- Abbaspour, A.; Tanyu, B.F.; Cetin, B. Impact of aging on leaching characteristics of recycled concrete aggregate. Environ. Sci. Pollut. Res. 2016, 23, 20835–20852. [Google Scholar] [CrossRef]

- Evangelista, L.; Guedes, M.; De Brito, J.; Ferro, A.C.; Pereira, M.F. Physical, chemical and mineralogical properties of fine recycled aggregates made from concrete waste. Constr. Build. Mater. 2015, 86, 178–188. [Google Scholar] [CrossRef]

- Qiu, J.; Tng, D.Q.S.; Yang, E.H. Surface treatment of recycled concrete aggregates through microbial carbonate precipitation. Constr. Build. Mater. 2014, 57, 144–150. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.; Alaejos, P.; De Juan, M.S. Durability of recycled aggregate concrete. Constr. Build. Mater. 2013, 40, 1054–1065. [Google Scholar] [CrossRef]

- Guedes, M.; Evangelista, L.; De Brito, J.; Ferro, A.C. Microstructural characterization of concrete prepared with recycled aggregates. Microsc. Microanal. 2013, 19, 1222–1230. [Google Scholar] [CrossRef] [PubMed]

- Vintimilla, C.; Etxeberria, M. Limiting the maximum fine and coarse recycled aggregates-type a used in structural concrete. Constr. Build. Mater. 2023, 380, 131273. [Google Scholar] [CrossRef]

- Wong, H.S.; Angst, U.M.; Geiker, M.R.; Isgor, O.B.; Elsener, B.; Michel, A.; Alonso, M.C.; Correia, M.J.; Pacheco, J.; Gulikers, J.; et al. Methods for characterising the steel–concrete interface to enhance understanding of reinforcement corrosion: A critical review by RILEM TC 262-SCI. Mater. Struct. 2022, 55, 124. [Google Scholar] [CrossRef]

- Leite, M.B.; Monteiro, P.J.M. Microstructural analysis of recycled concrete using X-ray microtomography. Cem. Concr. Res. 2016, 81, 38–48. [Google Scholar] [CrossRef]

- Kim, Y.; Hanif, A.; Usman, M.; Park, W. Influence of bonded mortar of recycled concrete aggregates on interfacial characteristics—Porosity assessment based on pore segmentation from backscattered electron image analysis. Constr. Build. Mater. 2019, 212, 149–163. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, Y.; Zhu, P.; Feng, J.; Hu, K. Mechanical Properties and ITZ Microstructure of Recycled Aggregate Concrete Using Carbonated Recycled Coarse Aggregate. J. Wuhan Univ. Technol. Sci. Ed. 2018, 33, 648–653. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, G.J. Recycled Concrete Aggregate Classification Based on Quality Parameters and Performance. Iran. J. Sci. Technol.-Trans. Civ. Eng. 2023, 47, 3211–3232. [Google Scholar] [CrossRef]

- DIN 4226–100; Aggregates for Concrete and Mortar—Part 100: Recycled Aggregates. Deutsches Institut Fur Normung: Berlin, Germany, 2002.

- ASHTO MP 16: 2013; Specification for Reclaimed Concrete Aggregate for Use as Coarse Aggregate in Hydraulic Cement Concrete. American Association of State and Highway Transportation Officials: Washington, DC, USA, 2013.

- Ouyang, K.; Liu, J.; Liu, S.; Song, B.; Guo, H.; Li, G.; Shi, C. Influence of pre-treatment methods for recycled concrete aggregate on the performance of recycled concrete: A review. Resour. Conserv. Recycl. 2022, 188, 106717. [Google Scholar] [CrossRef]

- Mazhoud, B.; Sedran, T.; Cazacliu, B.; Cothenet, A.; Torrenti, J.M. Influence of residual mortar volume on the properties of recycled concrete aggregates. J. Build. Eng. 2022, 57, 104945. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Muhammad, F.; Harun, M.; Ahmed, A.; Kabir, N.; Khalid, H.R.; Hanif, A. Influence of bonded mortar on recycled aggregate concrete properties: A review. Constr. Build. Mater. 2024, 432, 136564. [Google Scholar] [CrossRef]

- Martín-Morales, M.; Zamorano, M.; Ruiz-Moyano, A.; Valverde-Espinosa, I. Characterization of recycled aggregates construction and demolition waste for concrete production following the Spanish Structural Concrete Code EHE-08. Constr. Build. Mater. 2011, 25, 742–748. [Google Scholar] [CrossRef]

- ÖNORM B 3140:2020-11; Rezyklierte Gesteinskörnungen für das Bauwesen. Austrian Standards International: Wien, Austrian, 2020.

- ÖNORM EN 933-1:2012; Prüfverfahren für Geometrische Eigenschaften von Gesteinskörnungen, Teil 1: Bestimmung der Korngrößenverteilung-Siebverfahren (Konsolidierte Fassung). Austrian Standards International: Wienna, Austrian, 2006.

- ISO 13322-2; Particle Size Analysis—Image Analysis Methods—Part 2: Dynamic Image Analysis Methods. ISO: Geneva, Switzerland, 2006.

- ÖNORM EN 1097-6-1:2022-02; Prüfverfahren Für Mechanische und Physikalische Eigenschaften von Gesteinskörnungen—Teil 6: Bestimmung der Rohdichte und der Wasseraufnahme. Austrian Standards International: Vienna, Austrian, 2022.

- BS 812-110; 1990 Testing Aggregates-Part 110: Methods for Determination of Aggregate Crushing Value (ACV). BSI: London, UK, 1990.

- Duan, Z.H.; Poon, C.S. Properties of recycled aggregate concrete made with recycled aggregates with different amounts of old adhered mortars. Mater. Des. 2014, 58, 19–29. [Google Scholar] [CrossRef]

| Characteristics | HQ a | MQ b | LQ c | PQ d |

|---|---|---|---|---|

| Specific gravity | ≥2.6 | 2.3–2.6 | 2.0–2.3 | <2.0 |

| Water absorption (%) | ≤3 | 3–5 | 5–7 | >7 |

| Crushing value (%) | ≤25 | 25–35 | 35–45 | >45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ameri, F.; Merta, I. Second-Generation Recycled Concrete Aggregates: Comprehensive Characterization of Physical, Mechanical, and Microstructural Properties. Recycling 2025, 10, 193. https://doi.org/10.3390/recycling10050193

Ameri F, Merta I. Second-Generation Recycled Concrete Aggregates: Comprehensive Characterization of Physical, Mechanical, and Microstructural Properties. Recycling. 2025; 10(5):193. https://doi.org/10.3390/recycling10050193

Chicago/Turabian StyleAmeri, Farshad, and Ildiko Merta. 2025. "Second-Generation Recycled Concrete Aggregates: Comprehensive Characterization of Physical, Mechanical, and Microstructural Properties" Recycling 10, no. 5: 193. https://doi.org/10.3390/recycling10050193

APA StyleAmeri, F., & Merta, I. (2025). Second-Generation Recycled Concrete Aggregates: Comprehensive Characterization of Physical, Mechanical, and Microstructural Properties. Recycling, 10(5), 193. https://doi.org/10.3390/recycling10050193