1. Introduction

The European Waste Framework Directive was revised in 2018, setting stricter rules for the disposal of textiles. As of January 2025, the EU member states must organise a separate collection of textile waste, ultimately due to high discarding rates and low recycling rates [

1]. According to a 2019 finding [

2], the EU discards 12.6 million tonnes of textiles yearly. Majority of the discarded textiles, 87%, are post-consumer waste. Another widely quoted figure is the yearly discarding rate of 11.3 kg per European consumer [

3,

4]. Approximately 22% of post-consumer textile waste is collected for reuse or recycling, and the remainder is directed to landfills or incineration [

2]. The low recycling rates and obligations have led the industry to search for suitable collection methods, followed by identification, sorting and recycling technologies. Chemical, thermal or thermo-mechanical, and mechanical recycling are the most common methods for textile recycling. Mechanical recycling is considered a cost- and energy-efficient process [

5] that can, at least in theory, break down all materials similarly by shredding, as opposed to having to accommodate the different chemical or thermal properties of different fibres. In general, the staple fibres obtained in the mechanical recycling process can be converted into yarn again.

The global textile industry produced 124 million tonnes of textile fibres in 2023 [

6]. By 2030, that total is expected to grow to 160 million tonnes, a number that has been reevaluated from 147 million tonnes—the estimation made a year earlier [

7]. Invisible in the numbers is another issue: during the year 2023, the fashion industry was estimated to produce 2.5 to 5 billion garments too many [

8]. Cotton fibres represent 19.9% of the global fibre production, and recycled cotton fibres approximately 1% of that, totalling to 0.25 million tonnes in 2023. The most widely applied recycled fibres are thermo-mechanically recycled polyester fibres made from PET bottles [

6].

While the legislative obligation to collect consumer textiles suggests greater amounts of post-consumer textile in the future, it is more difficult to forecast the material content of the textile waste and the consequential supply of secondary markets. Consulting the care labels in one’s wardrobe gives valuable insight into estimating how challenging it will be to obtain an output of 100% desired fibre type by recycling consumer textiles. The material composition of a mechanical recycling process output is defined by the input. Therefore, the feasibility of closed-loop recycling of textiles, or fibre-to-fibre recycling, is directly dependent on efficient and traceable collection, identification and sorting of materials. Controlling the colour and material composition of post-consumer textiles is one of the greatest challenges of mechanical fibre-to-fibre recycling; see [

9,

10].

The other great challenge is related to the quality of mechanically recycled (MR) fibres. Mechanically recycled cotton is often referred to as possessing a “lower quality”, which is why it is often blended with other fibres, especially longer, virgin fibres [

5] to facilitate easier spinning. In the shredding process, the fibre is exposed to mechanical forces that shorten the fibre, contributing to a high short fibre content (SFC) [

11,

12,

13] and causing nepping [

14], characteristics that affect both the spinnability and overall quality of yarn. It is advised to use 20–30% of recycled fibres in yarns for fabric production [

15], although higher percentages have been obtained by many. Current research of yarns made with MR cotton (or post-consumer waste containing cotton fibres) covers blends with usually virgin cotton [

12,

14,

16] and virgin polyester [

17,

18], but also blends of recycled cotton and recycled polyester are researched by some [

17,

19]. Jamshaid et al. [

20] successfully spun a 100% recycled cotton yarn with pre-consumer cotton obtained from the different stages of spinning line. The term “mechanically recycled” in this context means a staple fibre obtained from mechanical opening or shredding. However, discussing recycled fibres often suggests the fibre comes from post-use, or other post-consumer sources. The literature presented in this paper is divided on the subject.

The short fibre length of MR fibres has been reported to affect the total strength [

11] and other qualities, such as uniformity and fineness [

12], in yarns, depending on the spinning method described in the respective papers. There is a slight upward trend in research into mechanical recycling currently; however, many of the papers present merely a case study. When it comes to fibre properties, there are a handful of recent studies about MR cotton or cotton blend fibre lengths and length distributions of both post-consumer [

11,

13,

14] and pre-consumer textiles [

14,

20,

21]. Yarns made with MR cotton have been produced mainly by open-end spinning [

12,

15,

16,

17,

18,

19,

20] but also by ring spinning [

14,

22] and compact ring spinning [

16]. There is a need for studies arching from the primary fibre or textile properties through to a thorough analysis of secondary textile properties. The opening parameters have been examined through reverse engineering to understand what kinds of textiles are more suitable for mechanical recycling [

11,

21,

23]. There is a gap linking this data to yarn spinning. There is another gap between understanding the fibre properties and their impact on yarn properties, as only a few studies [

14,

17,

20] touch upon the subject before this study. Disregarding the fibre analysis, the properties of MR yarns and their effect on fabric production has been studied by some [

12,

15,

17,

22].

In addition to the heterogeneity of textile waste and the short fibre length, the small number of available mechanical recycling technologies [

9], as well as the tendency of MR fibres often becoming raw material for products of lower value, such as insulation [

24,

25], are the other hurdles on the way to truly sustainable fibre-to-fibre recycling. To be preferred over recycling, the reduction of waste should be considered a priority within the textile industry. Considering the top position of cotton as the most abundant natural fibre, and all its widely reported negative environmental effects [

26], prioritizing recycling of cotton and consequently slowing down virgin cotton production is considered important.

One aim of this study is to characterise mechanically opened fibres and establish the properties of ring spun yarns and single jersey knits produced with the fibres. This study examined the properties—namely, the tenacity, elongation, fineness and length—of three different post-consumer cottons and one pre-consumer cotton. Moreover, a qualitative analysis of the composition of mechanically recycled cotton fibres was made against the virgin cotton. The fibres were ring spun into yarns obtaining various compositions and thicknesses and further knitted into single jersey fabrics that were tested for rubbing.

The other aim of this study is to highlight the significance of familiarizing oneself with post-consumer textiles, the amount of which can be expected to increase due to recent legislation. In this paper, the familiarization is conducted through an analytic comparison of virgin, post- and pre-consumer cotton fibres. The qualitative composition analysis of fibres offers valuable information about the thought-of quality of mechanically recycled cotton and its cleanness. While recycled cotton is often used in compositions below 50% [

12,

14,

15], this study shows a possibility of using at least 75% recycled content in a yarn.

3. Discussion

The fibre characterisation was conducted by comparing the efficiencies of opening, fibre length, tensile properties, appearance and the chemical composition of the fibres. The efficiency of opening is rather an opening line property than a fibre property [

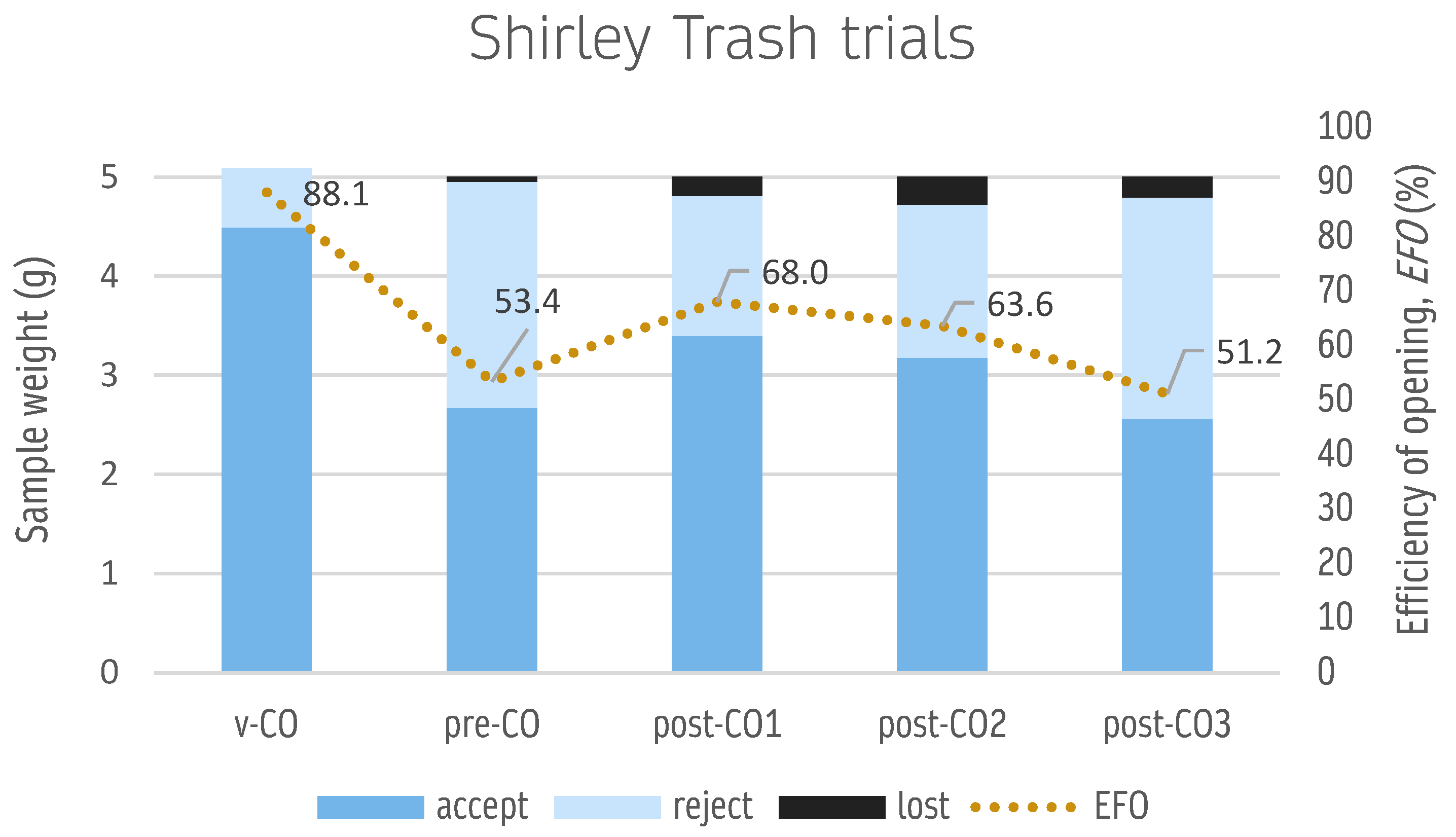

27], and its values were deviating even between the post-consumer samples opened on the same opening line. The ‘Shirley’ Trash Analyser is designed for the cleaning of cotton, which can also be seen in the results. The vCO cotton obtained an EFO of 88.1%, and

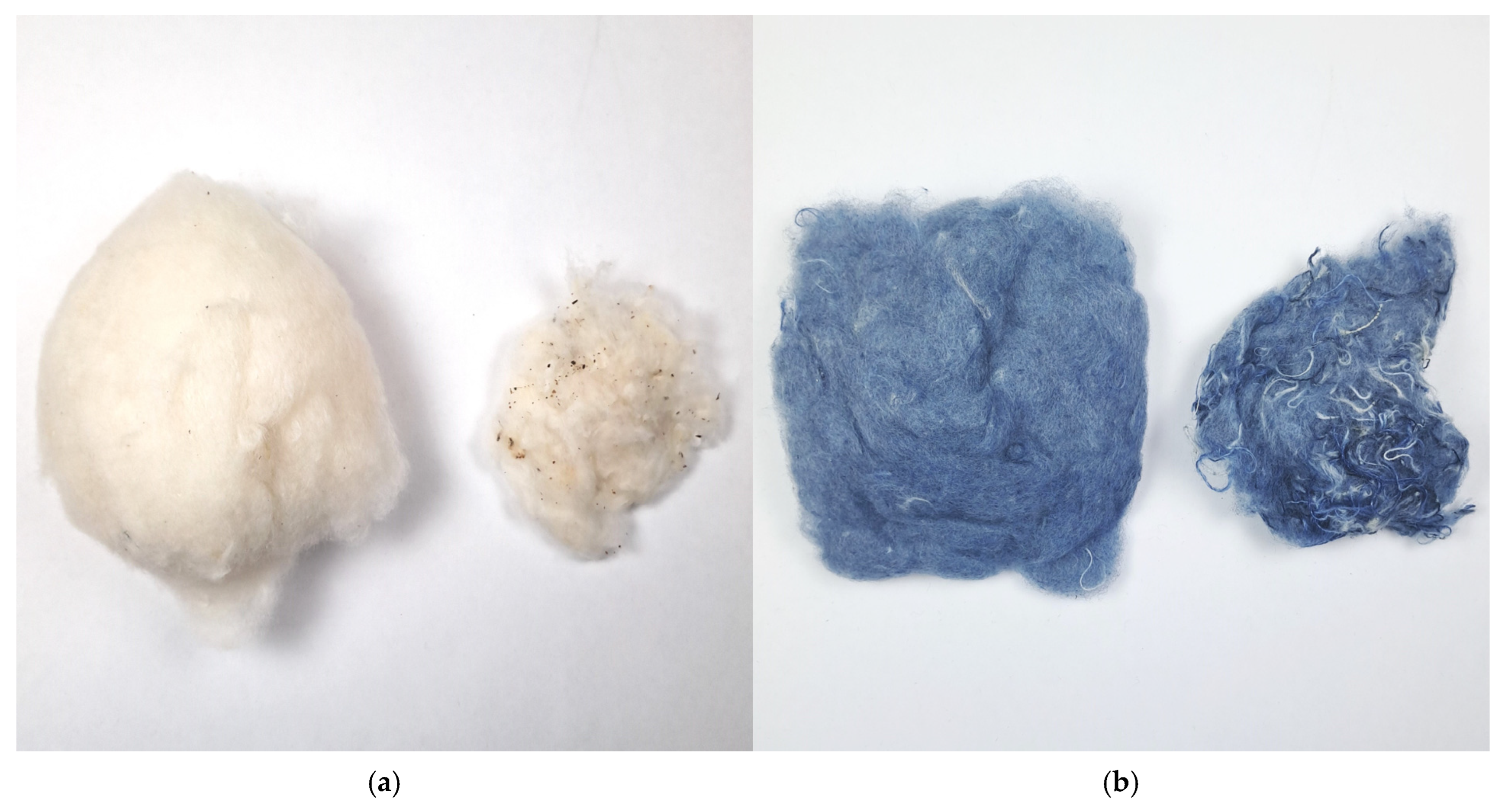

Figure 3a shows how only the lint and other dirt was separated off the clean fibre.

Figure 3b shows a similar result for pre-CO in terms of accept versus reject size, but the reported EFO for pre-CO in

Figure 1 is only 53.4%. The low EFO is most likely due to the instrument not being able to separate only the unopened threads but removing some opened fibre, too. On the other hand, the unopened threads are likely heavier than lint and take up a great share of the initial weight, thus decreasing the EFO. Conclusively, the EFO of vCO cotton should be compared with the EFOs of the mechanically opened cottons with caution. The EFOs can be increased by a more efficient opening of the textile on the opening line, by for example increasing the number of opening cycles. However, it has also been reported that an increase in the number of opening cycles may decrease the fibre length [

25] resulting in difficulties in spinning.

The result of the fibre length measurements suggests that the fibre lengths are reduced during mechanical opening. This result has also been reported by other studies [

11,

14,

25]. The suggestion is based on the result that the vCO mean length was longer than the studied mechanically opened fibres. However, there is no data of the actual fibre lengths before the mechanical opening for the textile waste. For the analysis and comparison of the results, it needs to be assumed that the vCO is similar to a type of cotton fibre suitable for use in denim production. The fibre length reduction is caused by a variety of factors: Firstly, the textile is cut in pieces for a more effective opening, and, depending on the cut size, the fibres can be shortened already under the guillotine. Secondly, the opening line parameters, such as speed, cylinder size, number of cylinders or opening settings, are adjusted to the shredded material to achieve the desired output [

23,

25]. Lastly, the inherent fibre properties such as fabric structure, yarn structure, colour, tenacity and fibre length, etc., could play their role in the output fibre properties. Denim is often produced with coarser, open end spun yarns that have been reported easier to detangle than ring spun yarns [

14]. Shorter fibres are also easier to detangle than long ones [

11]. It can be assumed that the denim fabric in pre-CO and the jeans in post-consumer samples are made with coarser yarns, but there is a possibility of deviation in the fibre lengths depending on the spinning methods, number of twists and other yarn and fabric properties.

In this study, a softener was used in the opening of pre-CO and post-CO2 fibres. Softener use has been reported to positively contribute to fibre length [

21], while other studies [

28] have shown softener use does not seem to have an effect on fibre quality but rather on the yarn quality. Similarly, in this paper, post-CO2 fibre length was not found to be significantly different from the other post-consumer cottons. The length of pre-CO was shown to be statistically significant from the post-consumer MR fibres; however, this can be due to other opening parameters or the overall quality of the denim fabric. The effect of softeners and lubricants should be studied further.

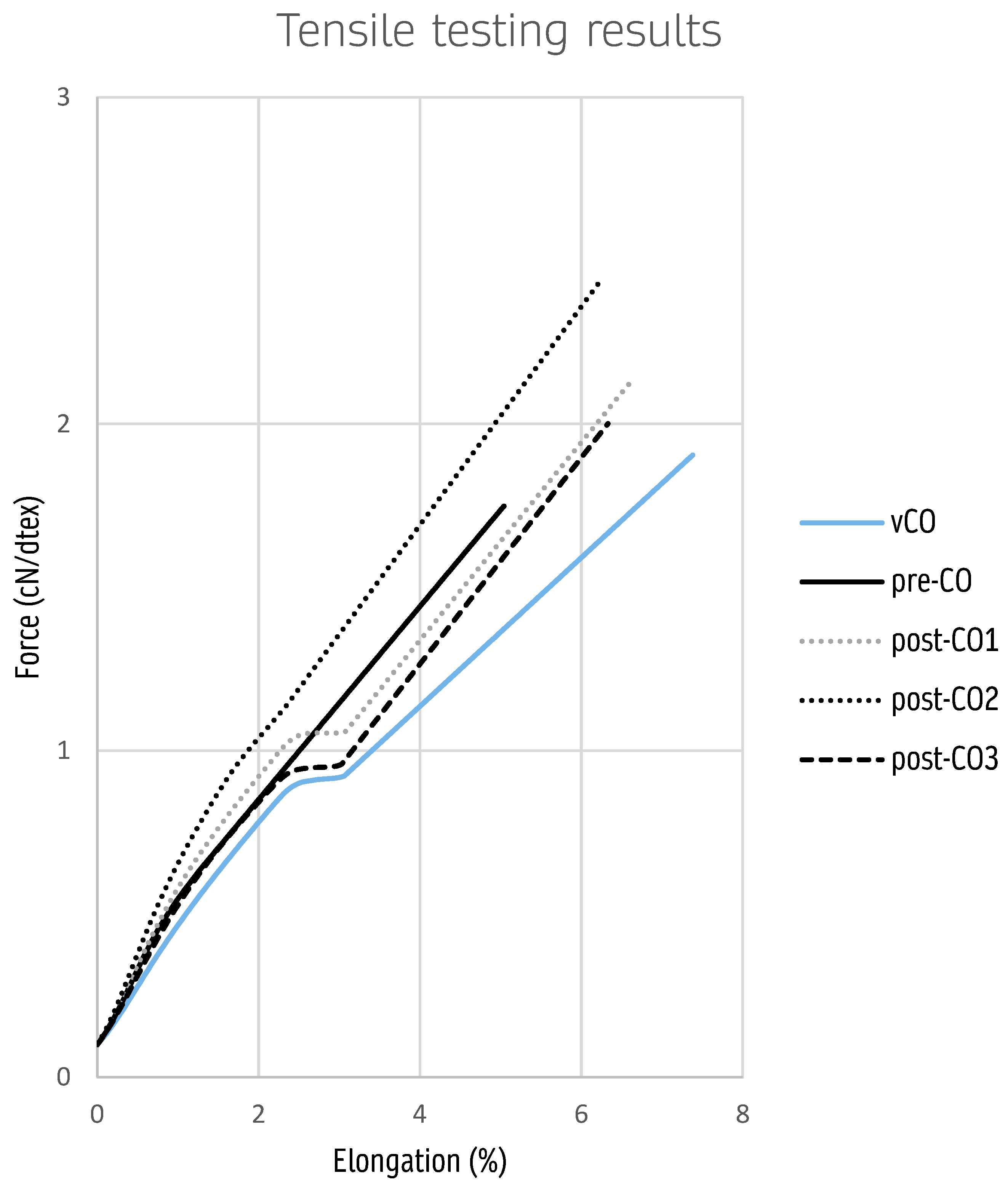

The tenacities of the opened fibres were established on single-fibre tensile tests. The measurements showed little to no difference between the different cotton types for the breaking tenacity and elongation or the linear density. Similar results, without significant differences in the linear density between virgin and mechanically opened cotton fibres, have been presented earlier [

14,

17]. Yuksekkaya et al. [

17] tested the tenacity of fibre bundles of virgin and mechanically recycled cotton fibres respectively. They found a subtle decrease in the tenacity of white pre-consumer cotton fibres compared to virgin fibres. Especially, the post-consumer samples presented in the results of this paper may consist of fibres other than cotton; there are yarns from seams, possible embroidery and care labels included in the mix. The fibres used to make these may deviate the result and not give a clear picture of what the breaking tenacity and elongation of pure cotton would be post-opening. Additionally, primary cotton fibres have differences, and it must be assumed that the vCO sample could be used for denim manufacturing to allow a somewhat objective comparison of the results. The ANOVA or Tukey test did not conclude any differences, so the hypotheses of MR fibres’ reduced or increased tenacity, elongation or linear density cannot be rejected. For the purpose of ring spinning and knitting, all the MR fibres were deemed suitable.

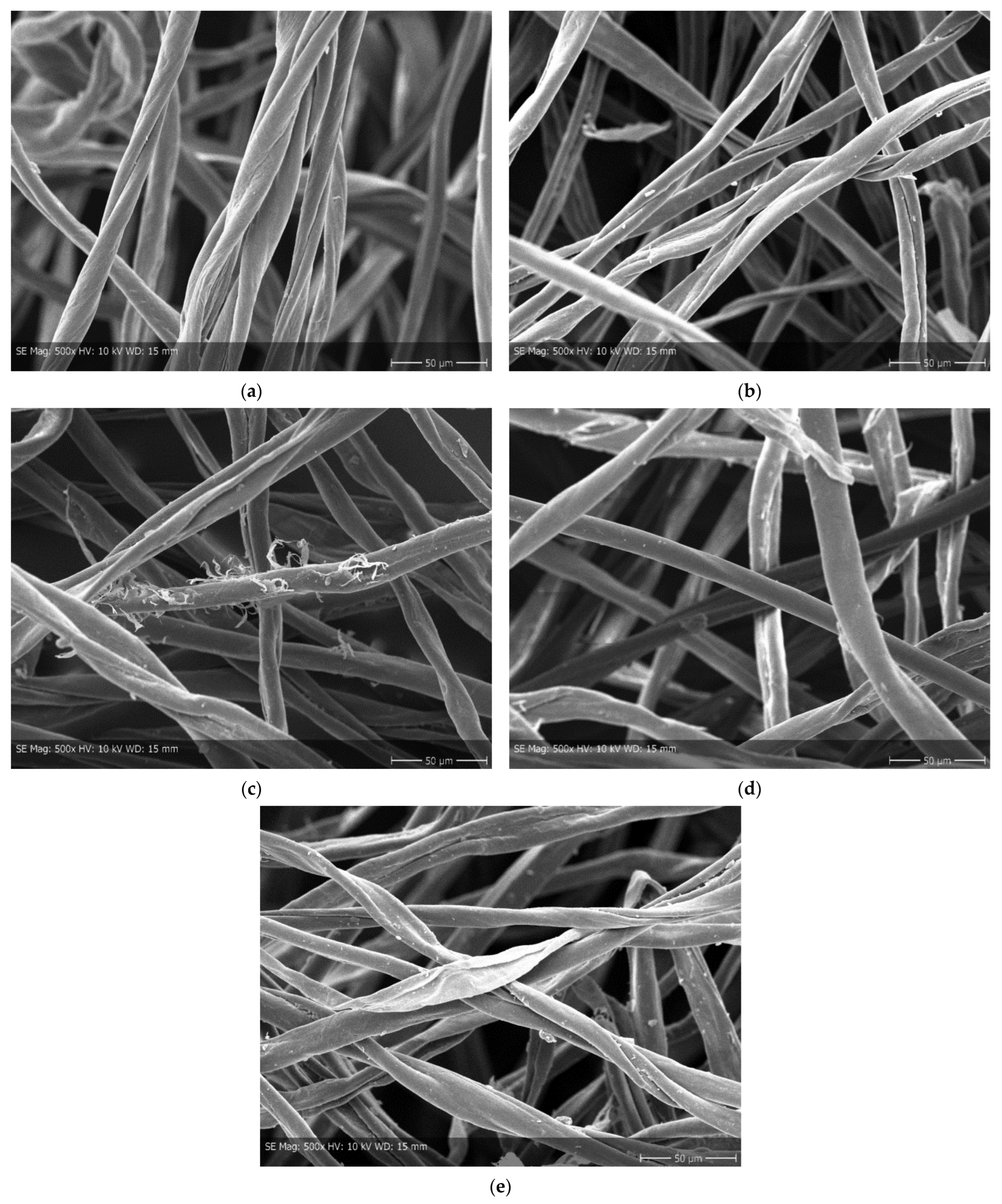

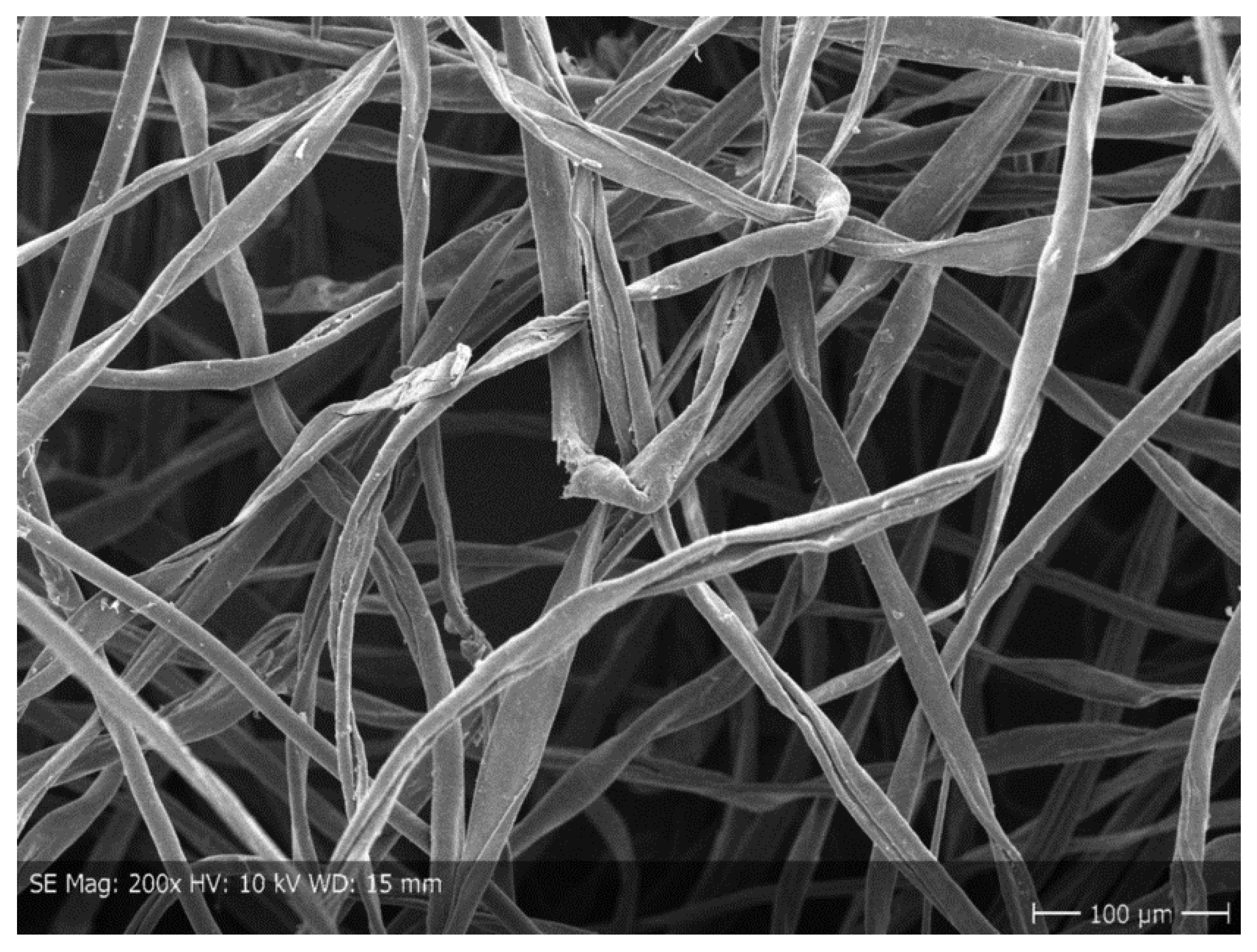

The SEM imaging showed no significant damage on the fibre surfaces of the MR fibres. Post-consumer textile waste can sometimes be worn out and thus damaged [

29], and the blades of the mechanical shredding lines could impose damage on the fibres. These results suggest, however, no surface damage is present on a wider scale, and only individual flaws could be detected. Aronsson et al. [

11] have earlier discovered the wearing out of garments does not necessarily reduce the fibre length. There is no way of knowing the level of wearing out of the post-consumer jeans studied here. However, the SEM pictures do not indicate any barriers for using these MR fibres as raw material for yarn spinning or other textile products.

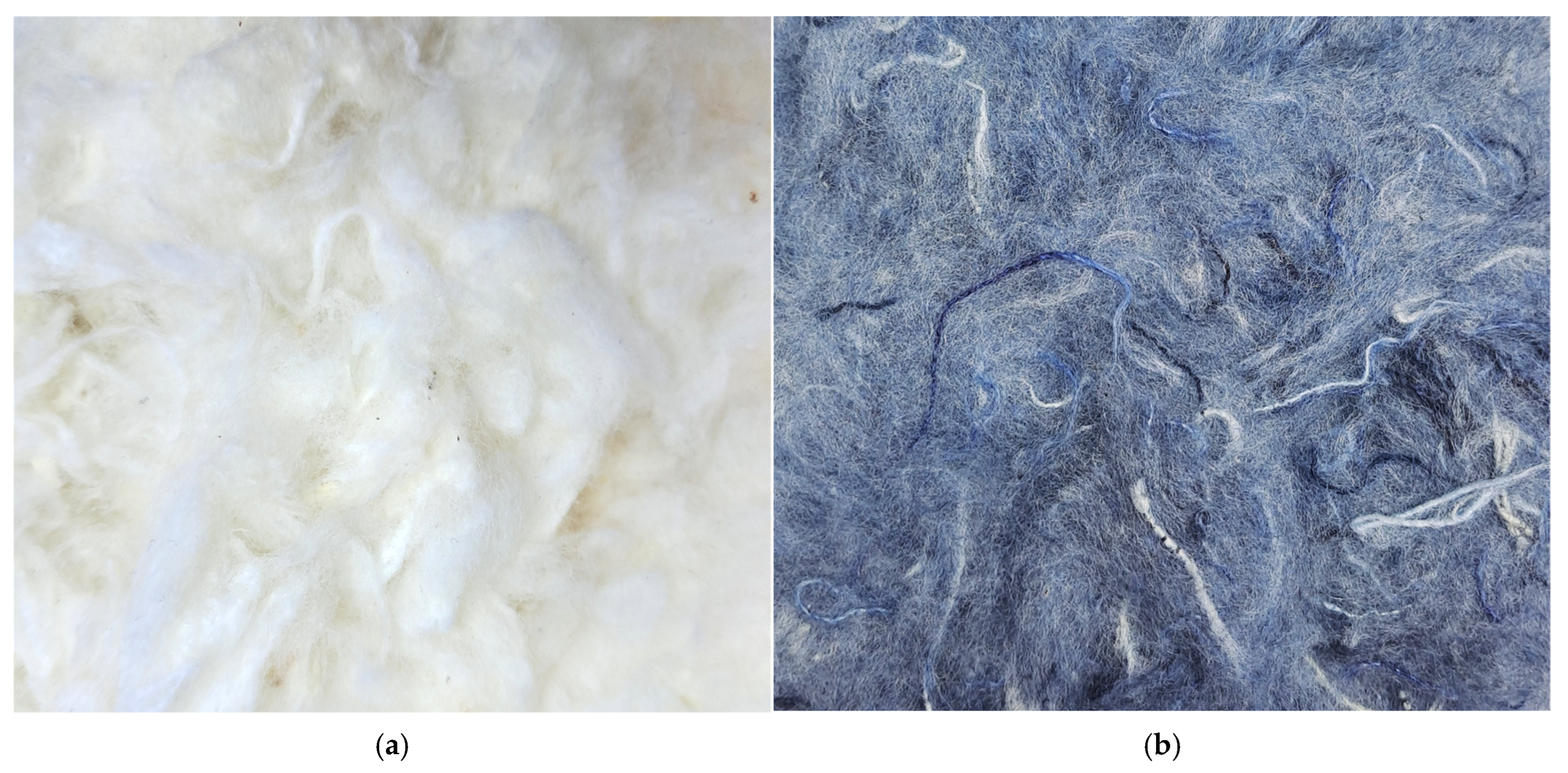

The sorting of post-consumer jeans was performed by colour and contents of the garments. Although samples post-CO1 and post-CO2 were first collected as “blue denim”, and post-CO3 as “black denim”, controlling the fractions is difficult. For pre-consumer samples the colour control may be easier. Nevertheless,

Figure 2b shows the variety of blue shades that made up the sample pre-CO. In cotton denim, warp yarns determine the colour, while weft yarns are often left undyed. Thus, natural colours will end up in the mechanically opened fibre mix with the dark warp yarns, resulting in a mélange colour; see [

14,

30].

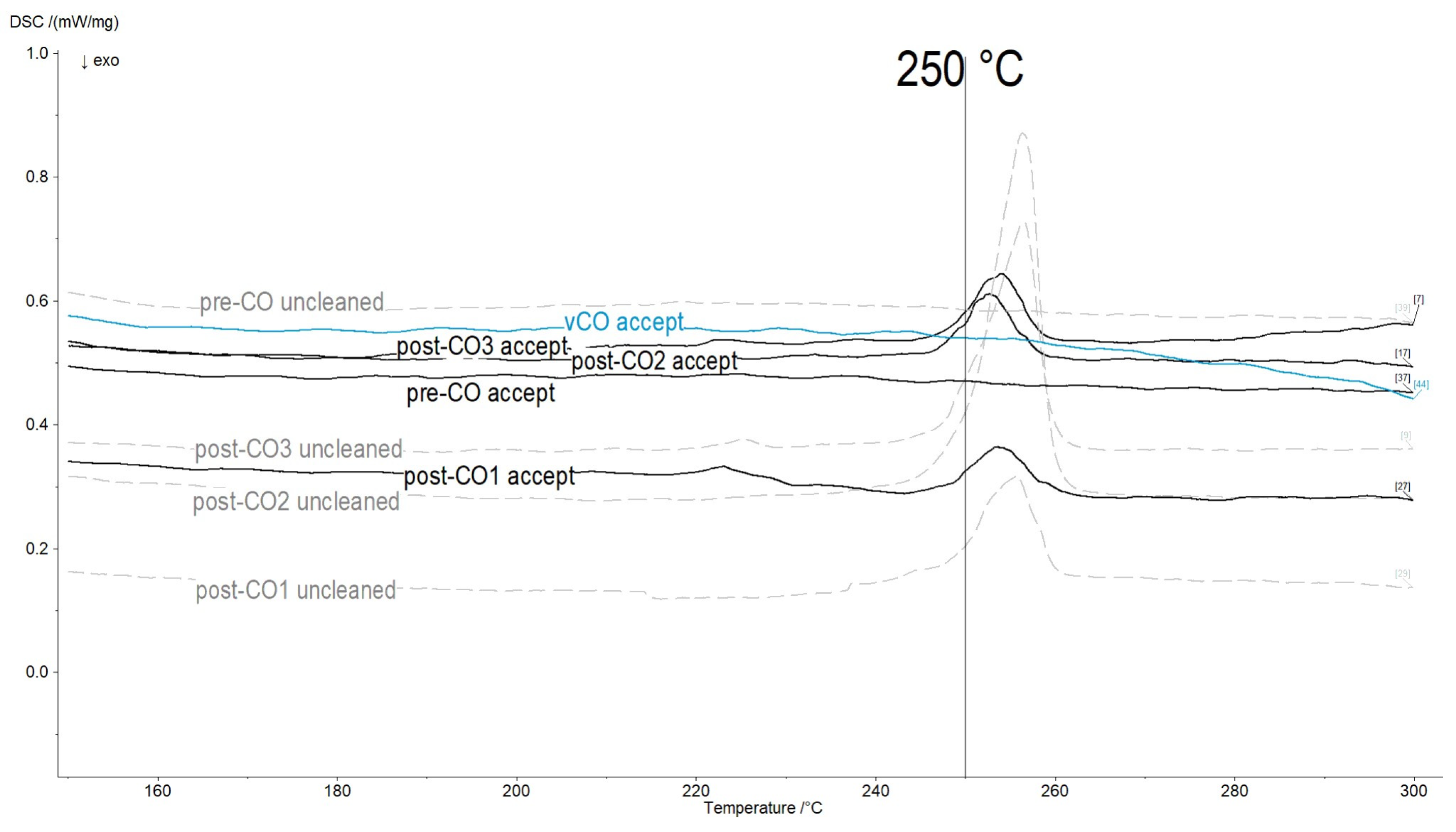

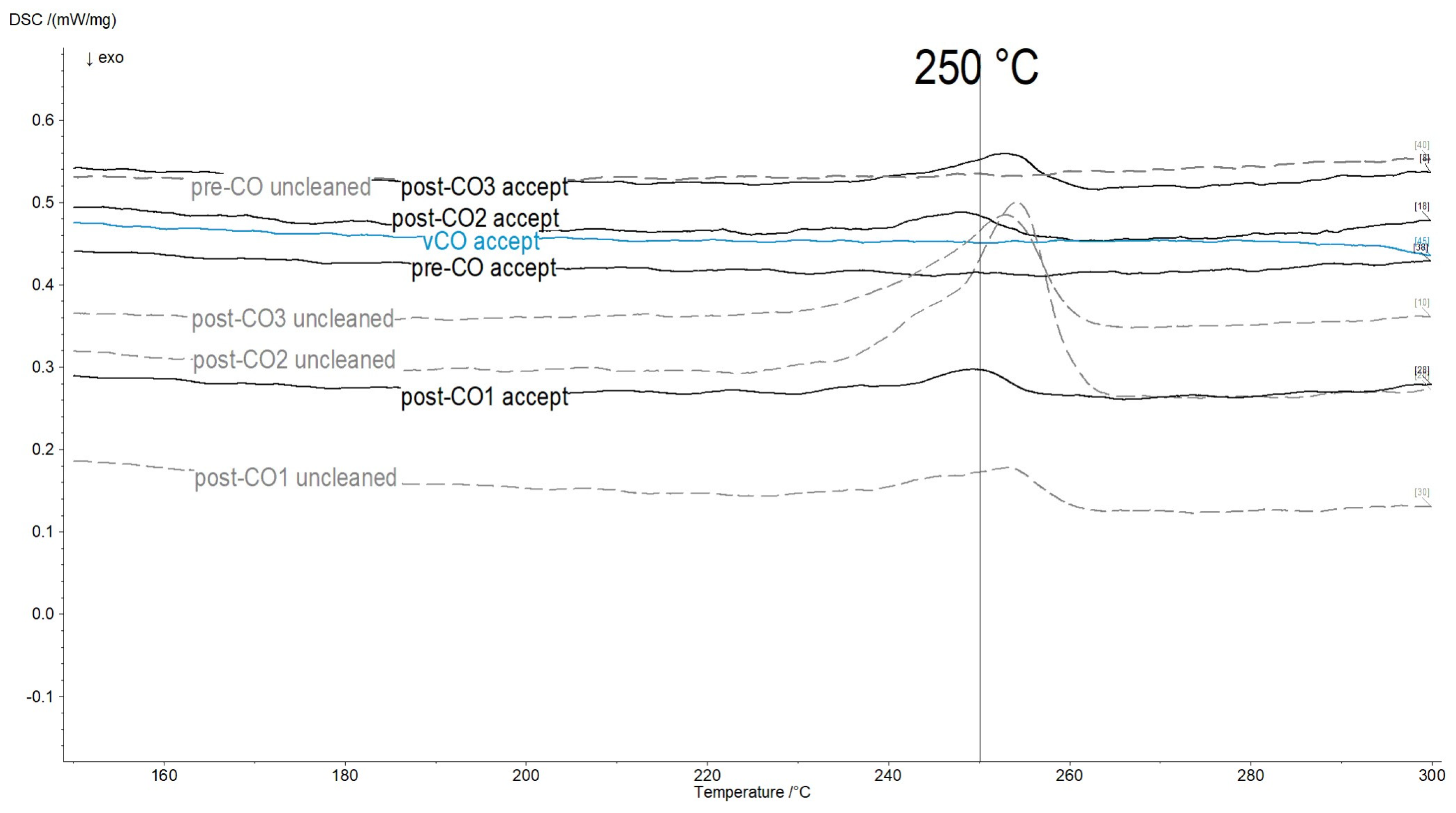

The fibre composition analysis was conducted with DSC. The melting peaks between 250 and 260 °C suggested the presence of a melting material, such as polyester, which is widely used in seam yarns and embroidery. A commonly used polyester, polyethylene terephthalate (PET), has melting points at 530–540 K, i.e., 256–266 °C [

31], and a moderate degree of crystallinity [

32]. The differences between the first and the second heating indicate that the molecular structure of the test specimen changes when heated. In the post-consumer cotton samples, where melting peaks can be observed, the peaks are less defined during the second heating. The cause of the melting peak differences can be due to the polymers melting and degrading, re-crystallising and presenting differently upon secondary heating. Due to its moderate crystallinity, PET is prone to side reactions, such as branching or crosslinking new reactive groups, when heated. The modification changes the crystalline structure of the polymer, presenting differently during new heating and cooling cycles. The differences between the total enthalpies of the melting peaks during first and second heating around the temperature of 250 °C are not significant but suggest the molecular structure and crystallinity of the melting polymer has changed. Nonetheless, the presence of the melting peaks indicates melting behaviour, a thermoplastic property, not detected in 100% cotton samples. The post-consumer cottons are collected from consumers, making it impossible to say what type of polyester they might include. It is also unknown what other types of polymers or textile fibres they contain, and how those may react with PET. There is a requirement for accurate technology in identification and content quantification [

33,

34,

35]. Inaccurate care labels [

36] or missing care labels present challenges for efficient textile sorting and recycling. There is another gap in research in identifying all the different chemical treatments included in textiles and thus understanding their effect in textile recycling. DSC analysis could offer one way of quickly identifying possible other materials in post-consumer waste collected as “cotton” when care labels are missing or inaccurate.

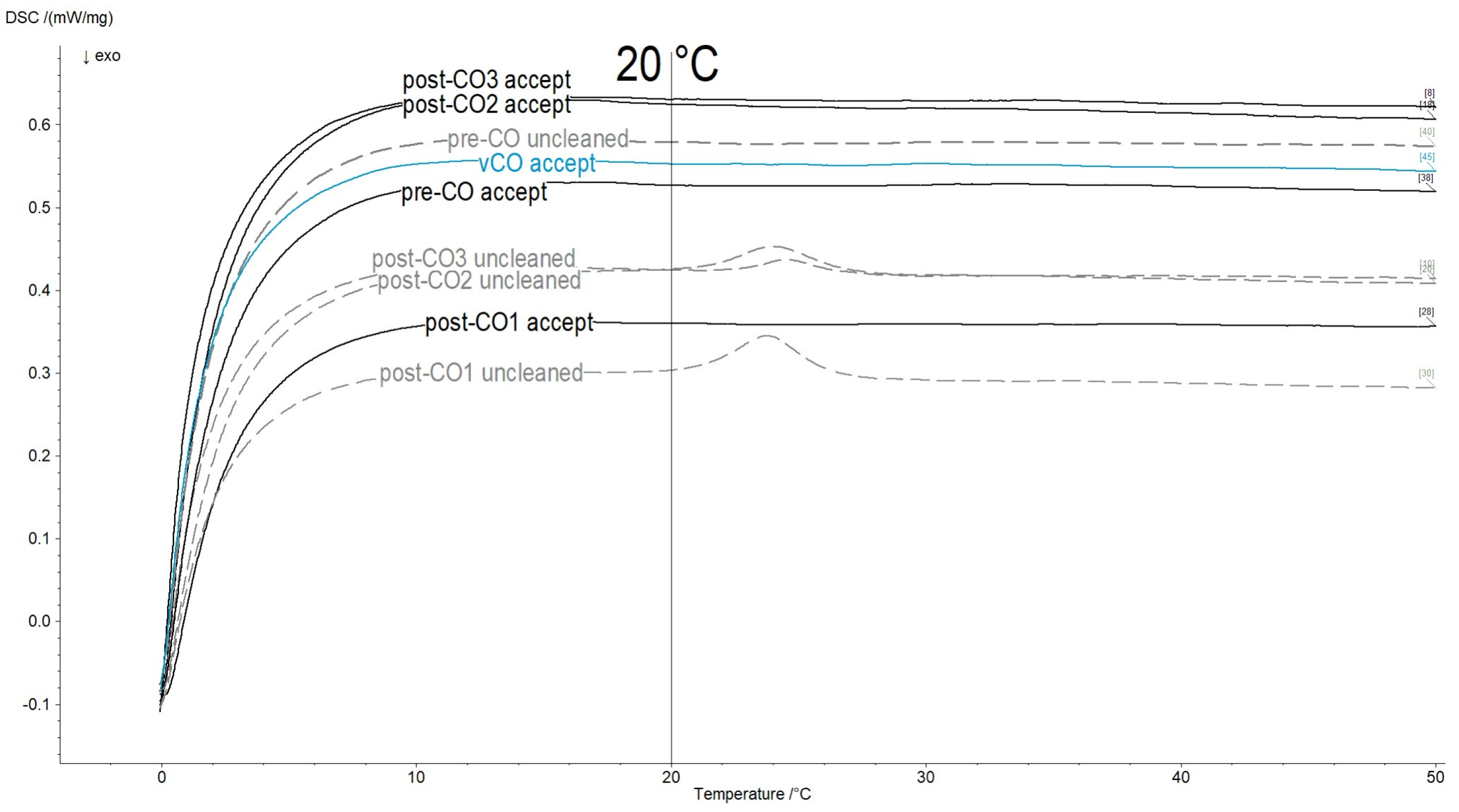

Boschmeier et al. [

34] reported a method for quantification of elastane in textiles. They found that the soft segments of elastane show a peak in the DSC second heating run at 20 °C, making them distinguishable from other commonly used textile fibres. In this study, melting peaks positioned between 20 °C and 30 °C were observed for post-consumer cottons during the DSC trials, as shown in

Figure 10. While post-CO3 was collected as “black denim containing up to 10% elastane”, it is likely that post-CO1 and post-CO2 also contain elastane, as elastane is added to jeans for comfort [

37]. As was earlier confirmed [

34], DSC offers a feasible method for identifying elastane prior to recycling.

One of the aims of this study was to showcase the possibility to make yarns and knits with a high recycled content. The use of softener in carding processes prior to spinning can allow the increasing of the ratio of recycled fibres to virgin fibres in ring spun yarns. In this study, a yarn containing 75% pre-consumer fibres was successfully spun with 25% primary fibres, when softener was applied in the carding phase. Moreover, post-CO2 cotton was successfully spun with primary fibres with a 75/25 ratio without an additional softener in the carding phase. However, the 75% post-CO2 yarn was thicker and not as strong as the one with 75% pre-CO fibres. Interestingly, the correlation results in

Table 5 suggest that increased single-fibre tenacity could decrease the overall yarn tenacity. This correlation has a

p-value of 0.023, and although it seems contradictory, the reason could lie in the composition of the samples. Post-CO cottons receive higher tenacity values in single-fibre testing than vCO and pre-CO fibres, possibly affected by the unknown contents of the sample; it is possible that the fibre tenacity for post-CO cottons is made up by polyester or other fibres or affected by chemical treatments and physical modifications present in post-consumer textiles. However, the fibre tensile testing results showed no statistically significant differences between the different cotton types, and other causing factors for yarn tenacities could be in applied twist, fibre orientation or fibre packing during spinning processes. Moreover, the fibre strength positively correlated with yarn linear density as well (

Table 5), with a

p-value of 0.011. These results indicate there could be a relationship between fibre tenacity and yarn thickness and yarn strength.

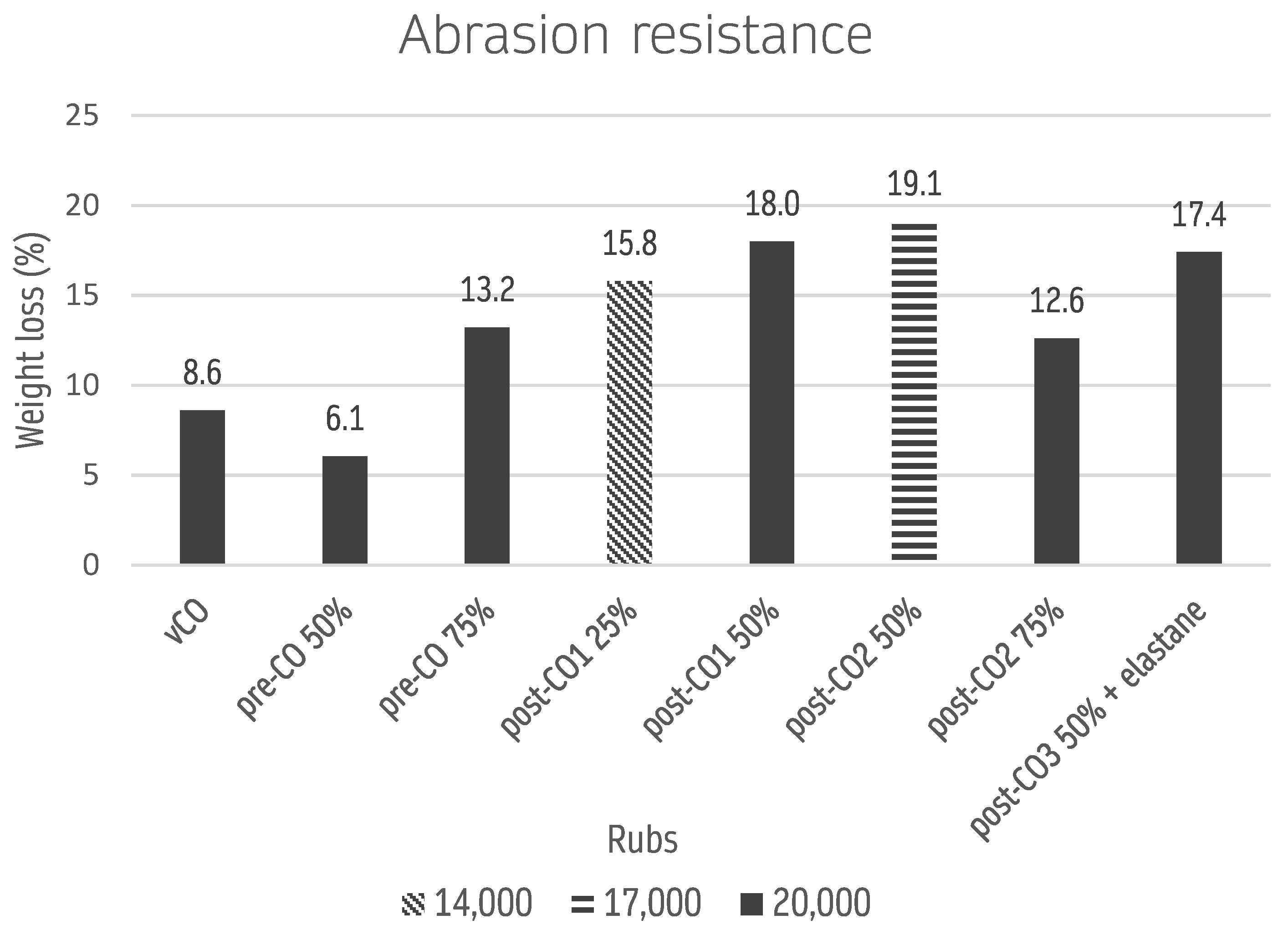

According to the yarn tensile testing results, the use of softener in the carding phase could increase the potential for a higher content of MR fibres. While increasing the recycled content generally decreases the fibre tenacity and increases the linear density, the effect of softener seems to give opposite results, as seen in the pre-CO yarns. The knits made from the two yarns with 75% MR fibres experienced similar abrasion resistances to each other, with a slightly higher percentual weight loss than yarns made with 100% primary cotton. It is difficult to say whether the softener had a significant effect on any of these results. While the use of softeners in opening processes has been studied, it should be further researched, as to how and to what extent the use of softener in yarn spinning can contribute to yarn tenacity.

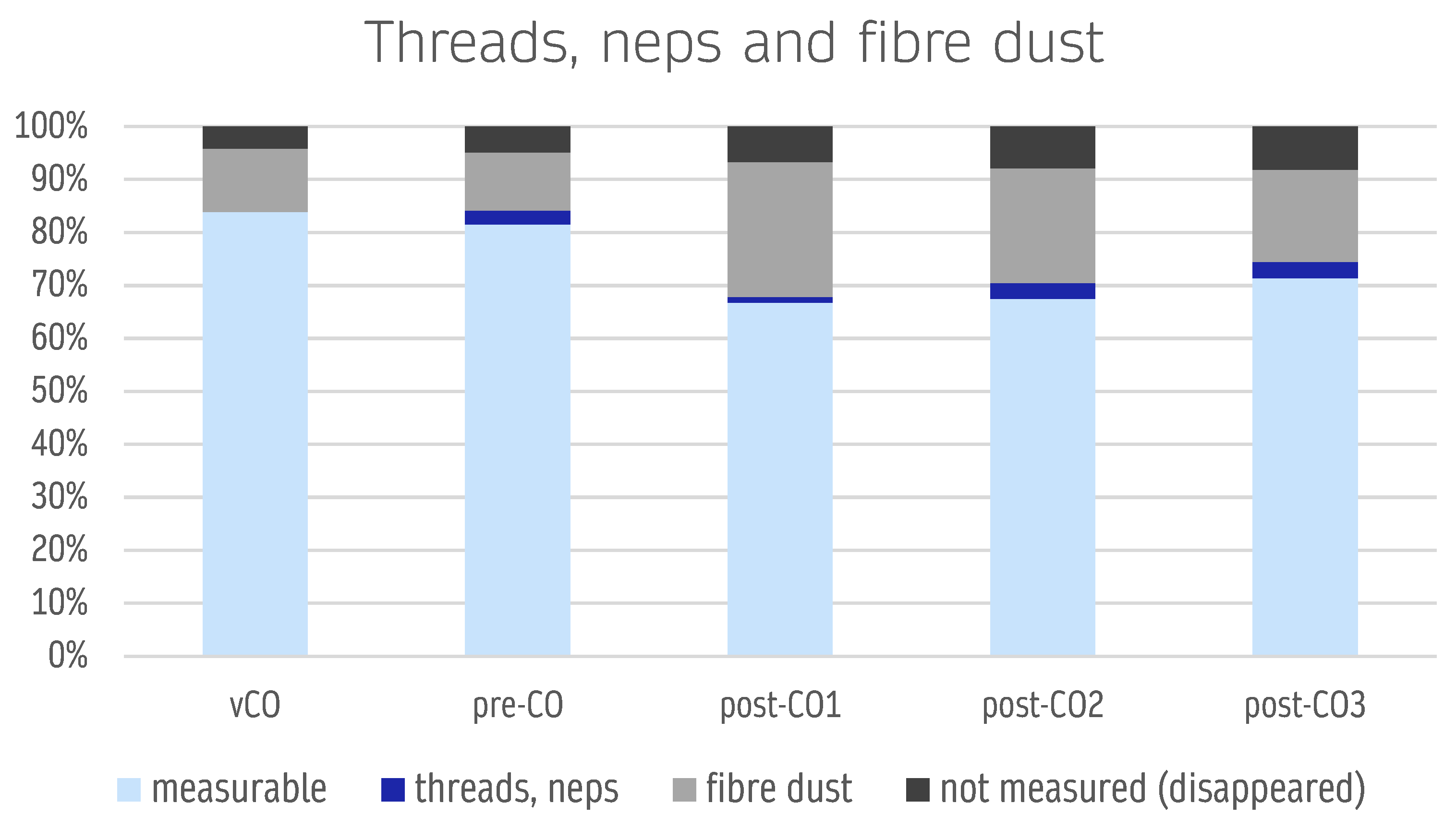

The fibre properties affecting spinnability, yarn properties and final knit properties are fibre type, fineness, length, tensile strength and resiliency [

37]. As was seen in the yarn tensile testing results (

Table 3), the addition of post-consumer recycled content increased the thickness and reduced the tenacity and elongation of yarns. As the tenacities of the MR fibres were like that of vCO (

Figure 5) with no statistically significant differences, and the measured linear densities did not differ notably (

Table 2), the resulting yarn tenacity must be attributed to something else. The fibre dust content (

Figure 4) was higher in post-consumer samples, and the fibre length was shorter (

Table 1) than the pre-consumer cotton and primary cotton fibres in this study. Reduced fibre length is often named as the most inhibiting parameter for the successful spinning of high-quality yarns [

10,

20,

23,

25]. The fibre length of vCO was statistically significantly different from the MR fibre lengths, and the pre-CO length was different from the other MR fibre lengths. The vCO and pre-CO yarns obtained higher tenacities than post-CO yarns, giving reason to believe fibre length also potentially affected the yarn strength in this study.

Lindström et al. [

23] earlier called for research to evaluate the abrasion properties of different MR fibres, yarns and fabrics. The abrasion resistance is strongest in samples made with 100% vCO, 50% pre-CO, 75% pre-CO and 75% post-CO2. The latter, the yarn with 75% post-CO2 fibres, obtained the lowest yarn strength, while the other yarns experienced the highest tenacities. The strongest yarn strength was measured for the yarn including 25% post-CO1 fibres. However, the knit made of this yarn broke after 14,000 rubs, the only knit breaking so early. A Martindale value of 14,000 rubs is considered enough for a knitted fashion garment intended for everyday use [

38]. Given the correlations between fibre or yarn properties and fabric weight loss, the most likely property to have some effect on abrasion resistance is the number of measurable fibres in the cotton. This hypothesis means that neps, unopened yarns, high short fibre content and other factors reducing the fibre length and quality should be limited in knits made with MR fibres. More research should be conducted to justify or elaborate the relationships between fibre, yarn and fabric properties.

Nevertheless, the abrasion resistance cannot be contributed to measurable fibres alone, but factors such as yarn twist, surface roughness and fibre blend homogeneity in the knit should be considered. The short fibres and a reduced fibre length uniformity lead to yarn irregularities [

20]. The fibre packing may be difficult to control with varying lengths of fibres. Yilmaz et al. [

39] used waste from cotton spinning processes and re-spun it into yarns with varying content. They found that ring spun yarns are sensitive to irregularities and thin and thick places the higher the waste content was. Properties such as yarn’s unevenness or hairiness could also play a role in abrasion resistance or resulting pilling [

40]. The high content of unmeasurable fibres likely result in uneven yarns, further causing pilling or breaking. The generally more apparent weight loss for the post-consumer knits could be attributed to the longer mean length of vCO and pre-CO fibres and the higher fibre dust content of post-CO cotton samples. The presence of long fibres allows for better entanglement of fibres, resulting in yarns with better durability and less pilling. A yarn twist is often applied to increase the strength of the yarn, but too high a twist can cause spirality during knitting [

41].

4. Materials and Methods

4.1. Fibres and Yarns

The recycled cotton materials studied in this report were obtained from two different mechanical opening lines, the pre-CO from one in Portugal and all the post-CO samples from another in Finland. The fibres are compared with a sample of primary cotton fibres, referred to as vCO (virgin cotton) in the text. All the fibre materials are reviewed in

Table 6.

The pre-CO sample was obtained from pre-consumer denim waste, a woven twill fabric with a 100% cotton composition. The opening of pre-CO was conducted at Citeve with a pilot-scale opening line. Pre-CO fabric was passed through the cutting line twice. After the cutting, a softener (PANTOCTAL CT-40; Dilube, Spain) was sprayed on the fabric pieces before feeding them to the opening line. The fabric pieces were fed through the mechanical opening line with five opening cylinders according to the parameters in

Table 7.

The post-consumer end-of-life textiles were collected by South-West Finland waste management company (LSJH). Jeans were manually identified and collected separately for mechanical opening. There were two classes for post-consumer jeans: blue denim clothing without elastane (post-CO1 and post-CO2) and black denim clothing with elastane (post-CO3). The material was identified with the help of care labels and occasionally with NIR. The identification of chemical treatments was not conducted, and it is therefore impossible to say if the post-consumer samples contain unknown chemical treatments or washing detergents. However, the post-consumer denim has been subject to use and laundering, so industrial treatments may have been washed off. The blue denim clothes were divided into two batches for the mechanical opening: one batch was opened as such (post-CO1), and for the other batch a softener was sprayed on directly after guillotine cutting and before fibre opening to reduce the friction in the shredding process (post-CO2). The post-consumer denims were mechanically opened with LSJH’s recycling line, which includes components for guillotine cutting, hard parts’ removal, fibre opening and fibre bale pressing. The fibre opening is based on mechanical opening cylinder technology, and the line has four opening cylinders. The capacity of the line is 1000 kg/h.

The fibres in

Table 6 were used in yarn production at Citeve. A reference yarn with 100% vCO fibre was spun to compare the properties of the yarns that had mechanically opened fibres. Seven different yarns with mechanically opened cotton fibres were produced, with the recycled fibres used in varying amounts, namely 25%, 50% or 75% of the yarn contents. The recycled and primary cotton fibres were mixed in the desired ratios by hand and fed to the card. Selected samples were sprayed with a softener before feeding to the card. Samples were carded twice with a laboratory carding machine (Mesdan, Italy). The carded webs were fed to the draw frame (Mesdan Stiro Roving Lab, Italy) and drawn twice, finally winding the roving on a spool. The rovings were moved to the ring spinning unit (Mesdan Ring Lab, Italy) and spun into yarns with 1.2 pre-draft, 1100 twist/m and machine speed 5400 rpm. The draft was adjusted from 22 to 36 based on the tex number of the roving and to obtain 40 tex yarns.

4.2. Knitting

Knitted samples of the produced yarns were made using a laboratory-scale circular knitting machine (Tricolab) with a 3.75″ cylinder, gauge 14 (corresponding to 168 needles) and one single feeder. The chosen knit was single jersey for all knitted samples.

4.3. Fibre Characterisation

The fibres were cleaned with the ‘Shirley’ Trash Analyser prior to the testing. The instrument is engineered for cotton cleaning i.e., separating the lint and other dirt from cotton. The instrument provides an “accept” in one compartment and a “reject” in another. The accept, reject and uncleaned (obtained from the opening lines) fibre samples were used in the different characterisation tests to better suit the different requirements of the tests.

The fibre length measurements were executed on a manually operated comb apparatus, adjusting the American standard (ASTM 1440-07) and Suter-Webb array method. A bundle of 75 ± 2 mg of fibres was taken for each measurement. The bundle was drawn apart by hand, and the separated parts were laid on top of each other repeatedly, so that the fibres were parallel and straightened prior to the testing. Accept fibres were used for the fibre length measurements, as the unopened threads of reject and uncleaned samples were caught in the combs. The parallel, straightened fibres were brushed against the combs of the apparatus and set down at one end of the combs, between the teeth. A pair of wide-grasp forceps was used to pick a small tuft of fibres from behind the combs and place the tuft from the one end of the combs to the other. The ends of the fibres were aligned as close to the outermost comb as possible. The whole sample was moved down this way, until no fibres could not be picked up. The remaining fibres were picked up with a narrow-grasp forceps, straightened and laid down as before. This allowed for further picking of fibres to increase the measurable sample size. The picking up and laying down of the remaining fibres was conducted an additional third time until only dust-like fibres were left. The fibres that were moved down to the other end were then compressed between the combs’ teeth with a teethed depressor. The apparatus was then pivoted 180˚, and the combs nearest to the tester were dropped down successively until a fringe of fibres was visible. The fringe was picked up with wide-grasp forceps and laid down on a velvet board. Further combs were dropped down to allow for picking up of the successively shorter fibres. The laid-down fibres formed an array on the velvet board. After that, the fibres were divided into length groups (1–3, 4–6, 7–9, … mm), and the length groups were weighed to calculate the weight-based mean length (mm).

The mechanical properties of fibres were determined as an average of 10 and 20 measurements according to the ISO 1973 and ISO 5079 standards, using a Favigraph testing machine (Textechno GmbH, Germany). The testing speed was 20 mm min−1 and the gauge length 10 mm. The tests included titre (dtex), tenacity (cN dtex−1) and elongation (%).

The surface structures of the mechanically opened fibres were studied with a JEOL scanning electron microscope, model T100, after coating them with gold.

Differential scanning calorimetry (DSC) measurements were performed for ~3–8 mg fibre samples encapsulated in aluminium pans using a Netzsch DSC instrument. The temperature range was 20 °C to 300 °C, and the dynamic heating rate was 10 °C/min with a constant nitrogen gas purge of 50 mL/min.

A single-factor Analysis of Variance (ANOVA) was calculated for the fibre length, tenacity, elongation and linear density results. A pairwise comparison of fibre lengths was executed with the Tukey method.

4.4. Yarn Analysis: Tensile Testing

The linear density of the yarns was determined according to EN-ISO 2060 as an average of ten measurements. The breaking force and elongation were determined according to EN-ISO2062:2009 as an average of ten measurements with an automatic single-yarn strength tester. The yarns were conditioned at 20 °C and 65% RH for 24 h.

4.5. Knit Analysis: Abrasion Resistance

Abrasion resistance of the knitted samples was evaluated by using the Martindale abrasion instrument (James Heal, Halifax, UK) according to EN-ISO 12947-2. Two parallel samples were tested, and mean values were calculated, using 9 kPa pressure and standard wool fabric as an abradant material specified in EN-ISO 12947-1. The samples were subjected to a rubbing motion until knitted fabric threads were broken, or the number of 20,000 revolutions was reached. Knitted fabric weight loss was determined as the difference in the weight of fabric samples before and after the Martindale abrasion test.

4.6. Correlation Analysis

A correlation analysis was conducted to test the effect of fibre properties on yarns and fabrics, and yarn properties on fabrics, to support the credibility of the results. For the analysis, averaged fibre properties were calculated for yarns consisting of more than one of the studied cotton samples.