Environmental Pollution Mitigation: The Chemical Transformation of Residual Frying Oil into Biodiesel

Abstract

1. Introduction

2. Materials and Methods

2.1. Residual Frying Oil

2.2. Process of Obtaining Biodiesel

2.3. Physicochemical Characterization

2.3.1. Fourier Transform Infrared Spectroscopy (FT-IR)

2.3.2. Oxidative Stability Determination

3. Results

3.1. Characterization of Residual Frying Oils

3.2. Obtaining Biodiesel

3.3. Physicochemical Characterization of Biodiesel

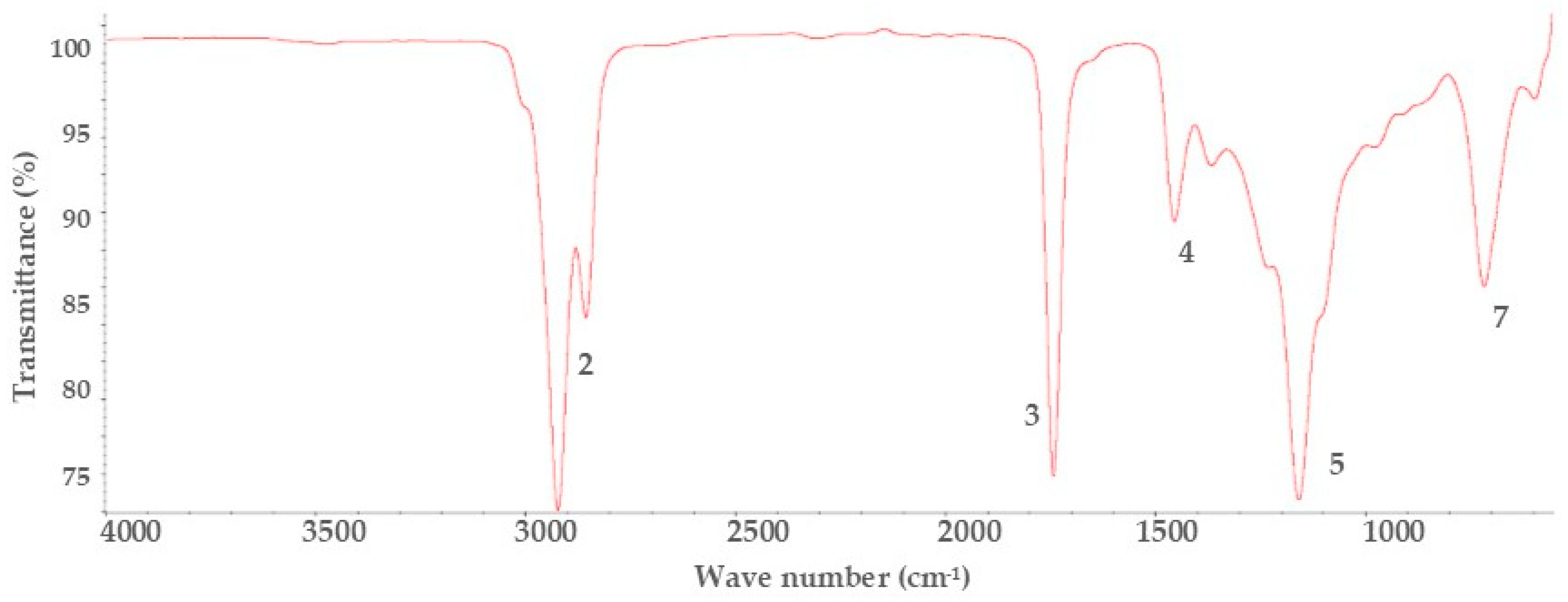

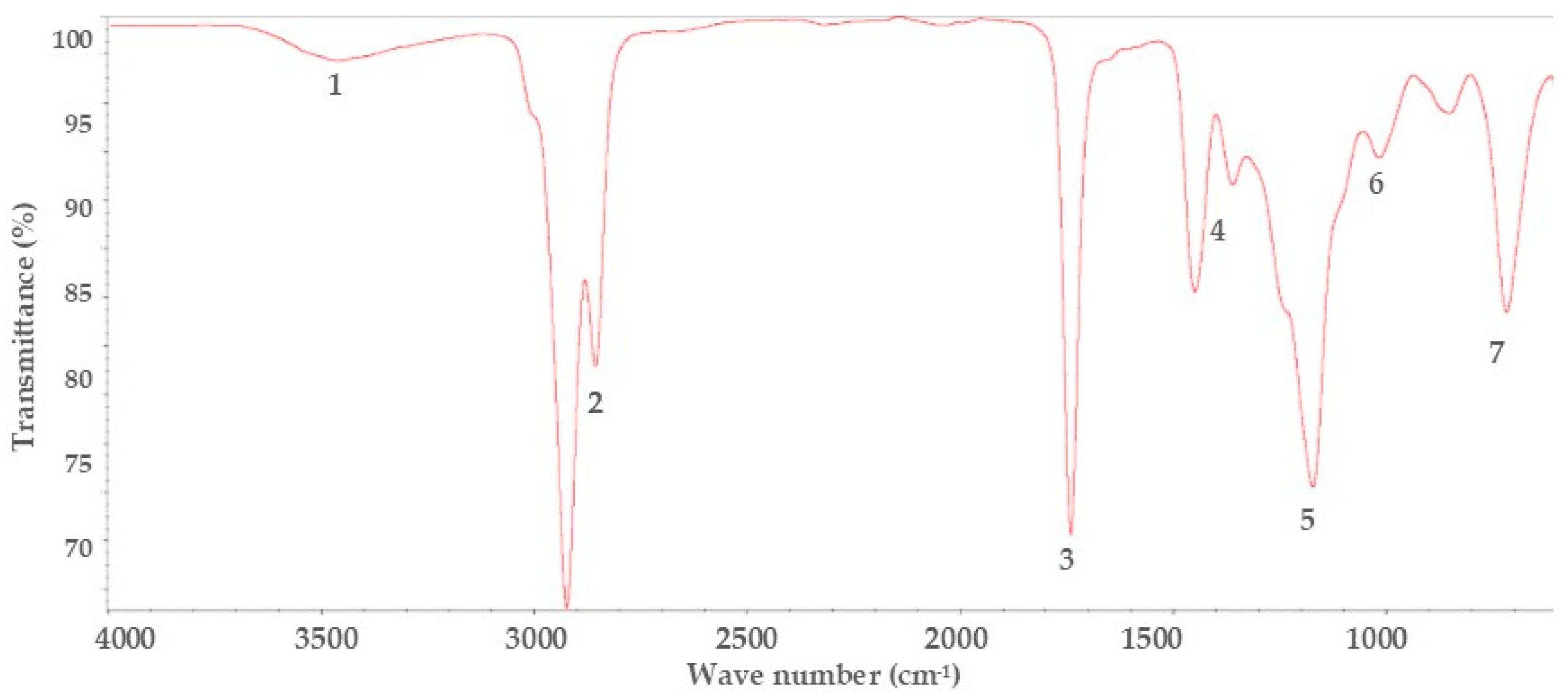

3.4. FT—IR

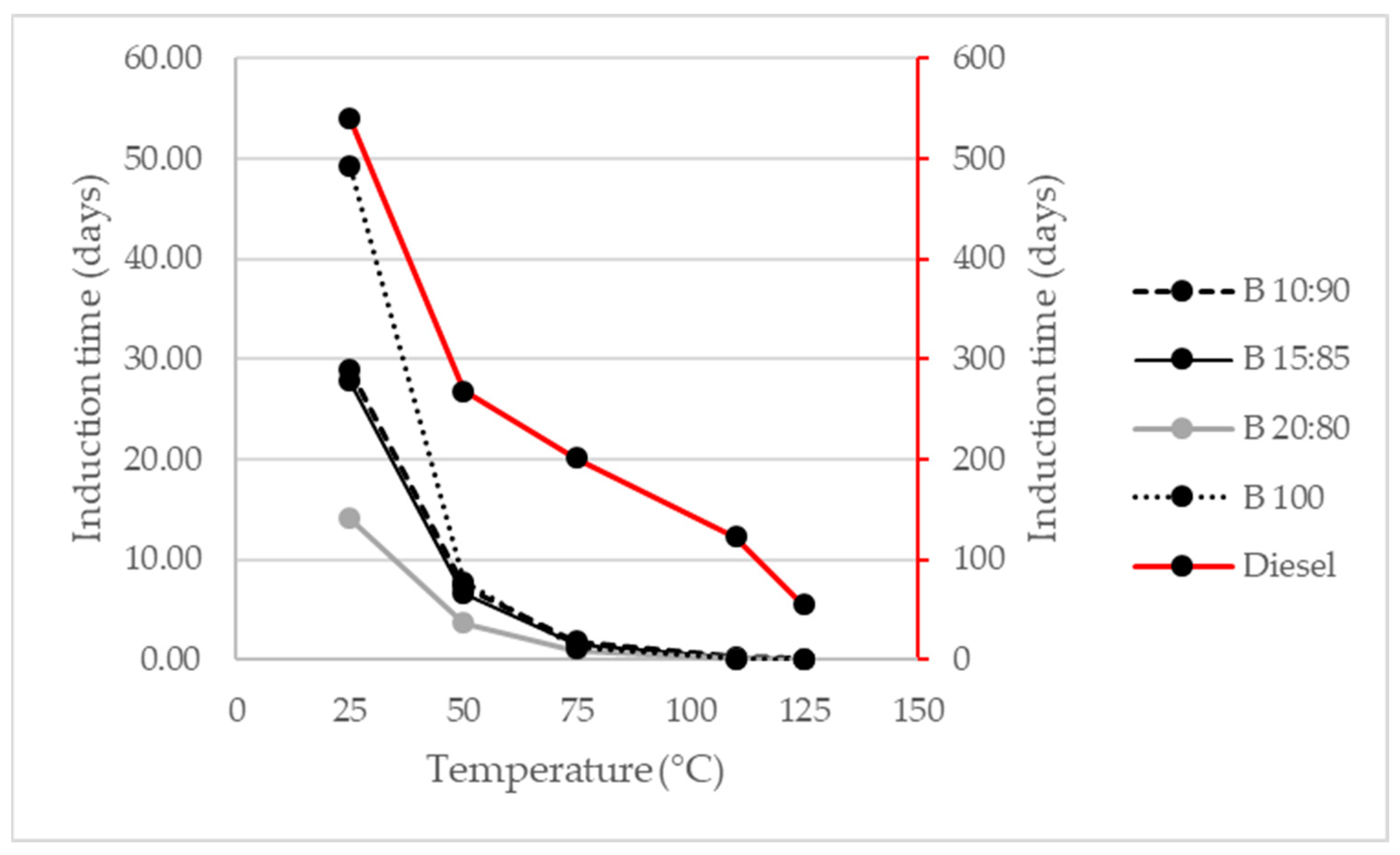

3.5. Oxidative Stability

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bárcena, A.; Prado, A. Agenda 2030 and the Sustainable Development Goals; D-CEPAL: Mexico City, Mexico, 2017. [Google Scholar]

- Landrigan, P.J.; Stegeman, J.J.; Fleming, L.E.; Allemand, D.; Anderson, D.M.; Backer, L.C.; Brucker-Davis, F.; Chevalier, N.; Corra, L.; Czerucka, D.; et al. Human Health and Ocean Pollution. Ann. Glob. Health 2020, 86, 151. [Google Scholar] [CrossRef] [PubMed]

- Al-Rubaye, A.H.; Jasim, D.J.; Ameen, H.F.M.; Al-Robai, H.A.; Al-Assal, J.R. The Impacts of Petroleum on the Environment. IOP Conf. Ser. Earth Environ. Sci. 2023, 1158, 032014. [Google Scholar] [CrossRef]

- Liu, Y.; Cruz-Morales, P.; Zargar, A.; Belcher, M.S.; Pang, B.; Englund, E.; Dan, Q.; Yin, K.; Keasling, J.D. Biofuels for a sustainable future. Cell 2021, 184, 1636–1647. [Google Scholar] [CrossRef] [PubMed]

- Beghetto, V. Waste cooking oils into high-value products: Where is the industry going? Polymers 2025, 17, 887. [Google Scholar] [CrossRef]

- Gui, C.; Wang, L.; Liu, G.; Ogunbiyi, A.T.; Li, W. The catalytic valorization of lignin from biomass for the production of liquid fuels. Energies 2025, 18, 1478. [Google Scholar] [CrossRef]

- ASTM D6751-20a; Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels. American Society for Testing and Materials: Conshohocken, PA, USA, 2023.

- Prado, E.R.L.; Rian, R.C. Advances in conversion technologies for biofuels from wheat and corn straws. Biocatal. Agric. Biotechnol. 2024, 63, 103481. [Google Scholar] [CrossRef]

- Puc-Blanco, N. Evaluation of Bioethanol Production from Lignocellulosic Waste of Tzalam Wood (Lysiloma latisiliquum). Bachelor’s Thesis, Quintana Roo University, Chetumal, Mexico, 2017. [Google Scholar]

- Ayala-Mendivil, N.; Sandoval, G. Bioenergy from forestry and Wood waste. Wood For. 2018, 24, e2401877. [Google Scholar] [CrossRef]

- Alvarado-Ludeña, G.R. Obtaining Bioethanol from Sugarcane Bagasse Through Enzymatic Hydrolysis. Bachelor’s Thesis, Salesian Polytechnic University, Cuenca, Ecuador, 2021. [Google Scholar]

- Garg, R.; Sabouni, R.; Ahmadipour, M. From waste to fuel: Challenging aspects in sustainable biodiesel production from lignocellulosic biomass feedstocks and role of metal organic framework as innovative heterogeneous catalysts. Ind. Crop. Prod. 2023, 206, 117554. [Google Scholar] [CrossRef]

- Sheinbaum, C.; Balam, M.V.; Robles, G.; Lelo de Larrea, S.; Mendoza, R. Biodiesel from waste cooking oil in Mexico City. Waste Manag. Res. 2015, 33, 730–739. [Google Scholar] [CrossRef]

- Sunil Kumar, K.; Babu, J.M.; Venu, H.; Muthuraja, A. Waste plastic as a source of biofuel for stationary diesel engine: A critical review. Int. J. Ambient Energy 2022, 43, 8577–8591. [Google Scholar] [CrossRef]

- Badui, S. Food Chemistry, 4th ed.; PEARSON Education: Mexico City, Mexico, 2006. [Google Scholar]

- González, C.I.; González, U.J.A. Used cooking oils. Environmental problems, incidents in sewage networks, and cost of treatment in wastewater treatment plants. Sewag. Info. 2015, 1–8. [Google Scholar]

- SEDEMA. Separate Used Oil and Take It to Collection Centers; Secretary of the Environment: Mexico City, Mexico, 2023. [Google Scholar]

- Sahoo, P.K.; Das, L.M. Process optimization for biodiesel production from Jatropha, Karanja and Polanga oils. Fuel 2009, 88, 1588–1594. [Google Scholar] [CrossRef]

- Suzihaque, M.U.H.; Alwi, H.; Ibrahim, U.K.; Abdullah, S.; Haron, N. Biodiesel production from waste cooking oil: A brief review. Mater. Today Proc. 2022, 63, S490–S495. [Google Scholar] [CrossRef]

- General Law for the Prevention and Integral Management of Waste. 2023. Available online: https://www.diputados.gob.mx/LeyesBiblio/pdf/LGPGIR.pdf (accessed on 8 September 2024).

- PROFECO. Despite the Damage to Health, Mexicans Reuse Cooking Oil; Consumer Attorney General: Mexico City, Mexico, 2023. [Google Scholar]

- Ganesan, K.; Sukalingam, K.; Xu, B. Impact of consumption and cooking manners of vegetable oils on cardiovascular diseases critical review. Trends Food Sci. Technol. 2018, 71, 132–154. [Google Scholar] [CrossRef]

- Tacias-Pascacio, V.G.; Rosales-Quintero, A.; Torrestiana-Sánchez, B. Evaluation and characterization of waste cooking fats and oils for biodiesel production: A case study. Rev. Int. Contam. Ambient 2016, 32, 303–313. [Google Scholar] [CrossRef]

- Rosas-Barajas, A.; Aguilar-Ortega, A.; Cornejo-Corona, I.; Rizo-Fernández, Z.; Córdova, S.E.; Ramos-Frausto, L.G.; Esparza-Claudio, J.D.J. Analysis of bioethanol and biodiesel supply chains in Mexico: Case study. Nova Sci. 2018, 10, 13–29. [Google Scholar] [CrossRef][Green Version]

- Sosa-Rodríguez, F.S.; Vazquez-Arenas, J. The biodiesel market in Mexico: Challenges and perspectives to overcome in Latin-American countries. Energy Convers. Manag. 2021, 12, 100–149. [Google Scholar] [CrossRef]

- Padilla, V.J. Jatropha curcas for Biodiesel Production in Chiapas. Participating Farmers, Land Used and Crop Replacement. Ph.D. Dissertation, The College of the Southern Border, Lerma, Mexico, 2010. [Google Scholar]

- SADER. Jatropha curcas Gold and Green Promise; Secretary of Agriculture and Rural Development: Mexico City, Mexico, 2015. [Google Scholar]

- Avila-Soler, E.; García-Salazar, J.A.; Valtierra-Pacheco, E.; García-Mata, R.; Hoyos-Fernández, G. Jathopha derived biodiesel production: A competitiveness study in the state of Chiapas, Mexico. Rev. Fitotec. Mex. 2018, 41, 461–468. [Google Scholar] [CrossRef]

- UNE-EN 14214; Liquid Petroleum Products—Fatty Acid Methyl Esters (FAME) for Use in Diesel Engines and Heating Applications—Requirements and Test Methods. Spanish Standardization Association: Madrid, Spain, 2018.

- Susa, D.A.H.; Samtaella, J.R.B.; Alvarez, C.E.C. Analysis of Power and Torque Performance of a Diesel Engine Operating with Palm Biodiesel Blends. Ingeniería 2020, 25, 250–263. [Google Scholar] [CrossRef]

- Caldera, M.; Martinez, R.A.; Stocchi, A. Effect of Biodiesel Use on Engine Component Materials. II Ibero-American Days the Thermal Engines and Lubrication. 2016, pp. 67–78. Available online: https://sedici.unlp.edu.ar/handle/10915/77352 (accessed on 15 February 2025).

- ASTM D4052; Standard Test Method for Density and Relative Density of Liquids by Digital Density Meter. American Society for Testing and Materials: Conshohocken, PA, USA, 2002.

- ASTM D664; Standard Test Method for Acid Number of Petroleum Products by Potentiometric Titration. American Society for Testing and Materials: Conshohocken, PA, USA, 2018.

- NMX-F-101-SCFI; Food—Vegetable or Animal Oils and Fats—Determination of Free Fatty Acids—Test Method. Mexican Standard: Mexico City, Mexico, 2012.

- ASTM D445; Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids. American Society for Testing and Materials: Conshohocken, PA, USA, 2024.

- NOM-116-SCFI; Automotive Industry—Lubricating Oils for Gasoline and Diesel Engines—Specifications, Test Methods and Commercial Information. Mexican Official Standard: Mexico City, Mexico 2018.

- ASTM D93; Standard Test Methods for Flash Point by Pensky–Martens Closed Cup Tester. American Society for Testing and Materials: Conshohocken, PA, USA, 2020.

- Ortiz-Tapia, M.D.C.; García-Alamilla, P.; Lagunes-Gálvez, L.M.; Arregoitia-Quezada, M.I.; García-Alamilla, R.; León-Chávez, M.A. Obtaining biodiesel from crude palm oil (Elaeis guineensis Jacq.). Application of the ascending path method. Acta Univ. 2016, 26, 3–10. [Google Scholar] [CrossRef]

- UNE-EN 14112; Derivatives of Oils and Fats. Fatty Acid Methyl Esters (FAME). Determination of Stability Against Oxidation (Accelerated Oxidation Test). Spanish Standardization Association: Madrid, Spain, 2021.

- De Menezes, L.C.; de Sousa, E.R.; da Silva, G.S.; Marques, A.L.B.; Viegas, H.D.C.; Dos Santos, M.J.C. Investigations on Storage and Oxidative Stability of Biodiesel from Different Feedstocks Using the Rancimat Method, Infrared Spectroscopy, and Chemometry. ACS Omega 2022, 7, 30746–30755. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, G.; Villanueva, E.; Glorio, P.; Baquerizo, M. Oxidative stability and shelf life estimation of sacha inchi oil (Plukenetia volubilis L.). Sci. Agropecu. 2015, 6, 155–163. [Google Scholar] [CrossRef]

- PANTONE PMS 146. 2024. Available online: https://www.logorapid.com/pantone (accessed on 3 May 2024).

- DOF. Guidelines Establishing the Quality Specifications and Characteristics for Pure Anhydrous Ethanol (Bioethanol), Biodiesel and Bioturbosine; Official Journal of the Federation: Mexico City, Mexico, 2018. [Google Scholar]

- García-Muentes, S.A.; Lafargue-Pérez, F.; Labrada-Vázquez, B.; Díaz-Velázquez, M.; Sánchez-Lafita, A.E. Physicochemical properties of oil and biodiesel produced from Jatropha curcas L. in the province of Manabí, Ecuador. Rev. Cuba Quím. 2018, 30, 142–158. [Google Scholar]

- Silverstein, R.M.; Bassier, G.C. Spectrometric identification of organic compounds. J. Chem. Edu. 2005, 39, 546. [Google Scholar] [CrossRef]

- Longanesi, L.; Pereira, A.P.; Johnston, N.; Chuck, C.J. Oxidative stability of biodiesel: Recent insights. Biofuels Bioprod. Bioref. 2022, 16, 265–289. [Google Scholar] [CrossRef]

- Catalogue, M.C. Oxidation stability of oils and fats–Rancimat method. Appl. Bull. 2022, 204, 1–4. [Google Scholar]

- Bennon, M.; Wilson, D. NEPA Litigation over Large Energy and Transport Infrastructure Projects. Environ. Law Report. 2023, 53, 10836. [Google Scholar]

- Santamaría-Juárez, J.D.; Juárez-Vidal, O.; Sánchez-Cantú, M.; Santamaría-Juárez, G.; Varela-Caselis, J.; Castañeda-Antonio, M.D.; López-Morales, S. Oxidative stability index as a reference for quality control in biodiesel production. Ingeniería 2022, 25, 44–56. [Google Scholar]

- Salguero, H.S.; Morejón, F.B.; Carranza, C.C. Components present in used frying oil and determinants before its conversion into biodiesel. J. Res. Inst. Fac. Geol. Min. Metall. Geogr. Eng. 2019, 22, 33–38. [Google Scholar]

- Silitonga, A.S.; Masjuki, H.H.; Mahlia, T.M.I.; Ong, H.C.; Atabani, A.E.; Chong, W.T. A global comparative review of biodiesel production from Jatropha curcas using different homogeneous acid and alkaline catalysts: Study of physical and chemical properties. Renew Sustain. Energy Rev. 2013, 24, 514–533. [Google Scholar] [CrossRef]

- Lafont, J.J.; Páez, M.S.; Torres, Y.C. Chemical analysis of biodiesel mixtures of used cooking oil and diesel by infrared spectroscopy. Technol. Inf. 2011, 22, 35–42. [Google Scholar] [CrossRef]

| Density (g mL−1) | Free Fatty Acids (%) | Acidity Index (%) | Viscosity (mm2 s−1) |

|---|---|---|---|

| 0.933 +/− 0.028 | 0.878 +/− 0.088 | 1.748 +/− 0.176 | 34.512 +/− 2.691 |

| Property | Units | Limit Value | Obtained Value | Other Study [19,44] | Testing Method |

|---|---|---|---|---|---|

| Density at 15 °C | g mL−1 | 0.86–0.90 | 0.886 +/− 0.042 | 0.88/0.875 | UNE-EN-14214 [29], ASTM D4052 [32] |

| Acidity | % | Maximum 0.995 | 0.516 +/− 0.053 | UN/0.40 | ASTM D664 [33] |

| Viscosity | mm2 s−1 | 1.9–6.0 | 7.535 +/− 0.026 | 4.5/3.55 | ASTM D445 [35] |

| Flash point | °C | Minimum 130 | 166.8 +/− 1.040 | 130/160 | ASTM D93 [37] |

| Number | Absorption (cm−1) | Functional Group | Literature Absorption (cm−1) [45] |

|---|---|---|---|

| 1 | 3460.26 | Hydroxyl, -OH | 3000–3700 |

| 2 | 2923.97–2856.87 | Alkanes, -CH | 2800–3000 |

| 3 | 1740.64 | Ester, RCOOR | 1735–1750 |

| Unsaturation, C=C | 1500–1900 | ||

| 4 | 1449.11–1360.78 | Methylenes, -CH2 | 1450 |

| 5 | 1172.38–1158.34 | Carbonyl, C=O | 1000–1200 |

| 6 | 1016.81–852.38 | Carboxylic acid, RCOOH | 960–875 |

| 7 | 717.35 | More than four methylenes together | 720 |

| Substance | Oxidative Stability (h) |

|---|---|

| Diesel | 2956 |

| Biodiesel (100) | 2.22 |

| Mix 90:10 (90% diesel + 10% biodiesel) | 6.5 |

| Mix 85:15 (85% diesel + 15% biodiesel) | 5.2 |

| Mix 80:20 (80% diesel + 20% biodiesel) | 3.4 |

| Residual frying oil | 2168 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez-Luna, Y.C.; Vázquez-Villegas, P.T.; Berrones-Hernández, R.; Sánchez-Roque, Y.; Saldaña-Trinidad, S.; Canseco-Pérez, M.A.; Gómez-Vázquez, E.G.; Lam-Gutiérrez, A.; Rodríguez-Hernández, L. Environmental Pollution Mitigation: The Chemical Transformation of Residual Frying Oil into Biodiesel. Recycling 2025, 10, 70. https://doi.org/10.3390/recycling10020070

Pérez-Luna YC, Vázquez-Villegas PT, Berrones-Hernández R, Sánchez-Roque Y, Saldaña-Trinidad S, Canseco-Pérez MA, Gómez-Vázquez EG, Lam-Gutiérrez A, Rodríguez-Hernández L. Environmental Pollution Mitigation: The Chemical Transformation of Residual Frying Oil into Biodiesel. Recycling. 2025; 10(2):70. https://doi.org/10.3390/recycling10020070

Chicago/Turabian StylePérez-Luna, Yolanda C., Paola T. Vázquez-Villegas, Roberto Berrones-Hernández, Yazmin Sánchez-Roque, Sergio Saldaña-Trinidad, Miguel A. Canseco-Pérez, Elvia G. Gómez-Vázquez, Anayancy Lam-Gutiérrez, and Ludwi Rodríguez-Hernández. 2025. "Environmental Pollution Mitigation: The Chemical Transformation of Residual Frying Oil into Biodiesel" Recycling 10, no. 2: 70. https://doi.org/10.3390/recycling10020070

APA StylePérez-Luna, Y. C., Vázquez-Villegas, P. T., Berrones-Hernández, R., Sánchez-Roque, Y., Saldaña-Trinidad, S., Canseco-Pérez, M. A., Gómez-Vázquez, E. G., Lam-Gutiérrez, A., & Rodríguez-Hernández, L. (2025). Environmental Pollution Mitigation: The Chemical Transformation of Residual Frying Oil into Biodiesel. Recycling, 10(2), 70. https://doi.org/10.3390/recycling10020070