Recycling Decommissioned Wind Turbine Blades for Post-Disaster Housing Applications

Abstract

1. Introduction

- Recycling the decommissioned wind turbine blades: Recycling wind turbine blades presents several challenges and complexities such as difficulties in recycling fiber-reinforced composites due to their complex composition. Moreover, recycling wind turbine blades involves technical and economic difficulties. Therefore, the aim of this study was to address these issues in line with sustainable energy production and environmental protection goals.

- Building resilient and economical post-disaster houses: Due to the high strength and light weight of the wind turbine blades, durable and cost-effective post-disaster housing strategies can be developed. Therefore, this study also aimed to build resilient and cost-effective post disaster housing applications. Besides the post-earthquake housing example in this study, these houses are also vulnerable to severe hurricanes and flooding.

- Decreasing energy consumption: Building relief camps from wind turbine blades can save energy since the wind turbine blades are made from durable, lightweight composite materials, and these materials provide extra insulation to the houses. Therefore, the aim of this study was to evaluate the energy saving potential of houses that are fully made from decommissioned wind turbine blades.

2. Materials and Methods

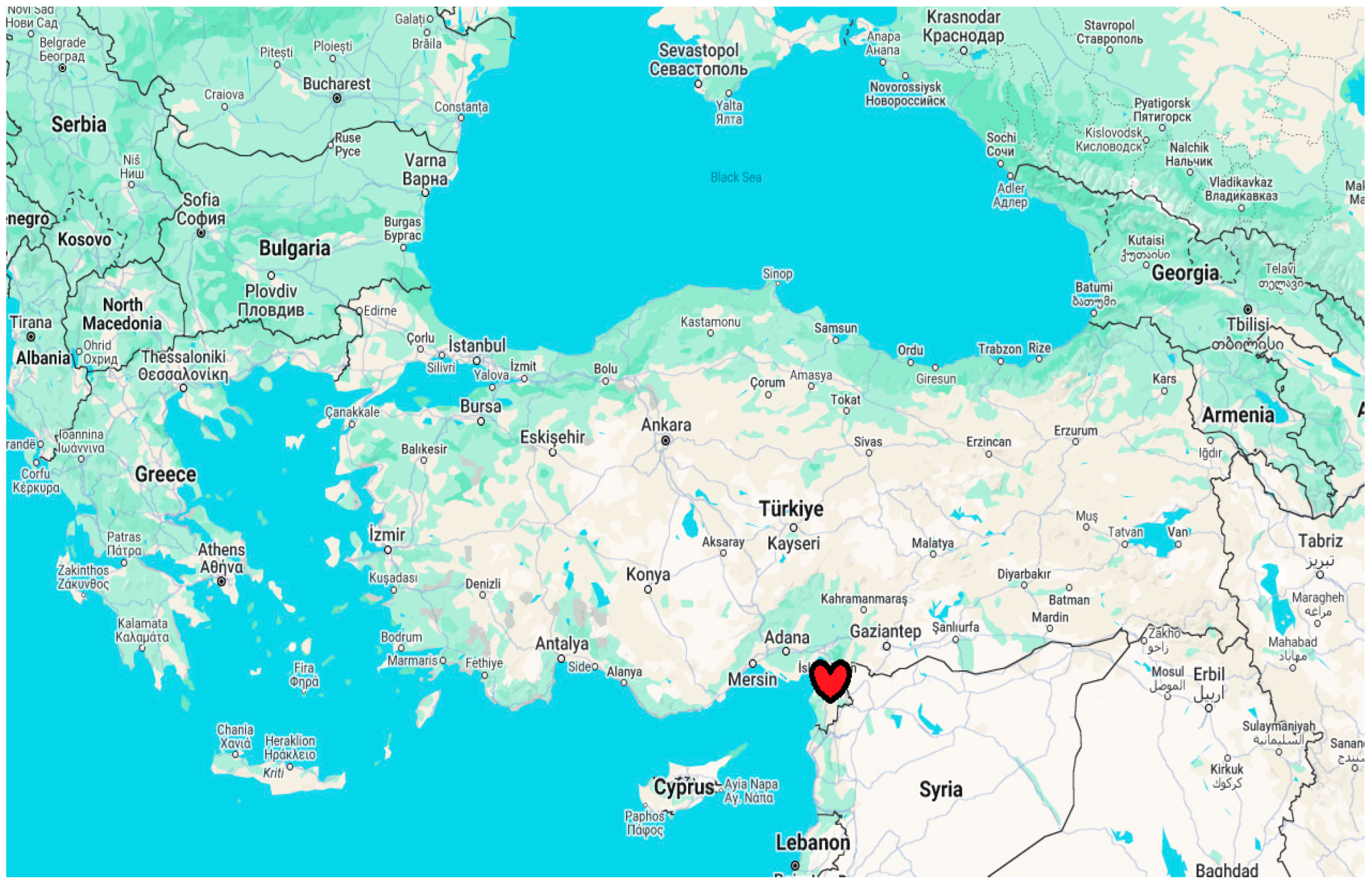

2.1. Case Zone: Hatay Relief Camp

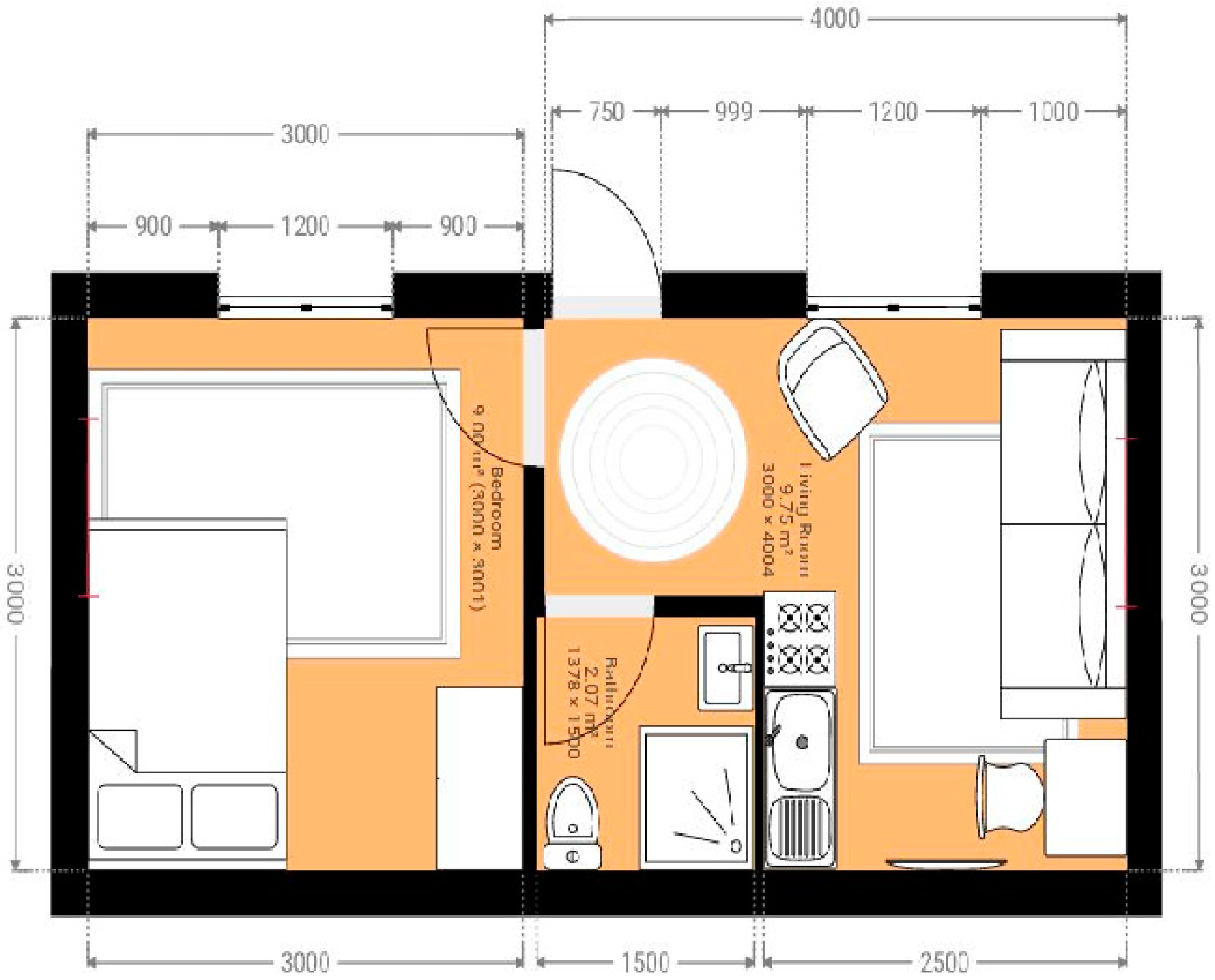

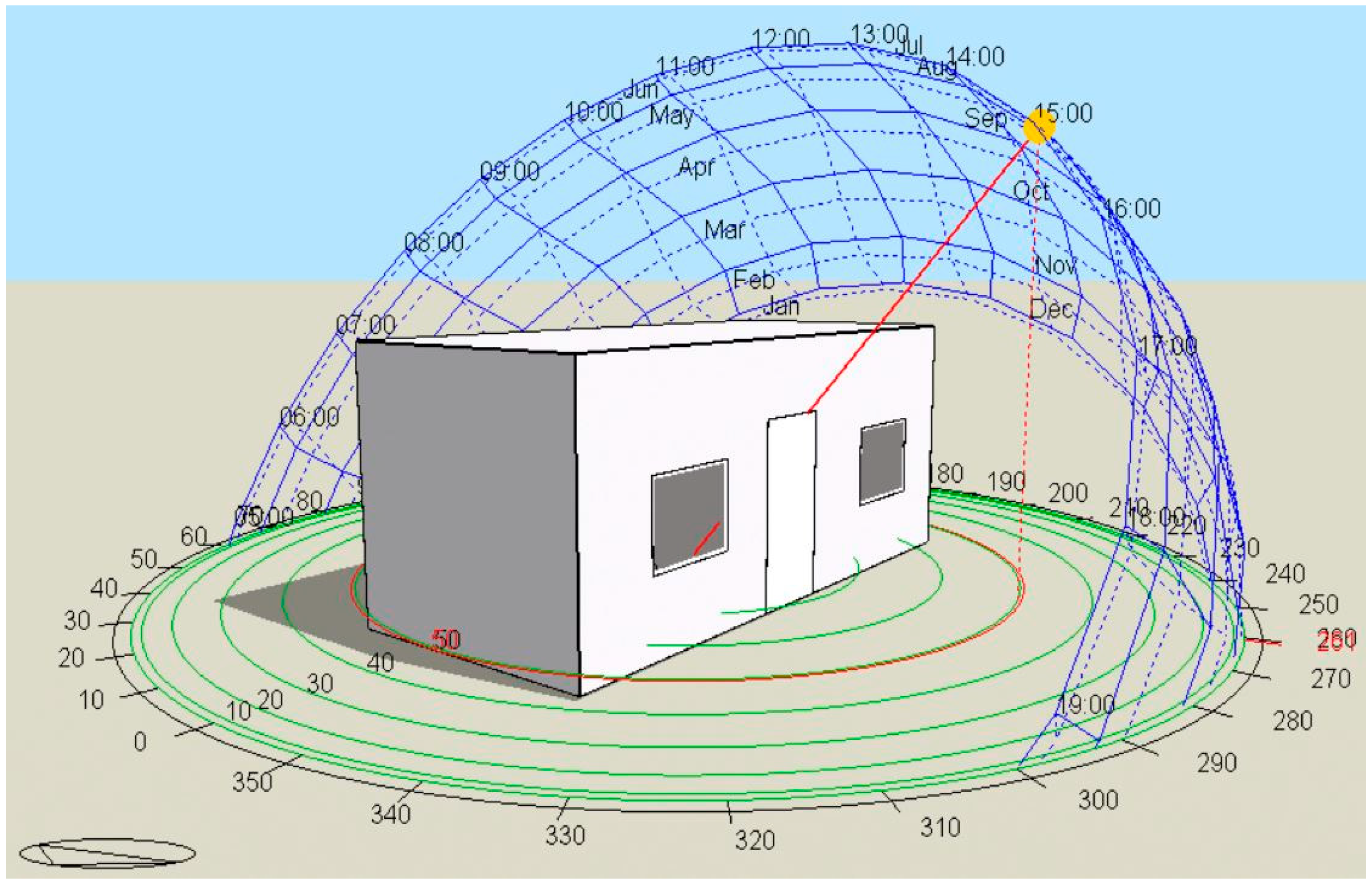

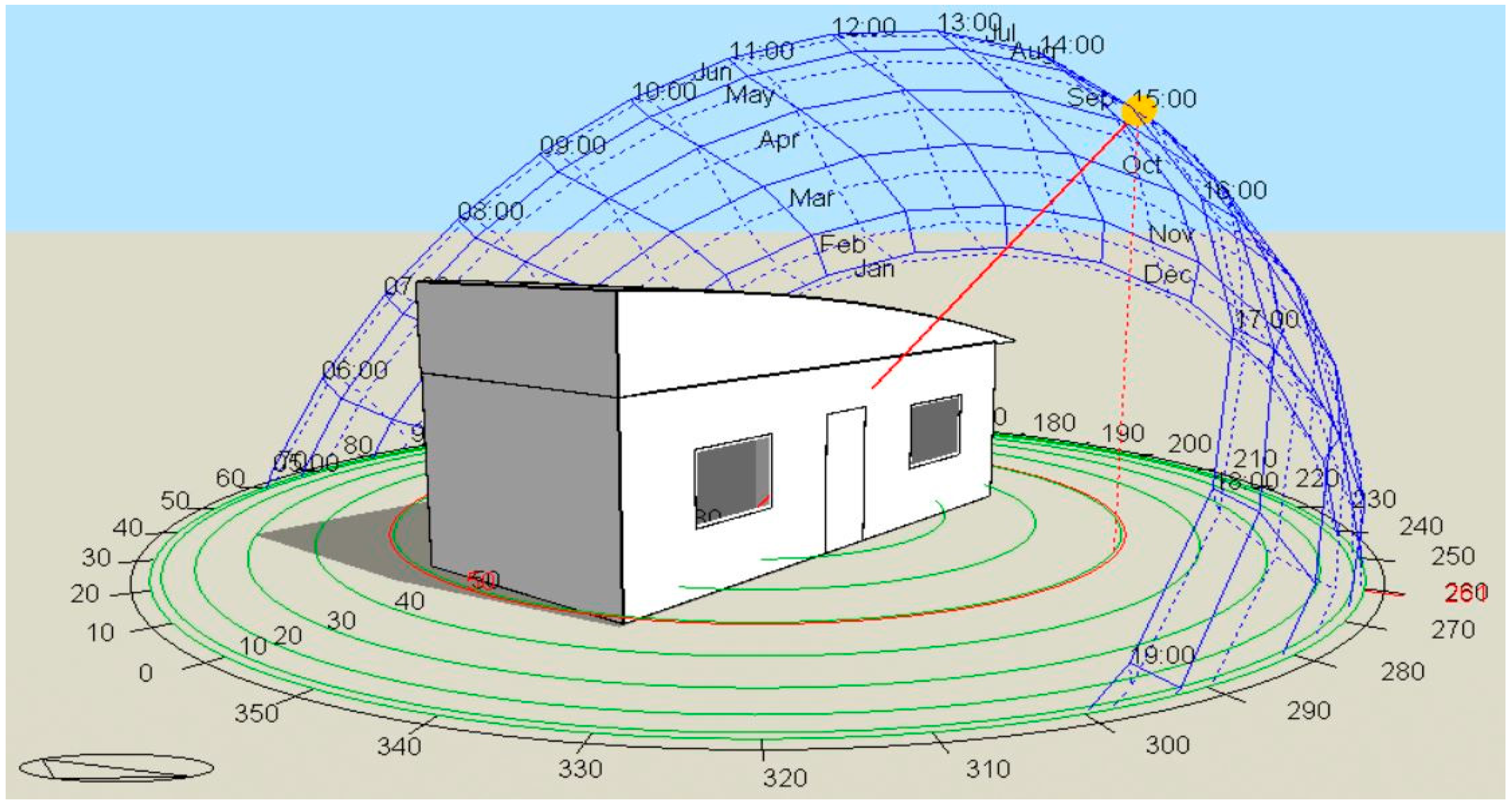

2.2. Energy Analysis of the Camp

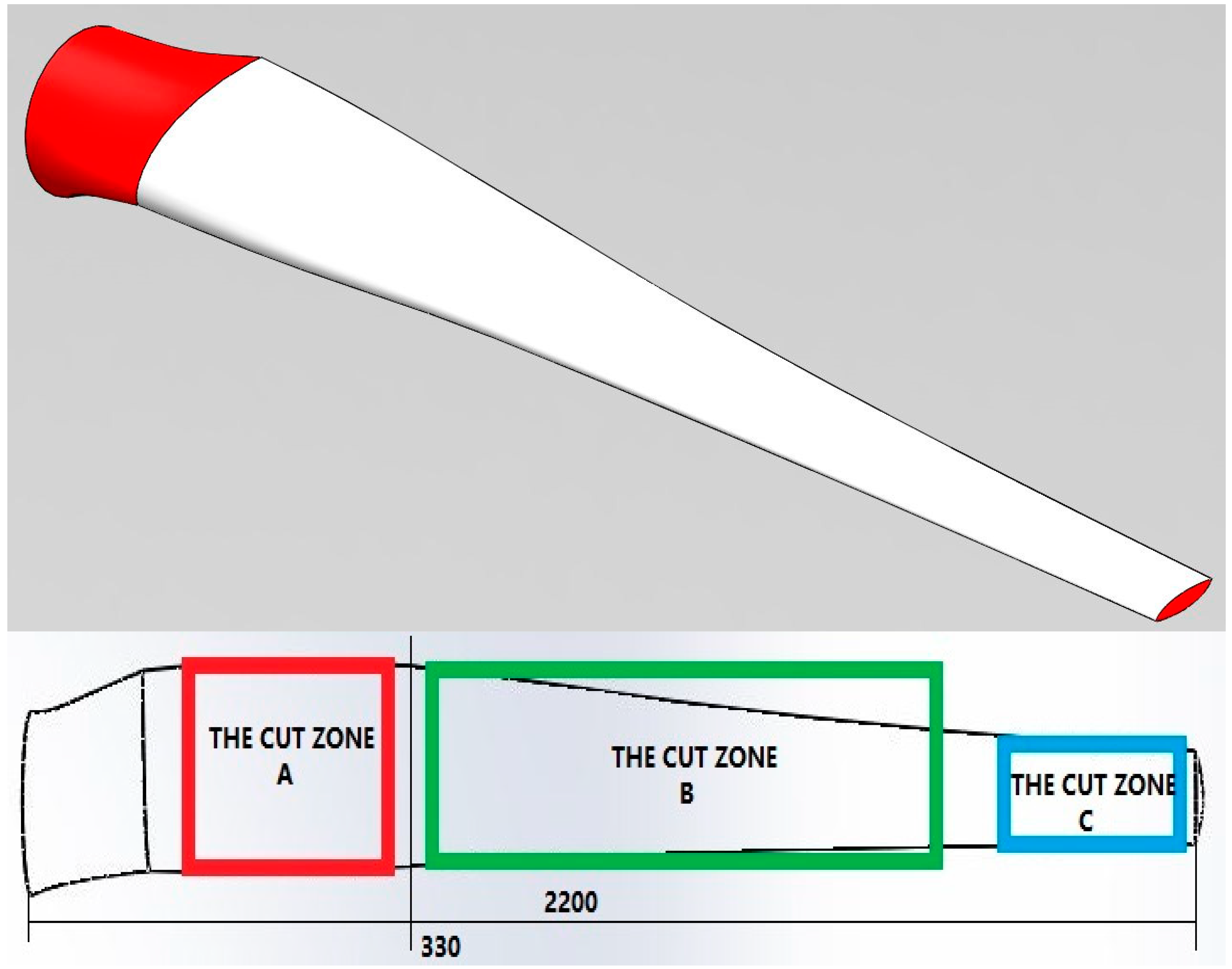

2.3. Wind Turbine Blade-Based Housing (WTB-bH)

- Safety process: The decommissioned blade was taken from the area via crane. The area around the blade was secured to prevent unauthorized access.

- Preparation process: The engineers evaluated the blade’s material composition (usually composite materials like fiberglass or carbon fiber, like in this study) and determined the best cutting approach. Additionally, the engineers developed a detailed cutting plan that specifies the cutting locations and the sequence of cuts.

- Cutting process: Engineers used diamond-coated blades for cutting, which were effective at cutting through fiberglass and carbon fiber without causing excessive heat or damage. At the same time, water jet cutters were used with high-pressure water jets.

- Handling process: After cutting, engineers carefully removed and transported the blade sections. These sections are often large and heavy, requiring cranes or other heavy machinery for safe handling.

- Bonding the cut sections: Engineers carefully aligned the two blade sections to ensure they matched perfectly. They used a high-strength adhesive, such as epoxy resins, that is compatible with the blade’s composite materials.

2.4. Economic Analysis of WTB-bH

- Project management costs;

- Labor costs;

- Cost of disassembly and reassembly for house construction;

- Cost of adhesive materials;

- Cost of cutting the blades;

- Transportation costs;

- VAT.

3. Results and Discussion

3.1. Comparison of Energy Consumptions

3.2. Comparison of the Cost

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Şevketoğlu, E. Management of pediatric emergencies during natural disasters: The 2023 earthquake in Turkey. Glob. Pediatr. 2024, 7, 100143. [Google Scholar] [CrossRef]

- Shinde, R.; Miyamoto, K.; Gilani, A. Field survey of buildings after Mw = 7.8 Turkey earthquake: Observations and remedial measures. In Proceedings of the World Conference on Earthquake Engineering (WCEE2024), Milan, Italy, 30 June–5 July 2024; Available online: https://www.researchgate.net/publication/381917764 (accessed on 24 January 2025).

- Çınaroğlu, M. Trauma, addiction, and the path to recovery after the Kahramanmaraş earthquakes. İstanbul Nişantaşı Üniversitesi Sosyal Bilimler Dergisi 2024, 12, 37–59. [Google Scholar] [CrossRef]

- Mavroulis, S.; Mavrouli, M.; Vassilakis, E.; Argyropoulos, I.; Carydis, P.; Lekkas, E. Debris management in Turkey provinces affected by the 6 February 2023 earthquakes: Challenges during recovery and potential health and environmental risks. Appl. Sci. 2023, 13, 8823. [Google Scholar] [CrossRef]

- Bilir, E.E.; Borman, P.; Ata, A.M.; Alemdaroğlu, E.; Bodur, H.; Yanık, B.; Yurdakul, F.; Kesikburun, B.; Güler, T.; Başkan, B.; et al. Clinical properties and rehabilitation needs of earthquake survivors in a subacute rehabilitation setting. Ulus. Travma Acil Cerrahi Derg. 2024, 30, 297–304. [Google Scholar] [CrossRef]

- Dinçer, A.E.; Dincer, N.N.; Tekin-Koru, A.; Yaşar, B.; Yılmaz, Z. The impact of Kahramanmaraş (2023) earthquakes: A comparative case study for Adıyaman and Malatya. Int. J. Disaster Risk Reduct. 2024, 110, 104647. [Google Scholar] [CrossRef]

- Ersoy, S. Evaluation of seismic behavior of the cultural heritage buildings in an ancient district of Antakya after the Kahramanmaraş earthquakes (Mw 7.7 and Mw 7.6). J. Build. Pathol. Rehabil. 2024, 9, 00392. [Google Scholar] [CrossRef]

- Balikuddembe, J.K.; Reinhardt, J.D.; Vahid, G.; Di, B. A scoping review of post-earthquake healthcare for vulnerable groups of the 2023 Turkey-Syria earthquakes. BMC Public Health 2024, 24, 945. [Google Scholar] [CrossRef]

- Ostachowicz, W.; McGugan, M.; Schröder-Hinrichs, J.-U.; Luczak, M. (Eds.) MARE-WINT: New Materials and Reliability in Offshore Wind Turbine Technology; Springer: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Liu, P.; Barlow, C.Y. Wind turbine blade waste in 2050. Waste Manag. 2017, 62, 229–240. [Google Scholar] [CrossRef]

- Nagle, A.J. Sustainability Assessment of the Repurposing of Wind Turbine Blades. Doctoral Thesis, University College Cork, Cork, Ireland, 2022. Available online: https://hdl.handle.net/10468/14976 (accessed on 20 January 2024).

- Saleh, Y.A.S.; Akkurt, G.G.; Turhan, C. Reconstructing energy-efficient buildings after a major earthquake in Hatay, Türkiye. Buildings 2024, 14, 2043. [Google Scholar] [CrossRef]

- Hasheminezhad, A.; Nazari, Z.; Yang, B.; Ceylan, H.; Kim, S. A comprehensive review of sustainable solutions for reusing wind turbine blade waste materials. J. Environ. Manag. 2024, 366, 121735. [Google Scholar] [CrossRef]

- Bank, L.C.; Arias, F.R.; Yazdanbakhsh, A.; Gentry, T.R.; Al-Haddad, T.; Chen, J.-F.; Morrow, R. Concepts for reusing composite materials from decommissioned wind turbine blades in affordable housing. Recycling 2018, 3, 3. [Google Scholar] [CrossRef]

- Delaney, E.L.; McKinley, J.M.; Megarry, W.; Graham, C.; Leahy, P.G.; Bank, L.C.; Gentry, R. An integrated geo-spatial approach for repurposing wind turbine blades. Resour. Conserv. Recycl. 2021, 170, 105601. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, Y.; Li, Y.; Wang, Y.; Li, G.; Liu, X. Wind turbine blade recycling: A review of the recovery and high-value utilization of decommissioned wind turbine blades. Resour. Conserv. Recycl. 2024, 210, 107813. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Hossain, M.; Umer, R. Recycling of wind turbine blades through modern recycling technologies: A road to zero waste. Renew. Energy Focus 2023, 44, 373–389. [Google Scholar] [CrossRef]

- Oliveira, P.S.; Antunes, M.L.P.; da Cruz, N.C.; Rangel, E.C.; de Azevedo, A.R.G.; Durrant, S.F. Use of waste collected from wind turbine blade production as an eco-friendly ingredient in mortars for civil construction. J. Clean. Prod. 2020, 274, 122948. [Google Scholar] [CrossRef]

- Zhang, W.; Yu, H.; Yin, B.; Akbar, A.; Liew, K.M. Sustainable transformation of end-of-life wind turbine blades: Advancing clean energy solutions in civil engineering through recycling and upcycling. J. Clean. Prod. 2023, 426, 139184. [Google Scholar] [CrossRef]

- Jensen, J.P.; Skelton, K. Wind turbine blade recycling: Experiences, challenges and possibilities in a circular economy. Renew. Sustain. Energy Rev. 2018, 97, 165–176. [Google Scholar] [CrossRef]

- Tyurkay, A.; Kirkelund, G.M.; Lima, A.T.M. State-of-the-art circular economy practices for end-of-life wind turbine blades for use in the construction industry. Sustain. Prod. Consum. 2024, 47, 17–36. [Google Scholar] [CrossRef]

- Dorigato, A. Recycling of thermosetting composites for wind blade application. Adv. Ind. Eng. Polym. Res. 2021, 4, 116–132. [Google Scholar] [CrossRef]

- Gentry, R.; Bank, L.; Chen, J.F.; Arias, F.; Al-Haddad, T. Adaptive reuse of FRP composite wind turbine blades for civil infrastructure construction. In Proceedings of the 9th International Conference on Fibre-Reinforced Polymer (FRP) Composites in Civil Engineering (CICE 2018), Paris, France, 17–19 July 2018; Available online: https://www.researchgate.net/publication/328610754 (accessed on 6 May 2024).

- André, A.; Kullberg, J.; Nygren, D.; Mattsson, C.; Nedev, G.; Haghani, R. Re-use of wind turbine blades for construction and infrastructure applications. IOP Conf. Ser. Mater. Sci. Eng. 2020, 942, 012015. [Google Scholar] [CrossRef]

- Martini, R.; Xydis, G. Repurposing and recycling wind turbine blades in the United States. Environ. Prog. Sustain. Energy 2022, 42, e13932. [Google Scholar] [CrossRef]

- Leahy, P.G. End-of-life options for composite material wind turbine blades: Recover, repurpose or reuse? In Proceedings of the 14th SDEWES Conference, Dubrovnik, Crotia, 1–6 October 2019. [Google Scholar]

- Mishnaevsky, L., Jr. Sustainable end-of-life management of wind turbine blades: Overview of current and coming solutions. Materials 2021, 14, 1124. [Google Scholar] [CrossRef] [PubMed]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World Map of the Köppen-Geiger climate classification updated. Meteorologische Zeitschrift 2006, 15, 259–263. [Google Scholar] [CrossRef]

- Climate Transparency. Turkey Country Profile 2022. Available online: https://www.climate-transparency.org/wp-content/uploads/2022/10/CT2022-Turkey-Web.pdf (accessed on 2 September 2024).

- DesignBuilder, v.7.0.2.006. Available online: http://www.designbuilder.co.uk/ (accessed on 2 September 2024).

- Onset Computer Corporation. HOBO MX2305 Series Weatherproof Data Loggers. Available online: https://www.onsetcomp.com/ (accessed on 24 September 2024).

- Răut, I.; Călin, M.; Vuluga, Z.; Oancea, F.; Paceagiu, J.; Radu, N.; Doni, M.; Alexandrescu, E.; Purcar, V.; Gurban, A.-M.; et al. Fungal-based biopolymer composites for construction materials. Materials 2021, 14, 2906. [Google Scholar] [CrossRef] [PubMed]

- ASHRAE. ASHRAE Guideline 14-2014: Measurement of Energy, Demand, and Water Savings; American Society of Heating, Refrigerating, and Air-Conditioning Engineers: Atlanta, GA, USA, 2014; Available online: https://www.ashrae.org (accessed on 11 May 2024).

| Thickness (m) | U Value (W/m2K) | |

|---|---|---|

| Walls | ||

| Steel and Aluminum Mixture | 0.04 | 0.46 |

| Roof | ||

| Steel and Aluminum Mixture | 0.10 | 0.26 |

| Ground | ||

| Steel and Aluminum Mixture | 0.20 | 1.24 |

| Model Code: E44-900 | |

|---|---|

| Rated Power | 0.9 MW |

| Cut-in wind speed | 3 m/s |

| Rated wind speed | 16.5 m/s |

| Cut-out wind speed | 34 m/s |

| Survival wind speed | 59.5 m/s |

| Rotor diameter | 44 m |

| Swept area | 1.52 m2 |

| Number of blades | 3 |

| Power density | 591.7 W/m2 |

| Tip speed | 78 m/s |

| Component Name | Layers | Average Thicknesses (m) | Thermal Conductivity (W/mK) | U Value (W/m2K) |

|---|---|---|---|---|

| Wall | Composite material mixture (GFK) | 0.18 | 0.04 | |

| Air gap | 0.17 | 0.02 | ||

| Composite material mixture (GFK) | 0.18 | 0.04 | ||

| 0.021 | ||||

| Roof | Composite material mixture (GFK) | 0.18 | 0.04 | |

| Air gap | 0.17 | 0.02 | ||

| Composite material mixture (GFK) | 0.18 | 0.04 | ||

| 0.021 | ||||

| Ground | Carpet/textile flooring | 0.015 | 0.06 | |

| Composite material mixture (GFK) | 0.18 | 0.04 | ||

| 0.22 |

| Total Energy Consumption (kWh) * | |

|---|---|

| Traditional Container | 217,690.2 (345.54 kWh/m2) |

| WTB-bH | 158,256 (251.2 kWh/m2) |

| Costs (USD) * | |

|---|---|

| Traditional Container | 370,261.53 |

| WTB-bH | 444,318.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turhan, C.; Durak, M.; Saleh, Y.A.S.; Kalaycı, A. Recycling Decommissioned Wind Turbine Blades for Post-Disaster Housing Applications. Recycling 2025, 10, 42. https://doi.org/10.3390/recycling10020042

Turhan C, Durak M, Saleh YAS, Kalaycı A. Recycling Decommissioned Wind Turbine Blades for Post-Disaster Housing Applications. Recycling. 2025; 10(2):42. https://doi.org/10.3390/recycling10020042

Chicago/Turabian StyleTurhan, Cihan, Murat Durak, Yousif Abed Saleh Saleh, and Alper Kalaycı. 2025. "Recycling Decommissioned Wind Turbine Blades for Post-Disaster Housing Applications" Recycling 10, no. 2: 42. https://doi.org/10.3390/recycling10020042

APA StyleTurhan, C., Durak, M., Saleh, Y. A. S., & Kalaycı, A. (2025). Recycling Decommissioned Wind Turbine Blades for Post-Disaster Housing Applications. Recycling, 10(2), 42. https://doi.org/10.3390/recycling10020042