Recycling of Post-Consumer Polystyrene Packaging Waste into New Food Packaging Applications—Part 3: Initial Contamination Levels in Washed Flakes from Europe

Abstract

1. Introduction

- Contaminants from possible misuse of the PET containers to store chemicals;

- Contaminants from non-food contact PET applications (e.g., non-authorized monomers and additives, or chemicals from non-food consumer products);

- Chemicals from materials other than PET (e.g., PVC, polyolefins, glues, caps, sleeves, labels, polyamides);

- Chemicals used in the recycling process (e.g., detergents);

- Degradation products during recycling;

- Components from packaged food.

2. Results

2.1. Study Design

2.2. Contamination Levels in rPS Flakes

2.3. Quantification of Substances in Conventionally Recycled PS

3. Discussion

3.1. Comparison Between PET Bottles and PS Pots/Trays

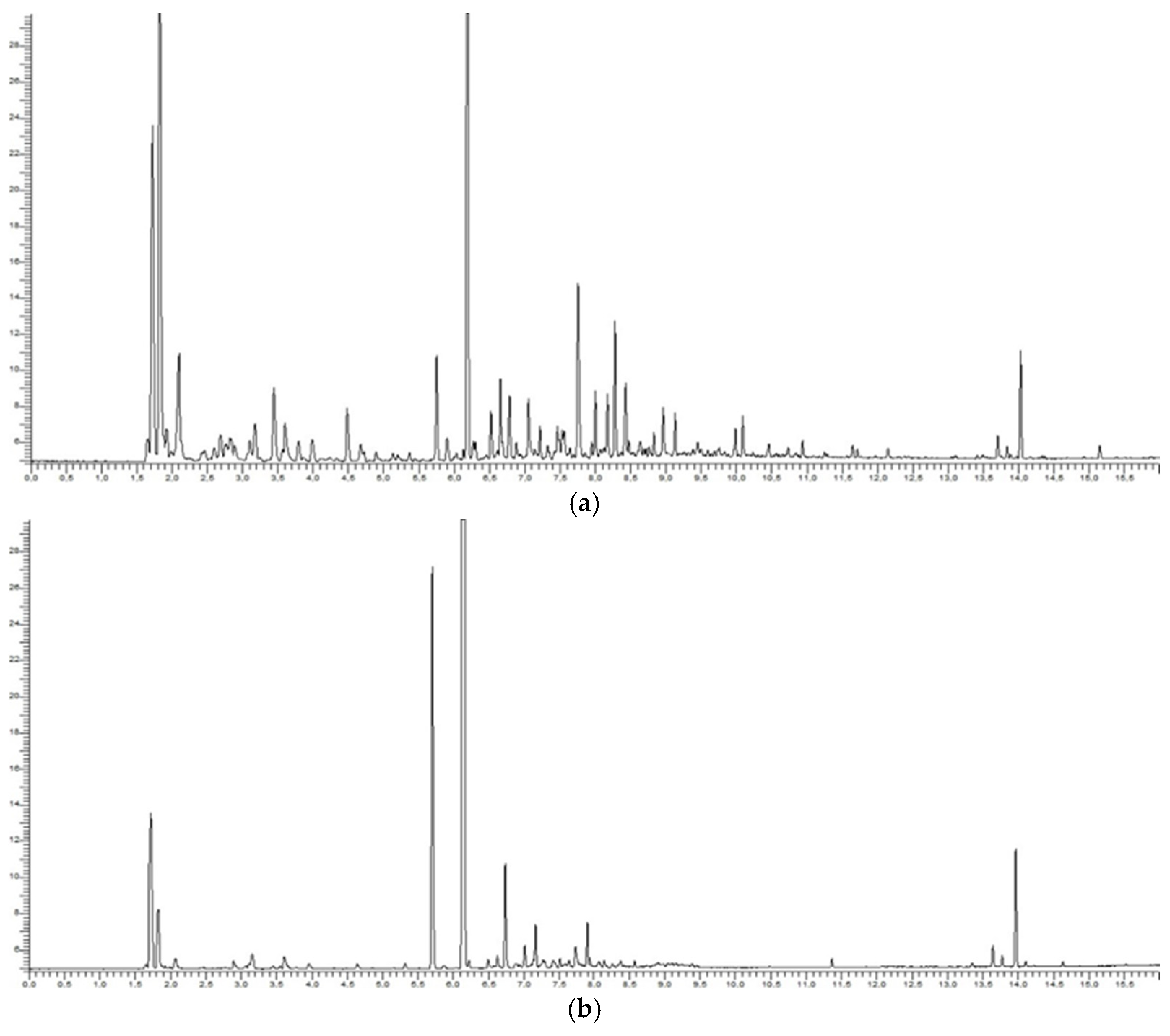

3.2. Regional and Seasonal Influences on the “Chromatographic Fingerprints”

3.3. Evaluation of the Initial Contamination Levels

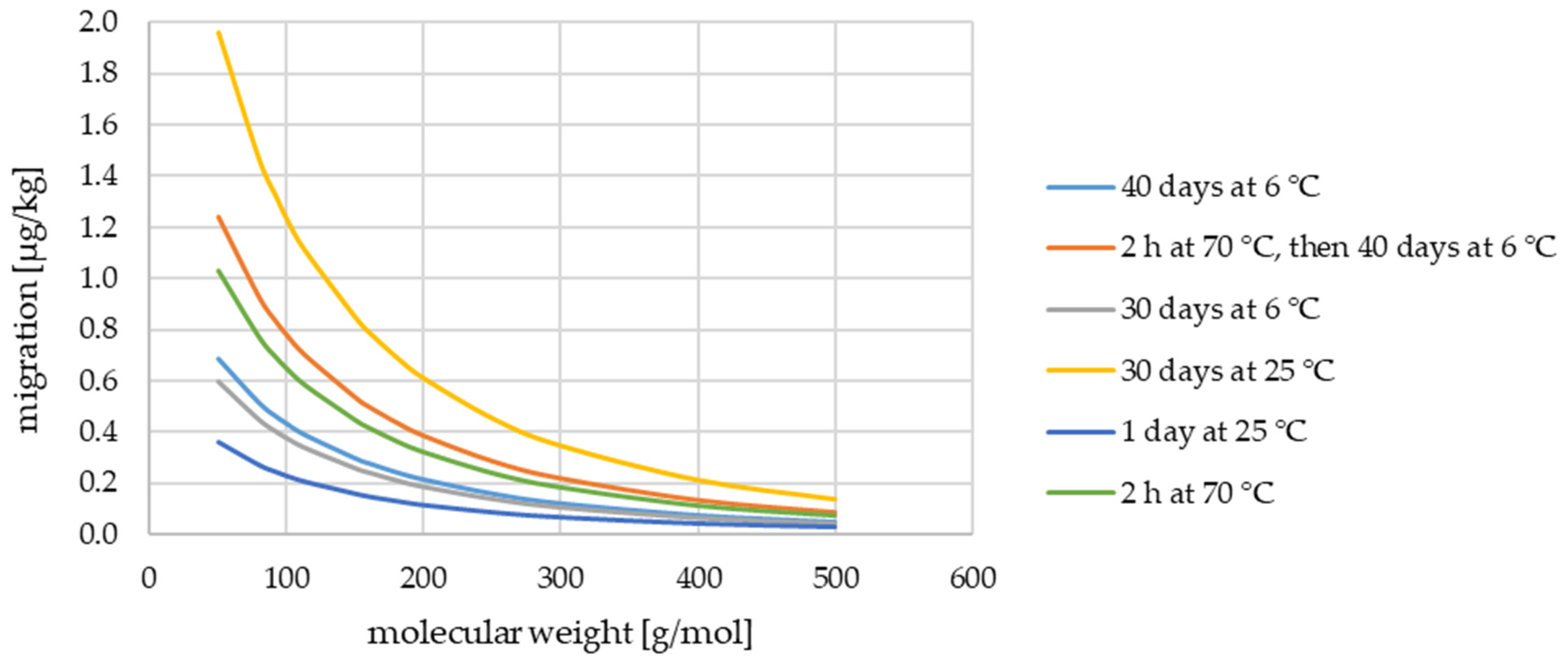

3.4. Molecular Weight Range Relevant for Migration

- Pots for cold-filled yogurt with storage conditions of 40 days at 6 °C;

- Pots for hot-filled yogurt with storage conditions of 2 h at 70 °C followed by storage for 40 days at 6 °C;

- Trays for meat, fish and cheese with storage conditions of 30 days at 6 °C;

- Trays for fruit and vegetables with storage conditions of 30 days at 25 °C;

- Pots for cold drinks with storage conditions of 1 day at 25 °C;

- Pots for hot drinks with storage conditions of 2 h at 70 °C.

4. Materials and Methods

4.1. Sample Materials

- Belgium 2 samples;

- France 10 samples;

- Germany 15 samples;

- Italy 2 samples

- Sweden 7 samples;

- Switzerland 13 samples.

4.2. Sampling for Screening

4.3. Screening of rPS Flakes for Volatile Substancess

4.4. Diffusion Modelling

5. Conclusions

- The applied non-target screening method is well suited for the assessment of post-consumer PS recyclates;

- The gas chromatographic fingerprints of the investigated post-consumer PS flake samples are similar, which shows that the collection of the PS input (in different countries and at different times of the year) as well as the conventional recycling is very homogeneous;

- The majority of the detected substance peaks were found in (nearly) all post-consumer PS samples and most of them also in virgin PS. All detected substances were semi-quantified using limonene as multi-analyte standard. The 30 substances with the highest concentrations were identified;

- Most of the PS untypical substance peaks are related to oxidation, degradation or cross contaminants from polyolefins. Substance peaks related to misuse for PS pots and trays with chemicals or solvents in high concentrations were found only in one sample. The incidence of misuse is therefore 0.0097%.

- The maximum concentration of substances from misuse, from non-food PS, cross-contamination from other packaging materials such as polyolefins, degradation products and components from packed food in post-consumer rPS is 0.069 mg/kg. Assuming worst-case contamination levels of 6750 mg/kg as found in PET [29] the initial concentration is 0.65 mg/kg.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Block, C.; Brands, B.; Gude, T. Packaging Materials 2: Polystyrene for Food Packaging Applications, Updated Version; ILSI Europe Report Series; ILSI Europe: Bruxelles, Belgium, 2017; pp. 1–36, Commissioned by the Packaging Materials Task Force; Available online: https://ilsi.eu/publication/packaging-materials-2-polystyrene-for-food-packaging-applications-updated-version/ (accessed on 7 February 2025).

- Begley, T.H.; McNeal, T.P.; Biles, J.E.; Pacquette, K.E. Evaluating the potential for recycling all PET bottles into new food packaging. Food Addit. Contam. 2002, 19, 135–143. [Google Scholar] [CrossRef]

- Franz, R. Programme on the recyclability of food-packaging materials with respect to food safety considerations—Polyethylene terephthalate (PET), paper & board and plastics covered by functional barriers. Food Addit. Contam. 2002, 19, 93–110. [Google Scholar] [CrossRef] [PubMed]

- Bayer, F.L. Polyethylene terephthalate recycling for food-contact applications: Testing, safety and technologies: A global perspective. Food Addit. Contam. 2002, 19, 111–134. [Google Scholar] [CrossRef] [PubMed]

- Benyathiar, P.; Kumar, P.; Carpenter, G.; Brace, J.; Mishra, D.K. Polyethylene terephthalate (PET) bottle-to-bottle recycling for the beverage industry: A review. Polymers 2022, 14, 2366. [Google Scholar] [CrossRef] [PubMed]

- Brouwer, M.T.; Chacon, F.A.; Thoden van Velzen, E.U. Effect of recycled content and rPET quality on the properties of PET bottles, part III: Modelling of repetitive recycling. Packag. Technol. Sci. 2020, 33, 373–383. [Google Scholar] [CrossRef]

- Bayer, F.L.; Jetten, J. Safety assessment of refillable and recycled plastics packaging for food use. In Tittle of the Present Knowledge in Food Safety—A Risk-Based Approach Through the Food Chain; Knowles, M.E., Anelich, L.E., Boobis, A.R., Popping, B., Eds.; Academic Press: Cambridge, MA, USA, 2022; Volume 15, pp. 240–259. ISBN 978-0-12-819470-6. [Google Scholar] [CrossRef]

- The European Commission. Regulation No 2022/1616 of 15 September 2022 on Recycled Plastic Materials and Articles Intended to Come into Contact with Foods, and Repealing Regulation (EC) No 282/2008. Off. J. Eur. Union 2022, L243/3. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32022R1616 (accessed on 16 March 2024).

- Welle, F. Recycling of post-consumer polystyrene packaging waste into new food packaging applications—Part 1: Direct food contact. Recycling 2023, 8, 26. [Google Scholar] [CrossRef]

- Feigenbaum, A.; Dole, P.; Aucejo, A.; Dainelli, D.; de la Cruz Garcia, C.; Hankemeier, T.; Ngono, Y.; Papaspyrides, C.G.; Paseiro, P.; Pastorelli, S.; et al. Functional barriers: Properties and evaluation. Food Addit. Contam. 2005, 22, 956–967. [Google Scholar] [CrossRef]

- Dole, P.; Feigenbaum, A.E.; de la Cruz, C.; Pastorelli, S.; Paseiro, P.; Hankemeier, T.; Voulzatis, Y.; Aucejo, S.; Saillard, P.; Papaspyrides, C. Typical diffusion behaviour in packaging polymers–application to functional barriers. Food Addit. Contam. Part A 2006, 23, 202–211. [Google Scholar] [CrossRef]

- Genualdi, S.; Addo Ntim, S.; Begley, T. Suitability of polystyrene as a functional barrier layer in coloured food contact materials. Food Addit. Contam. Part A 2015, 32, 395–402. [Google Scholar] [CrossRef]

- Welle, F. Recycling of post-consumer polystyrene packaging waste into new food packaging applications—Part 2: Co-extruded functional barriers. Recycling 2023, 8, 39. [Google Scholar] [CrossRef]

- The European Commission. Regulation No 1935/2004 of the European Parliament and of the Council of 27 October 2004 on Materials and Articles Intended to Come into Contact with Food and Repealing Directives 80/590/EEC and 89/109/EEC. Off. J. Eur. Union 2004, L338/4. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2004:338:0004:0017:en:PDF (accessed on 16 March 2024).

- The European Commission. Regulation No 10/2011 of 14 January 2011 on Plastic Materials and Articles Intended to Come into Contact with Food. Off. J. Eur. Union 2011, L12/1. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32011R0010&from=EN (accessed on 16 March 2024).

- US FDA Database on Post-Consumer Recycled (PCR) Plastics for Food-Contact Articles. Available online: https://www.cfsanappsexternal.fda.gov/scripts/fdcc/?set=RecycledPlastics (accessed on 21 February 2025).

- Use of Recycled Plastics in Food Packaging (Chemistry Considerations): Guidance for Industry. 2021. Available online: https://www.fda.gov/media/150792/download (accessed on 21 February 2025).

- Vilaplana, F.; Ribes-Greus, A.; Karlsson, S. Analytical strategies for the quality assessment of recycled high-impact polystyrene: A combination of thermal analysis, vibrational spectroscopy and chromatography. Anal. Chim. Acta 2007, 604, 18–28. [Google Scholar] [CrossRef]

- Vilaplana, F.; Ribes-Greus, A.; Karlsson, S. Chromatographic pattern in recycled high-impact polystyrene (HIPS)–Occurrence of low molecular weight compounds during the life cycle. Polym. Degrad. Stabil. 2010, 95, 172–186. [Google Scholar] [CrossRef]

- Vilaplana, F.; Martinez-Sanz, M.; Ribes-Greus, A.; Karlsson, S. Emission pattern of semi-volatile organic compounds from recycled styrenic polymers using headspace solid-phase microextraction gas chromatography-mass spectrometry. J. Chromatogr. A 2010, 1217, 359–367. [Google Scholar] [CrossRef]

- Lin, Q.-B.; Song, X.-C.; Fang, H.; Wu, Y.-M.; Wang, Z.-W. Migration of styrene and ethylbenzene from virgin and recycled expanded polystyrene containers and discrimination of these two kinds of polystyrene by principal component analysis. Food Addit. Contam. Part A 2017, 34, 126–132. [Google Scholar] [CrossRef] [PubMed]

- Song, X.-C.; Lin, Q.-B.; Chen, C.-F.; Chen, J.-H.; Hu, C.-Y. Discrimination between virgin and recycled polystyrene containers by Fourier transform infrared spectroscopy and principal component analysis. Packag. Technol. Sci. 2018, 31, 567–572. [Google Scholar] [CrossRef]

- Song, X.-C.; Wrona, M.; Nerin, C.; Lin, Q.-B.; Zhong, H.-N. Volatile non-intentionally added substances (NIAS) identified in recycled expanded polystyrene containers and their migration into food simulants. Food Packag. Shelf Life 2019, 20, 100318. [Google Scholar] [CrossRef]

- Huber, M.; Franz, R. Studies on contamination of post consumer plastics from controlled resources for recycling into food packaging applications. Dtsch. Lebensm.-Rundsch. 1997, 93, 328–331. [Google Scholar]

- EFSA CEF Panel (EFSA Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids). Scientific Opinion on the criteria to be used for safety evaluation of a mechanical recycling process to produce recycled PET intended to be used for manufacture of materials and articles in contact with food. EFSA J. 2011, 9, 2184. [Google Scholar] [CrossRef]

- Barthelemy, E.; Spyropoulos, D.; Milana, M.-R.; Pfaff, K.; Gontard, N.; Lampi, E.; Castle, L. Safety evaluation of mechanical recycling processes used to produce polyethylene terephthalate (PET) intended for food contact applications. Food Addit. Contam. Part A 2014, 31, 490–497. [Google Scholar] [CrossRef] [PubMed]

- EFSA CEF Panel (EFSA Panel on Food Contact Materials, Enzymes and Processing Aids). Scientific Guidance on the criteria for the evaluation and on the preparation of applications for the safety assessment of post-consumer mechanical PET recycling processes intended to be used for manufacture of materials and articles in contact with food. EFSA J. 2024, 22, e8879. [Google Scholar] [CrossRef]

- Register Open EFSA. Available online: https://www.efsa.europa.eu/en/register-of-questions (accessed on 16 March 2024).

- Franz, R.; Mauer, A.; Welle, F. European survey on post-consumer poly(ethylene terephthalate) materials to determine contamination levels and maximum consumer exposure from food packages made from recycled PET. Food Addit. Contam. 2004, 21, 265–286. [Google Scholar] [CrossRef] [PubMed]

- European Union. Practical Guidelines on the Application of Migration Modelling for the Estimation of Specific Migration; EU Report 27529 EN; Publications Office of the European Union: Luxembourg, 2015; ISBN 978-92-79-52790-6. Available online: https://op.europa.eu/de/publication-detail/-/publication/1b79bc61-97f6-11e5-983e-01aa75ed71a1 (accessed on 16 March 2024).

- Begley, T.; Castle, L.; Feigenbaum, A.; Franz, R.; Hinrichs, K.; Lickly, T.; Mercea, P.; Milana, M.; O’Brian, A.; Rebre, S.; et al. Evaluation of migration models that might be used in support of regulations for food-contact plastics. Food Addit. Contam. 2005, 22, 73–90. [Google Scholar] [CrossRef]

- Welle, F. Diffusion coefficients and activation energies of diffusion of organic molecules in polystyrene below and above glass transition temperature. Polymers 2021, 13, 1317. [Google Scholar] [CrossRef]

- Roduit, B.; Borgeat, C.H.; Cavin, S.; Fragniere, C.; Dudler, V. Application of finite element analysis (FEA) for the simulation of release of additives from multilayer polymeric packaging structures. Food Addit. Contam. Part A 2005, 22, 945–955. [Google Scholar] [CrossRef]

| Retention Time [min] | Substance | Mean Concentration [mg/kg] | Highest Concentration [mg/kg] | Median [mg/kg] | Frequency in the Samples |

|---|---|---|---|---|---|

| 6.13 | styrene | 110.4 ± 31.7 | 353.0 | 109.8 | 100% |

| 1.72 | propene | 29.1 ± 10.8 | 200.6 | 28.3 | 100% |

| 1.88 | n-pentane | 42.4 ± 76.3 | 178.9 | 8.4 | 2% |

| 1.83 | ethoxyethene | 51.5 ± 12.3 | 135.1 | 50.0 | 100% |

| 8.22 | limonene | 7.0 ± 6.9 | 99.0 | 6.6 | 98% |

| 5.70 | ethylbenzene | 15.6 ± 7.0 | 46.1 | 15.5 | 99% |

| 2.67 | cyclohexane | 5.5 ± 4.3 | 31.3 | 4.2 | 88% |

| 2.12 | iso-butene | 14.9 ± 4.0 | 28.1 | 14.1 | 99% |

| 2.74 | n-heptane | 3.3 ± 2.2 | 20.6 | 2.5 | 27% |

| 6.73 | iso-propylbenzene | 5.6 ± 1.8 | 20.4 | 5.4 | 100% |

| 2.21 | n-hexane | 8.8 ± 7.1 | 19.7 | 5.2 | 2% |

| 8.12 | 1-methyl-4-(1-methyl ethyl)-cyclohexene | 5.0 ± 4.3 | 17.5 | 3.4 | 84% |

| 7.52 | α- and β-pinene | 16.9 | 16.9 | 16.9 | 0.3% |

| 7.70 | branched alkane | 11.8 ± 1.7 | 16.7 | 11.7 | 99% |

| 10.03 | n-dodecane | 2.7 ± 2.4 | 15.6 | 2.1 | 11% |

| 7.00 | benzaldehyde | 5.9 ± 1.6 | 14.6 | 5.5 | 100% |

| 7.94 | n-decane | 3.0 ± 1.7 | 14.0 | 2.6 | 20% |

| 4.45 | hexanal | 4.5 ± 2.4 | 12.8 | 3.6 | 58% |

| 5.84 | 1,2-dimethylbenzene | 2.8 ± 1.1 | 11.8 | 2.6 | 44% |

| 7.15 | n-propylbenzene | 3.0 ± 1.5 | 11.8 | 2.5 | 53% |

| 3.42 | dimethylfurane | 7.4 ± 1.5 | 10.8 | 7.5 | 99% |

| 8.37 | acetophenone | 5.2 ± 1.3 | 10.4 | 5.0 | 99% |

| 7.48 | α-methylstyrene | 4.3 ± 1.9 | 9.7 | 3.7 | 56% |

| 3.95 | 1-octene | 2.9 ± 1.0 | 9.3 | 2.6 | 90% |

| 6.23 | 1,4-dimethylbenzene | 3.0 ± 1.1 | 9.3 | 2.6 | 59% |

| 2.83 | 2-methyltetrahydrofurane | 4.3 ± 1.6 | 8.9 | 4.4 | 97% |

| 2.57 | 2-butanol | 4.0 ± 1.5 | 8.9 | 3.3 | 26% |

| 2.41 | 2-butanone | 3.9 ± 2.1 | 8.7 | 3.3 | 2% |

| 8.90 | 2-nonanone | 3.3 ± 1.4 | 8.2 | 2.8 | 57% |

| 1.93 | tert-butanol | 2.9 ± 0.9 | 8.1 | 2.7 | 63% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guazzotti, V.; Welle, F. Recycling of Post-Consumer Polystyrene Packaging Waste into New Food Packaging Applications—Part 3: Initial Contamination Levels in Washed Flakes from Europe. Recycling 2025, 10, 37. https://doi.org/10.3390/recycling10020037

Guazzotti V, Welle F. Recycling of Post-Consumer Polystyrene Packaging Waste into New Food Packaging Applications—Part 3: Initial Contamination Levels in Washed Flakes from Europe. Recycling. 2025; 10(2):37. https://doi.org/10.3390/recycling10020037

Chicago/Turabian StyleGuazzotti, Valeria, and Frank Welle. 2025. "Recycling of Post-Consumer Polystyrene Packaging Waste into New Food Packaging Applications—Part 3: Initial Contamination Levels in Washed Flakes from Europe" Recycling 10, no. 2: 37. https://doi.org/10.3390/recycling10020037

APA StyleGuazzotti, V., & Welle, F. (2025). Recycling of Post-Consumer Polystyrene Packaging Waste into New Food Packaging Applications—Part 3: Initial Contamination Levels in Washed Flakes from Europe. Recycling, 10(2), 37. https://doi.org/10.3390/recycling10020037