Supply Chain (Re)Design and Pricing for Biomass Ash Valorization as Supplementary Cementitious Materials

Abstract

1. Introduction

2. Literature Review

2.1. Optimization Models for Supply Chains of Cement, Concrete, and SCMs

2.2. Bilevel Optimization of Biomass Supply Chain

2.3. Contributions

3. Methods

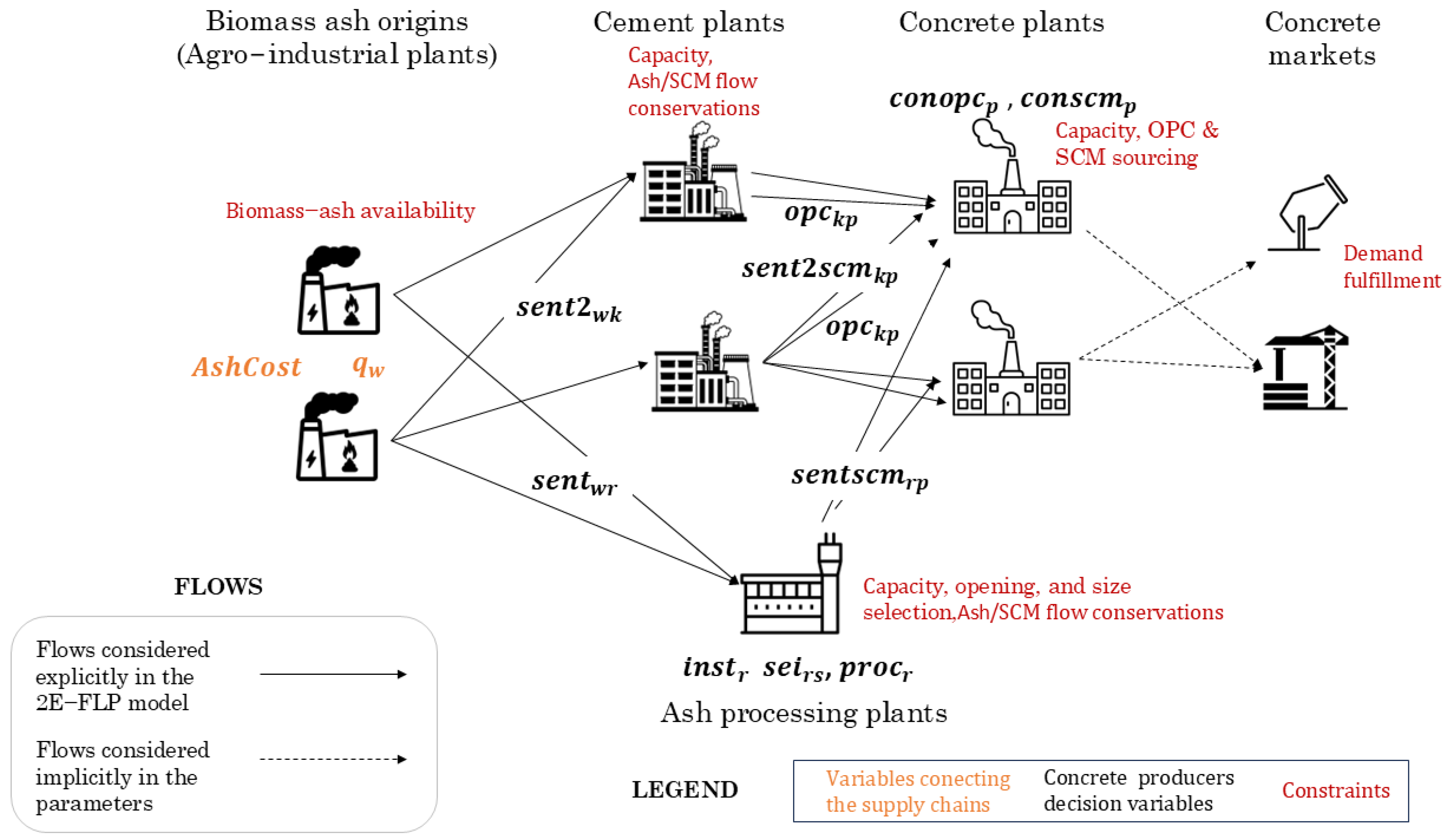

3.1. Biomass Ash-to-Concrete Supply Chain

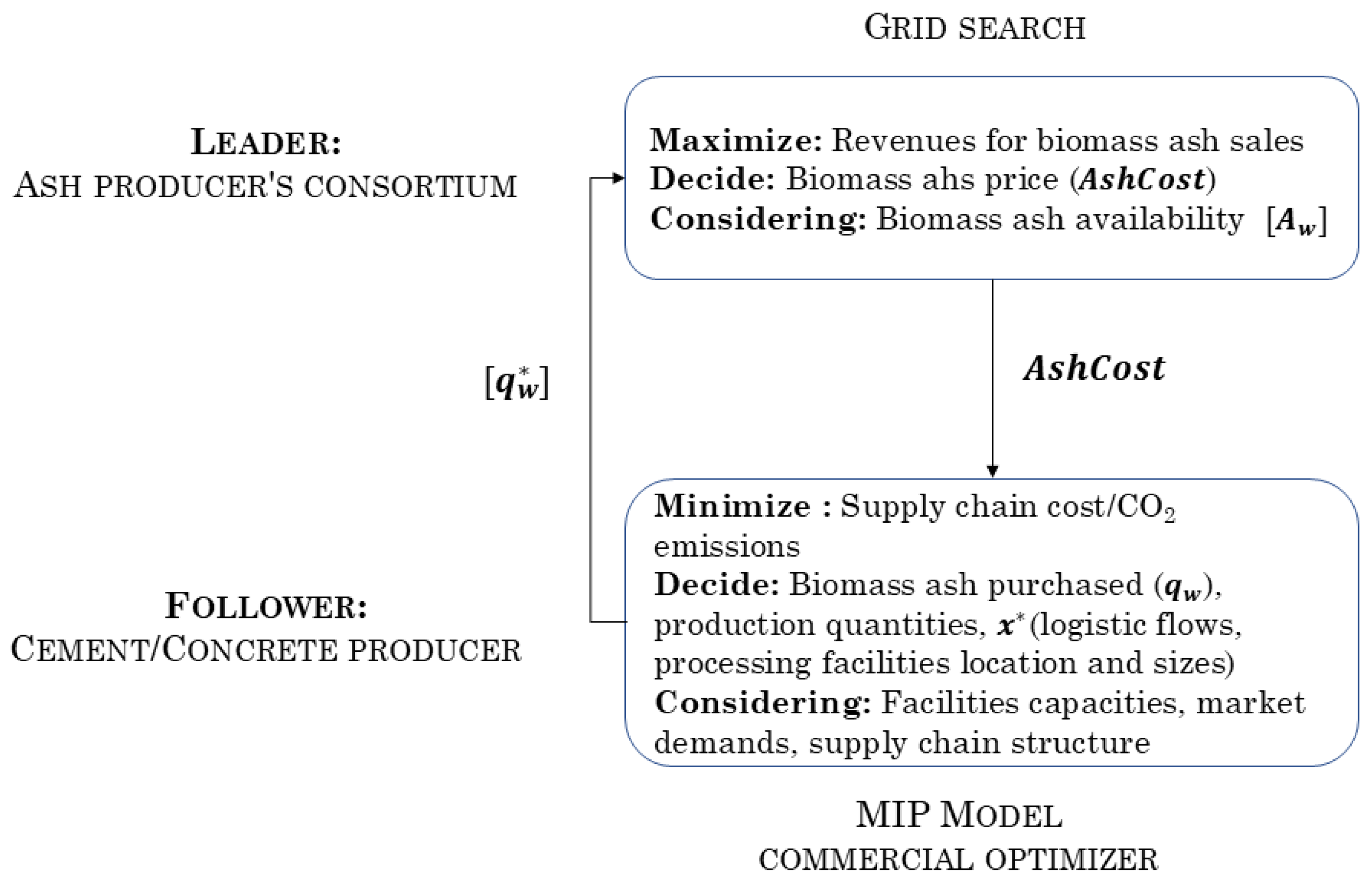

3.2. Bilevel Approach for the Ash Pricing Problem and Supply Chain Design

3.3. Unidimensional Grid Search Algorithm for the Solution to the Pricing Problem

| Algorithm 1. Unidimensional search for the solution to the pricing problem for the consortium of biomass ash producers | |

| 1. | Input: 2E-FLP data, |

| 2. | Output:, |

| 3. | , flagtrue |

| 4. | |

| 5. | While (flag) do |

| 6. | . |

| 7. | |

| 8. | ) then |

| 9. | |

| 10. | |

| 11. | |

| 12. | End-if |

| 13. | If then |

| 14. | flag false |

| 15. | |

| 16. | End-if |

| 17. | |

| 18. | |

| 19. | End-While |

| 20. | Return: |

3.4. Two-Echelon Facility Location Model (2E-FLP)

4. Case Study

4.1. Scenarios

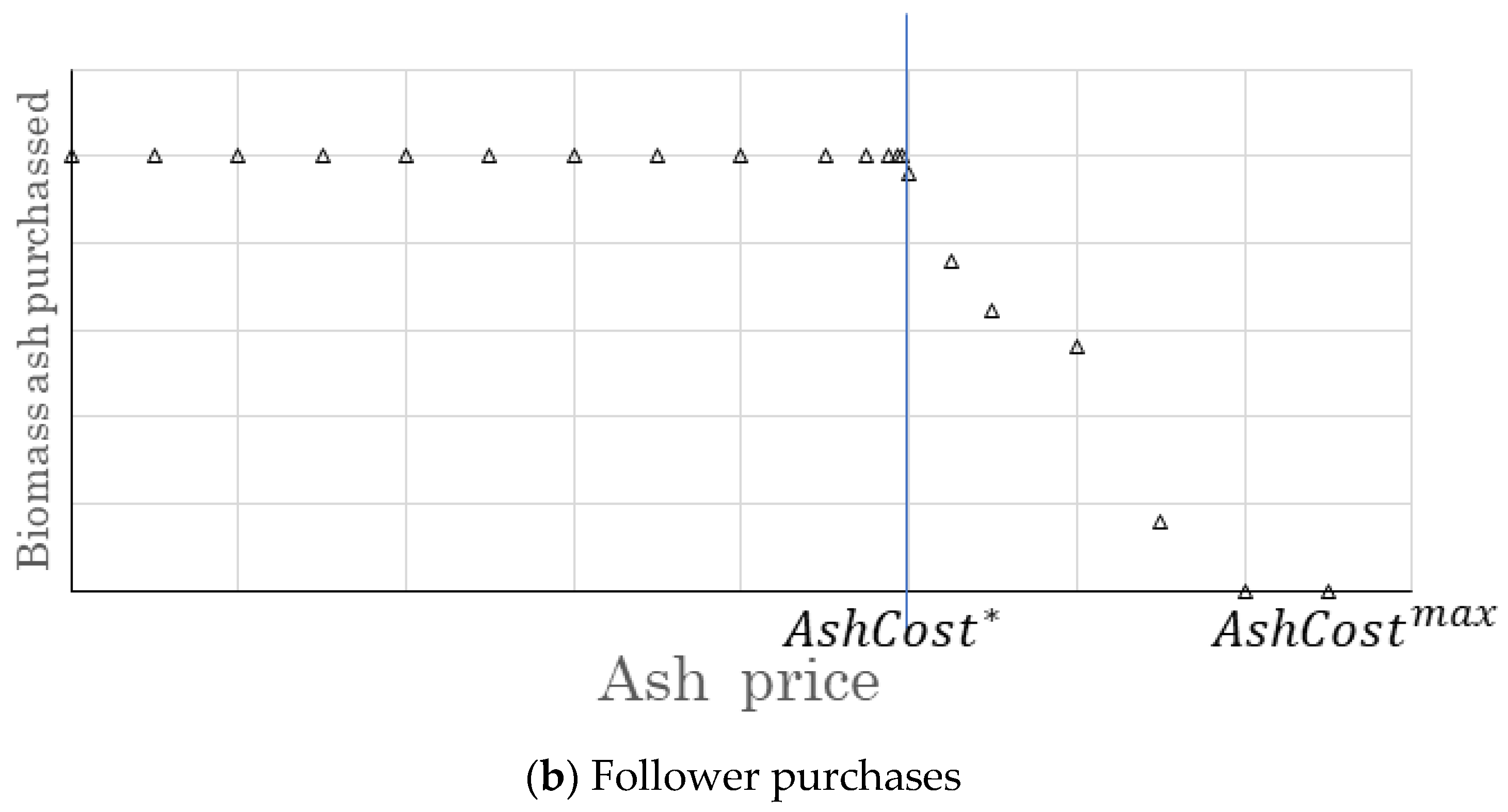

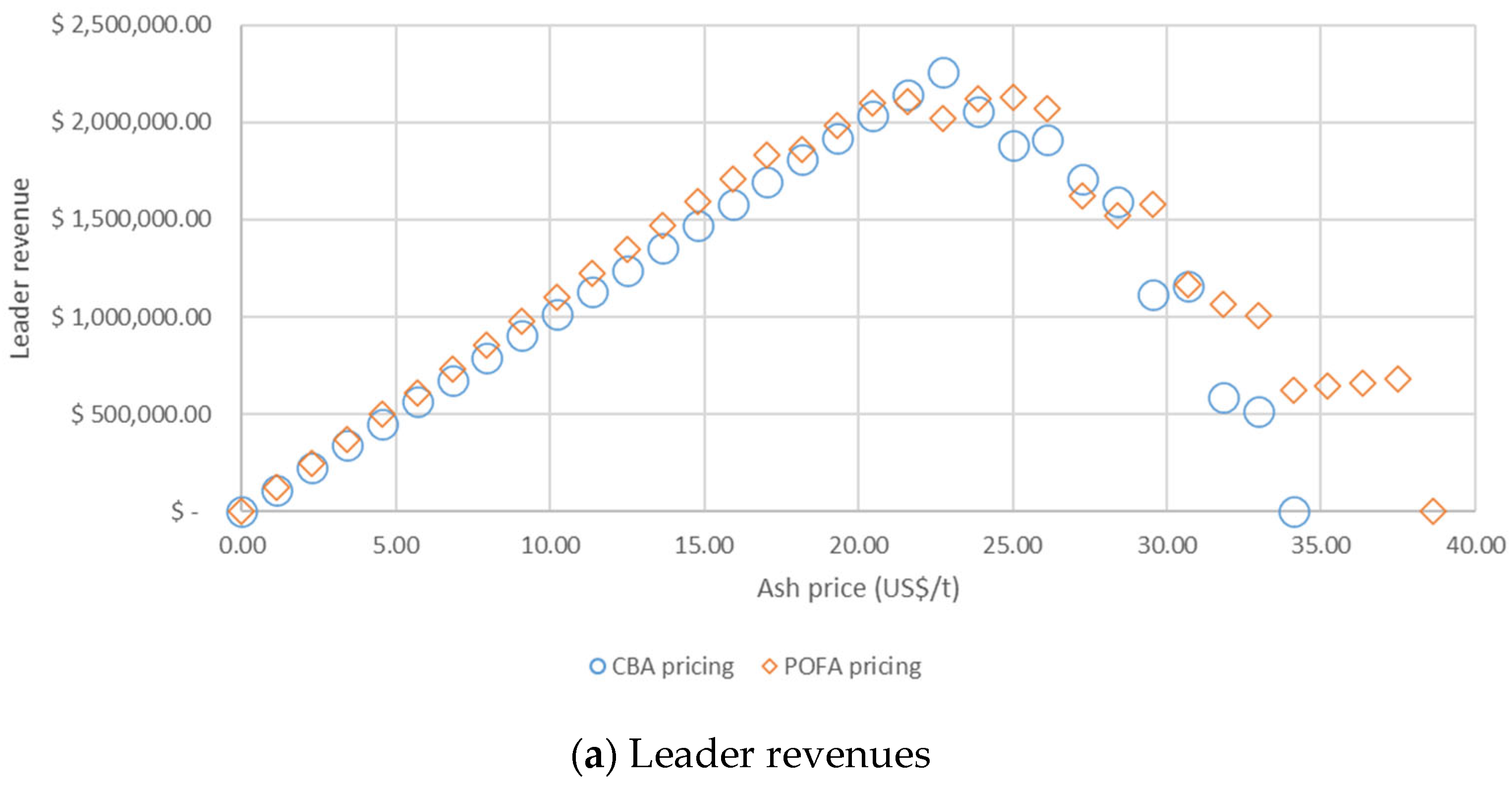

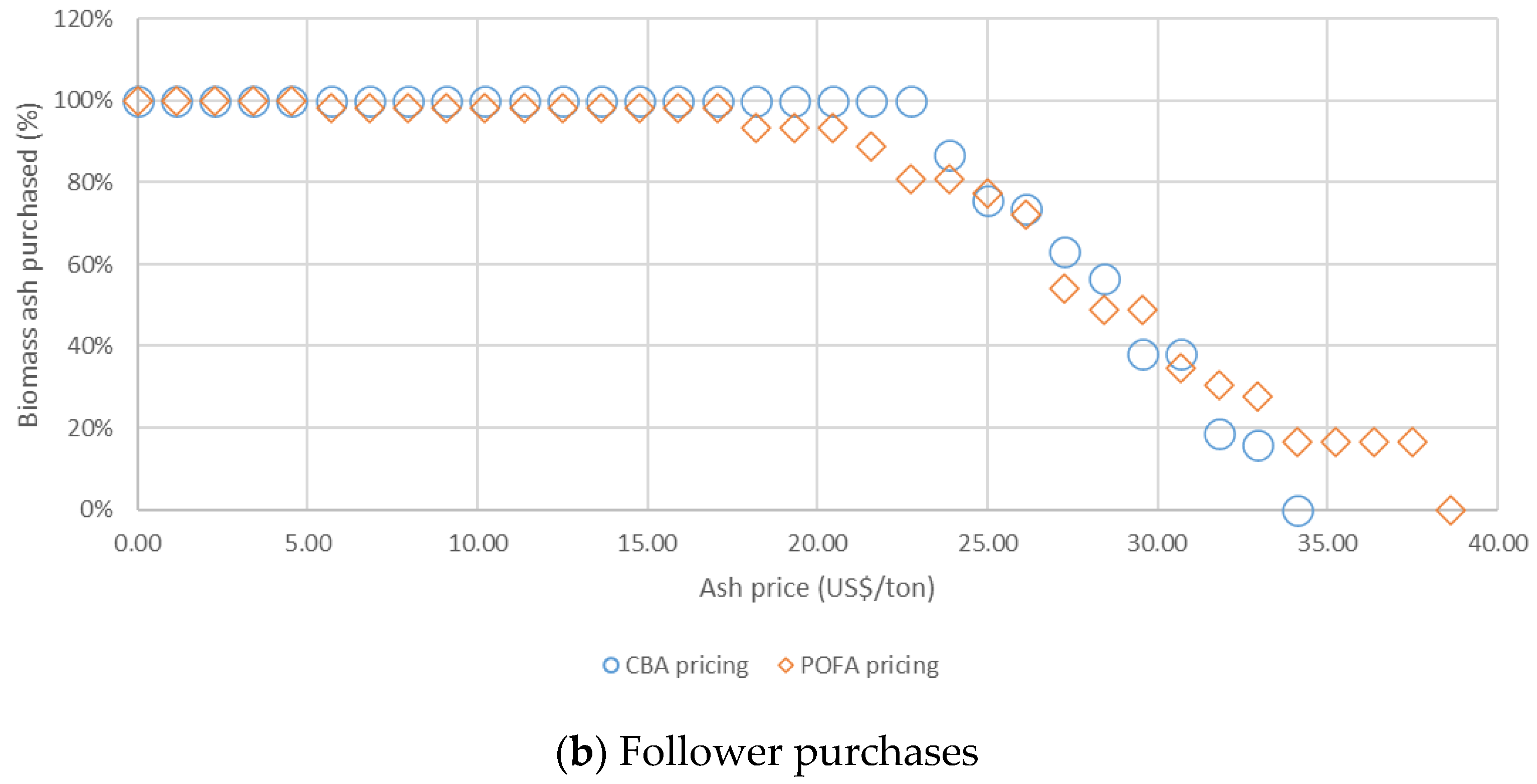

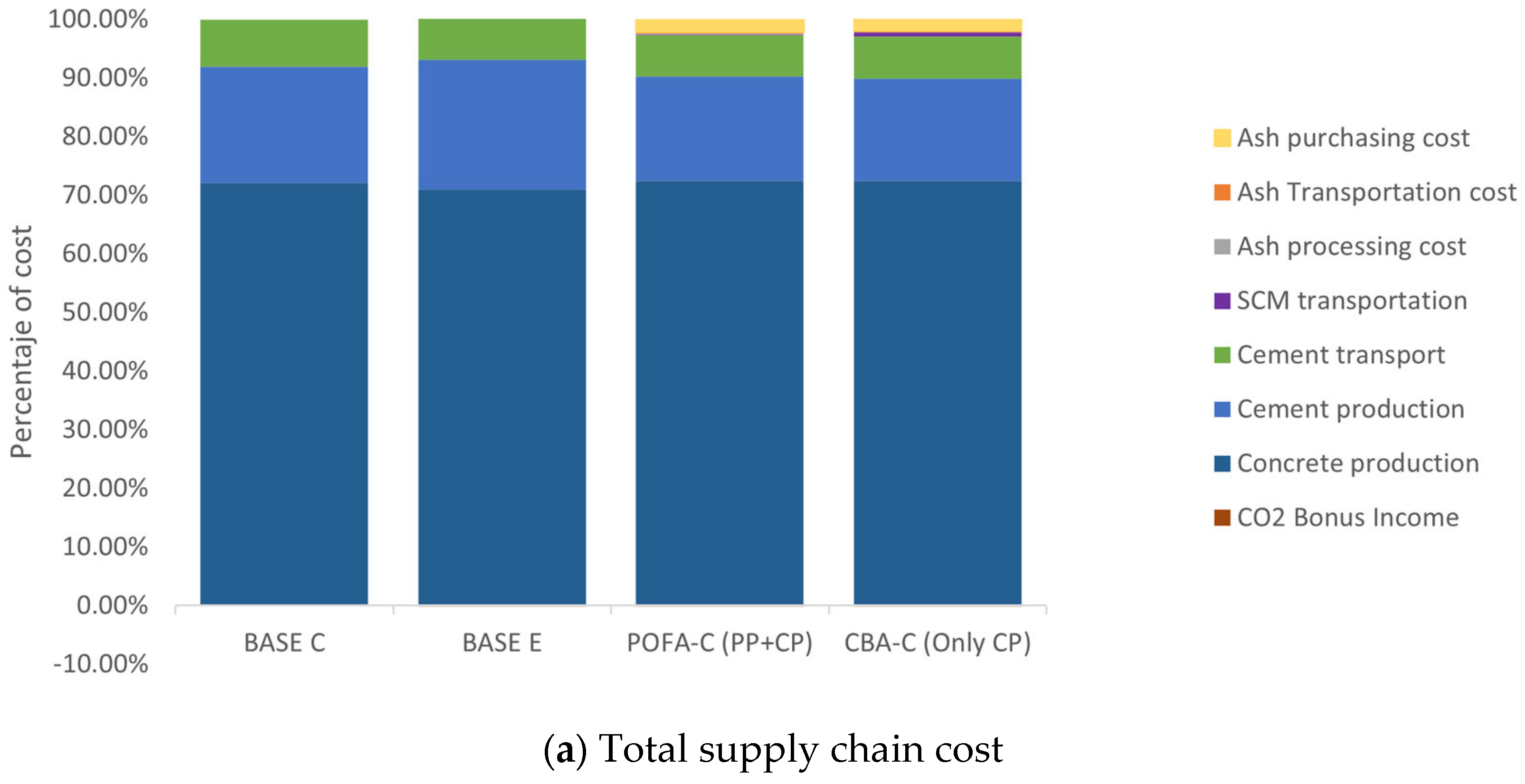

4.2. Discussion

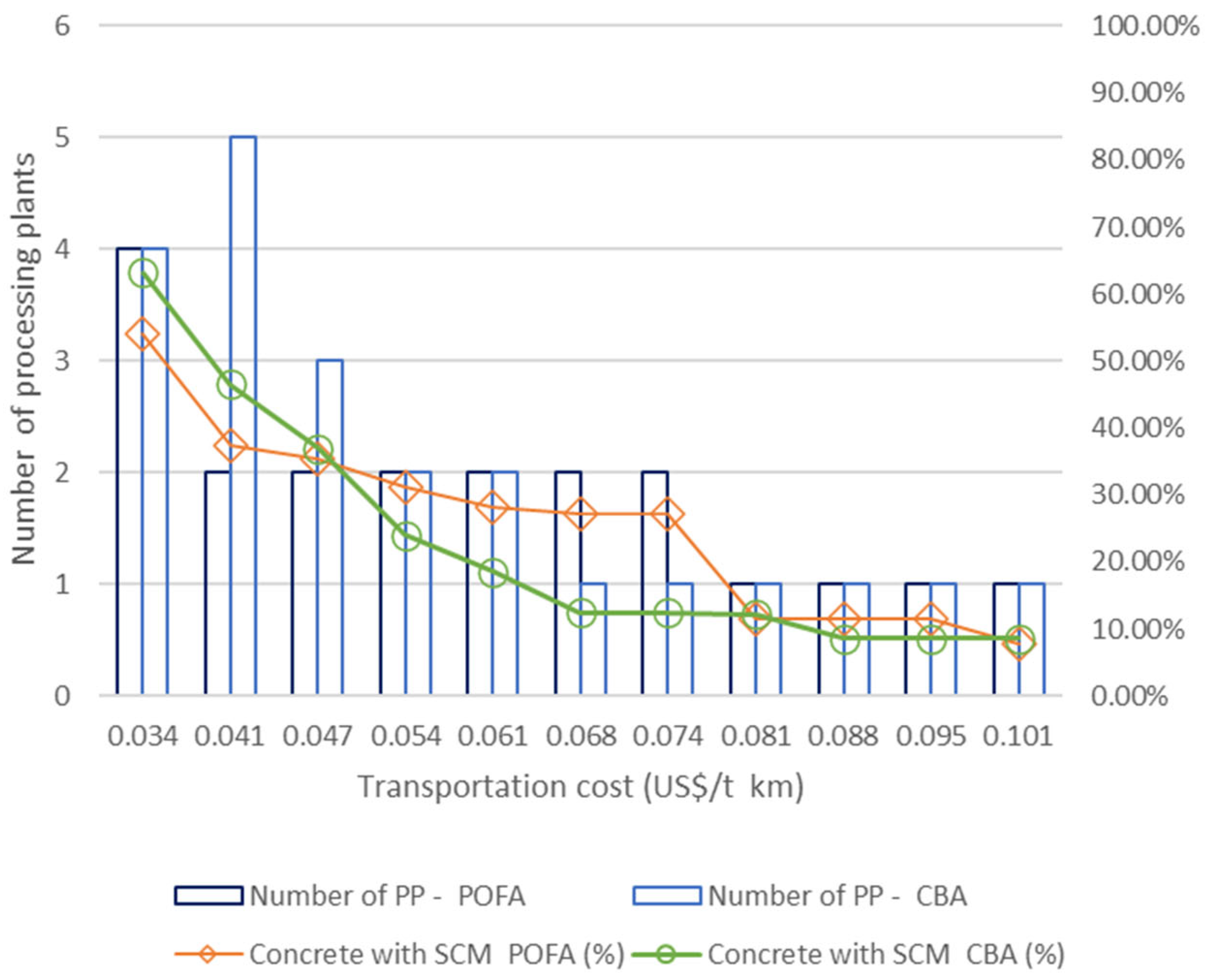

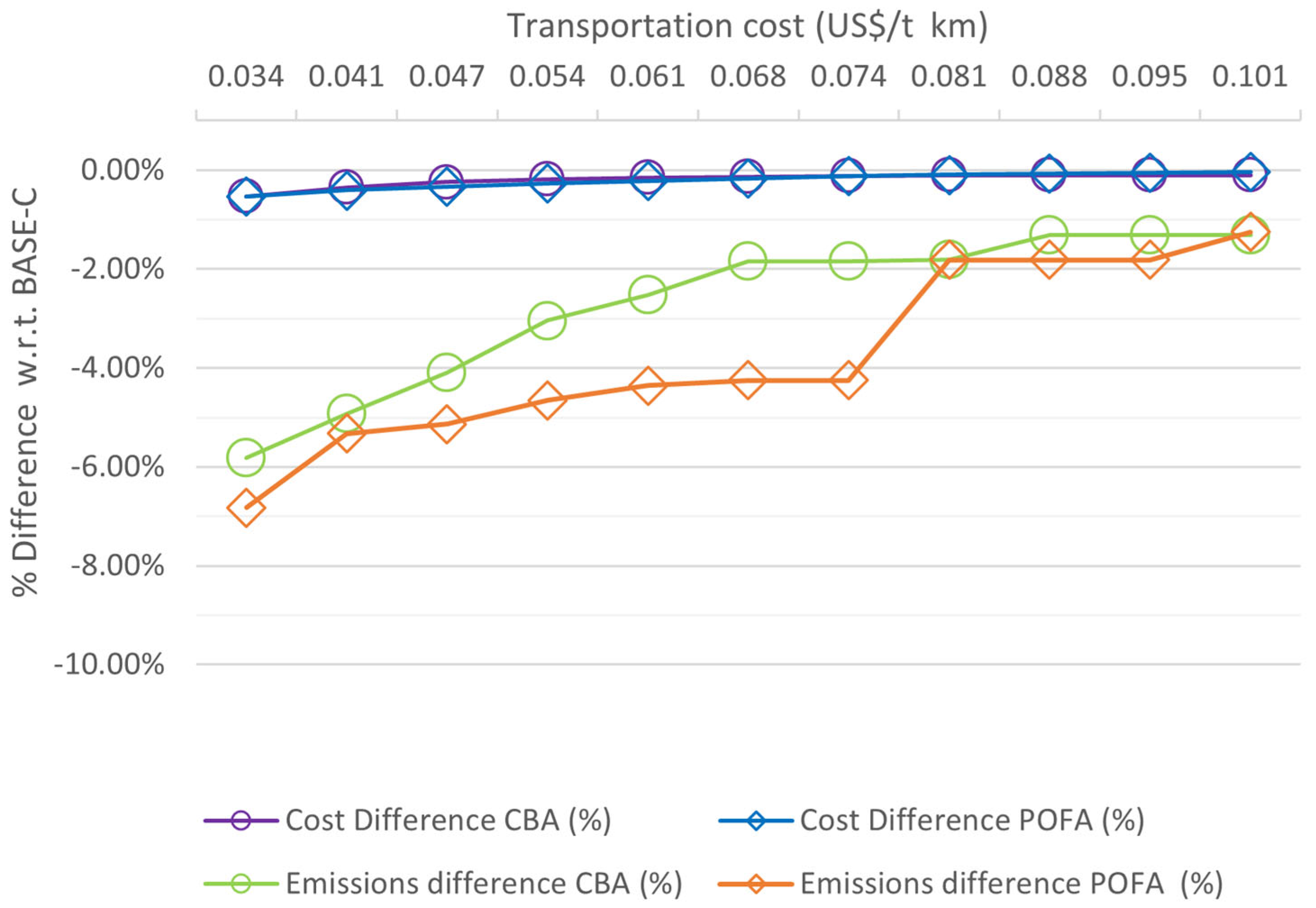

4.3. Sensitivity Analysis to Different Transportation Settings

4.3.1. Transportation Cost Impact on the New SCM Supply Chain

4.3.2. Alternative Supply Chain Structures

4.4. Managerial Insights

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Energy Agency. Cement; IEA: Paris, France, 2023; Available online: https://www.iea.org/energy-system/industry/cement (accessed on 2 September 2024).

- Miller, S.A.; Habert, G.; Myers, R.J.; Harvey, J.T. Achieving net zero greenhouse gas emissions in the cement industry via value chain mitigation strategies. One Earth 2021, 4, 1398–1411. [Google Scholar] [CrossRef]

- Busch, P.; Kendall, A.; Murphy, C.W.; Miller, S.A. Literature review on policies to mitigate GHG emissions for cement and concrete. Resour. Conserv. Recycl. 2022, 182, 106278. [Google Scholar] [CrossRef]

- Mission Possible Partnership. Concrete and Cement. Mission Possible Partnership. Available online: https://www.missionpossiblepartnership.org/action-sectors/concrete-cement/ (accessed on 2 September 2024).

- Thomas, B.S.; Yang, J.; Mo, K.H.; Abdalla, J.A.; Hawileh, R.A.; Ariyachandra, E. Biomass ashes from agricultural wastes as supplementary cementitious materials or aggregate replacement in cement/geopolymer concrete: A comprehensive review. J. Build. Eng. 2021, 40, 102332. [Google Scholar] [CrossRef]

- Blesson, S.; Rao, A.U. Agro-industrial-based wastes as supplementary cementitious or alkali-activated binder material: A comprehensive review. Innov. Infrastruct. Solut. 2023, 8, 125. [Google Scholar] [CrossRef]

- Olatoyan, O.J.; Kareem, M.A.; Adebanjo, A.U.; Olawale, S.; Alao, K.T. Potential use of biomass ash as a sustainable alternative for fly ash in concrete production: A review. Hybrid Adv. 2023, 4, 100076. [Google Scholar] [CrossRef]

- Osial, M.; Pregowska, A.; Wilczewski, S.; Urbańska, W.; Giersig, M. Waste Management for Green Concrete Solutions: A Concise Critical Review. Recycling 2022, 7, 37. [Google Scholar] [CrossRef]

- Gupta, S.; Chaudhary, S. State of the art review on supplementary cementitious materials in India—II: Characteristics of SCMs, effect on concrete and environmental impact. J. Clean. Prod. 2022, 357, 131945. [Google Scholar] [CrossRef]

- Snellings, R.; Suraneni, P.; Skibsted, J. Future and emerging supplementary cementitious materials. Cem. Concr. Res. 2023, 171, 107199. [Google Scholar] [CrossRef]

- Diaz-Loya, I.; Juenger, M.; Seraj, S.; Minkara, R. Extending supplementary cementitious material resources: Reclaimed and remediated fly ash and natural pozzolans. Cem. Concr. Compos. 2019, 101, 44–51. [Google Scholar] [CrossRef]

- Cruz, N.C.; Silva, F.C.; Tarelho, L.A.; Rodrigues, S.M. Critical review of key variables affecting potential recycling applications of ash produced at large-scale biomass combustion plants. Resour. Conserv. Recycl. 2019, 150, 104427. [Google Scholar] [CrossRef]

- Álvarez-López, G.; Múnera, A.M.; Villegas, J.G. Multicriteria Decision-Making Tools for the Selection of Biomasses as Supplementary Cementitious Materials. Sustainability 2023, 15, 10031. [Google Scholar] [CrossRef]

- Kochanski, M.; Lotz, M.T.; Korczak, K. Benchmarking circular economy measures in buildings along the 11R framework: A systematic review of quantified impacts on material use, energy consumption, GHG emissions, and costs. J. Clean. Prod. 2024, 485, 144337. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Jakobs, L.; Hofer, A.; Rauch, E. A Framework and Taxonomy for Categorizing Industrial Symbiosis in Manufacturing. J. Eng. Sci. 2025, 12, B1–B10. [Google Scholar] [CrossRef]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Turken, N.; Geda, A. Supply chain implications of industrial symbiosis: A review and avenues for future research. Resour. Conserv. Recycl. 2020, 161, 104974. [Google Scholar] [CrossRef]

- Dikos, G.; Spyropoulou, S. Supply Chain Optimization and Planning in Heracles General Cement Company. Interfaces 2013, 43, 297–3123. [Google Scholar] [CrossRef]

- Cadavid-Giraldo, N.; Vélez-Gallego, M.C.; Guillén-Gosálbez, G. Technology Updating Decisions for Improving the Environmental Performance of an Operating Supply Chain: A Multiobjective Optimization Model for the Cement Industry. Ind. Eng. Chem. Res. 2016, 55, 12287–12300. [Google Scholar] [CrossRef]

- Cadavid-Giraldo, N.; Velez-Gallego, M.C.; Restrepo-Boland, A. Carbon emissions reduction and financial effects of a cap and tax system on an operating supply chain in the cement sector. J. Clean. Prod. 2020, 275, 122583. [Google Scholar] [CrossRef]

- Suhaib, S.A.B.; Rasmi, S.A.B.; Türkay, M. Sustainability analysis of cement supply chains considering economic, environmental and social effects. Clean. Logist. Supply Chain 2023, 8, 100112. [Google Scholar] [CrossRef]

- Jamora, J.B.; Gudia, S.E.L.; Go, A.W.; Giduquio, M.B.; Loretero, M.E. Potential CO2 reduction and cost evaluation in use and transport of coal ash as cement replacement: A case in the Philippines. Waste Manag. 2020, 103, 137–145. [Google Scholar] [CrossRef]

- Göswein, V.; Gonçalves, A.B.; Silvestre, J.D.; Freire, F.; Habert, G.; Kurda, R. Transportation matters—Does it? GIS-based comparative environmental assessment of concrete mixes with cement, fly ash, natural and recycled aggregates. Resour. Conserv. Recycl. 2018, 137, 1–10. [Google Scholar] [CrossRef]

- Komkova, A.; Habert, G. Optimal supply chain networks for waste materials used in alkali-activated concrete fostering circular economy. Resour. Conserv. Recycl. 2023, 193, 106949. [Google Scholar] [CrossRef]

- Luo, L.; Liu, Y.; Zhuge, Y.; Chow, C.W.; Clos, I.; Rameezdeen, R. A multi-objective optimization approach for supply chain design of alum sludge-derived supplementary cementitious material. Case Stud. Constr. Mater. 2022, 17, e01156. [Google Scholar] [CrossRef]

- Mahjoubi, S.; Barhemat, R.; Meng, W.; Bao, Y. AI-guided auto-discovery of low-carbon cost-effective ultra-high performance concrete (UHPC). Resour. Conserv. Recycl. 2022, 189, 106741. [Google Scholar] [CrossRef]

- Caselli, G.; Iori, M.; Ljubić, I. Bilevel optimization with sustainability perspective: A survey on applications. arXiv 2024, arXiv:2406.07184. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Li, Q.; Üster, H.; Zhang, Z.-H. A Bilevel Model for Robust Network Design and Biomass Pricing Under Farmers’ Risk Attitudes and Supply Uncertainty. Transp. Sci. 2023, 57, 1296–1320. [Google Scholar] [CrossRef]

- Yue, D.; You, F. Stackelberg-game-based modeling and optimization for supply chain design and operations: A mixed integer bilevel programming framework. Comput. Chem. Eng. 2017, 102, 81–95. [Google Scholar] [CrossRef]

- Cheraghalipour, A.; Roghanian, E. A bi-level model for a closed-loop agricultural supply chain considering biogas and compost. Environ. Dev. Sustain. 2022. [Google Scholar] [CrossRef]

- Cobo, S.; Fengqi, Y.; Dominguez-Ramos, A.; Irabien, A. Noncooperative Game Theory to Ensure the Marketability of Organic Fertilizers within a Sustainable Circular Economy. ACS Sustain. Chem. Eng. 2020, 8, 3809–3819. [Google Scholar] [CrossRef]

- Choi, T.-M.; Taleizadeh, A.A.; Yue, X. Game theory applications in production research in the sharing and circular economy era. Int. J. Prod. Res. 2019, 58, 118–127. [Google Scholar] [CrossRef]

- Che, C.; Zhang, X.; Chen, Y.; Zhao, L.; Zhang, Z. A Model of Waste Price in a Symbiotic Supply Chain Based on Stackelberg Algorithm. Sustainability 2021, 13, 1740. [Google Scholar] [CrossRef]

- Atashbar, N.Z.; Labadie, N.; Prins, C. Modelling and optimisation of biomass supply chains: A review. Int. J. Prod. Res. 2017, 56, 3482–3506. [Google Scholar] [CrossRef]

- Nunes, L.J.R. Exploring the present and future of biomass recovery units: Technological innovation, policy incentives and economic challenges. Biofuels 2023, 15, 375–387. [Google Scholar] [CrossRef]

- Lo, S.L.Y.; How, B.S.; Leong, W.D.; Teng, S.Y.; Rhamdhani, M.A.; Sunarso, J. Techno-economic analysis for biomass supply chain: A state-of-the-art review. Renew. Sustain. Energy Rev. 2020, 135, 110164. [Google Scholar] [CrossRef]

- Rivera-Cadavid, L.; Manyoma-Velásquez, P.C.; Manotas-Duque, D.F. Supply Chain Optimization for Energy Cogeneration Using Sugarcane Crop Residues (SCR). Sustainability 2019, 11, 6565. [Google Scholar] [CrossRef]

- Labbé, M.; Violin, A. Bilevel programming and price setting problems. Ann. Oper. Res. 2015, 240, 141–169. [Google Scholar] [CrossRef]

- Kleinert, T.; Labbé, M.; Ljubić, I.; Schmidt, M. A Survey on Mixed-Integer Programming Techniques in Bilevel Optimization. Euro J. Comput. Optim. 2021, 9, 100007. [Google Scholar] [CrossRef]

- DeNegre, S.T.; Ralphs, T.K. A Branch-and-cut Algorithm for Integer Bilevel Linear Programs. In Operations Research and Cyber-Infrastructure; Chinneck, J.W., Kristjansson, B., Saltzman, M.J., Eds.; Springer: Boston, MA, USA, 2009; pp. 65–78. [Google Scholar] [CrossRef]

- Fischetti, M.; Ljubić, I.; Monaci, M.; Sinnl, M. A New General-Purpose Algorithm for Mixed-Integer Bilevel Linear Programs. Oper. Res. 2017, 65, 1615–1637. [Google Scholar] [CrossRef]

- Location Science; Laporte, G., Nickel, S., Da Gama, F.S., Eds.; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Daskin, M.S. What you should know about location modeling. Nav. Res. Logist. 2008, 55, 283–294. [Google Scholar] [CrossRef]

- Camacho-Vallejo, J.-F.; Corpus, C.; Villegas, J.G. Metaheuristics for bilevel optimization: A comprehensive review. Comput. Oper. Res. 2023, 161, 106410. [Google Scholar] [CrossRef]

- Bilevel Optimization: Advances and Next Challenges. In Springer Optimization and Its Applications; Dempe, S., Zemkoho, A., Eds.; Springer: Cham, Switzerland, 2020; Volume 161. [Google Scholar] [CrossRef]

- Ehrgott, M. Multicriteria Optimization; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Costa, Y.; Melo, T. Facility Location Modeling in Supply Chain Network Design: Current State and Emerging Trends. In The Palgrave Handbook of Supply Chain Management; Springer: Berlin/Heidelberg, Germany, 2022; pp. 1–36. [Google Scholar]

- Van Engeland, J.; Beliën, J.; De Boeck, L.; De Jaeger, S. Literature review: Strategic network optimization models in waste reverse supply chains. Omega 2018, 91, 102012. [Google Scholar] [CrossRef]

- Díaz-Ramirez, J.; Giraldo-Peralta, N.; Flórez-Ceron, D.; Rangel, V.; Mejía-Argueta, C.; Huertas, J.I.; Bernal, M. Eco-driving key factors that influence fuel consumption in heavy-truck fleets: A Colombian case. Transp. Res. Part D Transp. Environ. 2017, 56, 258–270. [Google Scholar] [CrossRef]

- DANE-Departamento Administrativo Nacional de Estadística. Encuesta Nacional Agropecuaria (ENA). Available online: https://www.dane.gov.co/index.php/estadisticas-por-tema/agropecuario/encuesta-nacional-agropecuaria-ena (accessed on 2 September 2024).

- Beck, Y.; Ljubić, I.; Schmidt, M. A survey on bilevel optimization under uncertainty. Eur. J. Oper. Res. 2023, 311, 401–426. [Google Scholar] [CrossRef]

- Li, Y.; Lin, J.; Qian, Y.; Li, D. Feed-in tariff policy for biomass power generation: Incorporating the feedstock acquisition process. Eur. J. Oper. Res. 2022, 304, 1113–1132. [Google Scholar] [CrossRef]

- Nowé, A.; Vrancx, P.; De Hauwere, Y.-M. Game Theory and Multi-agent Reinforcement Learning. In Reinforcement Learning; Wiering, M., Van Otterlo, M., Eds.; Adaptation, Learning, and Optimization; Springer: Berlin/Heidelberg, Germany, 2012; Volume 12, pp. 441–470. [Google Scholar] [CrossRef]

| Ref. | Purpose | Type of Model | Objective Function(s) | Solution Method | SCM |

|---|---|---|---|---|---|

| [19] | Design and plan of a cement supply chain | MILP | Min Cost | Commercial Optimizer | No |

| [20] | Evaluate the economic/environmental trade-off of technology upgrade options in the cement supply chain | MO MILP | Min Cost, Min CO2, Min NOx, Min SOx | constraints | No |

| [21] | Evaluate the economic and environmental effect of cap and tax policies in the cement supply chain | MO MILP | Min Cost, Min CO2 | constraints | No |

| [22] | Improve the sustainability of a cement supply chain from a triple-bottom-line perspective | MO MILP | Min Waste production, Air pollution, Water contamination, Land deformation Max gross profit Max hiring employees, Min social conflicts, Max employee safety | GonDEF + Commercial optimizer | No |

| [23] | Analyze the environmental and economic impact of coal ash as an SCM in concrete | GIS + Cost and emissions factors | None | None | Yes |

| [24] | Analyze the environmental impact of SCMs and recycled aggregates in concrete | LCA + GIS | None | None | Yes |

| [25] | Design the cement/concrete supply chain, minimizing the environmental impact obtained by producing alkali-activated concrete | MILP | Min CO2 | SimaPro + QGIS + Commercial Optimizer | Yes |

| [26] | Design the cement/concrete supply chain for alum sludge residues from drinking water treatment plants as SCM | MO MILP | Max new jobs, Min GHG, Max NPV | constraints | Yes |

| [27] | Automate the discovery of ultra-high-performance concrete incorporating alternative materials | ML + MO model | Max Compressive strength, Max Flexural strength, Min Porosity, Min Carbon footprint, Min Embodied energy, Min Cost | ML methods + Many objective EA | Yes |

| This work | Redesign the cement/concrete supply chain and pricing for biomass ash as SCM | BPP | Max revenue (L), Min costs or Min CO2 (F) | Commercial optimizer + grid search | Yes |

| Notation | Description |

|---|---|

| Locations of biomass ash generation | |

| Candidate locations for processing plants | |

| Available sizes for processing plants | |

| Cement plants (with known location) | |

| Concrete plants (with known location) | |

| Concrete markets |

| Notation | |

|---|---|

| Quantity of biomass ash to buy at each source | |

| Quantity of biomass ash to be sent from each source to each processing plant | |

| Quantity of biomass ash to be sent from each source to each cement plant | |

| Binary variable that defines whether a processing plant is installed in the candidate location or not | |

| Binary variable that defines the size s of the processing plant installed in the candidate location | |

| Quantity of biomass ash processed in each processing plant | |

| Quantity of SCM sent from each processing plant to each concrete plant p | |

| Quantity of SCM sent from each cement plant to each concrete plant p | |

| Quantity of ordinary Portland cement sent from each cement plant k to each concrete plant p | |

| Quantity of conventional concrete produced in each concrete plant p | |

| Quantity of concrete with SCM produced in each concrete plant p |

| Biomass ash sources | |

| Biomass ash purchase price | |

| Quantity of biomass ash available in each location | |

| Processing plants | |

| Biomass ash to SCM conversion rate | |

| Fixed cost of operating a processing plant of size | |

| Unit cost of processing biomass ash to be suitable as SCM | |

| Capacity of a processing plant of size | |

| emissions from processing biomass ash to SCM | |

| Cement Plants | |

| Production capacity of each cement plant | |

| Unit production cost per ton of cement in each cement plant | |

| emissions from cement production in each cement plant | |

| Concrete Plants | |

| Cement consumption per cubic meter of concrete produced without SCM | |

| Cement consumption per cubic meter of concrete produced with SCM | |

| SCM consumption per cubic meter of concrete | |

| Production capacity of each concrete plant | |

| Unit production cost per of conventional concrete in each concrete plant | |

| Unit production cost per of concrete with SCM in each concrete plant | |

| Concrete Markets | |

| Demand for concrete in each market | |

| Binary parameter indicating if market is served by the concrete plant or not | |

| Transportation | |

| Distance between each biomass ash origin and each candidate processing plant location | |

| Emission factor from biomass ash transport to the processing plants | |

| Cost per ton of biomass ash transported per km between sources and processing plants | |

| Distance between each processing plant location and each concrete plant p | |

| Emission factor for the transport of SCM from the processing plants to concrete plants | |

| Cost per ton of SCM transported per km between processing plants and concrete plants | |

| Distance between each biomass ash origin and each cement plant k | |

| Distance between each cement plant k and each concrete plant p | |

| Emission factor for cement transport from cement plants to concrete plants | |

| Cost per ton of cement transported per km between cement plants and concrete plants | |

| Emissions reduction terms | |

| BASECO2 | Total emissions of the supply chain without SCM |

| Price of CO2 bonds in the market [] | |

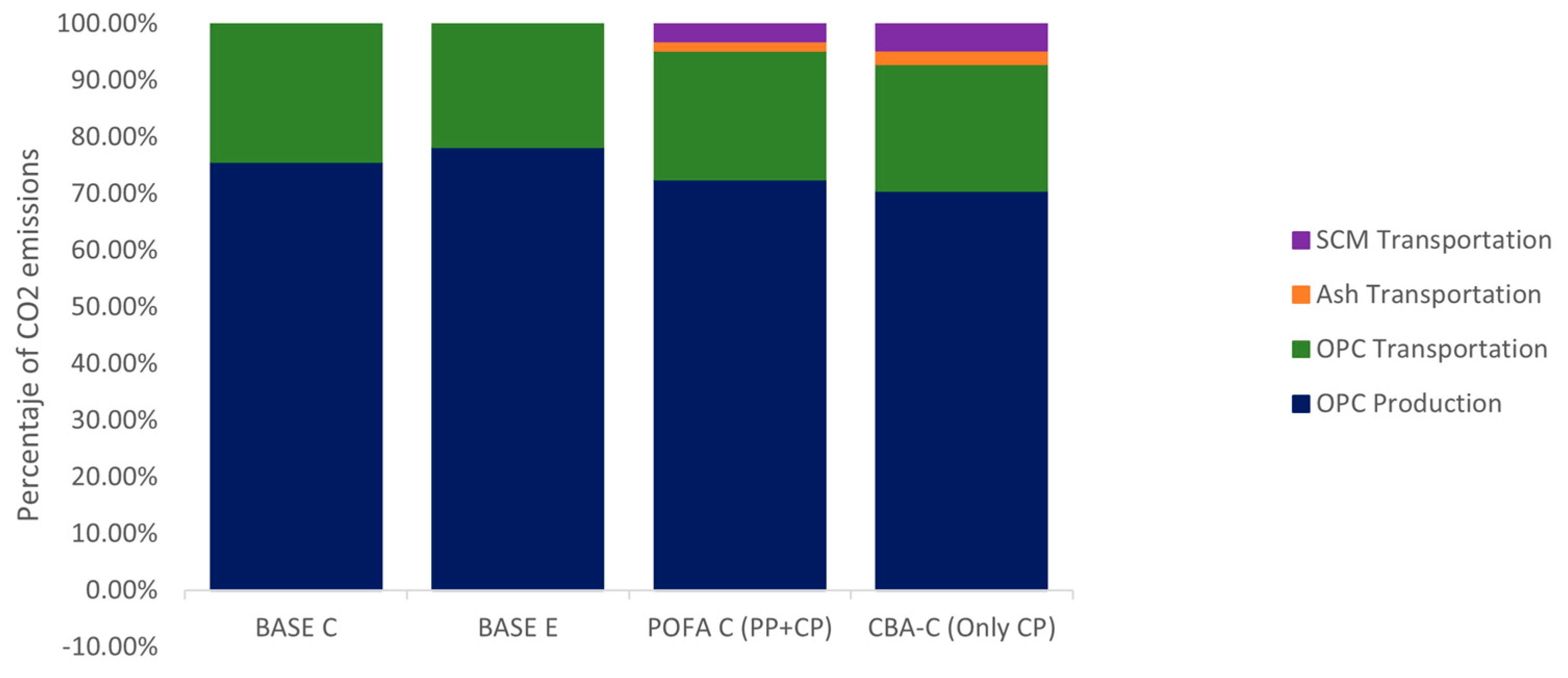

| Scenario | Base-C | Base-E | CBA-C | CBA-E | POFA-C | POFA-E |

|---|---|---|---|---|---|---|

| Total cost (%) | 100.00% | 101.47% | 99.46% | 101.29% | 99.47% | 102.22% |

| Total CO2 emissions (%) | 100.00% | 97.35% | 94.18% | 91.74% | 93.17% | 89.58% |

| Number of PP 1 | - | - | 4 | 13 | 4 | 32 |

| Use of available ash (%) | - | - | 100.00% | 100.00% | 77.48% | 98.08% |

| Ash cost * (US$/t) | - | - | 22.73 | 22.73 | 25.00 | 25.00 |

| Ash costmax (US$/t) | - | - | 34.09 | 34.09 | 38.64 | 38.64 |

| Ash processed at CP 1 (%) | - | - | 26.53% | 5.79% | 11.18% | 3.99% |

| Ash processed at PP 2 (%) | - | - | 73.47% | 94.21% | 88.82% | 96.01% |

| Cement use (%) | 100.00% | 100.00% | 87.36% | 87.36% | 89.18% | 86.31% |

| Concrete with SCM (%) | - | - | 63.22% | 63.22% | 54.08% | 68.47% |

| Scenario | CBA-C | POFA-C | ||||

|---|---|---|---|---|---|---|

| OnlyPP | OnlyCP | PP + CP | OnlyPP | OnlyCP | PP + CP | |

| Total cost (%) | 99.47% | 99.53% | 99.46% | 99.48% | 99.93% | 99.47% |

| Total CO2 emissions (%) | 94.08% | 94.92% | 94.18% | 93.28% | 98.60% | 93.17% |

| Number of PP 1 | 6 | 0 | 4 | 5 | 0 | 4 |

| Use of available ash (%) | 100.00% | 93.18% | 100.00% | 75.66% | 31.29% | 77.48% |

| Ash processed at CP 2 | 0.00% | 100.00% | 26.53% | 0.00% | 100.00% | 11.18% |

| Ash processed at PP | 100.00% | 0.00% | 73.47% | 100.00% | 0.00% | 88.82% |

| Cement use (%) | 87.36% | 88.22% | 87.36% | 89.44% | 95.63% | 89.18% |

| Concrete with SCM (%) | 63.22% | 58.91% | 63.22% | 52.81% | 21.85% | 54.08% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villegas, J.G.; Álvarez-López, G.; Jaramillo, L.Y.; Romero-Sáez, M. Supply Chain (Re)Design and Pricing for Biomass Ash Valorization as Supplementary Cementitious Materials. Recycling 2025, 10, 34. https://doi.org/10.3390/recycling10020034

Villegas JG, Álvarez-López G, Jaramillo LY, Romero-Sáez M. Supply Chain (Re)Design and Pricing for Biomass Ash Valorization as Supplementary Cementitious Materials. Recycling. 2025; 10(2):34. https://doi.org/10.3390/recycling10020034

Chicago/Turabian StyleVillegas, Juan G., Germán Álvarez-López, Leyla Y. Jaramillo, and Manuel Romero-Sáez. 2025. "Supply Chain (Re)Design and Pricing for Biomass Ash Valorization as Supplementary Cementitious Materials" Recycling 10, no. 2: 34. https://doi.org/10.3390/recycling10020034

APA StyleVillegas, J. G., Álvarez-López, G., Jaramillo, L. Y., & Romero-Sáez, M. (2025). Supply Chain (Re)Design and Pricing for Biomass Ash Valorization as Supplementary Cementitious Materials. Recycling, 10(2), 34. https://doi.org/10.3390/recycling10020034