Technical Recyclability and Carbon Footprint of Packaging for Butter, Yogurt, and Spreads

Abstract

1. Introduction

1.1. Current State of Food Packaging Recycling

1.2. Regulatory Framework

1.3. Aim of This Work

2. Results

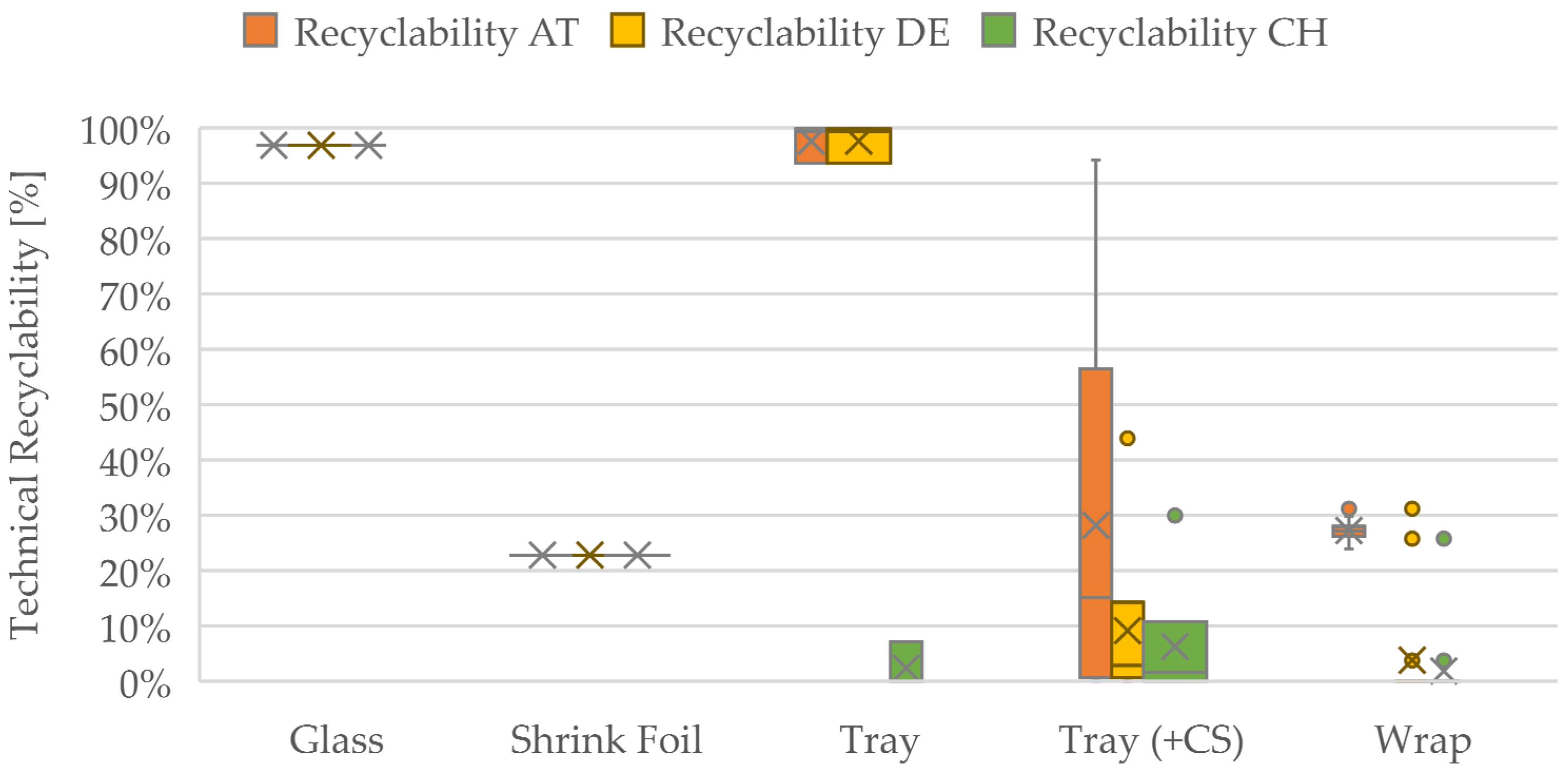

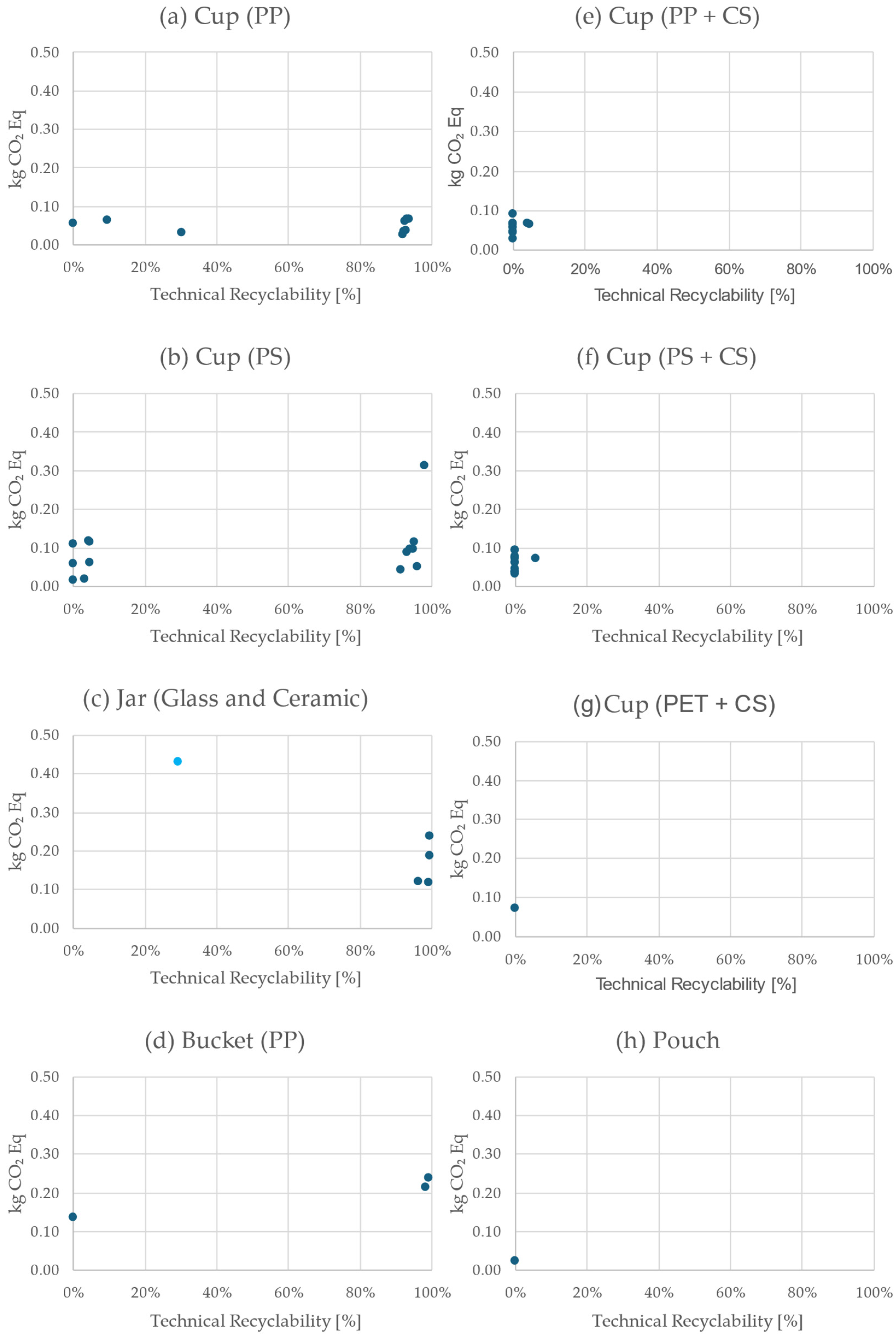

2.1. Recyclability Results for Butter Packaging

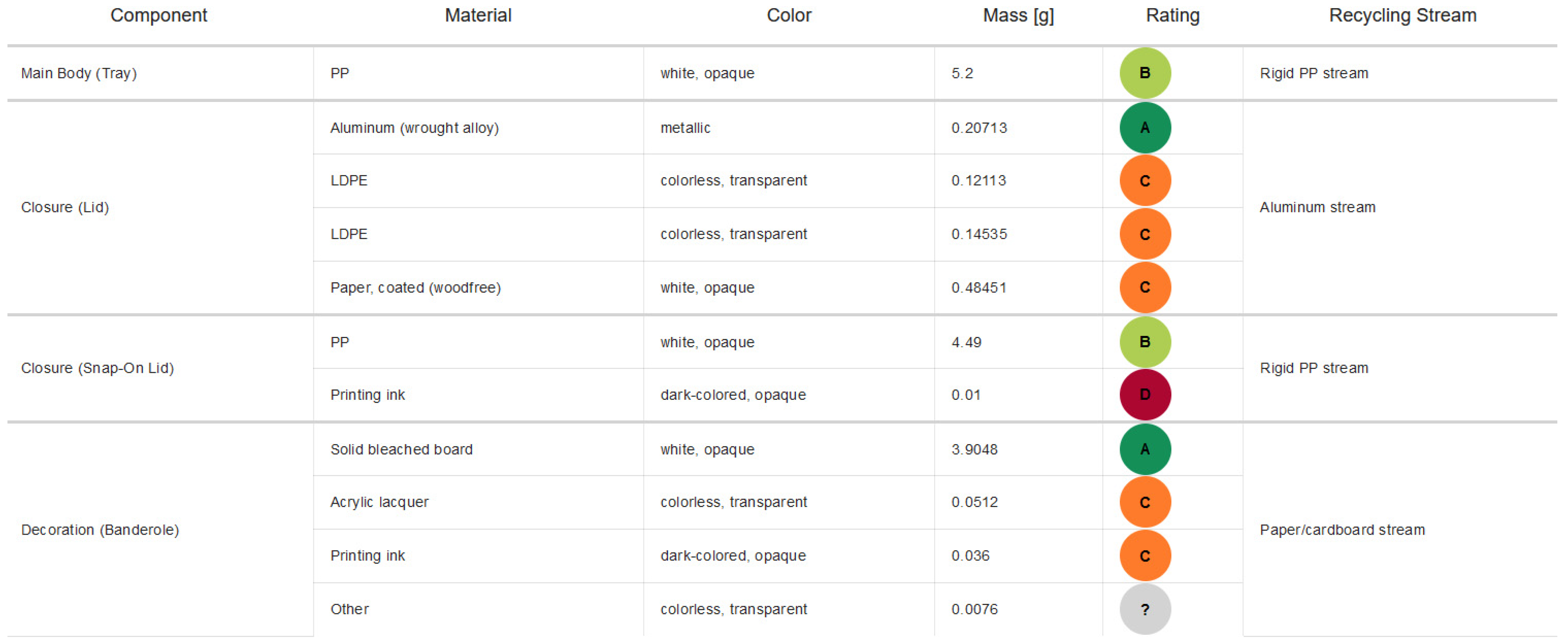

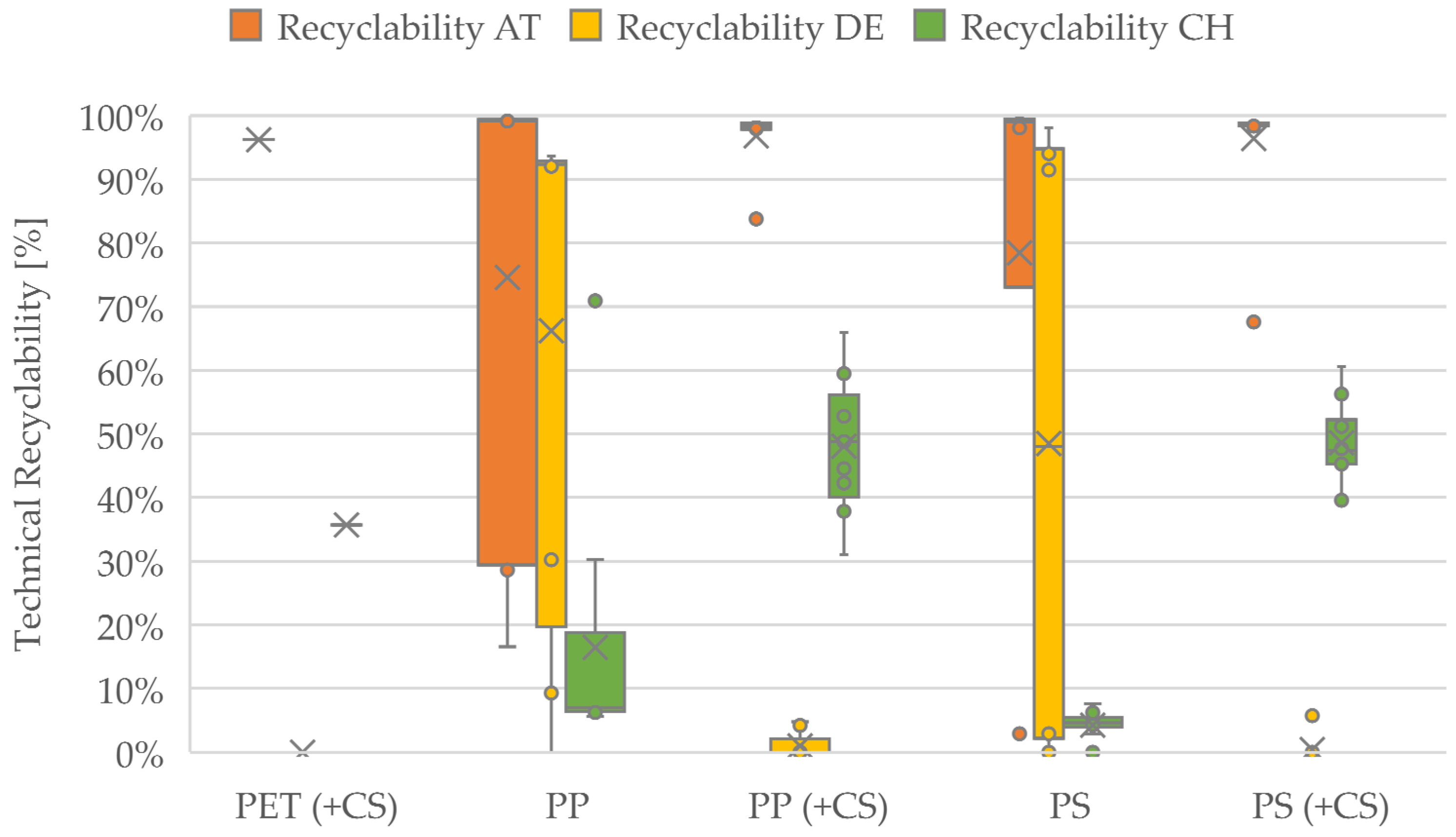

2.2. Recyclability Results for Yogurt Packaging

2.3. Recyclability Results for Spread Packaging

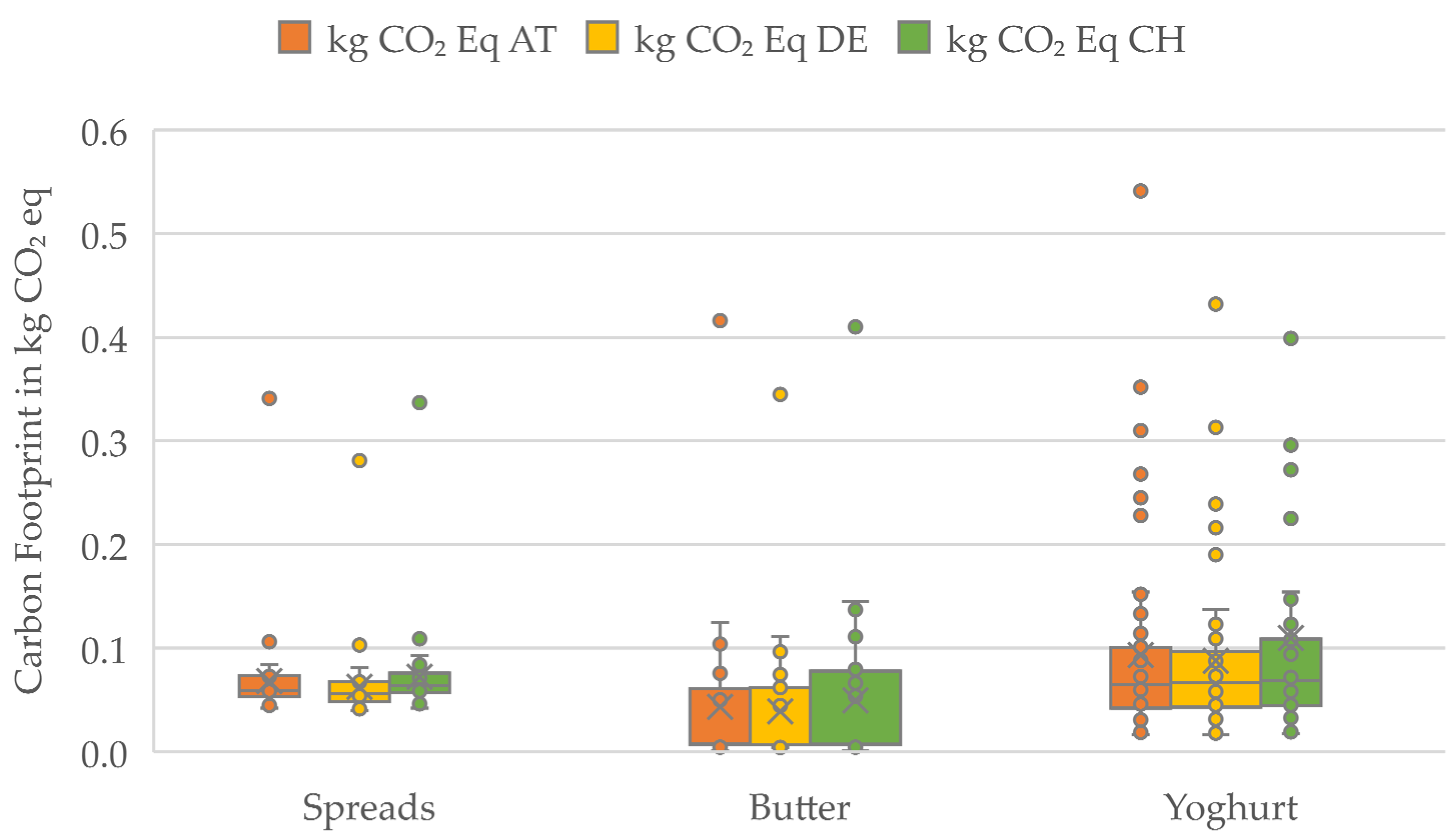

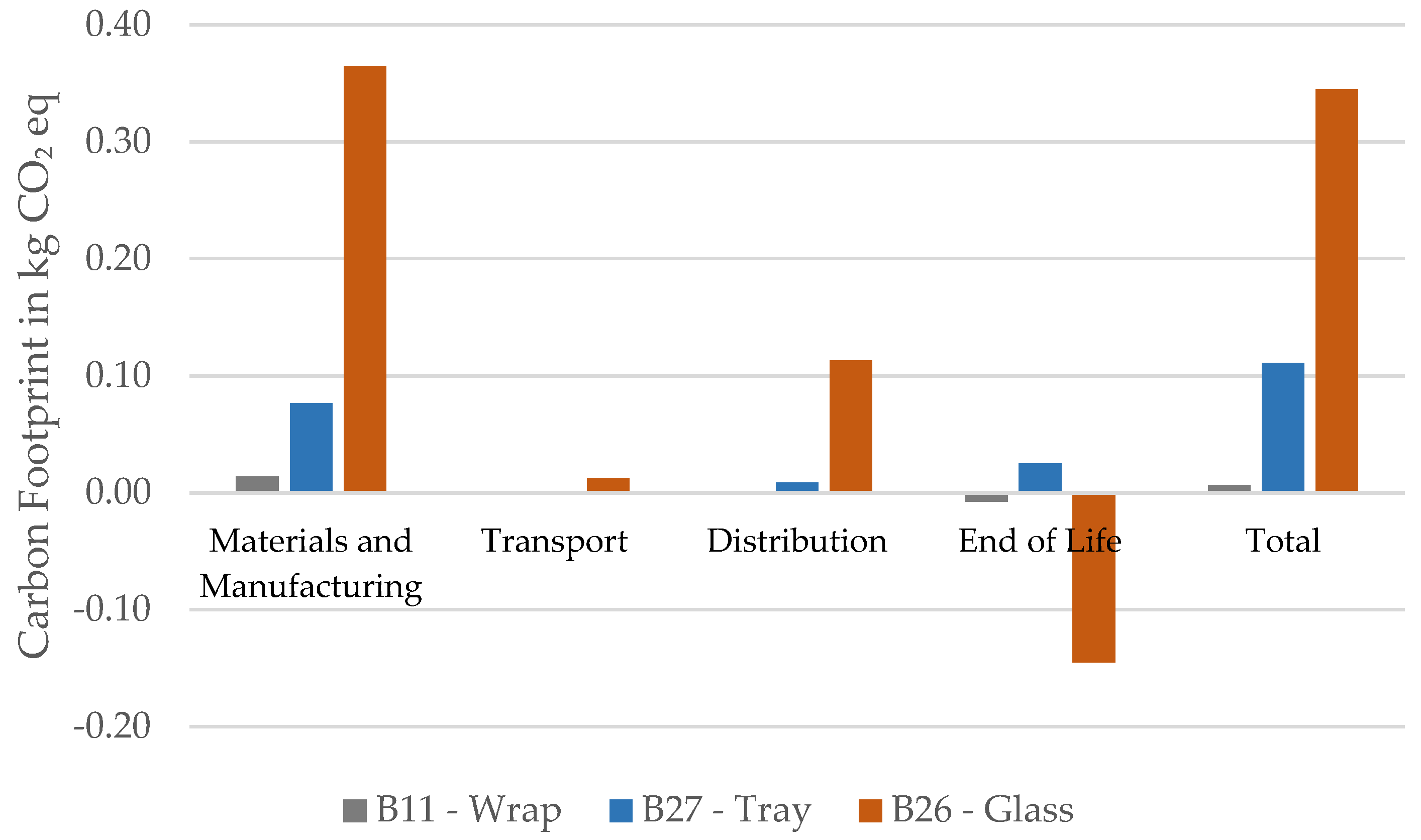

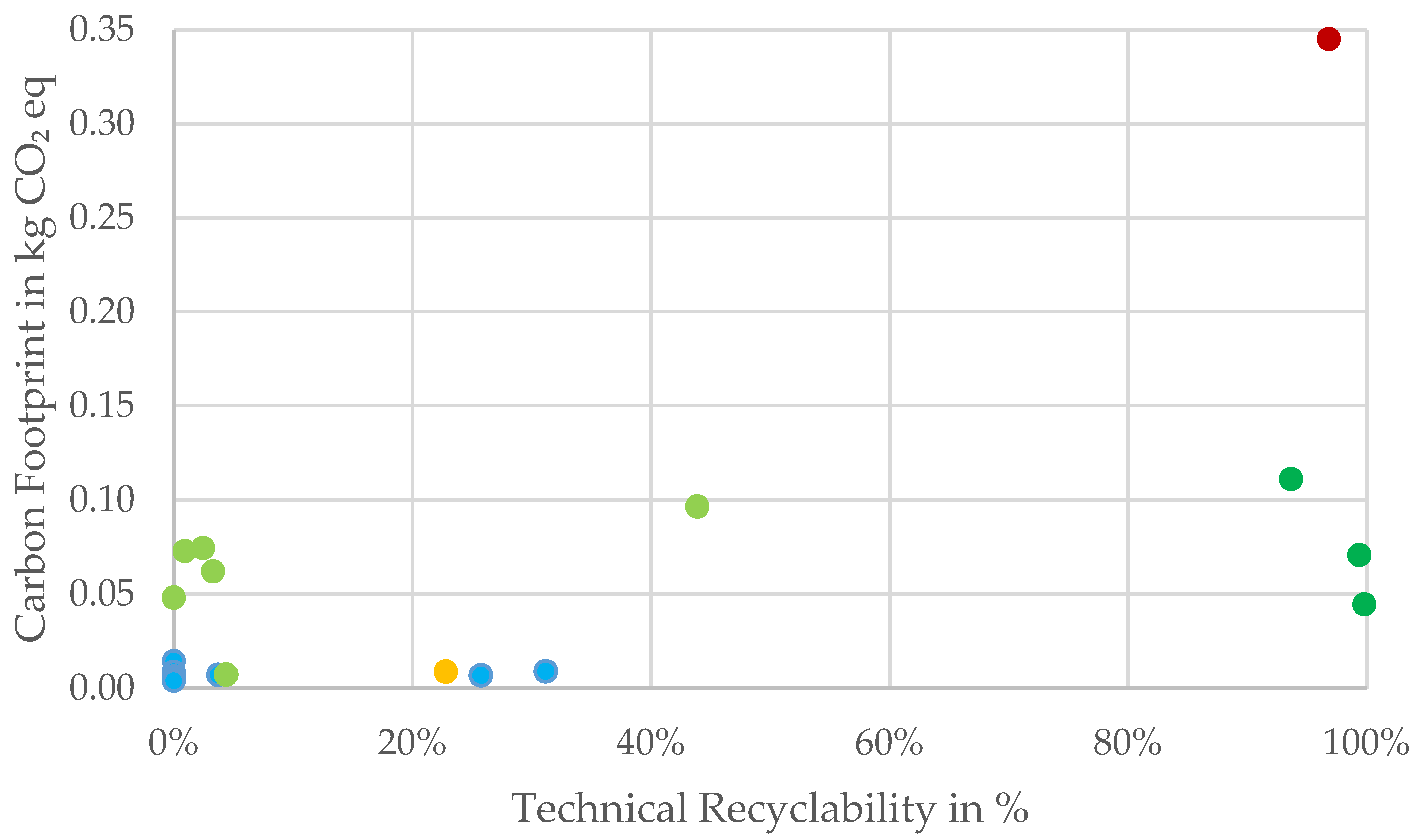

2.4. Carbon Footprint Results

3. Materials and Methods

3.1. Material

3.2. Assessment Recyclability and Global Warming Potential

- Printing coverage in %.

- Flexible or rigid component.

- Presence of an NIR-barrier.

- Information on Material Layer (each layer needs to be entered, and a detection layer needs to be selected):

- ○

- Material.

- ○

- Material Manifestation.

- ○

- Manufacturing Type.

- ○

- Content of Recyclate in %.

- ○

- Color.

- ○

- Mass in g.

- ○

- Material density.

- Type of Closure.

- Printing coverage in %.

- Flexible or rigid component.

- Presence of an NIR-barrier.

- Dimensions.

- Irreversible Removal through Consumption/Usage.

- Removal for Disposal by Average Consumer.

- Information on Material Layer (the same information as for the main body is relevant).

- Type of Decoration.

- Printing coverage in %.

- Covered Surface Area of Main Body in %.

- Presence of an NIR-barrier.

- Dimensions.

- Irreversible Removal through Consumption/Usage.

- Removal for Disposal by Average Consumer.

- Adhesion to Main Body.

- Information on Material Layer (the same information as for the main body is relevant).

4. Discussion

4.1. Carbon Footprint and Recyclability Comparison for Butter Packaging

4.2. Carbon Footprint and Recyclability Comparison for Yogurt Packaging in Germany

4.3. Limitations

- Data Availability and Accuracy: Data from packaging manufacturers and food producers were limited, potentially affecting the depth of the analysis.

- Variability in Waste Management Systems and Recyclability Assessment Methodology: A key finding of the study was the impact of variations in waste management infrastructure on the recyclability of packaging materials. However, the study was unable to fully account for all local and regional variations in waste collection, sorting, and recycling processes within each country. As a result, the recyclability assessments are based on national frameworks rather than on detailed local practices, which may differ significantly within each country.Additionally, there is currently no harmonized methodology available for recyclability assessments on a European level. Ongoing work in the standardization of recyclability assessments of packaging at the European Committee for Standardisation (CEN), which will be part of the upcoming delegated act of the EU Commission due on 1.1.2028, will provide a harmonized standard.

- Scope of Packaging Materials: This research focused on selected packaging formats for butter, yogurt, spreads, curd cheese, and cottage cheese. While acknowledging that these represent a significant share of dairy packaging, it must be noted that they do not cover the full spectrum of packaging solutions available on the global market. Other materials such as bio-based plastics, multilayer composites, and innovative alternative packaging solutions were not extensively analyzed, which may limit the comprehensiveness of the findings. Methodology of Carbon Footprint Assessment: This study assesses the carbon footprint of various packaging alternatives. However, it is important to note that variations in LCA methodologies and assumptions can introduce uncertainties. Factors such as energy sources, transportation distances, and end-of-life scenarios differ across regions and were estimated using available industry data. While these estimations are based on best practices, potential margins of error should be considered when interpreting the results.

- Consumer Behavior and Market Dynamics: This study acknowledges the pivotal role of consumer preferences and purchasing behaviors in determining packaging adoption. However, it does not provide a comprehensive analysis of consumer perceptions of sustainability or the market dynamics influencing packaging choices. While industry trends indicate a shift toward recyclable and lower-carbon packaging, the adoption rates of such packaging will be influenced by economic feasibility, retailer preferences, and consumer acceptance.

- Focus on the DACH Region: The geographical scope of the study is confined to the DACH region, implying that the findings might not be universally applicable to other EU member states with disparate waste management systems and consumer behaviors. The execution of comparative studies in other European regions could potentially offer further insights and enhance the generalizability of the conclusions.

4.4. Implications for Future Legislation

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lebreton, L.; Andrady, A. Future scenarios of global plastic waste generation and disposal. Palgrave Commun. 2019, 5, 6. [Google Scholar] [CrossRef]

- PlasticsEurope. Plastics—The Fast Facts; Plastics Europe: Brussels, Belgium, 2023. [Google Scholar]

- Jakobs, M.; Kroell, N. Influence of plastic packaging design on the sensor-based sortability in lightweight packaging waste sorting plants. Resour. Conserv. Recycl. 2024, 207, 107599. [Google Scholar] [CrossRef]

- Bundeministerium für Ernährung und Landwirtschaft. Entwicklungen am Deutschen Milchmarkt—Ein Überblick. Available online: https://www.bmel.de/DE/themen/landwirtschaft/agrarmaerkte/entwicklungen-milchmarkt-de.html (accessed on 11 June 2024).

- Bundesamt für Landwirtschaft BLW. Milch und Milchprodukte. Available online: https://www.blw.admin.ch/blw/de/home/nachhaltige-produktion/tierische-produktion/milch-und-milchprodukte.html (accessed on 11 June 2024).

- Bundesministerium für Land- und Forstwirtschaft, Regionen und Wasserwirtschaft. Milchwirtschaft in Österreich. Available online: https://info.bml.gv.at/themen/landwirtschaft/landwirtschaft-in-oesterreich/tierische-produktion/milch/milchwirtschaft.html (accessed on 11 June 2024).

- Aryana, K.J.; Olson, D.W. A 100-Year Review: Yogurt and other cultured dairy products. J. Dairy Sci. 2017, 100, 9987–10013. [Google Scholar] [CrossRef] [PubMed]

- Chandan, R.C.; Kilara, A. Manufacturing Yogurt and Fermented Milks, 2nd ed.; Wiley-Blackwell: Hoboken, NJ, USA, 2013; ISBN 9781119967088. [Google Scholar]

- Verriet, J.; Leroy, F. Yogurt’s flexible image during its rise in popularity in post-war Belgium. Appetite 2017, 108, 132–140. [Google Scholar] [CrossRef] [PubMed]

- Heidbreder, L.M.; Bablok, I.; Drews, S.; Menzel, C. Tackling the plastic problem: A review on perceptions, behaviors, and interventions. Sci. Total Environ. 2019, 668, 1077–1093. [Google Scholar] [CrossRef] [PubMed]

- Wohner, B.; Schwarzinger, N.; Gürlich, U.; Heinrich, V.; Tacker, M. Technical emptiability of dairy product packaging and its environmental implications in Austria. PeerJ 2019, 7, e7578. [Google Scholar] [CrossRef]

- European Commission. Regulation (EU) 2025/40 of the European Parliament and of the Council of 19 December 2024 on Packaging and Packaging Waste, Amending Regulation (EU) 2019/1020 and Directive (EU) 2019/904, and Repealing Directive 94/62/EC 2025; European Commission: Brussel, Belgium, 2025. [Google Scholar]

- BMK. Die Bestandsaufnahme der Abfallwirtschaft in Österreich; Bundesministerium: Berlin, Germany, 2024.

- European Environmenal Agency. Early Warning Assessment Related to the 2025 Targets for Municipal Waste and Packaging Waste; European Environmenal Agency: Copenhagen, Denmark, 2022. [Google Scholar]

- Umweltbundesamt. Weltrecyclingtag: Wieviel Recyceln wir Wirklich? Available online: https://www.umweltbundesamt.de/themen/weltrecyclingtag-wieviel-recyceln-wir-wirklich (accessed on 3 February 2025).

- Bundesrat. Kunststoffe in der Umwelt—Bericht des Bundesrates in Erfüllung der Postulate Thorens, Munz, Flach, CVP-Fraktion; Der Bundesrat: Berlin, Germany, 2022.

- World Packaging Organisation. Waste Stream Mapping Guides: Packaging Waste Streams Austria; World Packaging Organisation: Wien, Austria, 2022. [Google Scholar]

- World Packaging Organisation. Waste Stream Mapping Guides: Packaging Waste Streams Germany; World Packaging Organisation: Wien, Austria, 2022. [Google Scholar]

- World Packaging Organisation. Waste Stream Mapping Guides: Packaging Waste Streams Switzerland; World Packaging Organisation: Wien, Austria, 2022. [Google Scholar]

- prEN 18120-1:2024; Packaging—Design for Recycling of Plastic Packaging—Part 1: Definitions and Principles for Design-for-Recycling of Plastic Packaging. Austrian Standards International—Standardisierung und Innovation: Vienna, Austria, 2024.

- Eriksen, M.K.; Astrup, T.F. Characterisation of source-separated, rigid plastic waste and evaluation of recycling initiatives: Effects of product design and source-separation system. Waste Manag. 2019, 87, 161–172. [Google Scholar] [CrossRef] [PubMed]

- Ragaert, K.; Delva, L.; van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Brouwer, M.T.; van Thoden Velzen, E.U.; Augustinus, A.; Soethoudt, H.; de Meester, S.; Ragaert, K. Predictive model for the Dutch post-consumer plastic packaging recycling system and implications for the circular economy. Waste Manag. 2018, 71, 62–85. [Google Scholar] [CrossRef] [PubMed]

- Welle, F. Twenty years of PET bottle to bottle recycling—An overview. Resour. Conserv. Recycl. 2011, 55, 865–875. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Iacovidou, E. Closing the loop on plastic packaging materials: What is quality and how does it affect their circularity? Sci. Total Environ. 2018, 630, 1394–1400. [Google Scholar] [CrossRef]

- Eriksen, M.K.; Christiansen, J.D.; Daugaard, A.E.; Astrup, T.F. Closing the loop for PET, PE and PP waste from households: Influence of material properties and product design for plastic recycling. Waste Manag. 2019, 96, 75–85. [Google Scholar] [CrossRef] [PubMed]

- Jung, H.; Shin, G.; Kwak, H.; Hao, L.T.; Jegal, J.; Kim, H.J.; Jeon, H.; Park, J.; Oh, D.X. Review of polymer technologies for improving the recycling and upcycling efficiency of plastic waste. Chemosphere 2023, 320, 138089. [Google Scholar] [CrossRef] [PubMed]

- Prielinger, L.; Bandyopadhyay, S.; Ortner, E.; Novak, M.; Radusin, T.; Annfinsen, S.; Sharmin, N.; Rainer, B.; Pettersen, M.K. Investigation of the Effectiveness of Barrier Layers to Inhibit Mutagenic Effects of Recycled LDPE Films, Using a Miniaturized Ames Test and GC-MS Analysis. Recycling 2024, 9, 57. [Google Scholar] [CrossRef]

- Horodytska, O.; Cabanes, A.; Fullana, A. Non-intentionally added substances (NIAS) in recycled plastics. Chemosphere 2020, 251, 126373. [Google Scholar] [CrossRef]

- Kato, L.S.; Conte-Junior, C.A. Safety of Plastic Food Packaging: The Challenges about Non-Intentionally Added Substances (NIAS) Discovery, Identification and Risk Assessment. Polymers 2021, 13, 2077. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.L.; Saleh, M.A. Thermal degradation of azobenzene dyes. Results Chem. 2020, 2, 100085. [Google Scholar] [CrossRef]

- Mayrhofer, E.; Prielinger, L.; Sharp, V.; Rainer, B.; Kirchnawy, C.; Rung, C.; Gruner, A.; Juric, M.; Springer, A. Safety Assessment of Recycled Plastics from Post-Consumer Waste with a Combination of a Miniaturized Ames Test and Chromatographic Analysis. Recycling 2023, 8, 87. [Google Scholar] [CrossRef]

- Andreasi Bassi, S.; Boldrin, A.; Faraca, G.; Astrup, T.F. Extended producer responsibility: How to unlock the environmental and economic potential of plastic packaging waste? Resour. Conserv. Recycl. 2020, 162, 105030. [Google Scholar] [CrossRef]

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of post-consumer plastic packaging waste in the EU: Recovery rates, material flows, and barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef] [PubMed]

- Feil, A.; Pretz, T.; Jansen, M.; van Thoden Velzen, E.U. Separate collection of plastic waste, better than technical sorting from municipal solid waste? Waste Manag. Res. 2017, 35, 172–180. [Google Scholar] [CrossRef] [PubMed]

- Gritsch, L.; Lederer, J. A historical-technical analysis of packaging waste flows in Vienna. Resour. Conserv. Recycl. 2023, 194, 106975. [Google Scholar] [CrossRef]

- Horodytska, O.; Valdés, F.J.; Fullana, A. Plastic flexible films waste management—A state of art review. Waste Manag. 2018, 77, 413–425. [Google Scholar] [CrossRef] [PubMed]

- Lederer, J.; Bartl, A.; Blasenbauer, D.; Breslmayer, G.; Gritsch, L.; Hofer, S.; Lipp, A.-M.; Mühl, J. A review of recent trends to increase the share of post-consumer packaging waste to recycling in Europe. Detritus 2022, 19, 3–17. [Google Scholar] [CrossRef]

- Picuno, C.; Alassali, A.; Chong, Z.K.; Kuchta, K. Flows of post-consumer plastic packaging in Germany: An MFA-aided case study. Resour. Conserv. Recycl. 2021, 169, 105515. [Google Scholar] [CrossRef]

- Roosen, M.; Mys, N.; Kleinhans, K.; Lase, I.S.; Huysveld, S.; Brouwer, M.; van Thoden Velzen, E.U.; van Geem, K.M.; Dewulf, J.; Ragaert, K.; et al. Expanding the collection portfolio of plastic packaging: Impact on quantity and quality of sorted plastic waste fractions. Resour. Conserv. Recycl. 2022, 178, 106025. [Google Scholar] [CrossRef]

- Schuch, D.; Lederer, J.; Fellner, J.; Scharff, C. Separate collection rates for plastic packaging in Austria—A regional analysis taking collection systems and urbanization into account. Waste Manag. 2023, 155, 211–219. [Google Scholar] [CrossRef] [PubMed]

- Stotz, P.M.; Niero, M.; Bey, N.; Paraskevas, D. Environmental screening of novel technologies to increase material circularity: A case study on aluminium cans. Resour. Conserv. Recycl. 2017, 127, 96–106. [Google Scholar] [CrossRef]

- Tallentire, C.W.; Steubing, B. The environmental benefits of improving packaging waste collection in Europe. Waste Manag. 2020, 103, 426–436. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, S.; Laner, D. The multidimensional effects of single-use and packaging plastic strategies on German household waste management. Waste Manag. 2021, 131, 187–200. [Google Scholar] [CrossRef] [PubMed]

- Viscusi, W.K.; Huber, J.; Bell, J. Changes in household recycling behavior: Evidence from panel data. Ecol. Econ. 2023, 208, 107819. [Google Scholar] [CrossRef]

- Warrings, R.; Fellner, J. How to increase recycling rates. The case of aluminium packaging in Austria. Waste Manag. Res. 2021, 39, 53–62. [Google Scholar] [CrossRef] [PubMed]

- European Commission. A New Circular Economy Action Plan for a Cleaner and More Competetive Europe; European Commission: Brussel, Belgium, 2020. [Google Scholar]

- Turner, A. Black plastics: Linear and circular economies, hazardous additives and marine pollution. Environ. Int. 2018, 117, 308–318. [Google Scholar] [CrossRef] [PubMed]

- Stiftung Zentrale Stelle Verpackungsregister. Mindeststandard für die Bemessung der Recyclingfähigkeit von Systembeteiligungspflichtigen Verpackungen gemäß § 21 Abs. 3 VerpackG; Stiftung Zentrale Stelle Verpackungsregister: Osnabrück, Germany, 2024. [Google Scholar]

- RecyClass. Recyclability & Sorting Evaluation Protocols. Available online: https://recyclass.eu/recyclability/test-methods/ (accessed on 31 December 2024).

- Klein, M.; Neumair, C.; Primoceri, M.; Tacker, M.; Apprich, S. Fit for the Future: An Assessment of the Sustainability Parameters of Liquid Dairy Product Packaging in the DACH Region and the Implications of Upcoming Regulatory Changes. Foods 2025, 14, 195. [Google Scholar] [CrossRef] [PubMed]

| Packaging Type | Material | Butter | Yogurt | Spreads |

|---|---|---|---|---|

| Bucket | PP | 3 | ||

| Cup | PP | 9 | 6 | |

| Cup | PS | 14 | 6 | |

| Cup + CS | PP + Cardboard | 9 | 2 | |

| Cup + CS | PS + Cardboard | 14 | 5 | |

| Cup + CS | PET + Cardboard | 1 | 1 | |

| Jar | Glass | 1 | 4 | 1 |

| Jar | Ceramic | 1 | ||

| Shrink Foil | 1 | |||

| Tray | PP | 3 | 15 | |

| Tray | PS | 4 | ||

| Tray | PET | 1 | ||

| Tray + CS | PP + Cardboard | 6 | 3 | |

| Tray + CS | PS + Cardboard | 1 | ||

| Tray + CS | PET + Cardboard | 1 | ||

| Pouch | LDPE/HDPE | 1 | ||

| Wrap | Fiber Composite | 16 |

| Assessment Category | Definition |

|---|---|

| A | The material can be recycled within the designated material stream, and the resulting recyclate can be used for applications requiring materials of identical or superior quality. |

| B | The material can be recycled within the designated material stream; however, the resulting recycled material is of inferior quality. Furthermore, the quality of the recycled material for other materials in the same disposal unit is also negatively impacted. |

| C | It is not possible to recycle the material within the designated material stream. Nevertheless, the material does not affect the recyclability or quality of the recyclate of other materials in the same disposal unit to the same extent as other materials. |

| D | The material in question cannot be recycled within the assigned material stream. Furthermore, it is negatively affecting the recyclability and quality of the recyclate of other materials in the same disposal unit. |

| X | The material in question cannot be recycled within the assigned material stream. Furthermore, the material in question contaminates the disposal unit. All other materials in the disposal unit, which are processed with this material during the recycling process, are considered to be non-recyclable. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klein, M.; Neumair, C.; Tacker, M.; Apprich, S. Technical Recyclability and Carbon Footprint of Packaging for Butter, Yogurt, and Spreads. Recycling 2025, 10, 31. https://doi.org/10.3390/recycling10020031

Klein M, Neumair C, Tacker M, Apprich S. Technical Recyclability and Carbon Footprint of Packaging for Butter, Yogurt, and Spreads. Recycling. 2025; 10(2):31. https://doi.org/10.3390/recycling10020031

Chicago/Turabian StyleKlein, Michelle, Charlotte Neumair, Manfred Tacker, and Silvia Apprich. 2025. "Technical Recyclability and Carbon Footprint of Packaging for Butter, Yogurt, and Spreads" Recycling 10, no. 2: 31. https://doi.org/10.3390/recycling10020031

APA StyleKlein, M., Neumair, C., Tacker, M., & Apprich, S. (2025). Technical Recyclability and Carbon Footprint of Packaging for Butter, Yogurt, and Spreads. Recycling, 10(2), 31. https://doi.org/10.3390/recycling10020031