1. Introduction

Due to the widespread popularity of electric vehicles in recent years, the amount of retired power batteries will also increase rapidly [

1]. Among the retired power batteries, many still have high residual capacity (70% to 80% of the rated capacity of the battery), and these batteries can potentially be used in scenarios such as energy storage in power grids and backup in communication base stations to realize the secondary utilization of power batteries [

2,

3]. However, since the state of power batteries is usually unknown when they are retired, it is necessary to accurately estimate the State of Health (SOH) of the batteries before the batteries are used in the secondary process, so that the batteries with a greater degree of aging can be eliminated in time and the batteries with different aging states can enter the step-up environment in the corresponding stage. At the same time, the accurate estimation of State of Charge (SOC) in the process of step-up utilization can improve the utilization efficiency of retired batteries.

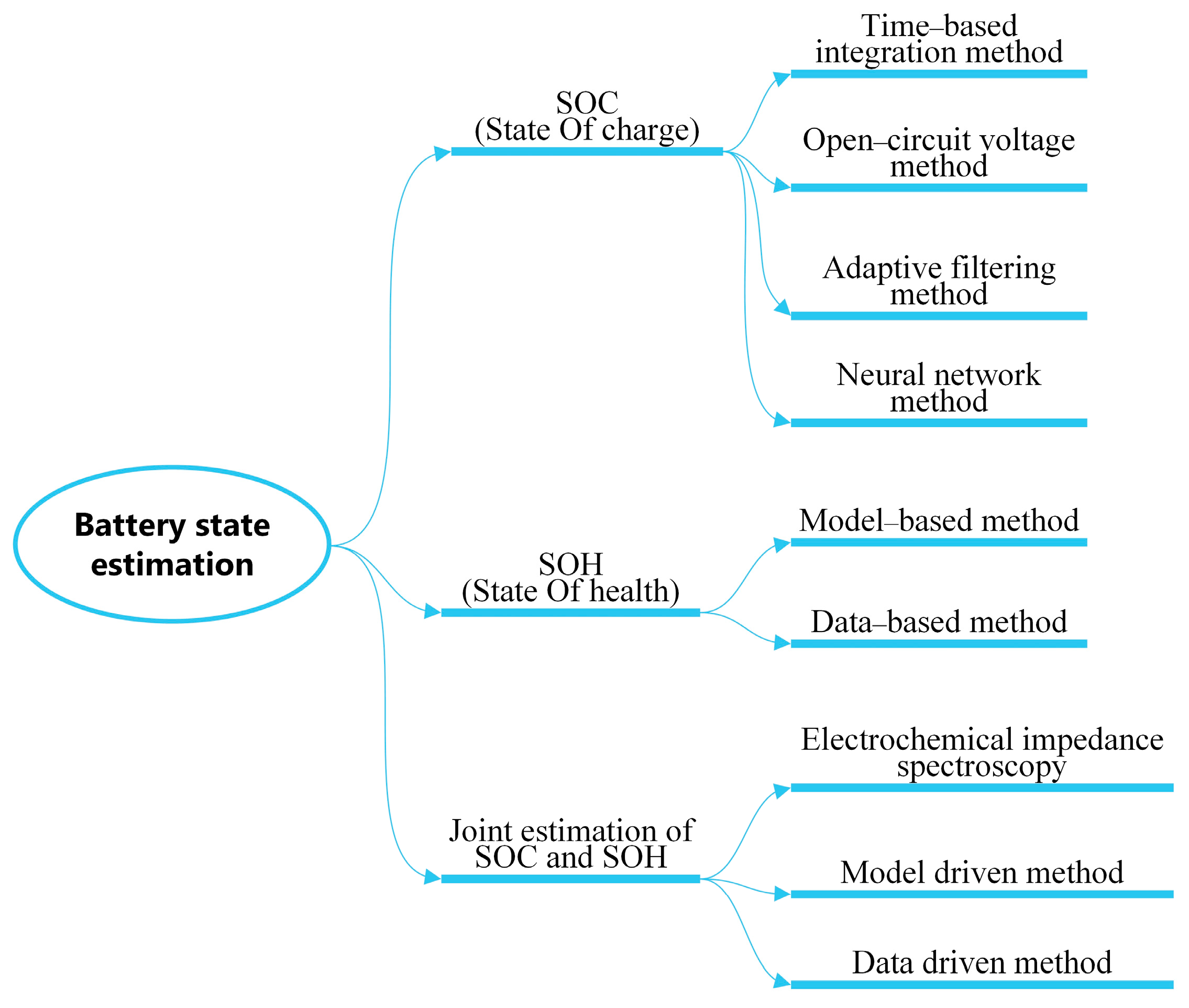

The existing SOC estimation methods mainly include time integration method [

4], open circuit voltage method [

5], adaptive filtering method [

6] and neural network method [

7]. Among them, the time-integral method discretely sums the current flowing through the battery, and obtains the SOC value through simple division [

8]. The open-circuit voltage method is to measure the open-circuit voltage of the battery and obtain the charge state according to the correspondence between the open-circuit voltage and the charge state [

9]. Adaptive filtering method is an optimal estimation of battery system in the sense of minimum variance, and is a model-based SOC estimation method [

10]. The neural network algorithm does not need to deeply understand the electrochemical mechanism inside the battery, nor does it need to establish additional complex physical and chemical models. Instead, it only needs to extract features by using the physical quantities measured during the battery charging and discharging process, and then use the features to train the model and establish a mapping model between the battery data features and SOC [

11].

SOH estimation algorithms mainly contain model-based methods [

12] and data-based methods [

13]. The research of model-based methods focuses on identifying and analyzing the main aging mechanisms of lithium-ion batteries and estimating the SOH values of batteries based on their correlation with model parameters. The commonly used models are generally classified into two main categories:physical models and equivalent circuit models. Usually, the parameters of the model are obtained by analyzing the performance of the battery, and then the SOH of the battery under different operating conditions can be obtained by analyzing the parameters of the model [

14]; the data-driven algorithm can learn the health condition and external characteristics of the battery autonomously and determine the nonlinear relationship between them, without understanding the working mechanism of the battery or establishing a clear battery The data-driven algorithm can estimate the battery health status by relying only on the aging data of the battery [

15]. Data-driven algorithms are increasingly used in battery state estimation due to their superiority.

The above algorithms are all single estimates of the battery SOC or SOH. However, in actual battery use, the effect of SOC estimation will be affected by the different degree of battery aging, while inaccurate SOC estimation will also affect SOH correction. And this situation becomes more obvious in the estimation of retired batteries because the aging degree of retired batteries varies with the actual operating environment they are in during their service. A fast prediction method for SOC and SOH of battery based on electrochemical impedance spectroscopy (EIS) was proposed in literature [

16], but this method achieved SOH prediction by comparing the difference of SOC with the discharge of constant current in a short time. In literature [

17], based on the DP-Thevenin model and least square parameter estimation method, the DP-Thevenin model was updated with time-varying parameters, and the improved extended Kalman filter algorithm was combined to complete the online collaborative prediction of SoC SOH for lithium ion batteries. However, the above methods have high requirements on the accuracy of the battery equivalent circuit model, so literature [

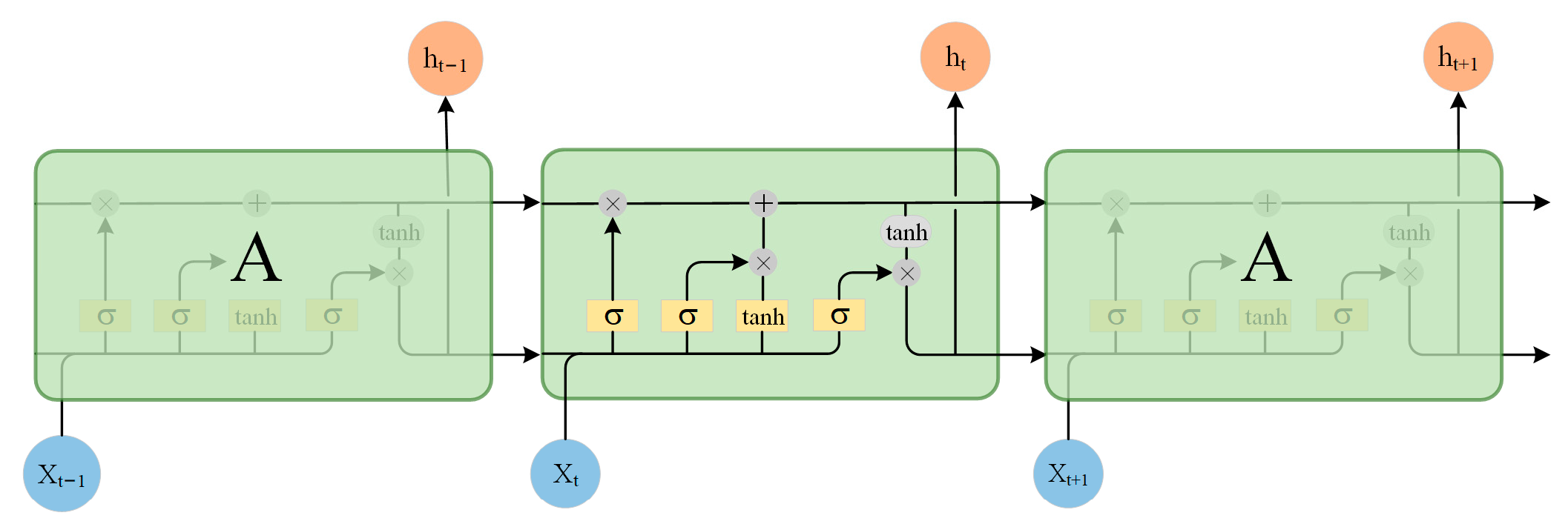

18] adopts a data-driven method to jointly predict the SOC and SOH of lithium batteries by constructing two recurrent neural networks (RNN). However, RNN can only store part of the sequence, which is not suitable for dealing with long sequence dependent problems, such as the estimation of the health state of lithium batteries. It is easy to produce large errors. Therefore, LSTM-RNN method was adopted in literature [

19] to predict battery remaining service life (RUL). Literature [

20] uses LSTM neural network combined with empirical mode decomposition to reduce the influence of capacity self-recovery effect and improve the prediction accuracy. Reference [

21] proposes a variant LSTM structure that includes a constant error turntable to reduce estimation errors. Literature [

22] analyzed the coupling relationship between battery SOC and SOH, and co-predicted SOC and SOH through LSTM deep learning network.

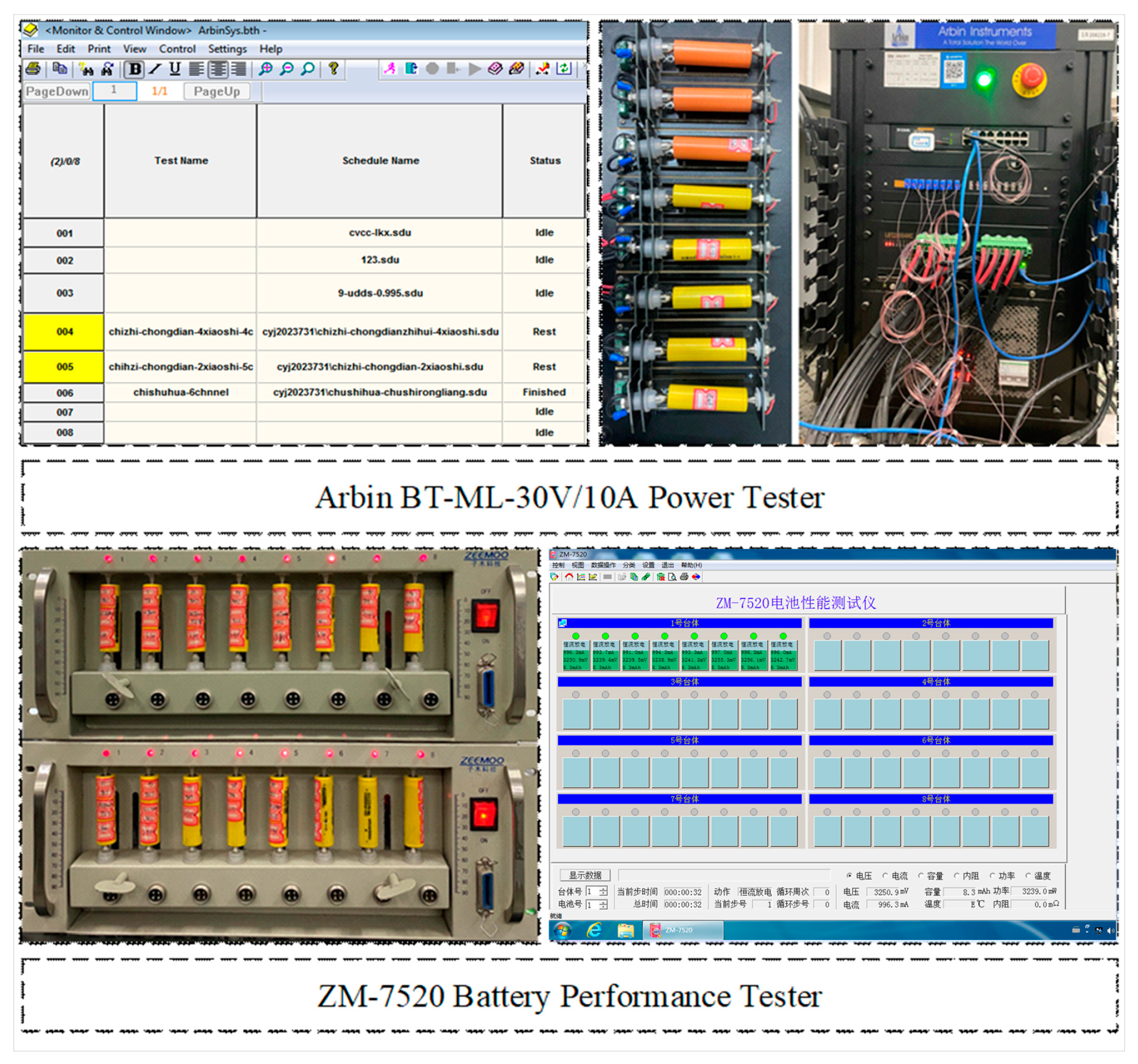

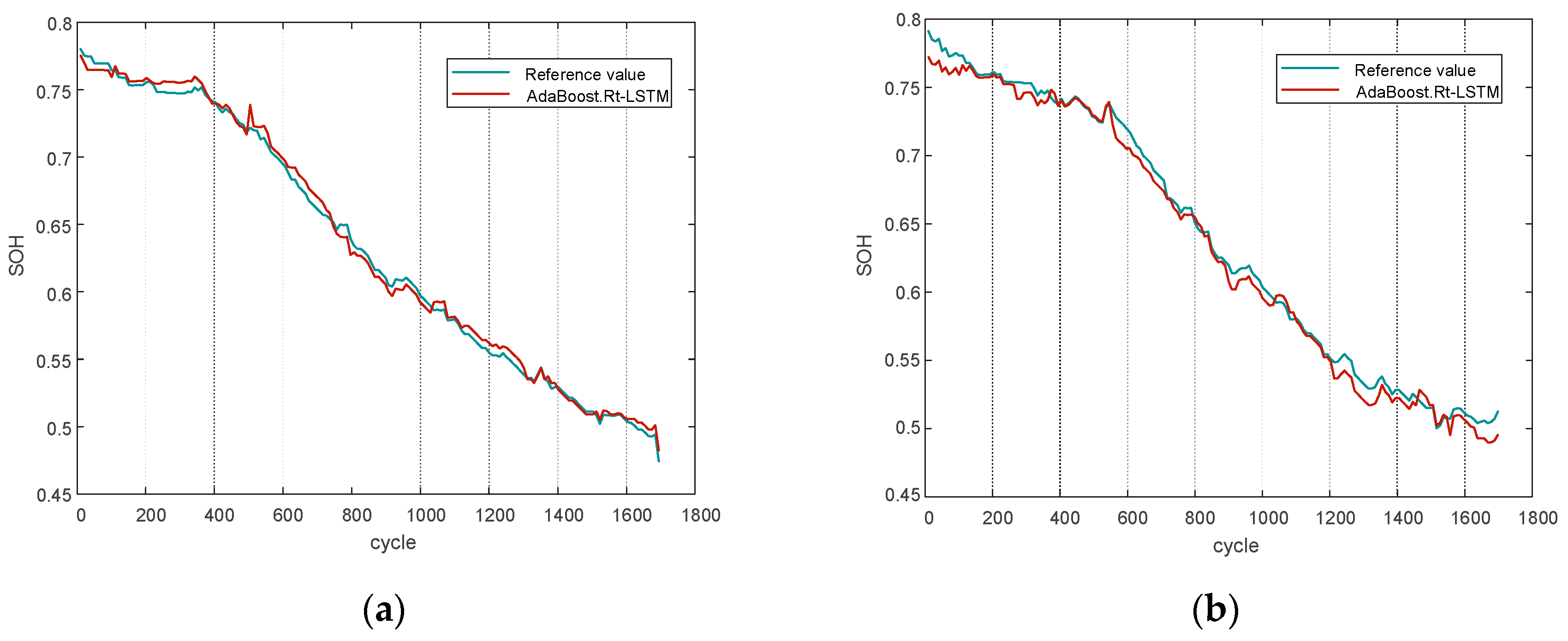

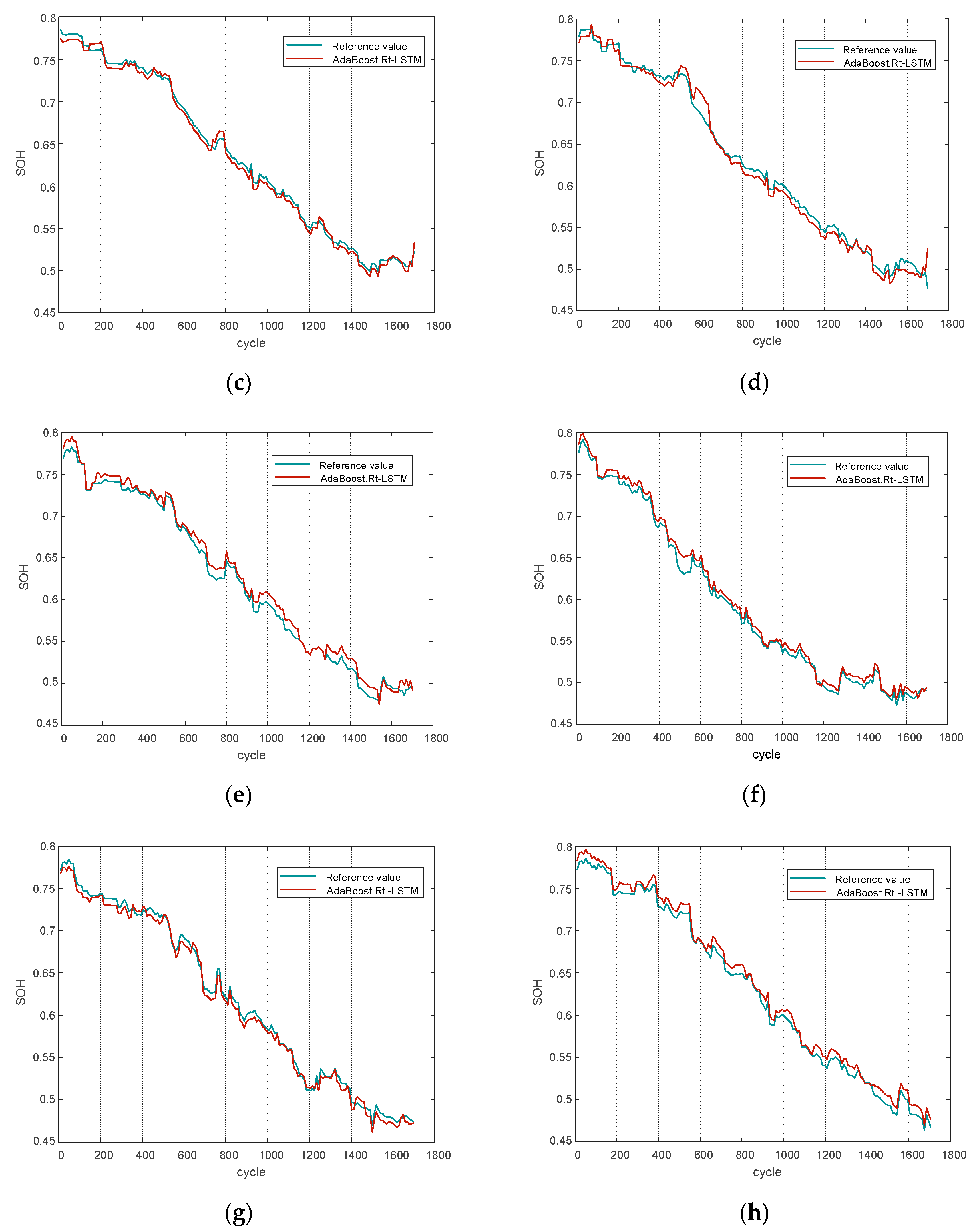

Figure 1 shows a breakdown of the battery state estimates.

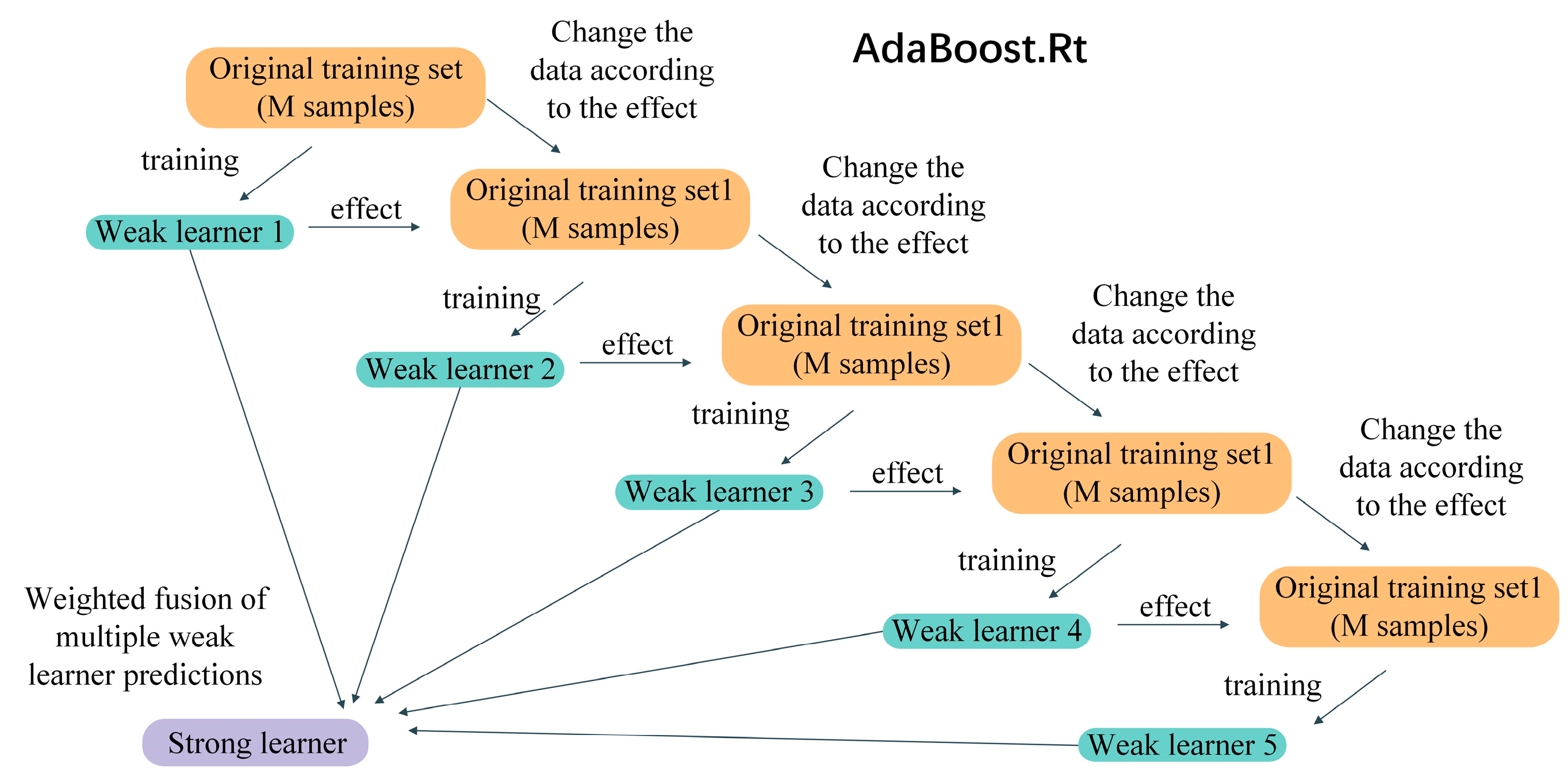

The above literature shows that data-driven algorithmic models have considerable potential and application prospects in joint battery estimation, but the large number of retired battery samples makes the previous data-driven algorithms face problems such as long learning time and low model update efficiency.AdaBoost, as one of the most typical Boosting algorithms, breaks the distribution law of the original samples by resampling. AdaBoost, as a typical Boosting algorithm, breaks the distribution of the original samples by resampling, so that the learning machine focuses more on the hard-to-learn samples, thus making Boosting an integrated algorithm with real practical value. The AdaBoost. RT algorithm, as one of the AdaBoost algorithm family, improves the AdaBoost algorithm by introducing a threshold constant, which transforms the regression problem into a simple binary classification problem, and combined with a specific weak learning machine, it can effectively achieve the prediction of time series, which greatly enhances the practicality of the AdaBoost algorithm and improves the learning efficiency of the algorithm as well as the model accuracy of the estimation [

23].

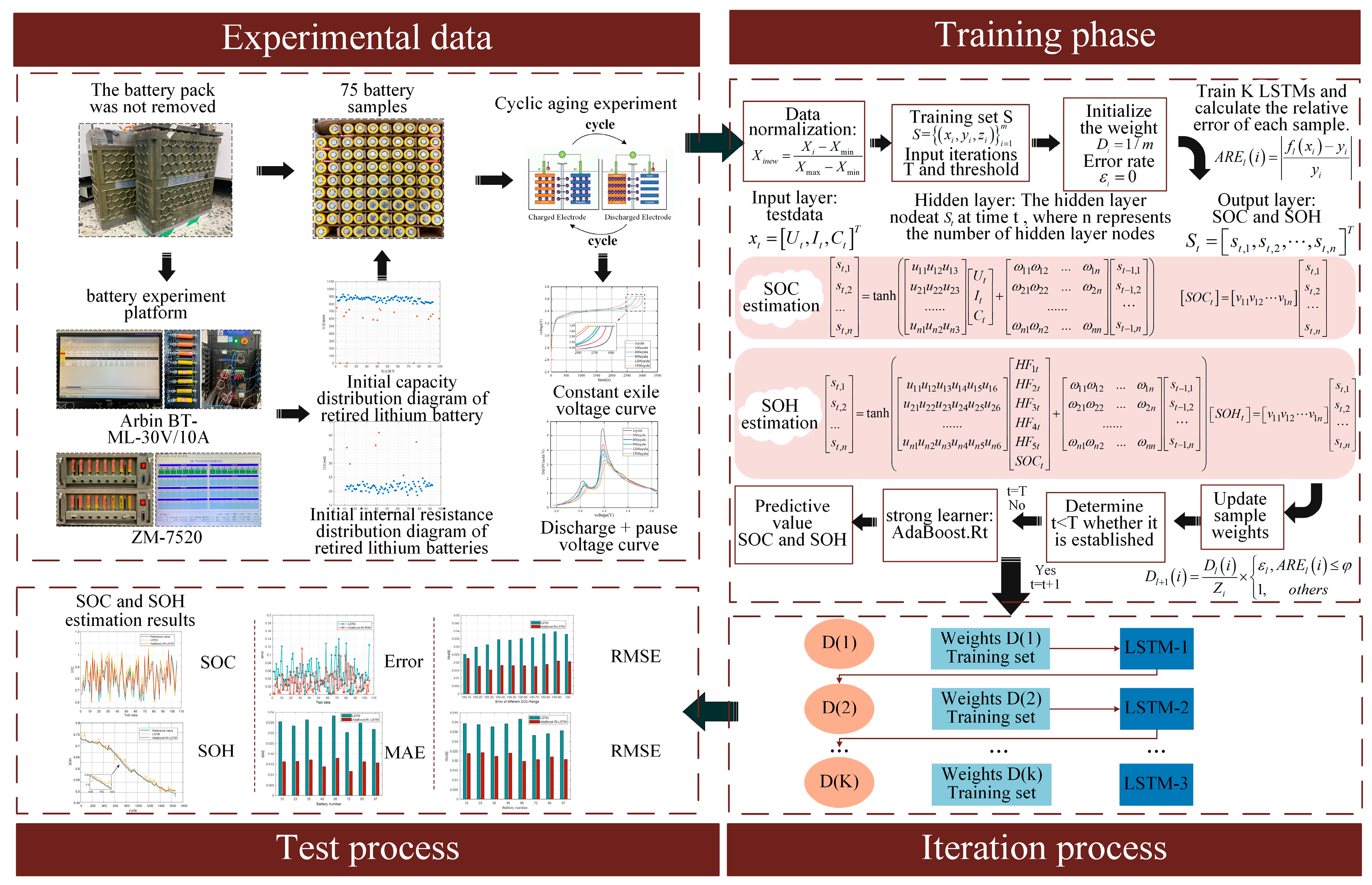

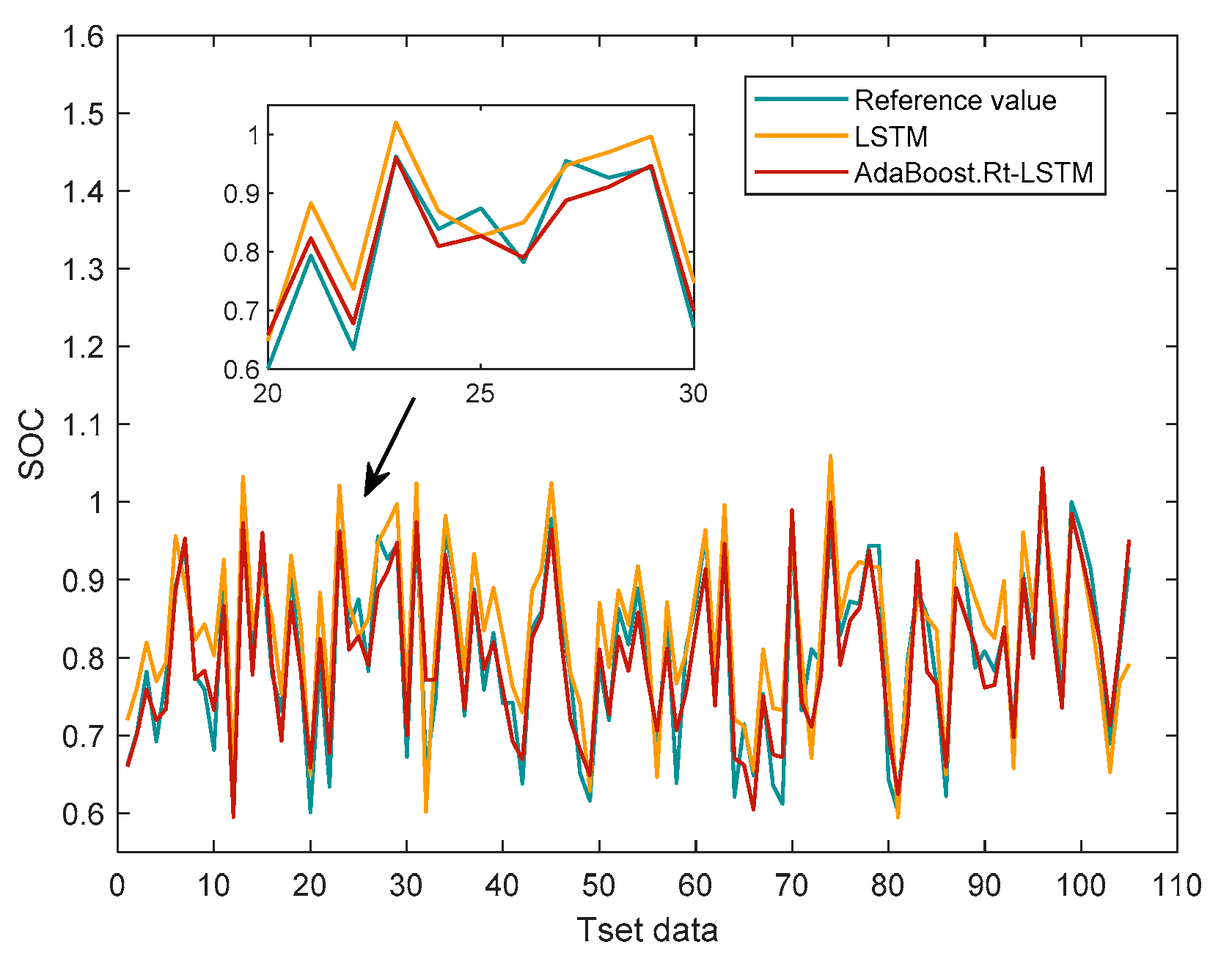

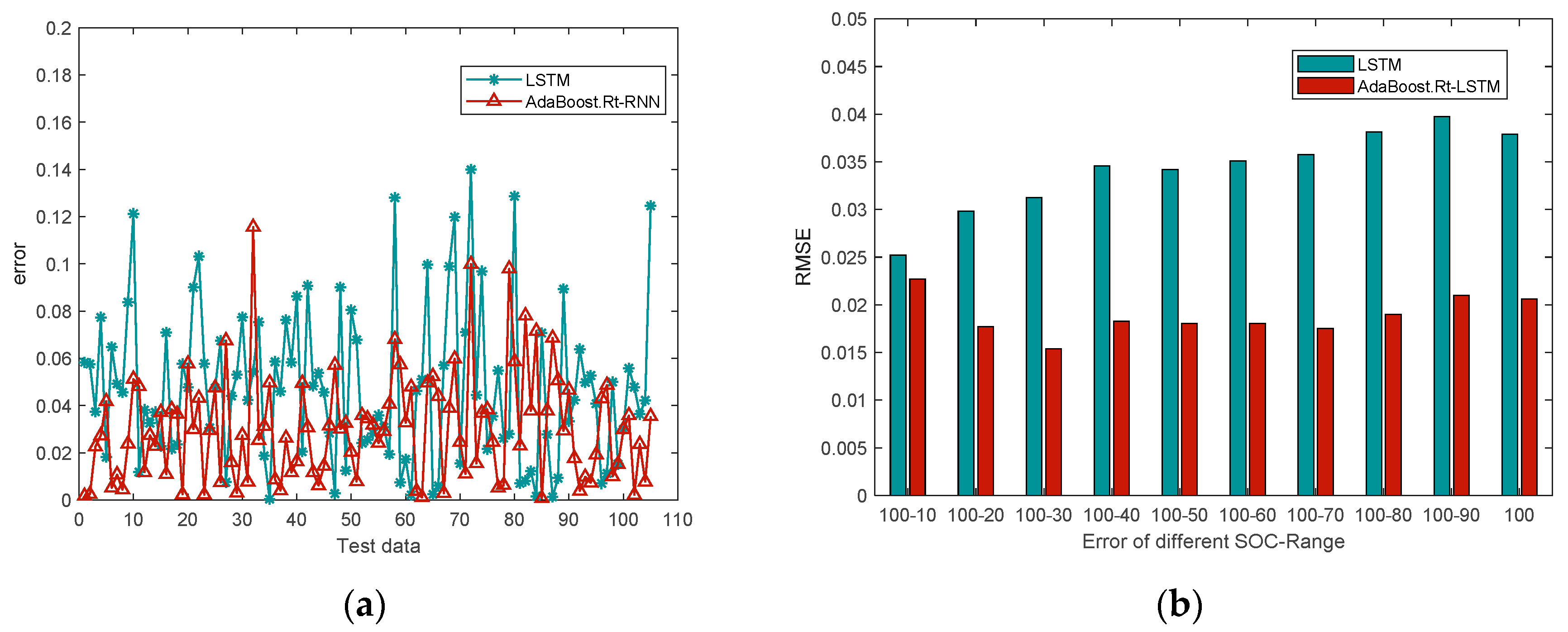

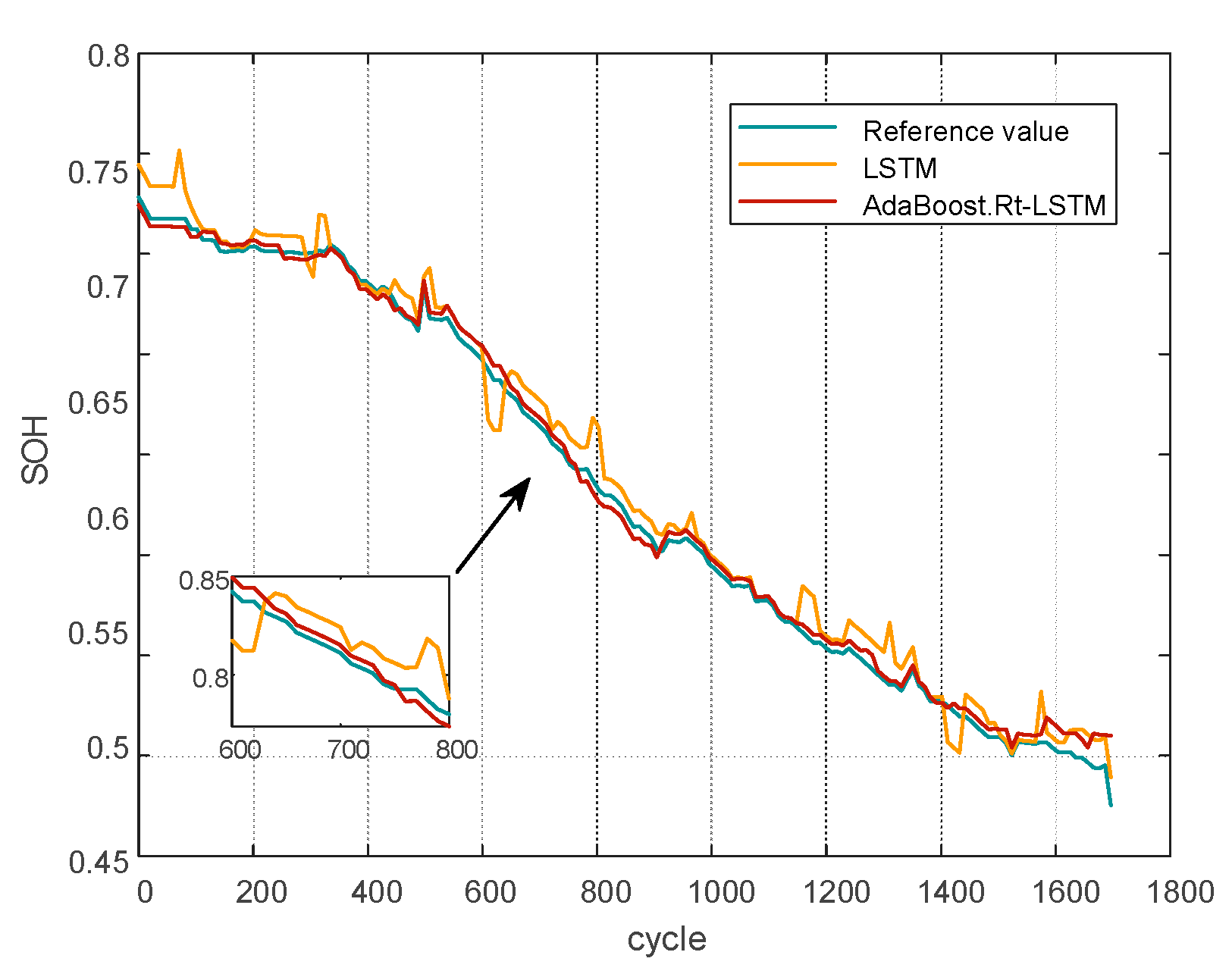

In summary, the data-driven battery estimation algorithm is simple and reliable and does not depend on the establishment of an accurate battery model, but most of the existing data-driven algorithms rely on the life cycle experimental data of a few batteries in the laboratory to estimate the SOH of the remaining battery cells, while in practice, the retired batteries are widely sourced and large in number, and the SOH estimation model established based on the laboratory environment has high accuracy but poor generalization The SOH estimation model based on the laboratory environment has high accuracy but poor generalization capability. Therefore, in this paper, an improved AdaBoost.Rt-LSTM battery SOC and SOH joint estimation method is proposed in a data-driven framework. The same batch of retired lithium battery packs are selected, and after screening and performance testing, 75 lithium iron phosphate batteries with good appearance and can be reused are finally obtained, five health characteristics of retired lithium batteries are extracted, and the correlation between health characteristics and capacity is analyzed using Pearson correlation coefficient, and the AdaBoost.Rt-LSTM model is used to jointly realize the retired lithium battery charge state and health state estimation. The long and short-term memory neural network used in this method not only has the advantages of recurrent neural network, but also can solve the problems of gradient disappearance and gradient explosion. The AdaBoost.Rt integration algorithm, which combines the LSTM weak predictors with weights to form a strong predictor, greatly solves the problem of low accuracy of state estimation due to the large number of retired batteries and large variability. Simulation and experimental comparison show that the proposed AdaBoost.Rt-LSTM algorithm can jointly estimate the SOC and SOH of Li-ion batteries, ensuring the prediction accuracy and generalization performance of the model.