Sustainable Development Goals and End-of-Life Electric Vehicle Battery: Literature Review

Abstract

1. Introduction

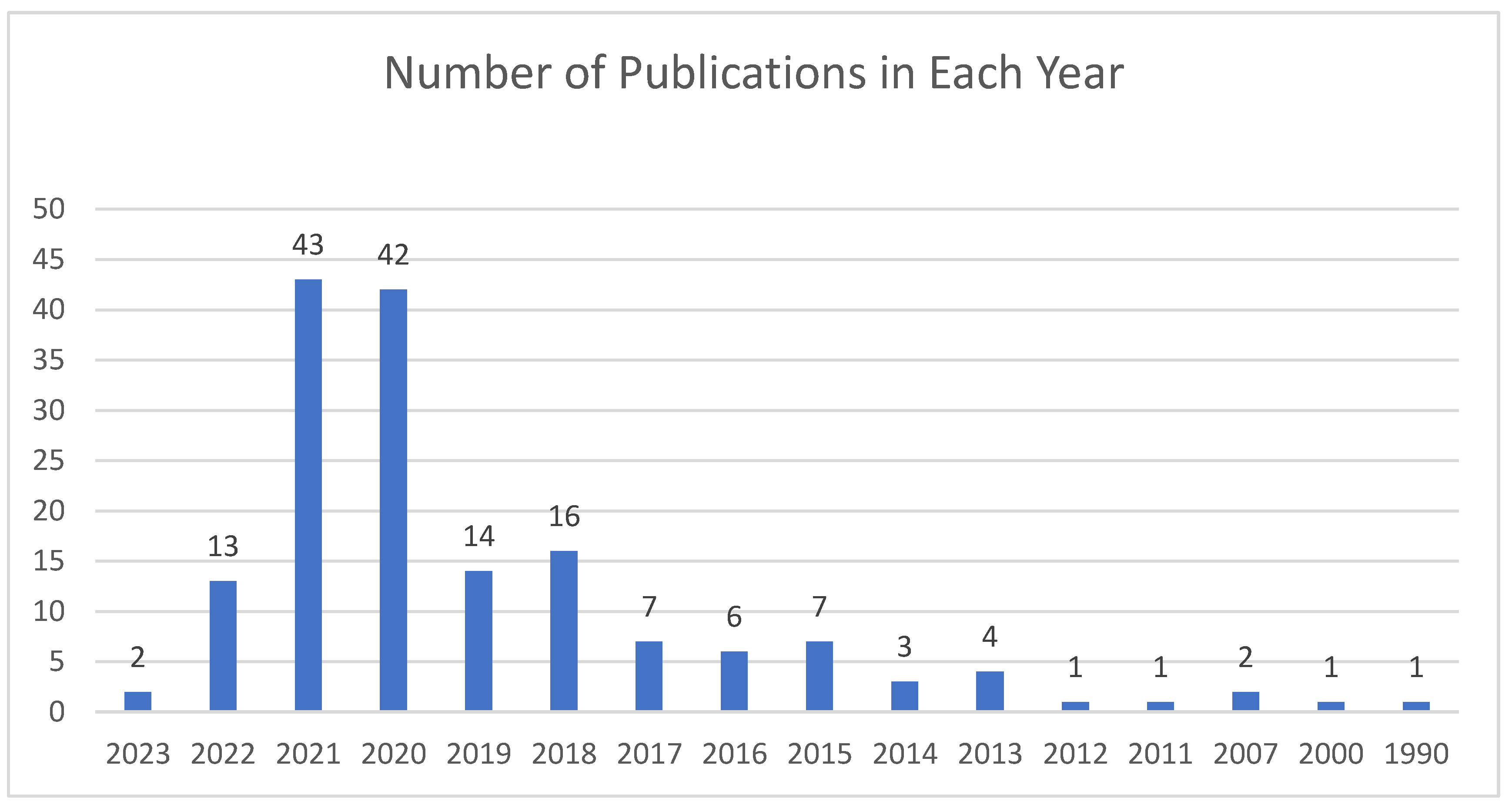

2. Research Methodology

3. Sustainable Development Goals (SDG)

4. Life Cycle Assessment

| Author | Year | Remarks |

|---|---|---|

| Koroma et al. | 2022 [32] | This study conducted an LCA for three contexts considering future changes in EV charging, battery efficiency fade and refurbishment, and recycling by determining their significance on battery life cycles and performance. |

| Shafique and Luo | 2022 [33] | This paper investigated the impacts on the environment caused by the production, transportation, and other EV phases; it found that China’s EVs had the high est impact when compared to other EVs, considering the 2019 and 2025 electricity mix scenarios. |

| Yang et al. | 2021 [34] | This study used an LCA to find the CO2 emissions from vehicle production, use, and EOL. |

| Sun et al. | 2020 [35] | This paper showed that, for a LIB’s lifecycle, the highest energy demand and global warming potential come from its material preparation, wrought aluminum, and electrolytes. |

| Qiao et al. | 2019 [36] | This paper showed that in 2015, the life cycle GHG emissions of an EV came out to be 41.0 t of CO2-eq, which was 18% lower than ICE vehicles. |

| Bicer and Dincer | 2018 [37] | The study conducted an in-depth comparison of ICE vehicles, hybrid electric vehicles, and EVs, with regards to environmental impact, by employing a process based LCA to analyze raw material extraction to vehicle disposal. |

| Burchart-Korol et al. | 2018 [38] | This paper focused on EVs in Poland and the Czech Republic, conducting an LCA about electricity production for charging batteries; it considered systems from 2015 to projected systems in 2050 to be used to charge EVs. |

| Wu et al. | 2018 [39] | This study conducted an LCA to quantify the GHG emissions from EVs and ICE vehicles across their lifecycles in 2010, 2014, and 2020 under various contexts; it found that there is potential for such GHGs to be reduced by adopting EVs as the main mode of transport, as their life cycle showed lower emissions than ICE vehicles. |

| Kim et al. | 2016 [40] | This paper assessed the emissions across the life cycle of a particular battery in an EV, namely, the LIB in the Ford Focus. It considered energy materials’ input and other data collected from the battery cell and pack supplier, and it concluded that the GHG emissions for these 24 kWh LIBs are 3.4 tons of CO2-eq across its lifespan, which translates to 140 kg per kWh or 11 kg per kg of the battery. |

| Tagliaferri et al. | 2016 [41] | This study conducted an LCA on a European LIB powered EV and compared it to an ICE vehicle; it showed that the GHG emissions for the former were half that of the latter during their use phases. |

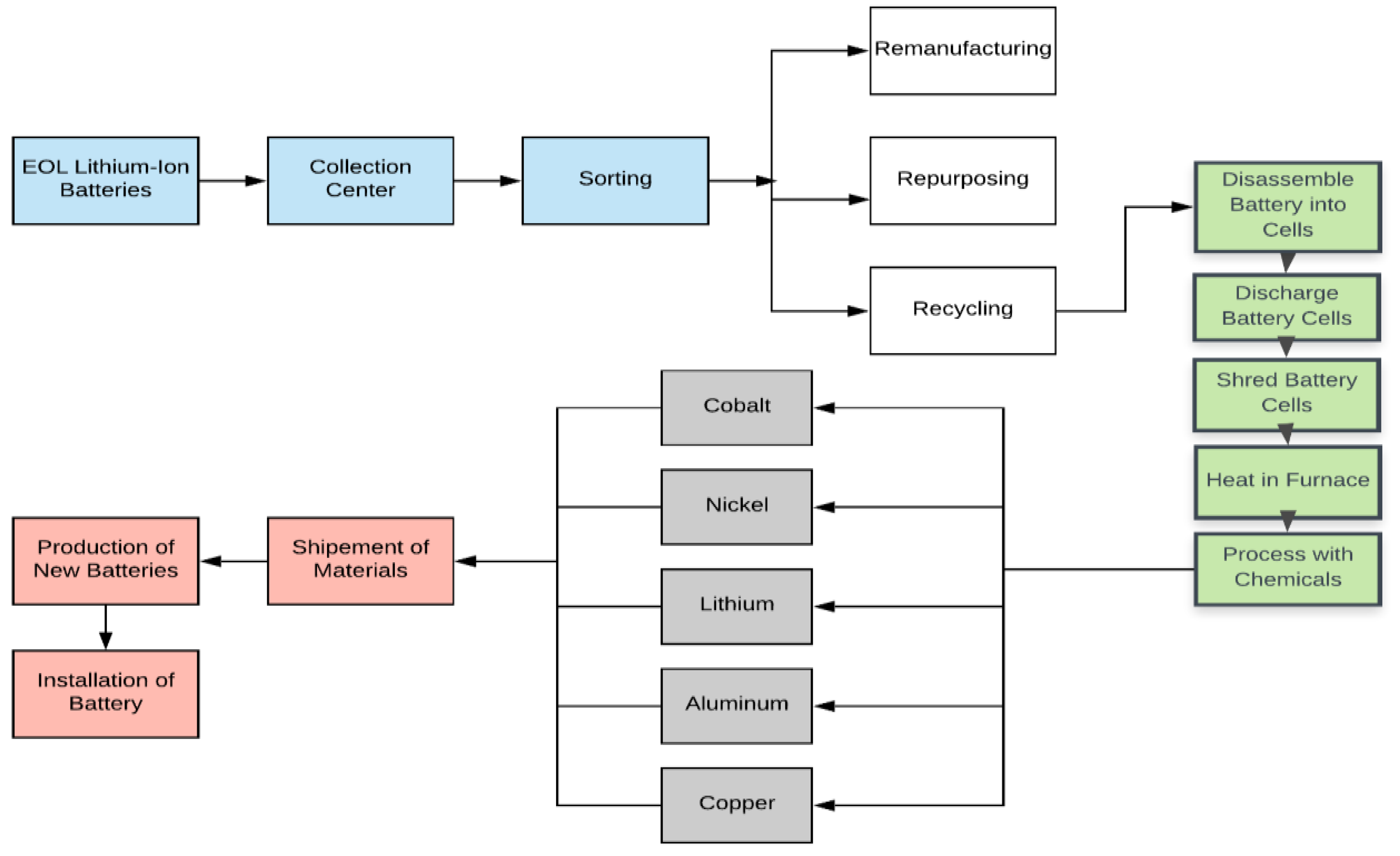

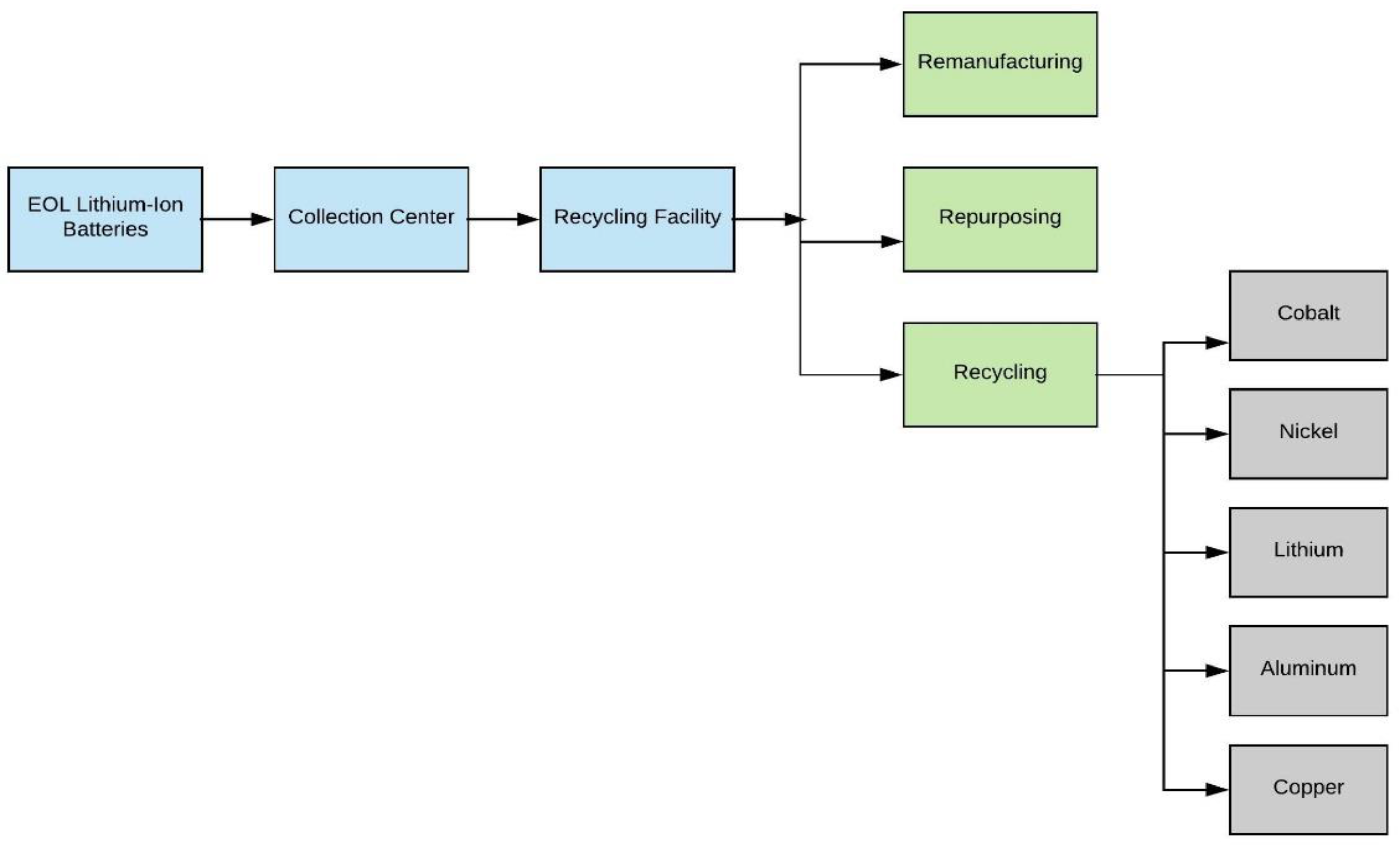

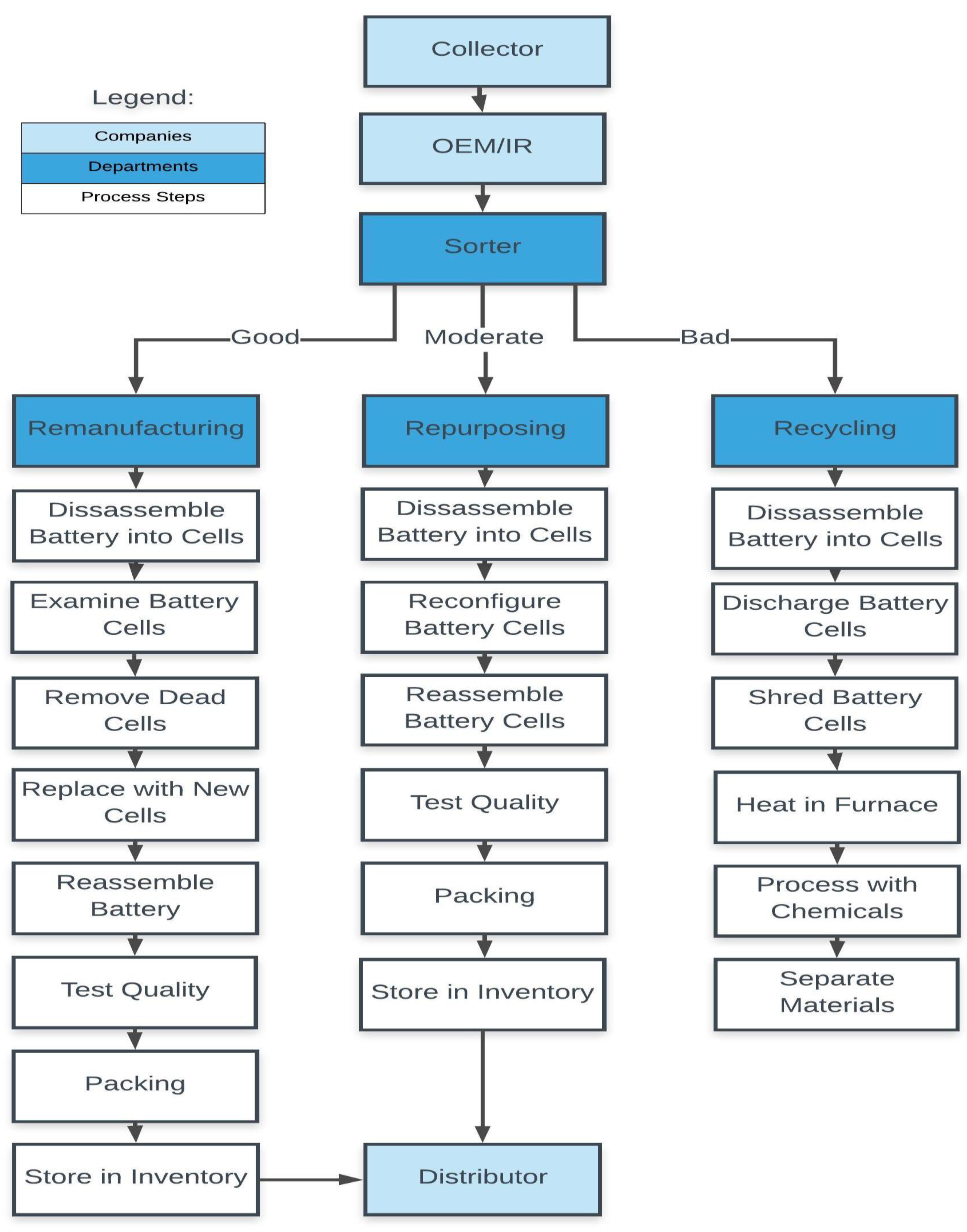

5. Recycling Processes

5.1. Recycling Steps

5.2. Pyrometallurgical Process

5.3. Special Recycling Process

5.4. Direct Recycling Process

5.5. Hydrometallurgical Process

5.6. Metallurgical and Mechanical Processes

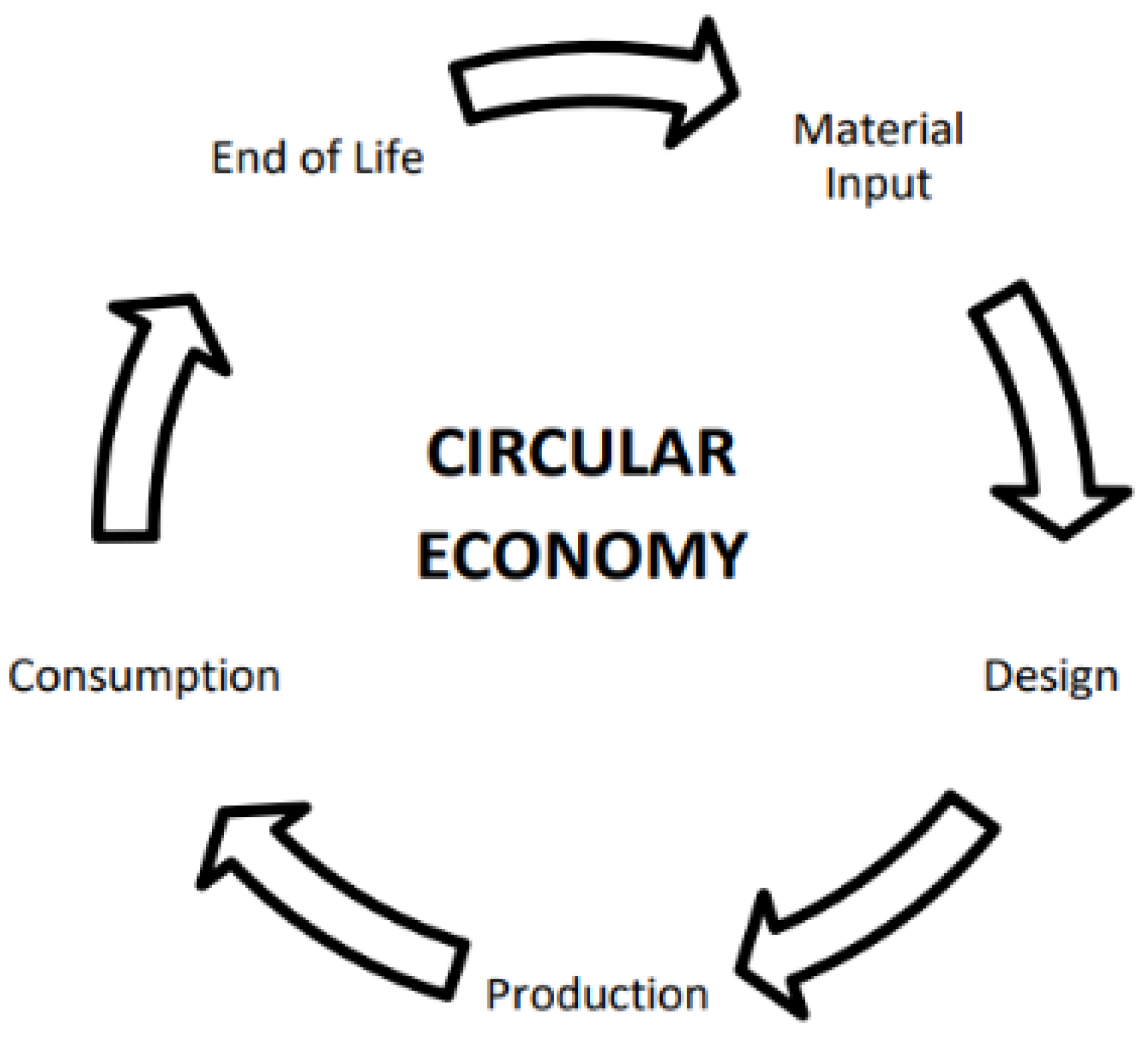

6. Circular Economy

7. Environmental Benefits

8. Discussion

9. Future Work

10. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- United Nations General Assembly. Transforming Our World: The 2030 Agenda for Sustainable Development. 2015. Available online: https://sustainabledevelopment.un.org/content/documents/21252030%20Agenda%20for%20Sustainable%20Development%20web.pdf (accessed on 13 March 2023).

- Nilsson, M.; Griggs, D.; Visbeck, M. Policy: Map the interactions between Sustainable Development Goals. Nature 2016, 534, 320–322. [Google Scholar] [CrossRef]

- Lu, Y.; Nakicenovic, N.; Visbeck, M.; Stevance, A.-S. Policy: Five priorities for the UN Sustainable Development Goals. Nature 2015, 520, 432–433. [Google Scholar] [CrossRef]

- Schmidt-Traub, G. Investment Needs to Achieve the Sustainable Development Goals: Understanding the Billions and Trillions. 12 November 2015. Available online: https://www.jstor.org/stable/resrep15864 (accessed on 16 January 2023).

- Bue, M.C.L.; Klasen, S. Identifying Synergies and Complementarities Between MDGs: Results from Cluster Analysis. Soc. Indic. Res. 2013, 113, 647–670. [Google Scholar] [CrossRef]

- Mathy, S.; Blanchard, O. Proposal for a poverty-adaptation-mitigation window within the Green Climate Fund. Clim. Policy 2015, 16, 752–767. [Google Scholar] [CrossRef]

- Smith, P.; Olesen, J.E. Synergies between the mitigation of, and adaptation to, climate change in agriculture. J. Agric. Sci. 2010, 148, 543–552. [Google Scholar] [CrossRef]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2015; Available online: https://sdgs.un.org/2030agenda (accessed on 21 December 2022).

- IPCC. Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5°C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty; IPCC: Geneva, Switzerland, 2018; Available online: https://www.ipcc.ch/sr15/ (accessed on 10 January 2023).

- UNEP. The Emissions Gap Report 2018. United Nations Environnent Programme, Nairobi. 2018. Available online: sources/emissions-gap-report-2018 (accessed on 10 February 2022).

- Pražanová, A.; Knap, V.; Stroe, D.-I. Literature Review, Recycling of Lithium-Ion Batteries from Electric Vehicles, Part I: Recycling Technology. Energies 2022, 15, 1086. [Google Scholar] [CrossRef]

- Loganathan, M.K.; Anandarajah, G.; Tan, C.M.; Msagati, T.A.M.; Das, B.; Hazarika, M. Review and selection of recycling technology for lithium-ion batteries made for EV application—A life cycle perspective. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022; Volume 1100, p. 012011. [Google Scholar] [CrossRef]

- Regatieri, H.R.; Junior, O.H.A.; Salgado, J.R.C. Systematic Review of Lithium-Ion Battery Recycling Literature Using ProKnow-C and Methodi Ordinatio. Energies 2022, 15, 1485. [Google Scholar] [CrossRef]

- Chakraborty, P.; Parker, R.; Hoque, T.; Cruz, J.; Du, L.; Wang, S.; Bhunia, S. Addressing the range anxiety of battery electric vehicles with charging en route. Sci. Rep. 2022, 12, 5588. [Google Scholar] [CrossRef]

- Leijon, J.; Boström, C. Charging Electric Vehicles Today and in the Future. World Electr. Veh. J. 2022, 13, 139. [Google Scholar] [CrossRef]

- United Nations. The Future We Want: Resolution Adopted by the General Assembly on 27 July 2012. 2012. Available online: https://www.un.org/ga/search/view_doc.asp?symbol=A/RES/66/288&Lang=E (accessed on 10 February 2023).

- Bose, S.; Khan, H.Z. Sustainable development goals (SDGs) reporting and the role of country-level institutional factors: International evidence. J. Clean. Prod. 2021, 335, 130290. [Google Scholar] [CrossRef]

- Pereira, P.; Zhao, W.; Symochko, L.; Inacio, M.; Bogunovic, I.; Barcelo, D. The Russian-Ukrainian armed conflict will push back the sustainable development goals. Geogr. Sustain. 2022, 3, 277–287. [Google Scholar] [CrossRef]

- Business Line. Sustainable Mobility: Role of EVs in Achieving SDGs. Retrieved from Sustainable Mobility: Role of EVs in Achieving SDGs; The Hindu Business Line: Chennai, India, 2021. [Google Scholar]

- Belmonte-Ureña, L.J.; Plaza-Úbeda, J.A.; Vazquez-Brust, D.; Yakovleva, N. Circular economy, degrowth and green growth as pathways for research on sustainable development goals: A global analysis and future agenda. Ecol. Econ. 2021, 185, 107050. [Google Scholar] [CrossRef]

- Zwiers, J.; Jaeger-Erben, M.; Hofmann, F. Circular literacy. A knowledge-based approach to the circular economy. Cult. Organ. 2020, 26, 121–141. [Google Scholar] [CrossRef]

- Hernandez, R.R.; Jordaan, S.M.; Kaldunski, B.; Kumar, N. Aligning Climate Change and Sustainable Development Goals With an Innovation Systems Roadmap for Renewable Power. Front. Sustain. 2020, 1, 583090. [Google Scholar] [CrossRef]

- Tremblay, D.; Fortier, F.; Boucher, J.; Riffon, O.; Villeneuve, C. Sustainable development goal interactions: An analysis based on the five pillars of the 2030 agenda. Sustain. Dev. 2020, 28, 1584–1596. [Google Scholar] [CrossRef]

- García-Feijoo, M.; Eizaguirre, A.; Rica-Aspiunza, A. Systematic Review of Sustainable-Development-Goal Deployment in Business Schools. Sustainability 2020, 12, 440. [Google Scholar] [CrossRef]

- UNDP. Impact of COVID-19 on the Sustainable Development Goals: Pursuing the Sustainable Development Goals (SDGs) in a World Reshaped by COVID-19; Josef Korbel School of International Studies, University of Denver: Denver, CO, USA, 2020. [Google Scholar]

- Vinuesa, R.; Azizpour, H.; Leite, I.; Balaam, M.; Dignum, V.; Domisch, S.; Felländer, A.; Langhans, S.D.; Tegmark, M.; Nerini, F.F. The role of artificial intelligence in achieving the Sustainable Development Goals. Nat. Commun. 2020, 11, 1–10. [Google Scholar] [CrossRef]

- Schroeder, P.; Anggraeni, K.; Weber, U. The Relevance of Circular Economy Practices to the Sustainable Development Goals. J. Ind. Ecol. 2019, 23, 77–95. [Google Scholar] [CrossRef]

- Allen, C.; Metternicht, G.; Wiedmann, T. Initial progress in implementing the Sustainable Development Goals (SDGs): A review of evidence from countries. Sustain. Sci. 2018, 13, 1453–1467. [Google Scholar] [CrossRef]

- Stafford-Smith, M.; Griggs, D.; Gaffney, O.; Ullah, F.; Reyers, B.; Kanie, N.; Stigson, B.; Shrivastava, P.; Leach, M.; O’connell, D. Integration: The key to implementing the Sustainable Development Goals. Sustain. Sci. 2016, 12, 911–919. [Google Scholar] [CrossRef] [PubMed]

- Hossain, E.; Murtaugh, D.; Mody, J.; Faruque, H.M.R.; Sunny, S.H.; Mohammad, N. A Comprehensive Review on Second-Life Batteries: Current State, Manufacturing Considerations, Applications, Impacts, Barriers & Potential Solutions, Business Strategies, and Policies. IEEE Access 2019, 7, 73215–73252. [Google Scholar] [CrossRef]

- Casals, L.C.; Amante García, B.; Canal, C. Second life batteries lifespan: Rest of useful life and environmental analysis. J. Environ. Manag. 2019, 232, 354–363. [Google Scholar] [CrossRef]

- Koroma, M.S.; Costa, D.; Philippot, M.; Cardellini, G.; Hosen, S.; Coosemans, T.; Messagie, M. Life cycle assessment of battery electric vehicles: Implications of future electricity mix and different battery end-of-life management. Sci. Total. Environ. 2022, 831, 154859. [Google Scholar] [CrossRef]

- Shafique, M.; Luo, X. Environmental life cycle assessment of battery electric vehicles from the current and future energy mix perspective. J. Environ. Manag. 2021, 303, 114050. [Google Scholar] [CrossRef]

- Yang, L.; Yu, B.; Yang, B.; Chen, H.; Malima, G.; Wei, Y.-M. Life cycle environmental assessment of electric and internal combustion engine vehicles in China. J. Clean. Prod. 2021, 285, 124899. [Google Scholar] [CrossRef]

- Sun, X.; Luo, X.; Zhang, Z.; Meng, F.; Yang, J. Life cycle assessment of lithium nickel cobalt manganese oxide (NCM) batteries for electric passenger vehicles. J. Clean. Prod. 2020, 273, 123006. [Google Scholar] [CrossRef]

- Qiao, Q.; Zhao, F.; Liu, Z.; Hao, H. Electric vehicle recycling in China: Economic and environmental benefits. Resour. Conserv. Recycl. 2019, 140, 45–53. [Google Scholar] [CrossRef]

- Bicer, Y.; Dincer, I. Life cycle environmental impact assessments and comparisons of alternative fuels for clean vehicles. Resour. Conserv. Recycl. 2018, 132, 141–157. [Google Scholar] [CrossRef]

- Burchart-Korol, D.; Jursova, S.; Folęga, P.; Korol, J.; Pustejovska, P.; Blaut, A. Environmental life cycle assessment of electric vehicles in Poland and the Czech Republic. J. Clean. Prod. 2018, 202, 476–487. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, M.; Zheng, J.; Sun, X.; Zhao, M.; Wang, X. Life cycle greenhouse gas emission reduction potential of battery electric vehicle. J. Clean. Prod. 2018, 190, 462–470. [Google Scholar] [CrossRef]

- Kim, H.C.; Wallington, T.J.; Arsenault, R.; Bae, C.; Ahn, S.; Lee, J. Cradle-to-Gate Emissions from a Commercial Electric Vehicle Li-Ion Battery: A Comparative Analysis. Environ. Sci. Technol. 2016, 50, 7715–7722. [Google Scholar] [CrossRef] [PubMed]

- Tagliaferri, C.; Evangelisti, S.; Acconcia, F.; Domenech, T.; Ekins, P.; Barletta, D.; Lettieri, P. Life cycle assessment of future electric and hybrid vehicles: A cradle-to-grave systems engineering approach. Chem. Eng. Res. Des. 2016, 112, 298–309. [Google Scholar] [CrossRef]

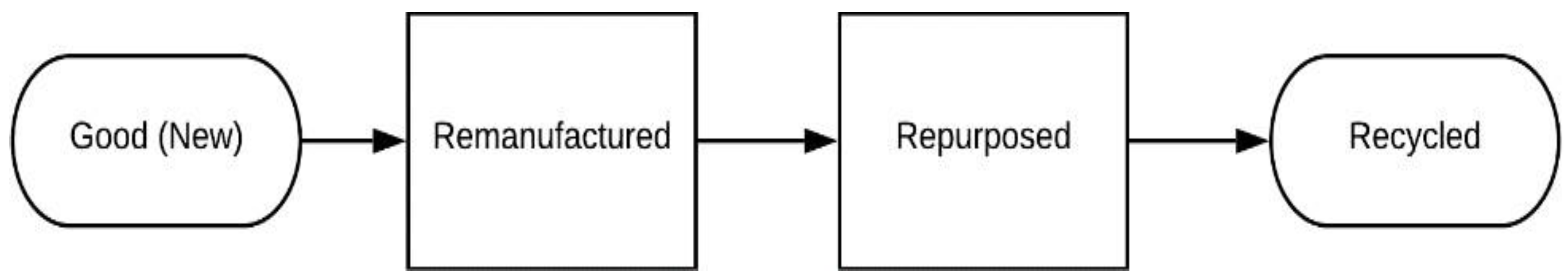

- Akram, M.N.; Abdul-Kader, W. Electric vehicle battery state changes and reverse logistics considerations. Int. J. Sustain. Eng. 2021, 14, 390–403. [Google Scholar] [CrossRef]

- Nordic Council of Ministers. Mapping of Lithium-Ion Batteries for Vehicles; Nordisk Ministerråd: Copenhagen, Denmark, 2019; ISBN 9789289362931. [Google Scholar]

- Dowa Holdings Co. Ltd. DOWA ECO-SYSTEM Expands Used Lithium-Ion Battery Recycling Capacity. 2021. Available online: https://ir.dowa.co.jp/en/ir/news/news20210419.html (accessed on 10 January 2023).

- Redux. Our Sites. 2021. Available online: https://www.redux-recycling.com/en/our-company/our-sites/ (accessed on 10 January 2023).

- Barker, K. Green Li-ion to Launch First Lithium-Ion Battery Recycling Technology in Singapore. Recycling Product News. 2020. Available online: https://www.recyclingproductnews.com/article/34573/green-li-ionto-launch-first-lithium-ion-battery-recy-cling-technology-in-Singapore (accessed on 10 January 2023).

- Jee-Hee, K.; Posco, H.Y. Clean Metal Breaks Ground on Battery Recycling Plant, Korea JoongAng Daily. 2021. Available online: https://korea-joongangdai-ly.joins.com/2021/09/30/business/industry/poscoposco-HY-clean-metal-battery-recycling/20210930191516184.html (accessed on 10 January 2023).

- Kumagai, J. Lithium-Ion Battery Recycling Finally Takes Off in North America and Europe. IEEE Spectrum. 2021. Available online: https://spec-trum.ieee.org/lithiumion-battery-recycling-finally-takes-off-in-northamerica-and-europe (accessed on 10 January 2023).

- Underwood, J. Canada’s Li-Cycle Plans EV Battery Recycling Facility in Alabama. Made in Alabama. 2021. Available online: https://www.madeinalabama.com/2021/09/canadas-li-cycle-plans-ev-batteryrecycling-facility-in-alabama/ (accessed on 10 January 2023).

- Fortum. Fortum Makes New Harjavalta Recycling Plant Investment to Expand Its Battery Recycling Capacity. 2021. Available online: https://www.for-tum.com/media/2021/06/fortum-makes-new-harjavaltarecycling-plant-investment-expand-its-battery-recycling-capacity (accessed on 10 January 2023).

- Jones, T. New Battery Recycling Plant to Launch in the Black Country. Business Live. 2020. Available online: https://www.business-live.co.uk/commercial-property/new-battery-recycling-plant-launch-18955327 (accessed on 10 January 2023).

- Roedel, K. Construction Could Begin Soon on Lithium-Ion Battery Plant in Fernley. Nevada Appeal. 2021. Available online: https://www.ne-vadaappeal.com/news/2021/apr/14/construction-could-beginsoon-lithium-ion-battery-/ (accessed on 10 January 2023).

- NAAT Batt International. Study of Large-Format EV Lithium-Ion Battery Recycling in China. 2019. Available online: https://naatbatt.org/wp-con-tent/uploads/2021/03/FINAL-Report-on-China-EV-Battery-RecyclingFeb.-2019.pdf (accessed on 10 January 2023).

- Shalu Agarwal, M.R. Lithium-Ion Battery Recycling Market & Technology Trends 2020. Yole Development. 2020. Available online: https://s3.i-micronews.com/uploads/2020/07/YDR20092_Li-ion_Battery_Recycling_Trends_2020_Sample.pdf (accessed on 10 January 2023).

- Lv, W.; Wang, Z.; Cao, H.; Sun, Y.; Zhang, Y.; Sun, Z.H. A Critical Review and Analysis on the Recycling of Spent Lithium-Ion Batteries. ACS Sustain. Chem. Eng. 2018, 6, 1504–1521. [Google Scholar] [CrossRef]

- Velázquez-Martínez, O.; Valio, J.; Santasalo-Aarnio, A.; Reuter, M.; Serna-Guerrero, R. A Critical Review of Lithium-Ion Battery Recycling Processes from a Circular Economy Perspective. Batteries 2019, 5, 68. [Google Scholar] [CrossRef]

- Randall, C. Gotion to Construct Battery Recycling Plant in Hefei. Electrive.com. 2021. Available online: https://www.electrive.com/2021/03/23/gotionto-construct-battery-recycling-plant-in-hefei/ (accessed on 11 April 2023).

- Fleischmann, M.; Krikke, H.; Dekker, R.; Flapper, S.A. Characterization of Logistics Networks for Product Recovery. Omega 2000, 6, 653–666. [Google Scholar] [CrossRef]

- Akram, M.N.; Abdul-Kader, W. EV Battery Recycling and Its Impact on Society. In Proceedings of the 5th NA International Conference on Industrial Engineering and Operations Management, Detroit, MI, USA, 10–14 August 2020. [Google Scholar]

- Szałatkiewicz, J.; Szewczyk, R.; Budny, E.; Missala, T.; Winiarski, W. Construction Aspects of Plasma Based Technology for Waste of Electrical and Electronic Equipment (WEEE) Management in Urban Areas. Procedia Eng. 2013, 57, 1100–1108. [Google Scholar] [CrossRef]

- Vezzini, A. Manufacturers, Materials and Recycling Technologies. In Lithium-Ion Batteries 2014 Jan 1; Elsevier: Amsterdam, The Netherlands, 2014; pp. 529–551. [Google Scholar]

- Cheret, D.; Santén, S. Battery Recycling. U.S. Patent 7169206B2, 30 January 2007. [Google Scholar]

- CEC. Environmentally Sound Management of End-of-Life Batteries from Electric-Drive Vehicles in North America. Montreal, Canada Commission for Environmental Cooperation. 2015. Available online: http://www3.cec.org/islandora/es/item/11637-environmentally-sound-management-end-life-batteries-from-electric-drive-vehicles-en.pdf (accessed on 12 February 2023).

- Assefi, M.; Maroufi, S.; Yamauchi, Y.; Sahajwalla, V. Pyrometallurgical recycling of Li-ion, Ni–Cd and Ni–MH batteries: A minireview. Curr. Opin. Green Sustain. Chem. 2020, 24, 26–31. [Google Scholar] [CrossRef]

- Brückner, L.; Frank, J.; Elwert, T. Industrial Recycling of Lithium-Ion Batteries—A Critical Review of Metallurgical Process Routes. Metals 2020, 10, 1107. [Google Scholar] [CrossRef]

- Li, L.; Zhang, X.; Li, M.; Chen, R.; Wu, F.; Amine, K.; Lu, J. The Recycling of Spent Lithium-Ion Batteries: A Review of Current Processes and Technologies. Electrochem. Energy Rev. 2018, 1, 461–482. [Google Scholar] [CrossRef]

- Makuza, B.; Tian, Q.; Guo, X.; Chattopadhyay, K.; Yu, D. Pyrometallurgical options for recycling spent lithium-ion batteries: A comprehensive review. J. Power Sources 2021, 491, 229622. [Google Scholar] [CrossRef]

- Holzer, A.; Windisch-Kern, S.; Ponak, C.; Raupenstrauch, H. A novel pyrometallurgical recycling process for lithium-ion batteries and its application to the recycling of LCO and LFP. Metals 2021, 11, 149. [Google Scholar] [CrossRef]

- Hu, X.; Mousa, E.; Ye, G. Recovery of Co, Ni, Mn, and Li from Li-ion batteries by smelting reduction—Part II: A pi-lot-scale demonstration. J. Power Sources 2021, 483, 229089. [Google Scholar] [CrossRef]

- Sommerfeld, M.; Vonderstein, C.; Dertmann, C.; Klimko, J.; Oráč, D.; Miškufová, A.; Havlík, T.; Friedrich, B. A Combined Pyro- and Hydrometallurgical Approach to Recycle Pyrolyzed Lithium-Ion Battery Black Mass Part 1: Production of Lithium Concentrates in an Electric Arc Furnace. Metals 2020, 10, 1069. [Google Scholar] [CrossRef]

- Arshad, F.; Li, L.; Amin, K.; Fan, E.; Manurkar, N.; Ahmad, A.; Yang, J.; Wu, F.; Chen, R. A Comprehensive Review of the Advancement in Recycling the Anode and Electrolyte from Spent Lithium Ion Batteries. ACS Sustain. Chem. Eng. 2020, 8, 13527–13554. [Google Scholar] [CrossRef]

- Pinegar, H.; Smith, Y.R. Recycling of End-of-Life Lithium-Ion Batteries, Part I: Commercial Processes. J. Sustain. Metall. 2019, 5, 402–416. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, N.; Hu, F.; Ye, L.; Xi, Y.; Yang, S. Thermal treatment and ammoniacal leaching for the recovery of valuable metals from spent lithium-ion batteries. Waste Manag. 2018, 75, 469–476. [Google Scholar] [CrossRef]

- Wang, M.-M.; Zhang, C.-C.; Zhang, F.-S. Recycling of spent lithium-ion battery with polyvinyl chloride by mechanochemical process. Waste Manag. 2017, 67, 232–239. [Google Scholar] [CrossRef]

- Chen, L.; Wang, P.; Shen, Y.; Guo, M. Spent lithium-ion battery materials recycling for catalytic pyrolysis or gasification of biomass. Bioresour. Technol. 2020, 323, 124584. [Google Scholar] [CrossRef]

- Cognet, M.; Condomines, J.; Cambedouzou, J.; Madhavi, S.; Carboni, M.; Meyer, D. An original recycling method for Li-ion batteries through large scale production of Metal Organic Frameworks. J. Hazard. Mater. 2019, 385, 121603. [Google Scholar] [CrossRef]

- Pindar, S.; Dhawan, N. Recycling of mixed discarded lithium-ion batteries via microwave processing route. Sustain. Mater. Technol. 2020, 25, e00157. [Google Scholar] [CrossRef]

- Norgren, A.; Carpenter, A.; Heath, G. Design for Recycling Principles Applicable to Selected Clean Energy Technologies: Crystalline-Silicon Photovoltaic Modules, Electric Vehicle Batteries, and Wind Turbine Blades. J. Sustain. Met. 2020, 6, 761–774. [Google Scholar] [CrossRef]

- Sommerville, R.; Shaw-Stewart, J.; Goodship, V.; Rowson, N.; Kendrick, E. A review of physical processes used in the safe recycling of lithium ion batteries. Sustain. Mater. Technol. 2020, 25, e00197. [Google Scholar] [CrossRef]

- Silvestri, L.; Forcina, A.; Arcese, G.; Bella, G. Recycling technologies of nickel–metal hydride batteries: An LCA based analysis. J. Clean. Prod. 2020, 273, 123083. [Google Scholar] [CrossRef]

- Mohr, M.; Peters, J.F.; Baumann, M.; Weil, M. Toward a cell-chemistry specific life cycle assessment of lithium-ion battery recycling processes. J. Ind. Ecol. 2020, 24, 13021. [Google Scholar] [CrossRef]

- Larouche, F.; Tedjar, F.; Amouzegar, K.; Houlachi, G.; Bouchard, P.; Demopoulos, G.P.; Zaghib, K. Progress and Status of Hydrometallurgical and Direct Recycling of Li-Ion Batteries and Beyond. Materials 2020, 13, 801. [Google Scholar] [CrossRef] [PubMed]

- Beaudet, A.; Larouche, F.; Amouzegar, K.; Bouchard, P.; Zaghib, K. Key Challenges and Opportunities for Recycling Electric Vehicle Battery Materials. Sustainability 2020, 12, 5837. [Google Scholar] [CrossRef]

- Montoya, A.T.; Yang, Z.; Dahl, E.U.; Pupek, K.Z.; Polzin, B.; Dunlop, A.; Vaughey, J.T. Direct Recycling of Lithium-Ion Battery Cathodes: A Multi-Stage Annealing Process to Recover the Pristine Structure and Performance. ACS Sustain. Chem. Eng. 2022, 10, 13319–13324. [Google Scholar] [CrossRef]

- Park, K.; Yu, J.; Coyle, J.; Dai, Q.; Frisco, S.; Zhou, M.; Burrell, A. Direct Cathode Recycling of End-Of-Life Li-Ion Batteries Enabled by Redox Mediation. ACS Sustain. Chem. Eng. 2021, 9, 8214–8221. [Google Scholar] [CrossRef]

- Li, L.; Yang, T.; Li, Z. Parameter optimization and yield prediction of cathode coating separation process for direct recycling of end-of-life lithium-ion batteries. RSC Adv. 2021, 11, 24132–24136. [Google Scholar] [CrossRef]

- Wu, C.; Hu, J.; Ye, L.; Su, Z.; Fang, X.; Zhu, X.; Zhuang, L.; Ai, X.; Yang, H.; Qian, J. Direct Regeneration of Spent Li-Ion Battery Cathodes via Chemical Relithiation Reaction. ACS Sustain. Chem. Eng. 2021, 9, 16384–16393. [Google Scholar] [CrossRef]

- Folayan, T.-O.; Lipson, A.L.; Durham, J.L.; Pinegar, H.; Liu, D.; Pan, L. Direct Recycling of Blended Cathode Materials by Froth Flotation. Energy Technol. 2021, 9, 2100468. [Google Scholar] [CrossRef]

- Sloop, S.; Crandon, L.; Allen, M.; Koetje, K.; Reed, L.; Gaines, L.; Sirisaksoontorn, W.; Lerner, M.A. Direct recycling case study from a lithium-ion battery recall. Sustain. Mater. Technol. 2020, 25, e00152. [Google Scholar] [CrossRef]

- Ross, B.J.; LeResche, M.; Liu, D.; Durham, J.L.; Dahl, E.U.; Lipson, A.L. Mitigating the Impact of Thermal Binder Removal for Direct Li-Ion Battery Recycling. ACS Sustain. Chem. Eng. 2020, 8, 12511–12515. [Google Scholar] [CrossRef]

- Xu, P.; Dai, Q.; Gao, H.; Liu, H.; Zhang, M.; Li, M.; Chen, Y.; An, K.; Meng, Y.S.; Liu, P.; et al. Efficient Direct Recycling of Lithium-Ion Battery Cathodes by Targeted Healing. Joule 2020, 4, 2609–2626. [Google Scholar] [CrossRef]

- Garole, D.J.; Hossain, R.; Garole, V.J.; Sahajwalla, V.; Nerkar, J.; Dubal, D.P. Recycle, Recover and Repurpose Strategy of Spent Li-ion Batteries and Catalysts: Current Status and Future Opportunities. Chemsuschem 2020, 13, 3079–3100. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; Hu, T.; Liang, C.; Long, H.L.; Zhou, L.; Song, W.; You, L.; Wu, Z.S.; Liu, J.W. Direct regeneration of cathode materials from spent lithium iron phosphate batteries using a solid phase sintering method. RSC Adv. 2017, 7, 4783–4790. [Google Scholar] [CrossRef]

- Manigandan, S.; Rajmohan, K.; Varjani, S. Current Trends in Gold Recovery from Electronic Wastes. In Current Development in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2020; pp. 307–325. [Google Scholar]

- Jung, J.C.Y.; Sui, P.C.; Zhang, J. A review of recycling spent lithium-ion battery cathode materials using hydrometal-lurgical treatments. J. Energy Storage 2021, 35, 102217. [Google Scholar] [CrossRef]

- Chen, X.; Chen, Y.; Zhou, T.; Liu, D.; Hu, H.; Fan, S. Hydrometallurgical recovery of metal values from sulfuric acid leaching liquor of spent lithium-ion batteries. Waste Manag. 2015, 38, 349–356. [Google Scholar] [CrossRef]

- Cerrillo-Gonzalez, M.; Villen-Guzman, M.; Vereda-Alonso, C.; Gomez-Lahoz, C.; Rodriguez-Maroto, J.; Paz-Garcia, J. Recovery of Li and Co from LiCoO2 via Hydrometallurgical–Electrodialytic Treatment. Appl. Sci. 2020, 10, 2367. [Google Scholar] [CrossRef]

- He, Y.; Yuan, X.; Zhang, G.; Wang, H.; Zhang, T.; Xie, W.; Li, L. A critical review of current technologies for the liberation of electrode materials from foils in the recycling process of spent lithium-ion batteries. Sci. Total Environ. 2021, 766, 142382. [Google Scholar] [CrossRef] [PubMed]

- Djoudi, N.; Mostefa, M.L.P.; Muhr, H. Hydrometallurgical Process to Recover Cobalt from Spent Li-Ion Batteries. Resources 2021, 10, 58. [Google Scholar] [CrossRef]

- Vieceli, N.; Nogueira, C.; Guimarães, C.; Pereira, M.; Durão, F.O.; Margarido, F. Hydrometallurgical recycling of lithium-ion batteries by reductive leaching with sodium Metabisulphite. Waste Manag. 2018, 71, 350–361. [Google Scholar] [CrossRef]

- Linda, G.; Kirti Richa, K.; Spangenberger, J. Key issues for Li-ion battery recycling. MRS Energy Sustain. 2018, 5, 12. [Google Scholar]

- Vieceli, N.; Casasola, R.; Lombardo, G.; Ebin, B.; Petranikova, M. Hydrometallurgical recycling of EV lithium-ion batteries: Effects of incineration on the leaching efficiency of metals using sulfuric acid. Waste Manag. 2021, 125, 192–203. [Google Scholar] [CrossRef]

- Kader, Z.A.; Marshall, A.; Kennedy, J. A review on sustainable recycling technologies for lithium-ion batteries. Emergent Mater. 2021, 4, 725–735. [Google Scholar] [CrossRef]

- Dalini, E.A.; Karimi, G.; Zandevakili, S.; Goodarzi, M. A Review on Environmental, Economic and Hydrometallurgical Processes of Recycling Spent Lithium-ion Batteries. Miner. Process. Extr. Met. Rev. 2020, 42, 451–472. [Google Scholar] [CrossRef]

- Verma, A.; Corbin, D.R.; Shiflett, M.B. Lithium and cobalt recovery for lithium-ion battery recycling using an improved oxalate process with hydrogen peroxide. Hydrometallurgy 2021, 203, 105694. [Google Scholar] [CrossRef]

- Chitre, A.; Freake, D.; Lander, L.; Edge, J.; Titirici, M. Towards a More Sustainable Lithium-Ion Battery Future: Recycling LIBs from Electric Vehicles. Batter. Supercaps 2020, 3, 1126–1136. [Google Scholar] [CrossRef]

- Anwani, S.; Methekar, R.; Ramadesigan, V. Resynthesizing of lithium cobalt oxide from spent lithium-ion batteries using an environmentally benign and economically viable recycling process. Hydrometallurgy 2020, 197, 105430. [Google Scholar] [CrossRef]

- Zhou, L.F.; Yang, D.; Du, T.; Gong, H.; Luo, W.B. The Current Process for the Recycling of Spent Lithium-Ion Bat-teries. Front. Chem. 2020, 8, 578044. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; An, N.; Wen, L.; Wang, L.; Jiang, X.; Hou, F.; Yin, Y.; Liang, J. Recent progress on the recycling technology of Li-ion batteries. J. Energy Chem. 2020, 55, 391–419. [Google Scholar] [CrossRef]

- Cerrillo-Gonzalez, M.D.; Villen-Guzman, M.; Acedo-Bueno, L.F.; Rodriguez-Maroto, J.M.; Paz-Garcia, J.M. Hydro-metallurgical extraction of Li and Co from LiCoO2 particles-experimental and modeling. Appl. Sci. 2020, 10, 6375. [Google Scholar] [CrossRef]

- Chan, K.H.; Malik, M.; Anawati, J.; Azimi, G. Recycling of End-of-Life Lithium-Ion Battery of Electric Vehicles. In Rare Metal Technology 2020; Springer: Berlin/Heidelberg, Germany, 2020; pp. 23–32. [Google Scholar] [CrossRef]

- Takacova, Z.; Havlik, T.; Kukurugya, F.; Orac, D. Cobalt and lithium recovery from active mass of spent Li-ion batteries: Theoretical and experimental approach. Hydrometallurgy 2016, 163, 9–17. [Google Scholar] [CrossRef]

- Joulié, M.; Laucournet, R.; Billy, E. Hydrometallurgical process for the recovery of high value metals from spent lithium nickel cobalt aluminum oxide based lithium-ion batteries. J. Power Sources 2014, 247, 551–555. [Google Scholar] [CrossRef]

- Meshram, P.; Pandey, B.; Mankhand, T. Extraction of lithium from primary and secondary sources by pre-treatment, leaching and separation: A comprehensive review. Hydrometallurgy 2014, 150, 192–208. [Google Scholar] [CrossRef]

- Su, B.; Heshmati, A.; Geng, Y.; Yu, X. A review of the circular economy in China: Moving from rhetoric to implementation. J. Clean. Prod. 2013, 42, 215–227. [Google Scholar] [CrossRef]

- Diekmann, J.; Hanisch, C.; Froböse, L.; Schälicke, G.; Loellhoeffel, T.; Fölster, A.-S.; Kwade, A. Ecological Recycling of Lithium-Ion Batteries from Electric Vehicles with Focus on Mechanical Processes. J. Electrochem. Soc. 2016, 164, A6184–A6191. [Google Scholar] [CrossRef]

- Yao, Y.; Zhu, M.; Zhao, Z.; Tong, B.; Fan, Y.; Hua, Z. Hydrometallurgical Processes for Recycling Spent Lithium-Ion Batteries: A Critical Review. ACS Sustain. Chem. Eng. 2018, 6, 13611–13627. [Google Scholar] [CrossRef]

- Munir, H.; Srivastava, R.R.; Kim, H.; Ilyas, S.; Khosa, M.K.; Yameen, B. Leaching of exhausted LNCM cathode batteries in ascorbic acid lixiviant: A green recycling approach, reaction kinetics and process mechanism. J. Chem. Technol. Biotechnol. 2020, 95, 2286–2294. [Google Scholar] [CrossRef]

- Porvali, A.; Aaltonen, M.; Ojanen, S.; Velazquez-Martinez, O.; Eronen, E.; Liu, F.; Wilson, B.P.; Serna-Guerrero, R.; Lundström, M. Mechanical, and hydrometallurgical processes in HCl media for the recycling of valuable metals from Li-ion battery waste. Resour. Conserv. Recycl. 2019, 142, 257–266. [Google Scholar] [CrossRef]

- Yun, L.; Linh, D.; Shui, L.; Peng, X.; Garg, A.; LE, M.L.P.; Asghari, S.; Sandoval, J. Metallurgical and mechanical methods for recycling of lithium-ion battery pack for electric vehicles. Resour. Conserv. Recycl. 2018, 136, 198–208. [Google Scholar] [CrossRef]

- Li, L.; Bian, Y.; Zhang, X.; Guan, Y.; Fan, E.; Wu, F.; Chen, R. Process for recycling mixed-cathode materials from spent lithium-ion batteries and kinetics of leaching. Waste Manag. 2018, 71, 362–371. [Google Scholar] [CrossRef] [PubMed]

- Xiao, J.; Li, J.; Xu, Z. Recycling metals from lithium ion battery by mechanical separation and vacuum metallurgy. J. Hazard. Mater. 2017, 338, 124–131. [Google Scholar] [CrossRef]

- Andersen, M.S. An introductory note on the environmental economics of the circular economy. Sustain. Sci. 2006, 2, 133–140. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Bennett, J.W.; Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment. Am. J. Agric. Econ. 1991, 73, 227–228. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy vol.1. Isle of Wight. 2013. Available online: https://ellenmacarthurfoundation.org/to-wards-a-circular-economy-business-rationale-for-an-accelerated-transition (accessed on 10 February 2023).

- Akram, M.N. EV Battery State Changes and RL Considerations. Master’s Thesis, University of Windsor, Windsor, ON, Canada, 2020. [Google Scholar]

- Gonzales-Calienes, G.; Yu, B.; Bensebaa, F. Development of a Reverse Logistics Modeling for End-of-Life Lithium-Ion Batteries and Its Impact on Recycling Viability—A Case Study to Support End-of-Life Electric Vehicle Battery Strategy in Canada. Sustainability 2022, 14, 15321. [Google Scholar] [CrossRef]

- Global Battery Alliance. A Vision for a Sustainable Battery Value Chain in 2030, Unlocking the Full Potential to Power Sustainable Development and Climate Change Mitigation. World Economic Forum. 2019. Available online: https://www3.weforum.org/docs/WEFA_Vision_for_a_Sustainable_Battery_Value_Chain_in_2030_Report.pdf (accessed on 10 February 2023).

- Trang, N.T.N.; Li, Y. Reverse supply chain for end- of- life vehicles treatment: An in- depth content review. Resour. Conserv. Recycl. Adv. 2023, 17, 200128. [Google Scholar] [CrossRef]

- Shafique, M.; Rafiq, M.; Azam, A.; Luo, X. Material flow analysis for end-of-life lithium-ion batteries from battery electric vehicles in the USA and China. Resour. Conserv. Recycl. 2021, 178, 106061. [Google Scholar] [CrossRef]

- Meegoda, J.N.; Malladi, S.; Zayas, I.C. End-of-Life Management of Electric Vehicle Lithium-Ion Batteries in the United States. Clean Technol. 2022, 4, 1162–1174. [Google Scholar] [CrossRef]

- Akram, M.N.; Abdul-Kader, W. Energy Transition and Environmental Benefit of Fuel Cell Electric Vehicles. In Proceedings of the 2nd African International Conference on Industrial Engineering and Operations Management, Harare, Zimbabwe, 8–10 December 2020; Available online: http://ieomsociety.org/harare2020/papers/227.pdf (accessed on 1 March 2023).

- Fujita, T.; Chen, H.; Wang, K.-T.; He, C.-L.; Wang, Y.-B.; Dodbiba, G.; Wei, Y.-Z. Reduction, reuse and recycle of spent Li-ion batteries for automobiles: A review. Int. J. Miner. Met. Mater. 2021, 28, 179–192. [Google Scholar] [CrossRef]

- Baars, J.; Domenech, T.; Bleischwitz, R.; Melin, H.E.; Heidrich, O. Circular economy strategies for electric vehicle batteries reduce reliance on raw materials. Nat. Sustain. 2020, 4, 71–79. [Google Scholar] [CrossRef]

- Kotak, Y.; Marchante Fernández, C.; Canals Casals, L.; Kotak, B.S.; Koch, D.; Geisbauer, C.; Trilla, L.; Gómez-Núñez, A.; Schweiger, H.G. End of Electric Vehicle Batteries: Reuse vs. Recycl. Energ. 2021, 14, 2217. [Google Scholar] [CrossRef]

- Curtis, T.; Smith, L.; Buchanan, H.; Heath, G. A Circular Economy for Lithium-Ion Batteries Used in Mobile and Stationary Energy Storage: Drivers, Barriers, Enablers, and U.S. Policy Considerations; NREL/TP-6A20-77035; National Renewable Energy Laboratory: Golden, CO, USA, 2020. [Google Scholar]

- Akram, M.N.; Abdul-Kader, W. Environmental and Economic Impacts of EV Battery Management and State Changes. In Proceedings of the 5th NA International Conference on Industrial Engineering and Operations Management, Detroit, MI, USA, 10–14 August 2020. [Google Scholar]

- Kouhizadeh, M.; Saberi, S.; Sarkis, J. Blockchain technology and the sustainable supply chain: Theoretically exploring adoption barriers. Int. J. Prod. Econ. 2020, 231, 107831. [Google Scholar] [CrossRef]

- Albertsen, L.; Richter, J.L.; Peck, P.; Dalhammar, C.; Plepys, A. Circular business models for electric vehicle lithium-ion batteries: An analysis of current practices of vehicle manufacturers and policies in the EU. Resour. Conserv. Recycl. 2021, 172, 105658. [Google Scholar] [CrossRef]

- Fan, E.; Li, L.; Wang, Z.; Lin, J.; Huang, Y.; Yao, Y.; Chen, R.; Wu, F. Sustainable Recycling Technology for Li-Ion Batteries and Beyond: Challenges and Future Prospects. Chem. Rev. 2020, 120, 7020–7063. [Google Scholar] [CrossRef]

- Ahuja, J.; Dawson, L.; Lee, R. A circular economy for electric vehicle batteries: Driving the change. J. Prop. Plan. Environ. Law 2020, 12, 235–250. [Google Scholar] [CrossRef]

- Sehnem, S.; Jabbour, C.J.C.; Pereira, S.C.F.; de Sousa Jabbour, A.B.L. Improving sustainable supply chains performance through operational excellence: Circular economy approach. Resour. Conserv. Recycl. 2019, 149, 236–248. [Google Scholar] [CrossRef]

- Giampietro, M. On the Circular Bioeconomy and Decoupling: Implications for Sustainable Growth. Ecol. Econ. 2019, 162, 143–156. [Google Scholar] [CrossRef]

- Oriekhova, T. Circular Economy as a Global Imperative. J. Eur. Econ. 2019, 18, 415–424. [Google Scholar] [CrossRef]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the Circular Economy: Evidence From the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular economy: The concept and its limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Geisendorf, S.; Pietrulla, F. The circular economy and circular economic concepts-a literature analysis and redefinition. Thunderbird Int. Bus. Rev. 2017, 60, 771–782. [Google Scholar] [CrossRef]

- Or, T.; Gourley, S.W.D.; Kaliyappan, K.; Yu, A.; Chen, Z. Recycling of mixed cathode lithium-ion batteries for electric vehicles: Current status and future outlook. Carbon Energy 2020, 2, 6–43. [Google Scholar] [CrossRef]

- Asokan, V.A.; Teah, H.Y.; Kawazu, E.; Hotta, Y. Ambitious EV policy expedites the e-waste and socio-environmental impacts in India. Resour. Conserv. Recycl. 2023, 190, 106829. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Raugei, M.; Steubing, B.; Hartwell, A.; Anderson, P.A.; Heidrich, O. Life cycle assessment of lithium-ion battery recycling using pyrometallurgical technologies. J. Ind. Ecol. 2021, 25, 1560–1571. [Google Scholar] [CrossRef]

- Mrozik, W.; Rajaeifar, M.A.; Heidrich, O.; Christensen, P. Environmental impacts, pollution sources and pathways of spent lithium-ion batteries. Energy Environ. Sci. 2021, 14, 6099–6121. [Google Scholar] [CrossRef]

- Xiong, S.; Ji, J.; Ma, X. Environmental and economic evaluation of remanufacturing lithium-ion batteries from electric vehicles. Waste Manag. 2019, 102, 579–586. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, Q.; Li, Y.; Li, H.; Pan, X.; McLellan, B. The social-economic-environmental impacts of recycling retired EV batteries under reward-penalty mechanism. Appl. Energy 2019, 251, 113313. [Google Scholar] [CrossRef]

- Rahman, A.; Afroz, R.; Safrin, M. Recycling and disposal of lithium batteries: An economical and environmental approach. IIUM Eng. J. 2017, 18, 238–252. [Google Scholar] [CrossRef]

- Dunn, J.B.; Gaines, L.; Kelly, J.C.; James, C.; Gallagher, K.G. The significance of Li-ion batteries in electric vehicle life-cycle energy and emissions and recycling’s role in its reduction. Energy Environ. Sci. 2014, 8, 158–168. [Google Scholar] [CrossRef]

- Bae, H.; Kim, Y. Technologies of lithium recycling from waste lithium ion batteries: A review. Mater. Adv. 2021, 2, 3234–3250. [Google Scholar] [CrossRef]

- Crespo, M.S.; González, M.V.G.; Peiró, L.T. Prospects on end of life electric vehicle batteries through 2050 in Catalonia. Resour. Conserv. Recycl. 2022, 180, 106133. [Google Scholar] [CrossRef]

- Castro, F.D.; Cutaia, L.; Vaccari, M. End-of-life automotive lithium-ion batteries (LIBs) in Brazil: Prediction of flows and revenues by 2030. Resour. Conserv. Recycl. 2021, 169, 105522. [Google Scholar] [CrossRef]

- Abdelbaky, M.; Peeters, J.R.; Dewulf, W. On the influence of second use, future battery technologies, and battery lifetime on the maximum recycled content of future electric vehicle batteries in Europe. Waste Manag. 2021, 125, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Buchert, M.; Jenseit, W.; Merz, C.; Schüler, D. Ökobilanz zum „Recycling von Lithium-Ionen-Batterien “(LithoRec); Öko-Institut: Darmstadt, Germany, 2011. [Google Scholar]

- Wang, S.; Yu, J. A comparative life cycle assessment on lithium-ion battery: Case study on electric vehicle battery in China considering battery evolution. Waste Manag. Res. J. Sustain. Circ. Econ. 2020, 39, 156–164. [Google Scholar] [CrossRef] [PubMed]

| Goals | ||

|---|---|---|

| Goal 1: No Poverty | Goal 2: Zero Hunger | Goal 3: Good Health and Well-being |

| Goal 4: Quality Education | Goal 5: Gender Equality | Goal 6: Clean Water and Sanitation |

| Goal 7: Affordable and Clean Energy | Goal 8: Decent Work and Economic Growth | Goal 9: Industry Innovation and Infrastructure |

| Goal 10: Reduce Inequalities | Goal 11: Sustainable cities and communities | Goal 12: Responsible consumption and production |

| Goal 13: Climate Action | Goal 14: Life Below Water | Goal 15: Life on Land |

| Goal 16: Peace, Justice, and Strong Institutions | Goal 17: Partnerships for Goals | |

| Section Number | No of Articles |

|---|---|

| 1.0 Introduction | 15 |

| 3.0 Sustainable Development Goals | 15 |

| 4.0 Life Cycle Assessment | 13 |

| 5.0 Recycling Processes 17 Pyrometallurgical 14 Hydrometallurgical 21 Special Recycling 8 Direct Recycling 12 Metallurgical and Mechanical 7 | 79 |

| 6.0 Circular Economy | 27 |

| 7.0 Environmental Benefits | 8 |

| 8.0 Discussions | 6 |

| Total | 163 |

| Author | Year | Remarks |

|---|---|---|

| Bose and Khan | 2022 [17] | The study examined how far the SDGs have progressed, as per testimony from companies across the globe; it also investigated how testimony regarding SDGs changes when considering national institutional factors. |

| Pereira et al. | 2022 [18] | The editorial team investigated the effects of the Russian-Ukrainian conflict on the SDGs relating to Biophysical, Social, and Economic values, as well as how they affected national partnerships. |

| Business Line | 2021 [19] | This article suggested that any sustainable development strategy to fight climate change (according to SDG 13: Climate Change) must be supported by a reduction in emissions from transportations; thus, adopting cleaner options. |

| Belmonte et al. | 2021 [20] | This study focused on four areas highly relevant to sustainable development and finding a balance between ecological and economic systems with respect to development: the circular economy, degrowth, green growth, and research specifically addressing the SDGs. |

| Zwiers et al. | 2020 [21] | This paper identified the required knowledge that allows for circular economical thinking and practices for sustainable development. |

| Hernandez et al. | 2020 [22] | The study used an innovation systems approach to develop a roadmap for solar and wind energy to predict and improve the effects of a transition to a low carbon future in a manner ensuring that climate goals and the SDGs are mutually reinforced. |

| Tremblay et al. | 2020 [23] | Considering people, planet, prosperity, peace, and partnership (5P), this paper presents the categorization of the Sustainable Development Goals and their objectives with the aim to offer a better perception of relationships for possible collaborations related the 5P categorization. |

| Feijoo et al. | 2020 [24] | A systemic literature review featuring the Sustainable Development Goals and business schools is presented in this paper with emphasis on the role these schools can play to favor the implementation and adoption of these goals. |

| UNDP | 2020 [25] | This report assessed the effect of various COVID-19 recovery situations on the SDGs, looking at the impact of the pandemic for the next 10 years (UNDP and the Pardee Center for International Futures at the University of Denver) |

| Vinuesa et al. | 2020 [26] | This paper demonstrated that the use of consensus-based artificial intelligence can result in the completion of 134 targets of the SDGs but may slow progress of fifty-nine other targets. |

| Schroeder et al. | 2019 [27] | This paper identified how relevant circular economical practices are for the progress of the SDGs. |

| Allen et al. | 2018 [28] | This paper provided a literature review for national efforts and experiences for progression of the SDGs in twenty-six countries by thoroughly investigating how the countries are considering and progressing through the key stages of SDG implementation provided by the literature. |

| Stafford-Smith et al. | 2017 [29] | This study determined that significant attention is required across the connections between each of the industry sectors, societal actors, and countries of ranging economic prosperity. |

| Company | Country | Process | Volume (tons/year) | Status |

|---|---|---|---|---|

| Recycling by using the Pyrometallurgical/Hydrometallurgical process | ||||

| Accurec | Germany | Pyro/hydro | 4000 | In Operation |

| Akkure | Finland | Pyro/hydro | 4000 | In Operation |

| Umicore Valeas | Belgium | Pyro/hydro | 7000 | In Operation |

| Brunnp Recycling Technologies | China | Pyro/hydro | 10,000 | In Operation |

| JX Nippon Mining | Japan | Pyro/hydro combo | 5000 | In Operation |

| Glencore | Switzerland | Pyro/hydro combo | 3000 | In Operation |

| Total | 33,000 | |||

| Recycling by using the Pyrometallurgical process | ||||

| Inmetco | US | Pyrometallurgical | 6000 | In Operation |

| Quzhou Huayo | China | Pyrometallurgical | 40,000 | In Operation |

| Validi | France | Pyrometallurgical | 20,000 | In Operation |

| Sony/Sumitomo | Japan | Pyrometallurgical | 150 | In Operation |

| Inmetco | US | Pyrometallurgical | 6000 | In Operation |

| Quzhou Huayou | China | Pyrometallurgical | 40,000 | In Operation |

| Dowa Eco-System | Japan | Pyrometallurgical | 6500 | In Operation |

| Total | 118,650 | |||

| Recycling by using the hydrometallurgical process | ||||

| Recupyl | France | Hydrometallurgical | 110 | In Operation |

| Redux | Germany, Austria | Hydrometallurgical | 50,000 | In Operation |

| Retriev (Toxco) | Canada | Hydrometallurgical | 4500 | In Operation |

| GEM | China | Hydrometallurgical | 30,000 | In Operation |

| Li-Cycle | US | Hydrometallurgical | 5000 | In Operation |

| Li-Cycle | Canada | Hydrometallurgical | 5000 | In Operation |

| Taisen | China | Hydrometallurgical | 6000 | In Operation |

| Li-Cycle | Gilbert, AZ, US | Hydrometallurgical | 10,000 | Planned |

| Li-Cycle | Tuscaloosa, AL, US | Hydrometallurgical | 10,000 | Planned |

| Fenix | UK | Hydrometallurgical | 10,000 | Planned |

| Total | 130,610 | |||

| Recycling by using the preprocessing process | ||||

| Envirostream | Australia | Preprocessing | 3000 | In Operation |

| Guanghua Sci-Tech | China | Preprocessing | 12,000 | In Operation |

| Total | 15,000 | |||

| ABT | US | Unknown | 20,000 | Planned |

| Northvolt | Norway | Unknown | 8000 | Planned |

| Fortum | Finland | Unknown | Unknown | Planned |

| Green Li-ion | Singapore | Unknown | Unknown | Planned |

| Gotion High-Tech | China | Unknown | Unknown | Planned |

| Tesla | China | Unknown | Unknown | Planned |

| Posco Hy Clean Metal | Korea | Unknown | 12,000 | Planned |

| Author | Year | Remarks |

|---|---|---|

| Makuza et al. | 2021 [67] | With the aim to recycle EOL LIBs, this article presented an overview of possible pyrometallurgical methods. The article outlined various methods to salvage the active cathode materials. |

| Holzer et al. | 2021 [68] | This paper investigated at an elevated temperature the behavior of the cathode materials to identify lithium cobalt oxide (LiCoO2) and lithium iron phosphate (LiFePO4) from LIB with a carbon addition. |

| Hu et al. | 2021 [69] | This paper provided information about the salvaging of Co, Ni, Mn, and Li through the use of a pilot-scale Electric Arc Furnace. |

| Assefi et al. | 2020 [64] | This brief article review discussed the available pyrometallurgical methods for recycling rechargeable batteries including “Lithium-ion, Nickel-Cadmium and Nickel-Metal-Hydride batteries”. |

| Sommerfeld et al. | 2020 [70] | This paper addressed an appropriate design to enrich slag by lithium and blended cobalt, nickel, and copper alloy “as intermediate products in a laboratory electric arc furnace”. |

| Arshad et al. | 2020 [71] | This paper summarized the recent progress of recycling anode, cathode, and electrolyte materials of LIBs. Through laboratory experimentation and industrial study, the paper focuses on the recovery of anode and electrolyte. |

| Pinegar and Smith | 2019 [72] | Metallurgic treatment of LIB modules and cells were addressed in this review with a focus on the excessive costs of managing organic and halogenic parts in the metallurgic process route. |

| Chen et al. | 2018 [73] | In their research work to salvage valuable metals from the cathode active powder, the authors proposed a thermal treatment-ammoniacal leaching process. |

| Author | Year | Remarks |

|---|---|---|

| Chen et al. | 2020 [75] | This research studied the pyrolysis characteristics of main biomass components (i.e., cellulose, lignin) in the presence of the EOL LIB cathodes enriched in transition-metals (e.g., Ni, Co). The battery cathode with a good thermostability could be used as a catalyst for biomass conversion. |

| Cognet et al. | 2020 [76] | Inspired by an open-loop method that limits the amount of waste while manufacturing a high volume of valuable materials, this manuscript proposed such an approach for recycling LIBs. |

| Pindar et al. | 2020 [77] | This report showed the effectiveness of metal extraction from the cathodes of EOL LIBs via microwave processes. The report presents a comparative study about microwave reduction of (pure and mixed) cathode materials. |

| Norgren et al. | 2020 [78] | This article discussed and proposed improvements for recycling (design for recycling) principles based on a review of published industrial and academic best practices, alongside a consultation with experts in the field. |

| Sommerville et al. | 2020 [79] | Separation methods employed in EV LIBs recycling are addressed in this review article with a focus on physical methods that are applied before starting chemical treatment and purification. |

| Silvestri et al. | 2020 [80] | This paper discussed the first life cycle assessment (LCA) for nickel–metal hydride (NiMH) batteries, which considers production and recycling processes. |

| Mohr et al. | 2020 [81] | This paper parametrized process models of optimized pyrometallurgical and hydrometallurgical recycling for LIBs, showing the possibilities for use beyond just LIB cell chemistries. |

| Author | Year | Remarks |

|---|---|---|

| Anthony et al. | 2022 [84] | This paper evaluated the process of thermal re-lithiation applied to end-of-life cathode materials. |

| Park et al. | 2021 [85] | This paper demonstrated oxidation-reduction mediators could deliver lithium ions and electrons from a lithium source to the cathode to “relithiate” the EOL cathode materials, making them (after a post heat treatment) ready for new battery fabrication. |

| Li et al. | 2021 [86] | This paper used the Taguchi Design of the Experiment method to study the efficiency of material recovery from cathodes of LIBs. Moreover, a regression model was presented to find the output and help with parameter selection. |

| Wu et al. | 2021 [87] | A method considering aclosed-loop LIB cathode regeneration chain with high atomic utilization was introduced in this research work where energy consumption is minimized. |

| Folayan et al. | 2021 [88] | This paper demonstrated a satisfactory separation of a “95% grade or higher of NMC111 in the froth product and 95% grade of LMO in the tailing product” when using separation methods with multiple phases. |

| Sloop et al. | 2020 [89] | Considering a case study, this research work showed, in an industrial model, the cathode-healing™ method for recycling lithium-ion found in both consumer electronic and EV batteries. |

| Ross et al. | 2020 [90] | A method using leftover LiOH·H2O to have a chemical reaction with fluorine can, prevent lithium elimination, and fix the cathode material. The paper also demonstrated that a thermal process can both eliminate the binder and add lithium to the cathode. |

| Xu et al. | 2020 [91] | This paper reported “an efficient and environmentally friendly LIB material recovery method based on deflect-targeted healing, which” is a very different perspective for LIB recycling. |

| Garole et al. | 2020 [92] | The paper summarized the strategies used to recover materials from EOL LIBs and spent catalysts. |

| Larouche et al. | 2020 [82] | This review paper investigated various approaches/alternatives pyrometallurgy method, namely leaching or direct recycling methods. |

| Song et al. | 2017 [93] | This paper proposed “a direct regeneration of cathode materials from spent LiFePO4 batteries using a solid phase sintering method”. |

| Author | Year | Remarks |

|---|---|---|

| Vieceli et al. | 2021 [102] | This paper assessed the consequences of incineration on the leaching yield of metals. Leaching efficiency of metals from EV LIBs (Mn, Ni, Co, and Li), was optimized at lower incineration temperatures of 400–500 °C and extended leaching times. This manner could be linked to the partial carbothermic reduction of the metals. |

| He et al. | 2021 [98] | They summarized current technologies used in the recovery of electrode materials derived from EOL LIBs. In addition, an alternative recycling flowchart of EOL LIBs was proposed. |

| Kader et al. | 2021 [103] | This paper discussed combined pre-treatment and hydrometallurgical processes as prospective mechanisms with a focus on the recovery value and benefits regarding the economy and environment. |

| Asadi et al. | 2021 [104] | This paper investigated the main aspects of spent LIBs’ recycling (environmental and economic) and determined the effectiveness of hydrometallurgical processes to retrieve valuable metals. |

| Djoudi et al. | 2021 [99] | This study focused on the recovery of cobalt from LIB leachate in hydroxide form. At 25 °C, the thermodynamic simulations confirmed the possibility of recovering 99.8% of cobalt (II) hydroxide. |

| Verma et al. | 2021 [105] | To recover and separate Li and Co from LiCoO2, this paper developed a closed-loop process based on oxalate. |

| Cerrillo-Gonzalez et al. | 2020 [100] | To process the battery waste, this research work identified a method coined combined hydrometallurgical-electro dialytic. |

| Chitre et al. | 2020 [106] | This paper focused on improvements to the hydrometallurgical processes used to extract materials from LIBs by sorting the batteries and using alternative water-soluble binders. The paper recommended a holistic design approach for LIBs that enables end-of-life recyclability. |

| Anwani et al. | 2020 [107] | This study focused on obtaining a purity of 90.13% of lithium cobalt oxide, thus, determining that battery fabrication is possible. |

| Zhou et al. | 2020 [108] | This paper reviewed the most recent developments of the technologies to recover materials from EOL LIBs. They also described the challenges and future economic and application prospects. |

| Wang et al. | 2020 [109] | This paper summarized the most up to date technologies to recycle LiNixCoyMnzO2 and LiFePO4-based LIBs regarding pre-treatment, hydrometallurgical recycling, and direct regeneration of the cathode materials. |

| Cerrillo-Gonzalez et al. | 2020 [110] | This paper presented experimental results for the hydrometallurgical treatment of LiCoO2 cathodes recovered from LIBs. A physicochemical model is shown to improve the knowledge of the leaching process and identify its limitations. |

| Chan et al. | 2020 [111] | This study focused on the development and optimization of efficient hydrometallurgical processes to recycle EV LIBs, using systematic experimental and theoretical approaches based on the design of experiment methodology. |

| Lv et al. | 2018 [56] | This work focused on hydrometallurgical processes and a summary of current LIB recycling and recycling processes are provided. |

| Takacova et al. | 2016 [112] | This paper analyzed how the extraction of cobalt and lithium affects the internal structure of the active mass composed primarily of LiCoO2. In addition, the paper shows that the cobalt extraction depends on the extraction of lithium from the LiCoO2 structure. |

| Chen et al. | 2015 [96] | This study considered a hydrometallurgical method to recapture high values of nickel, manganese, cobalt, and lithium from waste cathode materials, using a leaching solution of sulfuric acid. |

| Joulié, et al. | 2014 [113] | This study presented a metals recovery process based on hydrometallurgy. The emphasis is on the cathode materials of spent LIBs, where the efficiency rate of salvaging valuable metals reached 100% for cobalt and 99.99% for nickel. |

| Meshram et al. | 2014 [114] | This paper considered a pre-treatment process of EOL LIBs. Leaching solutions consisting of various acids were applied to the cathode materials. Next, a separation process of lithium and other metals from the leach solutions followed. |

| Sun and Qiu | 2011 [115] | To salvage cobalt and lithium from spent LIBs, this research work proposed a novel approach consisting of vacuum pyrolysis and a hydrometallurgical method. |

| Author | Year | Remarks |

|---|---|---|

| Munir et al. | 2020 [118] | The application of bio-producible/degradable ascorbic acid for the leaching of LiNixCoyMnzO2 (LNCM) cathode batteries was investigated while performing parametric variations. This study showed that using a biodegradable reagent instead of hazardous materials would be effective for sustainable metallurgy. |

| Brückner et al. | 2020 [65] | This review article investigated the progress achieved in the metallurgical treatment of lithium-ion battery modules and cells. |

| Porvali et al. | 2019 [119] | LIB waste by mechanical and hydrometallurgical techniques in a hydrochloric acid solution. |

| Yun et al. | 2018 [120] | This review article summarized the two foremost and fundamental aspects of recycling battery-packs’ mechanical methods, and chemical salvaging (metallurgical) methods. Accordingly, it is necessary to have a process/method that can be semi-automatic to fully automatic to warrant the quicker, more accurate dismantling of battery packs, and identify and detect residual energy in battery packs, as well as recuperate valuable materials from batteries. |

| Li et al. | 2018 [121] | To explain the kinetics of the leaching process, the authors proposed a novel formulation inspired from the shrinking-core model. Considering the leaching of Li, Co, Ni, and Mn, the initial energy per metal was found to be 66.86, 86.57, 49.46, and 45.23 kJ mol−1, respectively. Their findings confirm that the leaching process is a controlled chemical reaction. |

| Xiao et al. | 2017 [122] | “This study suggested an integrated method to oversee bulk spent lithium manganese (LiMn2O4) batteries to locally recycle high value-added products” without any additional materials. |

| Author | Year | Remarks |

|---|---|---|

| Trang and Li | 2023 [130] | This paper presented the literature review of a reverse supply chain for end-of-life vehicles. |

| Shafique et al. | 2021 [131] | This paper calculated that by efficient recycling methods, by 2030 there would be around 5–7 kilotons of recovered lithium, 35–60 kilotons of recovered nickel in China alone, as well as 2.3–2.6 kilotons of recovered lithium and 16–26 kilotons of nickel recovered in the US. |

| Meegoda et al. | 2022 [132] | This paper suggested improvements to EOL LIB management in the US, considering current and emerging recycling technologies, current collection, transportation, reuse applications, and regulatory policies in place. |

| Shafique and Luo | 2022 [33] | This paper presented a life cycle analysis of electric vehicles across ten countries using present and future electricity mix scenarios. |

| Akram and Abdul-Kader | 2021 [133] | This paper provided information about hydrogen production and the worldwide entities that are adopting green hydrogen. Moreover, the authors evaluated the benefits of fuel cell EVs on the environment in the case of using hydrogen generated by considering the surplus renewable energy in Canada. |

| Fujita et al. | 2021 [134] | The authors presented guidelines on the 3R of LIBs and methods to decrease the usage of valuable materials and the number of EOL LIBs, by salvaging and “remanufacturing used parts and designing new batteries considering the concepts of 3R”. |

| Szałatkiewicz et al. | 2013 [60] | The authors addressed various recycling methods that are currently available in the world (with particular attention, in Canada), by focusing on the Canadian job market for disposing spent LIBs. |

| Baars et al. | 2021 [135] | This paper described strategies to limit the extraction of raw materials, such as cobalt reserves. |

| Kotak et al. | 2021 [136] | This paper investigated the reuse and recycling of LIBs, with a focus on the discussion of whether to reuse the batteries or recycle them after their first use. |

| Curtis et al. | 2021 [137] | This report analyzes “drivers, barriers, and enablers to circular economy for LIBs used in United States mobile and stationary applications”. |

| Akram and Abdul-Kader | 2021 [138] | This research work examined the effects of recycling spent LIBs on the environment and the economy: reduced emissions through recycling and values of recoverable materials from the LIBs. |

| Kouhizadeh et al. | 2021 [139] | This paper analyzes the implementation of a circular economy, technology such as a blockchain may be helpful. One of the biggest issues in initiating a circular economy is the absence of collaboration between manufacturers and end-of-life product managers. Blockchain technology can improve collaboration while decreasing supply chain barriers. |

| Albertsen et al. | 2021 [140] | This report mentions circular business model canvases, like repair, refurbishing, repurposing, and recycling strategies. |

| Akram and Abdul-Kader | 2021 [42] | This paper calculated that an LIB could work for 12.5 years in an EV. It becomes available for recycling 22.5 years after its use in an Electric Vehicles and in a stationary application. |

| Fan et al. | 2020 [141] | This paper analyzed the EV battery market competition, with a focus on the economy, environment, and policy. They then propose a 4H method to recycle batteries to optimize efficiency, safety, economic return, and environmental benefits. |

| Ahuja et al. | 2020 [142] | This paper described the current issues to a sustainable value chain for LIBs, while making the case that interventions at the legislative and judicial level are required to steer the market in this direction. |

| Sehnem et al. | 2019 [143] | This paper focused on a major factor required for the successful adoption of a circular economy using focal companies selected from both emerging and mature economies, namely Brazil and Scotland, respectively. |

| Giampietro | 2019 [144] | This paper clarified the term circular bioeconomy, clearing misunderstandings around its definitions and interpretations. |

| Oriekhova | 2019 [145] | This paper presented the primary factors of a circular economy: the possibility of a Fourth Industrial Revolution, circular value chains based on recycled waste, leadership within a circular economy, and cooperation. |

| Kirchherr et al. | 2018 [146] | This paper focused on barriers for companies and legislators possible in a circular economy, such as hesitancy within staff and missing consumer awareness and/or interest. |

| Korhonen et al. | 2018 [147] | This paper focused on contributing to the scientific research on the circular economy. |

| Geisendorf and Pietrulla | 2017 [148] | This paper proposed a revised definition of the “circular economy” after assessing and comparing the related concepts tied most closely to it. |

| Author | Year | Remarks |

|---|---|---|

| Asokan et al. | 2023 [150] | This paper found the emissions generated from three different recycling processes, and it concluded that the net CO2-eq emissions of the pyrometallurgical treatment for lead acid batteries, hydrometallurgical treatment for LIBs, and pyrometallurgical for LIBs was 29.4, 31.7, and 43.3 kg per kWh, respectively. |

| Akram and Abdul-Kader | 2021 [143] | This paper investigated “the environmental and economic effects of recycling end of-life (EOL) LIBs entering the future market by finding the emissions mitigated through recycling and the values of materials recoverable from LIBs”. |

| Rajaeifar et al. | 2021 [151] | The study analyzed three pyrometallurgical technologies and determined that adopting a process known as direct current plasma smelting, coupled with a pre-treatment phase, could reduce emissions by five-fold when compared to our current processes. |

| Mrozik et al. | 2021 [152] | This paper discussed the diverse ways an EOL LIB can cause pollution, such as disposal and careless processing, and it provided evidence for how such practices can pollute the soil, water, and air. |

| Mohr et al. | 2020 [82] | This paper pointed out a potential concern for our current recycling processes, namely, that achieving the highest material recovery from a battery may not be the most environmentally beneficial; it mentioned that for there to be both, we would need to adapt our processes for various cell chemistries. |

| Xiong et al. | 2020 [153] | This paper evaluated the environmental benefit while remanufacturing lithium-nickel-manganese-cobalt oxide battery cells, and it determined that there is an 8.55% decrease in energy consumption and a 6.62% decrease in GHG emissions; it also considered the economic benefits, concluding that battery remanufacturing allows for cost savings of $1.87 per kg of cells produced. |

| Qiao et al. | 2019 [36] | This study viewed “the economic and environmental benefits of EV recycling in China.” It found “that the gross income per recycled EV is about $473.90, and energy consumption and greenhouse gas emissions were reduced by about 25.6 GJ and 4.1 t CO2eq, respectively. Also, the environmental benefits per technology cost are about 241.3 MJ per dollar and 36.3 kg CO2eq per dollar”. |

| Tang et al. | 2019 [154] | This paper investigated the impacts of recycling retired EV batteries at social, economic, and environmental levels while considering a Stackelberg game theoretical model using reward–penalty mechanisms. |

| Rahman et al. | 2017 [155] | This paper investigated the quantity of active materials that can be recovered through a hydrometallurgical process; its results showed that 41% of cathode material and 48.8% of its price, as well as 8.5% of anode materials and 23.4% of its price, can be recovered; furthermore, they found that a figure of 52.85% of GHG emissions from battery material extraction, manufacturing, transportation, etc., can be controlled through recycling batteries. |

| Dunn et al. | 2015 [156] | This research work proposed answers to three questions in the current discussion of the environmental impacts of LIBs whether there is a higher energy demand for material production versus battery assembly. The paper discussed the differences of facilities and how they impact the environment, for whether it is worthwhile to recycle batteries, it said that while energy consumption is high for assembling batteries from recycled materials, other environmental motivators take precedence. Finally, they found that EVs do, in fact, emit less GHGs when compared to ICE vehicles, which can be further improved via battery recycling. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akram, M.N.; Abdul-Kader, W. Sustainable Development Goals and End-of-Life Electric Vehicle Battery: Literature Review. Batteries 2023, 9, 353. https://doi.org/10.3390/batteries9070353

Akram MN, Abdul-Kader W. Sustainable Development Goals and End-of-Life Electric Vehicle Battery: Literature Review. Batteries. 2023; 9(7):353. https://doi.org/10.3390/batteries9070353

Chicago/Turabian StyleAkram, Muhammad Nadeem, and Walid Abdul-Kader. 2023. "Sustainable Development Goals and End-of-Life Electric Vehicle Battery: Literature Review" Batteries 9, no. 7: 353. https://doi.org/10.3390/batteries9070353

APA StyleAkram, M. N., & Abdul-Kader, W. (2023). Sustainable Development Goals and End-of-Life Electric Vehicle Battery: Literature Review. Batteries, 9(7), 353. https://doi.org/10.3390/batteries9070353