Battery Sharing: A Feasibility Analysis through Simulation

Abstract

1. Introduction

- The service life of batteries is decoupled from the service life of vehicles. In this way, the use of batteries might significantly increase.

- Batteries would be managed by a few easy-to-control companies, thus reducing the risk of illegal disposal.

- The need to redistribute batteries may give rise to many new job positions.

2. Related Work

3. Simulation Components and Architecture

3.1. Batteries

3.2. Vehicles

3.3. Distributors

3.4. Stations

3.5. Road Network

3.6. Runner

| Algorithm 1 Main simulation process |

| Instantiate N vehicle trip processes while Simulation is not concluded do Get the concluded vehicle trip processes for each process concluded do Instantiate a new vehicle trip process end for end while |

4. Incorporated Algorithms

4.1. Driver’s Path Definition

- 1.

- 2.

- If a path is not possible, we have a graph error and the trip is considered concluded as well as excluded from the final statistics.

- 3.

- If a path can be covered without stopping at the charging stations, the trip is simulated and the process concluded.

- 4.

- If b cannot be reached without stops, the algorithm iterates the nodes from a to b looking for a charging station s.

- 5.

- If s exists and is on the original path, we simulate a trip from a to s, set , and go to step 1. Otherwise, if there are no stations on the path or the station s cannot be reached with residual battery, the algorithm moves to the next step.

- 6.

- For each node i from the last reachable node to a, consider i as the root and start a breadth-first search method [39], looking for a station outside the original path. If a station is found, then simulate a trip to s, set , and go to step 1.

4.2. Battery Redistribution

5. Validation and Results

- The simulation handles three types of batteries—small, medium, and large—with respective capacities 10, 15, and 20 kWh. For experimental purposes, we have considered that the batteries do not reduce their performance with use. Thus, the simulator assumes that the capacity of the batteries does not decrease with the charge cycles.

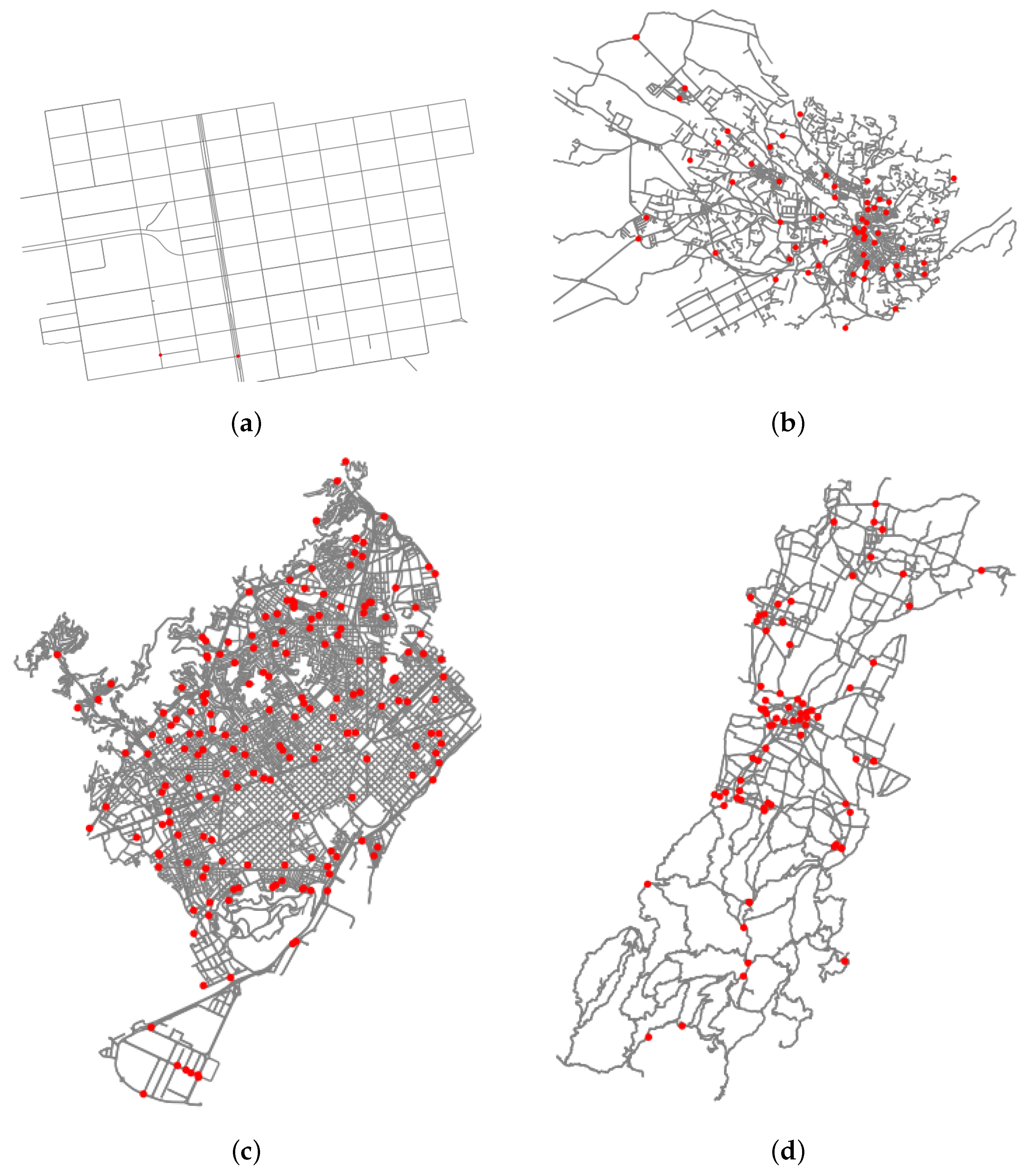

- In each road network, exactly of nodes are characterized by the presence of a charging station. This results in a different number of charging stations for each network: 4 charging stations in the test network, 69 in Sassari’s network, 66 in Modena’s network, and 196 in Barcelona’s network.

- The simulation handles three types of vehicles. The first two types are more frequent and powered by two batteries each, while the latter is less frequent and powered by three batteries.

- All vehicles have the same consumption rate, kWh/km, and their consumption is equally affected by the road slope.

- The simulation handles two types of equally spread charging station, small and large. The first one can process only one vehicle at a time and disburses a power of 10 kWh. The second one can process two vehicles together and disburses a power of 12 kWh. The charging time can be easily estimated using the following equation:

- The number of traveling vehicles is constant, exactly 1100 vehicles, during the entire duration of the simulation.

- Battery swapping takes 60 s.

- There are 10 vehicles dedicated to battery redistribution, and a new redistribution is carried out every hour if the previous one is already concluded.

- The simulation runs for 8 h.

6. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Milev, G.; Hastings, A.; Al-Habaibeh, A. The environmental and financial implications of expanding the use of electric cars—A Case study of Scotland. Energy Built Environ. 2021, 2, 204–213. [Google Scholar] [CrossRef]

- Sanguesa, J.A.; Torres-Sanz, V.; Garrido, P.; Martinez, F.J.; Marquez-Barja, J.M. A review on electric vehicles: Technologies and challenges. Smart Cities 2021, 4, 372–404. [Google Scholar] [CrossRef]

- Hoeft, F. Internal combustion engine to electric vehicle retrofitting: Potential customer’s needs, public perception and business model implications. Transp. Res. Interdiscip. Perspect. 2021, 9, 100330. [Google Scholar] [CrossRef]

- Verma, S.; Dwivedi, G.; Verma, P. Life cycle assessment of electric vehicles in comparison to combustion engine vehicles: A review. Mater. Today Proc. 2022, 49, 217–222. [Google Scholar] [CrossRef]

- Deng, J.; Bae, C.; Denlinger, A.; Miller, T. Electric vehicles batteries: Requirements and challenges. Joule 2020, 4, 511–515. [Google Scholar] [CrossRef]

- Kumar, A.; Prasad, L.B. Issues, challenges and future prospects of electric vehicles: A review. In Proceedings of the 2018 International Conference on Computing, Power and Communication Technologies (GUCON), Greater Noida, India, 28–29 September 2018; IEEE: New York, NY, USA, 2018; pp. 1060–1065. [Google Scholar]

- Liu, Z.; Song, J.; Kubal, J.; Susarla, N.; Knehr, K.W.; Islam, E.; Nelson, P.; Ahmed, S. Comparing total cost of ownership of battery electric vehicles and internal combustion engine vehicles. Energy Policy 2021, 158, 112564. [Google Scholar] [CrossRef]

- Jones, J.; Genovese, A.; Tob-Ogu, A. Hydrogen vehicles in urban logistics: A total cost of ownership analysis and some policy implications. Renew. Sustain. Energy Rev. 2020, 119, 109595. [Google Scholar] [CrossRef]

- Khalid, M.; Ahmad, F.; Panigrahi, B.K.; Al-Fagih, L. A comprehensive review on advanced charging topologies and methodologies for electric vehicle battery. J. Energy Storage 2022, 53, 105084. [Google Scholar] [CrossRef]

- Iwanski, G. Prioritized sharing of charging energy in a multiple charging unit based batteries swapping station at communication fault. J. Energy Storage 2022, 55, 105469. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, G. Optimal dispatch of electric vehicle batteries between battery swapping stations and charging stations. In Proceedings of the 2016 IEEE Power and Energy Society General Meeting (PESGM), Boston, MA, USA, 17–21 July 2016; IEEE: New York, NY, USA, 2016; pp. 1–5. [Google Scholar]

- Bobanac, V.; Pandzic, H. Lithium-ion batteries: Experimental research and application to battery swapping stations. In Proceedings of the 2018 IEEE International Energy Conference (ENERGYCON), Limassol, Cyprus, 3–7 June 2018; IEEE: New York, NY, USA, 2018; pp. 1–6. [Google Scholar]

- Revankar, S.R.; Kalkhambkar, V.N. Grid integration of battery swapping station: A review. J. Energy Storage 2021, 41, 102937. [Google Scholar] [CrossRef]

- Fiori, C.; Ahn, K.; Rakha, H.A. Power-based electric vehicle energy consumption model: Model development and validation. Appl. Energy 2016, 168, 257–268. [Google Scholar] [CrossRef]

- Kapustin, N.O.; Grushevenko, D.A. Long-term electric vehicles outlook and their potential impact on electric grid. Energy Policy 2020, 137, 111103. [Google Scholar] [CrossRef]

- Carlucci, F.; Cirà, A.; Lanza, G. Hybrid electric vehicles: Some theoretical considerations on consumption behaviour. Sustainability 2018, 10, 1302. [Google Scholar] [CrossRef]

- Rachid, A.; El Fadil, H.; Gaouzi, K.; Rachid, K.; Lassioui, A.; El Idrissi, Z.; Koundi, M. Electric Vehicle Charging Systems: Comprehensive Review. Energies 2022, 16, 255. [Google Scholar] [CrossRef]

- Singh, A.; Karandikar, P.; Kulkarni, N. Mitigation of sulfation in lead acid battery towards life time extension using ultra capacitor in hybrid electric vehicle. J. Energy Storage 2021, 34, 102219. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, B.; Shen, Y.; Wu, T.; Zang, X.; Zhao, Y.; Zhong, C.; Ma, F.; Hu, W. Comparative study of intrinsically safe zinc-nickel batteries and lead-acid batteries for energy storage. J. Power Sources 2021, 510, 230393. [Google Scholar] [CrossRef]

- Lach, J.; Wróbel, K.; Wróbel, J.; Podsadni, P.; Czerwiński, A. Applications of carbon in lead-acid batteries: A review. J. Solid State Electrochem. 2019, 23, 693–705. [Google Scholar] [CrossRef]

- Li, W.; Stanula, P.; Egede, P.; Kara, S.; Herrmann, C. Determining the main factors influencing the energy consumption of electric vehicles in the usage phase. Procedia Cirp 2016, 48, 352–357. [Google Scholar] [CrossRef]

- Yang, S.; Li, M.; Lin, Y.; Tang, T. Electric vehicle’s electricity consumption on a road with different slope. Phys. A Stat. Mech. Appl. 2014, 402, 41–48. [Google Scholar] [CrossRef]

- Mediouni, H.; Ezzouhri, A.; Charouh, Z.; El Harouri, K.; El Hani, S.; Ghogho, M. Energy Consumption Prediction and Analysis for Electric Vehicles: A Hybrid Approach. Energies 2022, 15, 6490. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, Y.; Ye, M.; Zhang, Y.; Li, G. A survey on key techniques and development perspectives of equivalent consumption minimisation strategy for hybrid electric vehicles. Renew. Sustain. Energy Rev. 2021, 151, 111607. [Google Scholar] [CrossRef]

- Wu, X.; Freese, D.; Cabrera, A.; Kitch, W.A. Electric vehicles’ energy consumption measurement and estimation. Transp. Res. Part D Transp. Environ. 2015, 34, 52–67. [Google Scholar] [CrossRef]

- Wager, G.; Whale, J.; Braunl, T. Driving electric vehicles at highway speeds: The effect of higher driving speeds on energy consumption and driving range for electric vehicles in Australia. Renew. Sustain. Energy Rev. 2016, 63, 158–165. [Google Scholar] [CrossRef]

- Chang, N.; Baek, D.; Hong, J. Power consumption characterization, modeling and estimation of electric vehicles. In Proceedings of the 2014 IEEE/ACM International Conference on Computer-Aided Design (ICCAD), San Jose, CA, USA, 2–6 November 2014; IEEE: New York, NY, USA, 2014; pp. 175–182. [Google Scholar]

- Anselma, P.G.; Huo, Y.; Roeleveld, J.; Belingardi, G.; Emadi, A. Slope-weighted energy-based rapid control analysis for hybrid electric vehicles. IEEE Trans. Veh. Technol. 2019, 68, 4458–4466. [Google Scholar] [CrossRef]

- Schulz-Mönninghoff, M.; Neidhardt, M.; Niero, M. What is the contribution of different business processes to material circularity at company-level? A case study for electric vehicle batteries. J. Clean. Prod. 2023, 382, 135232. [Google Scholar] [CrossRef]

- Liao, G.H.W.; Luo, X. Collaborative reverse logistics network for electric vehicle batteries management from sustainable perspective. J. Environ. Manag. 2022, 324, 116352. [Google Scholar] [CrossRef]

- Lu, J.; Chen, Y.; Hao, J.K.; He, R. The time-dependent electric vehicle routing problem: Model and solution. Expert Syst. Appl. 2020, 161, 113593. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, M.; Zhang, W.; Zhuang, X. Fuzzy optimization model for electric vehicle routing problem with time windows and recharging stations. Expert Syst. Appl. 2020, 145, 113123. [Google Scholar] [CrossRef]

- Asghari, M.; Al-e, S.M.J.M. Green vehicle routing problem: A state-of-the-art review. Int. J. Prod. Econ. 2021, 231, 107899. [Google Scholar] [CrossRef]

- Ahmad, F.; Saad Alam, M.; Saad Alsaidan, I.; Shariff, S.M. Battery swapping station for electric vehicles: Opportunities and challenges. IET Smart Grid 2020, 3, 280–286. [Google Scholar] [CrossRef]

- Li, J.; Wang, F.; He, Y. Electric vehicle routing problem with battery swapping considering energy consumption and carbon emissions. Sustainability 2020, 12, 10537. [Google Scholar] [CrossRef]

- Zeng, Z.; Wang, S.; Qu, X. On the role of battery degradation in en-route charge scheduling for an electric bus system. Transp. Res. Part E Logist. Transp. Rev. 2022, 161, 102727. [Google Scholar] [CrossRef]

- Cataldo-Díaz, C.; Linfati, R.; Escobar, J.W. Mathematical model for the electric vehicle routing problem considering the state of charge of the batteries. Sustainability 2022, 14, 1645. [Google Scholar] [CrossRef]

- Hart, P.; Nilsson, N.; Raphael, B. A Formal Basis for the Heuristic Determination of Minimum Cost Paths. IEEE Trans. Syst. Sci. Cybern. 1968, 4, 100–107. [Google Scholar] [CrossRef]

- Nilsson, N.J. Principles of Artificial Intelligence; Springer Science & Business Media: New York, NY, USA, 1982. [Google Scholar]

| Scenario | Relative Travel Time [min/km] | Waiting Time [s] | Queue |

|---|---|---|---|

| Sharing of partially charged batteries | 1.020 | 127 | 3.247 |

| Sharing of fully charged batteries | 1.091 | 3060 | 77.104 |

| No sharing | 1.200 | 5803 | 103.570 |

| Scenario | Relative Travel Time [min/km] | Waiting Time [s] | Queue |

|---|---|---|---|

| Sharing of partially charged batteries | 1.020 | 62 | 0.154 |

| Sharing of fully charged batteries | 1.2 | 5517 | 30.004 |

| No sharing | 1.38 | 8917 | 31.692 |

| Scenario | Relative Travel Time [min/km] | Waiting Time [s] | Queue |

|---|---|---|---|

| Sharing of partially charged batteries | 1.020 | 62 | 0.126 |

| Sharing of fully charged batteries | 1.14 | 2020 | 6.679 |

| No sharing | 1.200 | 4091 | 15.641 |

| Scenario | Relative Travel Time [min/km] | Waiting Time [s] | Queue |

|---|---|---|---|

| Sharing of partially charged batteries | 1.020 | 31 | 0.037 |

| Sharing of fully charged batteries | 1.083 | 1074 | 2.012 |

| No sharing | 1.267 | 2933 | 5.553 |

| Scenario | Relative Travel Time [min/km] | Waiting Time [s] | Queue |

|---|---|---|---|

| Test network | 1.158 | 3010 | 45.210 |

| Sassari | 1.28 | 2012 | 5.110 |

| Modena | 1.13 | 1920 | 3.029 |

| Barcelona | 1.083 | 433 | 1.512 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Neroni, M.; Herrera, E.M.; Juan, A.A.; Panadero, J.; Ammouriova, M. Battery Sharing: A Feasibility Analysis through Simulation. Batteries 2023, 9, 225. https://doi.org/10.3390/batteries9040225

Neroni M, Herrera EM, Juan AA, Panadero J, Ammouriova M. Battery Sharing: A Feasibility Analysis through Simulation. Batteries. 2023; 9(4):225. https://doi.org/10.3390/batteries9040225

Chicago/Turabian StyleNeroni, Mattia, Erika M. Herrera, Angel A. Juan, Javier Panadero, and Majsa Ammouriova. 2023. "Battery Sharing: A Feasibility Analysis through Simulation" Batteries 9, no. 4: 225. https://doi.org/10.3390/batteries9040225

APA StyleNeroni, M., Herrera, E. M., Juan, A. A., Panadero, J., & Ammouriova, M. (2023). Battery Sharing: A Feasibility Analysis through Simulation. Batteries, 9(4), 225. https://doi.org/10.3390/batteries9040225