A Techno-Economic Model for Benchmarking the Production Cost of Lithium-Ion Battery Cells

Abstract

:1. Introduction

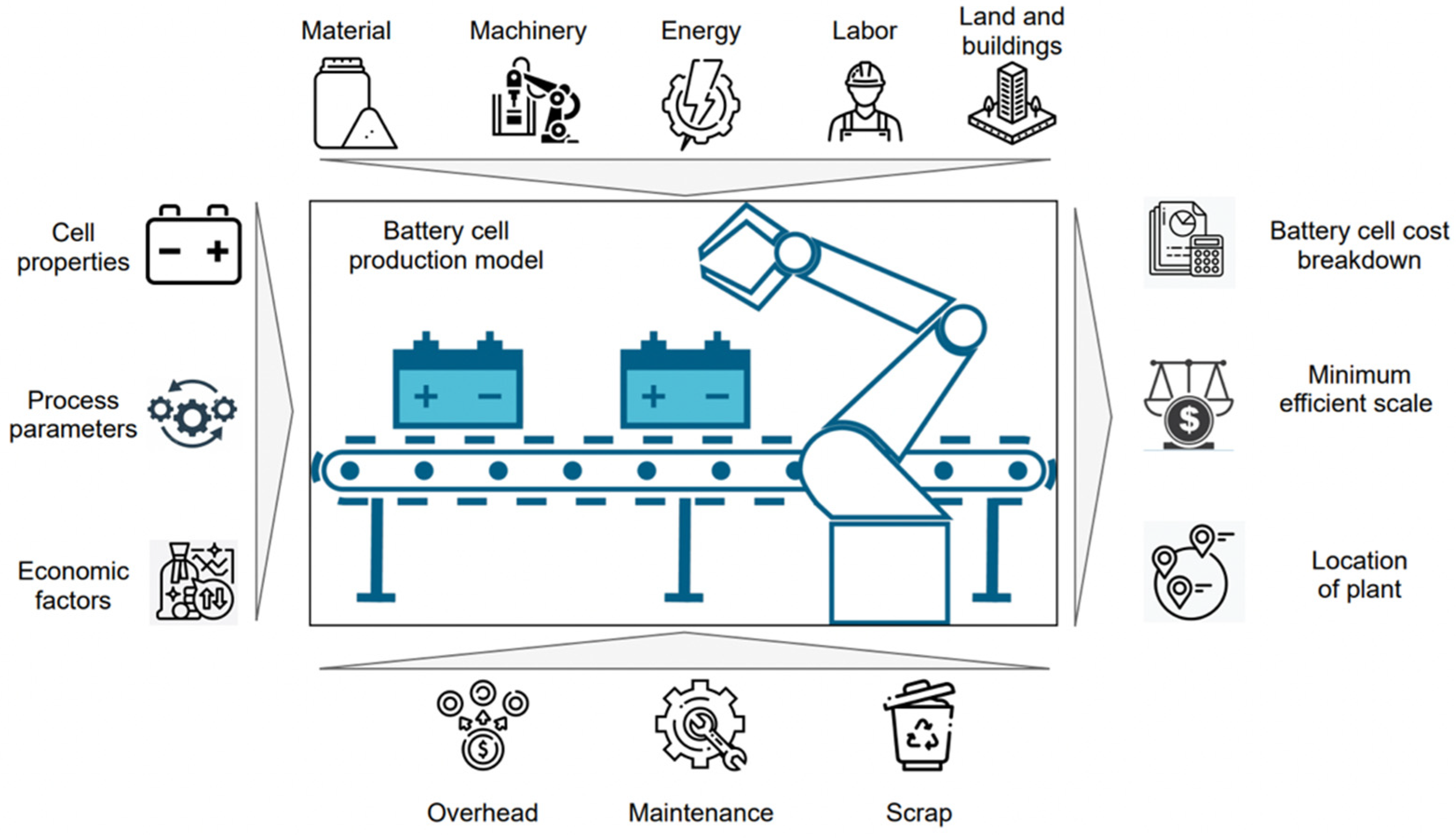

2. Methodology

2.1. Battery Process Model

2.2. Structure of Developed Cost Model

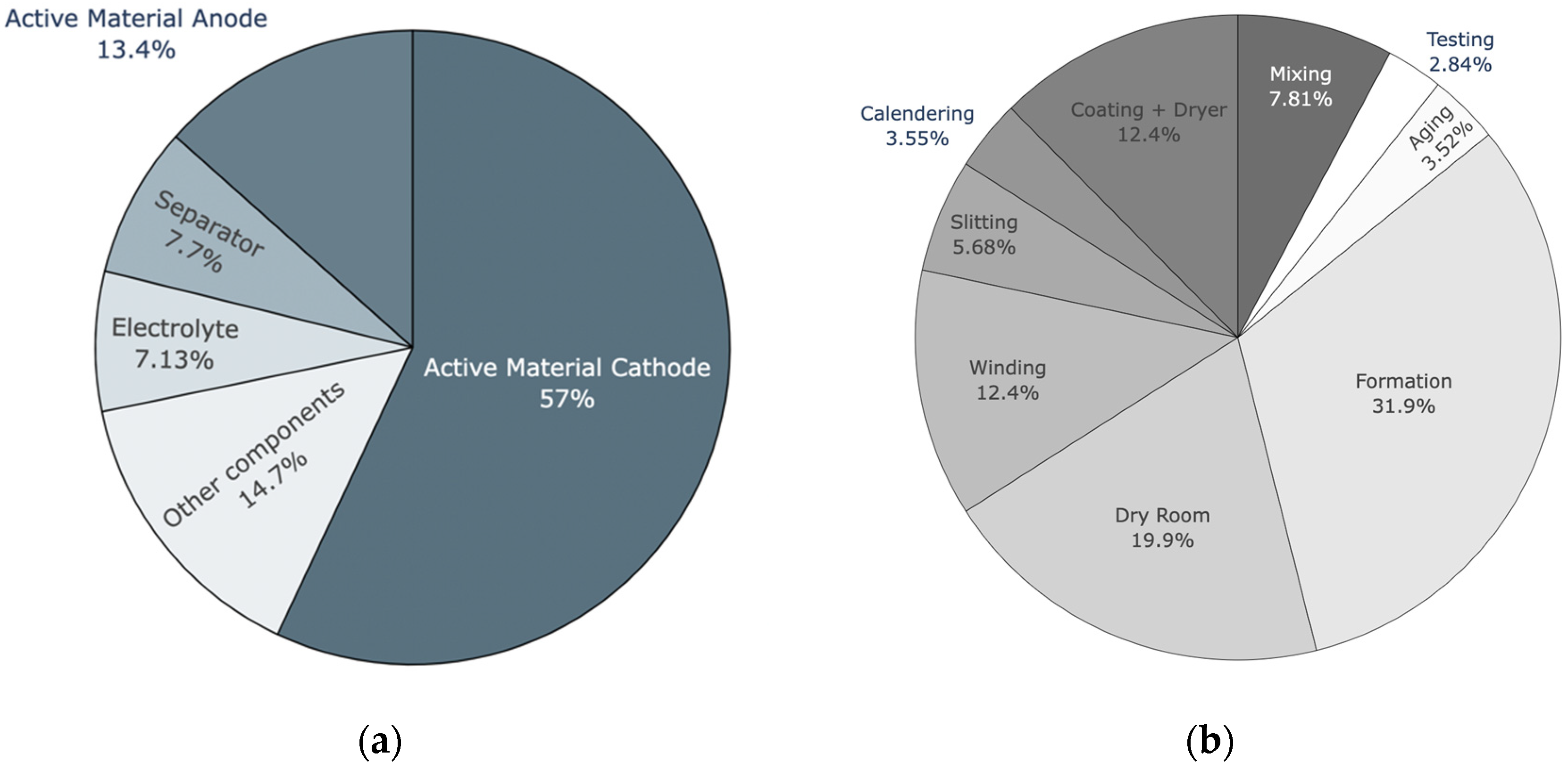

2.2.1. Material and Scrap

Mass-Related Components ( Set)

Area-Related Components ( Set)

Item-Related Components ( Set)

2.2.2. Energy

2.2.3. Machinery and Installation

2.2.4. Labor

2.2.5. Building and Land

2.2.6. Maintenance

2.2.7. Overhead

3. Results and Discussion

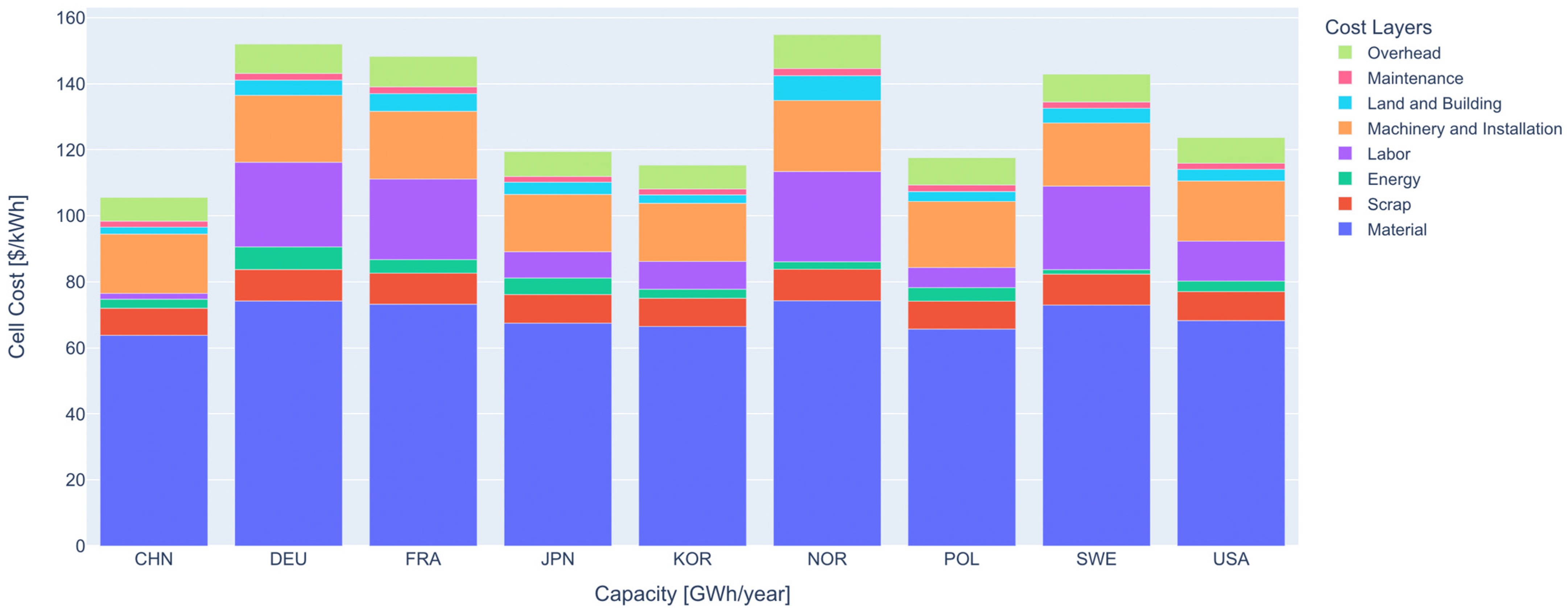

3.1. A Location-Wise Breakdown of the Cost Model with Further Focus on Key Drivers

3.2. Comparing Total Cell Cost of the Case Study with Literature

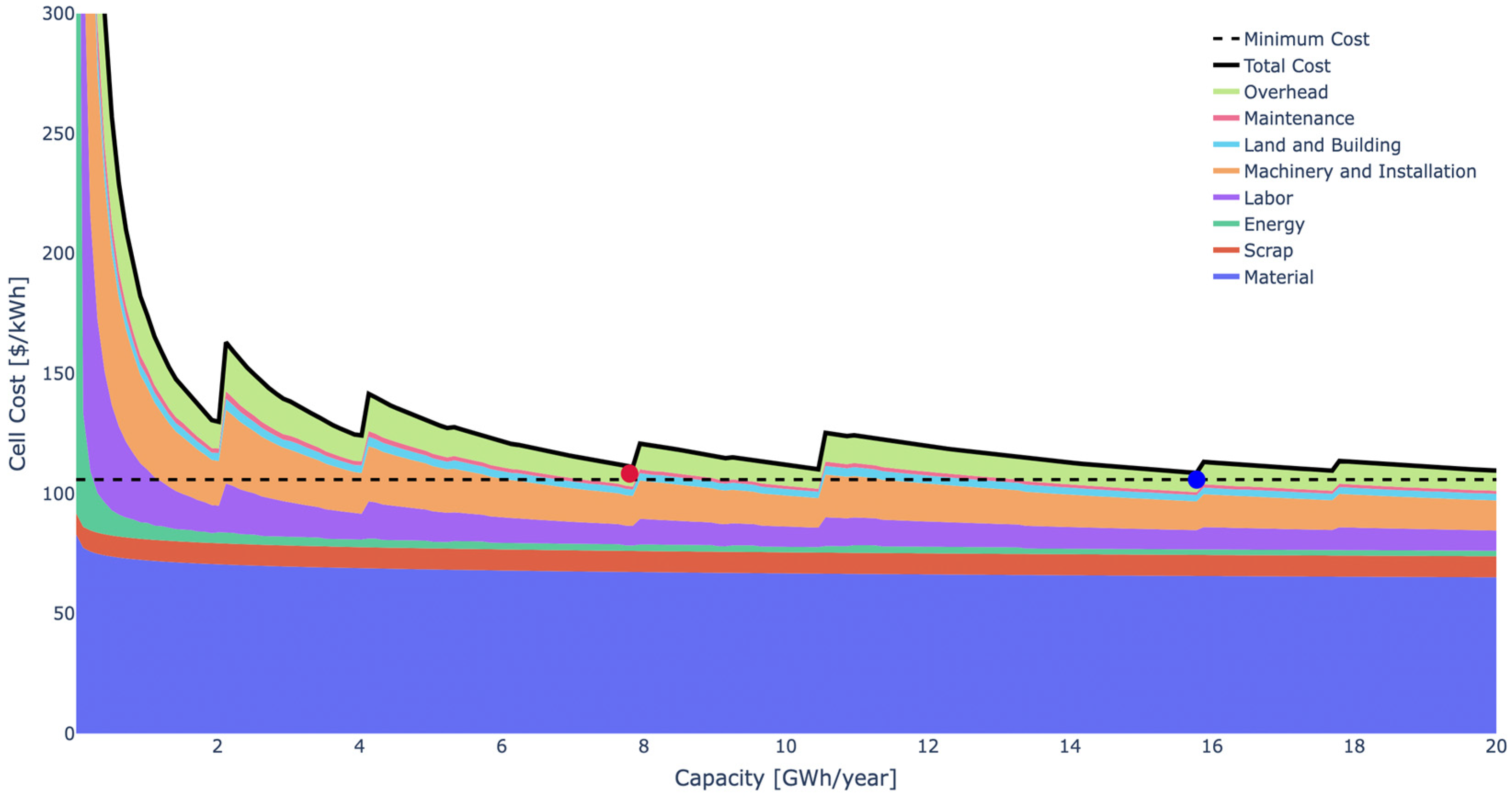

3.3. Study into the Cost-Effective Size of Battery Manufacturing Plant for the Case Study

3.4. Sensitivity Analysis of the Cost Model

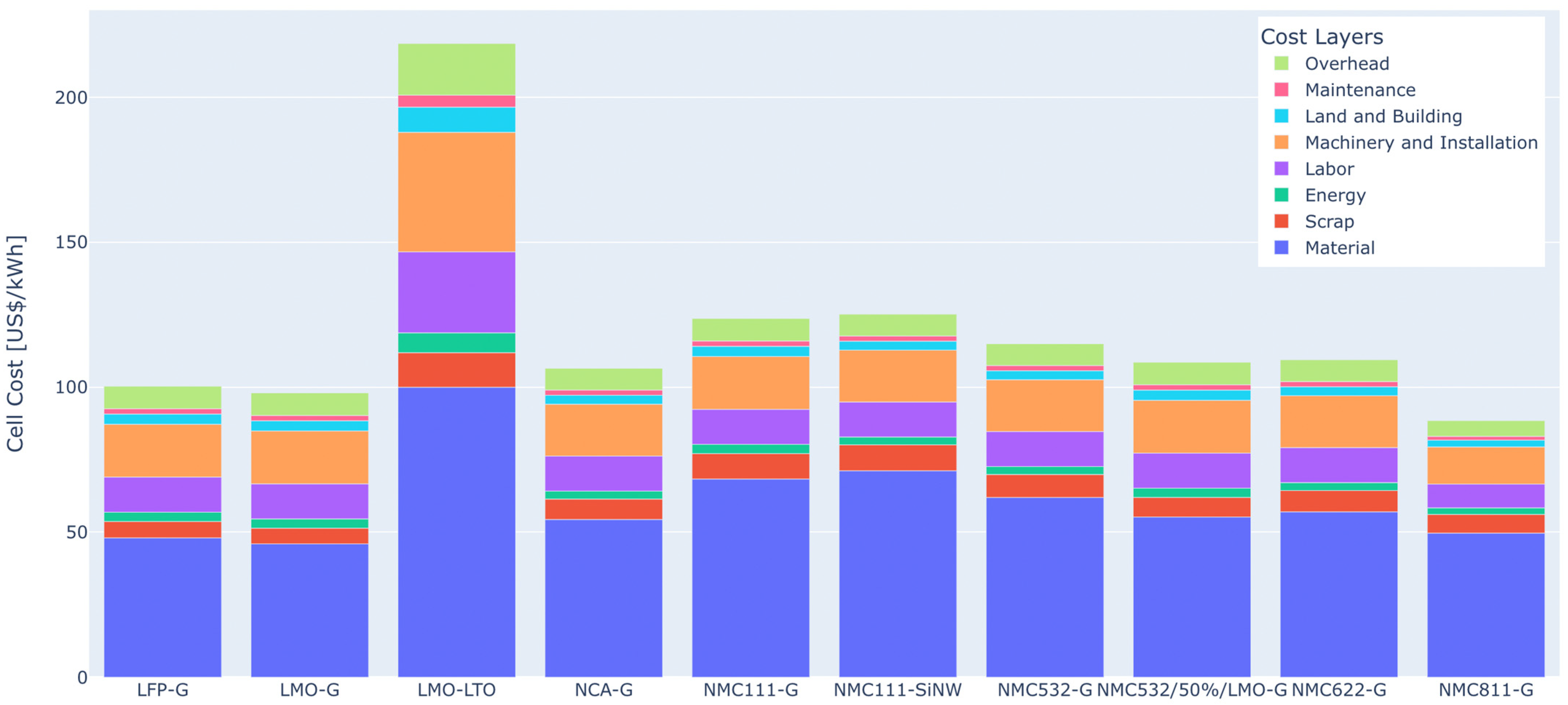

3.4.1. Sensitivity of the Current Cost Model to Battery Cell Chemistry

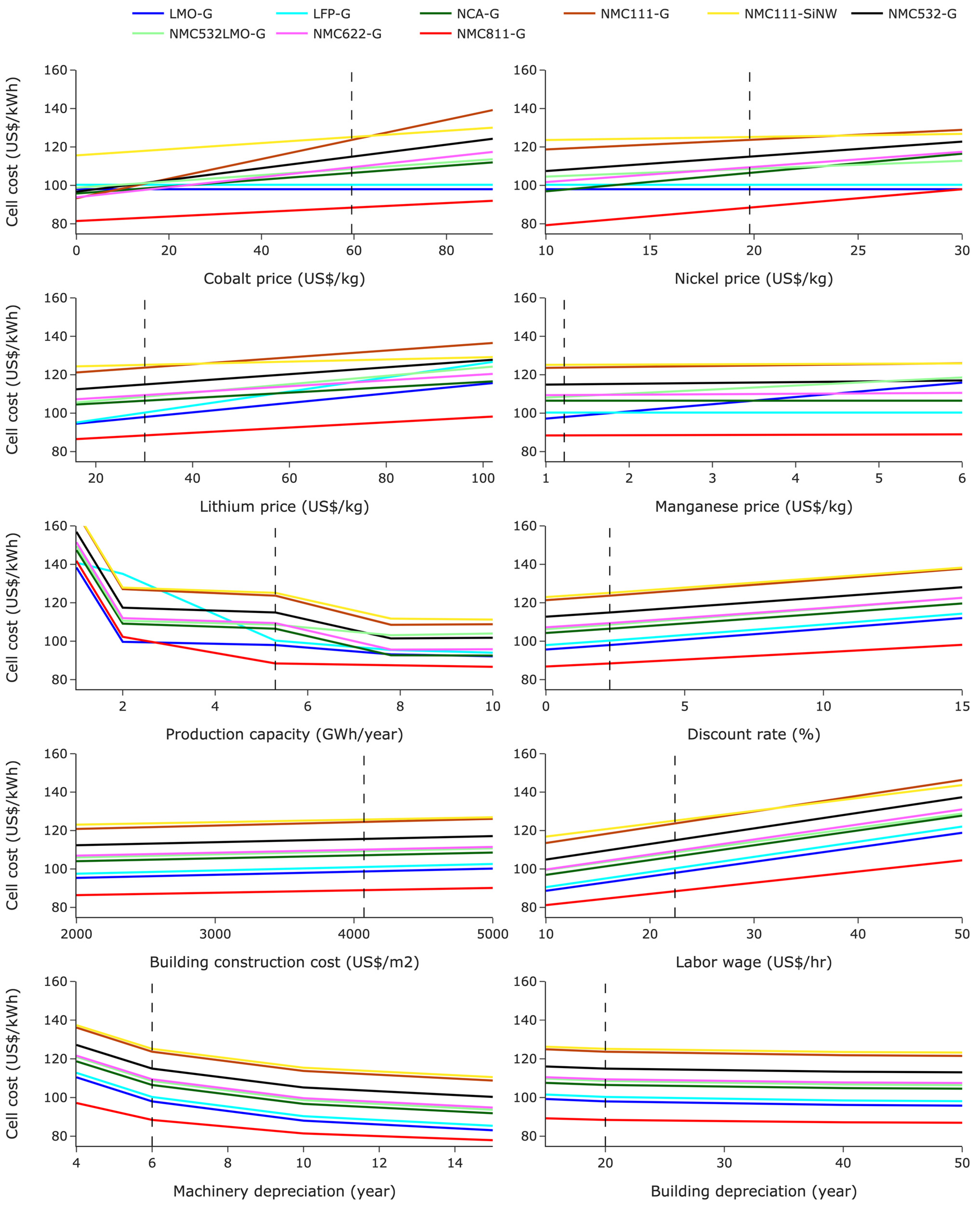

3.4.2. Sensitivity of the Cost Model to Commodities Prices, Economic Factors, and Production Volume

3.5. Limitations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Al | Aluminum |

| BCS | Base Case Study |

| CAM | Cathode Active Material |

| CellEst | Cell Estimation |

| CHN | China |

| CNY | Chinese Yuan Renminbi |

| Cu | Copper |

| DEU | Germany |

| EV | Electric vehicle |

| FRA | France |

| G | Graphite |

| GSA | General, Sales, and Administration |

| GWh | Gigawatt hour |

| ICV | Internal Combustion Vehicle |

| JPN | Japan |

| JPY | Japanese Yen |

| kg | Kilogram |

| KOR | South Korea |

| KRW | Korean Won |

| kWh | Kilowatt hour |

| MES | Minimum efficient Scale |

| NOR | Norway |

| OPS | Optimistic Scenario |

| PBCM | Process-Based Cost Modelling |

| Pol | Poland |

| R&D | Research and Development |

| SiNW | Silicon Nanowire |

| SWE | Sweden |

| USA | United States of America |

| US$ | United States Dollar |

References

- International Energy Agency. Global EV Outlook 2020-Entering the Decade of Electric Drive? International Energy Agency: Paris, France, 2020; pp. 19–20. [Google Scholar]

- Mauler, L.; Duffner, F.; Leker, J. Economies of scale in battery cell manufacturing: The impact of material and process innovations. Appl. Energy 2021, 286, 116499. [Google Scholar] [CrossRef]

- Projected Global Battery Demand by Application. Available online: https://www.statista.com/statistics/1103218/global-battery-demand-forecast/ (accessed on 20 February 2022).

- Duffner, F.; Mauler, L.; Wentker, M.; Leker, J.; Winter, M. Large-scale automotive battery cell manufacturing: Analyzing strategic and operational effects on manufacturing costs. Int. J. Prod. Econ. 2021, 232, 107982. [Google Scholar] [CrossRef]

- Pillot, C. The rechargeable battery market and main trends 2018–2030. In Proceedings of the 36th Annual International Battery Seminar & Exhibit, Fort Lauderdale, FL, USA, 25–28 March 2019; Avicenne Energy: Lyon, France, 2019. [Google Scholar]

- Wentker, M.; Greenwood, M.; Leker, J. A bottom-up approach to lithium-ion battery cost modeling with a focus on cathode active materials. Energies 2019, 12, 504. [Google Scholar] [CrossRef]

- König, A.; Nicoletti, L.; Schröder, D.; Wolff, S.; Waclaw, A.; Lienkamp, M. An Overview of parameter and cost for battery electric vehicles. World Electr. Veh. J. 2021, 12, 21. [Google Scholar] [CrossRef]

- Mahmoudzadeh Andwari, A.; Pesiridis, A.; Rajoo, S.; Martinez-Botas, R.; Esfahanian, V. A review of battery electric vehicle technology and readiness levels. Renew. Sustain. Energy Rev. 2017, 78, 414–430. [Google Scholar] [CrossRef]

- Mauler, L.; Duffner, F.; Zeier, W.G.; Leker, J. Battery cost forecasting: A Review of methods and results with an outlook to 2050. Energy Environ. Sci. 2021, 14, 4712–4739. [Google Scholar] [CrossRef]

- Schmuch, R.; Wagner, R.; Hörpel, G.; Placke, T.; Winter, M. Performance and cost of materials for lithium-based rechargeable automotive batteries. Nat. Energy 2018, 3, 267–278. [Google Scholar] [CrossRef]

- Mundada, A.S.; Shah, K.K.; Pearce, J.M. Levelized cost of electricity for solar photovoltaic, battery and cogen hybrid systems. Renew. Sustain. Energy Rev. 2016, 57, 692–703. [Google Scholar] [CrossRef]

- Michaelis, D.; Rahimzei, E.; Kampker, P.; Heimes, H.; Offermanns, C.; Locke, M.; Löbberding, H.; Wennemar, S.; Thielmann, A.; Hettesheimer, D.; et al. Roadmap Batterie-Produktionsmittel 2030-Update 2020; VDMA Verlag GmbH: Frankfurt am Main, Germany, 2021. [Google Scholar]

- Nykvist, B.; Nilsson, M. Rapidly falling costs of battery packs for electric vehicles. Nat. Clim Change 2015, 5, 329–332. [Google Scholar] [CrossRef]

- Duffner, F.; Wentker, M.; Greenwood, M.; Leker, J. Battery cost modeling: A review and directions for future research. Renew. Sustain. Energy Rev. 2020, 127, 109872. [Google Scholar] [CrossRef]

- Element Energy. Cost and Performance of EV batteries: Final Report for the Committee on Climate Change, Element Energy Limited, Cambridge. Available online: www.element-energy.co.uk/wordpress/wp-content/uploads/2012/06/CCC-battery-cost_-Element-Energy-report_March2012_Finalbispdf (accessed on 7 May 2016).

- Sakti, A.; Michalek, J.J.; Fuchs, E.R.H.; Whitacre, J.F. A techno-economic analysis and optimization of li-ion batteries for light-duty passenger vehicle electrification. J. Power Sources 2015, 273, 966–980. [Google Scholar] [CrossRef]

- Ciez, R.E.; Whitacre, J.F. Comparison between Cylindrical and prismatic lithium-ion cell costs using a process based cost model. J. Power Sources 2017, 340, 273–281. [Google Scholar] [CrossRef]

- Paul, A.N.; Shabbir, A.; Kevin, G.G.; Dennis, W.D. Modeling the Performance and Cost of Lithium-Ion Batteries for Electric-Drive Vehicles, 3rd ed.; Argonne National Lab. (ANL): Argonne, IL, USA, 2019. [Google Scholar]

- Peters, J.F.; Peña Cruz, A.; Weil, M. Exploring the economic potential of sodium-ion batteries. Batteries 2019, 5, 10. [Google Scholar] [CrossRef]

- Jinasena, A.; Burheim, O.S.; Strømman, A.H. A Flexible model for benchmarking the energy usage of automotive lithium-ion battery cell manufacturing. Batteries 2021, 7, 14. [Google Scholar] [CrossRef]

- Thomitzek, M.; Schmidt, O.; Röder, F.; Krewer, U.; Herrmann, C.; Thiede, S. Simulating process-product interdependencies in battery production systems. Procedia CIRP 2018, 72, 346–351. [Google Scholar] [CrossRef]

- Heimes, H.H. Lithium-Ion Battery Cell Production Process; VDMA Battery Production: Frankfurt am Main, Germany, 2018; ISBN 978-3-947920-03-7. [Google Scholar]

- Bryntesen, S.N.; Strømman, A.H.; Tolstorebrov, I.; Shearing, P.R.; Lamb, J.J.; Stokke Burheim, O. opportunities for the state-of-the-art production of LIB electrodes—A review. Energies 2021, 14, 1406. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, R.; Wang, J.; Wang, Y. Current and future lithium-ion battery manufacturing. iScience 2021, 24, 102332. [Google Scholar] [CrossRef]

- Lithium-2022 Data-2017–2021 Historical-2023 Forecast-Price-Quote-Chart. Available online: https://tradingeconomics.com/commodity/lithium (accessed on 1 October 2021).

- Hakimian, A.; Kamarthi, S.; Erbis, S.; Abraham, K.M.; Cullinane, T.P.; Isaacs, J.A. Economic analysis of CNT lithium-ion battery manufacturing. Environ. Sci. Nano 2015, 2, 463–476. [Google Scholar] [CrossRef]

- Admin. Cost of Setting up a Battery Manufacturing Plant. Available online: https://www.electronicsb2b.com/important-sectors/cost-of-setting-up-a-battery-manufacturing-plant/ (accessed on 1 October 2021).

- Kirchain, R.; Field, F. Process-based cost modeling: Understanding the economics of technical decisions. Encycl. Mater. Sci. Eng. 2000, 2, 1718–1727. [Google Scholar] [CrossRef]

- Aromada, S.A.; Eldrup, N.H.; Normann, F.; Øi, L.E. Techno-economic assessment of different heat exchangers for CO2 capture. Energies 2020, 13, 6315. [Google Scholar] [CrossRef]

- Orangi, S.; Aromada, S.A.; Razi, N.; Øi, L.E. Simulation and Economic Analysis of MEA+PZ and MDEA+MEA Blends in Post-Combustion CO2 Capture Plant. Master’s Thesis, University of South-Eastern Norway, Notodden, Norway, 2021. [Google Scholar]

- Chung, D.; Elgqvist, E.; Santhanagopalan, S. Automotive Lithium-Ion Cell Manufacturing: Regional Cost Structures and Supply Chain Considerations. Available online: https://www.nrel.gov/docs/fy16osti/66086.pdf (accessed on 11 October 2021).

- Simon, R. Qualitåts-und Kostenoptimierung in Lithium-Ionen-Batteriefabriken. Available online: https://www.mwgroup.net/ (accessed on 11 October 2021).

- Statistics on Labour Costs. Available online: https://ilostat.ilo.org/topics/labour-costs/ (accessed on 23 December 2021).

- Eberhardt, K. Lean-Clean-Green-Fast/Requirements for Cost Effective Battery Factories; M+W Group: Stuttgart, Germany, 2018. [Google Scholar]

- Barnett, B.; Rempel, J.; Ofer, D.; Oh, B.; Sriramulu, S.; Sinha, J.; Hastbacka, M.; McCoy, C. PHEV Battery Cost Assessment. Available online: https://www.energy.gov/sites/prod/files/2014/03/f11/es001_barnett_2010_o.pdf (accessed on 11 October 2021).

- Pillot, C. The rechargeable battery market and main trends 2016–2025. In Proceedings of the 33rd Annual International Battery Seminar & Exhibit, Fort Lauderdale, FL, USA, 20 March 2017. [Google Scholar]

- Patry, G.; Romagny, A.; Martinet, S.; Froelich, D. Cost Modeling of lithium-ion battery cells for automotive applications. Energy Sci. Eng. 2015, 3, 71–82. [Google Scholar] [CrossRef]

- Freyr. Clean Battery Solutions for a Better Planet. Available online: https://s27.q4cdn.com/476984837/files/doc_presentation/ALUS-FREYR-Capital-Markets-Day-Presentation_Final.pdf (accessed on 28 December 2021).

- RUSITH Advantages and Disadvantages of Economies of Scale. Available online: https://learnbusinessconcepts.com/economies-of-scale-advantages-and-disadvantages/ (accessed on 28 December 2021).

- Nelson, P.A.; Ahmed, S.; Gallagher, K.G.; Dees, D.W. Cost savings for manufacturing lithium batteries in a flexible plant. J. Power Sources 2015, 283, 506–516. [Google Scholar] [CrossRef]

- Eberhardt, K. Smart Size Battery Cell Factory—Battery Production Technology; M+W Group: Stuttgart, Germany, 2017. [Google Scholar]

- Leader, A.; Gaustad, G.; Babbitt, C. The effect of critical material prices on the competitiveness of clean energy technologies. Mater. Renew. Sustain. Energy 2019, 8, 8. [Google Scholar] [CrossRef]

- Goldie-Scot, L. A Behind the Scenes Take on Lithium-Ion Battery Prices. Available online: https://about.newenergyfinance.com/blog/behind-scenes-take-lithium-ion-battery-prices/ (accessed on 6 June 2022).

- Schnell, J.; Knörzer, H.; Imbsweiler, A.J.; Reinhart, G. Solid versus liquid—A bottom-up calculation model to analyze the manufacturing cost of future high-energy batteries. Energy Technol. 2020, 8, 1901237. [Google Scholar] [CrossRef]

- Brodd, R.J.; Helou, C. Cost comparison of producing high-performance li-ion batteries in the U.S. and in China. J. Power Sources 2013, 231, 293–300. [Google Scholar] [CrossRef]

- Bühler, A.G. Efficient Continuous Electrode Slurry Production; Bühler AG: Uzwil, Switzerland, 2021. [Google Scholar]

- Eggert, D. Michigan Considers New Incentives to Land Battery Plants, Major Business Expansions. Available online: https://www.clickondetroit.com/business/2021/12/08/michigan-considers-new-incentives-to-land-battery-plants-major-business-expansions/ (accessed on 23 December 2021).

- Activate Conductive Low Price Carbon Black Powder Rubber Ingredient For Pigment—Buy Activate Conductive Low Price Carbon Black Powder, Rubber Ingredient, Pigment Product on Alibaba.Com. Available online: https://www.alibaba.com/product-detail/Conductive-Price-Carbon-Black-Carbon-Powder_1600276095965.html?spm=a2700.7724857.normal_offer.d_title.3d10605cOH7ugH&s=p (accessed on 20 November 2021).

- Kennedy, T.; Brandon, M.; Ryan, K.M. Advances in the Application of Silicon and Germanium Nanowires for High-Performance Lithium-Ion Batteries. Advanced Mater. 2016, 28, 5696–5704. [Google Scholar] [CrossRef]

- High Quality Separator For Lithium Ion Battery–Buy Battery Separator, Battery Separator For Li-Ion Battery, Lithium Ion Battery Separator Product on Alibaba.Com. Available online: https://www.alibaba.com/product-detail/Separator-Lithium-Ion-Battery-High-Quality_62326953713.html?spm=a2700.7724857.normal_offer.d_title.3c757f29koxhON&s=p (accessed on 20 February 2022).

- 012mm 0.035mm 1235 1060 1070 H18 Aluminum Battery Foil For Lithium Ion Battery Current Collector Materials—Buy 0.012mm 0.035mm Which Product For Lithium Ion Battery Current Collector Materials 1235 1060 1070 H18 Aluminum Battery Foil, Aluminum Foil, 0.012mm 0.035mm Which Product For Lithium Ion Battery Current Collector Materials 1235 1060 1070 H18 Aluminum Battery Foil Product on Alibaba.Com. Available online: https://www.alibaba.com/product-detail/0-012mm-0-035mm-1235-1060_60793531762.html?spm=a2700.7724857.normal_offer.d_title.1fdc194c8nwBti (accessed on 1 October 2021).

- [Hot Item] High Purity Soft Temper Pure Copper Foil. Available online: https://intcnc.en.made-in-china.com/product/tSuQRDGyaCrW/China-High-Purity-Soft-Temper-Pure-Copper-Foil.html (accessed on 20 February 2022).

- Xe Currency Converter—Live Exchange Rates Today. Available online: https://www.xe.com/currencyconverter/ (accessed on 23 December 2021).

- Tribe, M.; Alpine, R.L.W. Scale Economies and the “0.6 Rule”. Eng. Costs Prod. Econ. 1986, 10, 271–278. [Google Scholar] [CrossRef]

- Zang, G.; Zhang, J.; Xu, S.; Xing, Y. Techno-Economic Analysis of Cathode Material Production Using Flame-Assisted Spray Pyrolysis. Energy 2021, 218, 119504. [Google Scholar] [CrossRef]

- Ahmed, S.; Nelson, P.A.; Gallagher, K.G.; Susarla, N.; Dees, D.W. Cost and Energy Demand of Producing Nickel Manganese Cobalt Cathode Material for Lithium Ion Batteries. J. Power Sources 2017, 342, 733–740. [Google Scholar] [CrossRef]

- Granata, G.; Ferreira, R.; Petrides, D. Production of Lithium Ion Battery Cathode Material (NMC 811) from Primary and Secondary Raw Materials—Techno-Economic Assessment with SuperPro Designer. Available online: https://www.researchgate.net/publication/340593316_Production_of_Lithium_Ion_Battery_Cathode_Material_NMC_811_from_Primary_and_Secondary_Raw_Materials_-_Techno-Economic_Assessment_with_SuperPro_Designer (accessed on 23 December 2021).

- Manufacturing Labor Costs per Hour: China, Vietnam, Mexico 2016–2020. Available online: https://www.statista.com/statistics/744071/manufacturing-labor-costs-per-hour-china-vietnam-mexico/ (accessed on 23 December 2021).

- National Bureau of Statistics of China Average Annual Wage of Employed Persons in Different Positions in Enterprises above Designated Size in 2019. Available online: http://www.stats.gov.cn/english/PressRelease/202005/t20200518_1746069.html (accessed on 23 December 2021).

- Workers in China Set to See a Real Salary Increase of 3.6% in 2020. Available online: https://www.eca-international.com/News/November-2019/Workers-in-China-set-to-see-a-real-salary-increase (accessed on 23 December 2021).

- South Korea Total Monthly Wages in Manufacturing—2021 Data—2022 Forecast. Available online: https://tradingeconomics.com/south-korea/wages-in-manufacturing (accessed on 1 December 2021).

- Australian Trade and Investment Commission THE LITHIUM-ION BATTERY VALUE CHAIN—New Economy Opportunities for Australia; Australian Trade and Investment Commission: Sydney, Australia, 2018.

- ホーム|厚生労働省. Available online: https://www.mhlw.go.jp/index.html (accessed on 26 July 2022).

- Electricity Prices around the World. Available online: https://www.globalpetrolprices.com/electricity_prices/ (accessed on 1 October 2021).

- International Construction Market Survey 2021. Available online: https://ontarioconstructionnews.com/wp-content/uploads/2021/07/798439_international-construction-market-survey-2021-web.pdf (accessed on 1 October 2021).

- Philippot, M.; Alvarez, G.; Ayerbe, E.; Van Mierlo, J.; Messagie, M. Eco-Efficiency of a Lithium-Ion Battery for Electric Vehicles: Influence of Manufacturing Country and Commodity Prices on GHG Emissions and Costs. Batteries 2019, 5, 23. [Google Scholar] [CrossRef]

- United States Average Hourly Wages in Manufacturing—January 2022 Data. Available online: https://tradingeconomics.com/united-states/wages-in-manufacturing (accessed on 23 December 2021).

- Real Interest Rate By Country. Available online: https://tradingeconomics.com/country-list/real-interest-rate-percent-wb-data.html (accessed on 1 December 2021).

- Republic of Korea Real Interest Rate, 1960–2021—Knoema.Com. Available online: https://knoema.com//atlas/Republic-of-Korea/topics/Economy/Financial-Sector-Interest-rates/Real-interest-rate (accessed on 1 December 2021).

- Berger, R. The Lithium-Ion Battery Value Chain. In Proceedings of the Name of the F-Cell Conference, Stuttgart, Germany, 9 October 2012. [Google Scholar]

- Wood, D.L.; Li, J.; Daniel, C. Prospects for Reducing the Processing Cost of Lithium Ion Batteries. J. Power Sources 2015, 275, 234–242. [Google Scholar] [CrossRef]

- Berckmans, G.; Messagie, M.; Smekens, J.; Omar, N.; Vanhaverbeke, L.; Van Mierlo, J. Cost Projection of State of the Art Lithium-Ion Batteries for Electric Vehicles Up to 2030. Energies 2017, 10, 1314. [Google Scholar] [CrossRef]

- Wang, F.; Deng, Y.; Yuan, C. Design and Cost Modeling of High Capacity Lithium Ion Batteries for Electric Vehicles through A Techno-Economic Analysis Approach. Procedia Manuf. 2020, 49, 24–31. [Google Scholar] [CrossRef]

- Henze, V. Battery Pack Prices Cited Below $100/KWh for the First Time in 2020, While Market Average Sits at $137/KWh. Available online: https://about.bnef.com/blog/battery-pack-prices-cited-below-100-kwh-for-the-first-time-in-2020-while-market-average-sits-at-137-kwh/ (accessed on 27 December 2021).

- Ziegler, M.S.; Trancik, J.E. Re-Examining Rates of Lithium-Ion Battery Technology Improvement and Cost Decline. Energy Environ. Sci. 2021, 14, 1635–1651. [Google Scholar] [CrossRef]

- Edelstein, S. Report: EV Battery Costs Hit Another Low in 2021, but They Might Rise in 2022. Available online: https://www.greencarreports.com/news/1134307_report-ev-battery-costs-might-rise-in-2022 (accessed on 1 December 2021).

- DOE Estimates That EV Battery Pack Costs in 2021 Are 87% Lower than in 2008. Available online: https://www.greencarcongress.com/2021/10/20211005-fotw.html (accessed on 23 December 2021).

- Kochhan, R.; Fuchs, S.; Reuter, B.; Burda, P.; Matz, S.; Lienkamp, M. An Overview of Costs for Vehicle Components, Fuels and Greenhouse Gas Emissions. Available online: https://www.researchgate.net/publication/260339436_An_Overview_of_Costs_for_Vehicle_Components_Fuels_and_Greenhouse_Gas_Emissions (accessed on 23 December 2021).

- Cano, Z.P.; Banham, D.; Ye, S.; Hintennach, A.; Lu, J.; Fowler, M.; Chen, Z. Batteries and Fuel Cells for Emerging Electric Vehicle Markets. Nat. Energy 2018, 3, 279–289. [Google Scholar] [CrossRef]

- Voelcker, J. Electric-Car Battery Costs: Tesla $190 per Kwh for Pack, GM $145 for Cells. Available online: https://www.greencarreports.com/news/1103667_electric-car-battery-costs-tesla-190-per-kwh-for-pack-gm-145-for-cells (accessed on 28 December 2021).

- Kittner, N.; Lill, F.; Kammen, D.M. Energy Storage Deployment and Innovation for the Clean Energy Transition. Nat Energy 2017, 2, 1–6. [Google Scholar] [CrossRef]

- Kwade, A.; Haselrieder, W.; Leithoff, R.; Modlinger, A.; Dietrich, F.; Droeder, K. Current Status and Challenges for Automotive Battery Production Technologies. Nat. Energy 2018, 3, 290–300. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orangi, S.; Strømman, A.H. A Techno-Economic Model for Benchmarking the Production Cost of Lithium-Ion Battery Cells. Batteries 2022, 8, 83. https://doi.org/10.3390/batteries8080083

Orangi S, Strømman AH. A Techno-Economic Model for Benchmarking the Production Cost of Lithium-Ion Battery Cells. Batteries. 2022; 8(8):83. https://doi.org/10.3390/batteries8080083

Chicago/Turabian StyleOrangi, Sina, and Anders Hammer Strømman. 2022. "A Techno-Economic Model for Benchmarking the Production Cost of Lithium-Ion Battery Cells" Batteries 8, no. 8: 83. https://doi.org/10.3390/batteries8080083

APA StyleOrangi, S., & Strømman, A. H. (2022). A Techno-Economic Model for Benchmarking the Production Cost of Lithium-Ion Battery Cells. Batteries, 8(8), 83. https://doi.org/10.3390/batteries8080083