Study of SOC Estimation by the Ampere-Hour Integral Method with Capacity Correction Based on LSTM

Abstract

:1. Introduction

1.1. Related Work

1.2. Contributions

- (1)

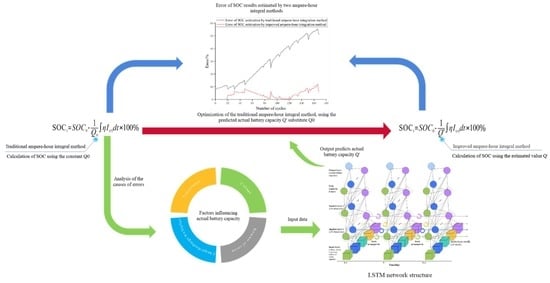

- This paper proposes an SOC estimation method based on an improved ampere-hour integral method; unlike the traditional ampere-hour integral method, which regards battery capacity as a constant, this method fully considers the influence of battery capacity loss on the SOC estimation, which is closer to the actual use of the battery, making the SOC value estimated by the improved ampere-hour integral method more accurate.

- (2)

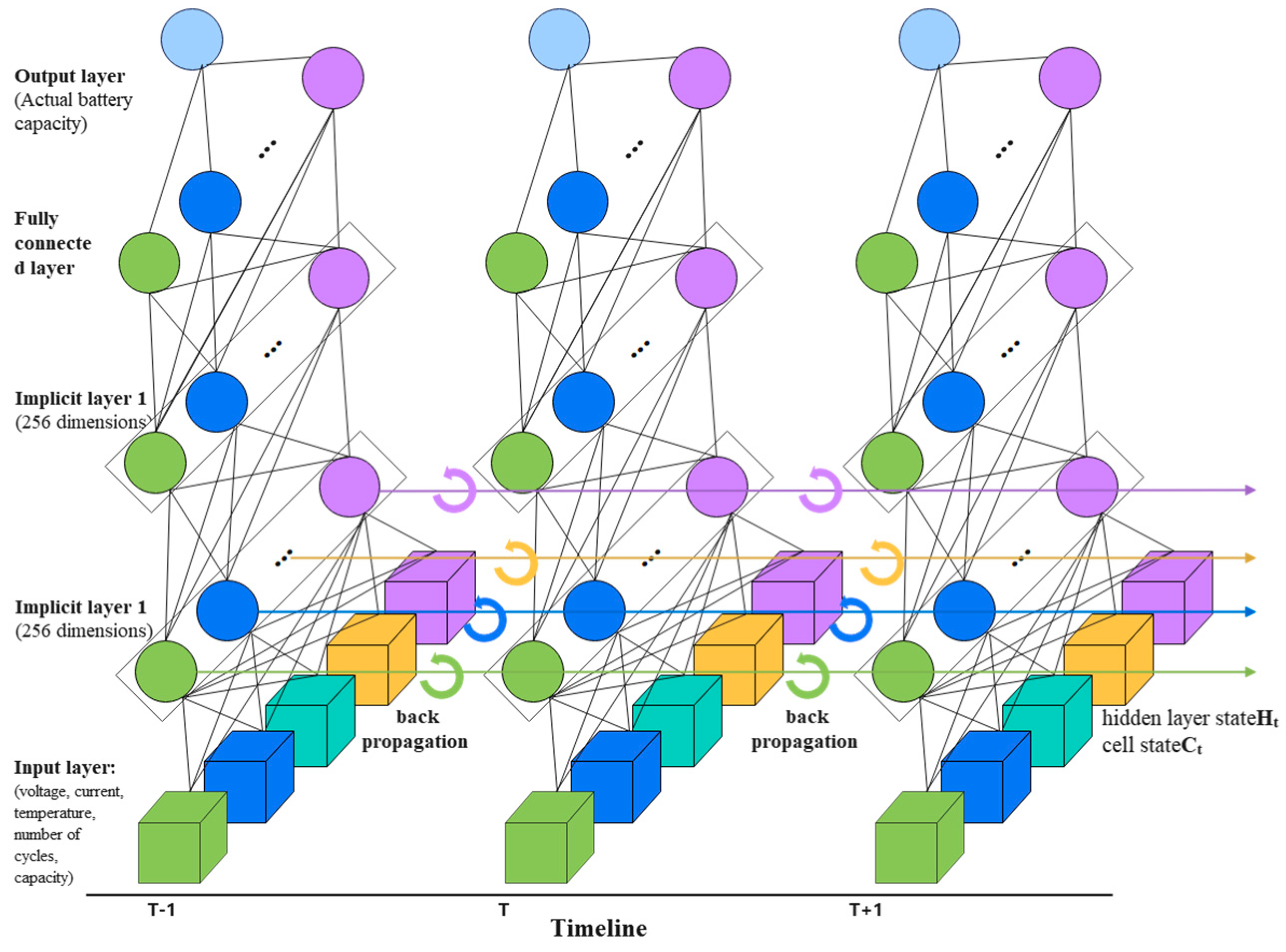

- Based on the improved ampere-hour integral method, we propose the following method: first, we build an LSTM neural network model to predict the actual battery capacity; then, we use the obtained predicted value of the actual battery capacity to replace the rated battery capacity in the traditional ampere-hour integral method. First, the factors that affect the actual capacity of the battery are analyzed, and four main influencing factors, namely voltage, current, temperature, and the number of battery cycles are determined. Then, the above four main influencing factors are used as the inputs to the LSTM neural network model to predict the actual capacity of the battery, and the predicted value is a value that changes dynamically with the use of the battery. Finally, the SOC estimation is carried out as follows: the actual battery capacity is predicted based on the LSTM model, and the predicted value is used to replace the rated battery capacity (constant) in the traditional ampere-hour integral method.

- (3)

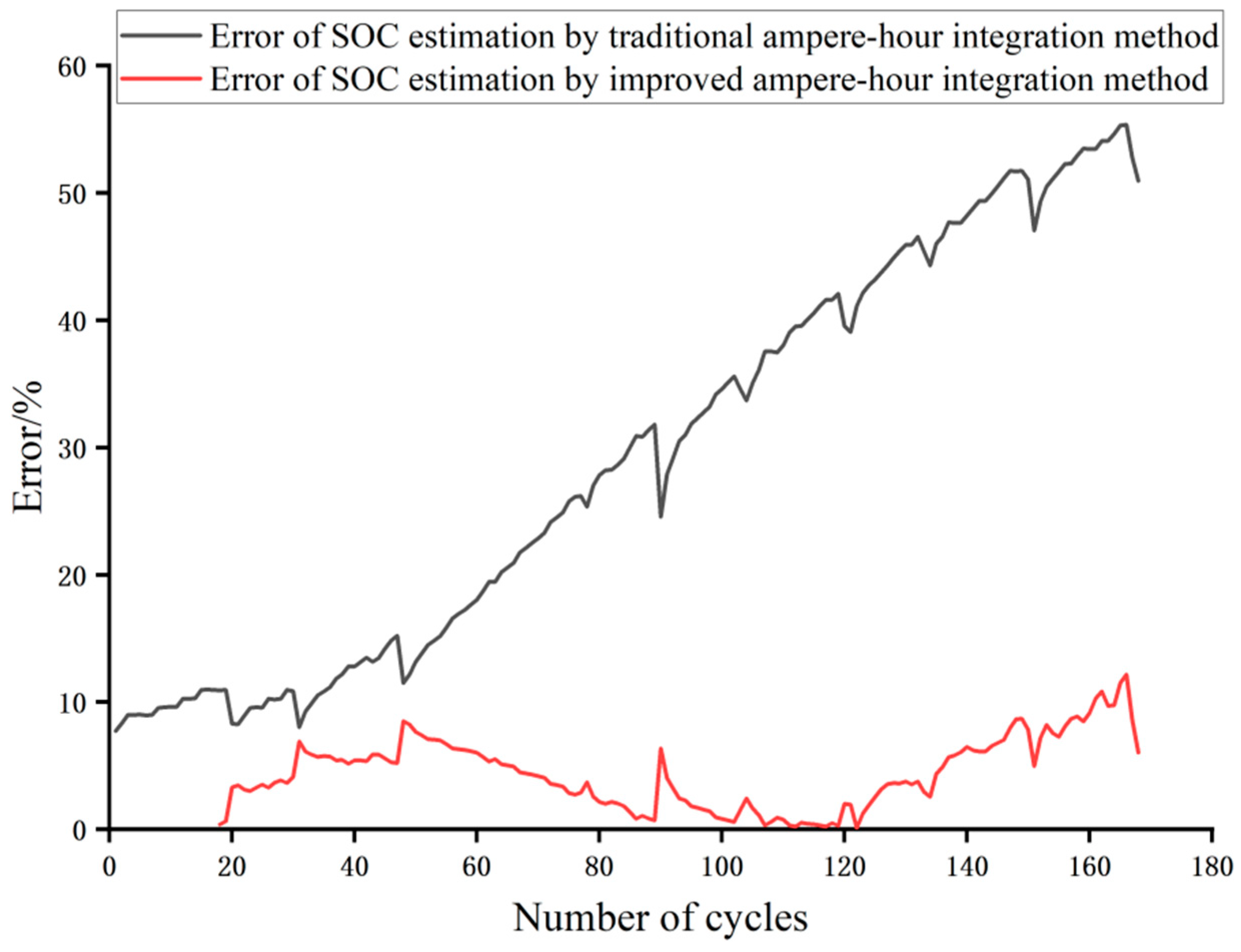

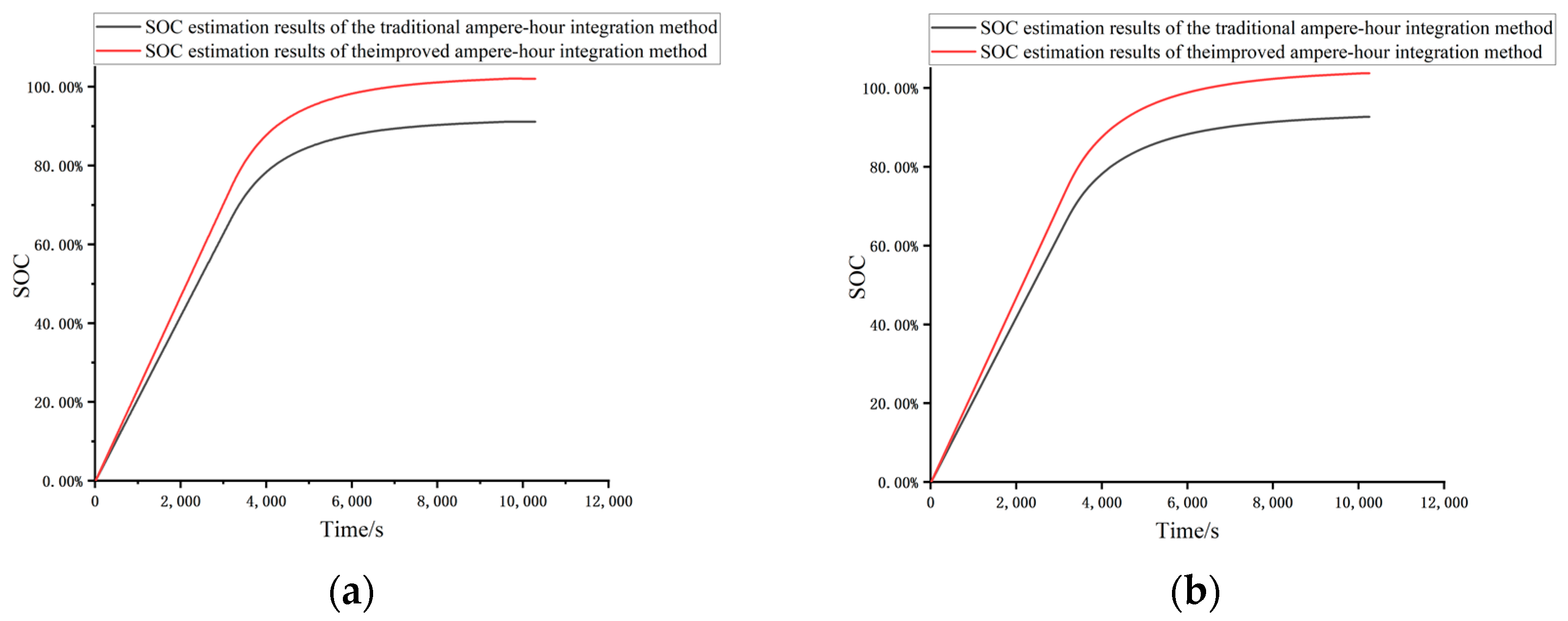

- We selected battery data from the NASA-Battery Data Set, conducted a comparative test between the improved ampere-hour integral method and the traditional ampere-hour integral method, and compared the errors caused by the SOC estimation using these two ampere-hour integral methods, respectively.

2. Theoretical Analysis

2.1. Analysis of the Principle of the Ampere-Hour Integral Method

2.2. Analysis of the Errors of the Ampere-Hour Integral Method

2.3. Principle Analysis of Improved Ampere-Hour Integral Method

3. Prediction of Actual Battery Capacity

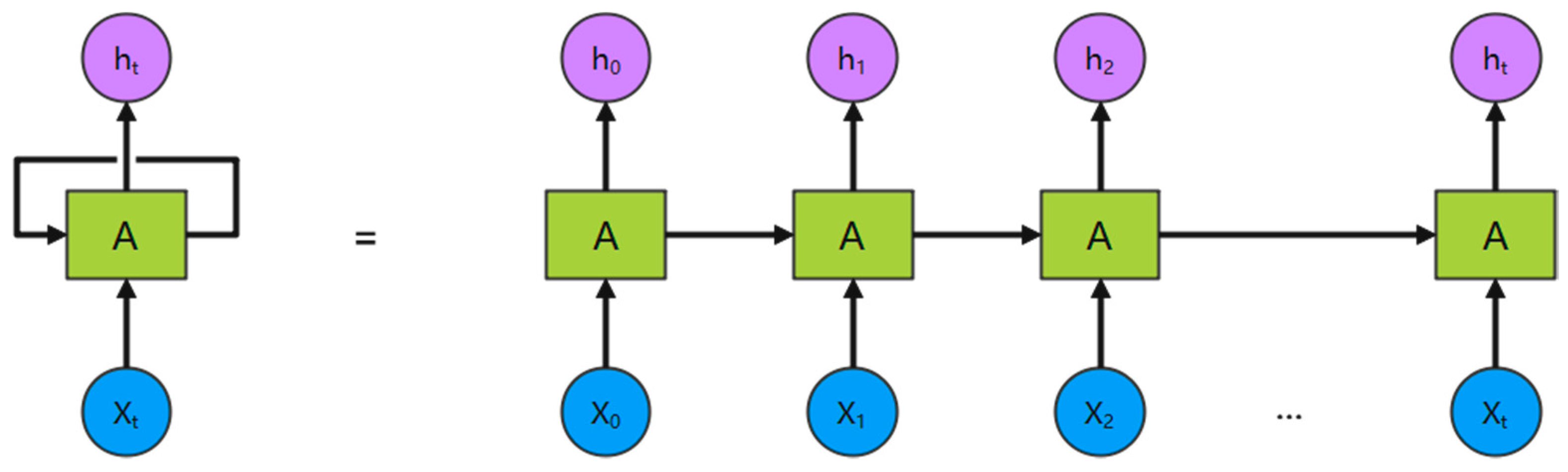

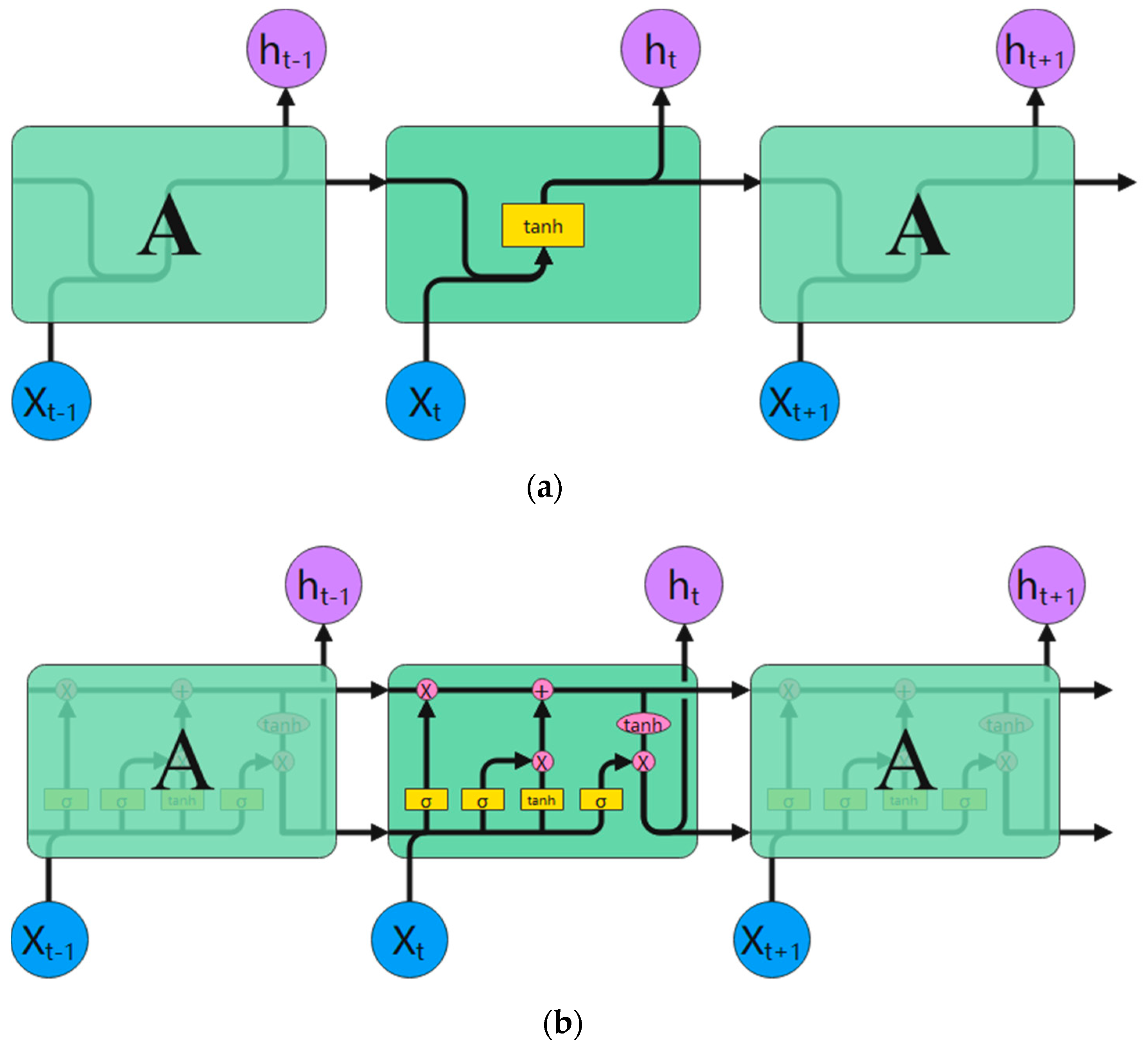

3.1. The Principle of the LSTM Neural Network

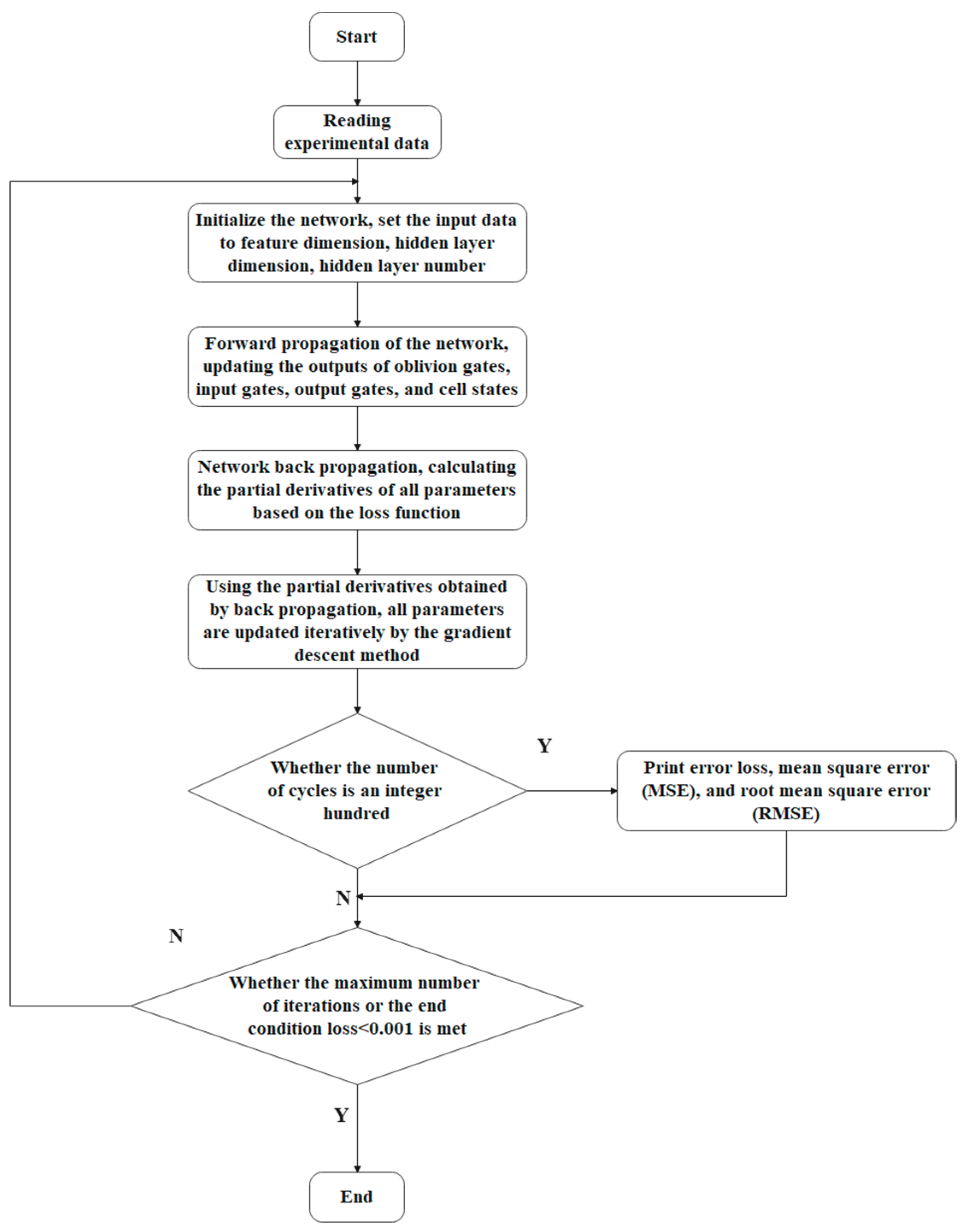

3.2. Building an LSTM Model for Predicting Actual Battery Capacity

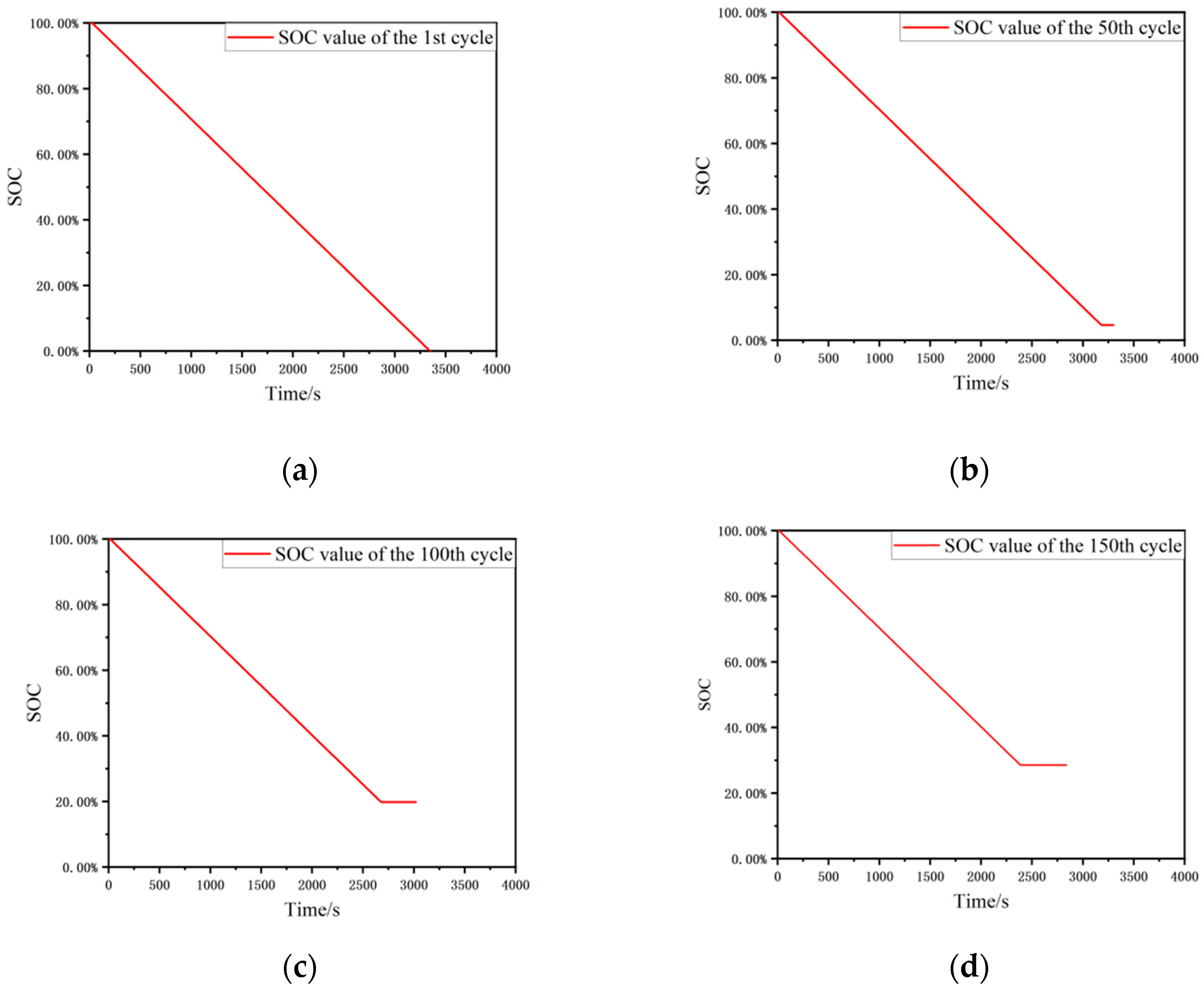

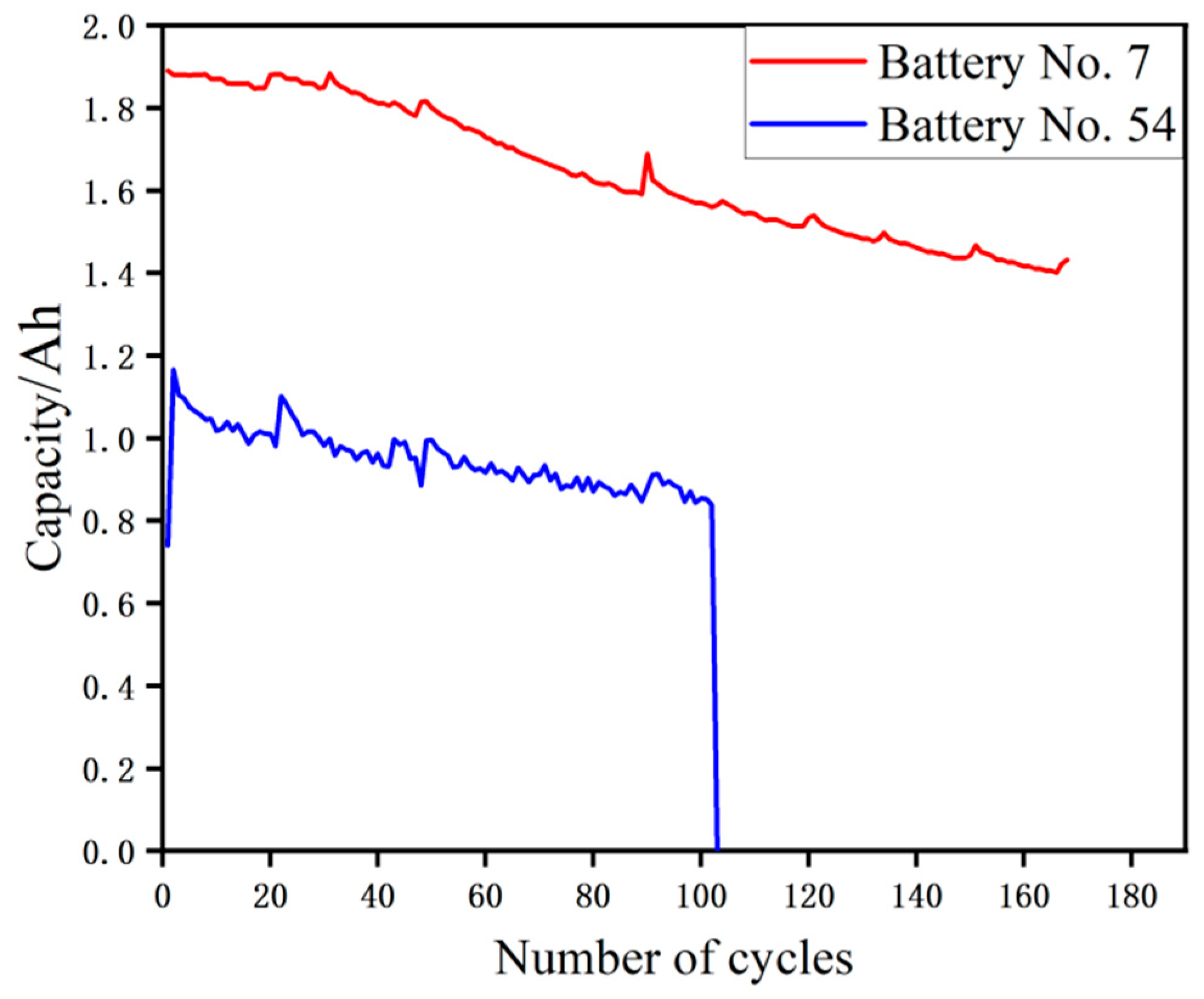

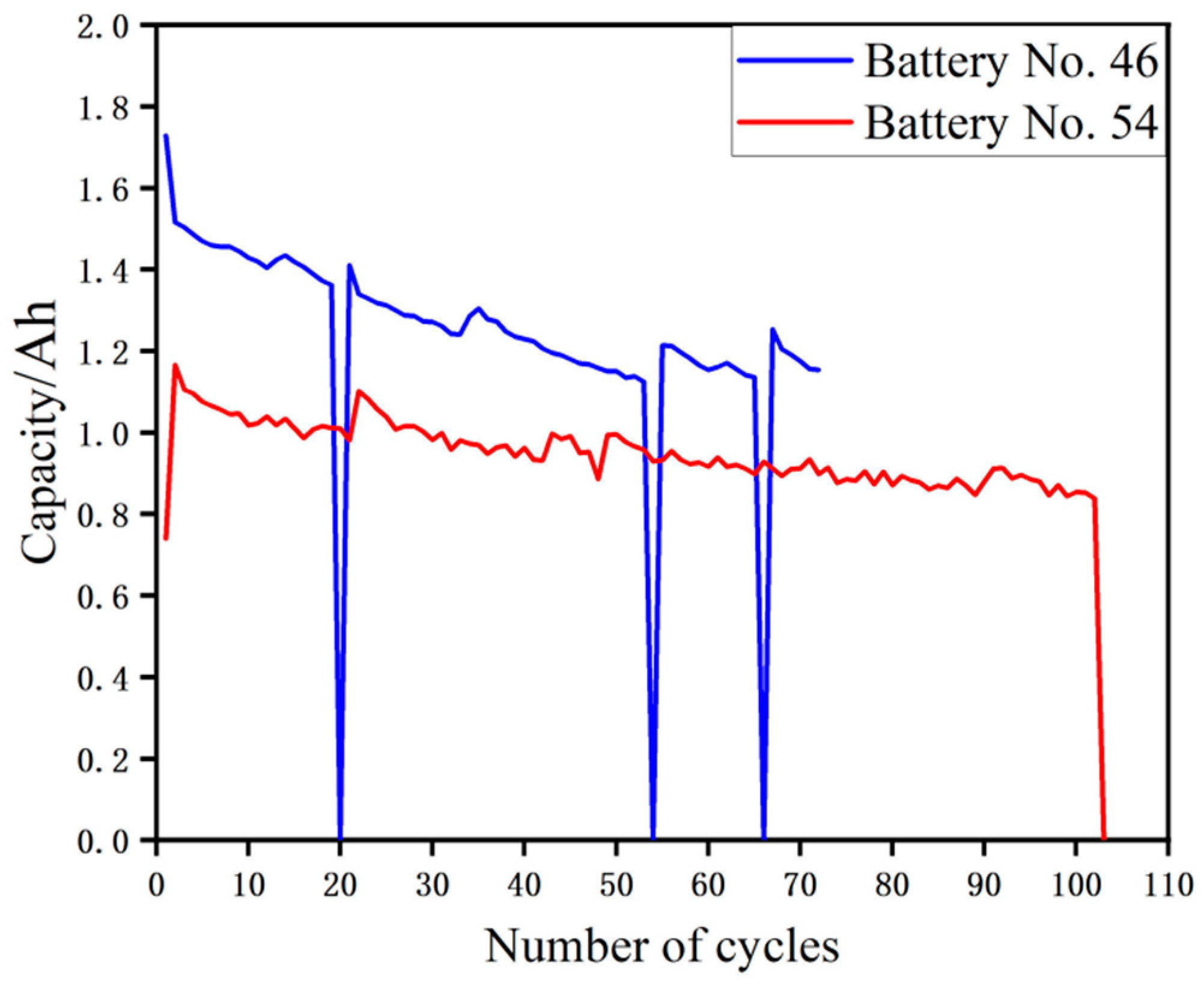

4. Experiment and Analysis

4.1. Test Environment Construction and Test Process

4.2. Analysis of Test Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, K.; Li, K.; Peng, Q.; Zhang, C. A brief review on key technologies in the battery management system of electric vehicles. Front. Mech. Eng. 2019, 14, 47–64. [Google Scholar] [CrossRef] [Green Version]

- Luo, Y.; Qi, P.; Huang, H.; Wang, J.; Wang, Y.; Li, P. Research on SOC estimation method of ampere-time integral based on capacity correction. Automot. Eng. 2020, 42, 681–687. [Google Scholar]

- Yang, Q.; Ma, K.; Xu, L.; Song, L.; Li, X.; Li, Y. A Joint Estimation Method Based on Kalman Filter of Battery State of Charge and State of Health. Coatings 2022, 12, 1047. [Google Scholar] [CrossRef]

- Li, C.; Xiao, F.; Fan, Y.; Tang, X.; Yang, G. Joint estimation of SOC and SOH for lithium-ion batteries based on deep learning. Chin. J. Electr. Eng. 2021, 41, 681–692. [Google Scholar]

- Ahmed, M.S.; Balasingam, B. A scaling approach for improved open circuit voltage modeling in Li-ion batteries. In Proceedings of the 2019 IEEE Electrical Power and Energy Conference (EPEC), Montréal, QC, Canada, 16–18 October 2019; pp. 1–6. [Google Scholar]

- Wei, Z.; Zhao, D.; He, H.; Cao, W.; Dong, G. A noise-tolerant model parameterization method for lithium-ion battery management system. Appl. Energy 2020, 268, 114932. [Google Scholar] [CrossRef]

- Jin, G.; Li, L.; Xu, Y.; Hu, M.; Fu, C.; Qin, D. Comparison of SOC Estimation between the Integer-Order Model and Fractional-Order Model Under Different Operating Conditions. Energies 2020, 13, 1785. [Google Scholar] [CrossRef] [Green Version]

- Hou, E.; Xu, Y.; Qiao, X.; Liu, G.; Wang, Z. State of power estimation of echelon-use battery based on adaptive dual extended Kalman filter. Energies 2021, 14, 5579. [Google Scholar] [CrossRef]

- Zhou, W.; Ma, X.; Wang, H.; Zheng, Y. SOC Estimation Based on Hysteresis Characteristics of Lithium Iron Phosphate Battery. Machines 2022, 10, 658. [Google Scholar] [CrossRef]

- Qiao, X.; Wang, Z.; Hou, E.; Liu, G.; Cai, Y. Online Estimation of Open Circuit Voltage Based on Extended Kalman Filter with Self-Evaluation Criterion. Energies 2022, 15, 4373. [Google Scholar] [CrossRef]

- Ding, Z.T.; Deng, T.; Li, Z.F.; Yin, Y.L. Research on SOC estimation method for lithium-ion batteries based on ampere-time integral and traceless Kalman filter. China Mech. Eng. 2020, 31, 1823–1830. [Google Scholar]

- Zhou, J.; Sun, X.; Liu, K.; Wang, M.; Yang, X.; Liu, G. Research on SOC estimation algorithm of sliding mode observer with joint extended Kalman filter. Chin. J. Electr. Eng. 2021, 41, 692–703. [Google Scholar]

- Pham, N.N.; Leuchter, J.; Pham, K.L.; Dong, Q.H. Battery Management System for Unmanned Electric Vehicles with CAN BUS and Internet of Things. Vehicles 2022, 4, 37. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Z.; Zhang, J.; Su, L.; Ge, H. Accurate and Efficient Estimation of Lithium-Ion Battery State of Charge with Alternate Adaptive Extended Kalman Filter and Ampere-Hour Counting Methods. Energies 2019, 12, 757. [Google Scholar] [CrossRef] [Green Version]

- Jafari, S.; Shahbazi, Z.; Byun, Y.-C.; Lee, S.-J. Lithium-Ion Battery Estimation in Online Framework Using Extreme Gradient Boosting Machine Learning Approach. Mathematics 2022, 10, 888. [Google Scholar] [CrossRef]

- Lin, C.T.; Qiu, B.; Chen, Q.S. A comparative study of equivalent circuit models for electric vehicle battery power input. Automot. Eng. 2006, 3, 229–234. [Google Scholar]

- Ruan, H.; Chen, J.; Ai, W.; Wu, B. Generalised diagnostic framework for rapid battery degradation quantification with deep learning. Energy AI 2022, 9, 100158. [Google Scholar] [CrossRef]

- Shankar, K.; Kumar, S.; Dutta, A.K.; Alkhayyat, A.; Jawad, A.J.M.; Abbas, A.H.; Yousif, Y.K. An Automated Hyperparameter Tuning Recurrent Neural Network Model for Fruit Classification. Mathematics 2022, 10, 2358. [Google Scholar] [CrossRef]

- Feng, Z.; Hu, P.; Li, S.; Mo, D. Prediction of Significant Wave Height in Offshore China Based on the Machine Learning Method. J. Mar. Sci. Eng. 2020, 10, 836. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Hou, J.; Wang, Z.; Jiang, Y. Study of SOC Estimation by the Ampere-Hour Integral Method with Capacity Correction Based on LSTM. Batteries 2022, 8, 170. https://doi.org/10.3390/batteries8100170

Zhang X, Hou J, Wang Z, Jiang Y. Study of SOC Estimation by the Ampere-Hour Integral Method with Capacity Correction Based on LSTM. Batteries. 2022; 8(10):170. https://doi.org/10.3390/batteries8100170

Chicago/Turabian StyleZhang, Xin, Jiawei Hou, Zekun Wang, and Yueqiu Jiang. 2022. "Study of SOC Estimation by the Ampere-Hour Integral Method with Capacity Correction Based on LSTM" Batteries 8, no. 10: 170. https://doi.org/10.3390/batteries8100170

APA StyleZhang, X., Hou, J., Wang, Z., & Jiang, Y. (2022). Study of SOC Estimation by the Ampere-Hour Integral Method with Capacity Correction Based on LSTM. Batteries, 8(10), 170. https://doi.org/10.3390/batteries8100170