Electric Vehicle Batteries: Status and Perspectives of Data-Driven Diagnosis and Prognosis

Abstract

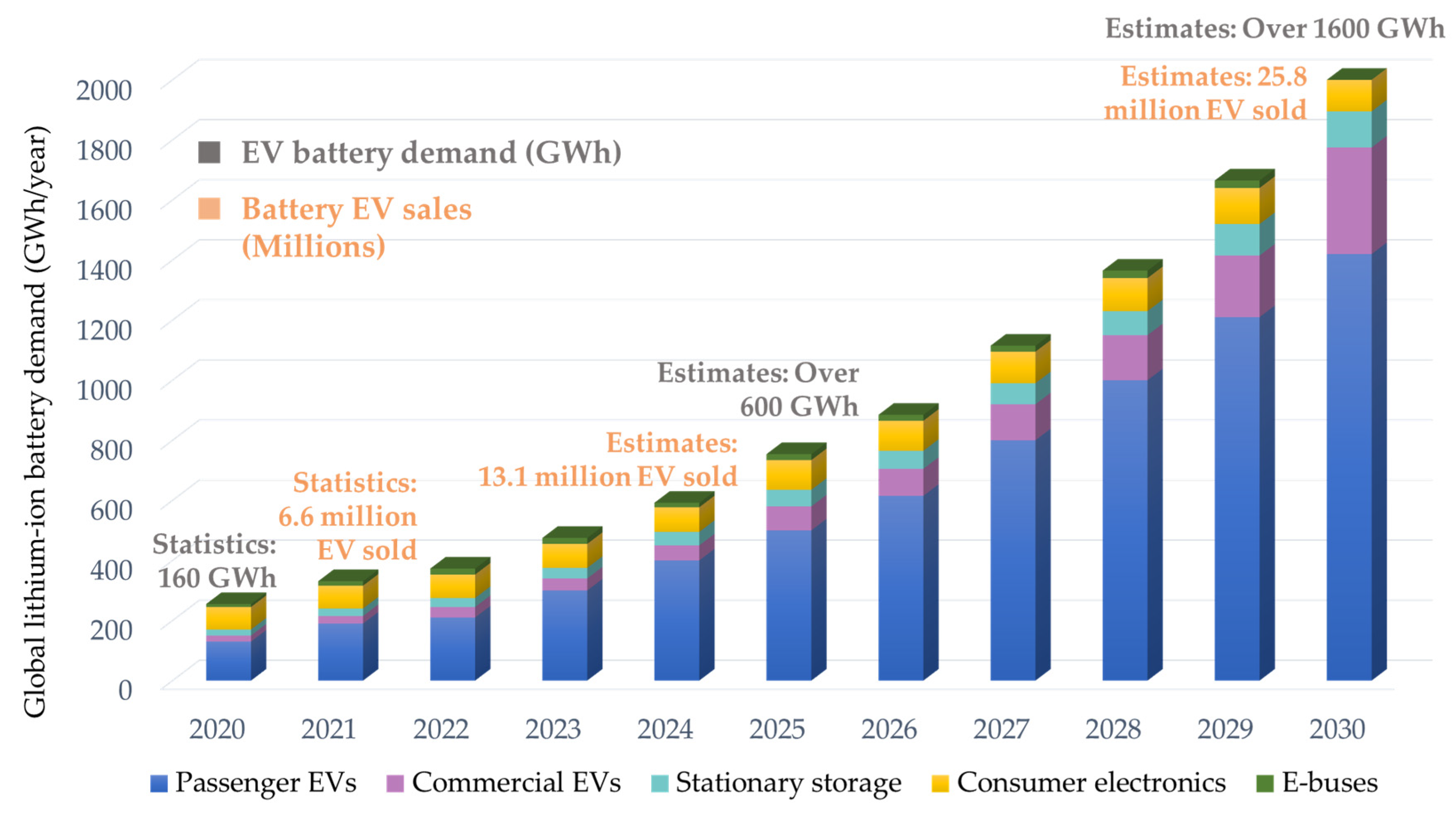

1. Introduction

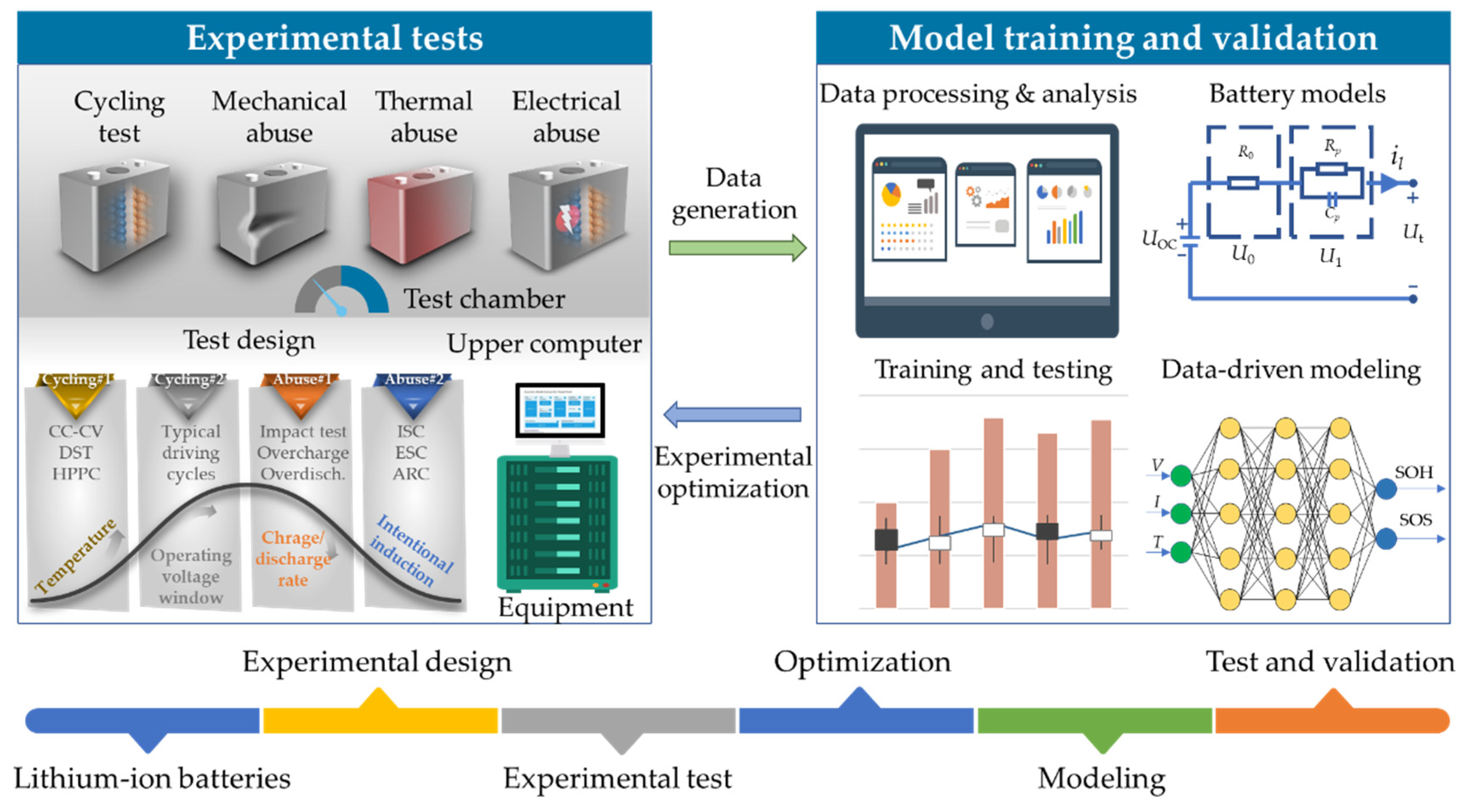

2. Approaches for Battery Diagnosis and Prognosis Using Laboratory Data

2.1. State of Health

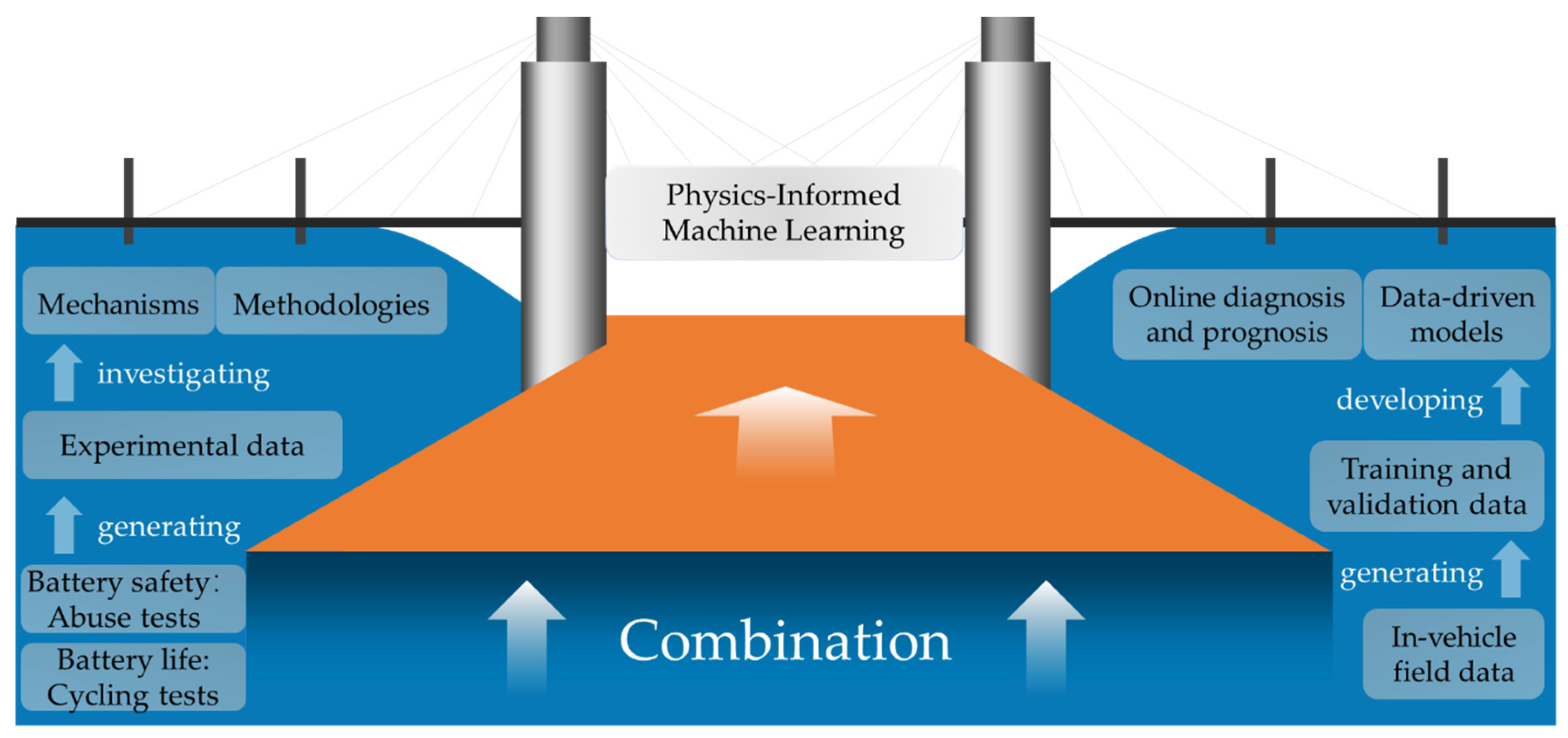

2.2. State of Safety

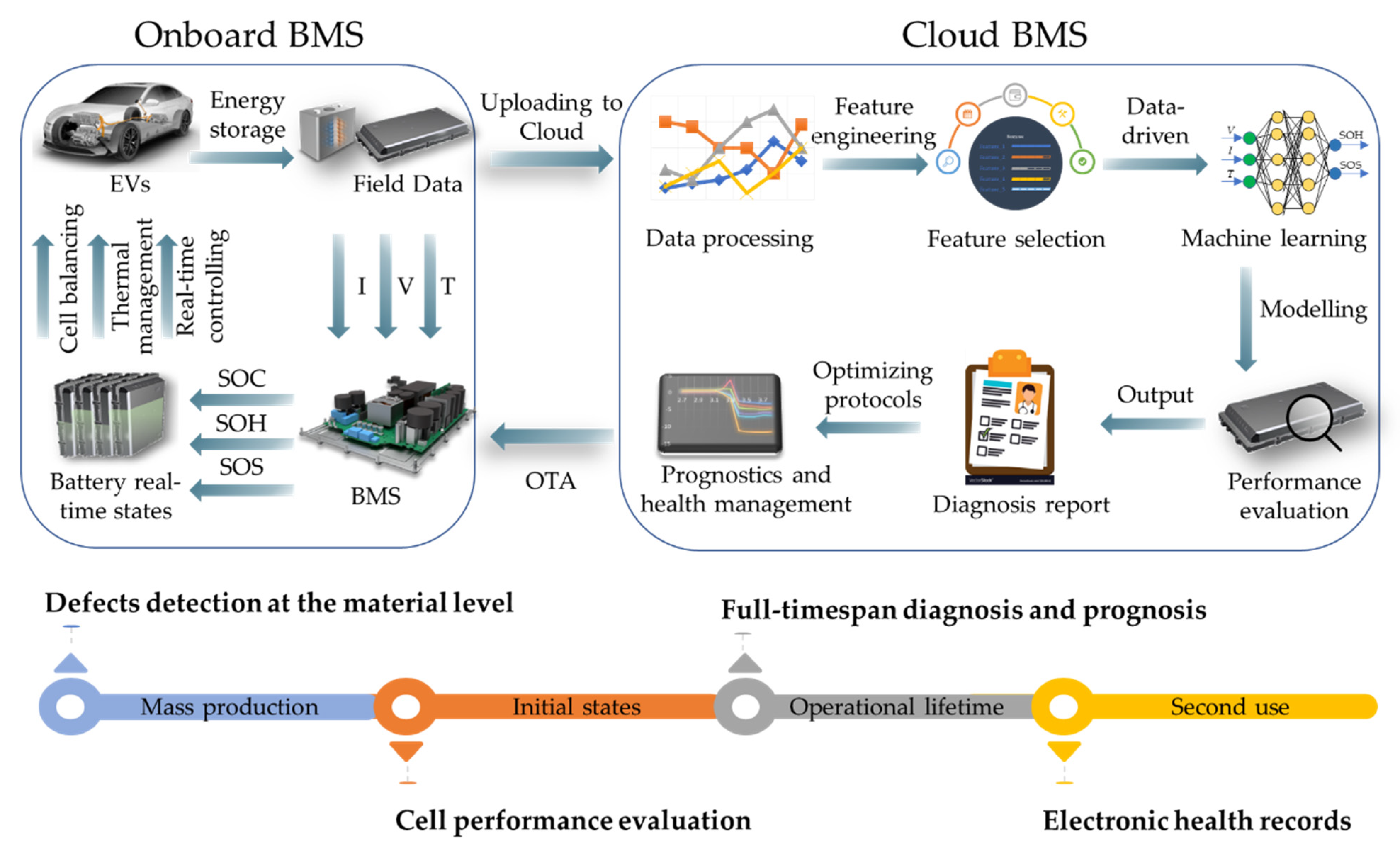

3. Battery Diagnosis and Prognosis Using Field Data from EVs

3.1. State of Health

3.2. State of Safety

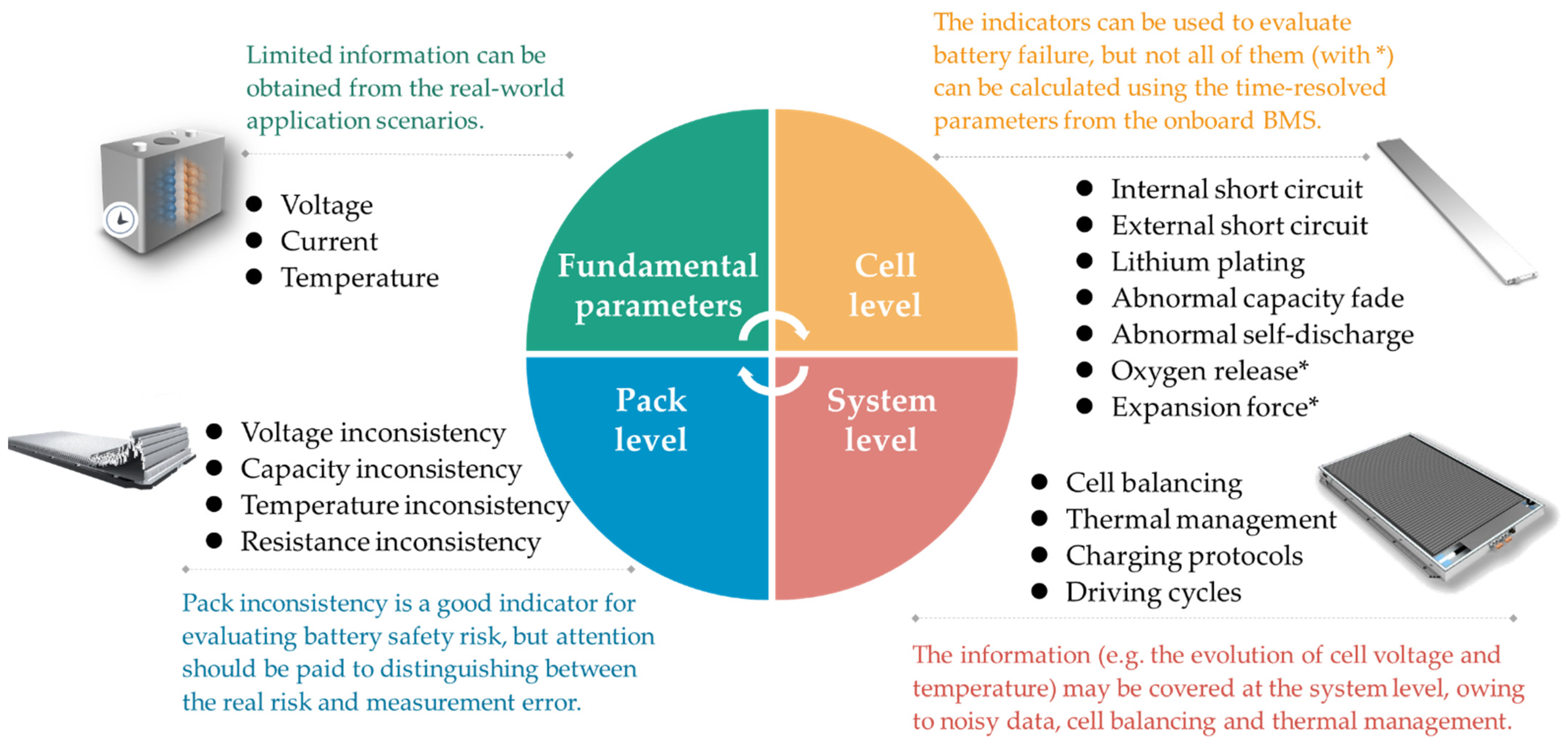

4. The Value and Key Issues for the Use of in-Vehicle Data to Monitor Battery Condition

4.1. Tracking EV Battery Performance and Health/Safety

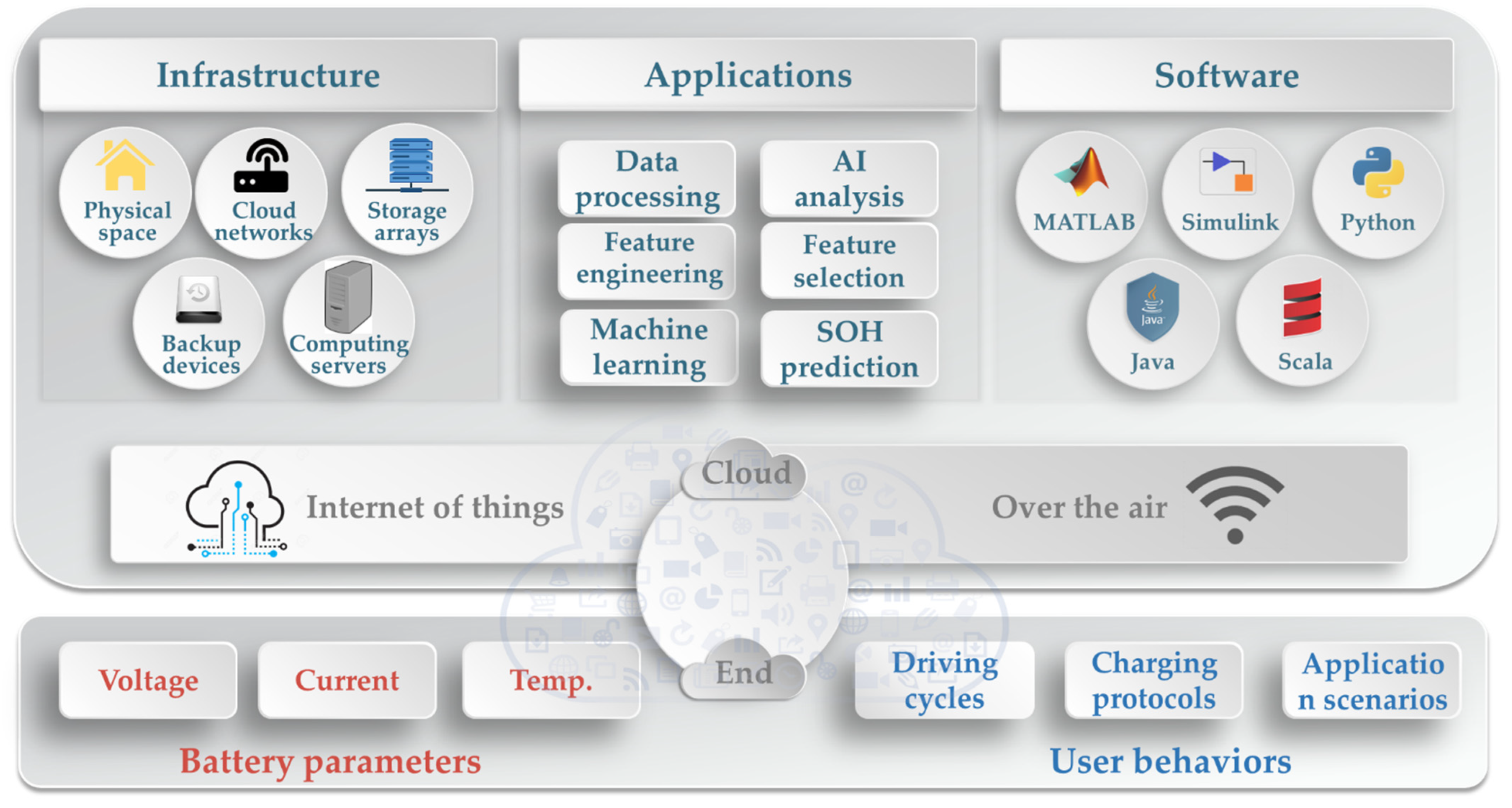

4.2. Issues in Using Cloud-Stored Battery Field Data

5. Outlook for Battery Prognosis in EV Applications

5.1. Cloud-Edge Applications and Battery Digital Twins

5.2. Full-Scale Battery Diagnosis and Prognosis for Health and Safety

5.3. Advanced Artificial Intelligence and Machine Learning Techniques

5.4. Battery Health Reports to Electric Vehicle Owners

6. Summary and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- International Energy Agency. Electric Cars Fend off Supply Challenges to More than Double Global Sales. Available online: https://www.iea.org/commentaries/electric-cars-fend-off-supply-challenges-to-more-than-double-global-sales (accessed on 19 August 2022).

- Global EV Outlook 2021. Global EV Sales by Scenario, 2020–2030. Available online: https://www.iea.org/data-and-statistics/charts/global-ev-sales-by-scenario-2020-2030 (accessed on 19 August 2022).

- Global EV Outlook 2021. Annual EV Battery Demand Projections by Region and Scenario, 2020–2030. Available online: https://www.iea.org/data-and-statistics/charts/annual-ev-battery-demand-projections-by-region-and-scenario-2020-2030 (accessed on 19 August 2022).

- Zeng, X.; Li, M.; Abd El-Hady, D.; Alshitari, W.; Al-Bogami, A.S.; Lu, J.; Amine, K. Commercialization of lithium battery technologies for electric vehicles. Adv. Energy Mater. 2019, 9, 1900161. [Google Scholar] [CrossRef]

- De Gennaro, M.; Paffumi, E.; Martini, G.; Giallonardo, A.; Pedroso, S.; Loiselle-Lapointe, A. A case study to predict the capacity fade of the battery of electrified vehicles in real-world use conditions. Case Stud. Transp. Policy. 2020, 8, 517–534. [Google Scholar] [CrossRef]

- Deng, J.; Bae, C.; Marcicki, J.; Masias, A.; Miller, T. Safety modelling and testing of lithium-ion batteries in electrified vehicles. Nat. Energy 2018, 3, 261–266. [Google Scholar] [CrossRef]

- Aykol, M.; Herring, P.; Anapolsky, A. Machine learning for continuous innovation in battery technologies. Nat. Rev. Mater. 2020, 5, 725–727. [Google Scholar] [CrossRef]

- Berecibar, M. Accurate predictions of lithium-ion battery life. Nature 2019, 568, 325–326. [Google Scholar] [CrossRef]

- Hatfield, P.W.; Gaffney, J.A.; Anderson, G.J.; Ali, S.; Antonelli, L.; Başeğmez du Pree, S.; Citrin, J.; Fajardo, M.; Knapp, P.; Kettle, B.; et al. The data-driven future of high-energy-density physics. Nature 2021, 593, 351–361. [Google Scholar] [CrossRef] [PubMed]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef] [PubMed]

- Hein, J.E. Machine learning made easy for optimizing chemical reactions. Nature 2021, 590, 40–41. [Google Scholar] [CrossRef]

- Roman, D.; Saxena, S.; Robu, V.; Pecht, M.; Flynn, D. Machine learning pipeline for battery state-of-health estimation. Nat. Mach. Intell. 2021, 3, 447–456. [Google Scholar] [CrossRef]

- Severson, K.A.; Attia, P.M.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z.; Chen, M.H.; Aykol, M.; Herring, P.K.; Fraggedakis, D.; et al. Data-driven prediction of battery cycle life before capacity degradation. Nat. Energy 2019, 4, 383–391. [Google Scholar] [CrossRef]

- Ma, Y.; Wu, L.; Guan, Y.; Peng, Z. The capacity estimation and cycle life prediction of lithium-ion batteries using a new broad extreme learning machine approach. J. Power Sources 2020, 476, 228581. [Google Scholar] [CrossRef]

- Ma, G.; Zhang, Y.; Cheng, C.; Zhou, B.; Hu, P.; Yuan, Y. Remaining useful life prediction of lithium-ion batteries based on false nearest neighbors and a hybrid neural network. Appl. Energy 2019, 253, 113626. [Google Scholar] [CrossRef]

- Chen, Z.; Shi, N.; Ji, Y.; Niu, M.; Wang, Y. Lithium-ion batteries remaining useful life prediction based on BLS-RVM. Energy 2021, 234, 121269. [Google Scholar] [CrossRef]

- Jiang, L.; Deng, Z.; Tang, X.; Hu, L.; Lin, X.; Hu, X. Data-driven fault diagnosis and thermal runaway warning for battery packs using real-world vehicle data. Energy 2021, 234, 121266. [Google Scholar] [CrossRef]

- Li, W.; Zhu, J.; Xia, Y.; Gorji, M.B.; Wierzbicki, T. Data-driven safety envelope of lithium-ion batteries for electric vehicles. Joule 2019, 3, 2703–2715. [Google Scholar] [CrossRef]

- Jia, Y.; Li, J.; Yuan, C.; Gao, X.; Yao, W.; Lee, M.; Xu, J. Data-driven safety risk prediction of lithium-ion battery. Adv. Energy Mater. 2021, 11, 2003868. [Google Scholar] [CrossRef]

- Schindler, M.; Sturm, J.; Ludwig, S.; Schmitt, J.; Jossen, A. Evolution of initial cell-to-cell variations during a three-year production cycle. ETransportation 2021, 8, 100102. [Google Scholar] [CrossRef]

- Tran, M.K.; Panchal, S.; Khang, T.D.; Panchal, K.; Fraser, R.; Fowler, M. Concept review of a cloud-based smart battery management system for lithium-ion batteries: Feasibility, logistics, and functionality. Batteries 2022, 8, 19. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, Z.; Cao, R.; Wang, M.; Cheng, H.; Zhang, L.; Jiang, Y.; Li, Y.; Chen, B.; Ling, H.; et al. Implementation for a cloud battery management system based on the CHAIN framework. Energy AI 2021, 5, 100088. [Google Scholar] [CrossRef]

- Li, W.; Rentemeister, M.; Badeda, J.; Jöst, D.; Schulte, D.; Sauer, D.U. Digital twin for battery systems: Cloud battery management system with online state-of-charge and state-of-health estimation. J. Energy Storage 2020, 30, 101557. [Google Scholar] [CrossRef]

- Zhao, J.; Ling, H.; Wang, J.; Burke, A.F.; Lian, Y. Data-driven prediction of battery failure for electric vehicles. Iscience 2022, 25, 104172. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Lu, L.; Zheng, Y.; Feng, X.; Li, Z.; Li, J.; Ouyang, M. A review on the key issues of the lithium ion battery degradation among the whole life cycle. ETransportation 2019, 1, 100005. [Google Scholar] [CrossRef]

- Atalay, S.; Sheikh, M.; Mariani, A.; Merla, Y.; Bower, E.; Widanage, W.D. Theory of battery ageing in a lithium-ion battery: Capacity fade, nonlinear ageing and lifetime prediction. J. Power Sources 2020, 478, 229026. [Google Scholar] [CrossRef]

- Winter, M.; Barnett, B.; Xu, K. Before Li ion batteries. Chem. Rev. 2018, 118, 11433–11456. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Xu, L.; Lin, X.; Pecht, M. Battery lifetime prognostics. Joule 2020, 4, 310–346. [Google Scholar] [CrossRef]

- Berecibar, M.; Gandiaga, I.; Villarreal, I.; Omar, N.; Van Mierlo, J.; Van den Bossche, P. Critical review of state of health estimation methods of Li-ion batteries for real applications. Renew. Sustain. Energy Rev. 2016, 56, 572–587. [Google Scholar] [CrossRef]

- Li, Y.; Guo, J.; Pedersen, K.; Gurevich, L.; Stroe, D.I. Recent Health Diagnosis Methods for Lithium-Ion Batteries. Batteries 2022, 8, 72. [Google Scholar] [CrossRef]

- Finegan, D.P.; Zhu, J.; Feng, X.; Keyser, M.; Ulmefors, M.; Li, W.; Bazant, M.Z.; Cooper, S.J. The application of data-driven methods and physics-based learning for improving battery safety. Joule 2021, 5, 316–329. [Google Scholar] [CrossRef]

- Attia, P.M.; Grover, A.; Jin, N.; Severson, K.A.; Markov, T.M.; Liao, Y.H.; Chen, M.H.; Cheong, B.; Perkins, N.; Yang, Z.; et al. Closed-loop optimization of fast-charging protocols for batteries with machine learning. Nature 2020, 578, 397–402. [Google Scholar] [CrossRef]

- Richardson, R.R.; Osborne, M.A.; Howey, D.A. Gaussian process regression for forecasting battery state of health. J. Power Sources 2017, 357, 209–219. [Google Scholar] [CrossRef]

- Jordan, M.I.; Mitchell, T.M. Machine learning: Trends, perspectives, and prospects. Science 2015, 349, 255–260. [Google Scholar] [CrossRef] [PubMed]

- Rusk, N. Deep learning. Nat. Methods 2016, 13, 35. [Google Scholar] [CrossRef]

- Zdeborová, L. Understanding deep learning is also a job for physicists. Nat. Phys. 2020, 16, 602–604. [Google Scholar] [CrossRef]

- Lombardo, T.; Duquesnoy, M.; El-Bouysidy, H.; Årén, F.; Gallo-Bueno, A.; Jørgensen, P.B.; Bhowmik, A.; Demortière, A.; Ayerbe, E.; Alcaide, F.; et al. Artificial intelligence applied to battery research: Hype or reality? Chem. Rev. 2021, 122, 10899–10969. [Google Scholar] [CrossRef]

- Gong, Q.; Wang, P.; Cheng, Z. An encoder-decoder model based on deep learning for state of health estimation of lithium-ion battery. J. Energy Storage 2022, 46, 103804. [Google Scholar] [CrossRef]

- Ma, G.; Xu, S.; Jiang, B.; Cheng, C.; Yang, X.; Shen, Y.; Yang, T.; Huang, Y.; Ding, H.; Yuan, Y. Real-time personalized health status prediction of lithium-ion batteries using deep transfer learning. Energy Environ. Sci. 2022. [Google Scholar] [CrossRef]

- Karniadakis, G.E.; Kevrekidis, I.G.; Lu, L.; Perdikaris, P.; Wang, S.; Yang, L. Physics-informed machine learning. Nat. Rev. Phys. 2021, 3, 422–440. [Google Scholar] [CrossRef]

- Raissi, M.; Perdikaris, P.; Karniadakis, G.E. Physics-informed neural networks: A deep learning framework for solving forward and inverse problems involving nonlinear partial differential equations. J. Comput. Phys. 2019, 378, 686–707. [Google Scholar] [CrossRef]

- Li, W.; Zhang, J.; Ringbeck, F.; Jöst, D.; Zhang, L.; Wei, Z.; Sauer, D.U. Physics-informed neural networks for electrode-level state estimation in lithium-ion batteries. J. Power Sources 2021, 506, 230034. [Google Scholar] [CrossRef]

- Kohtz, S.; Xu, Y.; Zheng, Z.; Wang, P. Physics-informed machine learning model for battery state of health prognostics using partial charging segments. Mech. Syst. Signal Process 2022, 172, 109002. [Google Scholar]

- Nascimento, R.G.; Corbetta, M.; Kulkarni, C.S.; Viana, F.A. Hybrid physics-informed neural networks for lithium-ion battery modeling and prognosis. J. Power Sources 2021, 513, 230526. [Google Scholar] [CrossRef]

- Raj, T.; Wang, A.A.; Monroe, C.W.; Howey, D.A. Investigation of Path-Dependent Degradation in Lithium-Ion Batteries. Batter. Supercaps 2020, 3, 1377–1385. [Google Scholar] [CrossRef]

- Mohtat, P.; Lee, S.; Siegel, J.B.; Stefanopoulou, A.G. Comparison of expansion and voltage differential indicators for battery capacity fade. J. Power Sources 2022, 518, 230714. [Google Scholar] [CrossRef]

- Chen, X.; Hu, Y.; Li, S.; Wang, Y.; Li, D.; Luo, C.; Xue, X.; Xu, F.; Zhang, Z.; Gong, Z.; et al. State of health (SoH) estimation and degradation modes analysis of pouch NMC532/graphite Li-ion battery. J. Power Sources 2021, 498, 229884. [Google Scholar] [CrossRef]

- Li, Y.; Abdel-Monem, M.; Gopalakrishnan, R.; Berecibar, M.; Nanini-Maury, E.; Omar, N.; van den Bossche, P.; Van Mierlo, J. A quick on-line state of health estimation method for Li-ion battery with incremental capacity curves processed by Gaussian filter. J. Power Sources 2018, 373, 40–53. [Google Scholar] [CrossRef]

- Feng, X.; Weng, C.; He, X.; Han, X.; Lu, L.; Ren, D.; Ouyang, M. Online state-of-health estimation for Li-ion battery using partial charging segment based on support vector machine. IEEE Trans. Veh. Technol. 2019, 68, 8583–8592. [Google Scholar] [CrossRef]

- Anseán, D.; García, V.M.; González, M.; Blanco-Viejo, C.; Viera, J.C.; Pulido, Y.F.; Sánchez, L. Lithium-ion battery degradation indicators via incremental capacity analysis. IEEE Trans. Ind. Appl. 2019, 55, 2992–3002. [Google Scholar] [CrossRef]

- Weng, C.; Feng, X.; Sun, J.; Peng, H. State-of-health monitoring of lithium-ion battery modules and packs via incremental capacity peak tracking. Appl. Energy 2016, 180, 360–368. [Google Scholar] [CrossRef]

- Lewerenz, M.; Marongiu, A.; Warnecke, A.; Sauer, D.U. Differential voltage analysis as a tool for analyzing inhomogeneous aging: A case study for LiFePO4| Graphite cylindrical cells. J. Power Sources 2017, 368, 57–67. [Google Scholar] [CrossRef]

- Stroe, D.I.; Schaltz, E. Lithium-ion battery state-of-health estimation using the incremental capacity analysis technique. IEEE Trans. Ind. Appl. 2019, 56, 678–685. [Google Scholar] [CrossRef]

- Wei, Z.; Ruan, H.; Li, Y.; Li, J.; Zhang, C.; He, H. Multistage state of health estimation of lithium-ion battery with high tolerance to heavily partial charging. IEEE Trans. Power Electron. 2022, 37, 7432–7442. [Google Scholar] [CrossRef]

- Dubarry, M.; Truchot, C.; Liaw, B.Y. Synthesize battery degradation modes via a diagnostic and prognostic model. J. Power Sources 2012, 219, 204–216. [Google Scholar] [CrossRef]

- Pastor-Fernández, C.; Uddin, K.; Chouchelamane, G.H.; Widanage, W.D.; Marco, J. A comparison between electrochemical impedance spectroscopy and incremental capacity-differential voltage as Li-ion diagnostic techniques to identify and quantify the effects of degradation modes within battery management systems. J. Power Sources 2017, 360, 301–318. [Google Scholar] [CrossRef]

- Cabrera-Castillo, E.; Niedermeier, F.; Jossen, A. Calculation of the state of safety (SOS) for lithium ion batteries. J. Power Sources 2016, 324, 509–520. [Google Scholar] [CrossRef]

- Seong, W.M.; Park, K.Y.; Lee, M.H.; Moon, S.; Oh, K.; Park, H.; Lee, S.; Kang, K. Abnormal self-discharge in lithium-ion batteries. Energy Environ. Sci. 2018, 11, 970–978. [Google Scholar] [CrossRef]

- Zhang, G.; Wei, X.; Tang, X.; Zhu, J.; Chen, S.; Dai, H. Internal short circuit mechanisms, experimental approaches and detection methods of lithium-ion batteries for electric vehicles: A review. Renew. Sustain. Energy Rev. 2021, 141, 110790. [Google Scholar] [CrossRef]

- Xiong, R.; Yang, R.; Chen, Z.; Shen, W.; Sun, F. Online fault diagnosis of external short circuit for lithium-ion battery pack. IEEE Trans. Ind. Electron. 2019, 67, 1081–1091. [Google Scholar] [CrossRef]

- Lin, X.; Khosravinia, K.; Hu, X.; Li, J.; Lu, W. Lithium plating mechanism, detection, and mitigation in lithium-ion batteries. Prog. Energy Combust. Sci 2021, 87, 100953. [Google Scholar] [CrossRef]

- Liu, X.; Ren, D.; Hsu, H.; Feng, X.; Xu, G.L.; Zhuang, M.; Gao, H.; Lu, L.; Han, X.; Chu, Z.; et al. Thermal runaway of lithium-ion batteries without internal short circuit. Joule 2018, 2, 2047–2064. [Google Scholar] [CrossRef]

- Cai, T.; Valecha, P.; Tran, V.; Engle, B.; Stefanopoulou, A.; Siegel, J. Detection of Li-ion battery failure and venting with Carbon Dioxide sensors. ETransportation 2021, 7, 100100. [Google Scholar] [CrossRef]

- Doughty, D.H. SAE “EV & HEV rechargeable energy storage system (RESS) safety and abuse testing procedure”. SAE Tech. Pap. 2010, 0148-7191. [Google Scholar]

- Doughty, D.H. Vehicle Battery Safety Roadmap Guidance (No. NREL/SR-5400-54404); National Renewable Energy Lab (NREL): Golden, CO, USA, 2012. [Google Scholar]

- Bleier, A.; Goldfarb, A.; Tucker, C. Consumer privacy and the future of data-based innovation and marketing. Int. J. Res. Mark. 2020, 37, 466–480. [Google Scholar] [CrossRef]

- Naha, A.; Khandelwal, A.; Agarwal, S.; Tagade, P.; Hariharan, K.S.; Kaushik, A.; Yadu, A.; Kolake, S.M.; Han, S.; Oh, B. Internal short circuit detection in Li-ion batteries using supervised machine learning. Sci. Rep. 2020, 10, 1301. [Google Scholar] [CrossRef]

- Xu, H.; Zhu, M.; Marcicki, J.; Yang, X.G. Mechanical modeling of battery separator based on microstructure image analysis and stochastic characterization. J. Power Sources 2017, 345, 137–145. [Google Scholar] [CrossRef]

- Avdeev, I.; Gilaki, M. Structural analysis and experimental characterization of cylindrical lithium-ion battery cells subject to lateral impact. J. Power Sources 2014, 271, 382–391. [Google Scholar] [CrossRef]

- Zhang, X.; Sahraei, E.; Wang, K. Deformation and failure characteristics of four types of lithium-ion battery separators. J. Power Sources 2016, 327, 693–701. [Google Scholar] [CrossRef]

- Muresanu, A.D.; Dudescu, M.C. Numerical and Experimental Evaluation of a Battery Cell under Impact Load. Batteries 2022, 8, 48. [Google Scholar] [CrossRef]

- Yang, R.; Xiong, R.; Shen, W.; Lin, X. Extreme learning machine-based thermal model for lithium-ion batteries of electric vehicles under external short circuit. Engineering 2021, 7, 395–405. [Google Scholar] [CrossRef]

- Yang, R.; Xiong, R.; Ma, S.; Lin, X. Characterization of external short circuit faults in electric vehicle Li-ion battery packs and prediction using artificial neural networks. Appl. Energy 2020, 260, 114253. [Google Scholar] [CrossRef]

- Zhang, W.; Ouyang, N.; Yin, X.; Li, X.; Wu, W.; Huang, L. Data-driven early warning strategy for thermal runaway propagation in Lithium-ion battery modules with variable state of charge. Appl. Energy 2022, 323, 119614. [Google Scholar] [CrossRef]

- Heinrich, F.; Noering, F.D.; Pruckner, M.; Jonas, K. Unsupervised data-preprocessing for long short-term memory based battery model under electric vehicle operation. J. Energy Storage 2021, 38, 102598. [Google Scholar] [CrossRef]

- Haider, S.N.; Zhao, Q.; Li, X. Data driven battery anomaly detection based on shape based clustering for the data centers class. J. Energy Storage 2020, 29, 101479. [Google Scholar] [CrossRef]

- Schmid, M.; Kneidinger, H.G.; Endisch, C. Data-driven fault diagnosis in battery systems through cross-cell monitoring. IEEE Sens. J. 2020, 21, 1829–1837. [Google Scholar] [CrossRef]

- Ma, G.; Xu, S.; Cheng, C. Fault detection of lithium-ion battery packs with a graph-based method. J. Energy Storage 2021, 43, 103209. [Google Scholar] [CrossRef]

- Kong, X.; Lu, L.; Yuan, Y.; Sun, Y.; Feng, X.; Yang, H.; Zhang, F.; Zhang, J.; Liu, X.; Han, X.; et al. Foreign matter defect battery and sudden spontaneous combustion. ETransportation 2022, 12, 100170. [Google Scholar] [CrossRef]

- Höschele, P.; Heindl, S.F.; Schneider, B.; Sinz, W.; Ellersdorfer, C. Method for In-Operando Contamination of Lithium Ion Batteries for Prediction of Impurity-Induced Non-Obvious Cell Damage. Batteries 2022, 8, 35. [Google Scholar] [CrossRef]

- Zhang, E.; Dao, M.; Karniadakis, G.E.; Suresh, S. Analyses of internal structures and defects in materials using physics-informed neural networks. Sci. Adv. 2022, 8, eabk0644. [Google Scholar] [CrossRef]

- Drake, N. Cloud computing beckons scientists. Nature 2014, 509, 543–544. [Google Scholar] [CrossRef]

- Gibney, E. Europe sets its sights on the cloud: Three large labs hope to create a giant public--private computing network. Nature 2015, 523, 136–138. [Google Scholar] [CrossRef]

- Khan, W.Z.; Aalsalem, M.Y.; Khan, M.K.; Arshad, Q. Data and privacy: Getting consumers to trust products enabled by the Internet of Things. IEEE Consum. Electron. Mag. 2019, 8, 35–38. [Google Scholar] [CrossRef]

- Data Service Center for Electric Vehicles. Available online: http://en.aesa.net.cn/About.aspx?ClassID=65 (accessed on 19 August 2022).

- Zhao, Y.; Liu, P.; Wang, Z.; Zhang, L.; Hong, J. Fault and defect diagnosis of battery for electric vehicles based on big data analysis methods. Appl. Energy 2017, 207, 354–362. [Google Scholar] [CrossRef]

- Li, K.; Zhou, P.; Lu, Y.; Han, X.; Li, X.; Zheng, Y. Battery life estimation based on cloud data for electric vehicles. J. Power Sources 2020, 468, 228192. [Google Scholar] [CrossRef]

- Song, L.; Zhang, K.; Liang, T.; Han, X.; Zhang, Y. Intelligent state of health estimation for lithium-ion battery pack based on big data analysis. J. Energy Storage 2020, 32, 101836. [Google Scholar] [CrossRef]

- She, C.; Wang, Z.; Sun, F.; Liu, P.; Zhang, L. Battery aging assessment for real-world electric buses based on incremental capacity analysis and radial basis function neural network. IEEE Trans. Ind. Inf. 2019, 16, 3345–3354. [Google Scholar] [CrossRef]

- Battery Failure Databank. National Renewable Energy Laboratory. Available online: https://www.nrel.gov/transportation/battery-failure.html (accessed on 19 August 2022).

- Kellner, Q.; Hosseinzadeh, E.; Chouchelamane, G.; Widanage, W.D.; Marco, J. Battery cycle life test development for high-performance electric vehicle applications. J. Energy Storage 2018, 15, 228–244. [Google Scholar] [CrossRef]

- National Monitoring and Management Platform for NEVs. Available online: http://www.bitev.org.cn/a/48.html (accessed on 19 August 2022).

- Hong, J.; Wang, Z.; Ma, F.; Yang, J.; Xu, X.; Qu, C.; Zhang, J.; Shan, T.; Hou, Y.; Zhou, Y. Thermal runaway prognosis of battery systems using the modified multiscale entropy in real-world electric vehicles. IEEE Trans. Transp. Electrif. 2021, 7, 2269–2278. [Google Scholar] [CrossRef]

- Hong, J.; Wang, Z.; Qu, C.; Ma, F.; Xu, X.; Yang, J.; Zhang, J.; Zhou, Y.; Shan, T.; Hou, Y. Fault Prognosis and Isolation of Lithium-ion Batteries in Electric Vehicles Considering Real-Scenario Thermal Runaway Risks. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9271. [Google Scholar] [CrossRef]

- Hong, J.; Wang, Z.; Qu, C.; Zhou, Y.; Shan, T.; Zhang, J.; Hou, Y. Investigation on overcharge-caused thermal runaway of lithium-ion batteries in real-world electric vehicles. Appl. Energy 2022, 321, 119229. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, Z.; Liu, P.; Qin, Z.; Chen, Y.; Han, Y.; Wang, P.; Bauer, P. An online data driven fault diagnosis and thermal runaway early warning for electric vehicle batteries. IEEE Trans. Power Electron. 2022, 37, 12636–12646. [Google Scholar] [CrossRef]

- National Big Data Alliance of New Energy Vehicles. Available online: http://www.ndanev.com/%e8%81%94%e7%9b%9f%e4%bb%8b%e7%bb%8d/ (accessed on 19 August 2022).

- Bosch Mobility Solutions: Battery in the Cloud. Available online: https://www.bosch-mobility-solutions.com/en/solutions/software-and-services/battery-in-the-cloud/battery-in-the-cloud/ (accessed on 19 August 2022).

- Panasonic Announces UBMC Service: A Cloud-Based Battery Management Service to Ascertain Battery State in Electric Mobility Vehicles. Available online: https://news.panasonic.com/global/press/data/2020/12/en201210-1/en201210-1.pdf (accessed on 19 August 2022).

- HUAWEI: CloudLi. Available online: https://carrier.huawei.com/en/products/digital-power/telecom-energy/Central-Office-Power (accessed on 19 August 2022).

- Satyanarayanan, M. How we created edge computing. Nat. Electron. 2019, 2, 42. [Google Scholar] [CrossRef]

- Vaughan, O. Working on the edge. Nat. Electron. 2019, 2, 2–3. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q. Make more digital twins. Nature 2019, 573, 490–491. [Google Scholar] [CrossRef] [PubMed]

- Sanabria, D.M.; Mihaita, A.; Garcia, R.E. Digital twin technology challenges and applications: A comprehensive review. Remote Sens. 2022, 14, 1335. [Google Scholar] [CrossRef]

- Wu, B.; Widanage, W.D.; Yang, S.; Liu, X. Battery Digital Twins: Perspectives on the fusion of Models, Data and artifice Intelligence for Smart Battery Management Systems. Energy AI 2020, 1, 100016. [Google Scholar] [CrossRef]

- Lewis, M. A UK Collective Says it Can Now Accurately Predict an EV Battery Life Span. 2021, Internet. Available online: https://electrek.co/2021/09/22/a-uk-collective-says-it-can-now-accurately-predict-an-ev-batterys-life-span-heres-how/ (accessed on 19 August 2022).

- Mnih, V.; Kavukcuoglu, K.; Silver, D.; Rusu, A.A.; Veness, J.; Bellemare, M.G.; Hassabis, D. Human-level control through deep reinforcement learning. Nature 2015, 518, 529–533. [Google Scholar] [CrossRef]

- Lake, B.M.; Salakhutdinov, R.; Tenenbaum, J.B. Human-level concept learning through probabilistic program induction. Science 2015, 350, 1332–1338. [Google Scholar] [CrossRef]

- Savage, N. How AI and neuroscience drive each other forwards. Nature 2019, 571, S15. [Google Scholar] [CrossRef] [PubMed]

- Parisi, G.I.; Kemker, R.; Part, J.L.; Kanan, C.; Wermter, S. Continual lifelong learning with neural networks: A review. Neural Netw. 2019, 113, 54–71. [Google Scholar] [CrossRef]

- Liu, B. Lifelong machine learning: A paradigm for continuous learning. Front. Comput. Sci 2017, 11, 359–361. [Google Scholar] [CrossRef]

- Nature Outlook. Powering Up: A Revolution in Robotics and Artificial Intelligence. Available online: https://www.nature.com/immersive/robotics-ai/index.html (accessed on 19 August 2022).

- Li, X.; Sun, Z.; Xue, J.H.; Ma, Z. A concise review of recent few-shot meta-learning methods. Neurocomputing 2021, 456, 463–468. [Google Scholar] [CrossRef]

- Xu, H.; Wang, J.; Li, H.; Ouyang, D.; Shao, J. Unsupervised meta-learning for few-shot learning. Pattern Recognit. 2021, 116, 107951. [Google Scholar] [CrossRef]

- Kirkpatrick, J.; Pascanu, R.; Rabinowitz, N.; Veness, J.; Desjardins, G.; Rusu, A.A.; Milan, K.; Quan, J.; Ramalho, T.; Grabska-Barwinska, A.; et al. Overcoming catastrophic forgetting in neural networks. In Proceedings of the National Academy of Sciences, Stanford, CA, USA, 14 March 2017; pp. 3521–3526. [Google Scholar]

- Hayes, T.L.; Kafle, K.; Shrestha, R.; Acharya, M.; Kanan, C. Remind your neural network to prevent catastrophic forgetting. In Proceedings of the European Conference on Computer Vision, Glasgow, UK, 23–28 August 2020; pp. 466–483. [Google Scholar]

- Ritter, H.; Botev, A.; Barber, D. Online structured laplace approximations for overcoming catastrophic forgetting. Adv. Neural. Inf. Process Syst. 2018, 31, 3742–3752. [Google Scholar]

- Parisi, G.I.; Tani, J.; Weber, C.; Wermter, S. Lifelong learning of human actions with deep neural network self-organization. Neural Netw. 2017, 96, 137–149. [Google Scholar] [CrossRef] [PubMed]

- Parisi, G.I.; Tani, J.; Weber, C.; Wermter, S. Lifelong learning of spatiotemporal representations with dual-memory recurrent self-organization. Front. Neurorobotics 2018, 12, 78. [Google Scholar] [CrossRef] [PubMed]

- Monitor and Control Your Vehicle with Your Phone. Available online: https://my.gm.ca/chevrolet/en/how-to-support/entertainment-connections/bluetooth-smartphones-wifi/mychevroletmobileapp (accessed on 19 August 2022).

- Battery Analytics and Diagnostics: How Big Data Makes EV Batteries Smarter, Increases Longevity, and Unlocks Second Life Use. Available online: https://www.cleantech.com/battery-analytics-and-diagnostics-how-big-data-makes-ev-batteries-smarter-increases-longevity-and-unlocks-second-life-use/ (accessed on 19 August 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Burke, A.F. Electric Vehicle Batteries: Status and Perspectives of Data-Driven Diagnosis and Prognosis. Batteries 2022, 8, 142. https://doi.org/10.3390/batteries8100142

Zhao J, Burke AF. Electric Vehicle Batteries: Status and Perspectives of Data-Driven Diagnosis and Prognosis. Batteries. 2022; 8(10):142. https://doi.org/10.3390/batteries8100142

Chicago/Turabian StyleZhao, Jingyuan, and Andrew F. Burke. 2022. "Electric Vehicle Batteries: Status and Perspectives of Data-Driven Diagnosis and Prognosis" Batteries 8, no. 10: 142. https://doi.org/10.3390/batteries8100142

APA StyleZhao, J., & Burke, A. F. (2022). Electric Vehicle Batteries: Status and Perspectives of Data-Driven Diagnosis and Prognosis. Batteries, 8(10), 142. https://doi.org/10.3390/batteries8100142