Design and Implementation of an Electrolyte Temperature Control System for AgO-Al Batteries

Abstract

1. Introduction

2. Materials and Methods

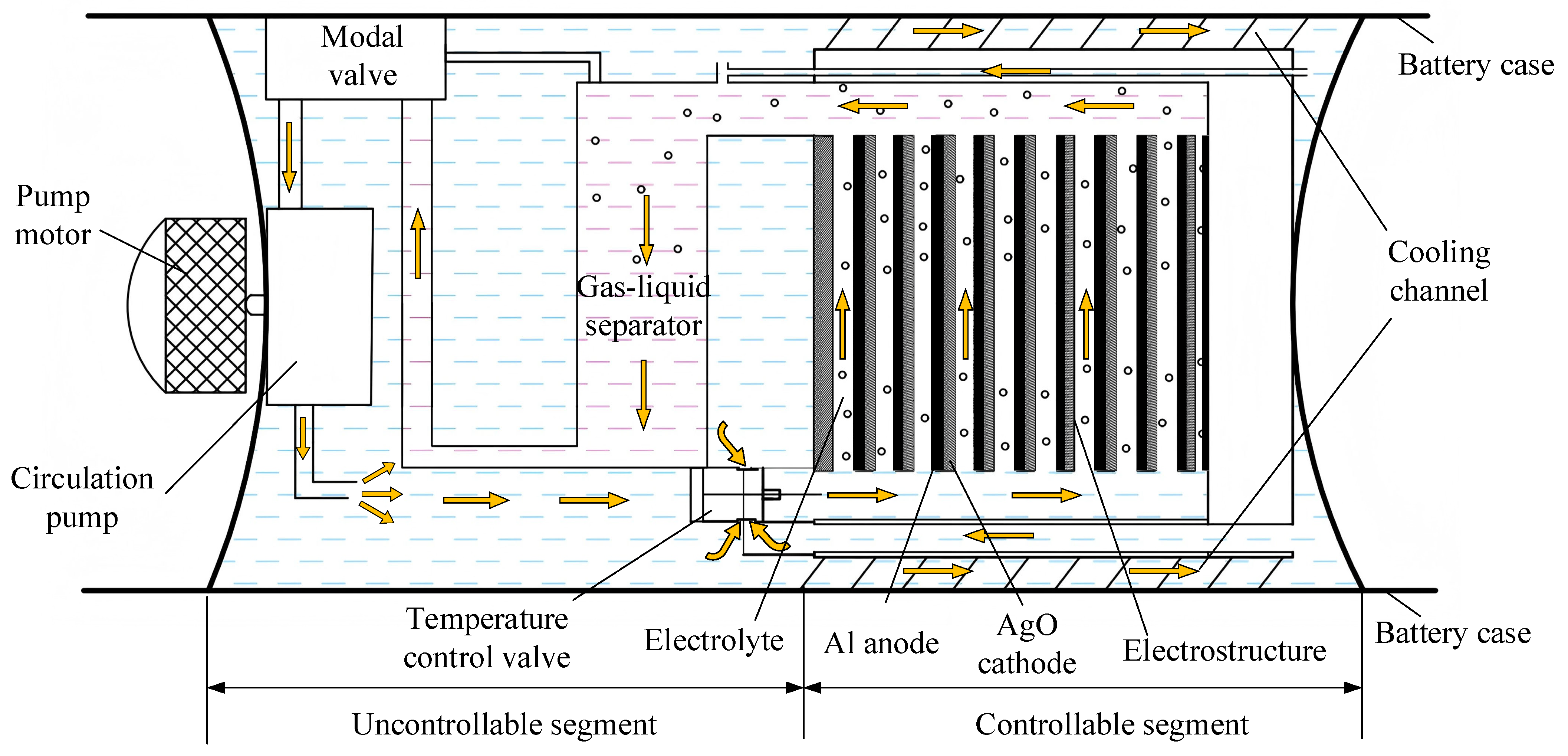

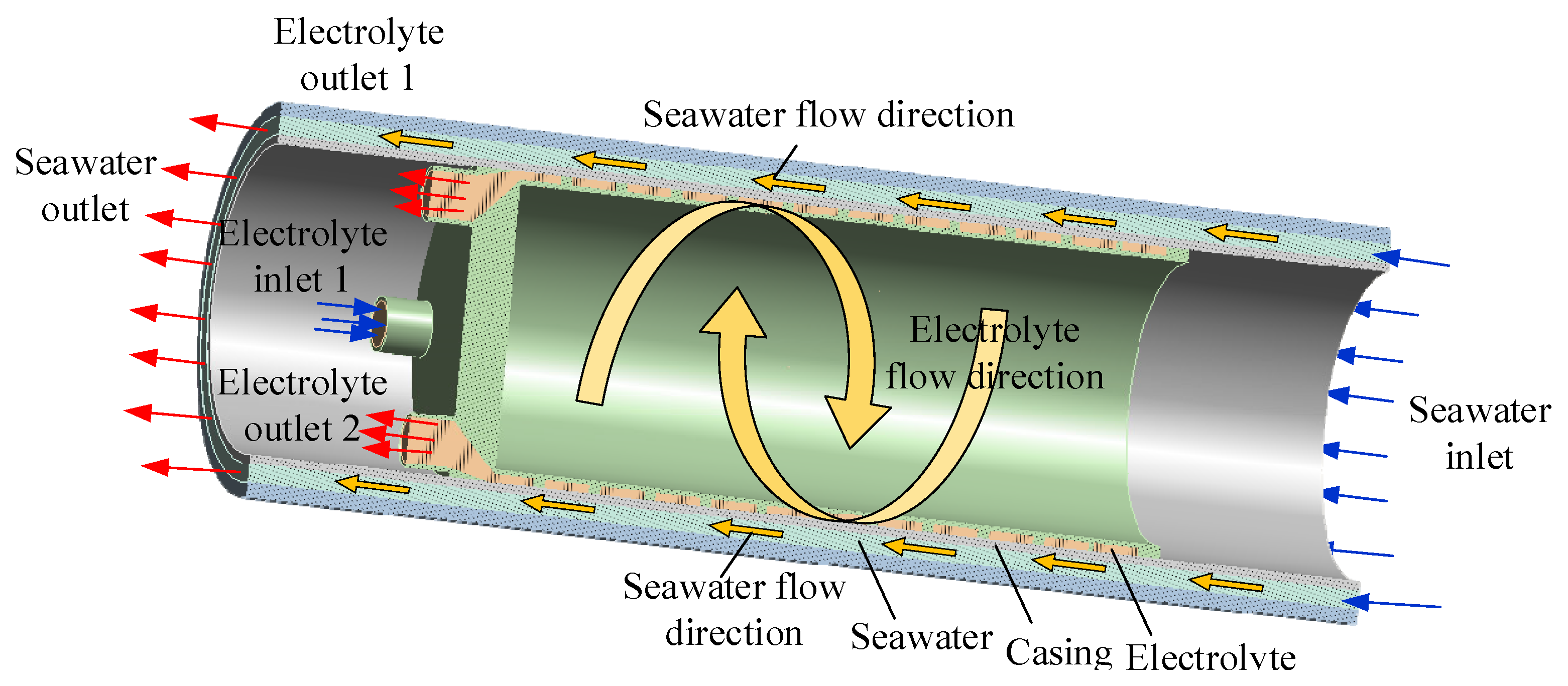

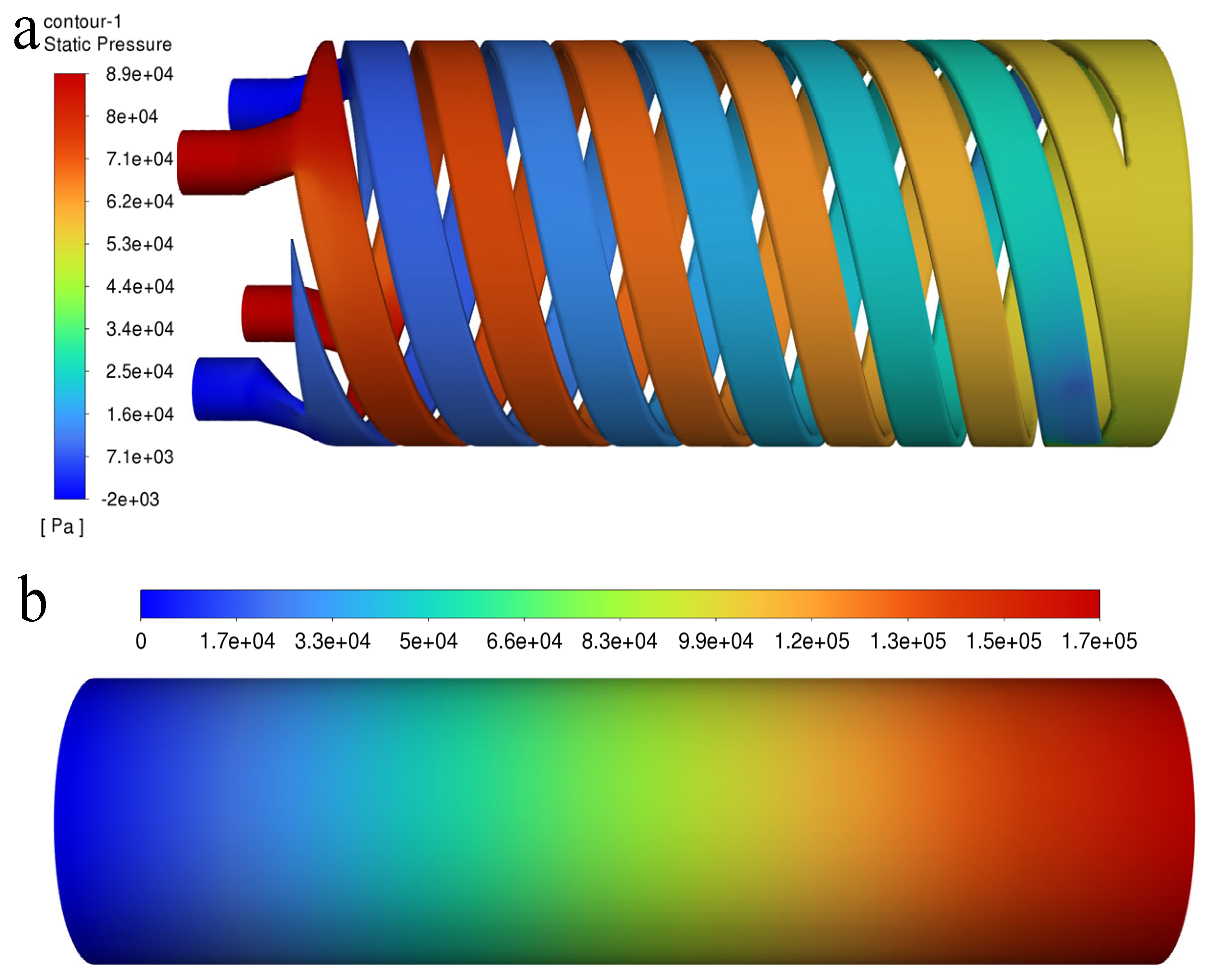

2.1. Model Building

2.2. Boundary Condition

2.3. Grid Delineation and Independence Verification

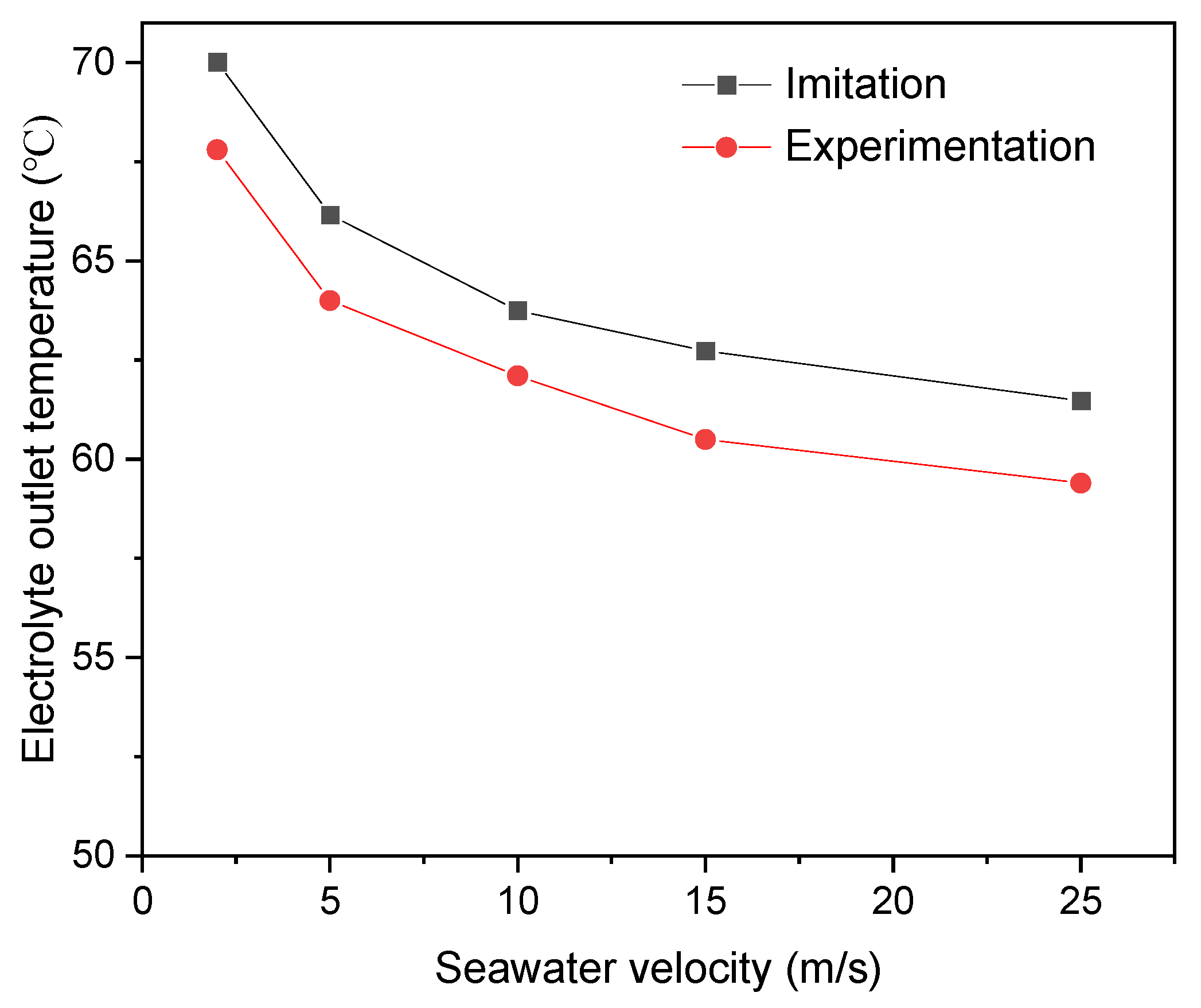

2.4. Experimental Validation

3. Analysis and Discussion

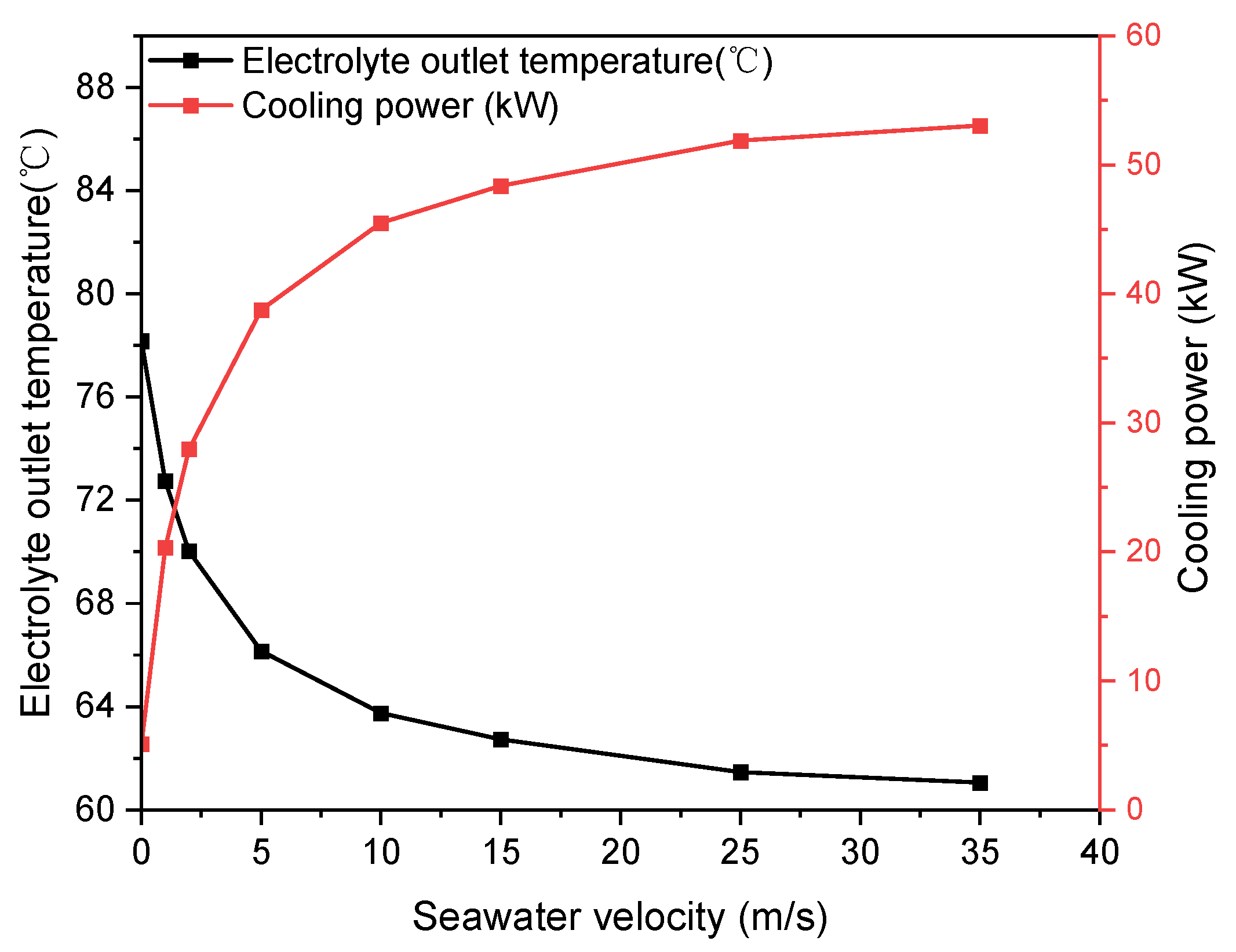

3.1. Effect of Seawater Flow Rate on Thermal Power Dissipation

3.2. Effect of Seawater Temperature on Cooling Power

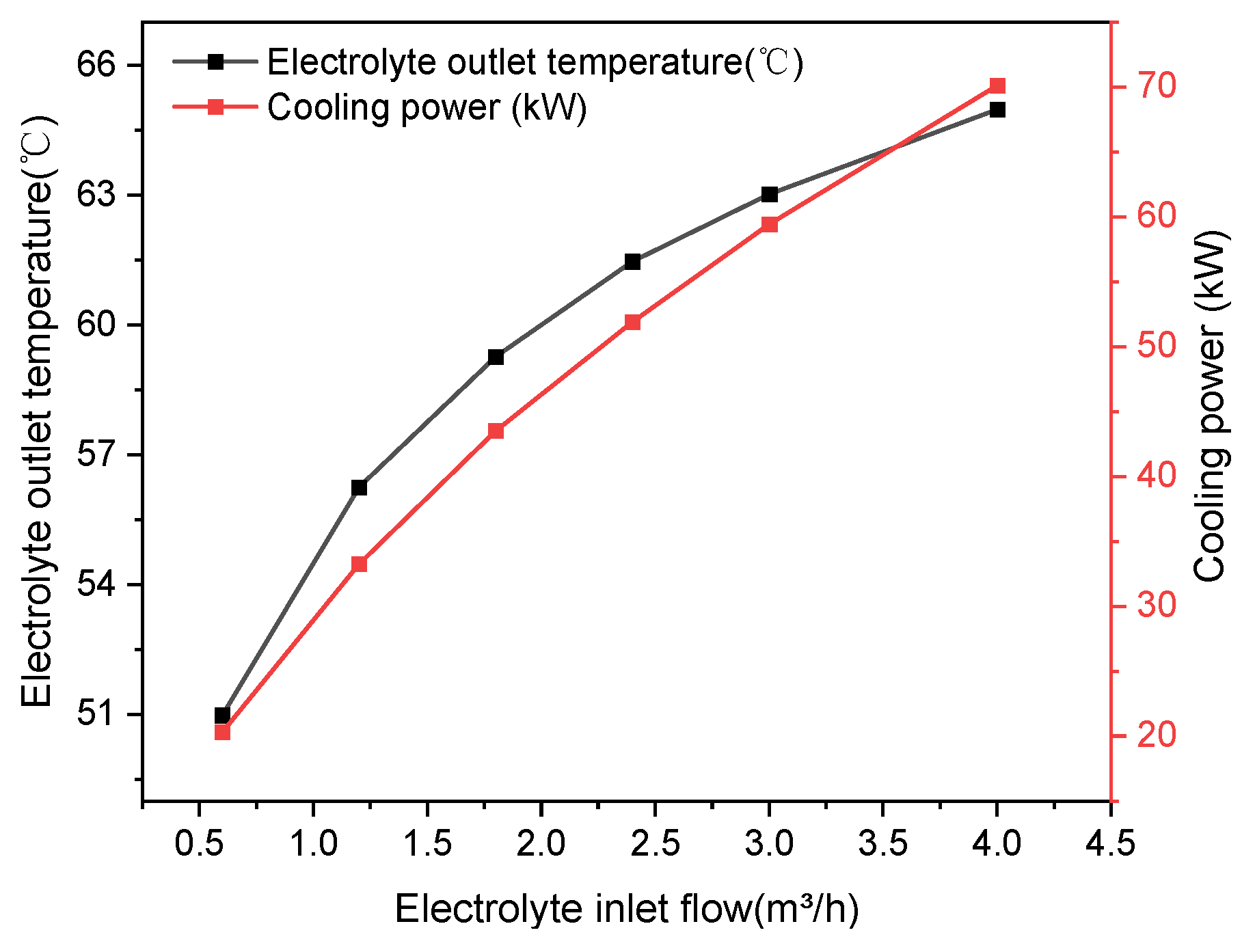

3.3. Effect of Electrolyte Flow on Thermal Power Dissipation

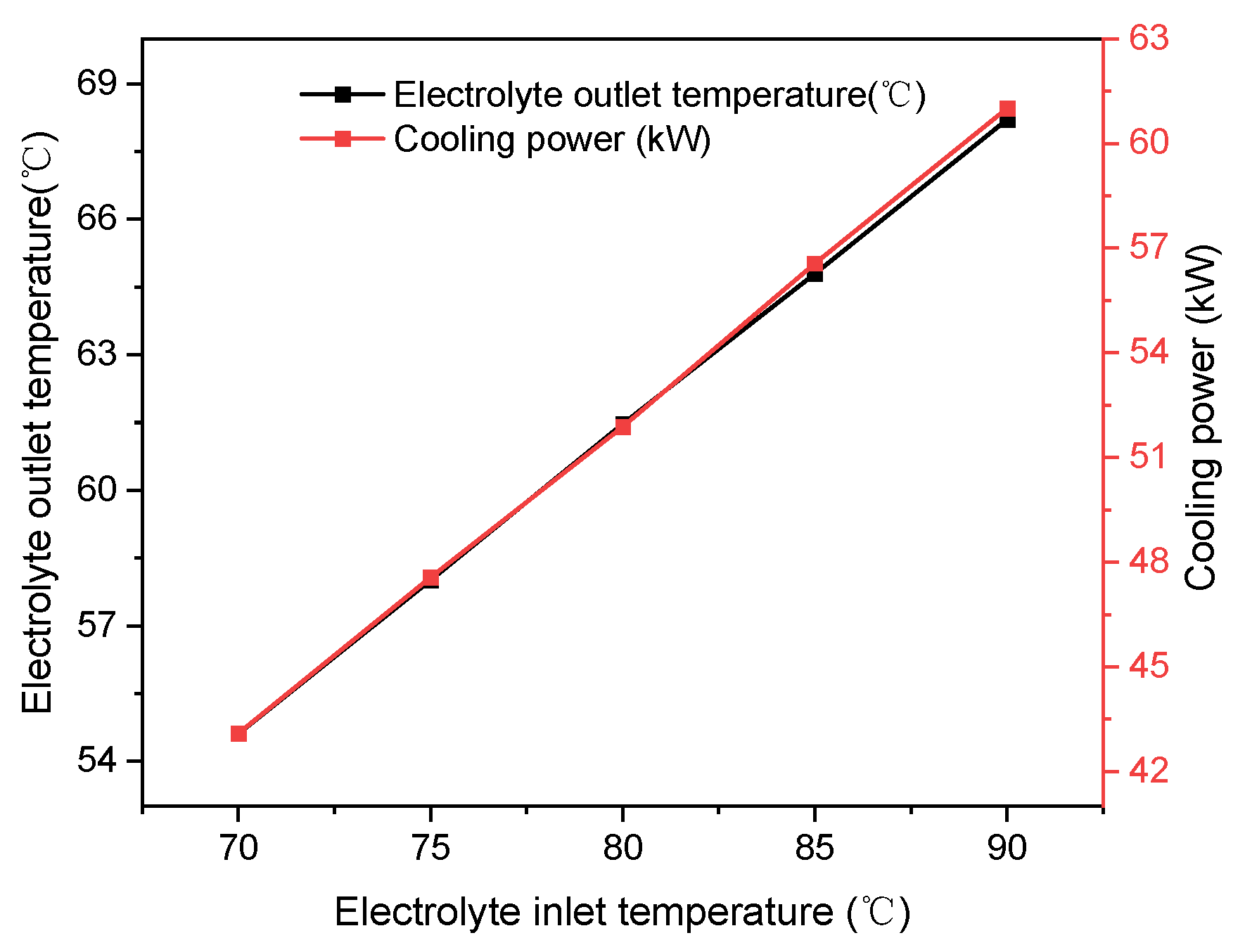

3.4. Effect of Initial Electrolyte Temperature on Heat Dissipation Power

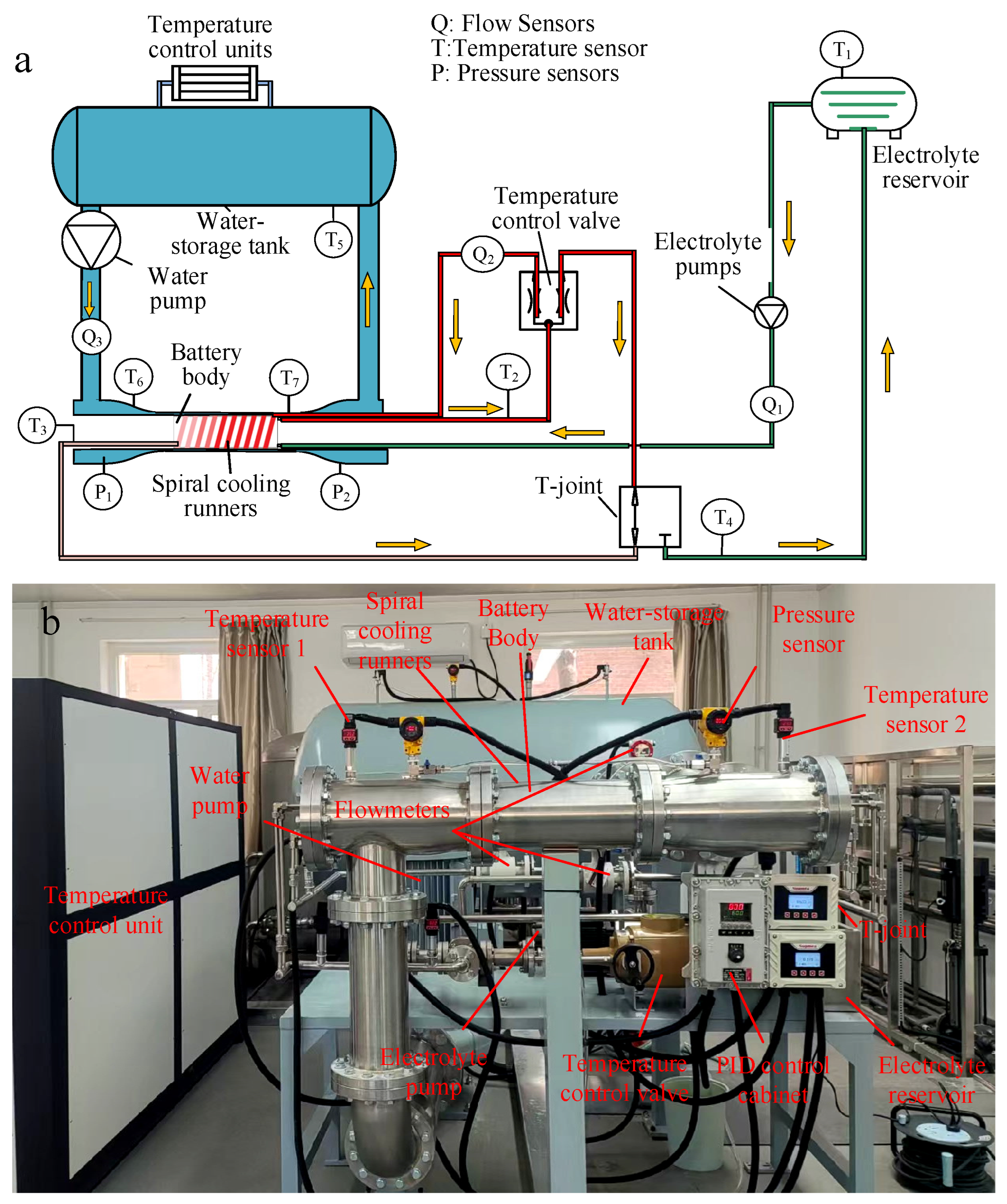

4. Design and Realization

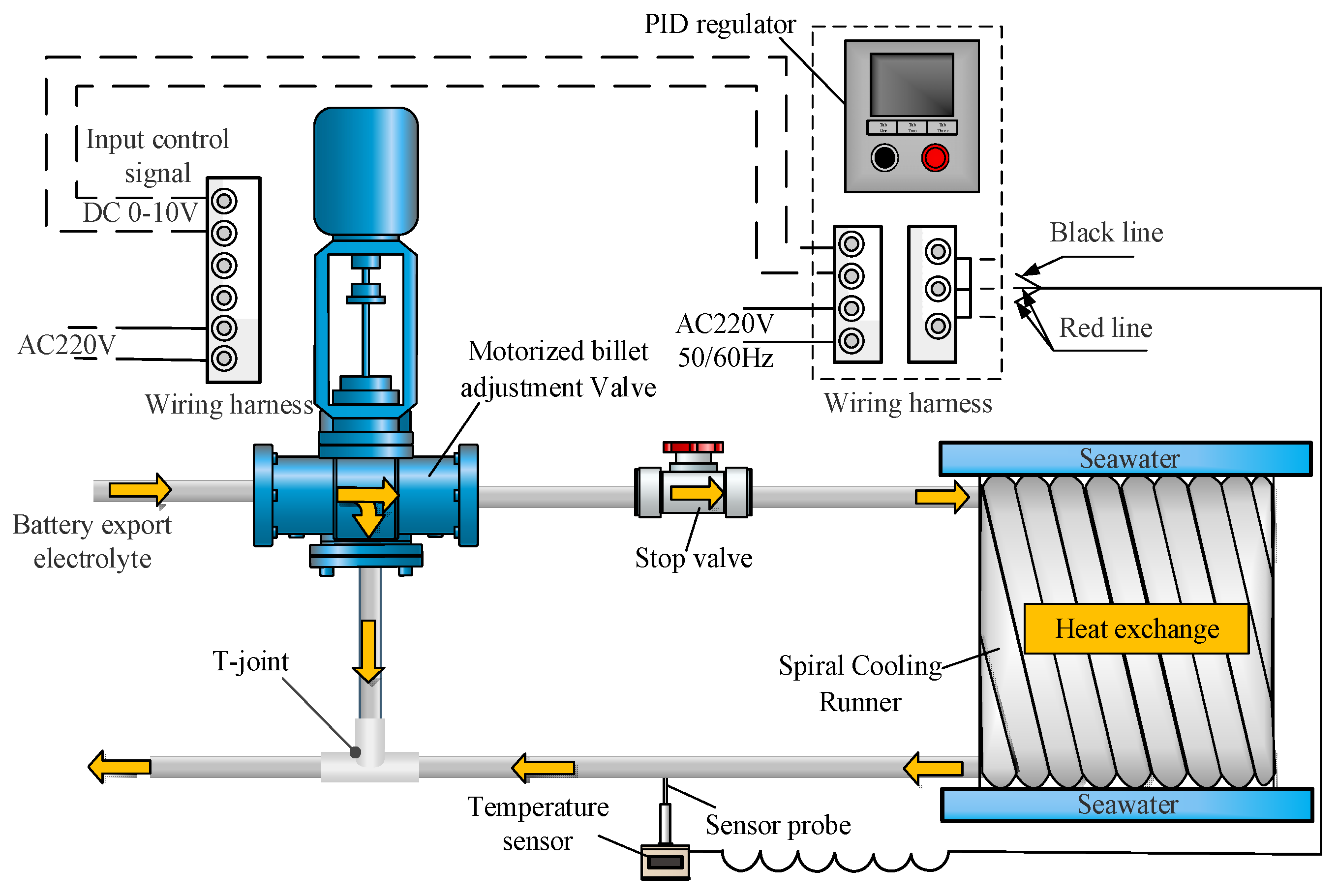

4.1. Temperature Control Design

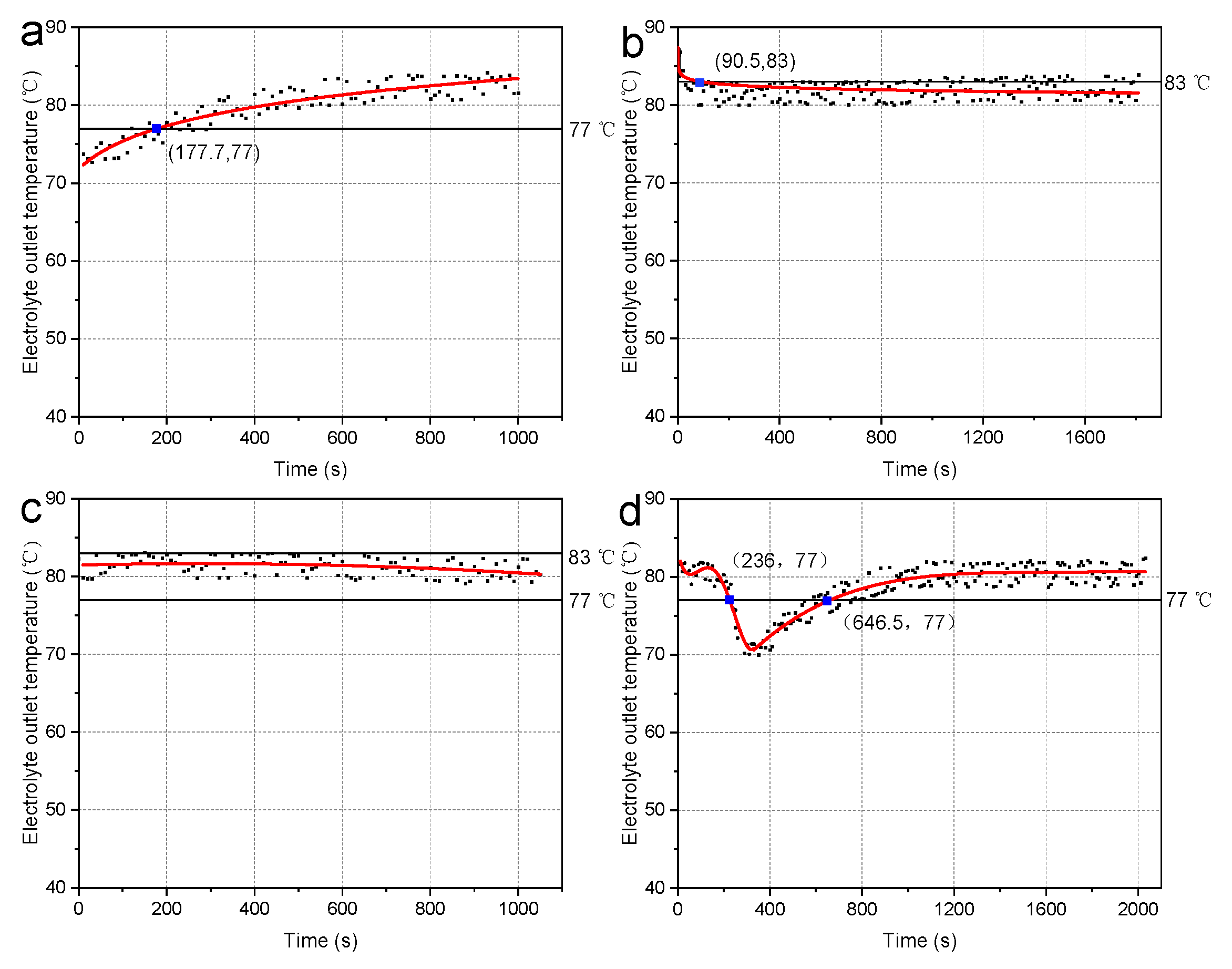

4.2. Performance Experimental Validation

5. Conclusions

- (1)

- Seawater flow rate, seawater temperature, electrolyte flow rate, and initial electrolyte temperature exert differential impacts on the thermal performance of the AgO-Al battery temperature control system. Specifically, cooling power exhibits an inverse proportionality to seawater temperature: a 5.0 °C increase in seawater temperature leads to an average decrease of 4.5 kW in cooling power. Conversely, it shows a positive correlation with inlet electrolyte temperature, increasing by approximately 4.3 kW on average for every 5.0 °C rise in inlet electrolyte temperature. Cooling power also increases with both electrolyte and seawater flow rates; however, when the seawater flow rate exceeds 10.0 m/s, the cooling capacity stabilizes, indicating negligible gains from further flow rate increases.

- (2)

- Under a 15 kW electric heating load, the system exhibited robust temperature regulation and operational resilience across varying initial electrolyte temperatures, electrolyte flow rates, seawater temperatures, and seawater velocities, with the electrolyte outlet temperature stabilized within the target range of 80.0 ± 3 °C through adaptive cooling power modulation. Dynamically, it demonstrated pronounced thermal stability and constraint capabilities—especially under high initial temperatures and during electrolyte flow rate adjustments—while seawater velocity variations highlighted its dynamic regulation and temperature tracking precision. All thermal response times remained below 7 min across tested scenarios, collectively validating the system’s ability to achieve precise electrolyte outlet temperature control and provide critical thermal management support for the experimental AgO-Al batteries’ discharges.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, X.; Shang, J.; Luo, Z.; Tang, L.; Zhang, X.; Li, J. Reviews of power systems and environmental energy conversion for unmanned underwater vehicles. Renew. Sustain. Energy Rev. 2012, 16, 1958–1970. [Google Scholar] [CrossRef]

- Li, X.; Li, W. Numerical simulation of portable AUV hydrodynamic coefficient. Ship Sci. Technol. 2023, 45, 61–65. [Google Scholar]

- Lu, J.; Tang, T.; Bai, C.; Gao, H.; Wang, J.; Li, C.; Gao, Y.; Guo, Z.; Zong, X. Reviews of Fuel Cells and Energy Storage Systems for Unmanned Undersea Vehicles. Energy Sources Part Recovery Util. Environ. Eff. 2024, 46, 11867–11888. [Google Scholar] [CrossRef]

- Zhen, Q.; Chen, P.; Wang, C. Electrolyte flow characteristics of seawater activated battery. CIESC J. 2024, 75, 4770–4779. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, W. Primary Seawater Batteries. In Seawater Batteries: Principles, Materials and Technology; Springer Nature: Singapore, 2022; pp. 37–90. [Google Scholar] [CrossRef]

- Li, S.; Tian, X. Progress of Seawater Batteries: From Mechanisms, Materials to Applications. J. Power Sources 2024, 617, 235161. [Google Scholar] [CrossRef]

- Chen, J.; Sun, L.; Wang, K.; Zhang, Y. Research and Applications of Rechargeable Seawater Battery. J. Energy Storage 2024, 76, 109659. [Google Scholar] [CrossRef]

- Jia, Y.; Richards, K.J.; Annamalai, H. The Impact of Vertical Resolution in Reducing Biases in Sea Surface Temperature in a Tropical Pacific Ocean Model. Ocean Model. 2021, 157, 101722. [Google Scholar] [CrossRef]

- Qin, H.; Fan, X.; Cai, Z.; Ye, Y. Acoustic detection of flow rate and flux of bubbles in cold spring area of the ocean. J. Trop. Oceanogr. 2016, 35, 35–39. [Google Scholar] [CrossRef]

- Valdes, P.J.; Scotese, C.R.; Lunt, D.J. Deep Ocean Temperatures through Time. Clim. Past 2021, 17, 1483–1506. [Google Scholar] [CrossRef]

- Jiang, H.; Bai, R.; Fang, Z.; Lu, H.; Yu, J. A review on development trend of power battery for torpedo. Mar. Electr. Electron. Eng. 2023, 43, 57–61. [Google Scholar] [CrossRef]

- Mathiyazhagan, S.; Rani, M.; Kumar, A.; Rao, V.; Ramesh, K.V. Effect of Flow Rate on the Discharge Characteristics of Magnesium Sea Water Activated Batteries. Chem. Technol. Indian J. 2015, 10, 43–50. [Google Scholar]

- Chen, P.; Zheng, Q. Investigation on Flow Field Optimization of Seawater Activated Battery Based on Flow Channel Structure Design. J. Energy Storage 2024, 84, 110798. [Google Scholar] [CrossRef]

- Lu, Y.; Ding, F.; Jia, Y.; San, L.; Xu, H. Advance in application of seawater battery based on its principle and characteristic. J. Power Sources 2020, 44, 1697–1700. [Google Scholar] [CrossRef]

- Lu, Y.; Yang, L.; Zhang, Y.; Zhao, Q.; Sang, L.; Ding, F.; Xu, H. Influence of Simulating Deep-Sea Environmental Factors on Cathodic Performance of Seawater Battery. J. Oceanol. Limnol. 2020, 38, 334–341. [Google Scholar] [CrossRef]

- Wen, J. Thermal design of aluminum silver oxide battery. J. Power Sources 2016, 40, 1823–1825. [Google Scholar] [CrossRef]

- Chen, H.; Wen, J.; Li, X.; Hu, Y. Cooling structure design of silver aluminum oxide battery based on Fluent. J. Power Sources 2023, 47, 668–670. [Google Scholar] [CrossRef]

- Yang, C.; Bai, R.; Wang, W. Study on electrode performance improvement of AgO seawater battery. Mar. Electr. Electron. Eng. 2024, 44, 84–86+91. [Google Scholar] [CrossRef]

- Gu, Z.; Lu, D.; Xu, M.; Tang, H.; Cao, H.; Liu, X.; Wu, Y. Preparation and performance of Al/AgO batteries. Met. Funct. Mater. 2010, 17, 27–30. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, H. Temperature control of a silver oxide torpedo battery section. Mar. Electr. Electron. Eng. 2020, 40, 19–22. [Google Scholar] [CrossRef]

- Tang, Q.; Dou, Z.; Du, Y.; Chen, Q.; Liu, F. Design of Experimental Section of a Water Tunnel for Simulation of Heat Dissipation Condition of Seawater-Activated Battery. J. Phys. Conf. Ser. 2024, 2865, 12036. [Google Scholar] [CrossRef]

- Cheng, H.; Wen, J.; Li, X. Finite element analysis of Al/AgO primary battery shell structure. J. Power Sources 2023, 47, 918–921. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Z.; Liu, J.; Wang, N. Thermal management with fast temperature convergence based on optimized fuzzy PID algorithm for electric vehicle battery. Appl. Energy 2023, 352, 121936. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; He, T.; Mao, N. A numerical study on a hybrid battery thermal management system based on PCM and wavy microchannel liquid cooling. Renew. Energy 2024, 235, 121273. [Google Scholar] [CrossRef]

- Yue, Q.; He, C.; Jiang, H.; Wu, M.; Zhao, T. A hybrid battery thermal management system for electric vehicles under dynamic working conditions. Int. J. Heat Mass Transf. 2021, 164, 120528. [Google Scholar] [CrossRef]

- Li, K.; Sun, C.; Zhang, M.; Wang, S.; Wei, B.; Cheng, Y.; Ju, X.; Xu, C. A Study of the Thermal Management and Discharge Strategies of Lithium-Ion Batteries in a Wide Temperature Range. Energies 2024, 17, 2319. [Google Scholar] [CrossRef]

- Chen, W.; Hou, S.; Shi, J.; Han, P.; Liu, B.; Wu, B.; Lin, X. Numerical Analysis of Novel Air-Based Li-Ion Battery Thermal Management. Batteries 2022, 8, 128. [Google Scholar] [CrossRef]

- Dai, H.; Wang, Y. Study on the Influence of Air Inlet and Outlet on the Heat Dissipation Performance of Lithium Battery. World Electr. Veh. J. 2023, 14, 113. [Google Scholar] [CrossRef]

- Chen, P.; Xiong, C.; Zheng, Q.; Ruan, M.; Xu, W. Numerical Simulation and Experimental Investigation on the Optimization of Flow-Guided Structures for High-Performance Aqueous AgO-al Batteries. Int. J. Heat Mass Transf. 2024, 235, 126167. [Google Scholar] [CrossRef]

| Material Name | Density [kg·m3] | Specific Heat Capacity [J/(kg·K)] | Heat Conductivity [W/(m·K)] | Viscosity [kg/(m·s)] |

|---|---|---|---|---|

| Electrolyte | 1250 | 4182 | 0.6 | 0.002500 |

| Seawater | 1025 | 3890 | 0.6 | 0.001003 |

| Aluminum alloy | 2719 | 871 | 150 | - |

| Epoxy sheet | 1800 | 550 | 0.5 | - |

| Working Condition Number | Seawater Velocity [m/s] | Seawater Temperature (°C) | Electrolyte Inlet Flow [m3/h] | Electrolyte Inlet Temperature (°C) | Electrolyte Outlet Temperature (°C) | Cooling Power (kW) |

|---|---|---|---|---|---|---|

| 1 | 0.01 | 22.0 | 2.4 | 80.0 | 78.17 | 5.12 |

| 2 | 1.0 | 22.0 | 2.4 | 80.0 | 72.74 | 20.33 |

| 3 | 2.0 | 22.0 | 2.4 | 80.0 | 70.02 | 27.94 |

| 4 | 5.0 | 22.0 | 2.4 | 80.0 | 66.16 | 38.75 |

| 5 | 10.0 | 22.0 | 2.4 | 80.0 | 63.75 | 45.50 |

| 6 | 15.0 | 22.0 | 2.4 | 80.0 | 62.73 | 48.36 |

| 7 | 25.0 | 22.0 | 2.4 | 80.0 | 61.47 | 51.88 |

| 8 | 35.0 | 22.0 | 2.4 | 80.0 | 61.06 | 53.03 |

| 8 | 25.0 | 5.0 | 2.4 | 80.0 | 55.96 | 67.31 |

| 9 | 25.0 | 10.0 | 2.4 | 80.0 | 57.56 | 62.83 |

| 10 | 25.0 | 15.0 | 2.4 | 80.0 | 59.15 | 58.38 |

| 11 | 25.0 | 30.0 | 2.4 | 80.0 | 63.96 | 44.91 |

| 12 | 25.0 | 35.0 | 2.4 | 80.0 | 65.56 | 40.43 |

| 13 | 35.0 | 22.0 | 2.4 | 80.0 | 61.06 | 53.03 |

| 14 | 25.0 | 22.0 | 0.6 | 80.0 | 50.98 | 20.31 |

| 15 | 25.0 | 22.0 | 1.2 | 80.0 | 56.25 | 33.25 |

| 16 | 25.0 | 22.0 | 1.8 | 80.0 | 59.27 | 43.53 |

| 17 | 25.0 | 22.0 | 3.0 | 80.0 | 63.02 | 59.43 |

| 18 | 25.0 | 22.0 | 4.0 | 80 | 64.98 | 70.09 |

| 19 | 25.0 | 22.0 | 2.4 | 70.0 | 54.61 | 43.09 |

| 20 | 25.0 | 22.0 | 2.4 | 75.0 | 58.01 | 47.57 |

| 21 | 25.0 | 22.0 | 2.4 | 85.0 | 64.80 | 56.56 |

| 22 | 25.0 | 22.0 | 2.4 | 90.0 | 68.21 | 61.01 |

| Name | Equipment Parameters |

|---|---|

| Thermostatic water tank | Power: 1.8 kW Temperature control range: indoor temperature −99.9 °C Temperature control precision: ±0.1 °C |

| Electrolyte pump | Lining material: PTFE Maximum flow rate: 3.4 m3/h Medium temperature: −10–120 °C |

| Spiral runner | Sizes:350 mm × Φ150 mm Material: Aluminum alloy |

| Temperature control valve | Medium temperature: 0–120 °C Lining material: 316L stainless steel Flow rate characteristics: Equal percentage |

| Water pump | Power: 90 kW Flow rate: 440 m3/h Lift: 45 m |

| Temperature control unit | Cooling capacity: 60 kW Heating capacity: 60 kW Temperature control range: 5 °C–35 °C Temperature control precision: ±1 °C |

| Temperature sensor | Measuring range: 0–200 °C Accuracy Class: ±0.2% |

| Working Condition Number | Seawater Velocity [m/s] | Seawater Temperature (℃) | Initial Electrolyte Temperature (℃) | Electrolyte Inlet Flow [m3/h] | Electrolyte Outlet Temperature (℃) |

|---|---|---|---|---|---|

| 1 | 2.0 | 22.0 | 80.0 | 2.4 | About 80 |

| 2 | 5.0 | 22.0 | 80.0 | 2.4 | About 80 |

| 3 | 10.0 | 22.0 | 80.0 | 2.4 | About 80 |

| 4 | 10.0 | 5.0 | 80.0 | 2.4 | About 80 |

| 5 | 10.0 | 35.0 | 80.0 | 2.4 | About 81 |

| 6 | 10.0 | 22.0 | 70.0 | 2.4 | About 82 |

| 7 | 10.0 | 22.0 | 90.0 | 2.4 | About 82 |

| 8 | 10.0 | 22.0 | 80.0 | 0.5 | About 81 |

| 9 | 10.0 | 22.0 | 80.0 | 1.2 | About 80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dou, Z.; Tang, Q.; Du, Z.; Du, Y.; Li, S.; Liu, F. Design and Implementation of an Electrolyte Temperature Control System for AgO-Al Batteries. Batteries 2025, 11, 244. https://doi.org/10.3390/batteries11070244

Dou Z, Tang Q, Du Z, Du Y, Li S, Liu F. Design and Implementation of an Electrolyte Temperature Control System for AgO-Al Batteries. Batteries. 2025; 11(7):244. https://doi.org/10.3390/batteries11070244

Chicago/Turabian StyleDou, Zhaoliang, Qingyan Tang, Zhuangzhuang Du, Yue Du, Shuang Li, and Fengbin Liu. 2025. "Design and Implementation of an Electrolyte Temperature Control System for AgO-Al Batteries" Batteries 11, no. 7: 244. https://doi.org/10.3390/batteries11070244

APA StyleDou, Z., Tang, Q., Du, Z., Du, Y., Li, S., & Liu, F. (2025). Design and Implementation of an Electrolyte Temperature Control System for AgO-Al Batteries. Batteries, 11(7), 244. https://doi.org/10.3390/batteries11070244