SOC-Dependent Compression of Lithium-Ion Battery Electrodes

Abstract

1. Introduction

1.1. MaterialLevel

1.2. Electrode Level

1.3. Problem Statement & Goal

2. Experimental Procedure

2.1. Electrodes

2.2. Preconditioning

2.3. Electrode Harvesting and Preparation

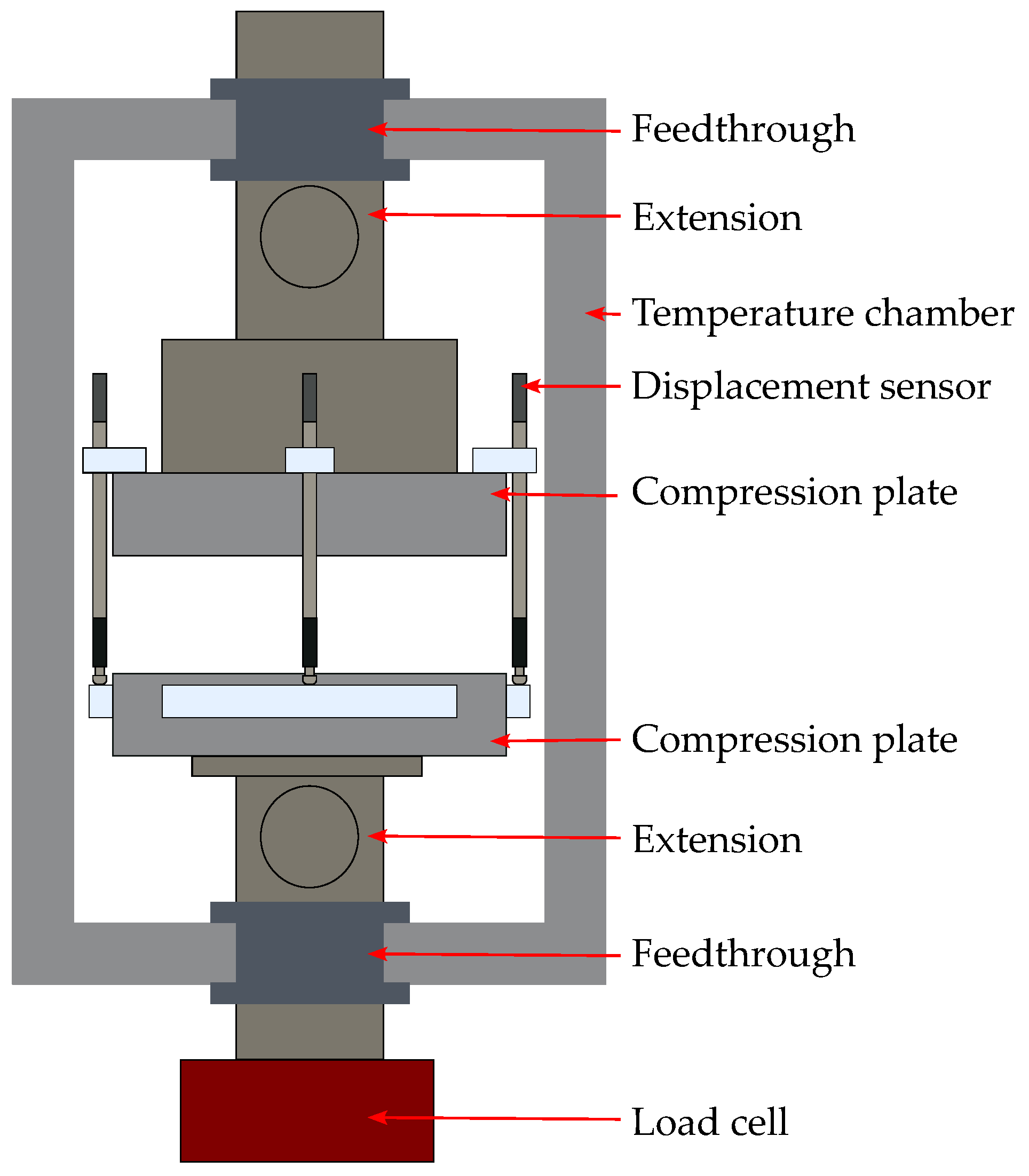

2.4. Mechanical Test Setup

2.5. Mechanical Test Procedure

2.6. Electrical Potential Measurement

3. Results and Discussion

- The electrode compression is dominated by compression of the porous structure. Soft binder and movement of active material particles account for the majority of the total compression. Small points of contact between active material particles can result in high local pressure values, which can lead to particle deformation. This particle deformation contributes a small fraction to the total electrode deformation. With changing lithium content in the electrode, Young’s modulus of the inactive components does not change. However, Young’s modulus of graphite and NMC increases with lithium content on material, while Young’s modulus of LFP remains unchanged. Thus, the behavior of Young’s modulus propagates from material to electrode level via the small contribution of active material deformation to the total electrode compression.

- The particle size of the LFP electrode is about an order of magnitude smaller than that of the AG and NMC electrodes. Consequently, changes in the porous structure due to intercalation expansion/contraction may be less pronounced for the LFP electrode with smaller particles compared to the AG and NMC electrodes with larger particles. Thus, the SOC-dependent compression of the AG and NMC electrodes could be attributed to microstructural changes induced by particle expansion and contraction, whereas the smaller LFP particles have a reduced impact on the electrode microstructure, resulting in the absence of an SOC-dependent trend on electrode level.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AG | artificial graphite |

| CC | constant current |

| CV | constant voltage |

| LFP | lithium-iron-phosphate |

| LIB | lithium-ion battery |

| NMC | nickel-manganese-cobalt-oxide |

| NMC811 | Li(Ni0.8Mn0.1Co0.1)O2 |

| SOC | state of charge |

| UTM | universal testing machine |

| electrical potential |

References

- Cannarella, J.; Arnold, C.B. Stress evolution and capacity fade in constrained lithium-ion pouch cells. J. Power Sources 2014, 245, 745–751. [Google Scholar] [CrossRef]

- Wünsch, M.; Kaufman, J.; Sauer, D.U. Investigation of the influence of different bracing of automotive pouch cells on cyclic liefetime and impedance spectra. J. Energy Storage 2019, 21, 149–155. [Google Scholar] [CrossRef]

- Müller, V.; Scurtu, R.G.; Richter, K.; Waldmann, T.; Memm, M.; Danzer, M.A.; Wohlfahrt-Mehrens, M. Effects of Mechanical Compression on the Aging and the Expansion Behavior of Si/C-Composite|NMC811 in Different Lithium-Ion Battery Cell Formats. J. Electrochem. Soc. 2019, 166, A3796–A3805. [Google Scholar] [CrossRef]

- Deich, T.; Storch, M.; Steiner, K.; Bund, A. Effects of module stiffness and initial compression on lithium-ion cell aging. J. Power Sources 2021, 506, 230163. [Google Scholar] [CrossRef]

- Daubinger, P.; Schelter, M.; Petersohn, R.; Nagler, F.; Hartmann, S.; Herrmann, M.; Giffin, G.A. Impact of Bracing on Large Format Prismatic Lithium–Ion Battery Cells during Aging. Adv. Energy Mater. 2022, 12, 2102448. [Google Scholar] [CrossRef]

- Aufschläger, A.; Kücher, S.; Kraft, L.; Spingler, F.; Niehoff, P.; Jossen, A. High precision measurement of reversible swelling and electrochemical performance of flexibly compressed 5 Ah NMC622/graphite lithium-ion pouch cells. J. Energy Storage 2023, 59, 106483. [Google Scholar] [CrossRef]

- Sauerteig, D.; Hanselmann, N.; Arzberger, A.; Reinshagen, H.; Ivanov, S.; Bund, A. Electrochemical-mechanical coupled modeling and parameterization of swelling and ionic transport in lithium-ion batteries. J. Power Sources 2018, 378, 235–247. [Google Scholar] [CrossRef]

- Pereira, D.J.; Fernandez, M.A.; Streng, K.C.; Hou, X.X.; Gao, X.; Weidner, J.W.; Garrick, T.R. Accounting for Non-Ideal, Lithiation-Based Active Material Volume Change in Mechano-Electrochemical Pouch Cell Simulation. J. Electrochem. Soc. 2020, 167, 080515. [Google Scholar] [CrossRef]

- Spingler, F.B.; Kücher, S.; Phillips, R.; Moyassari, E.; Jossen, A. Electrochemically Stable In Situ Dilatometry of NMC, NCA and Graphite Electrodes for Lithium-Ion Cells Compared to XRD Measurements. J. Electrochem. Soc. 2021, 168, 040515. [Google Scholar] [CrossRef]

- Zhang, X.; Klinsmann, M.; Chumakov, S.; Li, X.; Kim, S.U.; Metzger, M.; Besli, M.M.; Klein, R.; Linder, C.; Christensen, J. A Modified Electrochemical Model to Account for Mechanical Effects Due to Lithium Intercalation and External Pressure. J. Electrochem. Soc. 2021, 168, 020533. [Google Scholar] [CrossRef]

- Pegel, H.; von Kessel, O.; Heugel, P.; Deich, T.; Tübke, J.; Birke, K.P.; Sauer, D.U. Volume and thickness change of NMC811|SiOx-graphite large-format lithium-ion cells: From pouch cell to active material level. J. Power Sources 2022, 537, 231443. [Google Scholar] [CrossRef]

- von Kessel, O.; Hoehl, T.; Heugel, P.; Brauchle, F.; Vrankovic, D.; Birke, K.P. Electrochemical-Mechanical Parameterization and Modeling of Expansion, Pressure, and Porosity Evolution in NMC811|SiOx-Graphite Lithium-Ion Cells. J. Electrochem. Soc. 2023, 170, 090534. [Google Scholar] [CrossRef]

- Pannala, S.; Movahedi, H.; Garrick, T.R.; Stefanopoulou, A.G.; Siegel, J.B. Consistently Tuned Battery Lifetime Predictive Model of Capacity Loss, Resistance Increase, and Irreversible Thickness Growth. J. Electrochem. Soc. 2024, 171, 010532. [Google Scholar] [CrossRef]

- Garrick, T.R.; Koch, B.J.; Fernandez, M.A.; Efimoff, E.; Teel, H.; Jones, M.D.; Tu, M.; Shimpalee, S. Modeling Reversible Volume Change in Automotive Battery Cells with Porous Silicon Oxide-Graphite Composite Anodes. J. Electrochem. Soc. 2024, 171, 103509. [Google Scholar] [CrossRef]

- Durdel, A.; Brehm, J.; Elender, V.; Bitschnau, L.; Aufschläger, A.; Altmann, M.; Kotter, P.; Jossen, A. Modeling Volume and Porosity Change of Lithium-Ion Cells Due to Lithium Intercalation and External Pressure. J. Electrochem. Soc. 2025, 172, 050508. [Google Scholar] [CrossRef]

- Gomadam, P.M.; Weidner, J.W. Modeling Volume Changes in Porous Electrodes. J. Electrochem. Soc. 2006, 153, A179. [Google Scholar] [CrossRef]

- Garrick, T.R.; Kanneganti, K.; Huang, X.; Weidner, J.W. Modeling Volume Change due to Intercalation into Porous Electrodes. J. Electrochem. Soc. 2014, 161, E3297–E3301. [Google Scholar] [CrossRef]

- Garrick, T.R.; Huang, X.; Srinivasan, V.; Weidner, J.W. Modeling Volume Change in Dual Insertion Electrodes. J. Electrochem. Soc. 2017, 164, E3552–E3558. [Google Scholar] [CrossRef]

- Garrick, T.R.; Higa, K.; Wu, S.L.; Dai, Y.; Huang, X.; Srinivasan, V.; Weidner, J.W. Modeling Battery Performance Due to Intercalation Driven Volume Change in Porous Electrodes. J. Electrochem. Soc. 2017, 164, E3592–E3597. [Google Scholar] [CrossRef]

- Spingler, F.B.; Friedrich, S.; Kücher, S.; Schmid, S.; López-Cruz, D.; Jossen, A. The Effects of Non-Uniform Mechanical Compression of Lithium-Ion Cells on Local Current Densities and Lithium Plating. J. Electrochem. Soc. 2021, 168, 110515. [Google Scholar] [CrossRef]

- Kücher, S.; Durdel, A.; Schabenberger, T.; Spingler, F.B.; Reuter, L.; Jossen, A. Investigating the Impact of Various Binder Contents and Compression on Graphite Single-Electrode Dilatometry Measurements. J. Electrochem. Soc. 2025, 172, 020537. [Google Scholar] [CrossRef]

- Daubinger, P.; Ebert, F.; Hartmann, S.; Giffin, G.A. Impact of electrochemical and mechanical interactions on lithium-ion battery performance investigated by operando dilatometry. J. Power Sources 2021, 488, 229457. [Google Scholar] [CrossRef]

- Qi, Y.; Guo, H.; Hector, L.G.; Timmons, A. Threefold Increase in the Young’s Modulus of Graphite Negative Electrode during Lithium Intercalation. J. Electrochem. Soc. 2010, 157, A558. [Google Scholar] [CrossRef]

- Qi, Y.; Hector, L.G.; James, C.; Kim, K.J. Lithium Concentration Dependent Elastic Properties of Battery Electrode Materials from First Principles Calculations. J. Electrochem. Soc. 2014, 161, F3010–F3018. [Google Scholar] [CrossRef]

- Maxisch, T.; Ceder, G. Elastic properties of olivine LixFePO4 from first principles. Phys. Rev. B 2006, 73, 174112. [Google Scholar] [CrossRef]

- Min, K.; Cho, E. Intrinsic origin of intra-granular cracking in Ni-rich layered oxide cathode materials. Phys. Chem. Chem. Phys. PCCP 2018, 20, 9045–9052. [Google Scholar] [CrossRef]

- Xu, R.; Sun, H.; de Vasconcelos, L.S.; Zhao, K. Mechanical and Structural Degradation of LiNixMnyCozO2 Cathode in Li-Ion Batteries: An Experimental Study. J. Electrochem. Soc. 2017, 164, A3333–A3341. [Google Scholar] [CrossRef]

- Li, D.; Wang, Y. In-situ measurements of mechanical property and stress evolution of commercial graphite electrode. Mater. Des. 2020, 194, 108887. [Google Scholar] [CrossRef]

- Zhou, D.; Kim, C.; Yun, S. Effective modulus of graphite electrode in Li-ion battery by considering ion concentration, porosity, and binding energy during lithium intercalation. Mater. Lett. 2018, 224, 46–49. [Google Scholar] [CrossRef]

- Müller, V.; Scurtu, R.G.; Memm, M.; Danzer, M.A.; Wohlfahrt-Mehrens, M. Study of the influence of mechanical pressure on the performance and aging of Lithium-ion battery cells. J. Power Sources 2019, 440, 227148. [Google Scholar] [CrossRef]

- Schabenberger, T.; Kücher, S.; Aufschläger, A.; Jossen, A. Impact of applied and preceding pressure on performance and reversible swelling of lithium-ion pouch cells with varying microporous separators. J. Energy Storage 2024, 102, 113910. [Google Scholar] [CrossRef]

- Brehm, J.; Durdel, A.; Kussinger, T.; Kotter, P.; Altmann, M.; Jossen, A. Mechanical Characterization and Modeling of Large-Format Lithium-Ion Battery Cell Electrodes and Separators for Real Operating Scenarios. Batteries 2024, 10, 422. [Google Scholar] [CrossRef]

- Xu, J.; Liu, B.; Hu, D. State of Charge Dependent Mechanical Integrity Behavior of 18650 Lithium-ion Batteries. Sci. Rep. 2016, 6, 21829. [Google Scholar] [CrossRef] [PubMed]

- Lai, W.J.; Ali, M.Y.; Pan, J. Mechanical behavior of representative volume elements of lithium-ion battery cells under compressive loading conditions. J. Power Sources 2014, 245, 609–623. [Google Scholar] [CrossRef]

- Sedlatschek, T.; Krämer, M.; Gibson, J.S.L.; Korte-Kerzel, S.; Bezold, A.; Broeckmann, C. Mechanical properties of heterogeneous, porous LiFePO4 cathodes obtained using statistical nanoindentation and micromechanical simulations. J. Power Sources 2022, 539, 231565. [Google Scholar] [CrossRef]

- Linders, K.; Jenu, S.; Hentunen, A.; Chandra Mouli, G.R. The impact of V2X on battery degradation: A quantitative review. J. Power Sources 2025, 660, 238482. [Google Scholar] [CrossRef]

- Kücher, S.; Schabenberger, T.; Zonta, E.; Jossen, A. Performance and Properties of Laboratory and Commercial Separators under Compression and Varying Temperature. J. Electrochem. Soc. 2025, 172, 070512. [Google Scholar] [CrossRef]

- Wang, Y.; Dang, D.; Li, D.; Hu, J.; Cheng, Y.T. Influence of polymeric binders on mechanical properties and microstructure evolution of silicon composite electrodes during electrochemical cycling. J. Power Sources 2019, 425, 170–178. [Google Scholar] [CrossRef]

- Qian, J.; Wiener, C.G.; Zhu, Y.; Vogt, B.D. Swelling and plasticization of polymeric binders by Li-containing carbonate electrolytes using quartz crystal microbalance with dissipation. Polymer 2018, 143, 237–244. [Google Scholar] [CrossRef]

- Jäckel, N.; Dargel, V.; Shpigel, N.; Sigalov, S.; Levi, M.D.; Daikhin, L.; Aurbach, D.; Presser, V. In situ multi-length scale approach to understand the mechanics of soft and rigid binder in composite lithium ion battery electrodes. J. Power Sources 2017, 371, 162–166. [Google Scholar] [CrossRef]

| Electrode | Unit | AG | NMC811 | LFP |

|---|---|---|---|---|

| Porosity | % | 33 | 31 | 35 |

| Coating thickness | 76.5 | 52 | 84 | |

| Current collector thickness | 8 | 12 | 15 | |

| Mass loading | 11.5 | 16.7 | 18 | |

| Areal capacity | 3.44 | 3.41 | 2.83 | |

| Active material fraction | 95.7 | 96.4 | 96.5 | |

| D50 particle diameter | 13.5 | 10.5 | 1.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schabenberger, T.; Durdel, A.; Kücher, S.; Jossen, A. SOC-Dependent Compression of Lithium-Ion Battery Electrodes. Batteries 2025, 11, 430. https://doi.org/10.3390/batteries11120430

Schabenberger T, Durdel A, Kücher S, Jossen A. SOC-Dependent Compression of Lithium-Ion Battery Electrodes. Batteries. 2025; 11(12):430. https://doi.org/10.3390/batteries11120430

Chicago/Turabian StyleSchabenberger, Tom, Axel Durdel, Simon Kücher, and Andreas Jossen. 2025. "SOC-Dependent Compression of Lithium-Ion Battery Electrodes" Batteries 11, no. 12: 430. https://doi.org/10.3390/batteries11120430

APA StyleSchabenberger, T., Durdel, A., Kücher, S., & Jossen, A. (2025). SOC-Dependent Compression of Lithium-Ion Battery Electrodes. Batteries, 11(12), 430. https://doi.org/10.3390/batteries11120430